A kind of inhibitor and application thereof for inhibiting the coking of petroleum sulfonate sulfonation reaction

A technology of petroleum sulfonate and sulfonation reaction, applied in the preparation of sulfonate, sulfonic acid, organic chemistry, etc., can solve the problem of product stratification and reduced interfacial activity, irritating odor, and stable storage of petroleum sulfonate It can alleviate the problems such as the deterioration of the product interface, reduce the activity of the product interface, reduce the amount of coking, and prolong the continuous reaction cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for preparing petroleum sulfonate using a coking inhibitor, comprising the following steps:

[0039] 1) Pretreatment of raw oil:

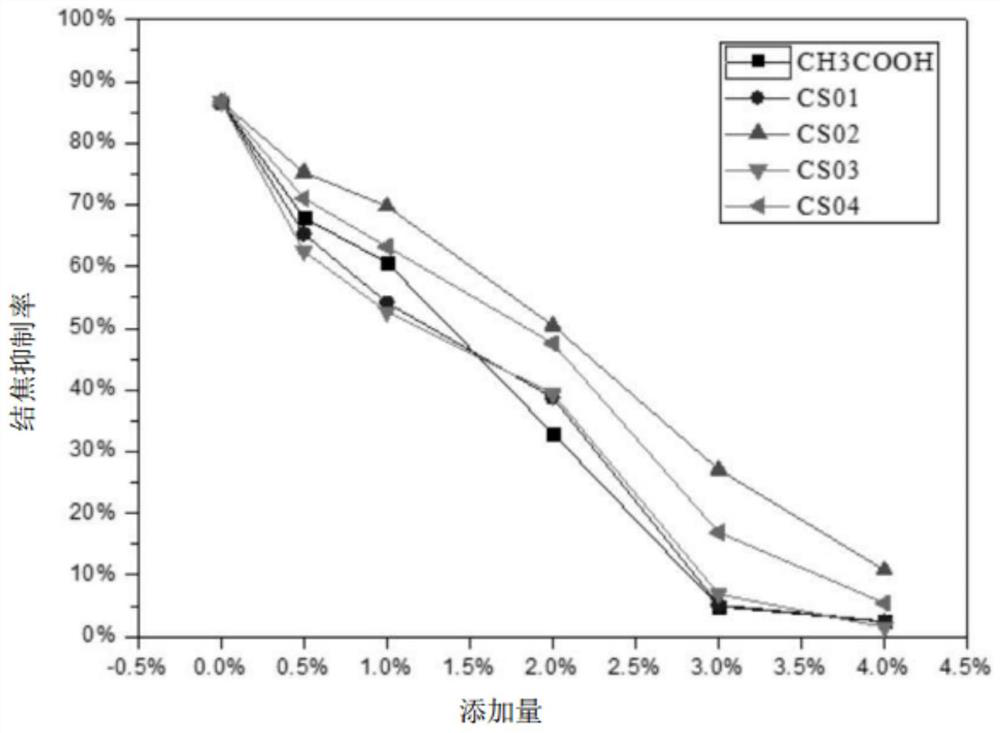

[0040] Put 50g of raw material oil (minus second-line distillate oil) into a 250mL four-necked bottle, add 0.5g of coking inhibitor CS01 (maleic anhydride: methyl isobutyl ketone: sulfolane = 70%: 10%: 20%), 60 ° C Stir at 200r / min for 10min in a water bath;

[0041] 2) Sulfonation:

[0042] Weigh 18g of chlorosulfonic acid in the dropping funnel, drop it into the four-necked bottle slowly at a uniform speed, open one mouth of the four-necked bottle to discharge the hydrogen chloride tail gas, and drop the chlorosulfonic acid in 40 minutes. After completion, continue to keep warm in a 60°C water bath for 80 minutes;

[0043] 3) Hydrolysis:

[0044] Weigh 5g of deionized water into the four-necked bottle slowly dropwise, and keep warm in a water bath at 45°C for 30min;

[0045] 4) Neutralization:

[004...

Embodiment 2

[0048] 1) Pretreatment of raw oil:

[0049]Put 50g of raw material oil into a 250mL four-necked bottle, add 0.5g of coking inhibitor CS02 (methyl isobutyl ketone: sulfolane: dioxane = 30%: 30%: 40%), 200r / min in a water bath at 60°C Stir for 10 minutes;

[0050] 2) Sulfonation:

[0051] Weigh 18g of chlorosulfonic acid in the dropping funnel, drop it into the four-necked bottle slowly at a uniform speed, open one mouth of the four-necked bottle to discharge the hydrogen chloride tail gas, and drop the chlorosulfonic acid in 40 minutes. After completion, continue to keep warm in a 60°C water bath for 80 minutes;

[0052] 3) Hydrolysis:

[0053] Weigh 5g of deionized water into the four-necked bottle slowly dropwise, and keep warm in a water bath at 45°C for 30min;

[0054] 4) Neutralization:

[0055] Slowly add 5wt% NaOH aqueous solution dropwise, control the temperature of the system not to exceed 60°C, take a small amount of reactant and dilute it with water, and then ch...

Embodiment 3

[0057] 1) Pretreatment of raw oil:

[0058] Put 50g of raw material oil into a 250mL four-necked bottle, add 0.1g of coking inhibitor CS03 (sulfolane: maleic anhydride: dioxane = 50%: 30%: 20%), stir in a 60°C water bath at 200r / min for 10min;

[0059] 2) Sulfonation:

[0060] Weigh 18g of chlorosulfonic acid in the dropping funnel, drop it into the four-necked bottle slowly at a uniform speed, open one mouth of the four-necked bottle to discharge the hydrogen chloride tail gas, and drop the chlorosulfonic acid in 40 minutes. After completion, continue to keep warm in a 60°C water bath for 80 minutes;

[0061] 3) Hydrolysis:

[0062] Weigh 5g of deionized water into the four-necked bottle slowly dropwise, and keep warm in a water bath at 45°C for 30min;

[0063] 4) Neutralization:

[0064] Slowly add 5wt% NaOH aqueous solution dropwise, control the temperature of the system not to exceed 60°C, take a small amount of reactant and dilute it with water, and then check the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com