High-efficiency flame-retardant polycarbonate material and preparation method thereof

A technology of flame-retardant polycarbonate and polycarbonate, which is applied in the field of high-efficiency flame-retardant polycarbonate materials and its preparation, can solve the problem of the decrease of impact strength, tensile strength and bending strength of flame-retardant PC, and affect the welding and welding of flame-retardant PC. Encapsulation effect, reduced toughness and transparency of flame-retardant PC, to achieve the effect of promoting char formation and cross-linking, improving char formation and cross-linking efficiency, and reducing smoke density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

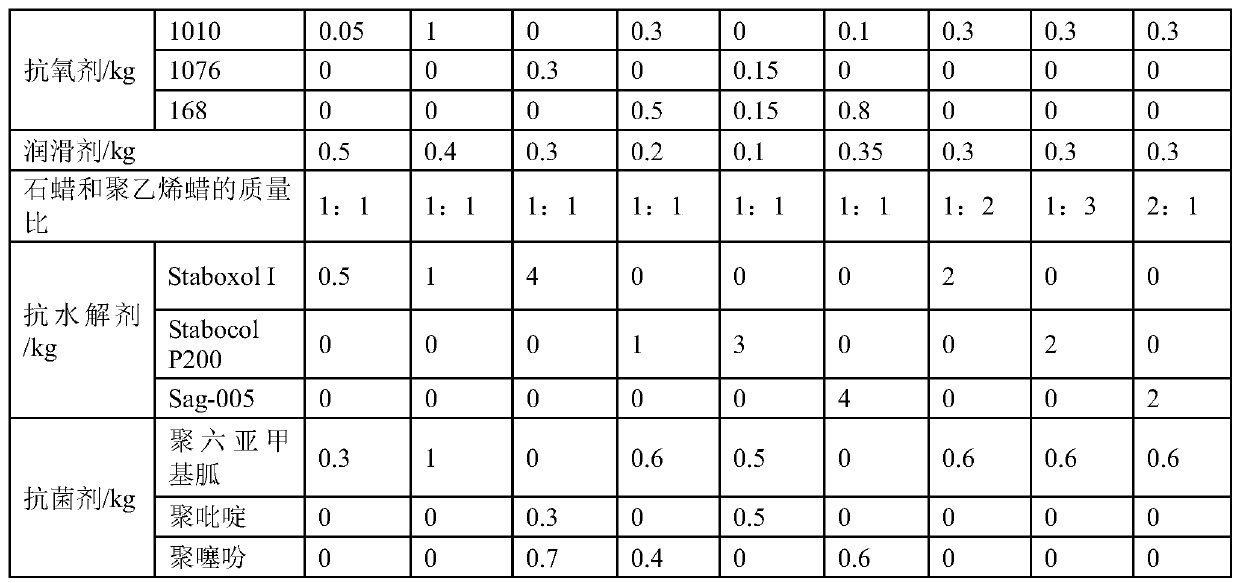

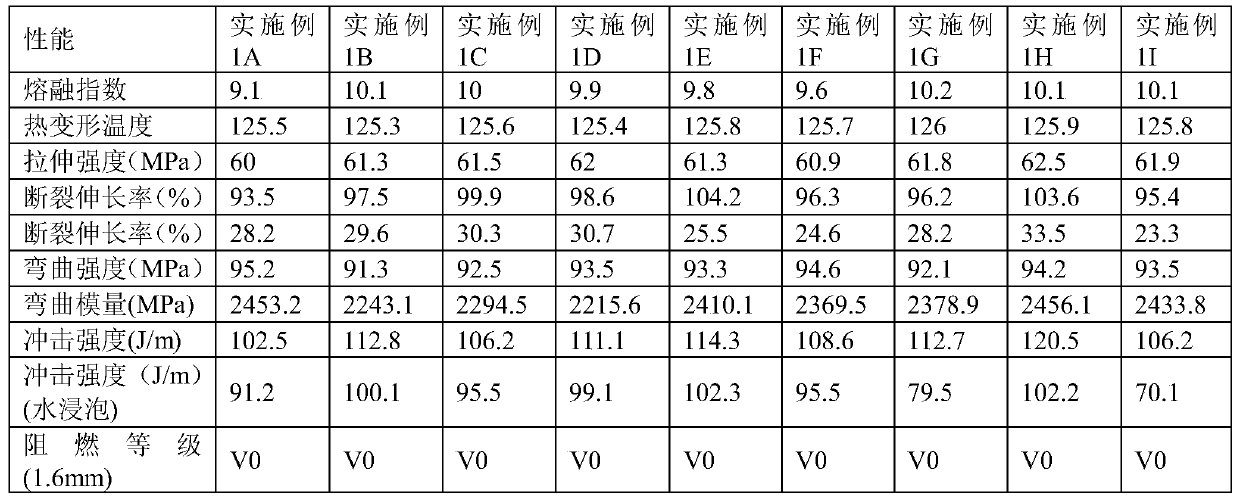

Embodiment 1

[0050] A high-efficiency flame-retardant polycarbonate material is made of the following raw materials in parts by mass,

[0051] PC resin 100 parts

[0052] Sulfonate flame retardant 0.02-0.2 part,

[0053] Fill 1-9 parts of mineral powder,

[0054] 0.5-4 parts of silicon-based toughening agent,

[0055] Anti-hydrolysis agent 0.5-4 parts,

[0056] Lubricant 0.1-0.5 parts,

[0057] Anti-dripping agent 0.05-1 part,

[0058] 0.3-1 part of antibacterial agent,

[0059] Antioxidant 0.2-0.6 part.

[0060] PC resin can be selected according to actual needs, and its fluidity is 9-25g / 10min. The PC resin here is PC-1020 produced by Zhetie Dafeng Chemical Industry Co., Ltd., which is isosorbide polycarbonate, and its MFR=10g / 10min.

[0061] The sulfonate flame retardant is one of potassium perfluorobutane sulfonate (KFBS), potassium diphenyl sulfone sulfonate (KSS) or sodium trichlorobenzene sulfonate (STB) or a combination of two. Potassium perfluorobutanesulfonate (KFBS), po...

Embodiment 2

[0095] A method for preparing a high-efficiency flame-retardant polycarbonate material, based on Example 1H, the difference is that the amount of silicon-based toughening agent is 0.

Embodiment 3

[0097] A method for preparing a high-efficiency flame-retardant polycarbonate material, based on Example 1H, the difference is that the amount of anti-hydrolysis agent is 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com