Desalination method and device in petroleum sulfonate production

A petroleum sulfonate and desalination technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, chilled water/sewage treatment, etc., can solve the problems of low processing capacity, resource waste environment, and long time consumption, and achieve automation High degree, saving production cost, avoiding the effect that cannot be deposited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

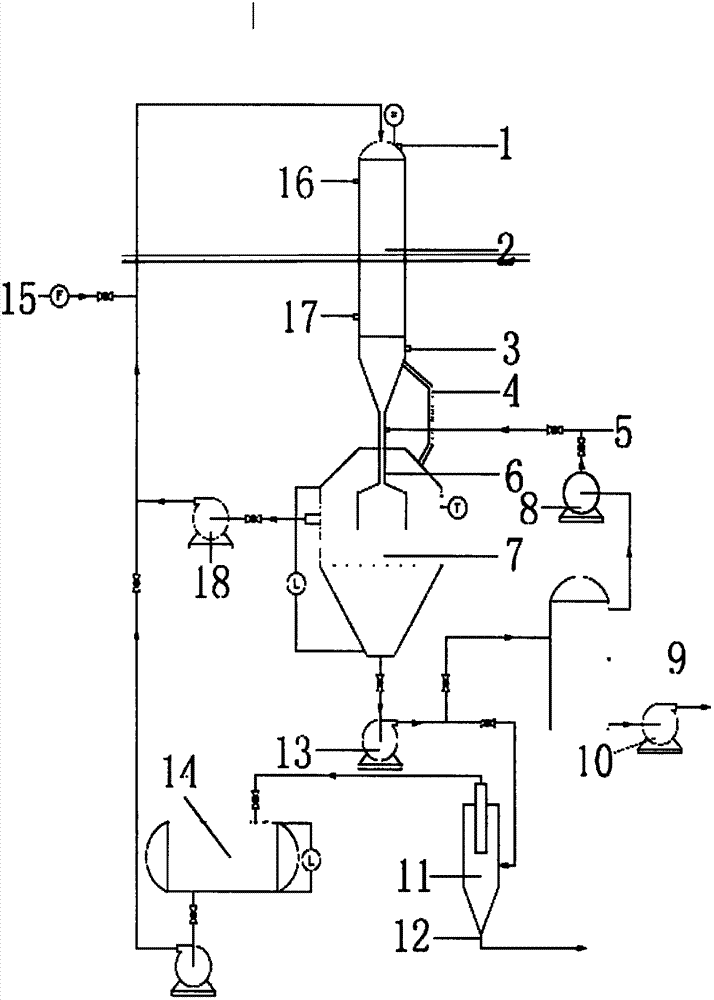

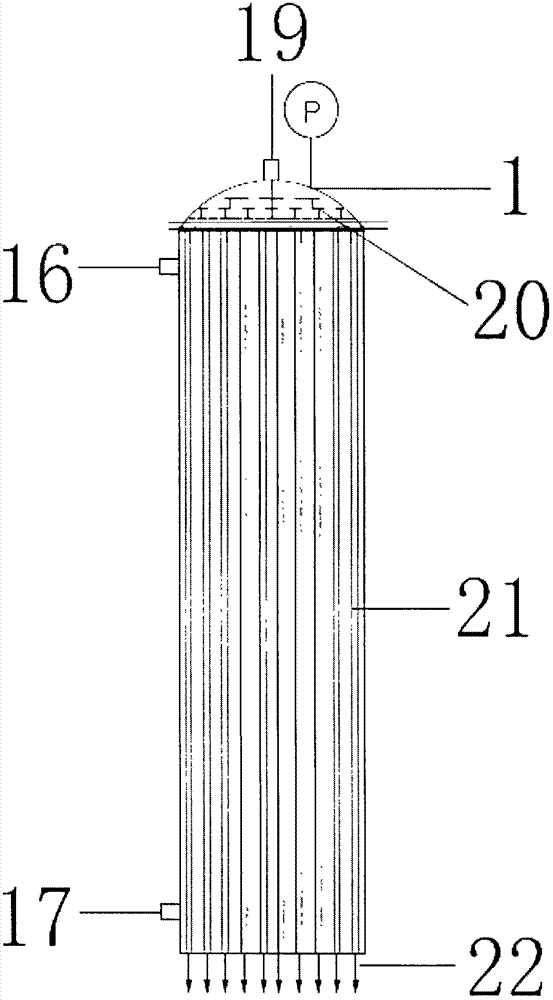

[0021] Such as figure 1 As shown, the device includes a cooler 2, a crystallizer 7, a cyclone 11 and a buffer tank 14, the cooler 2 is provided with a refrigerant liquid outlet 16, a refrigerant liquid inlet 17, and the top is provided with an exhaust port 1, and the cooler 2 It is connected with the crystallizer 7 through a connecting device 6, a delivery pump 13 and a flash tank 9 are arranged between the crystallizer 7 and the cyclone 1, the cyclone 11 is connected with the buffer tank 14, and the cyclone 11 is provided with a solid Material outlet 12, buffer tank 14 is connected with delivery pump and is communicated with cooler 2, is provided with circulation pump 18, waste water source inlet 15 on the pipeline that buffer tank 14 communicates with cooler 2, and circulation pump 18 is connected with crystallizer 7 , the flash tank 9 is provided with a feed pump 10, a vacuum pump 8 is provided between the flash tank 9 and the connector 6, the connector 6 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com