Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Petroleum sulphonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SULFOL, a natural sulfonate, is a petroleum sulfonic acid bonded to metal elements (Na, Ca, and Ba). Sulfonates are primarily used as additive agents for metal working oils and engine oils. The SULFOL series uses natural mineral oils as a raw material, allowing compatibility with other base oils and additives.

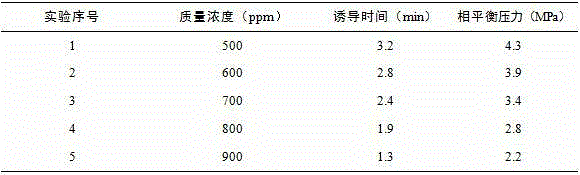

Composite gas hydrate accelerant and application method thereof

ActiveCN104893660APromote generationEasy to prepareOther chemical processesGaseous fuelsSulfonateAcetic acid

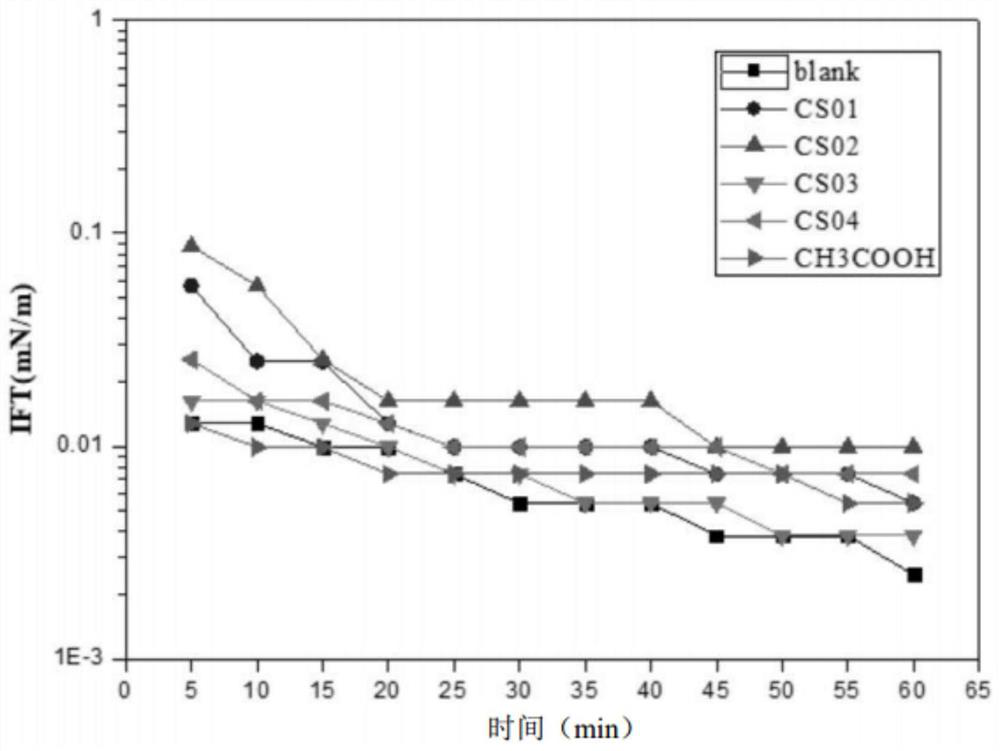

The invention relates to the technical field of the production and utilization of natural gas hydrate, and particularly relates to a composite gas accelerant and an application method thereof. The composite accelerant is prepared by mixing betaine acetate used as an additive, mahogany petroleum sulfonate used as a surface active agent and alkyl amine oxide, wherein by total mass of a mixed aqueous solution, the mass percentage of betaine acetate is 1 to 3 percent; the mass percentage of the surface active agent mahogany petroleum sulfonate is 1.2 to 4.5 percent; the mass percentage of amphiprotic surface active agent alkyl amine oxide is 3 to 5 percent; and the rest is deionized water. The prepared hydrate accelerant is simple in preparation method and good in accelerating effect; the accelerant can effectively improve the generation of hydrate, and the gas hydrate generation condition and generation time can be greatly reduced by virtue of little accelerant, so that the energy consumption can be effectively reduced, and the energy and cost can be saved.

Owner:泉州职业技术大学

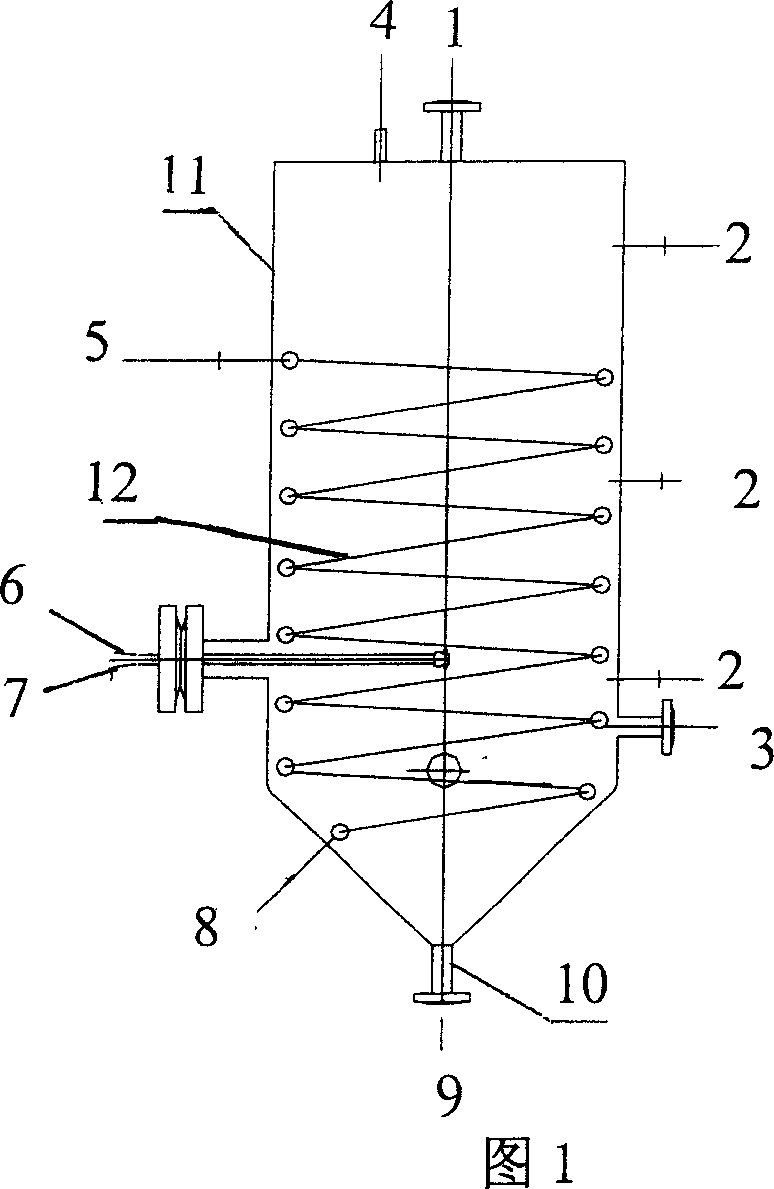

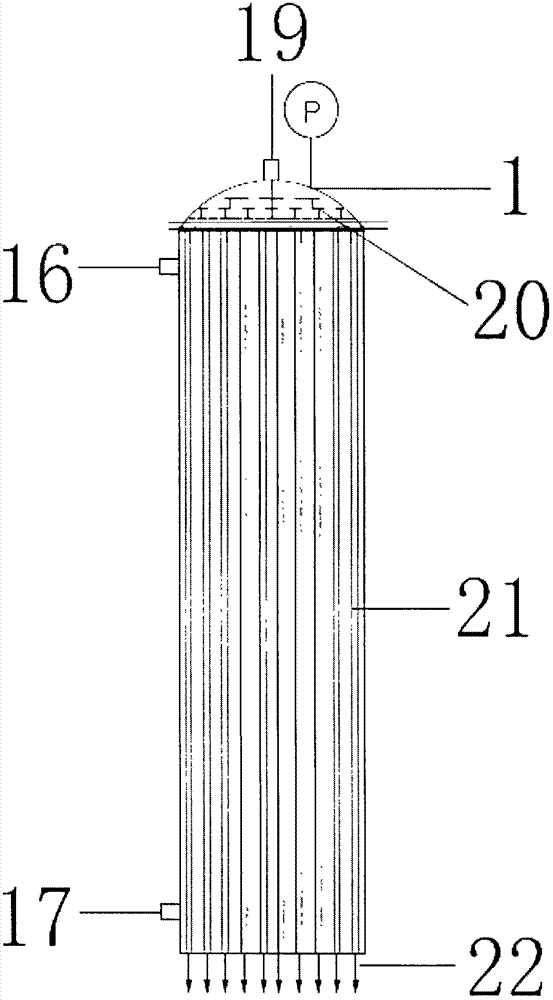

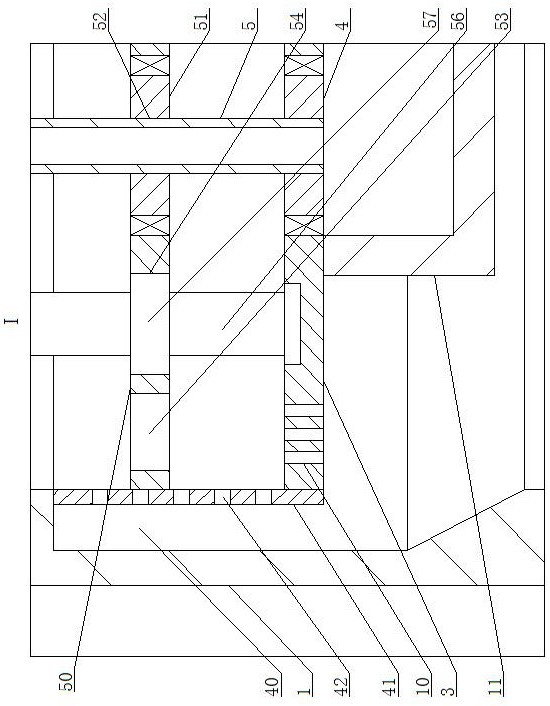

Spray mist film sulphonation reactor

The invention relates to an ejection atomize sulfonation reactor, used in mahogany sulfonate production. Wherein, it comprises ejector atomizer 6, ejector oil inlet 7, ejector 10, etc; the bottom of reaction pot 11 has tail gas outlet 3; the ejector oil inlet 7 has ejector atomizer 6; the bottom of reaction pot 11 has slag discharger 9, the pot 11 contains heating coil tube 12 whose two ends are mounted with temperature increase and decrease medium outlet 5 and inlet 8, to shorten reaction time, reduce side effect, improve yield and reduce the SO3 content.

Owner:PETROCHINA CO LTD

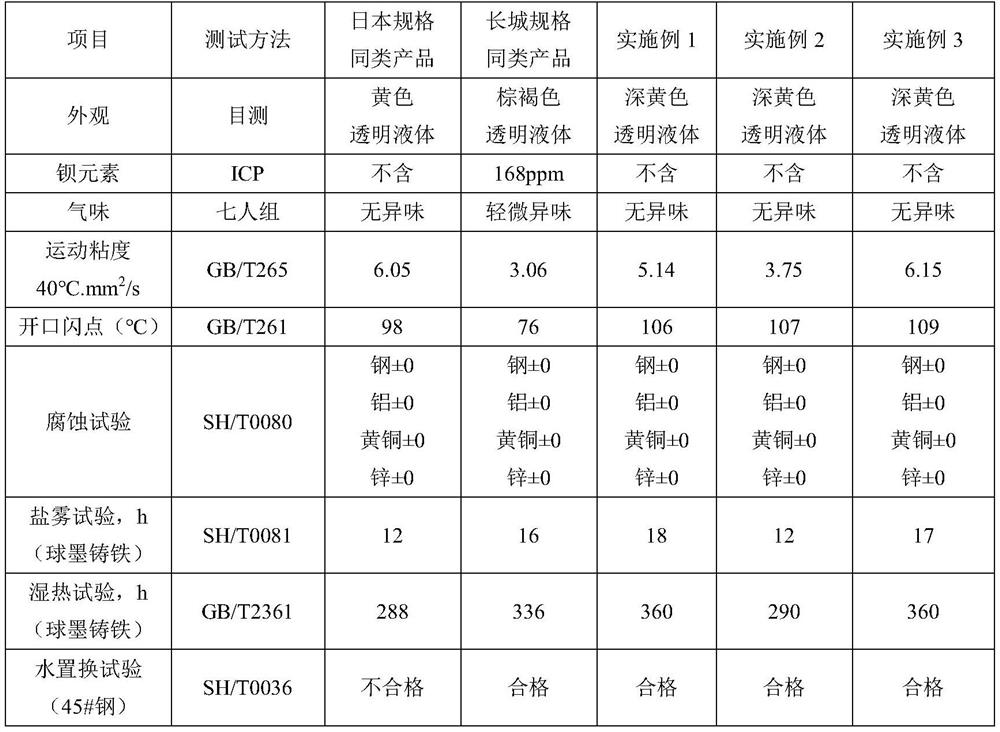

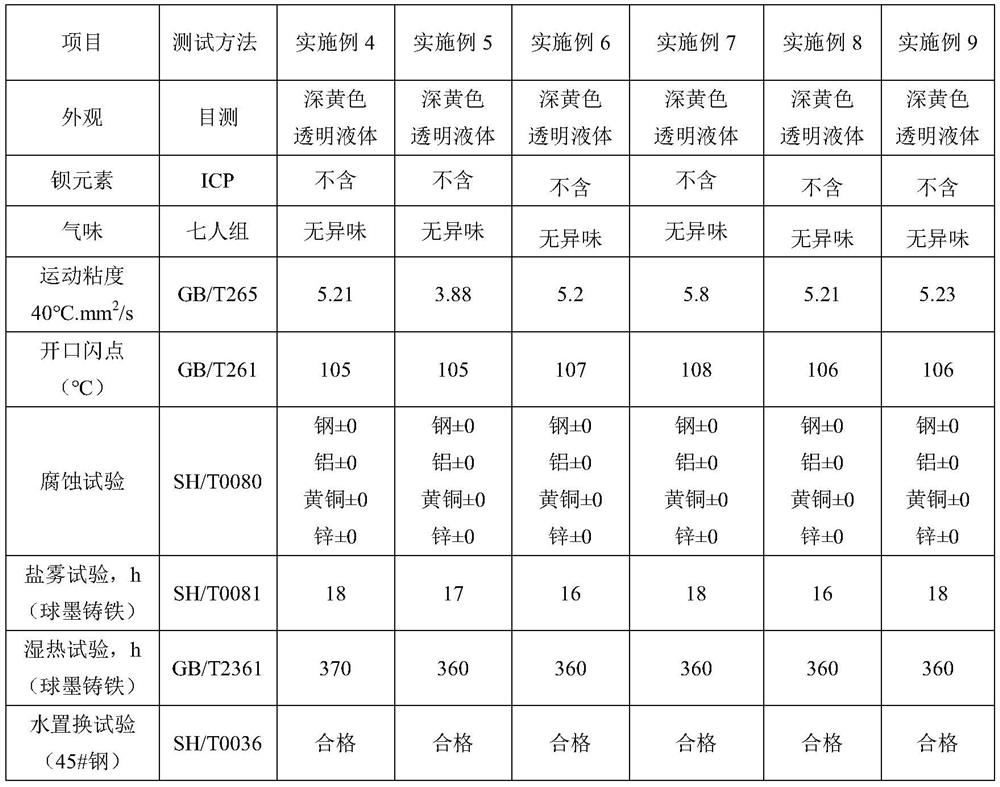

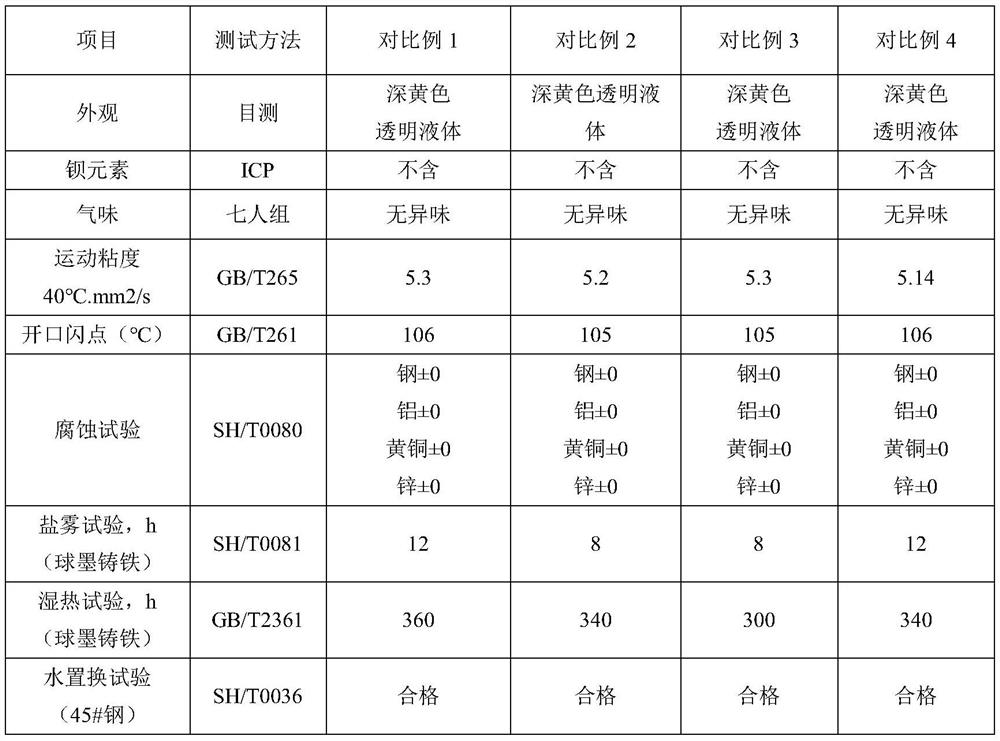

Environment-friendly nodular cast iron antirust oil

PendingCN112011391APlay a role in corrosion inhibitionAnti-rustLubricant compositionLanolinDuctile iron

The invention discloses environment-friendly nodular cast iron antirust oil which comprises the following components in parts by weight: 0.2-1 part of a corrosion inhibitor, 17-26 parts of an antirustagent, 0.1-1 part of an antioxidant, 1-3 parts of a film-forming agent, 2-8 parts of a dispersing agent, 30-50 parts of base oil and 20-50 parts of environment-friendly solvent oil. The antirust agent comprises lanolin metallic soap and mahogany petroleum sulfonate. Under the condition that barium and other heavy metal elements are not contained, the salt mist resistance, the damp-heat resistanceand the water replacement performance of the ductile iron casting all reach the rust prevention effect of barium-containing rust prevention oil, the long-term marine transportation rust prevention requirement can be met, and marine transportation is facilitated; and because of not containing barium and other heavy metal elements, the application range is wider, and export is facilitated.

Owner:希玛石油制品(镇江)有限公司

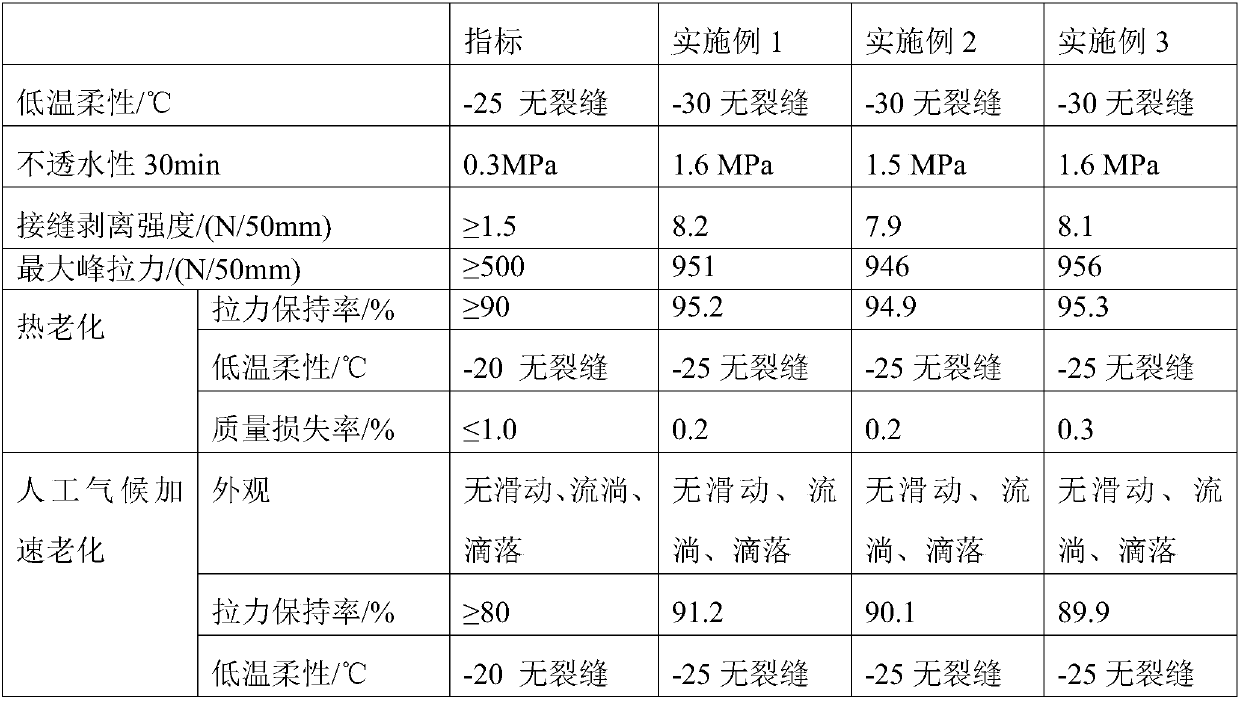

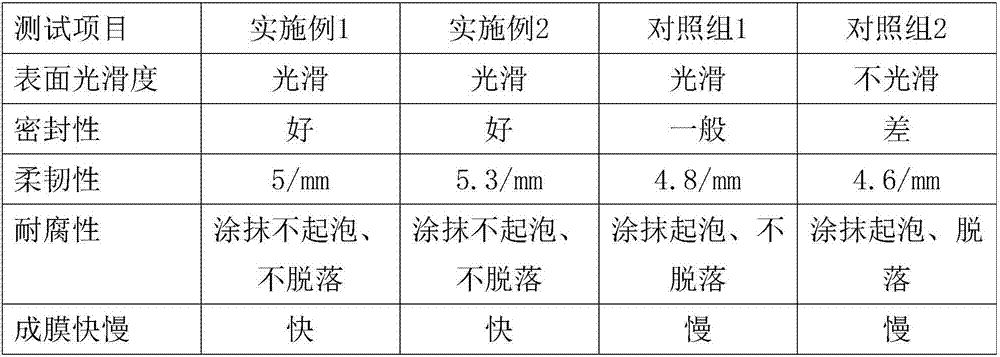

PE composite modified asphalt waterproof coil material and preparation method thereof

InactiveCN110484146AGood high and low temperature performance and storage stabilityImproves water resistance and aging resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesMethyl celluloseSodium oleate

Owner:芜湖市颂晖商贸有限公司

Mahogany petroleum sulfonate preparation method for oil exploitation

InactiveCN103450056AEnhanced overall recoveryHigh content of active substancesSulfonic acids salts preparationDrilling compositionSulfonateChemical reaction

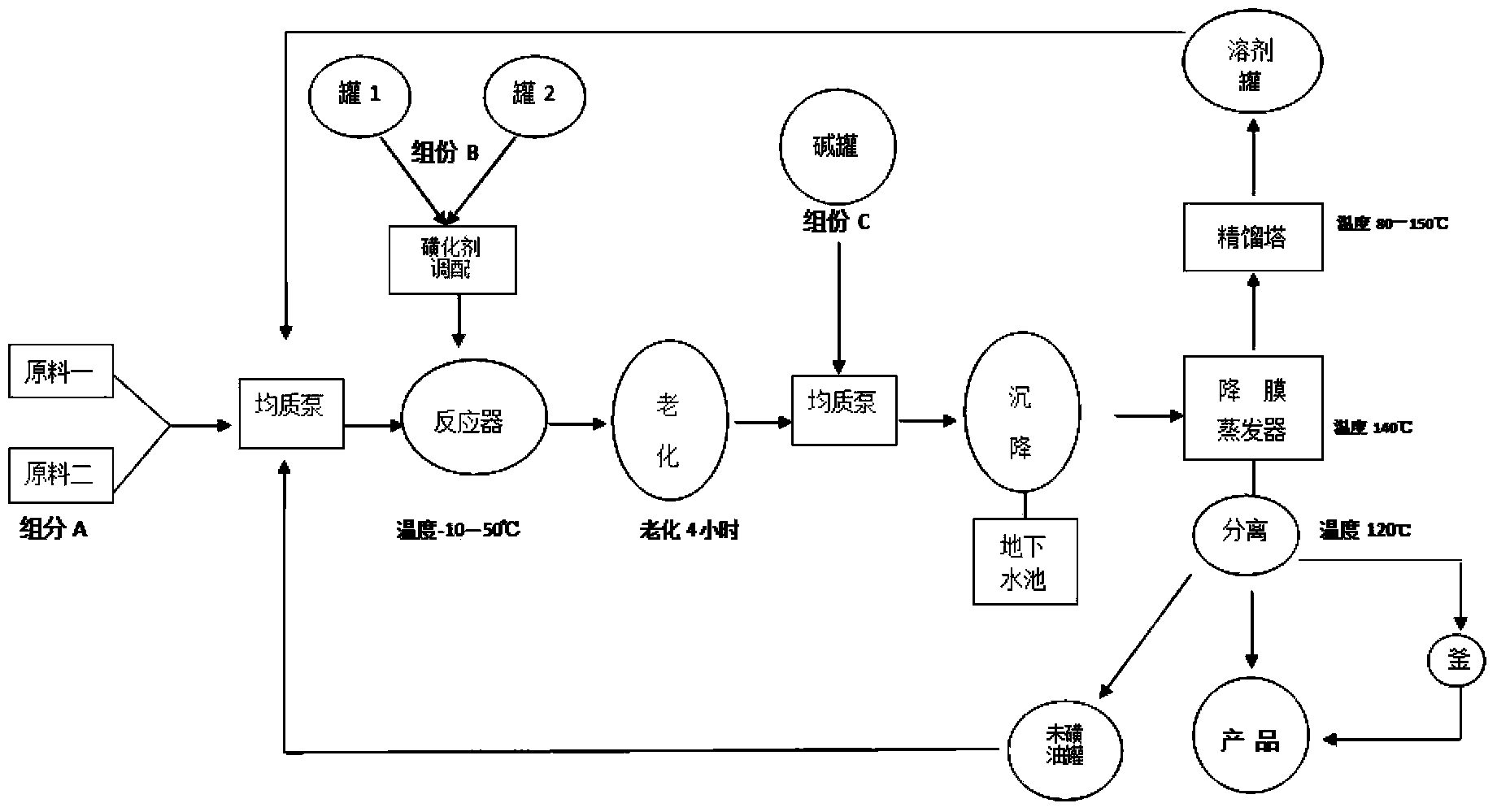

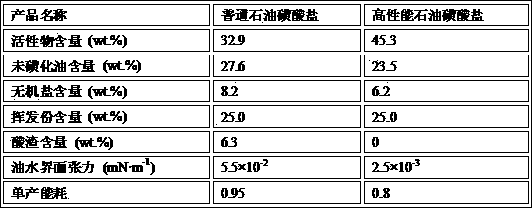

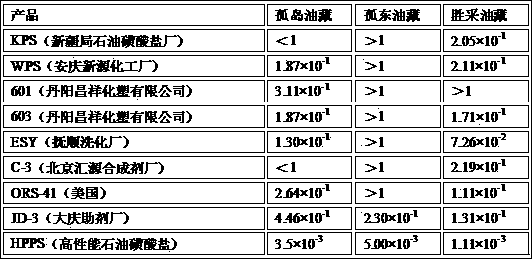

The invention discloses a high-performance mahogany petroleum sulfonate preparation method for enhanced oil recovery in oil exploitation. A mahogany petroleum sulfonate product is prepared from mahogany petroleum sulfonate as well as crude distillate oil on a distillate fraction of 240-590 DEG C, liquid SO3, NH3H2O and dichloroethane or dichloromethane through sulfonating in a rotary packed bed sulfonation reactor, neutralizing by a homogenizing pump and other chemical reactions, as well as carrying out settling separation, film falling and desolventizing processes. The macro-molecule oil soluble mahogany petroleum sulfonate product is prepared from un-sulfonated oil from settling separation and distillate oil at different proportions through repeated sulfonation and neutralization processes. The mahogany petroleum sulfonate product is high in sulfonating rate and high in performance. The invention provides a mahogany petroleum sulfonate product which is high in recovery rate and wide in application as well as a preparation technology of the mahogany petroleum sulfonate product. The mahogany petroleum sulfonate product is a preferred surfactant for chemical displacement of reservoir oil, which is for enhanced oil recovery in oil exploitation.

Owner:王晓晨

Liquid phase additive for use in thermal cracking process to improve product yields

The present invention relates to a liquid phase additive comprising an alkyl nitrate; a petroleum sulphonates; an aliphatic, aromatic, cyclohexylamines or hetroalkylated lower amines; a hindered phenol based compounds; a phosphate esters and an aliphatic alcohols for use in delayed coking process with decreased coke yield and increased yield of liquid and / or gaseous product and a process for preparing the liquid phase additive. The present invention also relates to a process for thermal cracking of petroleum residue producing petroleum coke and lighter hydrocarbon products by using liquid phase additive.

Owner:INDIAN OIL CORPORATION

Antirust paint used for electrical equipment

InactiveCN107267042AEnhanced rust inhibitorAnti-rust agent acts as a modifier to enhance the oxidation resistance enhancementAnti-corrosive paintsPolyurea/polyurethane coatingsSilicon dioxideMaterials science

The invention discloses an antirust paint used for electrical equipment. The antirust paint used for electrical equipment is prepared from, by weight, 20 to 30 parts of modified alkyd resin, 8 to 15 parts of polyurethane modified acrylic emulsion, 10 to 15 parts of polyether modified siloxane, 5 to 10 parts of a petroleum sulfonate, 4 to 8 parts of xylene, 7 to 15 parts of an oily wax, 8 to 12 parts of a polyphosphate, 2 to 4 parts of chlorinated polyvinyl chloride, 5 to 10 parts of C5 hydrogenated petroleum resin, 1 to 3 parts of silicon dioxide, and 4 to 6 parts of an antirust agent. The beneficial effects are that: modified alkyd resin, polyurethane modified acrylic emulsion, and polyether modified siloxane are taken as main raw materials, xylene, the oily wax, the polyphosphate, C5 hydrogenated petroleum resin, silicon dioxide, and the antirust agent are added as modifying agents, so that oxidation resistance, stability, and antirust properties are improved.

Owner:安徽新智电力科技有限公司

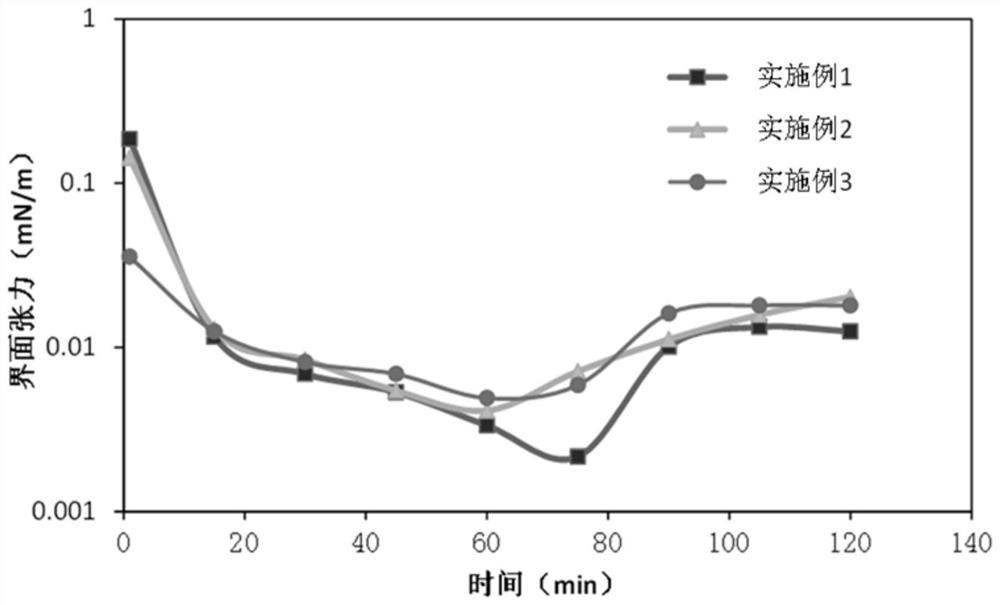

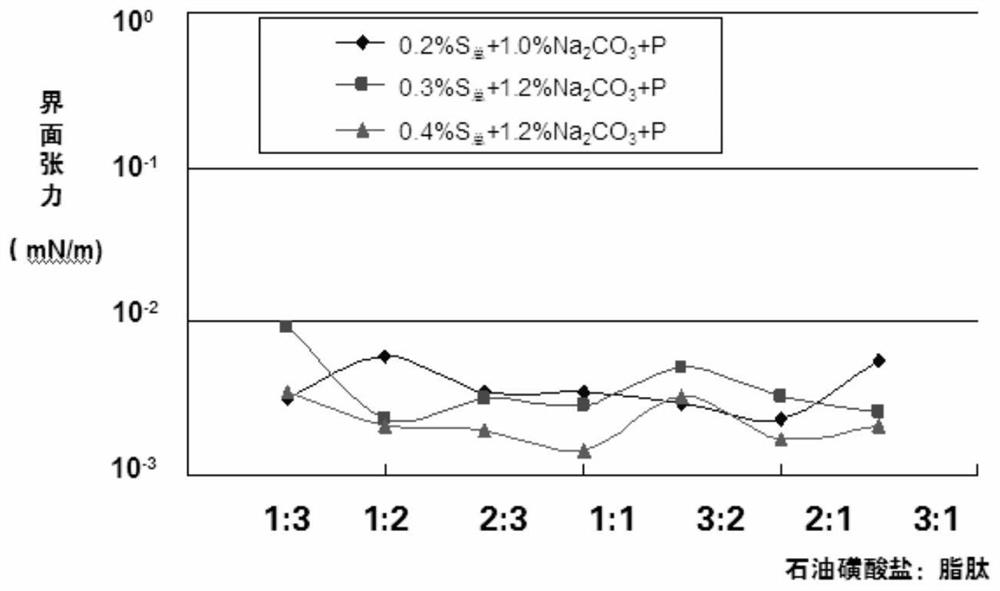

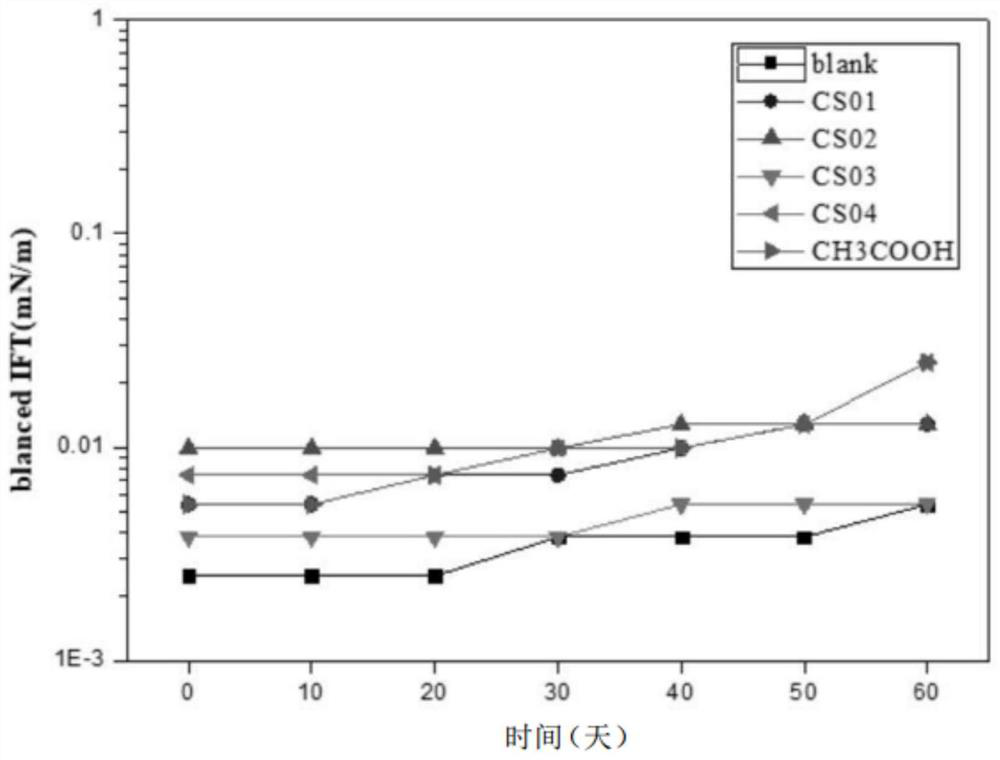

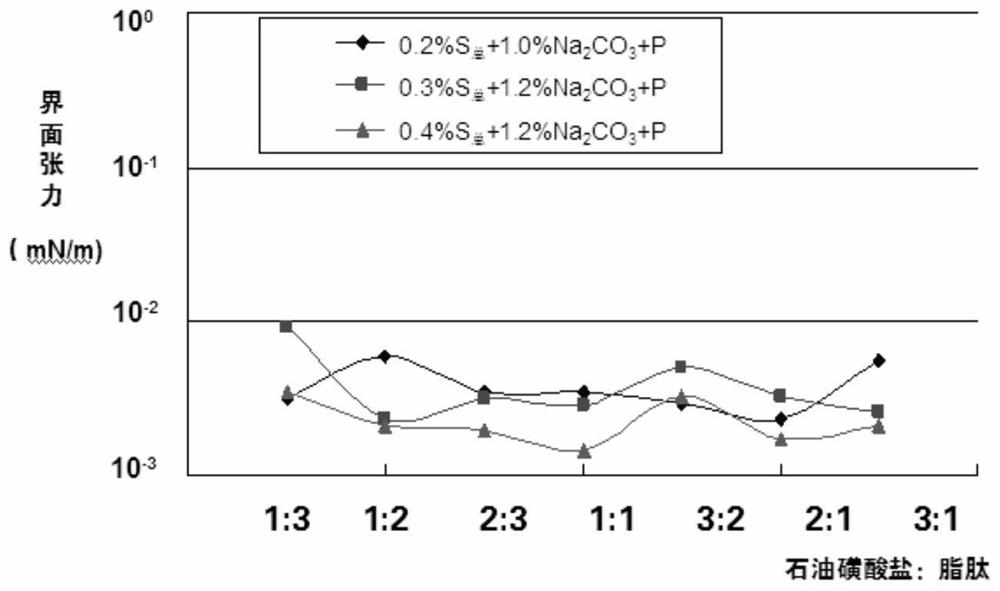

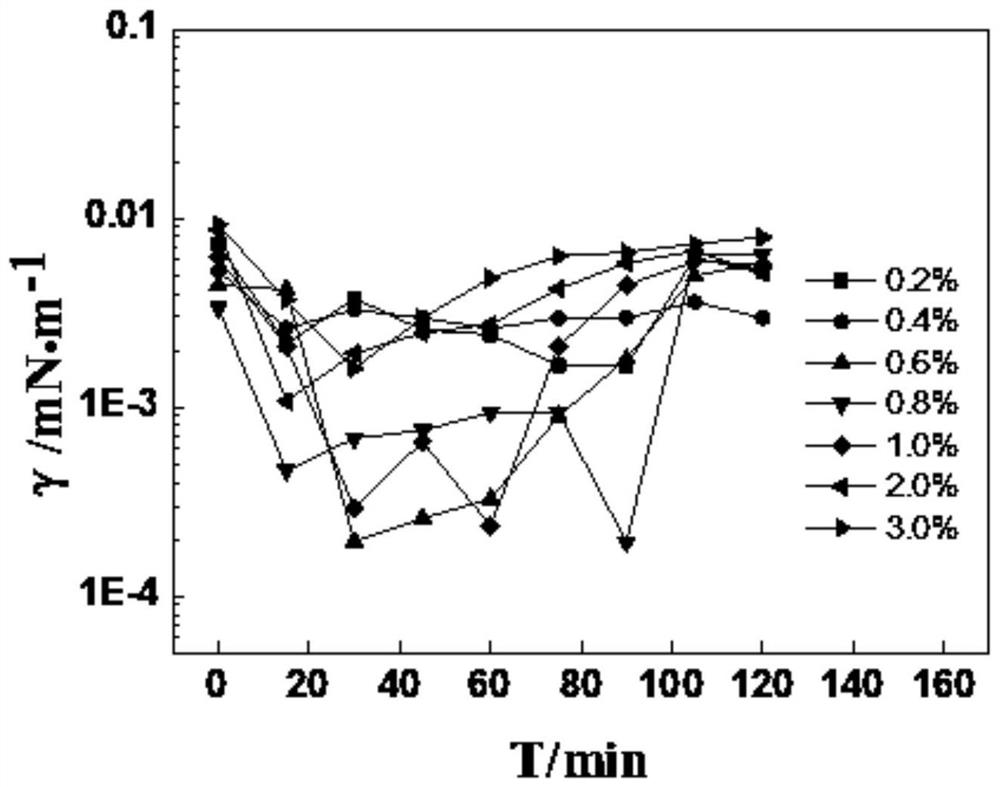

Naphthenic petroleum sulfonate compound oil-displacing agent for fracturing fluid and preparation method thereof

The invention relates to the technical field of oil and gas exploitation, in particular to a naphthenic petroleum sulfonate compound oil-displacing agent for a fracturing fluid and a preparation method thereof. The naphthenic petroleum sulfonate compound oil-displacing agent for the fracturing fluid is prepared from the following raw materials of: naphthenic petroleum sulfonate, ethylenediamine tetraacetic acid disodium salt and the balance of the fracturing fluid. The preparation method comprises the following steps of: mixing naphthenic petroleum sulfonate with water, adding a naphthenic petroleum sulfonate solution and ethylenediamine tetraacetic acid disodium salt into the fracturing fluid, and uniformly mixing to obtain the naphthenic petroleum sulfonate compound oil-displacing agentfor the fracturing fluid. The naphthenic petroleum sulfonate is used as a surfactant to be compounded with the fracturing fluid; the obtained naphthenic petroleum sulfonate compound oil-displacing agent for the fracturing fluid can have ultralow interfacial tension in a relatively wide calcium ion mass concentration range; the problem of low crude oil recovery ratio caused by single exploitation mode in the prior art is solved; the crude oil recovery ratio can be increased to the maximum; raw materials are low-cost and easily available; and safety and high efficiency are achieved.

Owner:克拉玛依金昇油田助剂有限公司

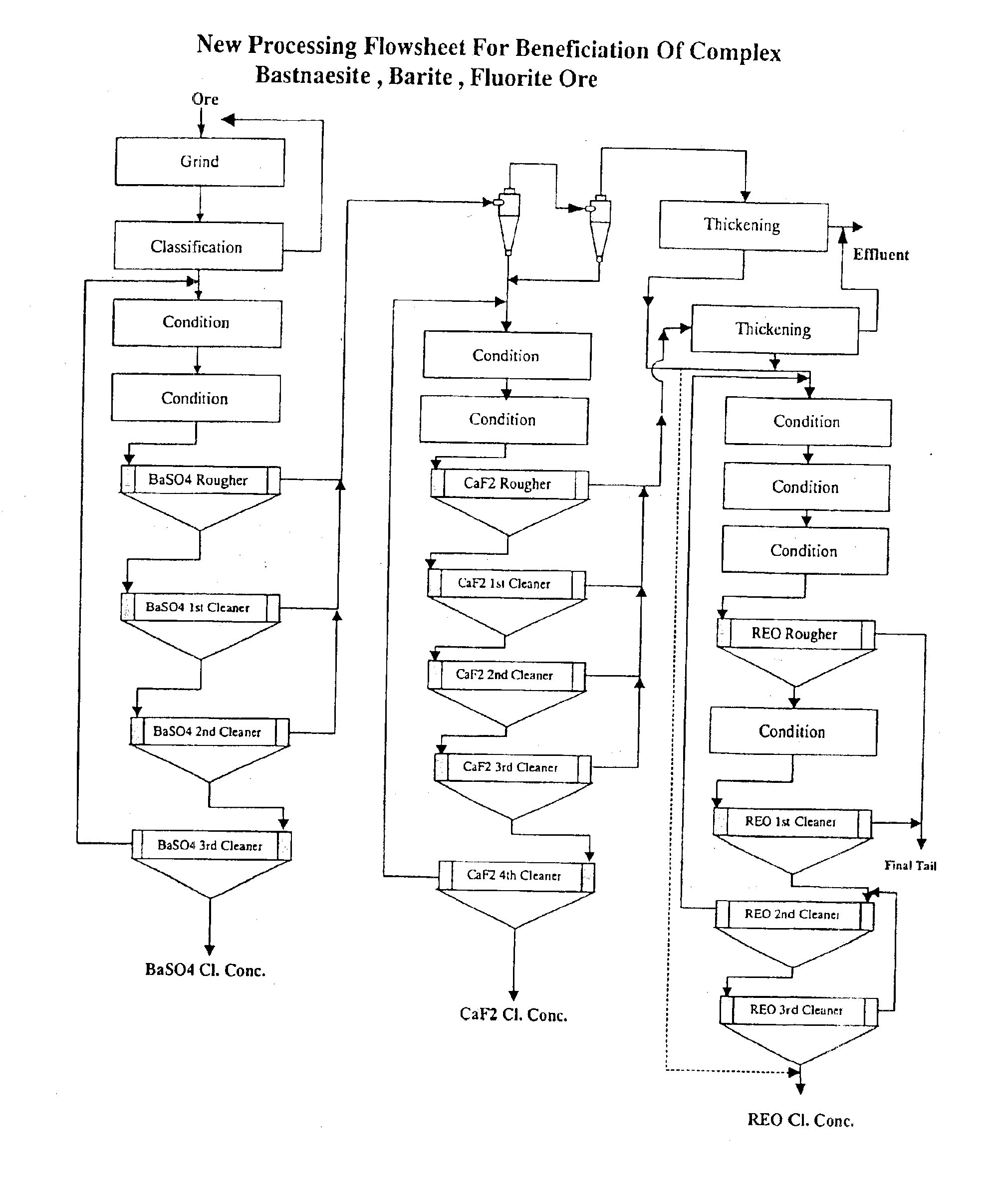

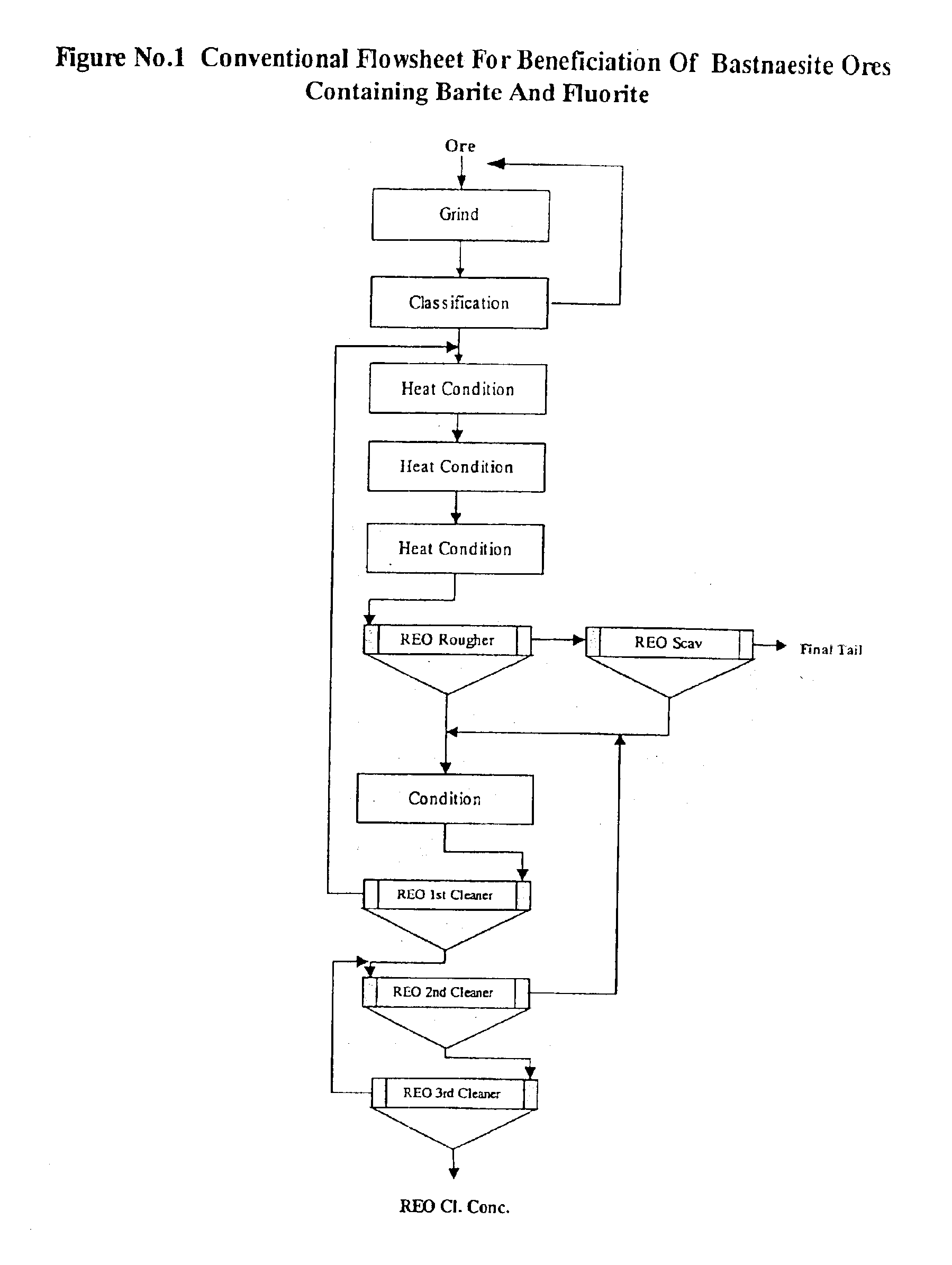

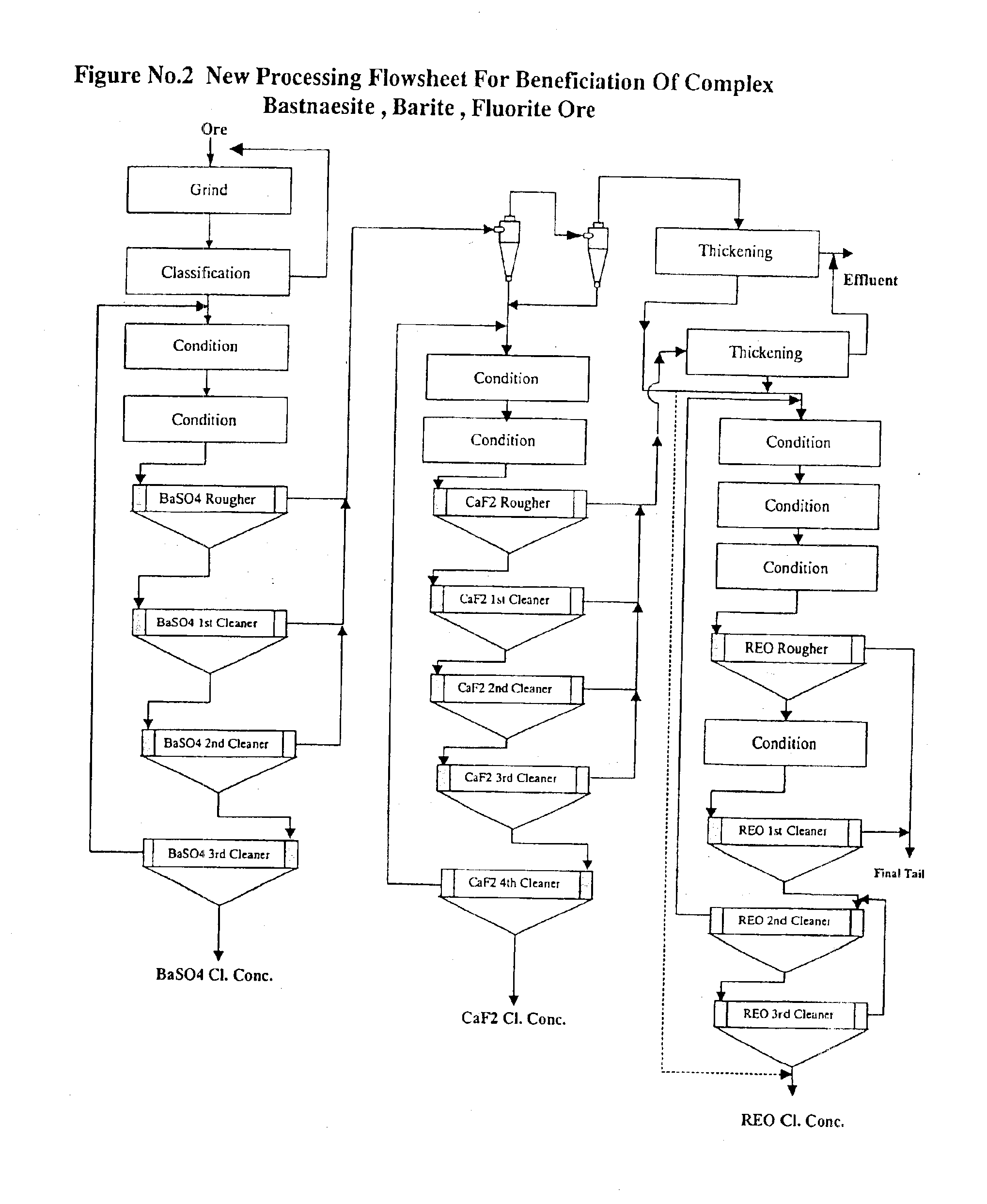

Process for separation of bastnaesite from weathered bastnaesite barite fluorite ores

The present invention provides a process for the recovery of bastnaesite and other minerals containing rate earth oxide from complex, weathered ores containing barite, borite, fluorites and / or barite, fluorites, silicates and iron oxides, and comprises reverse barite flotation using a barite collector containing the following individual reagents:1. Petroleum sulphonate30-40% by weight2. Sulphosuccinate30-40% by weight3. Sulphosuccinamate30-40% by weight

Owner:SUMIKO RESOURCES EXPLORATION & DEV

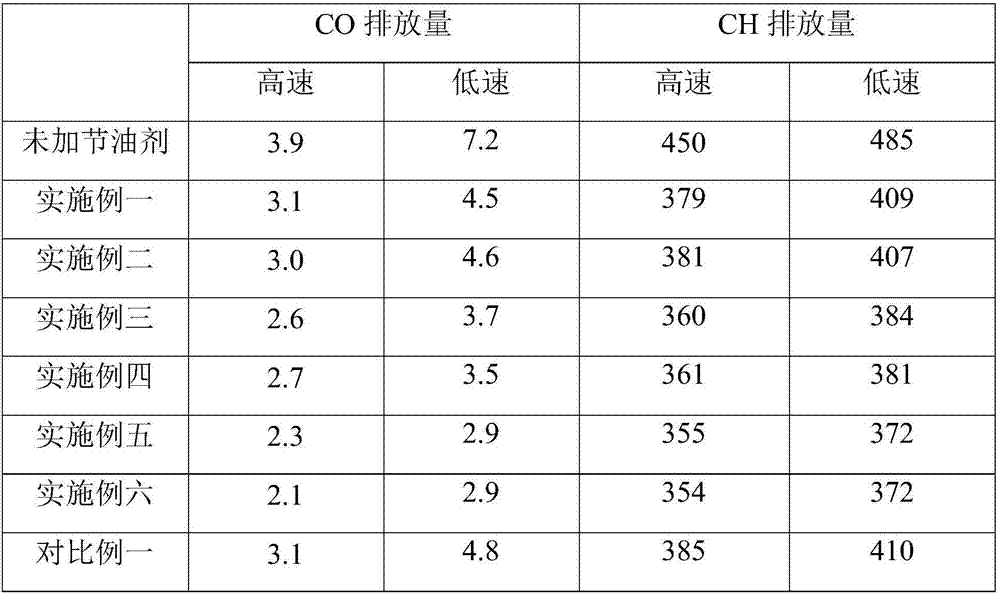

Efficient maintenance oil-saving agent for fuel engine as well as preparation method and application of efficient maintenance oil-saving agent

InactiveCN107460011AGuaranteed combustion qualityImprove powerLiquid carbonaceous fuelsFuel additivesTert butyl phenolKerosene

The invention relates to an efficient maintenance oil-saving agent for a fuel engine as well as a preparation method and application of the efficient maintenance oil-saving agent. The efficient maintenance oil-saving agent contains the following raw materials in parts by weight: 15-20 parts of fuel, 3-8 parts of petroleum sulfonate, 1-3 parts of dimethlbenzene, 2-5 parts of an engine lubricant, 1-5 parts of titanium dioxide, 0.1-0.5 part of graphene, 1-2 parts of 4,6-tri-tert-butyl phenol and 1-2 parts of hydroxide. According to the efficient maintenance oil-saving agent provided by the invention, the combustion quality of fuel can be effectively guaranteed, the power performance of the energy is improved, the emission of pollutants is reduced, the utilization rate of the fuel is remarkably increased, and the service life of the fuel engine is remarkably prolonged; and besides, the oil-saving agent is simple in process formula, relatively low in production cost and strong in maneuverability, has good energy conservation and emission reduction effects and very good economic benefit and social benefit and is beneficial to subsequent large-scale application.

Owner:广东国藩节能环保科技有限公司

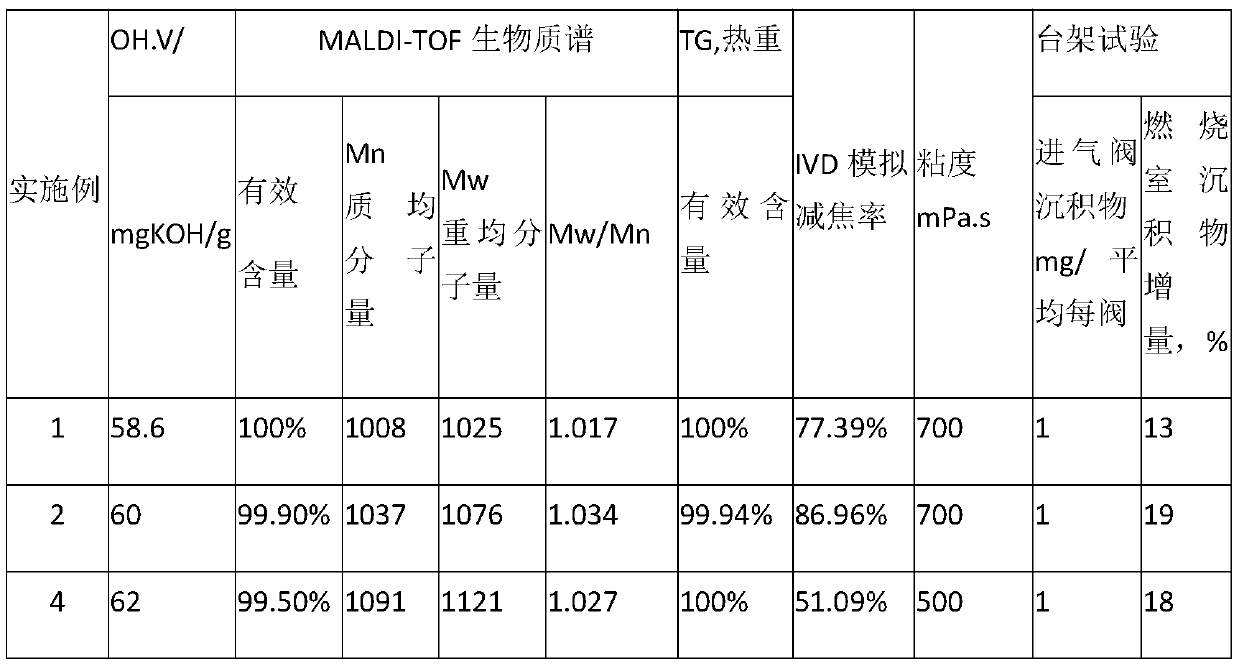

Polyether polyol for fuel additive, and preparation method and application of polyether polyol

ActiveCN110862529AShorten the production cycleReduce residualLiquid carbonaceous fuelsFuel additivesEpoxyPolymer science

The invention discloses a preparation method of polyether polyol and an application thereof. In an inert atmosphere, a C4-C18 unitary fatty alcohol, an epoxy compound and a catalyst are added into a reactor together, and reacting is carried out for 2-3 hours at 70-180 DEG C under 0.3-0.6 MPa to obtain the polyether polyol, wherein the weight ratio of the C4-C18 unitary fatty alcohol to the epoxy compound is (1-5):(10-22), and the catalyst is one or more selected from potassium methoxide, sodium methoxide, potassium hydroxide and sodium hydroxide. The polyether polyol can be mixed with polyisobutylene amine, an auxiliary agent, a dispersant, an antioxidation agent, glycerin and petroleum sulfonate to prepare a fuel additive. The preparation method provided by the invention improves purity of polyether polyol, reduces emission of waste gas, avoids air pollution, improves a catalyst, and strengthens operation safety of personnel.

Owner:武汉帕浦安科技有限公司

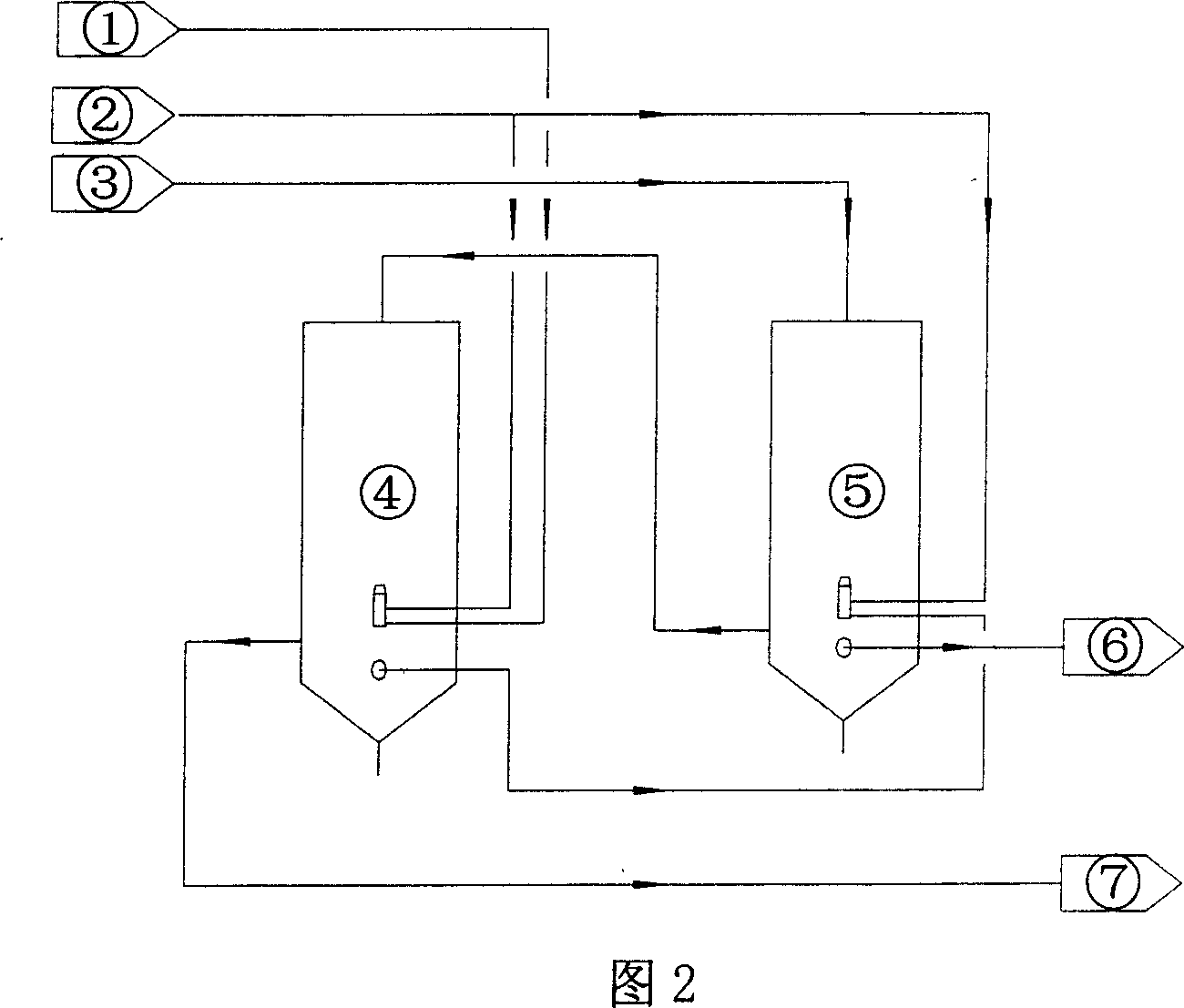

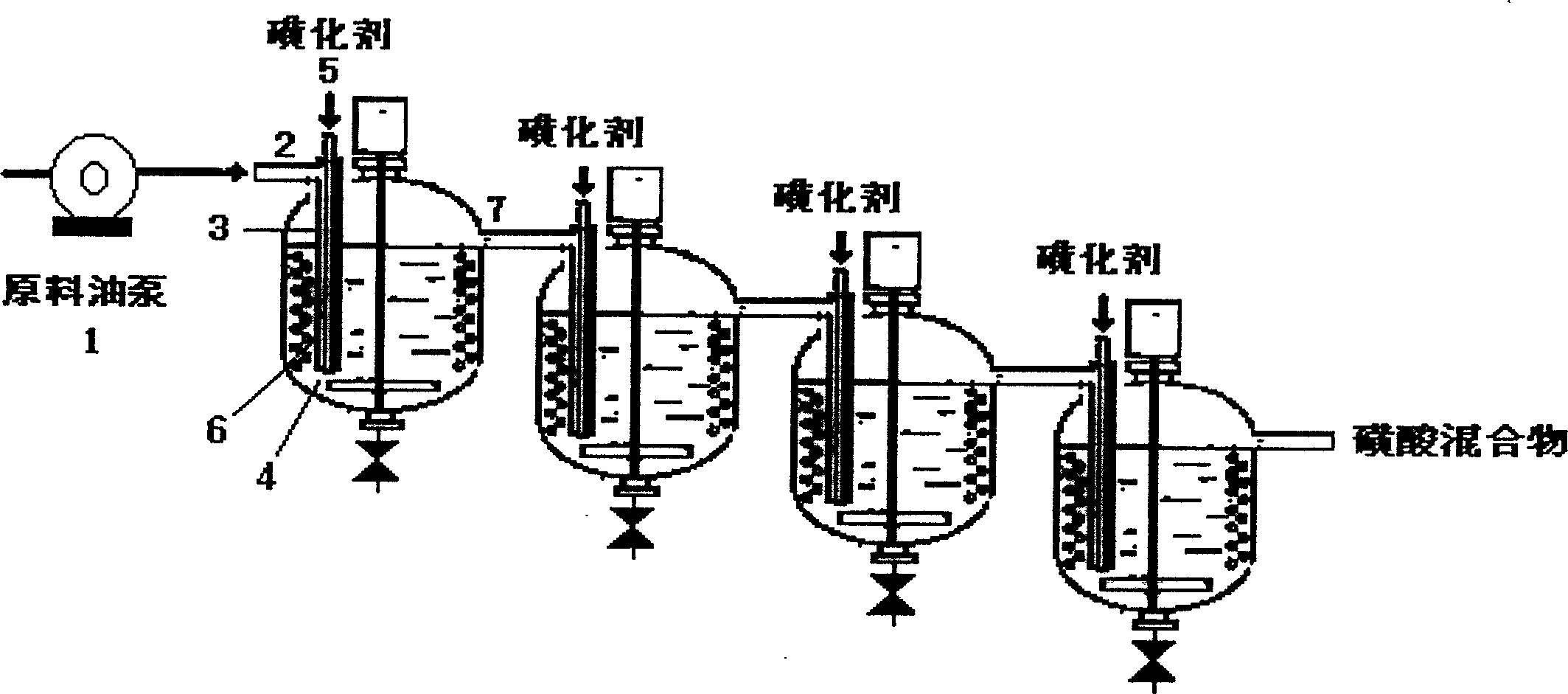

Continuous preparing method for petroleum sulfosalt

A process for continuously preparing petroleum sulfonate with serially connected 2-8 sulfonating reactors includes such steps as feeding the crude oil and sulfonating agent respectively in the first reactor, sulfonating reacting, feeding the resultant mixture in the second reactor, and so on, and neutralizing the sulfonic acid discharged from the last reactor to obtain petroleum sulfonate. Its advantage is high sulfonating rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

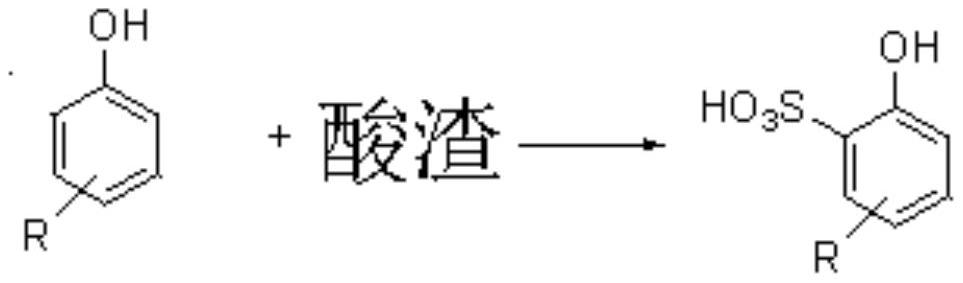

Acid residue treatment method and binary oil displacement surfactant

InactiveCN113666849AHarm reductionImprove performanceDrilling compositionSulfonic acid preparationSulfonateActive agent

The invention provides an acid residue treatment method and a binary oil displacement surfactant. The treatment method comprises the following steps: carrying out a sulfonation reaction on acid residue and long-chain alkylphenol to obtain sulfonic-substituted long-chain alkylphenol, wherein the long-chain alkyl in the long-chain alkylphenol refers to alkyl with the C atom number of 10-22; and carrying out a neutralization reaction on the sulfonic-substituted long-chain alkylphenol to obtain the benzene sulfonate. According to the treatment method, innocent treatment is conducted on the acid residue, harm of the acid residue to the environment is reduced, benzene sulfonate with excellent performance is obtained, and in subsequent tertiary oil recovery, the benzene sulfonate and naphthenic base petroleum sulfonate are compounded to form a binary oil displacement surfactant with better interfacial tension performance and higher oil displacement efficiency; and the binary oil-displacing agent with excellent performance is obtained by utilizing the acid residue, so that harmless recycling of wastes is realized, and outdated incineration and burying methods which pollute the environment are eliminated.

Owner:PETROCHINA CO LTD

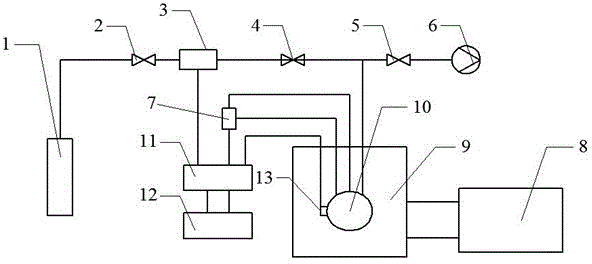

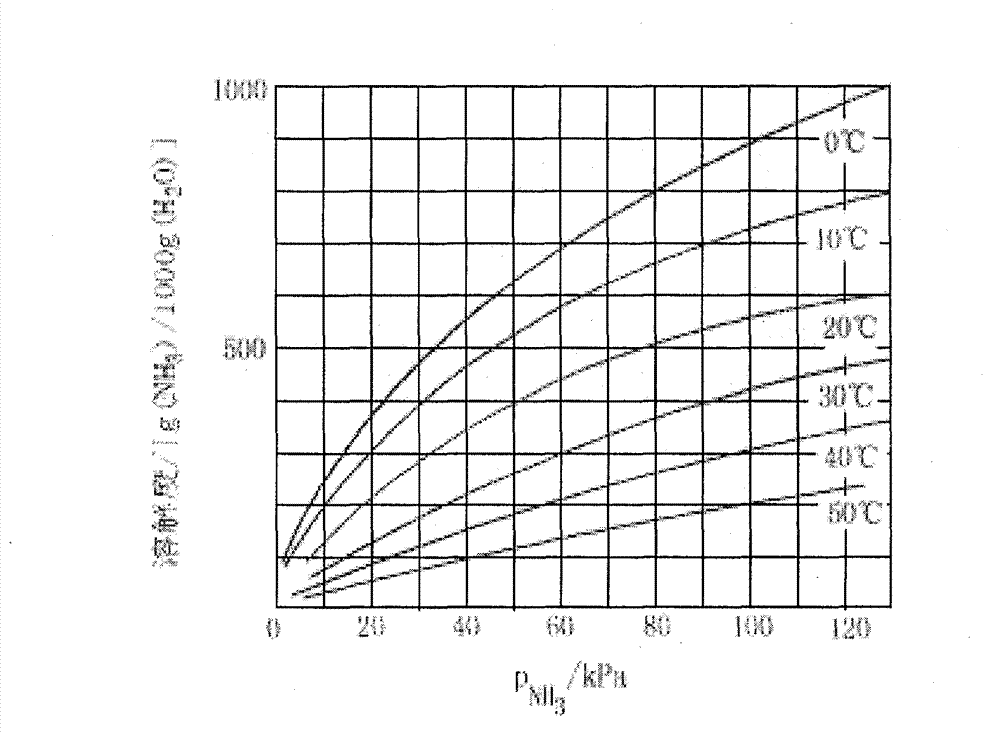

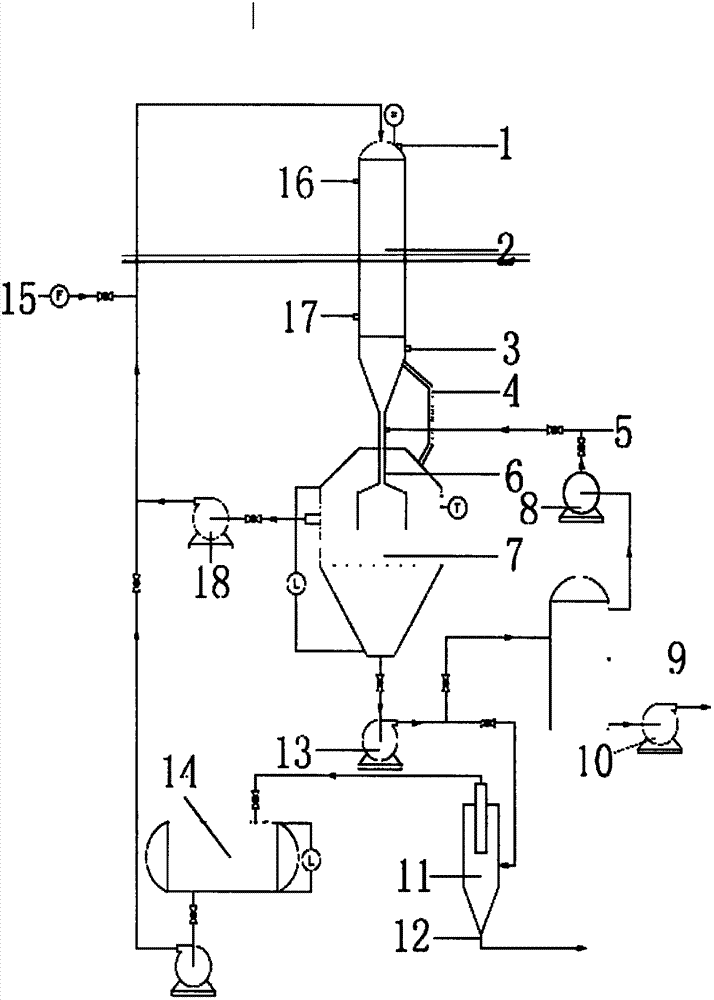

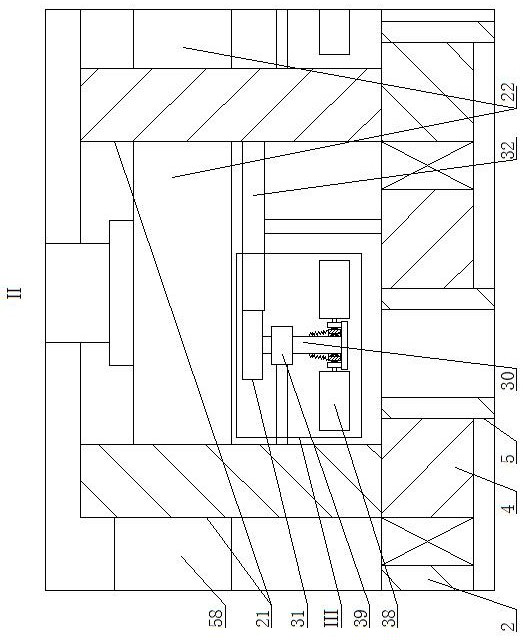

Desalination method and device in petroleum sulfonate production

ActiveCN102849884AEasy to operateHigh degree of automationGeneral water supply conservationMultistage water/sewage treatmentCommunicating vesselsDissolution

The invention relates to a method and a device for precipitating salt from salt-containing waste water in sulfonate production, and provides a desalination method and a device with low energy consumption and simple process. Ammonia is dissolved in cooled salt-containing waste water for salt crystallization and precipitation; the salt-containing waste water after salt separation is recycled for cooling and ammonia dissolution; and thus salts are precipitated and separated continuously which allows the waste water to reach the desalination requirements. The device comprises a cooler, a crystallizer, a cyclone separator, and buffer tank; the cooler is provided with a refrigerant fluid outlet, a refrigerant fluid inlet, and an exhaust port at the top; the cooler is connected with the crystallizer through a communicating vessel; a transfer pump and a flash evaporation tank are disposed between the crystallizer and the cyclone separator; the cyclone separator is connected with the buffer tank; the cyclone separator is provided with a solid material outlet. With the above technical scheme, the desalination speed is high, and the efficiency is high. The operation is simple; the automation degree is high; the device maintenance is convenient; and the labor intensity is low. Ammonia in waste water after production can be recovered and recycled, which saves production cost.

Owner:SHANDONG DAMING FINE CHEM CO LTD

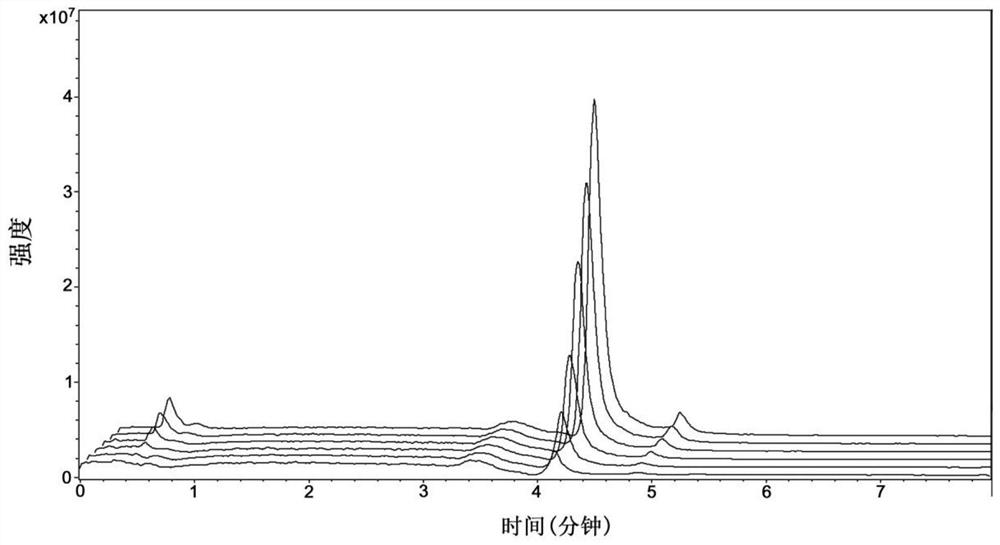

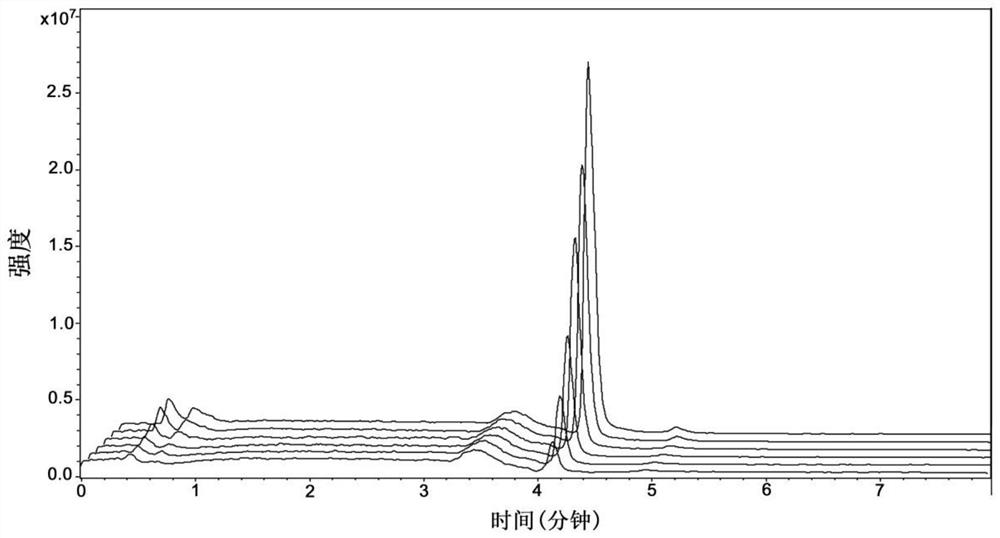

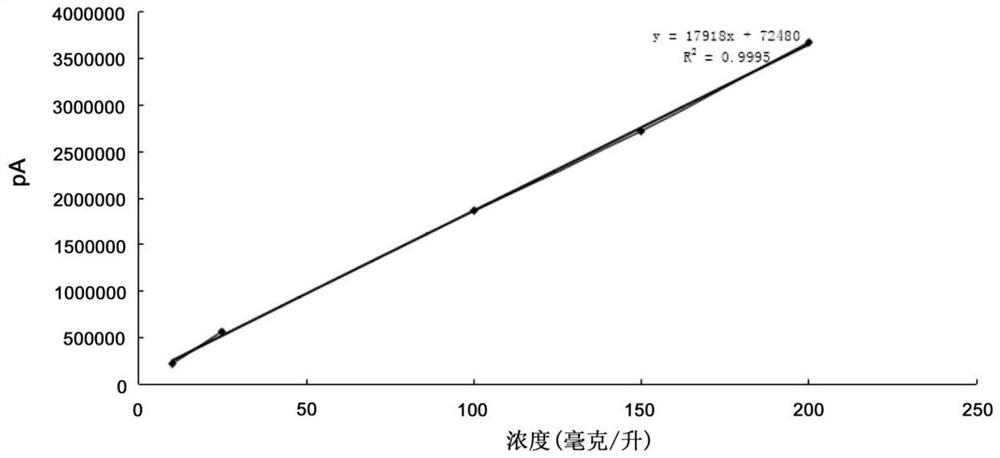

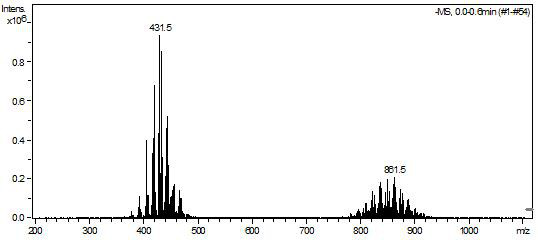

Method for quantitatively detecting naphthenic sulfonate components and residual oil sulfonate components in petroleum production liquid

ActiveCN112697892AAccurate quantitative analysisAccurate detection result information volumeComponent separationSulfonateFluid phase

The invention relates to a method for quantitatively detecting naphthenic sulfonate components and residual oil sulfonate components in petroleum production liquid. The method comprises the following steps: establishing a first standard curve of naphthenic sulfonate content and a second standard curve of residual oil sulfonate content by adopting a liquid chromatography-mass spectrometry method; by adopting the liquid chromatography-mass spectrometry method, obtaining a spectrogram of a naphthenic sulfonate component and a residual oil sulfonate component in the petroleum production liquid; and according to the first standard curve and the spectrogram, obtaining the content of the naphthenic sulfonate component in the petroleum production liquid, and according to the second standard curve and the spectrogram, obtaining the content of the residual oil sulfonate component in the petroleum production liquid. The method provided by the invention can be used for accurately and quantitatively detecting the contents of the two petroleum sulfonate surfactants in the petroleum production liquid.

Owner:PETROCHINA CO LTD

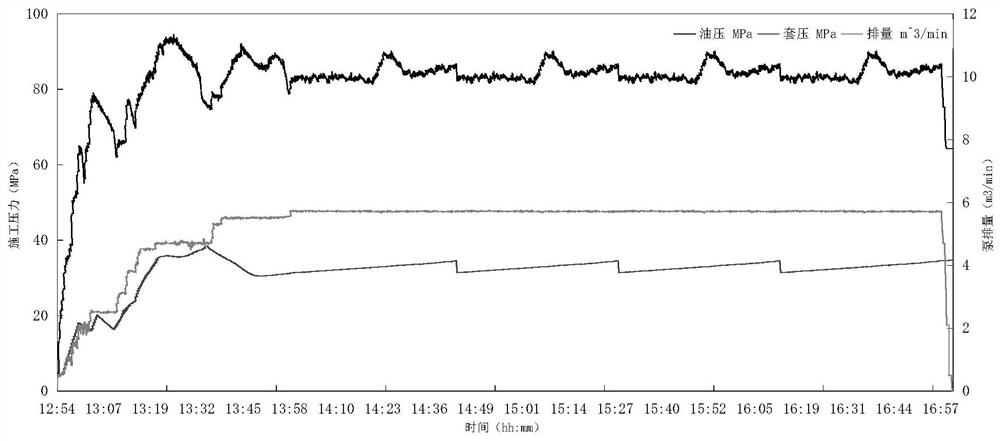

Method for storing crude oil by using low-permeability ultra-low-permeability stratum

ActiveCN111636921AMinimize or even eliminate damageService securityMining devicesFluid removalSulfonateKerosene

The invention relates to a method for storing crude oil by using a low-permeability ultra-low-permeability stratum. The method comprises the steps that the crude oil or a crude oil-based system is injected into the low-permeability ultra-low-permeability stratum through reservoir fracturing, flowback is avoided after fracturing is completed, and crude oil storage or integration of reservoir fracturing and crude oil storage is achieved; the crude oil-based system consists of petroleum sulfonate, a thickening agent and a solvent; and the solvent is the crude oil or a mixture of the crude oil andgasoline, diesel oil, kerosene or condensate oil. According to the method, on the basis of low oil price and low-permeability ultra-low permeability stratum characteristics, the pollution of a systemto a reservoir can be reduced or even eliminated, and the single-well production capacity is improved; after fracturing construction, a well can be duly opened for production according to crude oil consumption requirements, and the function of an underground oil storage depot is achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Chemical augmented injection system for improving injectivity of oil displacement polymer

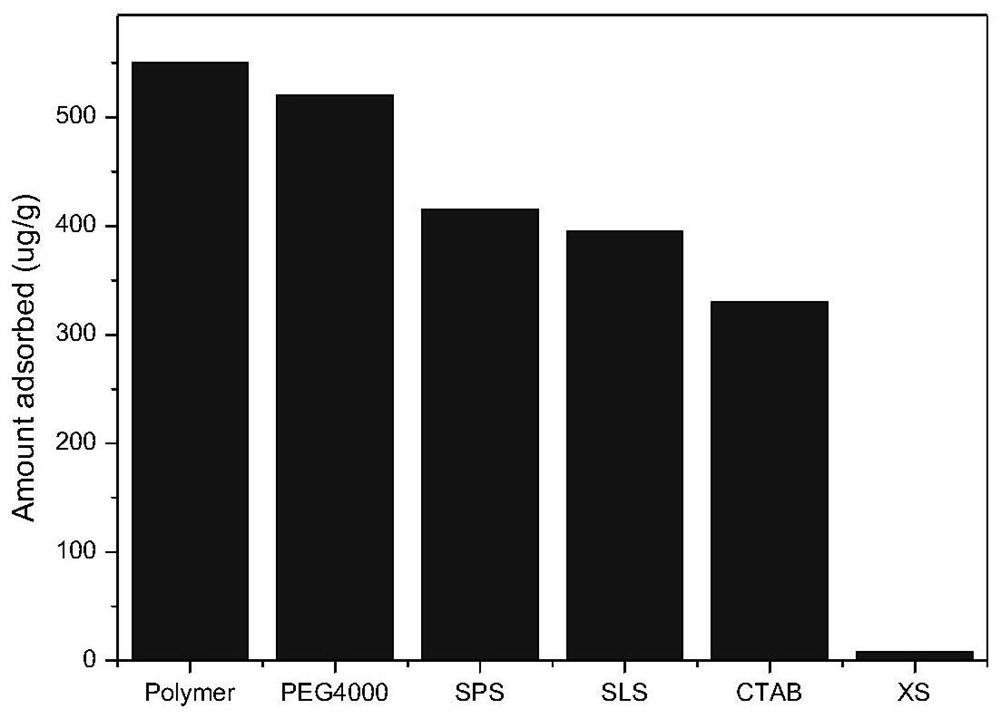

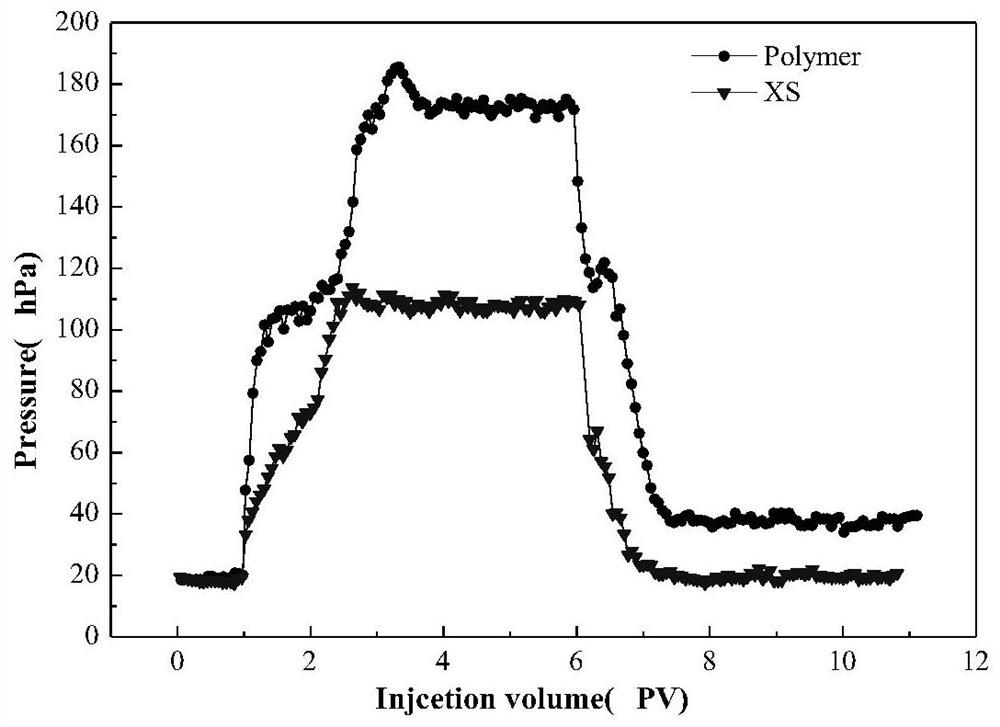

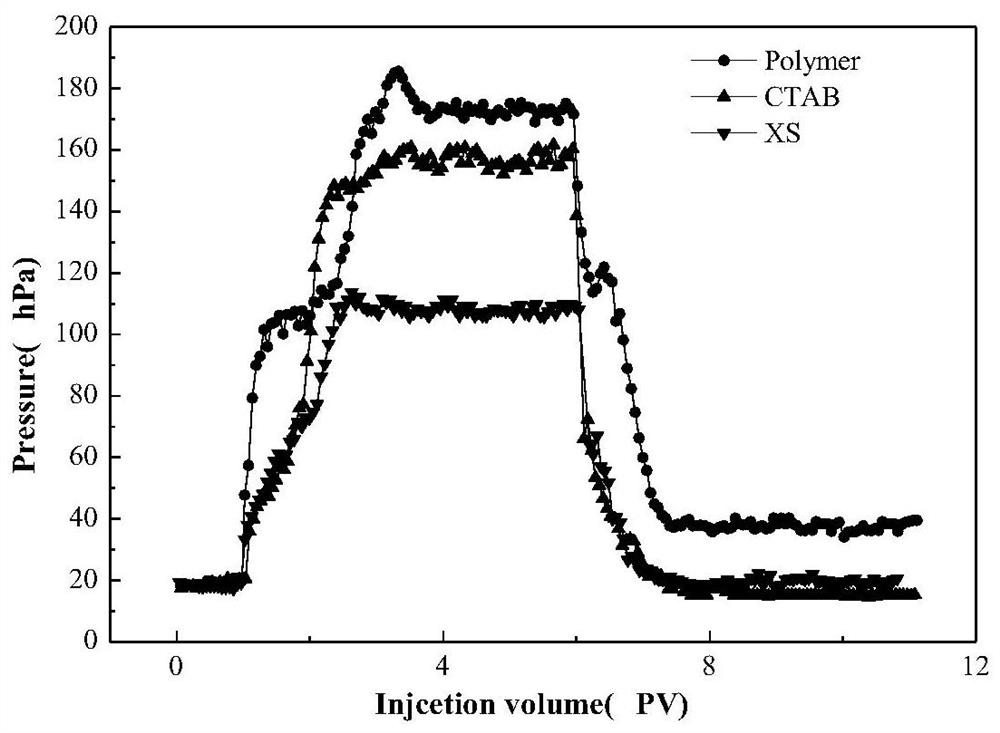

ActiveCN112210361AReduce the amount of adsorptionReduce injection pressureFluid removalDrilling compositionPetroleum oilMethyl palmoxirate

The invention discloses a chemical augmented injection system for improving injectivity of an oil displacement polymer. The chemical augmented injection system consists of an organic silicon sacrificial agent and an auxiliary agent, wherein the molecular formula of the organic silicon sacrificial agent is R1-Si(OR2)3, in the formula, R1 is substituted or unsubstituted C1-C15 alkyl or C2-C15 alkenyl, and R2 is C1-C15 alkyl; the auxiliary agent is a mixture of N-methyldiethanolamine and mahogany petroleum sulfonate or a mixture of N,N,N',N'-tetrakis(2-hydroxypropyl)ethylenediamine and mahogany petroleum sulfonate; the chemical augmented injection system comprises the following components in percentage by mass: 50-90% of an organic silicon sacrificial agent, and 10-50% of an assistant. The chemical augmented injection system provided by the invention is a composite system formed by the organic silicon sacrificial agent and the auxiliary agent thereof, the organic silicon sacrificial agentplays a role in changing reservoir wettability and reducing polymer adsorption, and the auxiliary agent of the sacrificial agent plays a role in cleaning residual crude oil near a wellbore, activating the surface of rock and promoting the reaction of organosilane and the surface of rock.

Owner:CNOOC TIANJIN BRANCH +1

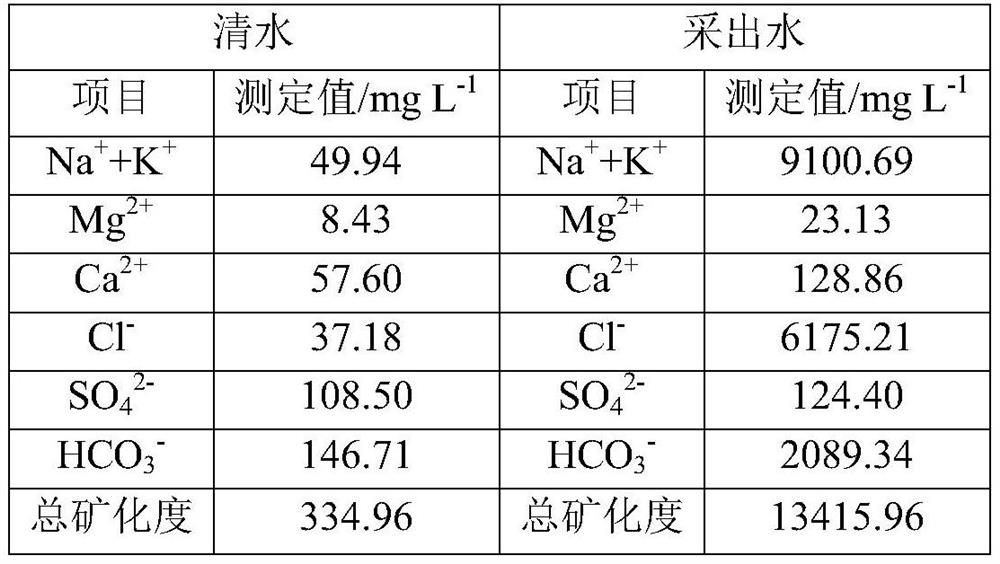

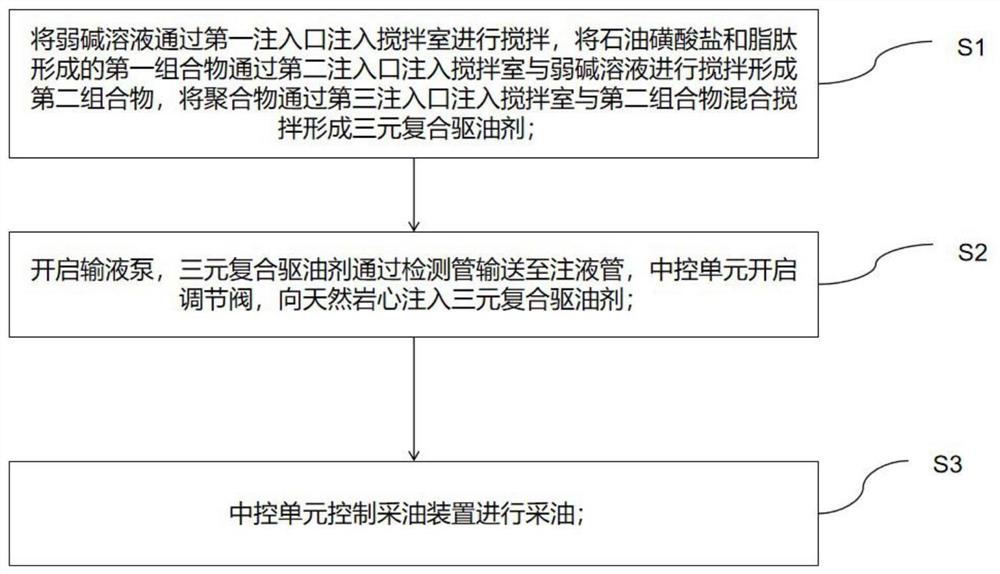

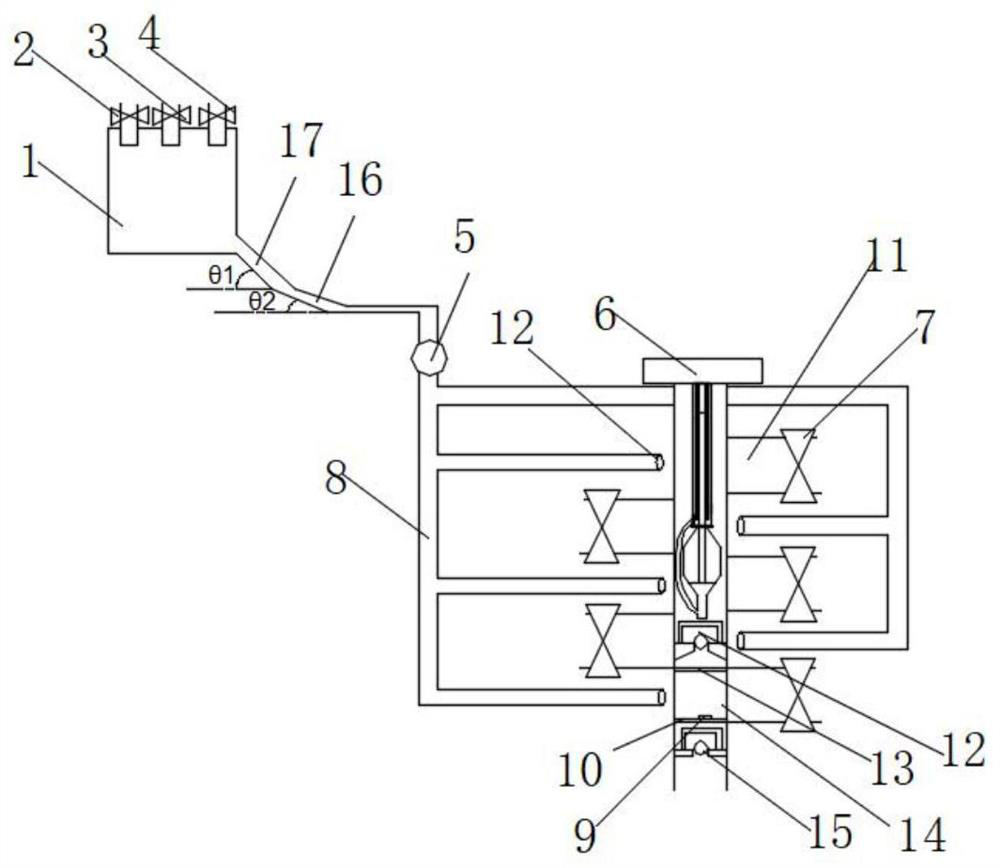

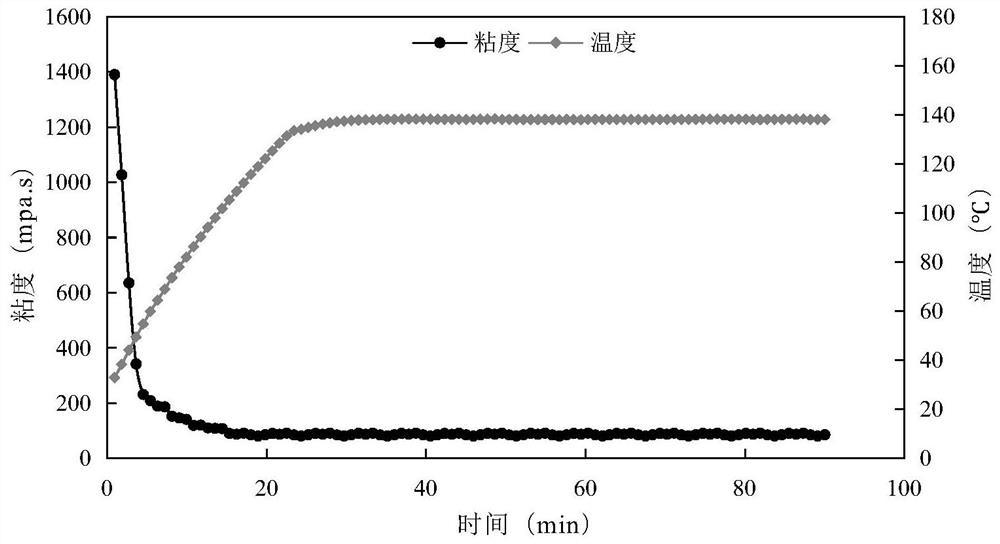

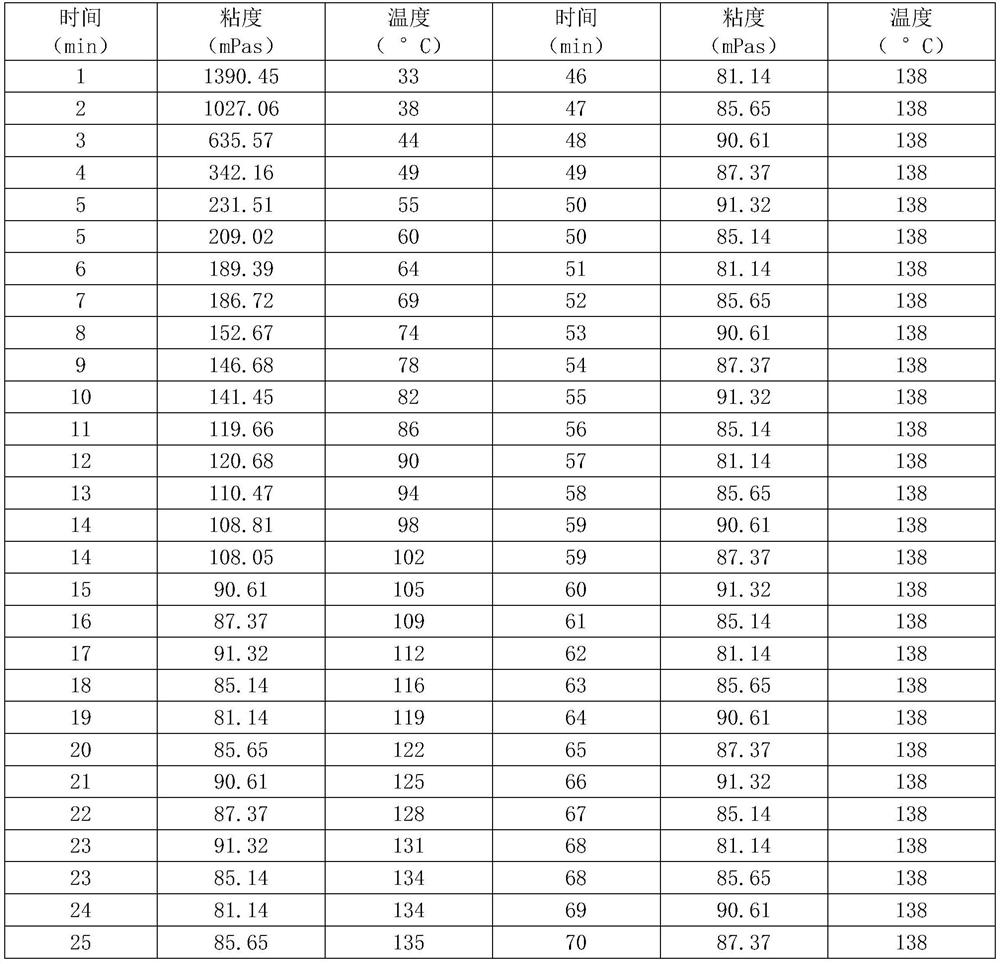

Lipopeptide-containing composite oil displacement agent and use method thereof

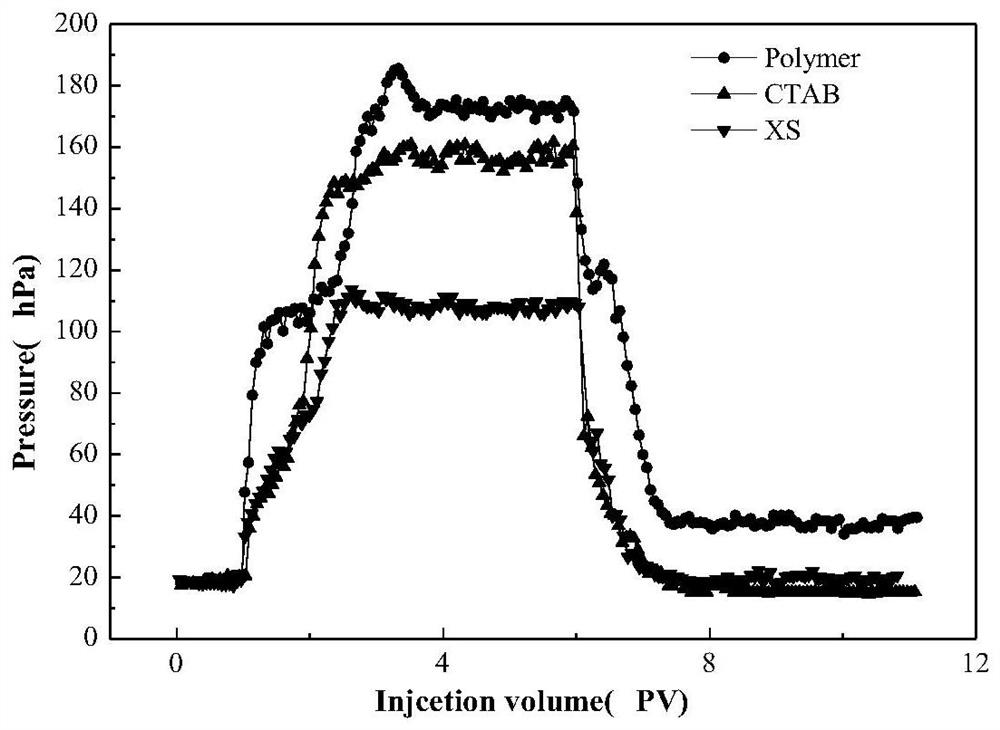

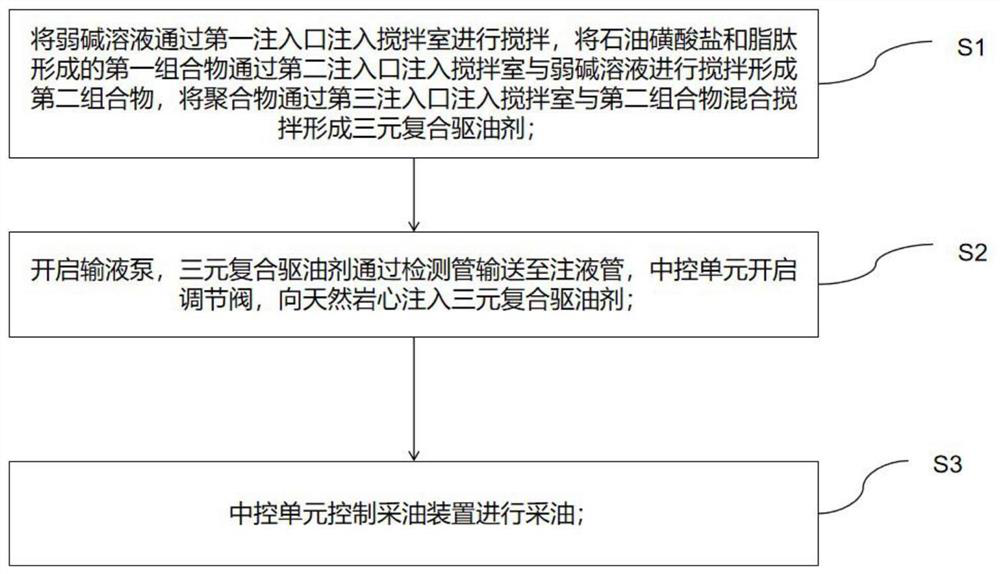

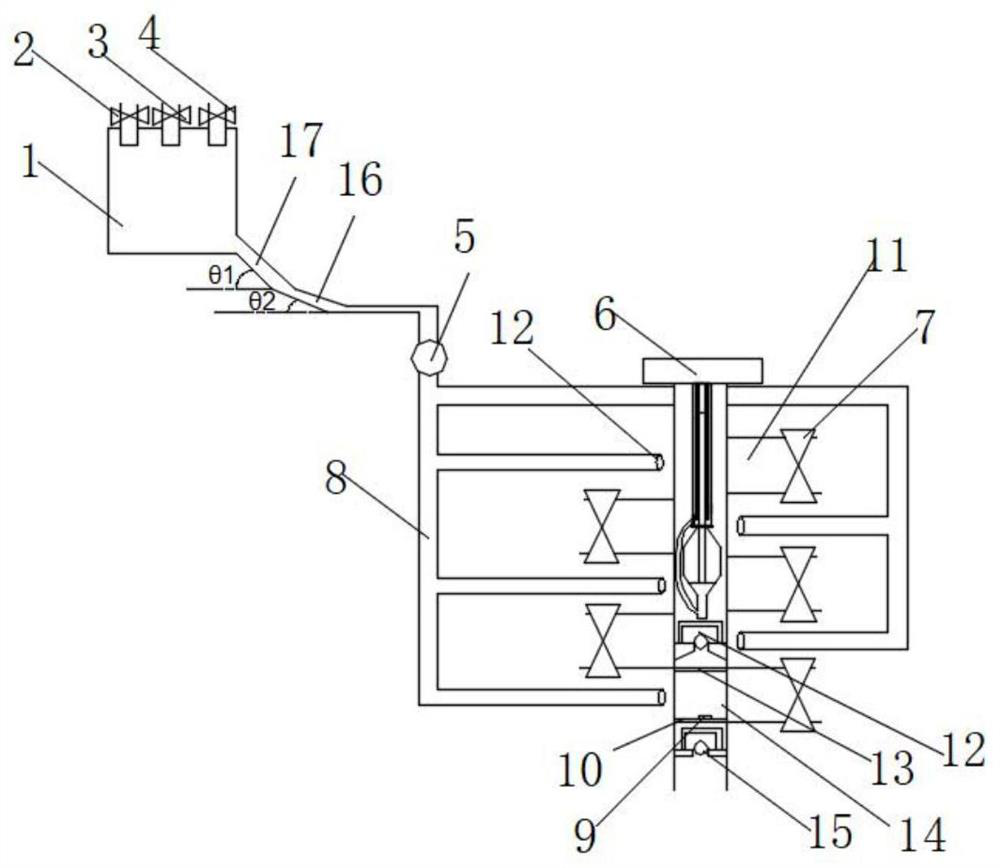

ActiveCN113565480AReduce contentEnhanced overall recoveryFluid removalDrilling compositionSulfonateRock core

The invention relates to a lipopeptide-containing composite oil displacement agent and a use method thereof. The use method comprises the steps that S1, a weak base solution is injected into a stirring chamber through a first injection port to be stirred, a first composition formed by petroleum sulfonate and lipopeptide is injected into the stirring chamber through a second injection port to be stirred with the weak base solution to form a second composition, a polymer is injected into the stirring chamber through a third injection port, and the polymer is mixed and stirred with the second composition to form a lipopeptide-containing composite oil displacement agent; S2, a liquid conveying pump is started, the lipopeptide-containing composite oil displacement agent is conveyed to a liquid injection pipe through a detection pipe, a regulating valve is opened by a central control unit, and the lipopeptide-containing composite oil displacement agent is injected into the natural rock core; and S3, the central control unit controls an oil extraction device to extract oil. According to the use method, the central control unit is arranged, the input amount of different materials is controlled by arranging different injection ports according to the real-time viscosity of the formed lipopeptide-containing composite oil displacement agent, and the oil recovery rate is increased by adjusting the conveying pressure of the input pump and the opening area of the liquid injection pipeline adjusting valve.

Owner:DAQING OILFIELD CO LTD +1

Enhanced multi-effect rust remover

The invention discloses an enhanced multi-effect rust remover. The enhanced multi-effect rust remover comprises the following components in percentage by weight of 22% of petroleum sulfonate, 23% of oxalic acid, 12% of sodium carbonate, 25% of naphthenic acid, 25% of potassium tetraborate, 20% of calcium sulfate, 8% of emulsifier and 40% of purified water. The enhanced multi-effect rust remover has the advantages of good rust removal effect, low cost and very little corrosion to the machine itself.

Owner:仪征市伟尔机械服务部

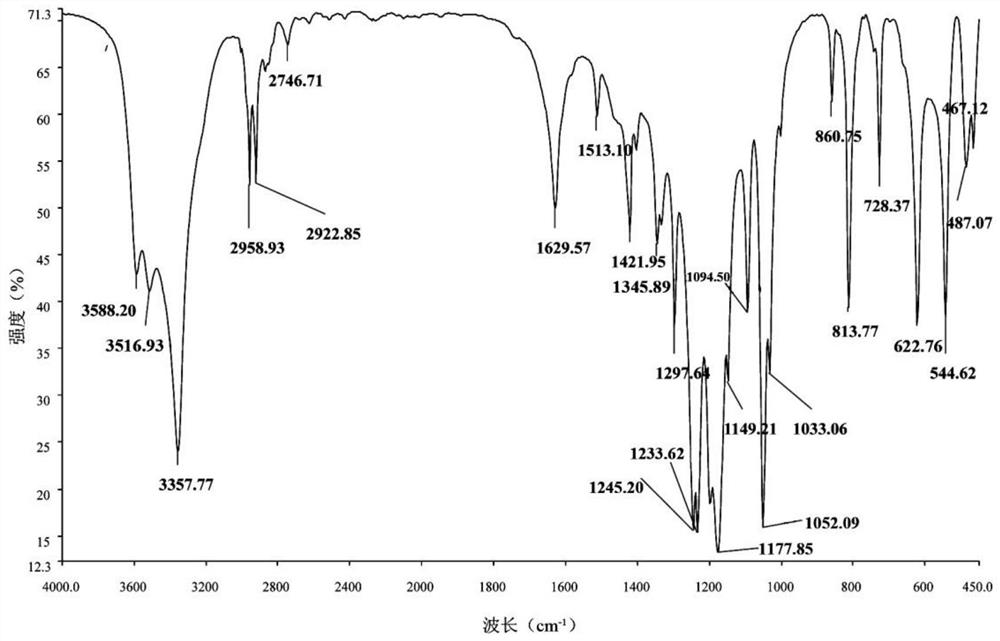

Modified petroleum sulfonate and preparation method thereof

InactiveCN113979900AReduce chemical flooding costsImprove resistance to hard waterSulfonic acids salts preparationDrilling compositionHydrogen halidePtru catalyst

The invention discloses modified mahogany petroleum sulfonate and a preparation method thereof, and mainly belongs to the field of surfactants. The preparation method comprises the following steps of: 1, by taking an organic matter containing double bonds as an alkylating agent and organic acid and hydrogen halide as catalysts, grafting the alkylating agent to raw oil through alkylation reaction to synthesize modified raw oil; 2, sulfonating the modified raw oil by using liquid sulfur trioxide which is dissolved and diluted by a solvent; 3, after completing sulfonation, using alkali liquor or ammonia water to perform neutralization; and 4, evaporating a neutralized solution to remove the solvent to obtain the modified mahogany petroleum sulfonate product. The modified mahogany petroleum sulfonateis a cheap and efficient chemical flooding agent suitable for high-salinity oil reservoirs or heavy oil and super heavy oil at present.

Owner:SHANDONG DAMING FINE CHEM CO LTD

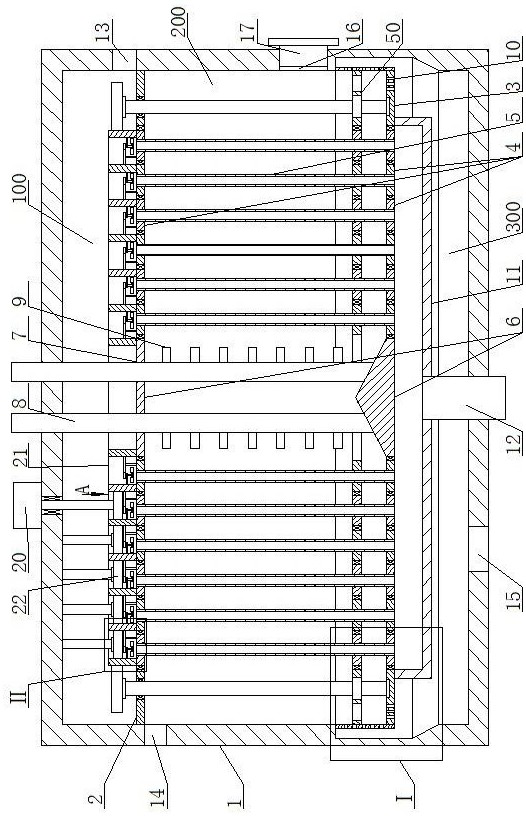

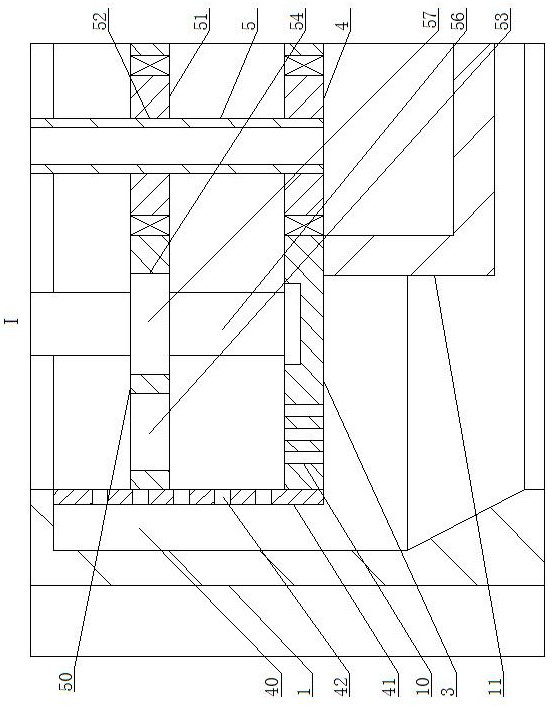

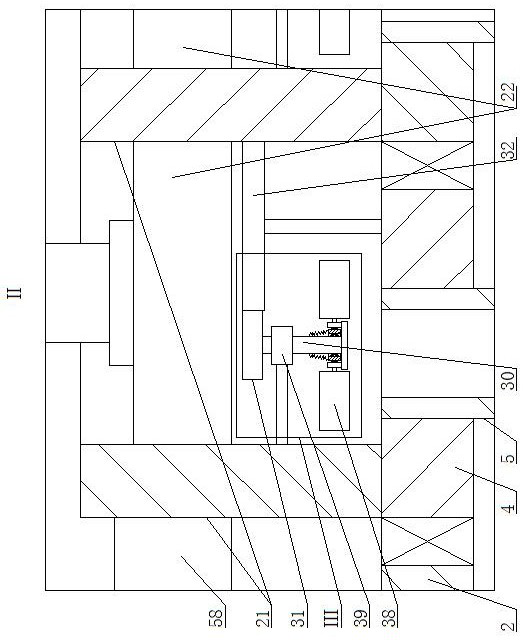

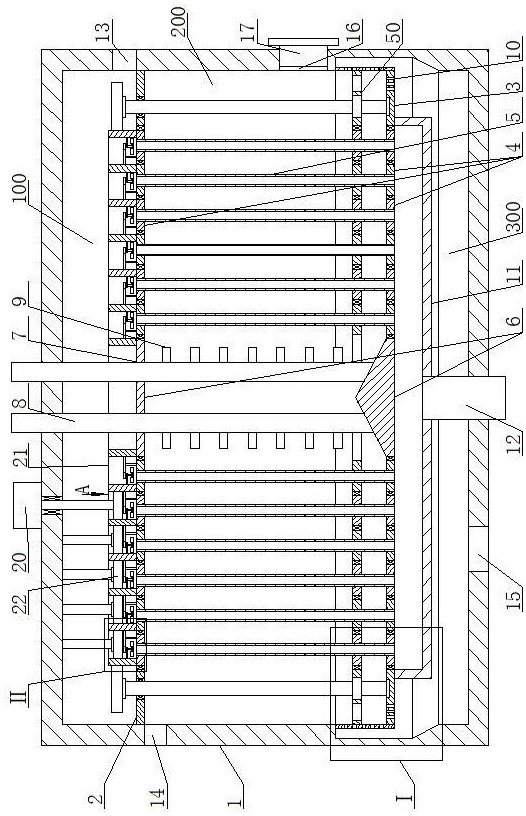

Reinforced mass and heat transfer reactor suitable for petroleum sulfonate production

ActiveCN113318690AAppropriate reaction temperatureImprove the mixing effectChemical/physical/physico-chemical stationary reactorsFeed devicesCold airSulfonate

The invention discloses a mass transfer and heat transfer enhanced reactor suitable for petroleum sulfonate production, and belongs to the field of petroleum sulfonation reaction devices. The reactor comprises a tank body, an upper support ring and a lower support ring are fixedly mounted in the tank body, and a plurality of rotating rings are arranged in the upper support ring and the lower support ring respectively; the inner circumference of the upper supporting ring and the inner circumference of the lower supporting ring are rotationally connected with the outer circumference of the corresponding outermost rotating ring through sealing bearings, and the bottom side of the lower supporting ring is fixedly connected with the top side of a round box; the lower end of a connecting pipe is communicated with the interior of the round box, and a gas outlet hole, a waste gas hole, a discharging opening and a slag discharging hole are sequentially formed in the tank body; and a driving device capable of driving the inner and outer adjacent rotating rings to rotate reversely is fixedly mounted on the tank body. Atomized raw oil and a sulfonating agent are fully stirred through staggered rotation of a connecting pipe, and the mixing effect of the raw oil and the sulfonating agent is improved; and meanwhile, the connecting pipe is cooled through cold air in the connecting pipe, and the reaction temperature of the raw oil and the sulfonating agent is kept to be proper.

Owner:SHANDONG DAMING FINE CHEM CO LTD

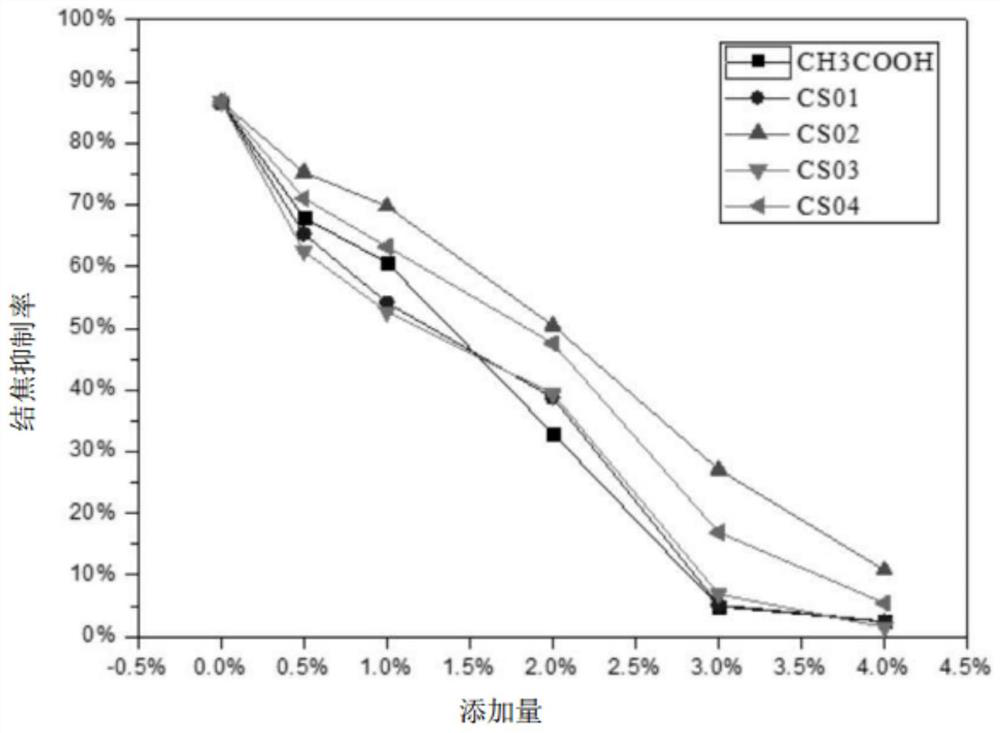

A kind of inhibitor and application thereof for inhibiting the coking of petroleum sulfonate sulfonation reaction

ActiveCN112250602BExtended continuous reaction cycleReduce the amount of cokingSulfonic acids salts preparationSulfonic acid preparationSulfolaneSulfonate

The invention provides an inhibitor for inhibiting the coking of petroleum sulfonate sulfonation reaction and application thereof. Wherein, the coking inhibitor includes organic oxygen-containing compounds with a molecular weight below 150, specifically, the organic oxygen-containing compounds include one or more of maleic anhydride, methyl isobutyl ketone, sulfolane and dioxane . Compared with the existing sulfonation process, adding the coking inhibitor of the present invention can reduce the amount of coking by more than 80%, which can effectively alleviate the decrease in product interface activity caused by excessive coking amount; meanwhile, it can prolong the sulfonation process The continuous reaction cycle reduces the energy consumption and production efficiency reduction caused by shutdown maintenance.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

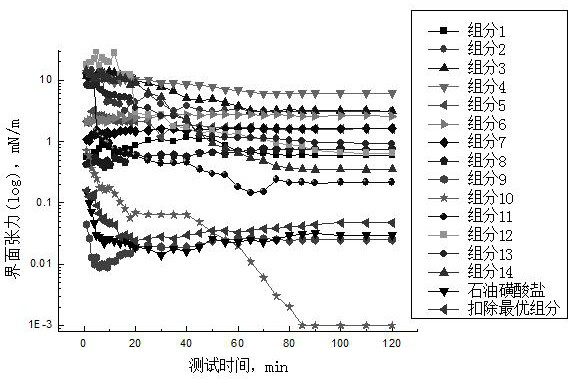

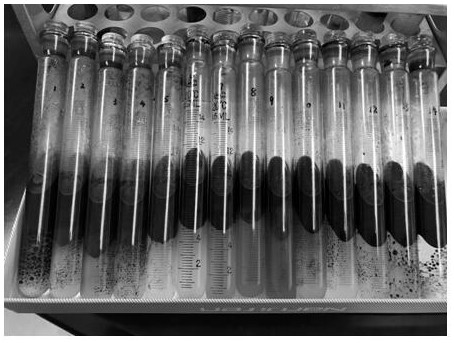

A kind of separation method of active component in petroleum sulfonate

ActiveCN110066232BIncrease production capacityPrecise Selection GuideOrganic chemistryOrganic compound preparationSulfonateMass Spectrometry-Mass Spectrometry

The invention discloses a method for separating active components in petroleum sulfonate, which adopts chromatographic technology to cut petroleum sulfonate samples in sections according to time periods in a gradient elution manner, and divides them into 24 groups According to the results of mass spectrometry, the components with relatively similar structural composition were combined, and finally 14 components with different structures were obtained. The interface activity and emulsification properties of these components were tested respectively, and the components with better interface activity and emulsification properties in the petroleum sulfonate samples were screened and accurately separated to provide accurate preparation for the production of petroleum sulfonate samples with excellent performance Raw material selection guide.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Mining method suitable for low-permeability conglomerate oil reservoir

PendingCN112943192AEnhanced overall recoveryReduce interfacial tensionFluid removalDrilling compositionSulfonateActive agent

The invention provides a mining method suitable for a low-permeability conglomerate oil reservoir. The mining method suitable for the low-permeability conglomerate oil reservoir comprises the steps that a polyacrylamide aqueous solution is prepared, and the molecular weight of polyacrylamide is 3-7 million; a surfactant aqueous solution is prepared, the surfactant aqueous solution comprises 1000-1800mg / L of petroleum sulfonate surfactants, and the molar mass of the petroleum sulfonate surfactants is 300-650g / mol; and the polyacrylamide aqueous solution and the surfactant aqueous solution are alternately injected into a target oil reservoir mining point. By adopting the mining method, the injection pressure and viscosity of an oil displacement system can be reduced, and the construction convenience and oil reservoir recovery efficiency of the oil displacement system are improved.

Owner:PETROCHINA CO LTD

A kind of compound oil-displacing agent containing lipopeptide and using method thereof

ActiveCN113565480BReduce contentEnhanced overall recoveryFluid removalDrilling compositionSulfonateInjection port

The present invention relates to a compound oil displacement agent containing lipopeptide and its use method, including step S1, injecting a weak alkali solution into a stirring chamber through a first injection port for stirring, and mixing petroleum sulfonate and lipopeptide into the first The composition is injected into the stirring chamber through the second injection port and stirred with the weak base solution to form a second composition, and the polymer is injected into the stirring chamber through the third injection port and mixed with the second composition to form a composite oil displacement agent containing lipopeptide; Step S2, turn on the infusion pump, the composite oil displacement agent containing lipopeptide is delivered to the liquid injection pipe through the detection tube, the central control unit opens the regulating valve, and injects the composite oil displacement agent containing lipopeptide into the natural core; step S3, the central control unit Control the oil extraction device to extract oil. In the present invention, a central control unit is set, and according to the real-time viscosity of the formed composite oil-displacing agent, different injection ports are set to control the input amount of different materials; Oil recovery rate.

Owner:DAQING OILFIELD CO LTD +1

A method for storing crude oil by using low-permeability and ultra-low-permeability formation

The invention relates to a method for storing crude oil in a low-permeability and extra-low-permeability formation. The method includes: injecting crude oil or a crude oil-based system into a low-permeability and ultra-low-permeability formation through reservoir fracturing, and not flowing back after the fracturing is completed, so as to realize crude oil storage or the integration of reservoir fracturing and crude oil storage; The system is composed of petroleum sulfonate, thickener and solvent; the solvent is crude oil or the mixture of crude oil and gasoline, diesel oil, kerosene or condensed oil. The invention is based on the characteristics of low oil price and low-permeability and ultra-low-permeability formation, which can reduce or even eliminate the pollution of the system to the reservoir, and improve the production capacity of a single well; after fracturing, the well can be opened in time according to the consumption demand of crude oil, and the underground storage can be realized. The function of the oil depot.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for improving injectivity of oil-displacing polymer

ActiveCN112196503AReduce the amount of adsorptionReduce injection pressureFluid removalDrilling compositionSurface reactionSulfonate

The invention discloses a method for improving the injectivity of an oil-displacing polymer. The method comprises the following steps: injecting a chemical augmented injection system into a near wellbore area as a front slug, then injecting the oil-displacing polymer for polymer flooding, and finally performing water flooding, so that the adsorption amount of the oil-displacing polymer in the nearwellbore area is reduced, and the injectivity of the oil-displacing polymer is improved; and the chemical augmented injection system is composed of an organosilicon sacrificial agent and an auxiliaryagent; the molecular formula of the organosilicon sacrificial agent is R1-Si (OR2)3, and the auxiliary agent is a mixture of N-methyldiethanolamine and petroleum sulfonate OR a mixture of ethylenediamine-N, N, N', N'-tetra-2-ol and petroleum sulfonate. The chemical augmented injection system adopted by the method is a composite system formed by the organosilicon sacrificial agent and the auxiliary agent thereof, wherein the organosilicon sacrificial agent plays a role in changing the reservoir wettability and reducing the polymer adsorption, and the sacrificial agent auxiliary agent plays a role in cleaning residual crude oil in the near wellbore area, activating the rock surface and promoting the reaction between the organosilicon and the rock surface.

Owner:CNOOC TIANJIN BRANCH +1

Environmental protection enhancer for vehicles and preparation method thereof

InactiveCN110643400AReduce manufacturing costReduce production costs, meet the requirements of low carbon and environmental protectionLiquid carbonaceous fuelsXylyleneStorage tank

The invention relates to an environmental protection enhancer for vehicles. The environmental protection enhancer is made of the following raw materials in percent by weight: 20%-25% of PEA (230 / 400),10%-12.5% of liquid paraffin, 20% of butanol, 30% of xylene, 10%-12.5% of triethanolamine, and 5% of a petroleum sulfonate. The liquid paraffin and the petroleum sulfonate are heated and stirred in water bath heating (with stirring) equipment to obtain a mixed solution a, PEA (230 / 400), butanol and triethanolamine are added to a storage tank through a pre-mixer, a mixed solution b is obtained after circulation is completed, the mixed solution a, the mixed solution b and xylene are pumped into a storage tank through a pre-mixer by using a metering pump, and standing is carried out for 3 h after circulation is completed to obtain the environmental protection enhancer for vehicles. The required raw materials are abundant and readily available, the mixing and blending are all carried out under normal pressure, and the obtained finished product can effectively solve related technical problems such as vehicle exhaust emission.

Owner:山西新源煤化燃料有限公司

An Enhanced Mass Transfer and Heat Transfer Reactor Applicable to Petroleum Sulfonate Production

ActiveCN113318690BAppropriate reaction temperatureImprove the mixing effectChemical/physical/physico-chemical stationary reactorsFeed devicesSulfonateSlag

Owner:SHANDONG DAMING FINE CHEM CO LTD

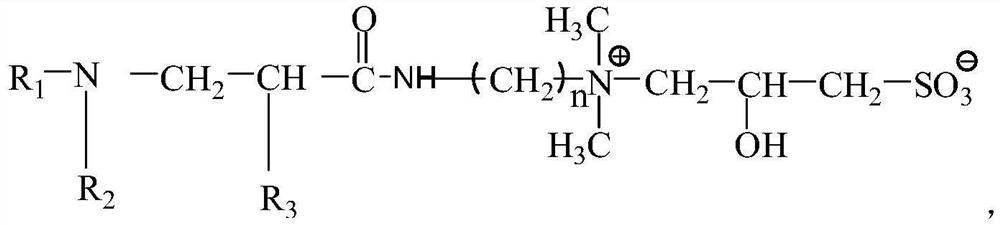

Surfactant, composition and preparation method for amphiphilic gamma type oil displacement

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com