Reinforced and toughened PP single-wall corrugated pipe and preparation method thereof

A single-wall corrugated pipe, strengthening and toughening technology, applied in the field of reinforced and toughened PP single-wall corrugated pipe and its preparation, can solve the problems of inability to meet application requirements, complex production process, low strength and toughness, etc., and achieve improved performance. , The effect of improving elongation at break and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

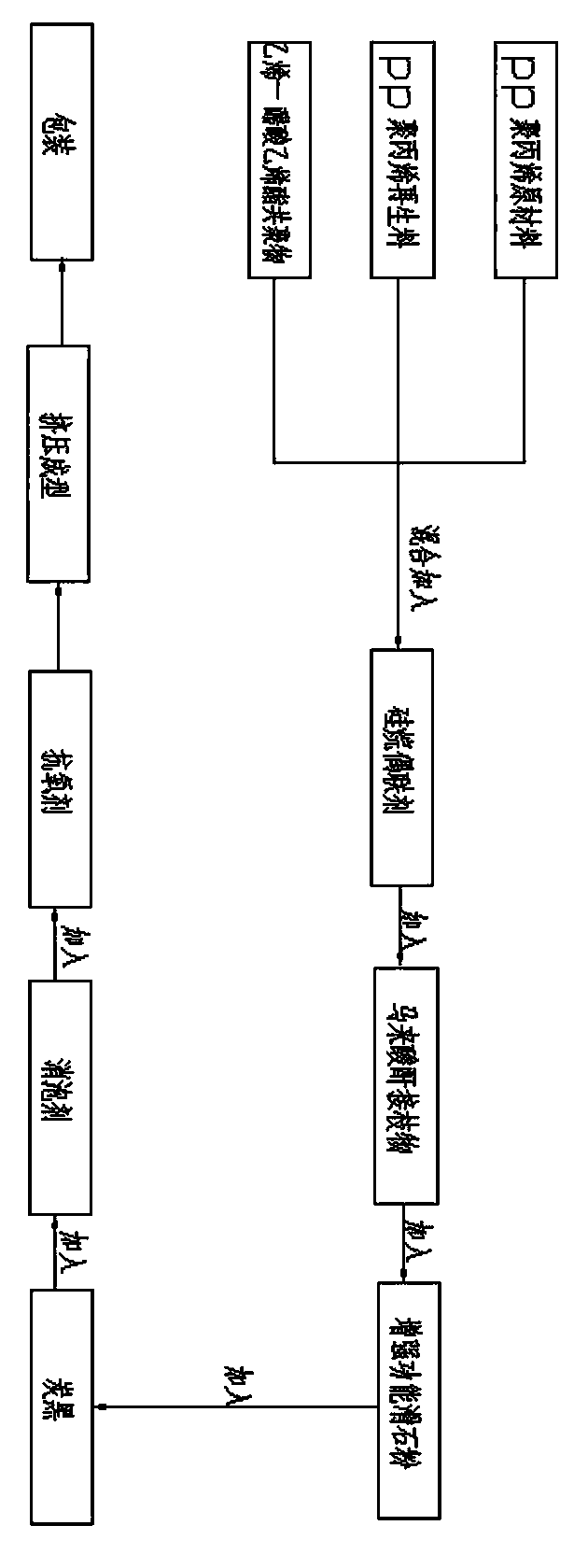

Image

Examples

Embodiment 1

[0034] A reinforced and toughened PP single-wall corrugated pipe is prepared from the following raw materials according to the following mass ratio:

[0035] PP polypropylene raw material 70 parts

[0036] 5 parts of PP polypropylene recycled material

[0037] Enhancing function talcum powder 8 servings

[0038] Carbon black 4 parts

[0039] 0.6 parts of defoamer

[0040] 2.8 parts of silane coupling agent

[0041] 0.4 parts of maleic anhydride graft

[0042] Antioxidant 1.2 parts

[0043] 8 parts of ethylene-vinyl acetate copolymer.

[0044] A method for preparing a reinforced and toughened PP single-wall corrugated pipe, specifically comprising the following steps:

[0045] (1) First weigh 70 parts of PP polypropylene raw material, 5 parts of PP polypropylene recycled material, 8 parts of enhanced function talcum powder, 4 parts of carbon black, 0.6 parts of defoamer, 2.8 parts of Silane coupling agent, 0.4 parts of maleic anhydride graft, 1.2 parts of antioxidant, 8...

Embodiment 2

[0054] A reinforced and toughened PP single-wall corrugated pipe is prepared from the following raw materials according to the following mass ratio:

[0055] PP polypropylene raw material 70 parts

[0056] 5 parts of PP polypropylene recycled material

[0057]Enhancing Functional Talc 9 servings

[0058] carbon black 3

[0059] 0.55 parts of defoamer

[0060] Silane coupling agent 3.5

[0061] Maleic anhydride graft 0.25 parts

[0062] Antioxidant 1.35 parts

[0063] Ethylene-vinyl acetate copolymer 7.35 parts.

[0064] A method for preparing a reinforced and toughened PP single-wall corrugated pipe, specifically comprising the following steps:

[0065] (1) First weigh 70% PP polypropylene raw material, 5% PP polypropylene recycled material, 8%-10% enhanced function talcum powder, 2%-4% carbon black, 0.5%-0.6 % defoamer, 2%-3% silane coupling agent, 0.3%-0.4% maleic anhydride graft, 1.2%-1.3% antioxidant, 5%-7% ethylene-vinyl acetate Lipid copolymer;

[0066] (2) Pou...

Embodiment 3

[0074] A reinforced and toughened PP single-wall corrugated pipe is prepared from the following raw materials according to the following mass ratio:

[0075] PP polypropylene raw material 70 parts

[0076] 5 parts of PP polypropylene recycled material

[0077] Enhancing function talcum powder 10 parts

[0078] Carbon black 2 parts

[0079] 0.5 parts of defoamer

[0080] 4 parts of silane coupling agent

[0081] 0.2 parts of maleic anhydride graft

[0082] Antioxidant 1.3 parts

[0083] 7 parts of ethylene-vinyl acetate copolymer.

[0084] A method for preparing a reinforced and toughened PP single-wall corrugated pipe, specifically comprising the following steps:

[0085] (1) First weigh 70 parts of PP polypropylene raw material, 5 parts of PP polypropylene recycled material, 10 parts of enhanced function talcum powder, 2 parts of carbon black, 0.5 parts of defoamer, 4 parts of Silane coupling agent, 0.2 parts of maleic anhydride graft, 1.3 parts of antioxidant, 7 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com