Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Reduce the amount of coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature chain oil and preparation method thereof

InactiveCN101117609AHigh temperature thermal oxidation performanceReduce evaporation lossAdditivesPentaerythritolEvaporation

The present invention discloses high temperature chain oil, the components and the contents are: high temperature antioxygen 1 to 5 percent, extreme pressure / anti-wear agent 1 to 10 percent, corrosion inhibitor 0.01 to 0.5 percent, and high temperature detergent dispersant 1 to 20 percent, the rest is base oil; the components and the contents of the base oil (weight ratio) are: dipentaerythritol ester 50 to 90 percent, and aromatic ester 10 to 50 percent. The preparation is as follows: the dipentaerythritol ester and the aromatic ester are mixed together according to the above ratio to prepare the base oil, a certain volume of the high temperature antioxygen, the extreme pressure anti-wear agent, the high temperature detergent dispersant and the corrosion inhibitor is added into the base oil, then the base oil is heated to 80 to 100 DEG C, and is agitated at the constant temperature for 0.5 to 1 hour, and is filtrated, thus the product is got. The present invention is characterized in that the coking volume can be obviously reduced, the anti-high temperature coking performance and the high temperature detergency performance can be improved, the product can be used under the 280 DEG C high temperature condition, the evaporation loss is little, and the coking volume is little, the lubrication performance and the high temperature detergency and dispersing performance is good.

Owner:中国石油天然气股份有限公司大连润滑油研究开发中心

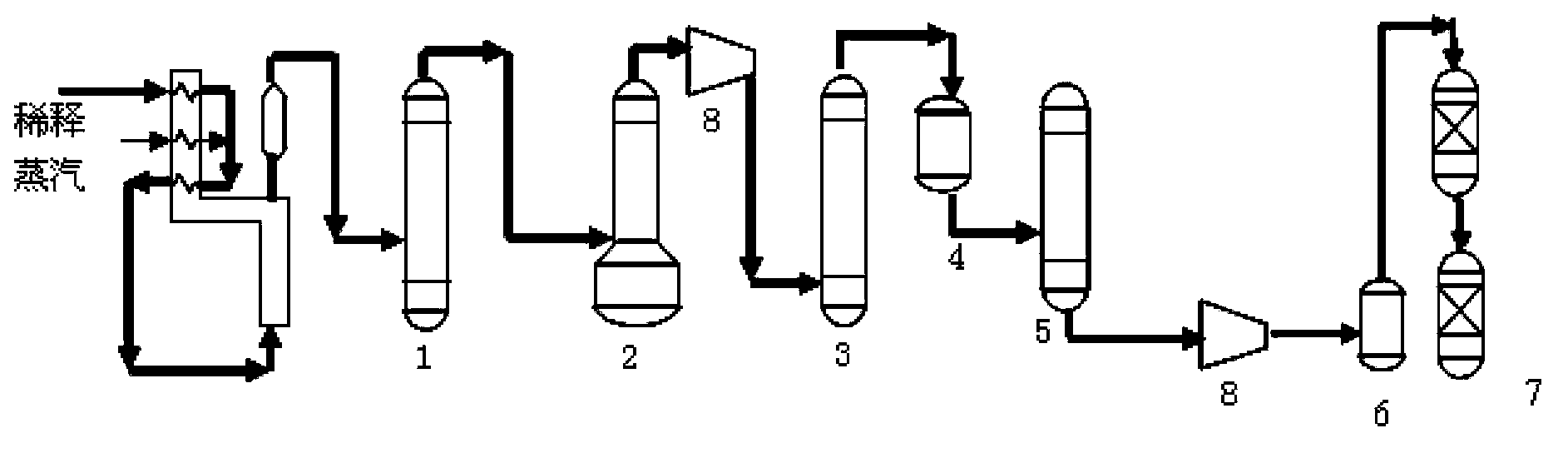

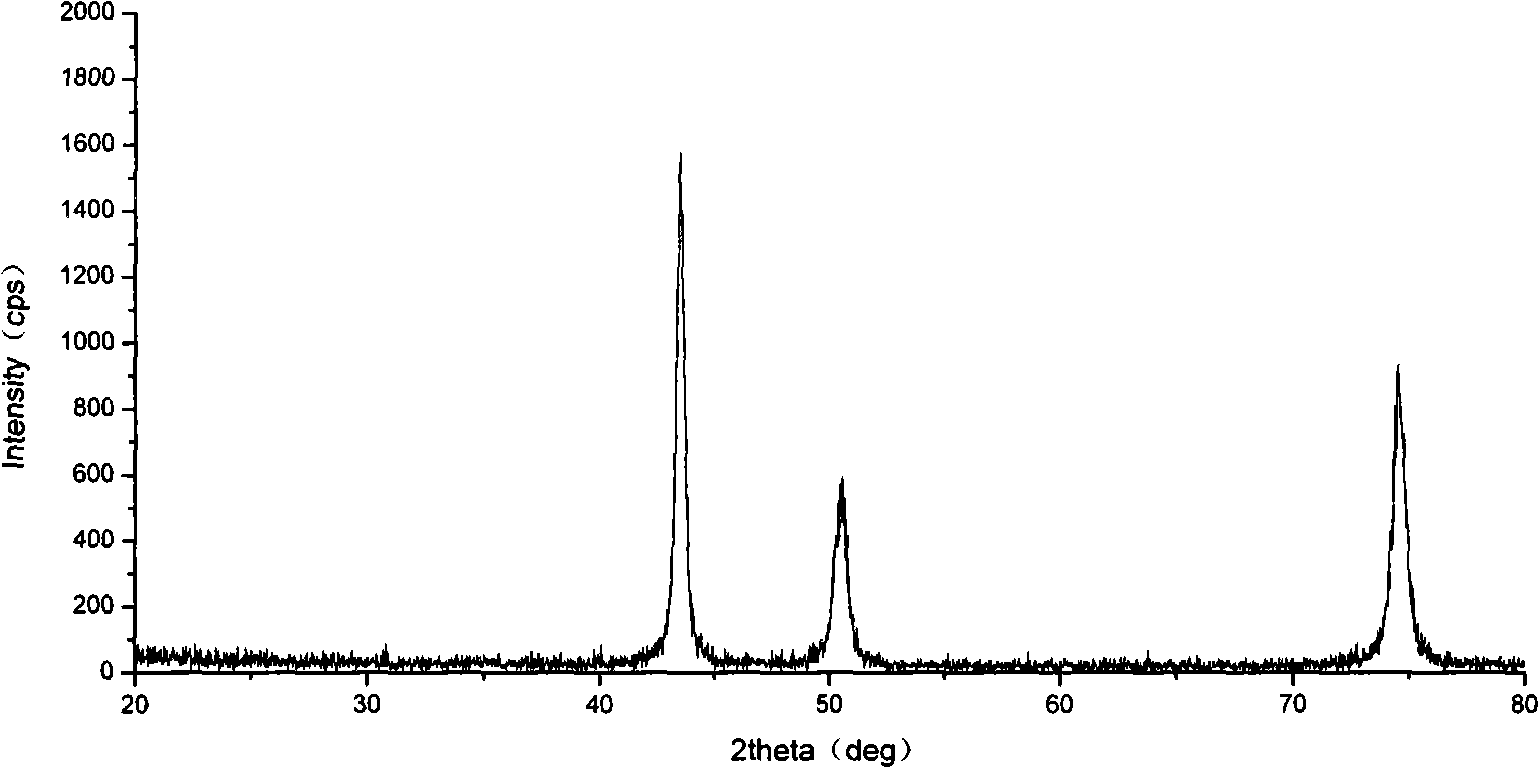

C2 fraction selective-hydrogenation method

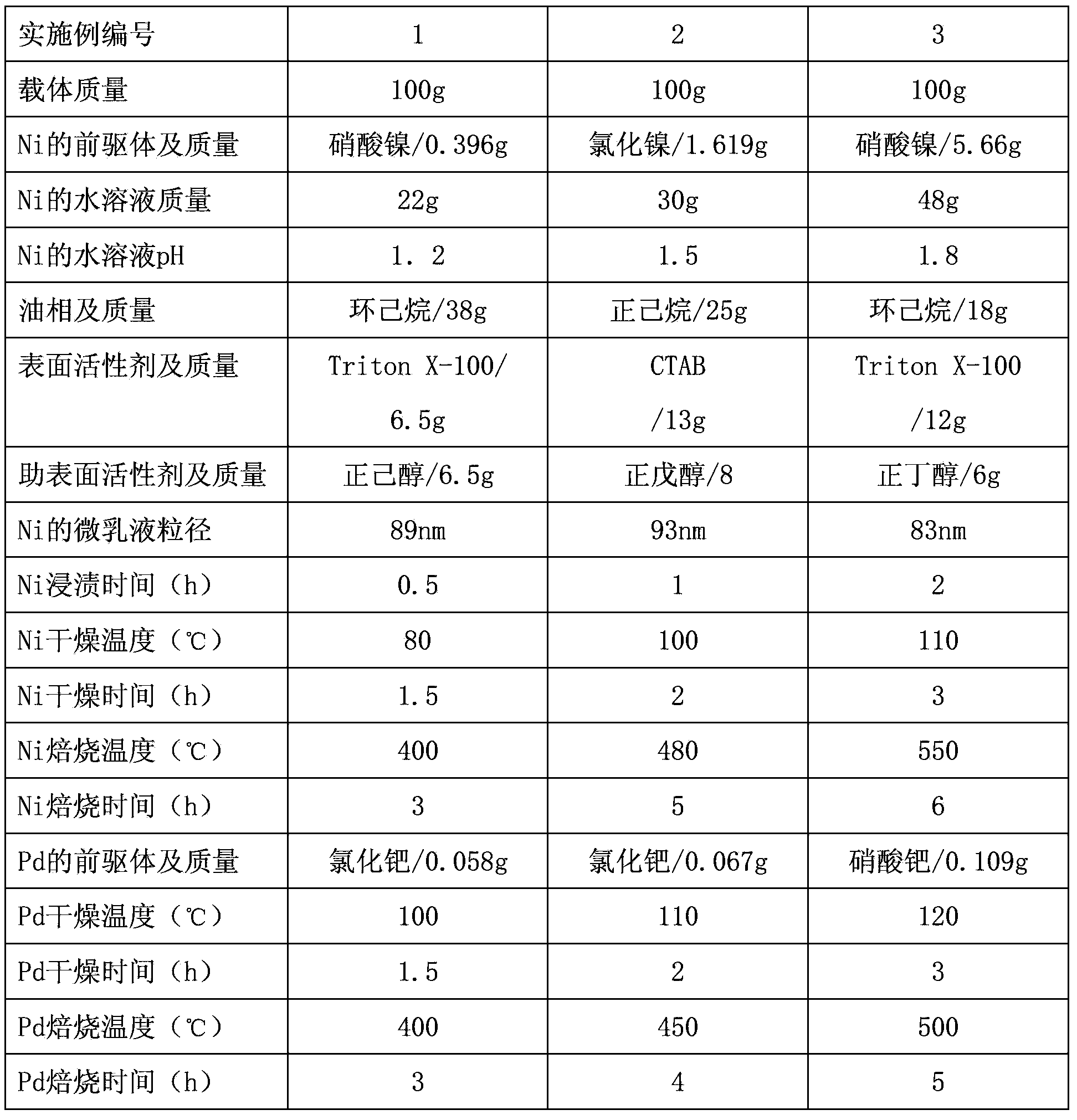

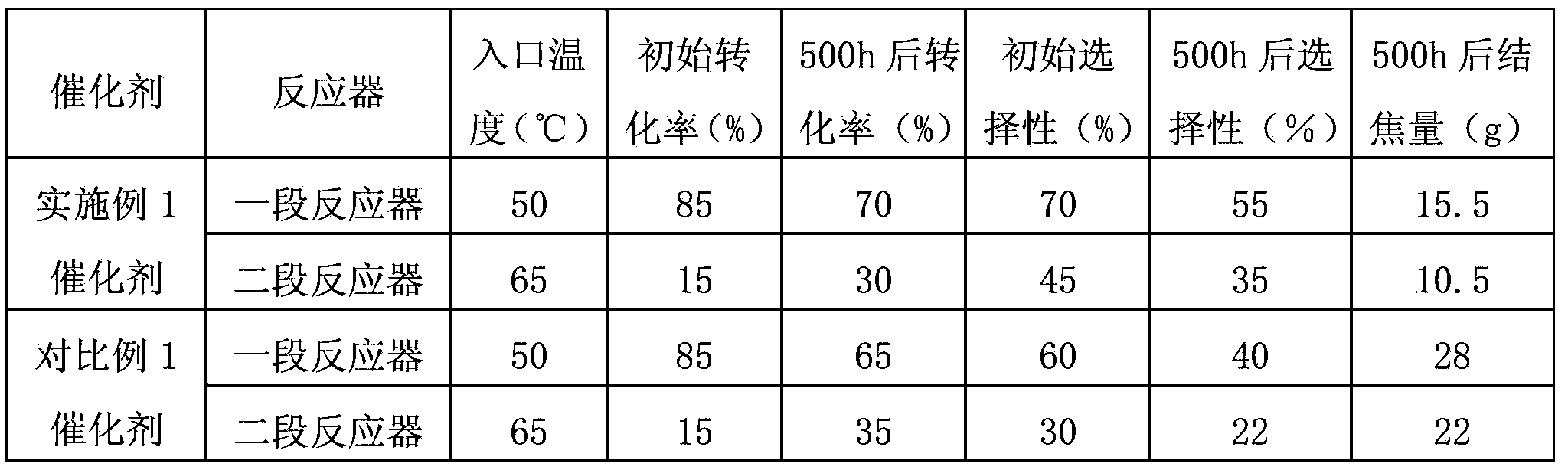

ActiveCN104098426AReduce the amount of cokingExtended service lifeCatalyst carriersHydrocarbon purification/separationInlet temperatureChemistry

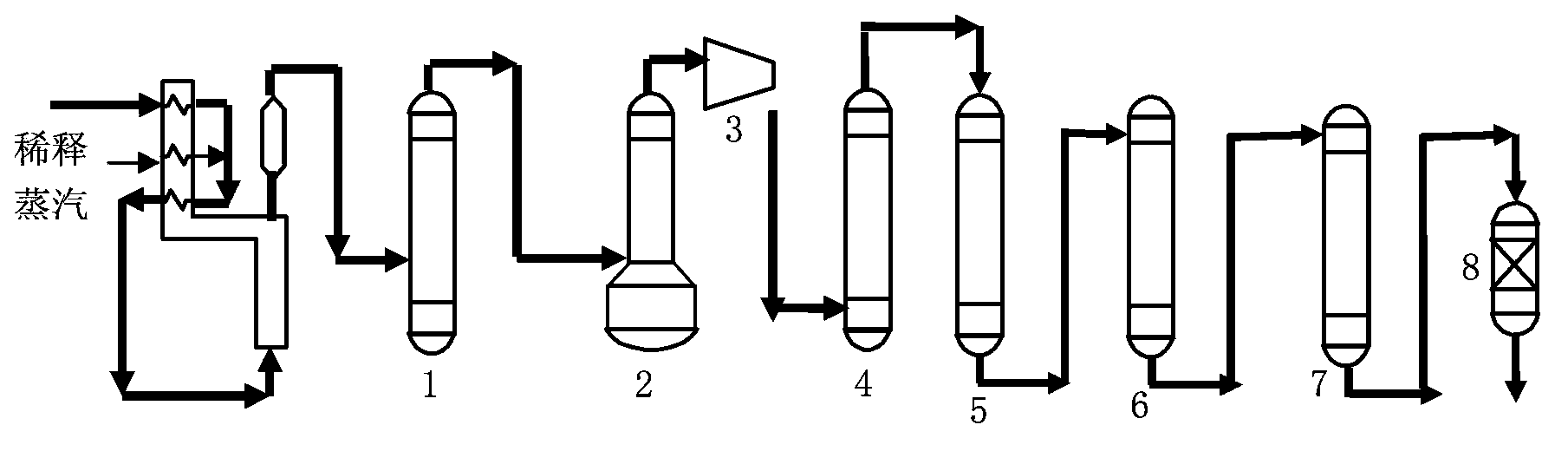

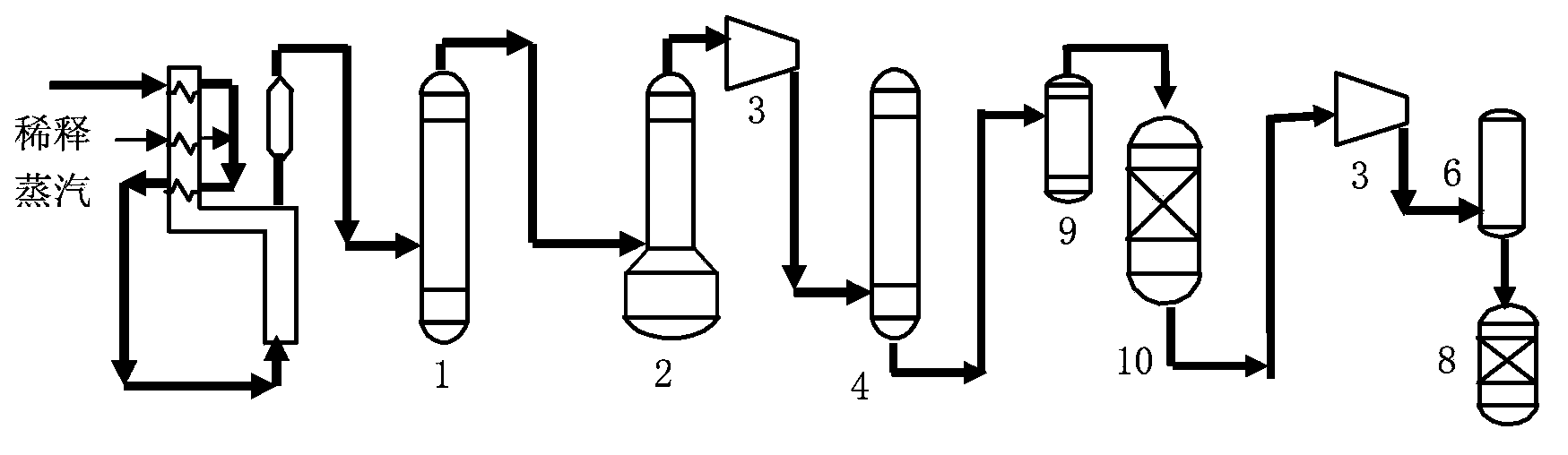

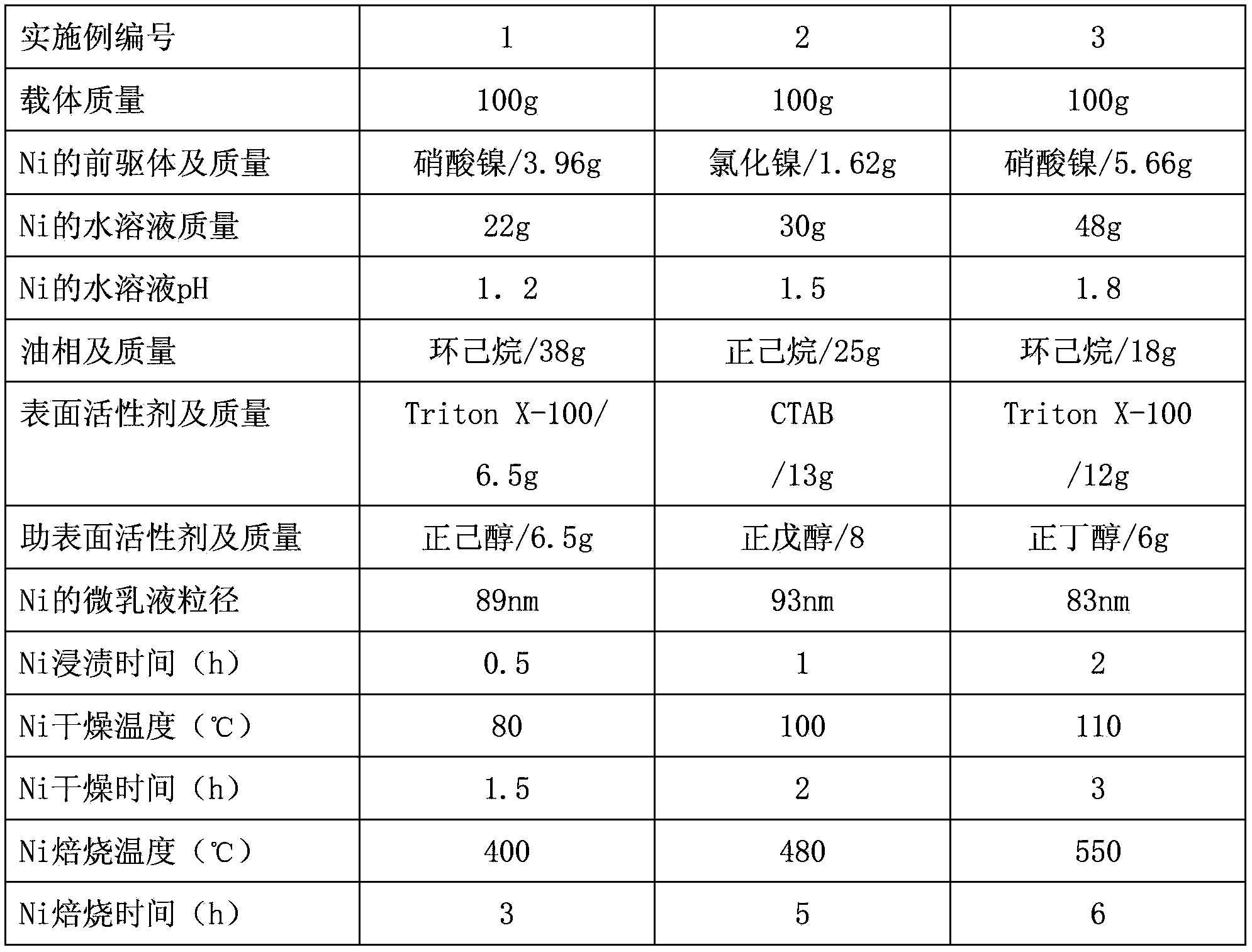

The invention discloses a C2 fraction selective-hydrogenation method. The C2 fraction selective-hydrogenation method is characterized in that a front hydrogenation technology adopting a front depropanization process is used, tower top effluent from a front depropanization tower in an ethylene device is fed into an adiabatic bed reactor and undergoes a selective-hydrogenation reaction so that alkynes and dialkene are removed, a selective-hydrogenation catalyst used by the adiabatic bed reactor utilizes carriers which comprise alumina or mainly comprise alumina, have bimodal pore distributed structures and contain double active components of Pd and Ni, Ni as a coking-resistant component is mainly distributed in large pores, the catalyst comprises, by mass, 0.010-0.1% of Pd and 0.1-1% of Ni and has specific surface area of 1-20m<2> / g and pore volume of 0.1-0.35ml / g, and the reaction conditions comprise an adiabatic bed reactor inlet temperature of 35-180 DEG C, reaction pressure of 2-4MPa and gaseous hourly space velocity of 4000-25000h<-1>. The C2 fraction selective-hydrogenation method has the advantages of difficult coking and greatly-prolonged catalyst service life.

Owner:PETROCHINA CO LTD

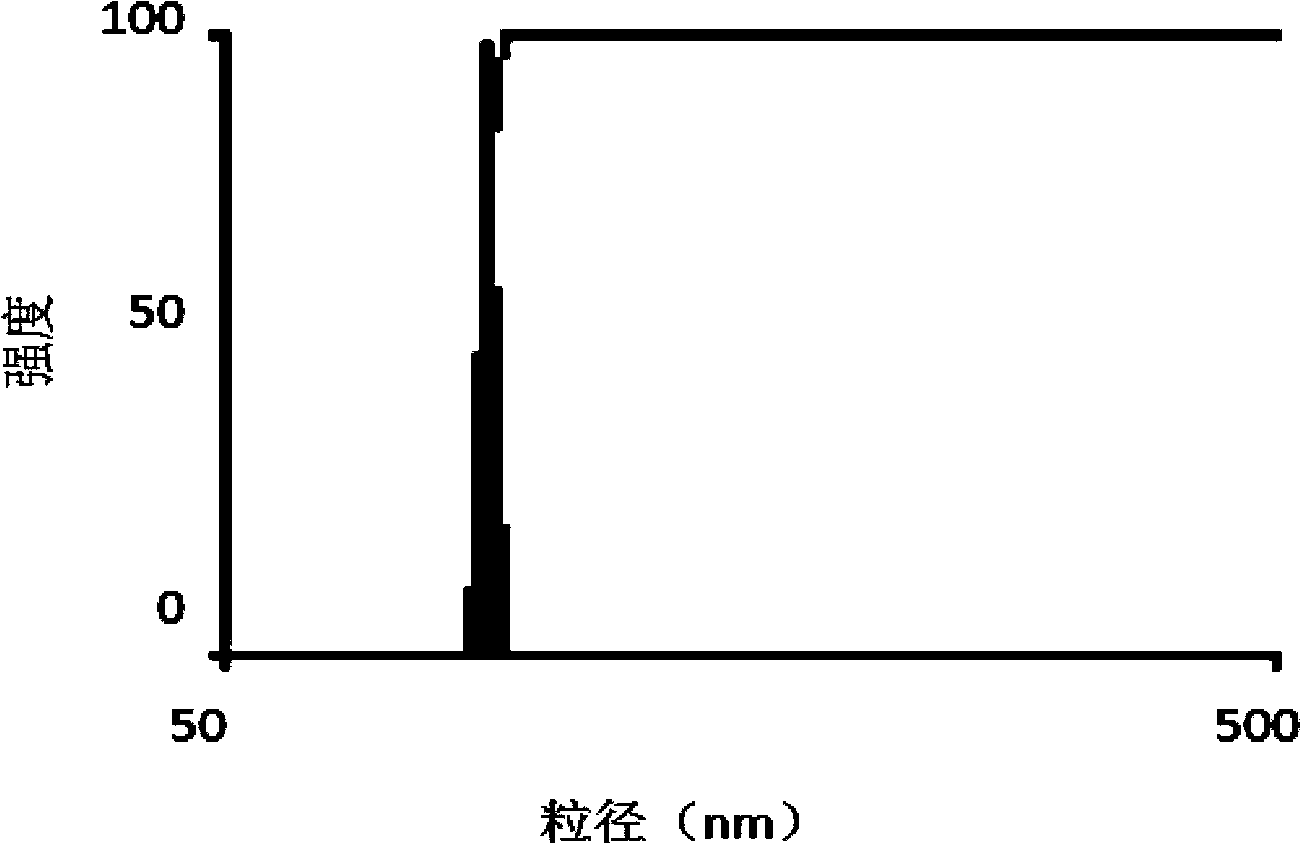

C2 fraction selective hydrogenation method

ActiveCN104098425AReduce the amount of cokingExtended service lifeCatalyst carriersHydrocarbon purification/separationActive componentDistributed structure

The invention relates to a C2 fraction selective hydrogenation method. The C2 fraction selective hydrogenation method comprises the following steps of feeding an effluent which is in an ethylene device and is discharged from the top of a demethanizer into an adiabatic bed reactor, and carrying out selective hydrogenation to remove ethyne. The C2 fraction selective hydrogenation method is characterized in that selective hydrogenation catalyst carriers comprise alumina or mainly comprising alumina, have a double-humped hole distributed structures and contain double active components of Pd and Ni. In catalyst preparation, a coking-resistant component Ni in the form of microemulsion enters into large holes of the carriers so that the coking-resistant component Ni is mainly distributed in the large holes of the carriers and thus a catalyst surface coking degree is greatly reduced, the compound subjected to hydrogenation saturation is gradually diffused into catalyst channels, channel blocking is avoided, a catalyst service life is greatly prolonged, a green oil yield and catalyst coking are obviously reduced and device operation economic benefits are improved.

Owner:PETROCHINA CO LTD

Method for restraining cracking furnace pipe from coking

ActiveCN103421531AThe method is simpleSimple technologyThermal non-catalytic crackingCoke ratePre treatment

The invention provides a method for restraining a cracking furnace pipe from coking. The method comprises the following steps: pre-treating the inner surface of the cracking furnace pipe before a coking restraining coating of the inner surface of the cracking furnace pipe is coated; coating a coking resistant coating on the inner surface of the cracking furnace pipe; adding a coking inhibitor into cracking raw materials. According to the invention, the coke formation is reduced through the recombination of the coking resistant technology, so that the hydrocarbon high-temperature cracking coking rate is greatly reduced, and the use cycle of hydrocarbon cracking equipment is prolonged.

Owner:内蒙古冠泰环保科技有限公司

C3 fraction selective hydrogenation method

ActiveCN104098427AReduce the amount of cokingExtended service lifeHydrocarbon purification/separationHydrocarbonsActive componentDistributed structure

The invention relates to a C3 fraction selective hydrogenation method. The C3 fraction selective hydrogenation method comprises the following steps of feeding a C3 fraction into an adiabatic bed reactor, and carrying out selective hydrogenation to remove allylene and allene. The C3 fraction selective hydrogenation method is characterized in that selective hydrogenation catalyst carriers comprise alumina or mainly comprise alumina, have double-humped hole distributed structures and contain double active components of Pd and Ni. In catalyst preparation, a coking-resistant component Ni in the form of microemulsion enters into large holes of the carriers so that the coking-resistant component Ni is mainly distributed in the large holes of the carriers and thus a catalyst surface coking degree is greatly reduced, the compound subjected to hydrogenation saturation is gradually diffused into catalyst channels, channel blocking is avoided, a catalyst service life is greatly prolonged, a green oil yield and catalyst coking are obviously reduced and device operation economic benefits are improved.

Owner:PETROCHINA CO LTD

Coal gasification method

InactiveCN102373089ALow investment costLow running costGranular/pulverulent flues gasificationFluidized bedOxygen

The invention provides a fluidized bed-entrained flow bed gas gasification method. The method comprises the following steps: 1) carrying out reaction on raw material coal and a mixture of air and steam or a mixture of oxygen and steam to obtain gas containing incompletely reacted coal and ash; 2) separating the gas obtained from the step 1) to obtain condensed fine coal air-flow and light fine coal air-flow, and carrying out reaction on the condensed fine coal air-flow with air or oxygen to obtain gas containing coal and ash; 3) carrying out reaction on the gas obtained from the step 2) and steam to obtain gas containing coal and ash; 4) carrying out reaction on the gas obtained from the step 3), the light fine coal air-flow separated from the step 2) and a mixture of steam and carbon dioxide to obtain final gas containing coal and ash. The method lowers investment and operating cost of a traditional pulverizing system by an entrained flow bed gasification method and has a substantially increased gasification temperature than a traditional fluidized bed gasification method, so as to reduce equipment cost and increase gasification efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

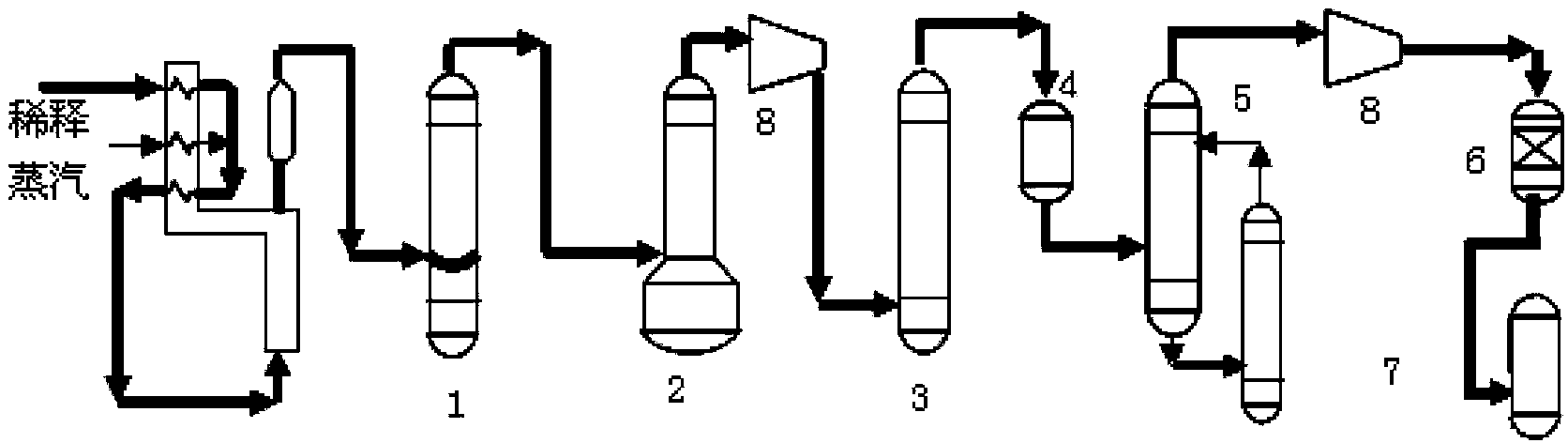

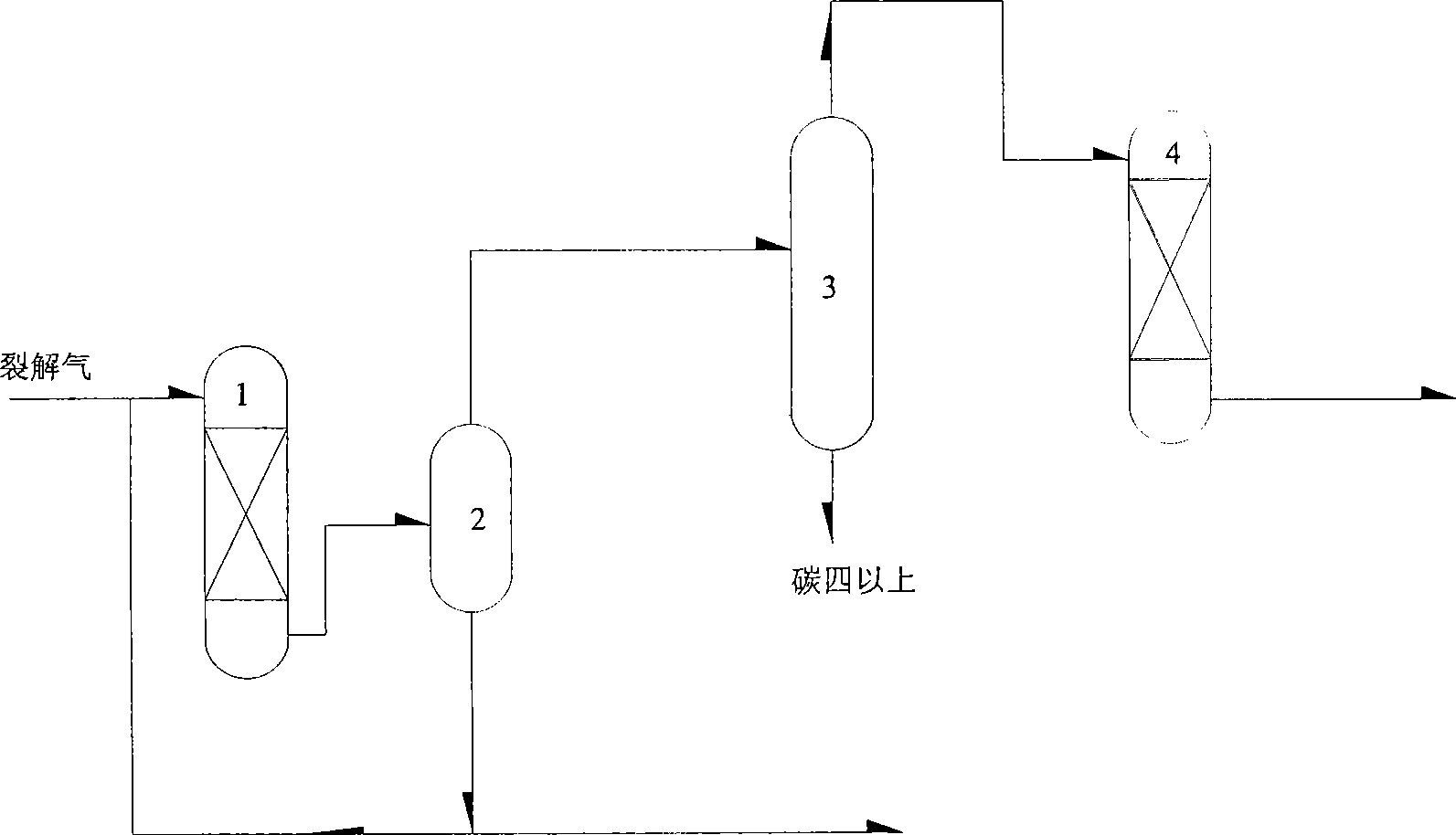

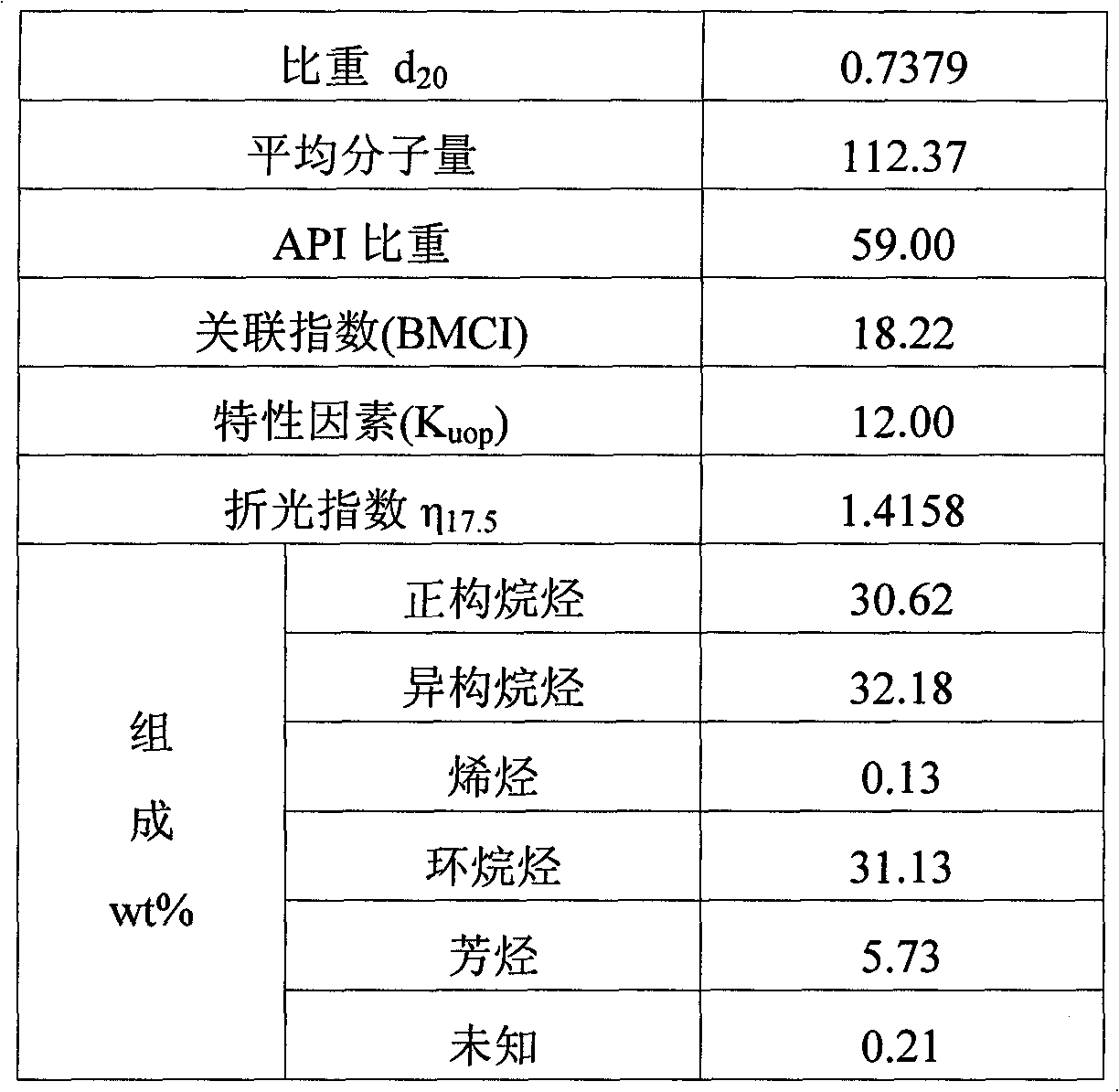

Selective hydrogenation method of acetylene hydrocarbon and dialkene in cracking gas

ActiveCN101451077AReduce the numberReduce hydrogen contentHydrocarbon by hydrogenationRefining by selective hydrogenationUnsaturated hydrocarbonHigh energy

The invention discloses a selective hydrogenation method for acetylene hydrocarbon and diene in pyrolysis gas and belongs to the technical field of selective hydrogenation of unsaturated hydrocarbon. In order to solve the problems in the prior art of high energy consumption, large equipment size, high operation cost, incapable of improvement of C3 selectivity, and the like, due to the facts that liquid phase flow of a mixed phase hydrogenation reactor contains a large amount of C3, C4 and C5 components, can not realize full rinse in the reactor, and repeatedly enters into a front depropanizing tower. The invention provides the method which comprises: carrying out preferential selective hydrogenation of C2-C10 highly unsaturated hydrocarbon (acetylene hydrocarbon and diene) on the upstream of the front depropanizing tower; condensing heavy components above C6 through dephlegmation; and using the heavy components as the fluid phase flow of the mixed phase hydrogenation reactor. The method makes full use of the liquid phase flow of the mixed phase hydrogenation reactor, reduces feeding quantity of the front depropanizing tower, energy consumption and equipment investment, and is propitious to improve selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

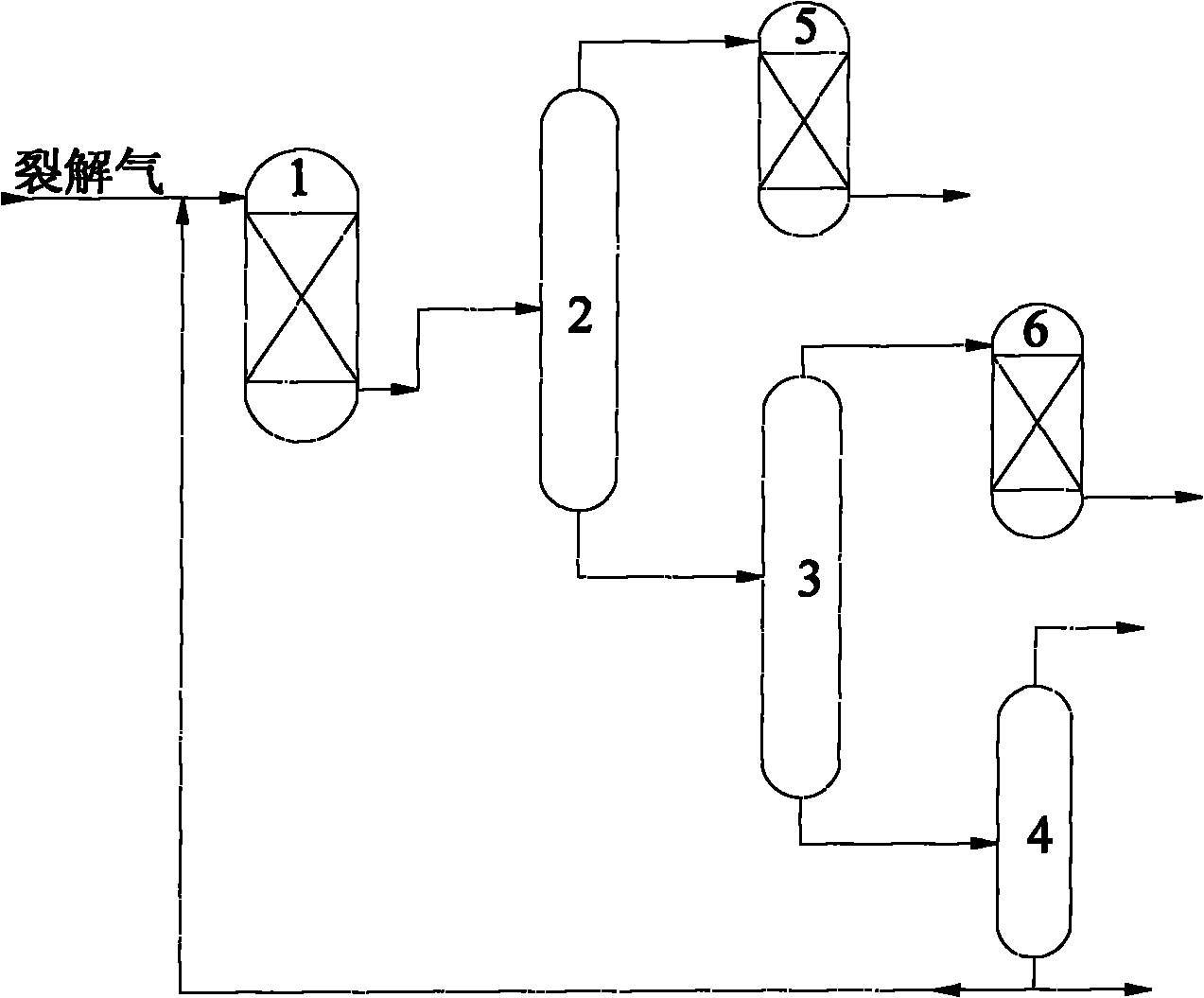

Selective hydrogenation method of highly unsaturated hydrocarbons in cracking gas

ActiveCN101818077AFully expected effectGood choiceGaseous mixture working upUnsaturated hydrocarbonAlkyne

The invention discloses a selective hydrogenation method of cracking gas, belongs to the technical field of selective hydrogenation of unsaturated hydrocarbons, aims at solving the problem that the prior art does not have higher conversion rate for both acetylene and alkynes and dienes containing more carbon atoms and provides a method for carrying out selective hydrogenation on the C2-C10 highlyunsaturated hydrocarbons (alkynes and dienes) on the upstream side of a front dethanizer of an olefin production device with the adoption of acting liquid phase flow of substrate flow of the dethanizer, which is characterized by loading a non-noble metal catalyst in an upper layer in a reactor for carrying out the hydrogenation on the alkynes and the dienes of C3 and above, and loading a noble metal catalyst in a lower layer for carrying out the selective hydrogenation on the acetylene. The method can carry out the hydrogenation on the alkynes and the dienes in the cracking gas as far as possible, simultaneously fully play the role of the liquid phase flow of the mixed phase hydrogenation reactor, reduce the feed rate entering into the front dethanizer, reduce the energy consumption and the equipment investment and be conductive to improving the selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation catalyst aid for residual oil suspended bed and its use

InactiveCN1632070AImprove coke suppression effect of hydrogenationReduce the amount of cokingLiquid hydrocarbon mixture productionRefining to eliminate hetero atomsCarboxylateActive agent

Disclosed is a suspended bed hydrogenation catalyst assistant belongs to the fields of oil procession and oil chemical technology. The assistant contains are or the combination of several ones willingly chosen from high molecule, synthesis organic high molecule, natural surface active agent, synthesis surface active agent, condensed aromatics, organic alcohol, organic carboxylate surfactant, organic carboxylic acid amide, organic carboxylic acid halogen, organic phosphide. It can be applied in the course of suspended bed hydrogenation, as well as that of hydrogenation mixing of hydrogenation and liquidifying coal. By adding the assistant, the hydrogenation effect of catalyst can be increased, as well as decreasing scale formation in reactor in the time of decreasing scale formation in fractional distillation part of the reacting pipe.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

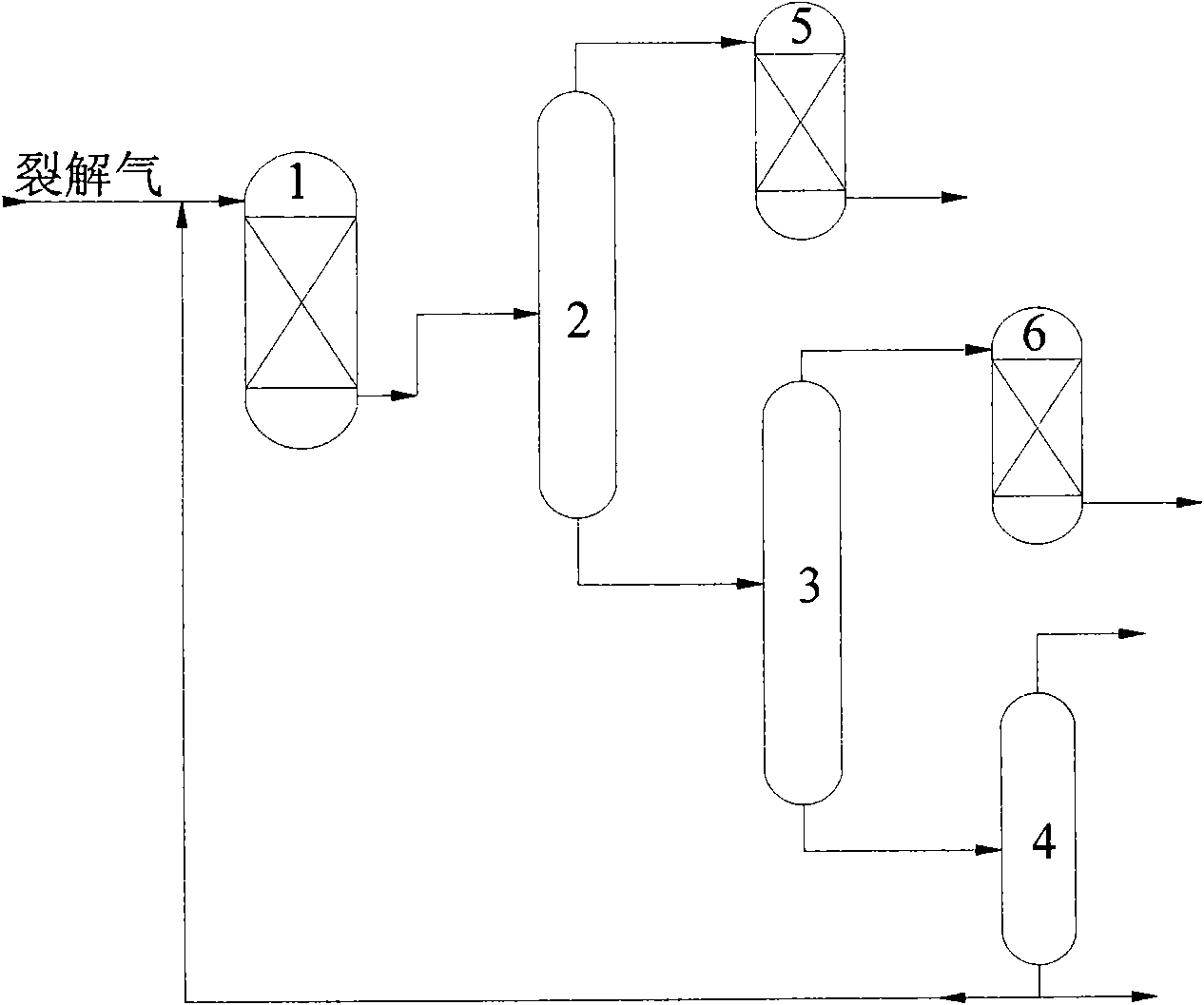

Method for selective hydrogenation and separation for pyrolysis gas

ActiveCN101613621AImproved selectivity and safetyExtend catalyst lifeRefining by selective hydrogenationChemistryHigh energy

The invention discloses a method for selective hydrogenation and separation for pyrolysis gas, and belongs to the technical field of selective hydrogenation of unsaturated hydrocarbon. In order to solve the problems existing in the prior art that the liquid flow of a mixed phase hydrogenation reactor contains a large number of C3 and C4 components, cannot fully play a role in flushing in the reactor and repeatedly enters a front-end deethanization tower to cause high energy consumption, large equipment size, high operation cost and disadvantage to improve C3 selectivity and the like, the invention provides the method for selective hydrogenation for C2-C10 high unsaturated hydrocarbon (alkyne and diolefin) by using material flow at the bottom of the deethanization tower as liquid flow at the upstream side of the front-end deethanization tower of an olefin production device. The method enables the liquid flow of the mixed phase hydrogenation reactor to fully come into play, reduces the charging amount entering the front-end deethanization tower and energy consumption and equipment investment, and is favorable for improving the selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

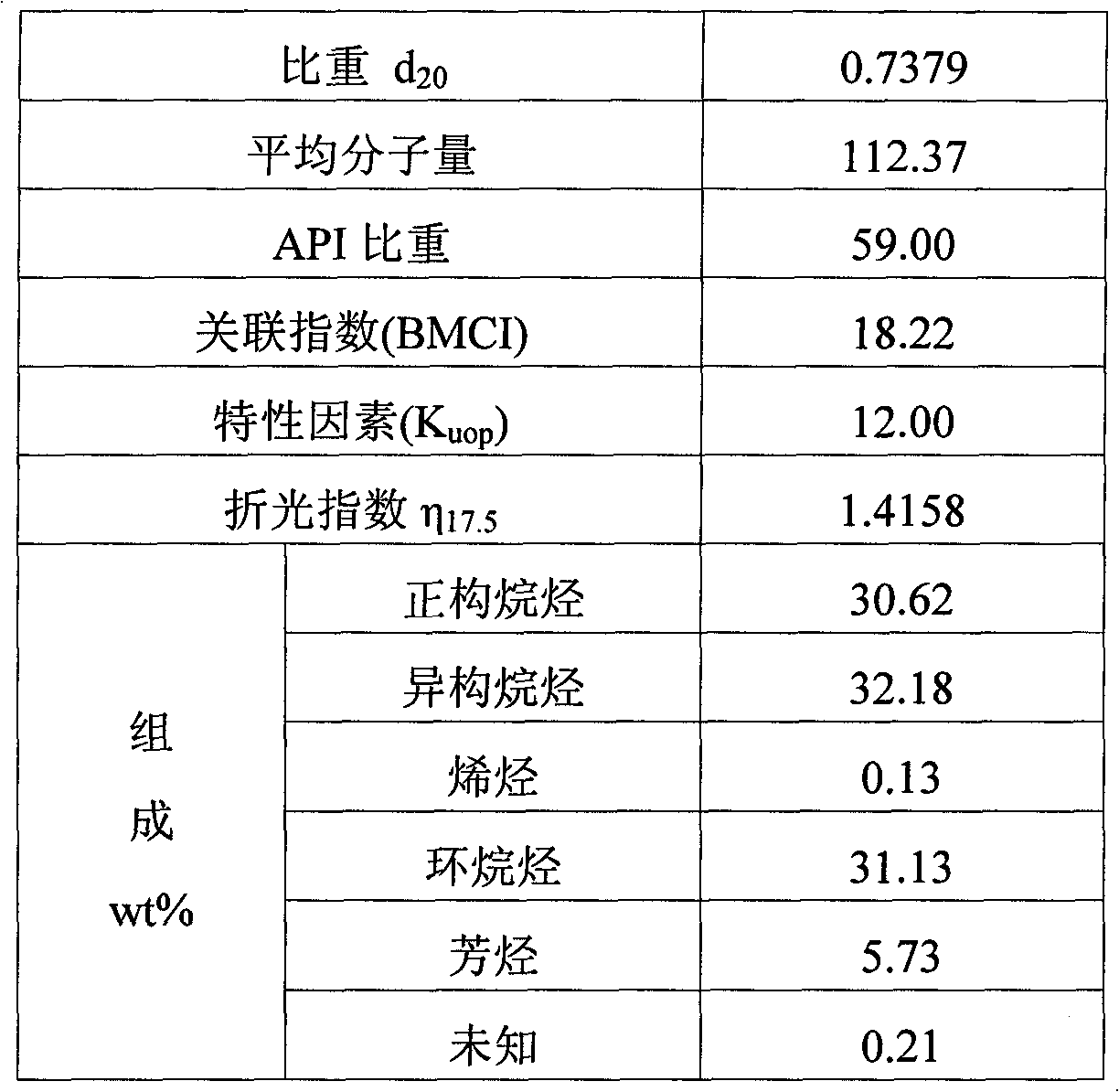

Method for restraining thermal oxidation coking and deposition of aviation fuel RP-3

InactiveCN101892488AReduce microscopic roughnessReduce peakCorrosion preventionMetallic material coating processesAcid washingEngineering

The invention relates to a method for restraining and delaying the thermal oxidation coking and deposition of an aviation fuel RP-3 in an air-oil heat exchanger pipe and on a metal wall face of an aero-engine. In the method, a metal surface is pretreated and passivated, so that the catalytic activity of the surface to coking is reduced, the coking of the entire heat exchanger is reduced, the service life of the entire heat exchanger is prolonged, reliability is enhanced and maintenance cost is lowered. The pretreatment comprises the steps of performing acid-washing passivation and electrolytic polishing on the metal surface.

Owner:BEIHANG UNIV

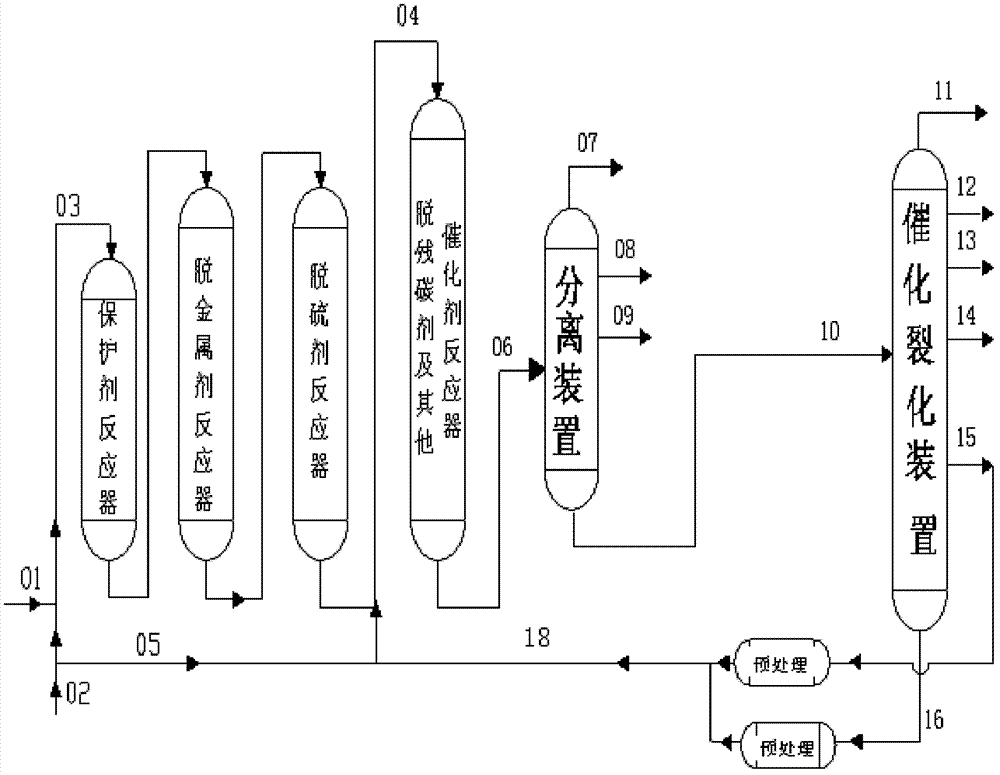

Method for producing gasoline and diesel oil by mixing and refining plastic oil, coal tar, ethylene tar or tire oil

InactiveCN102839020AImprove conversion rateHigh selectivityHydrocarbon distillationTreatment with hydrotreatment processesFractionationCatalytic distillation

The invention discloses a method for producing gasoline and diesel oil by mixing and refining plastic oil, coal tar, ethylene tar or tire oil, and belongs to the field fields of environmental protection and energy. The method is characterized in that the waste plastic oil and the coal tar, the ethylene tar or the tire oil are mixed in a ratio of 1:(0.1-1.1) to form a raw material, and the raw material is catalytically distilled and hydrofined into the high-quality gasoline and diesel oil; and the method comprises the following steps of: fractionating the raw oil into light components and heavy components at the temperature of 300 DEG C through a pre-fractionation tower, directly performing hydrofining reaction on the light components, performing catalytic distillation cracking on the heavy components, regulating the fraction proportion of the gasoline and the diesel oil to reduce the colloid content of the fraction, performing hydrofining reaction, reducing the sulfur and nitrogen content of the oil, regulating the octane value and the acid value, distilling the obtained distillate oil, and thus obtaining high-quality gasoline, diesel oil and the like. By the method, the conversion rate of balanced reaction and the selectivity of consecutive reaction are improved, the coking quantity is greatly reduced, the consumption is reduced, energy is saved, the service life of a catalyst is prolonged, the flow is simple and the investment is saved.

Owner:DALIAN UNIV OF TECH

Method for inhibiting coking of hydrocarbon cracking furnace tube during on-line coke burning process

ActiveCN102807886AReduce cokingReduce pyrolysis cokingThermal non-catalytic crackingProcess engineeringAtmospheric pressure

The present invention relates to a method for inhibiting coking of a hydrocarbon cracking furnace tube during an on-line coke burning process. The method comprises that carrier gas carrying organosilicon steam enters a radiation section of the cracking furnace tube under 1-5 atmospheric pressure at an on-line coke burning later stage of a hydrocarbon cracking furnace tube, wherein the organosilicon is subjected to vapor deposition on the inner wall of the furnace tube to form a SiO2 coating. According to the method of the present invention, cracking coking in the next cycle can be reduced with the generated SiO2 coating; the technology of the present invention has characteristics of simple process, easy implementation, and no adverse effect on the downstream system; and oxidation on the furnace tube during the coke burning process can be effectively reduced so as to prolong a service life of the furnace tube, coke burning amount during the cracking process can be reduced, and the operation cycle of the cracking furnace can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

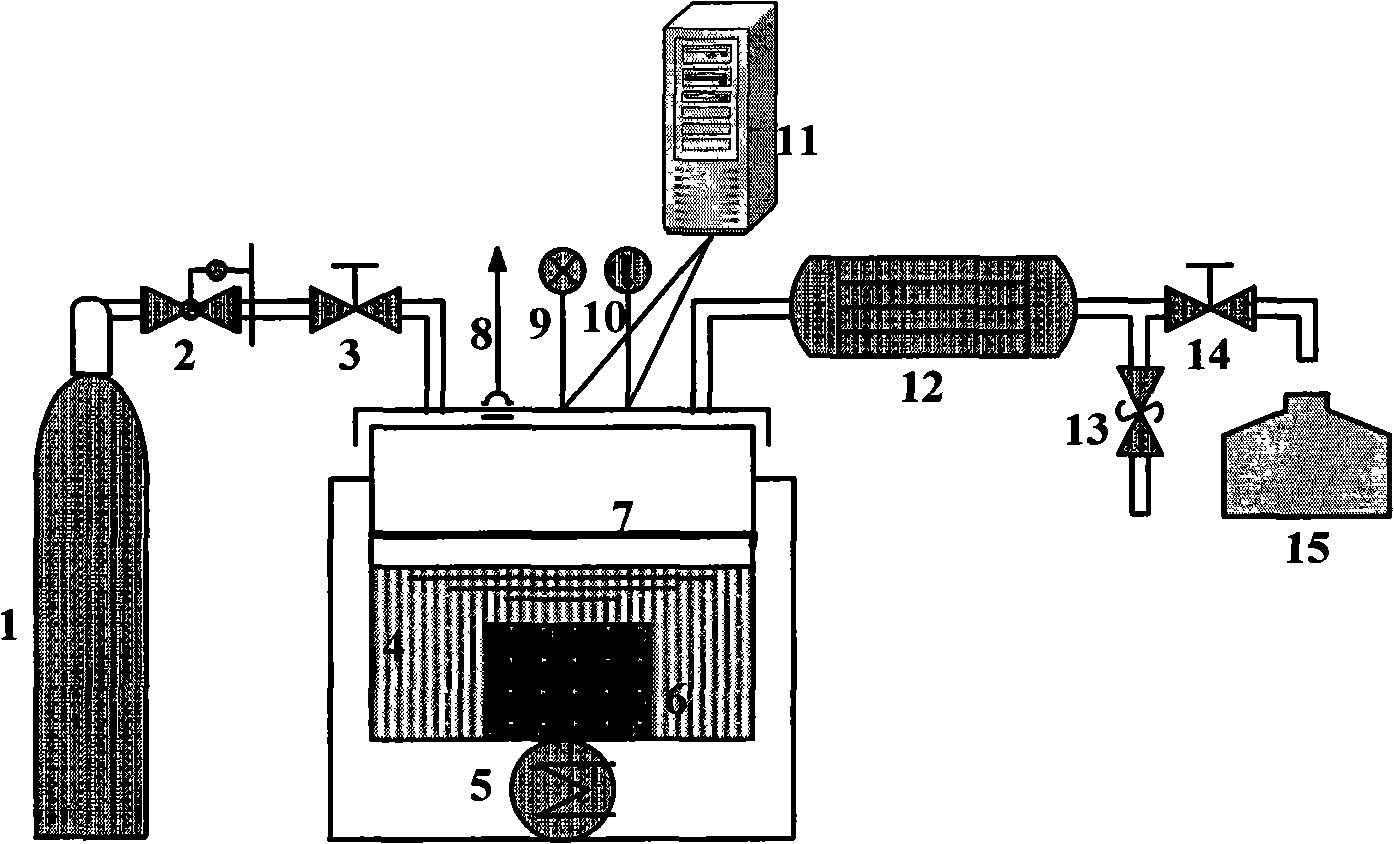

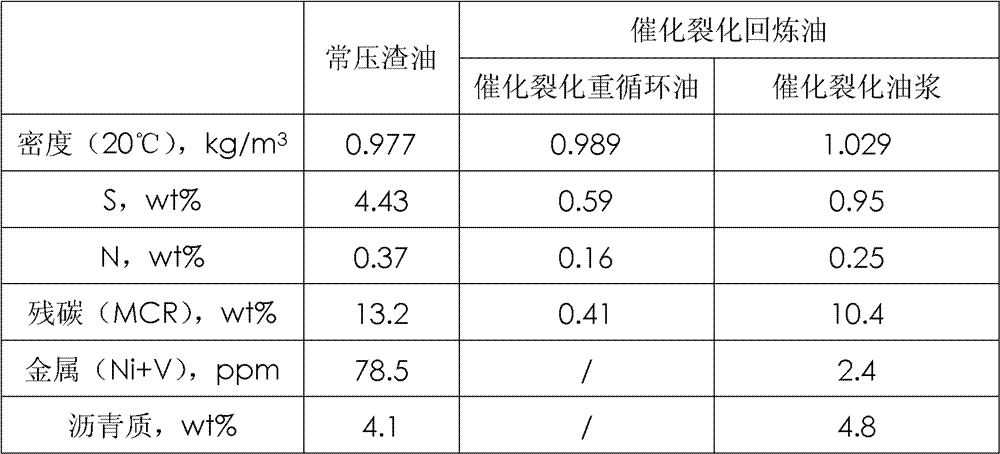

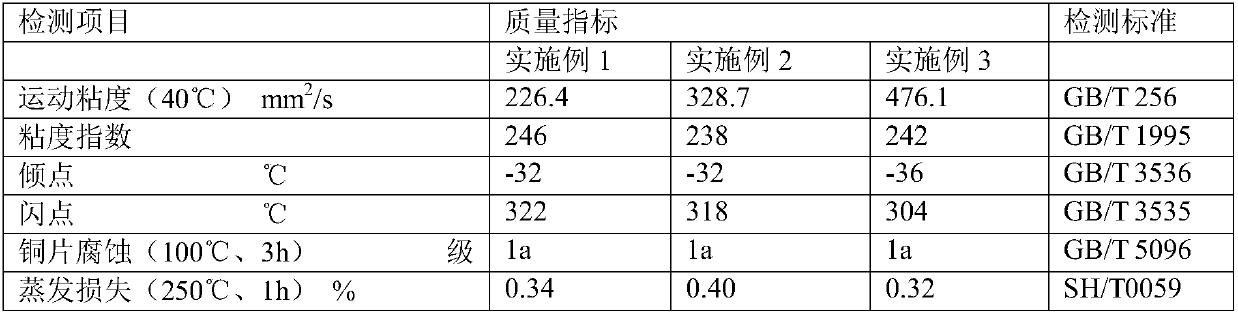

Method for decreasing carbon deposits on carbon residue removing catalyst of residual oil hydrotreater

ActiveCN102816598AReduce the amount of cokingExtended cokingTreatment with hydrotreatment processesHydrogenResidual oil

Provided is a method for decreasing carbon deposits on a carbon residue removing catalyst of a residual oil hydrotreater. The method comprises the steps of adding a feeding port in front of a carbon residue removing agent bed layer of the residual oil hydrotreater, introducing catalytic cracking recycle oil with 1-30% of raw residual oil by weight and high aromaticity through the feeding port, improving the dissolving capacity of gradually precipitating asphaltene of the raw residual oil and accordingly decreasing the carbon deposit amount on the catalyst. By means of the method, the carbon residue removing agent and the carbon deposits on the catalyst can be effectively decreased, an operation period of the residual oil hydrotreater can be prolonged, and the cold hydrogen using amount can be decreased.

Owner:PETROCHINA CO LTD

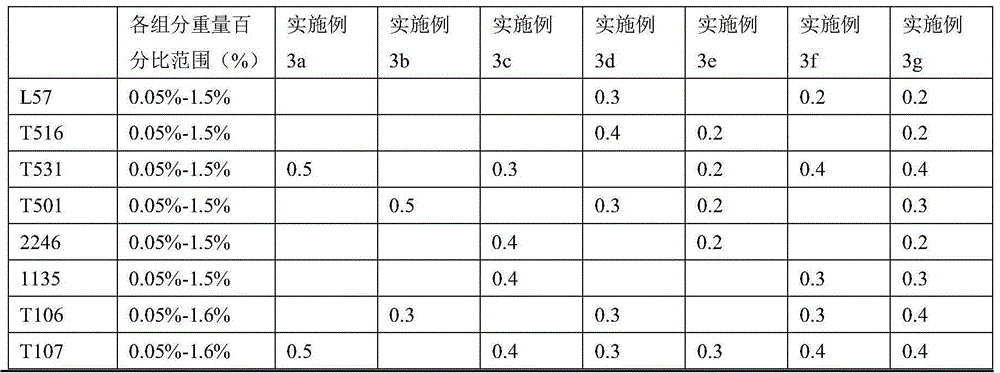

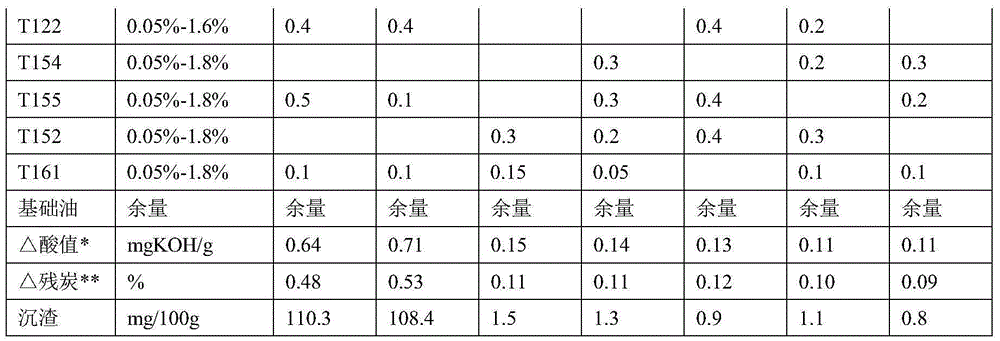

Saturated polyol-ester type high-temperature chain oil and preparation method of chain oil

InactiveCN107699322AReduce evaporation lossReduce the amount of cokingLubricant compositionAntioxidantBase oil

The invention relates to the field of lubricating oil, and discloses a saturated polyol-ester type high-temperature chain oil and a preparation method of the chain oil. The chain oil comprises the following components in percentage by mass: 1-8% of at least two antioxidants, 0.1-1% of at least one metal passivator, 0.1-5% of at least one extreme-pressure antiwear agent, 1-20% of at least one high-temperature detergent dispersant, 1-15% of at least one anti-dripping agent, and the balance of saturated polyol-ester base oil. According to the invention, saturated polyol ester is completely adopted as the base oil for preparing the high-temperature chain oil, so that the chain oil has the characteristics of low evaporation loss, small coking amount, good lubricity, dripping resistance, environment-friendly products and the like.

Owner:浙江实美润滑科技有限公司

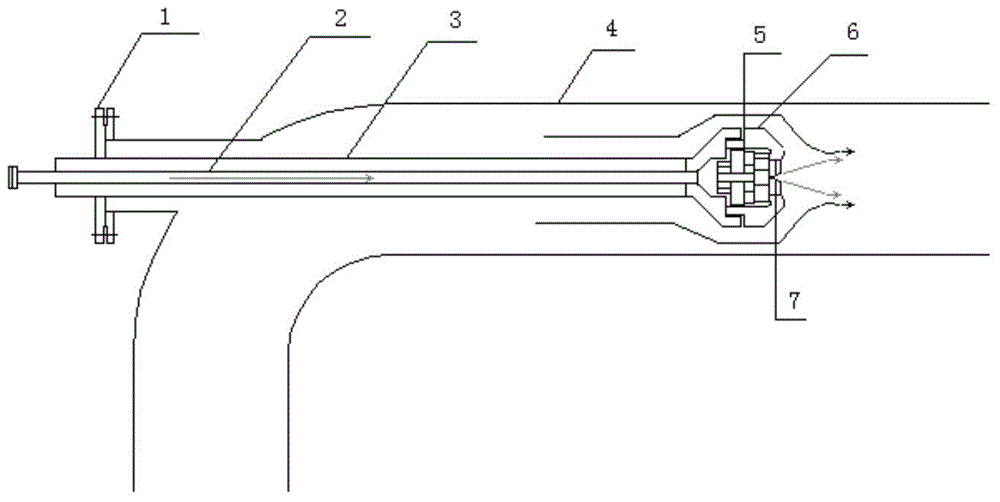

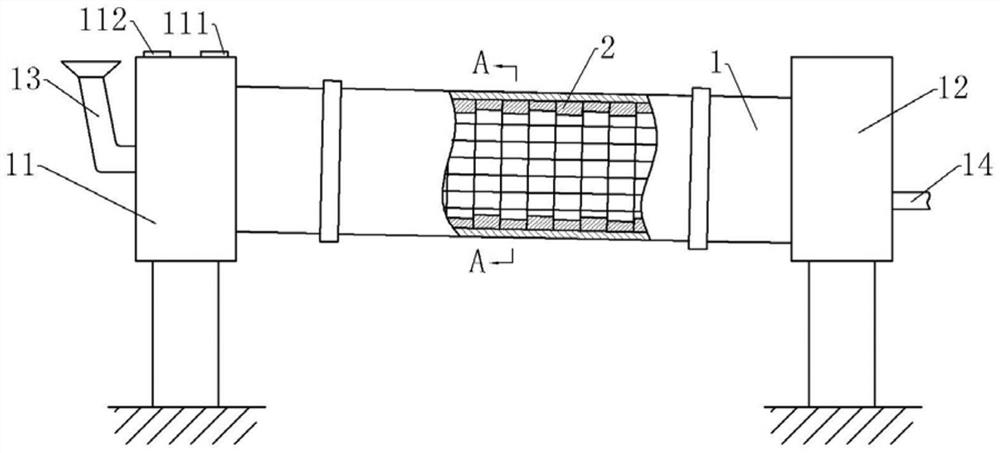

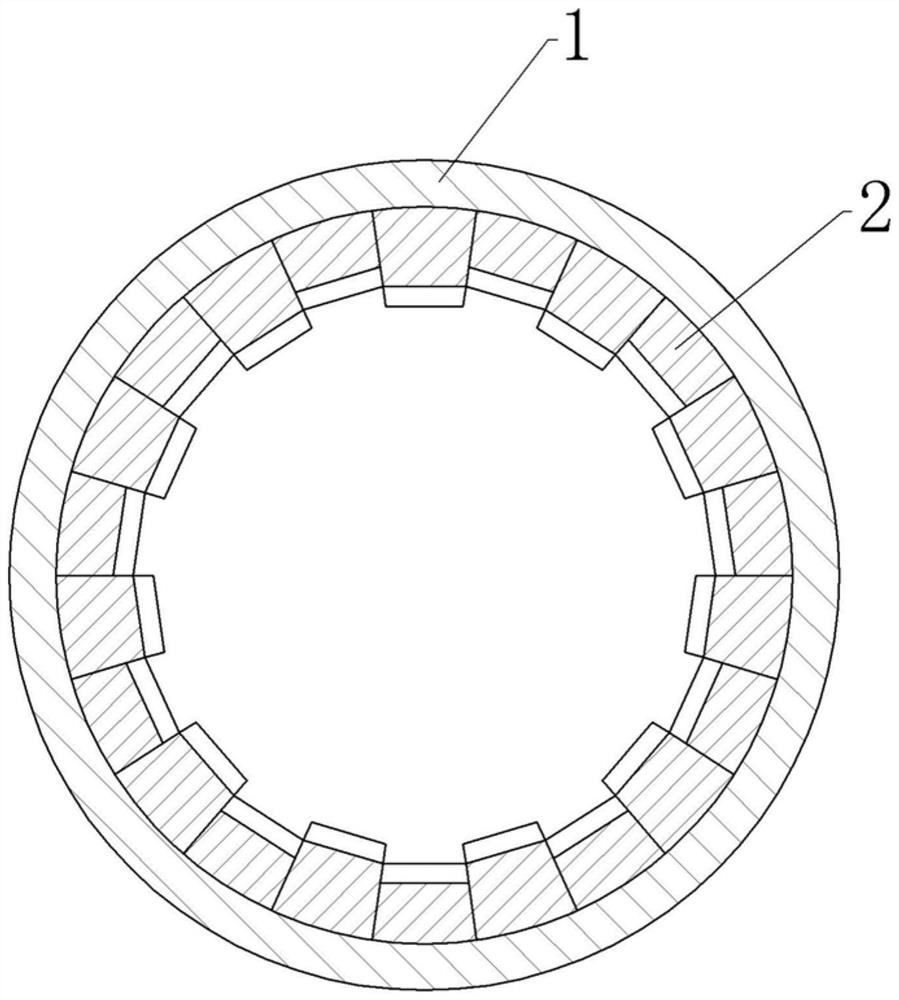

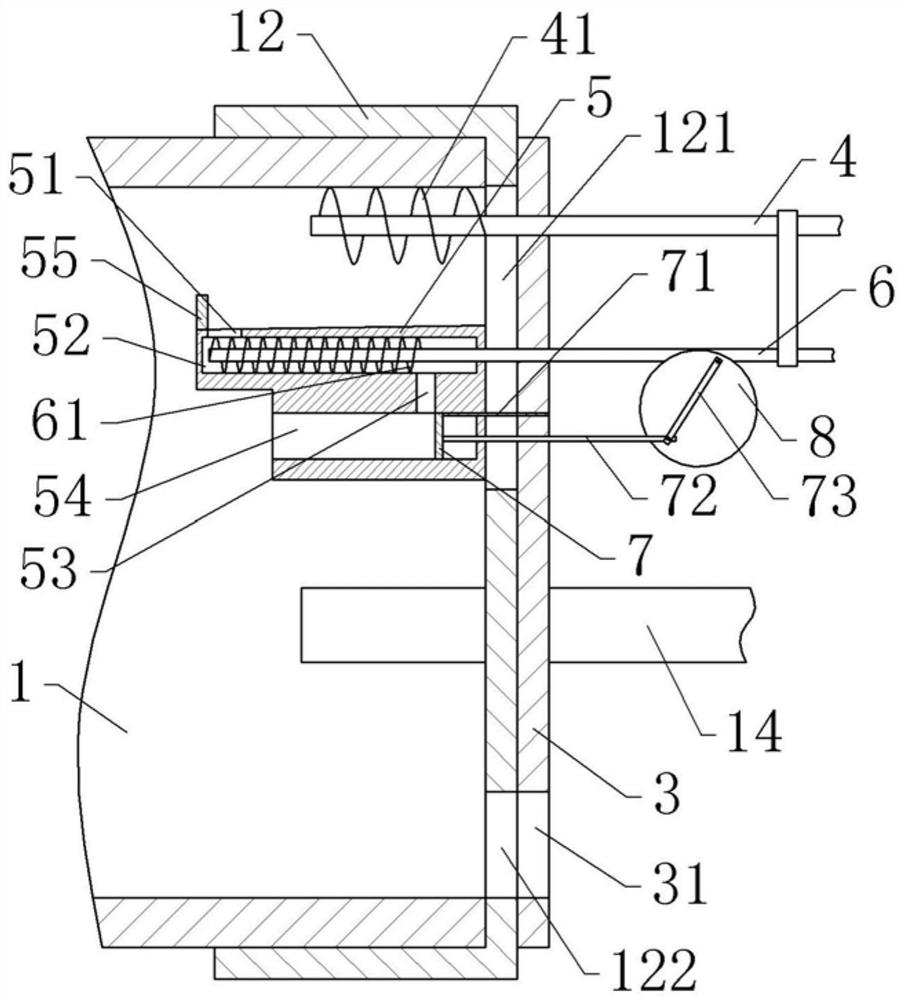

Inhibitor and device for slowing down coking of ethylene cracking furnace pipe, and application method

InactiveCN104560106AReduce cokingReduce the amount of cokingThermal non-catalytic crackingFatigue damageGas phase

The invention relates to an inhibitor and device for slowing down coking of an ethylene cracking furnace pipe, and an application method. The inhibitor is a composition of alkali metal salt and boron compounds. An injectant nozzle comprises a guide pipe, wherein the guide pipe is covered with a heat insulating pipe; a nozzle is arranged at the front end of the heat insulating pipe; a guiding screw piece is arranged inside a spray cavity of the nozzle; a spraying piece is arranged at the front end of the nozzle; the injectant nozzle is mounted at the crossover section of the cracking furnace pipe. The application method comprises the following steps: the inhibitor is injected into high-temperature raw material gas in the crossover section of the cracking furnace pipe through an atomizing nozzle; aqueous solution spray of the inhibitor is injected into a cracking raw material in the cracking process; the inhibitor is used for catalyzing coke on the inner wall of a gasifying furnace pipe and gas-phase matrix coking in the presence of water vapor to slow down apparent furnace pipe coking. The inhibitor is good in coking inhibiting effect and less in added dose, and avoids sedimentation or fatigue damage of the inhibitor; the inhibitor is applied to a vapor cracking ethylene preparing device, can remarkably reduce furnace pipe coking, reduces the temperature of the pipe wall, guarantees the yield of triene, and greatly prolongs the operation cycle of the cracking furnace.

Owner:CHINA PETROLEUM & CHEM CORP

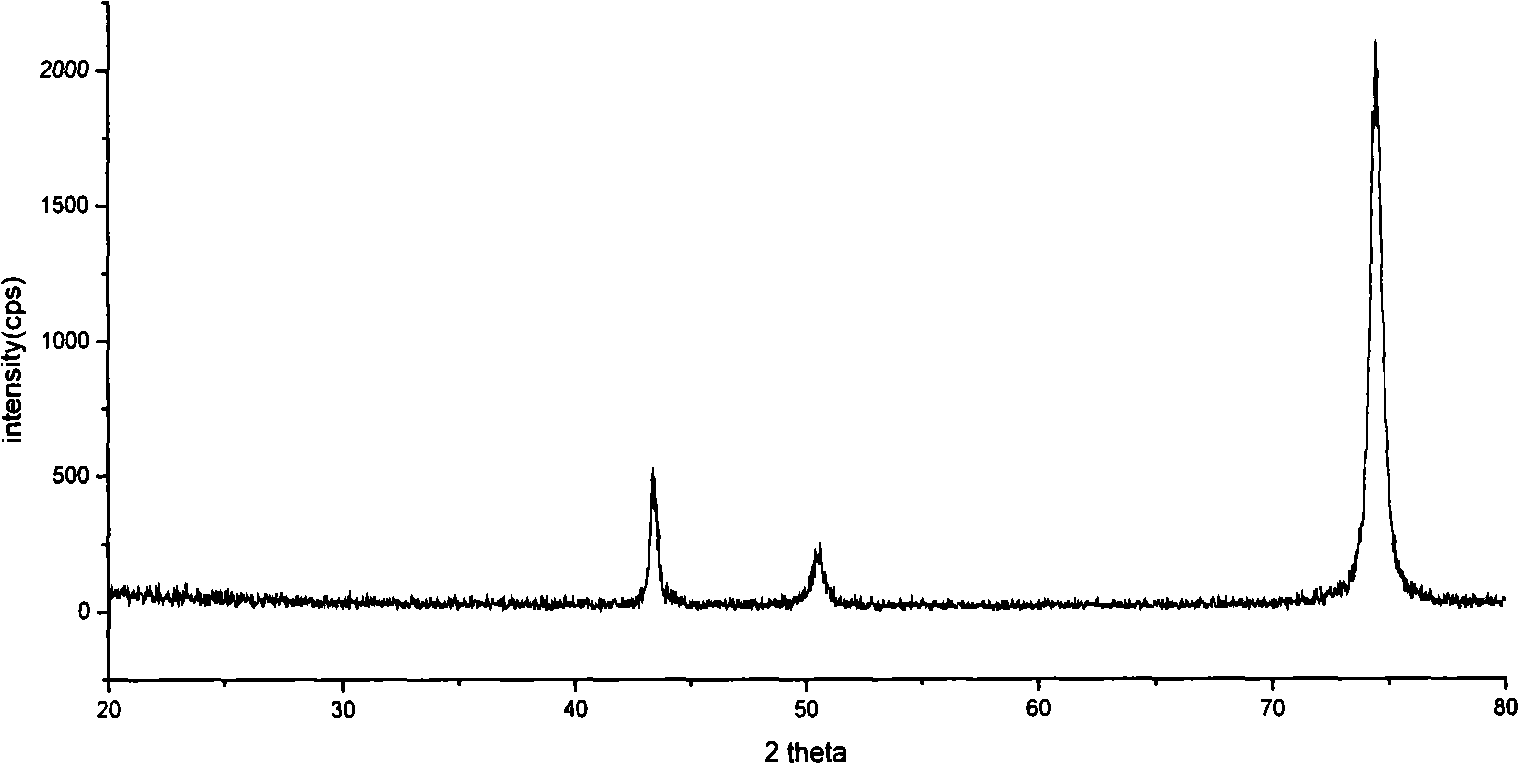

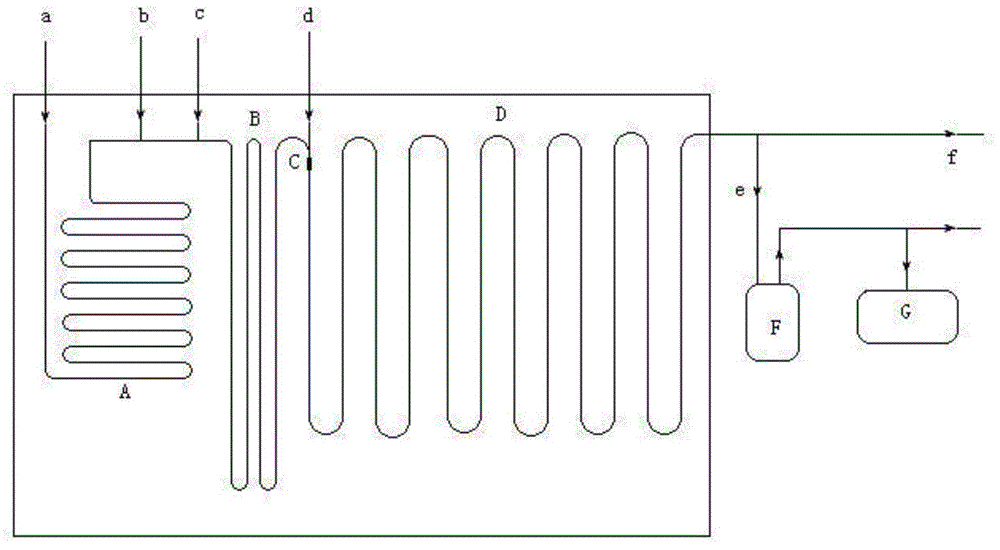

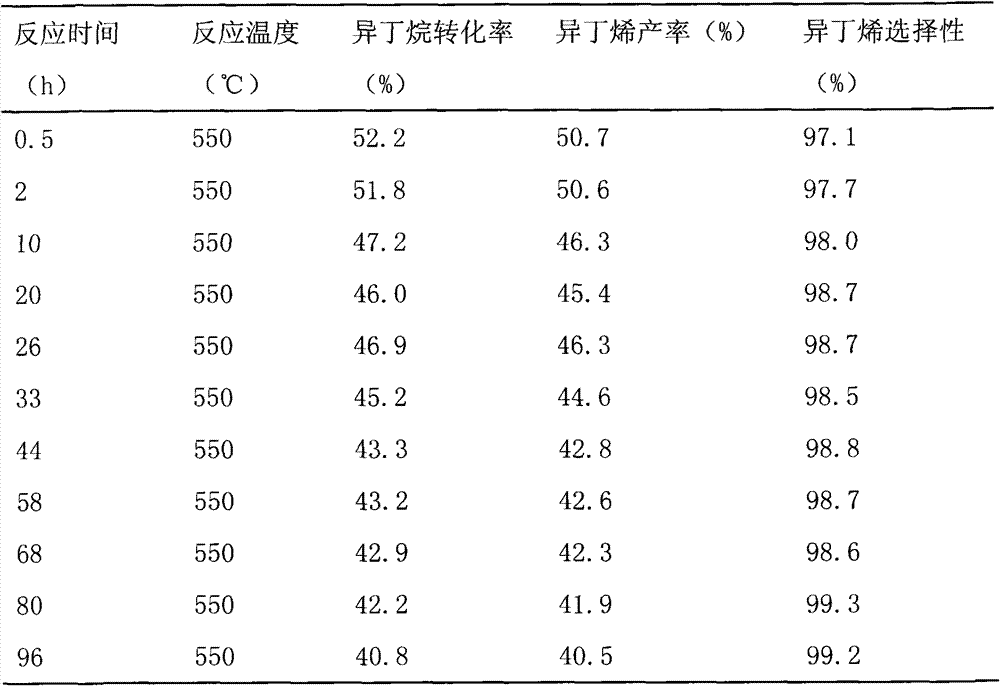

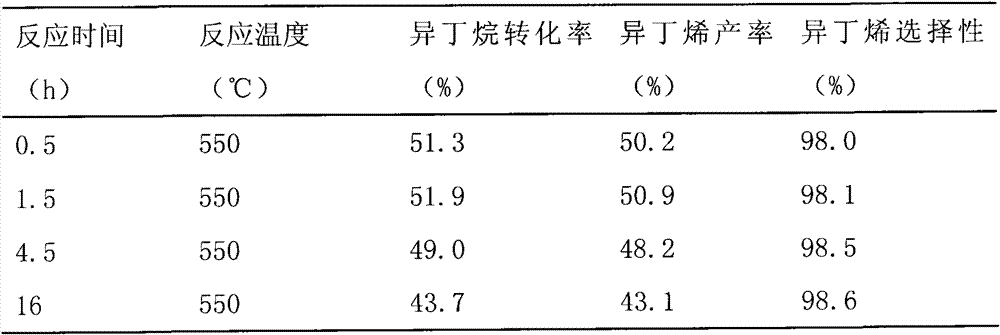

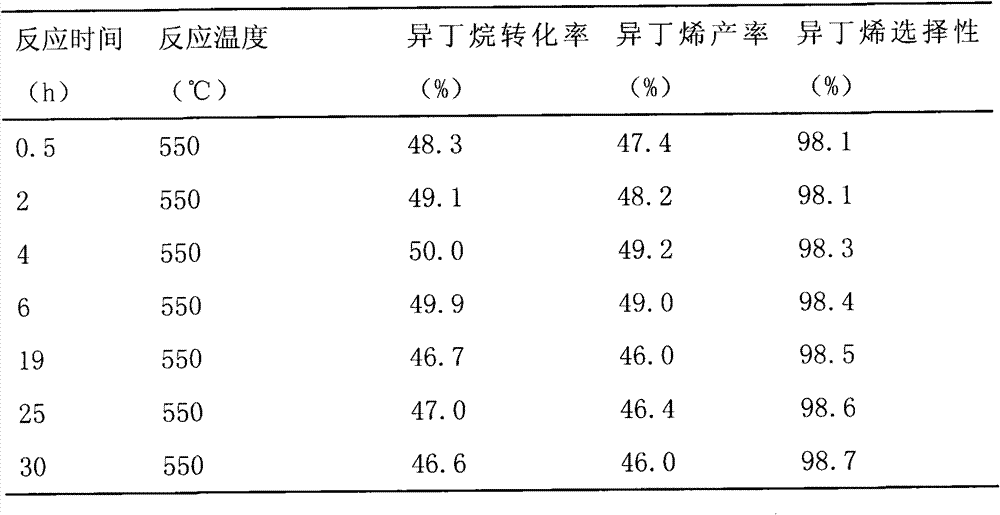

Isobutane dehydrogenation catalyst, preparation method and dehydrogenation technology of isobutane dehydrogenation catalyst

InactiveCN107282078AGood dispersionImprove uniformityCatalyst regeneration/reactivationCatalystsPtru catalystPhysical chemistry

The invention relates to the technical field of catalytic dehydrogenation, in particular to an isobutane dehydrogenation catalyst, and a preparation method and a dehydrogenation technology of the isobutane dehydrogenation catalyst. The preparation method comprises the following steps of: step I, preparing an appropriate amount of platinum metal dipping solution, adding into a carrier, performing dipping at negative pressure, drying and roasting the dipped carrier, step II, preparing an appropriate amount of first assistant dipping solution, adding into the carrier treated in step I, performing the dipping at the negative pressure, drying and roasting the dipped carrier, step III, preparing an appropriate amount of second assistant dipping solution, adding into the carrier treated in step II, performing the dipping at the negative pressure, drying and roasting the dipped carrier, and step IV, repeating step I to step III for many times, and obtaining the isobutane dehydrogenation catalyst. An active component is loaded onto the catalyst stepwise for many times by a dipping method, so that the active component can be distributed on the catalyst more uniformly, and the activity of the catalyst is higher and more stable.

Owner:NANJING CHEM CHEM TECH CO LTD

Method for preparing far infrared ceramic honeycomb type anti-high temperature energy saving furnace plate

The present invention discloses the preparation process of far infrared ceramic honeycomb type heat resisting energy saving furnace plate and belongs to the field of environment friendly energy saving product technology. The materials comprising silica 58-78wt%, alumina 16.9-25.5wt%, potassium oxide 1-5wt%, zirconium oxide 1-3 wt%, titania 0.1-0.5 wt%, sodium oxide 1-3wt% and calcium oxide 2-5wt% are produced into the far infrared ceramic honeycomb type heat resisting energy saving furnace plate through mixing, high temperature sintering and cooling. The present invention can convert peripheral far infrared heat energy into useful energy, and this can reduce the consumption of coal gas and natural gas greatly.

Owner:寇莉祯 +1

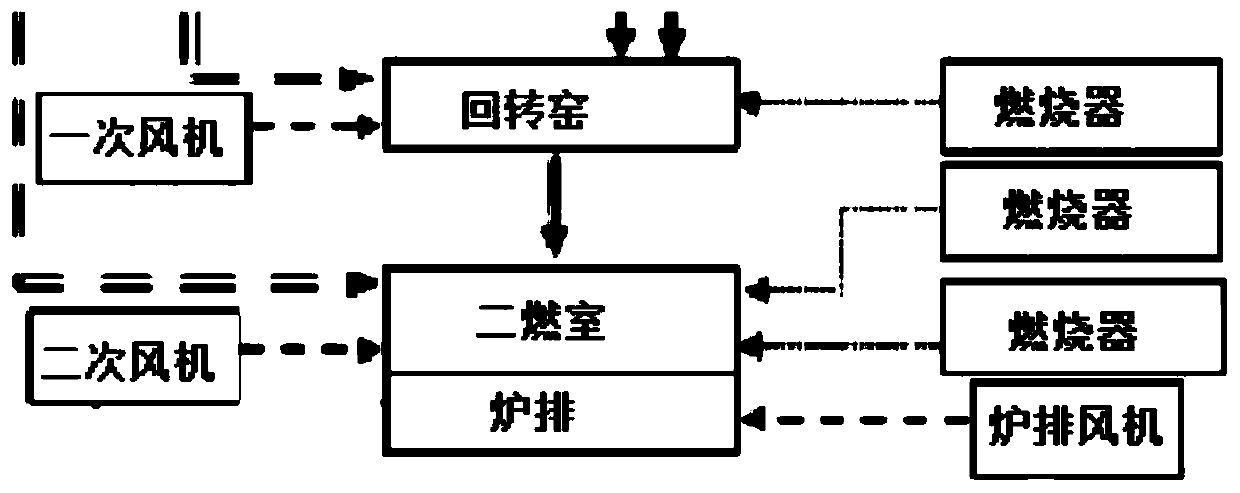

Hazardous waste rotary kiln incineration process

The invention belongs to the technical field of hazardous waste incineration, and discloses a hazardous waste rotary kiln incineration process which is realized by adopting a hazardous waste rotary kiln. The hazardous waste rotary kiln comprises a cylinder body, the two ends of the cylinder body are respectively provided with a kiln head cover and a kiln tail cover in a rotatably and hermeticallyconnected manner, the lower part of the kiln tail cover is provided with a slag outlet, and the kiln head cover is cylindrical; a main air hole and an auxiliary air hole are formed in the side wall ofthe kiln head cover, the main air hole is located in the top of the kiln head cover, the main air hole and the auxiliary air hole are not located in the same circumferential line of the kiln head cover, the main air hole is formed close to the cylinder body, and the auxiliary air hole is formed in the side away from the cylinder body; hazardous waste is thrown into the cylinder body to be incinerated, after the temperature in the cylinder body rises to 1000-1150 DEG C, air is supplied into the kiln head cover from the main air hole and the auxiliary air hole, and the air speed of the main airhole and the air speed of the auxiliary air hole are consistent; and after the hazardous waste is incinerated, ash slag is guided out from the slag outlet. By means of the hazardous waste rotary kilnincineration process, it can be guaranteed that the ignition loss rate is low after hazardous waste is incinerated, and the excess air coefficient is low, so that the hazardous waste can be fully incinerated, and heat losses in the incineration process can be reduced.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

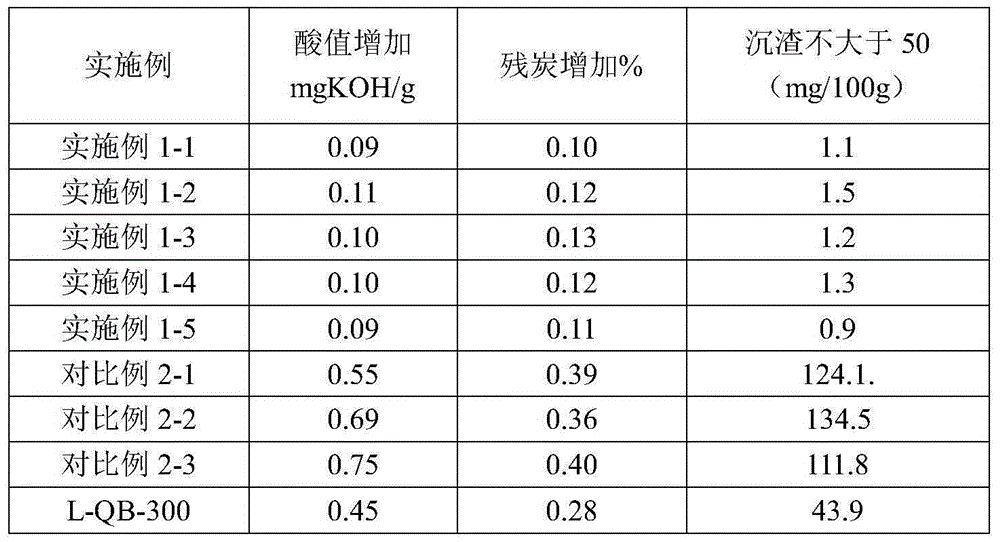

Anti-coking semisynthesis heat conduction oil and preparation method thereof

ActiveCN105038717AImprove thermal stabilityHigh temperature stabilityHeat-exchange elementsAntioxidantCleansing Agents

The invention discloses anti-coking semisynthesis heat conduction oil (modified heat conduction oil). The anti-coking semisynthesis heat conduction oil mainly comprises the following components: mineral basic oil, synthetic basic oil, an amine antioxidant, a phenol antioxidant, a cleaning agent and a dispersing agent, wherein the content of the basic oil is more than or equal to 95 percent by weight; the basic oil consists of the mineral basic oil and the synthetic basic oil, and the weight ratio of the mineral basic oil to the synthetic basic oil is (1 to 9) to (9 to 1); the mixed basic oil: the initial boiling point is higher than 300 DEG C, the spontaneous ignition point is higher than 350 DEG C, the acid value is less than 0.03 mg KOH / g, the residual carbon is less than 0.05 percent, the pour point is less than minus 15 DEG C, the motion viscosity (40 DEG C) is 10 to 28 mm<2> / s, and the open flash point is more than 180 DEG C. The anti-coking semisynthesis heat conduction oil can be suitable for various open-type or close-type heat conduction oil boiler systems, the service life is long when working at the temperature of 300 DEG C, and the anti-coking performance is high.

Owner:CHENGDU MAX TOP NEW ENERGY LUBRICATING MATERIALS

A method for reducing coking in cracking furnace tubes

The invention provides a method for alleviating coking of cracking furnace tubes. The following steps are adopted: before coating the coke suppression coating on the inner surface of the cracking furnace tube, the inner surface of the cracking furnace tube is pretreated; the inner surface of the cracking furnace tube is coated with an anti-coking coating; and the coking inhibitor is added to the cracking raw material. The present invention reduces the formation of coking by compounding anti-coking technology, greatly reduces the coking rate of high-temperature cracking of hydrocarbons, and prolongs the service life of hydrocarbon cracking equipment.

Owner:内蒙古冠泰环保科技有限公司

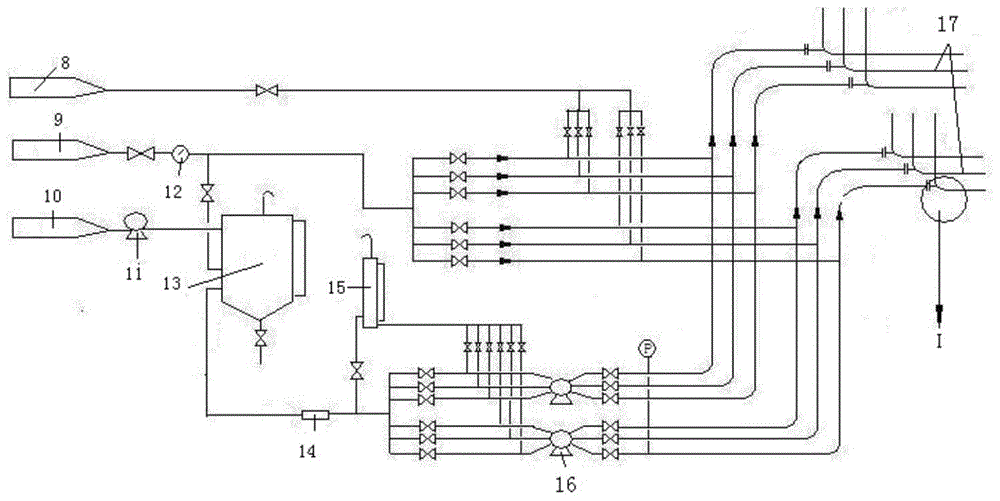

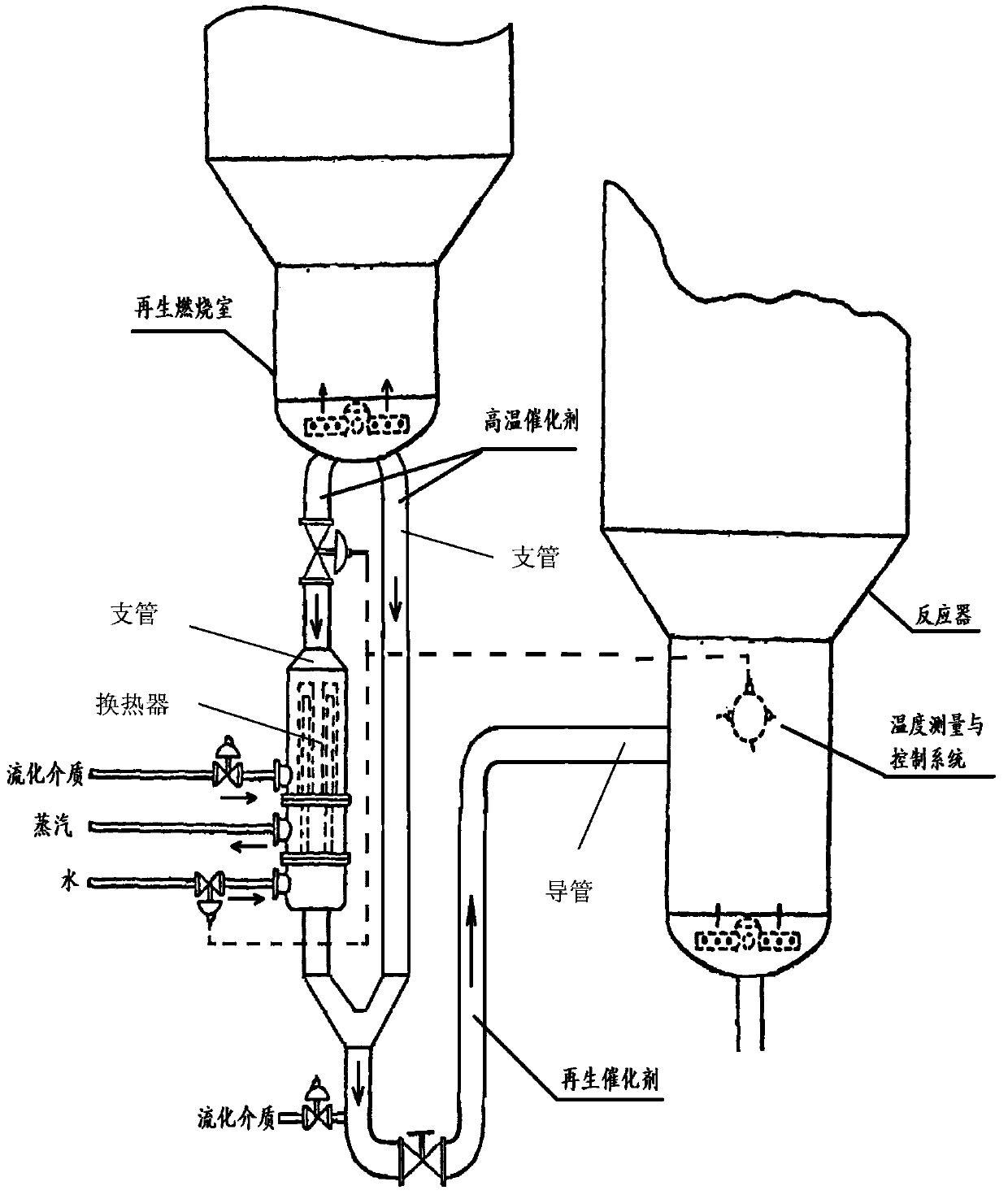

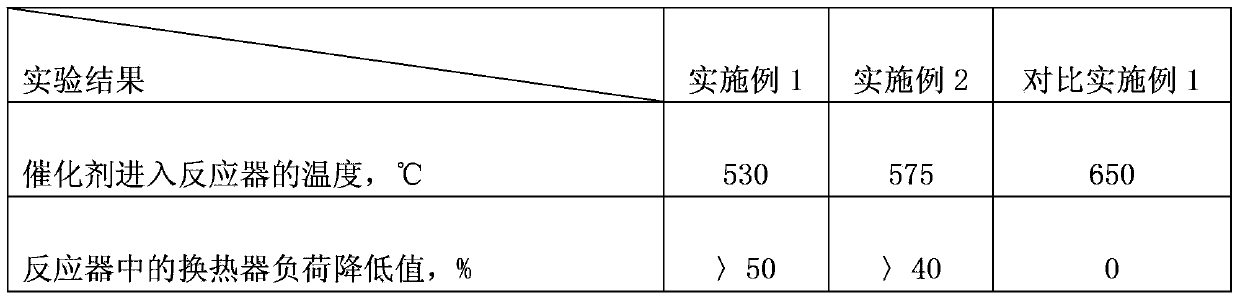

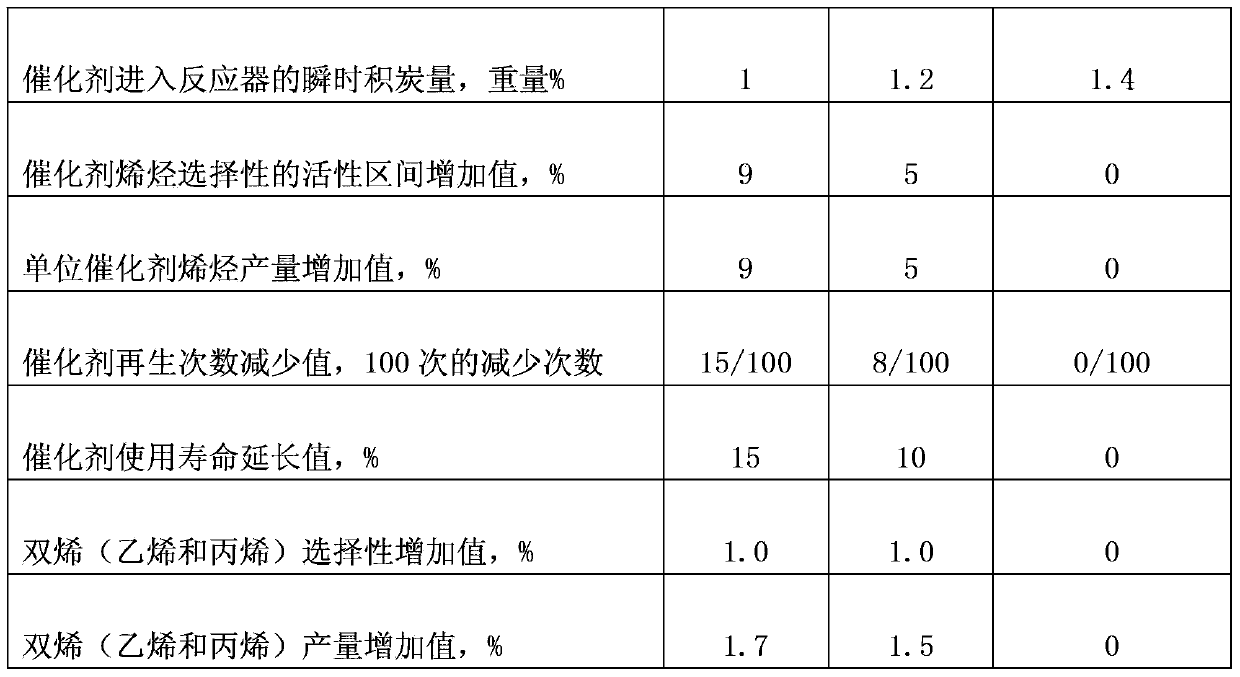

System and process for preparing olefin from oxygen-contained compound for reducing catalyst coking

ActiveCN103387477AReduce the temperatureReduce the amount of cokingHydrocarbon from oxygen organic compoundsChemical recyclingEngineeringOxygen

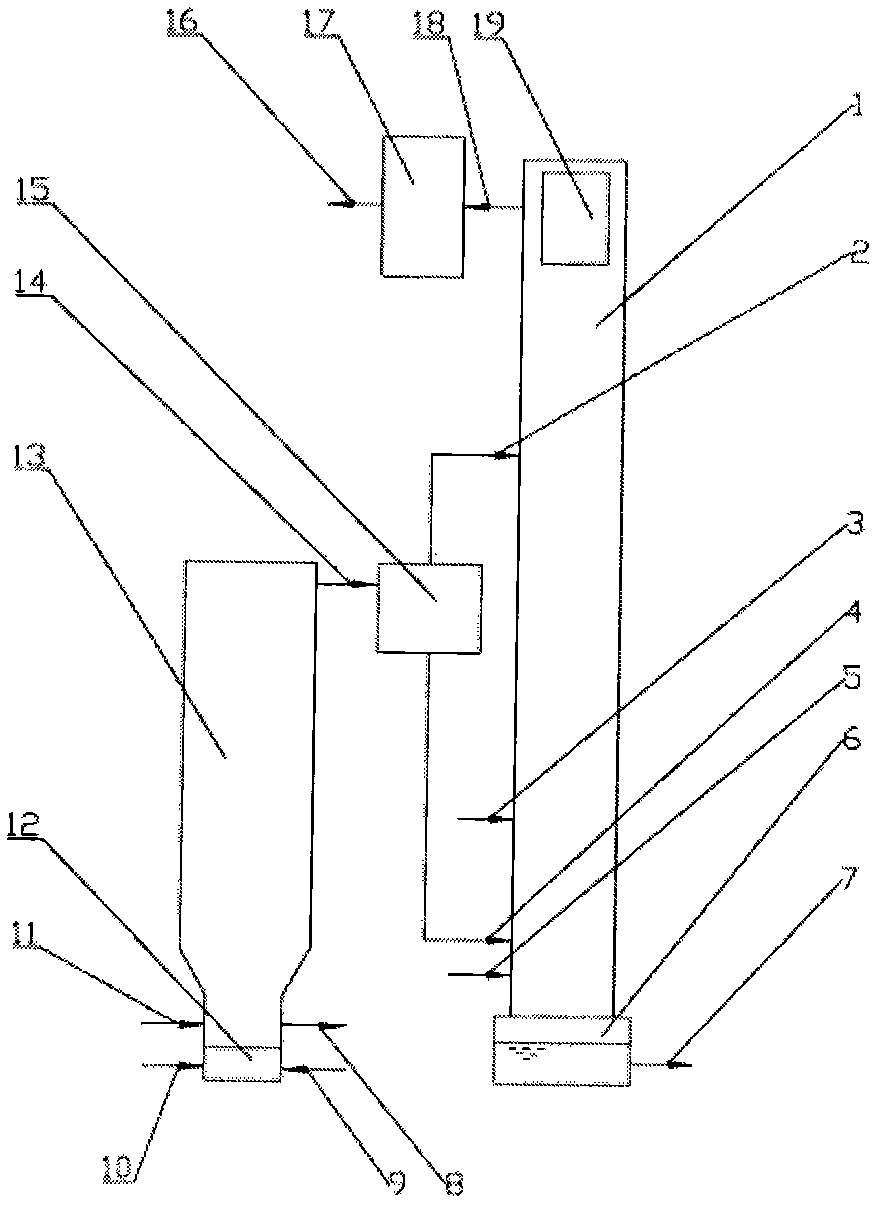

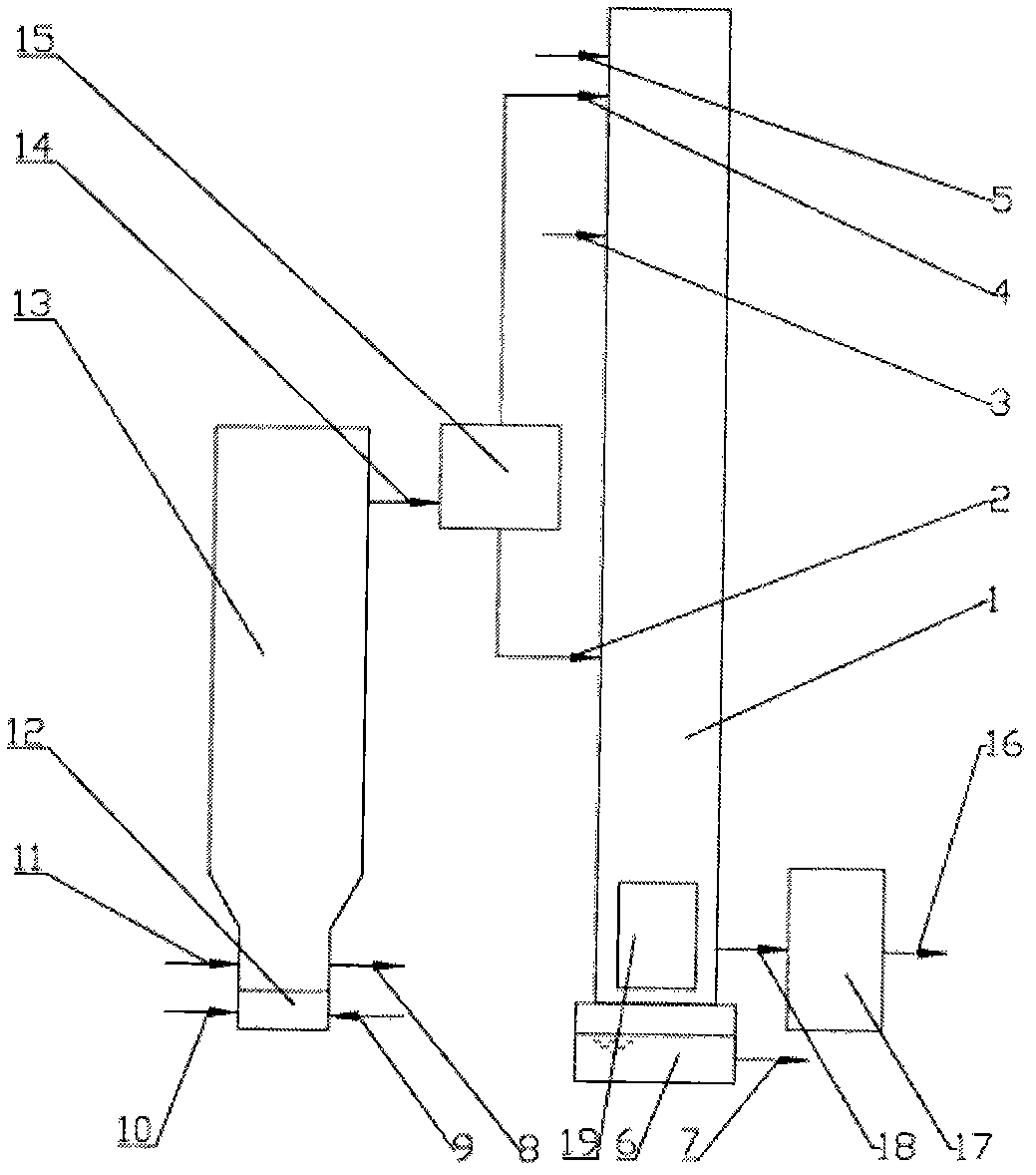

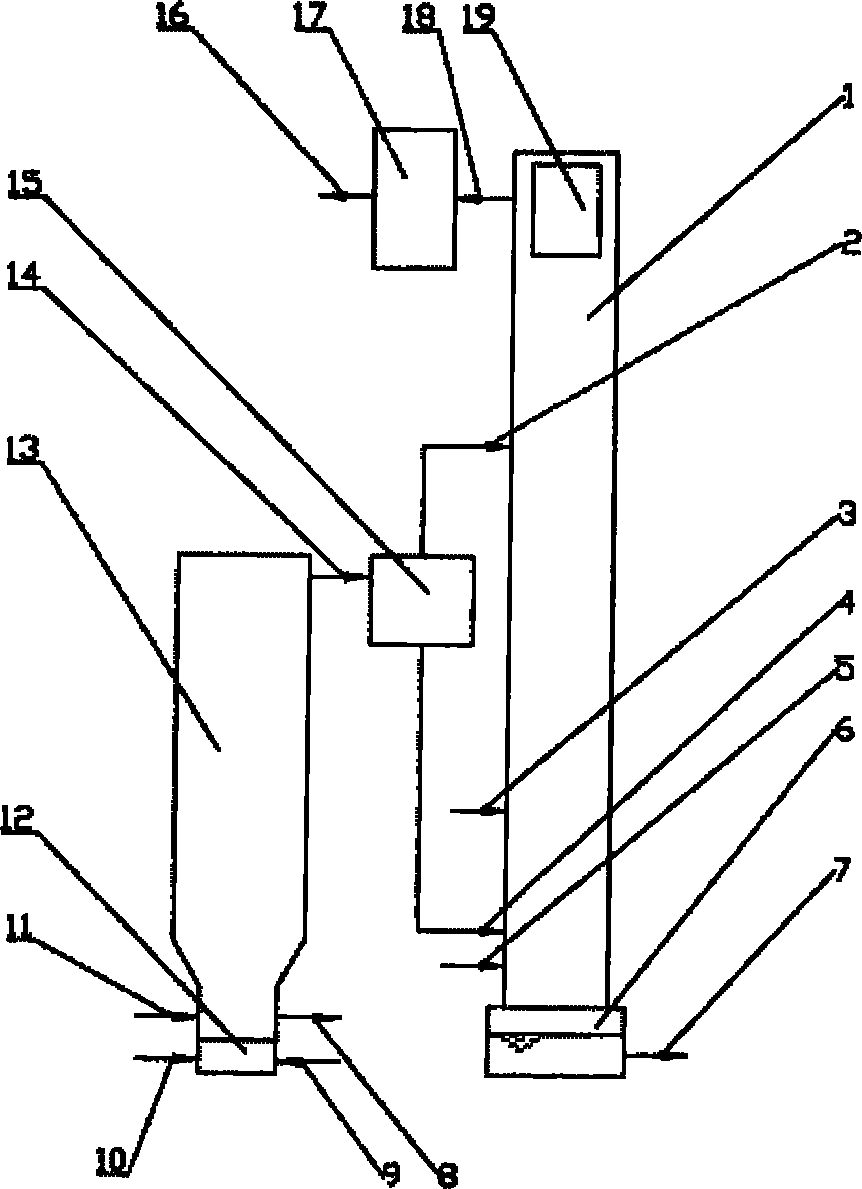

The invention discloses a system for preparing olefin from an oxygen-contained compound for reducing catalyst coking. The system comprises at least one reactor, at least one regenerator, at least one deactivated catalyst conveying pipeline and at least one regenerated catalyst conveying pipeline, wherein a part, close to the regenerator, of the regenerated catalyst conveying pipeline comprises at least two branch pipes, a part, close to the reactor, of the regenerated catalyst conveying pipeline comprises at least one guide pipe, the branch pipes are communicated with the guide pipe, at least one of the branch pipes is provided with at least one indirect heat exchanger for cooling a regenerated catalyst entering into the branch pipe, and the cooled regenerated catalyst is mixed with the regenerated catalyst from other branch pipes in a connecting area between the branch pipe and the guide pipe and enters into the reactor through the guide pipe, so as to prevent overtemperature of the regenerated catalyst entering into the reactor and prevent the surface of the regenerated catalyst from being quickly carbonized when the regenerated catalyst is in contact with the oxygen-contained compound in the reactor.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Special high-temperature lubricating oil for steel belt of continuous press for plate processing industry and preparation method of high-temperature lubricating oil

InactiveCN104087392AImprove high temperature stabilityImprove anti-coking performanceBase-materialsAlcoholAntioxidant

The invention provides special high-temperature lubricating oil for a steel belt of a continuous press for the plate processing industry. The special high-temperature lubricating oil comprises the following components in percentage by mass: 45-94wt% of aromatic acid mixed alcohol ester, 5-54wt% of a thickening agent, 0.1-5wt% of an antioxidant, 0.1-5wt% of an extreme pressure antiwear additive, 0.005-0.5wt% of a corrosion inhibitor and 0.01-0.5wt% of a balancing agent, wherein the aromatic acid mixed alcohol ester is an ester compound of a mixed alcohol composed of C8-C16 fatty alcohols and / or C8-C16 branched-chain alcohols, and the sum of the mass percentage of all the components is 100wt%. The special high-temperature lubricating oil for the steel belt of the continuous press for the plate processing industry has the characteristics of excellent low temperature resistance performance, high corrosion resistance and good wear resistance and can meet the requirement for a complex condition of the continuous press.

Owner:CHINA PETROLEUM & CHEM CORP

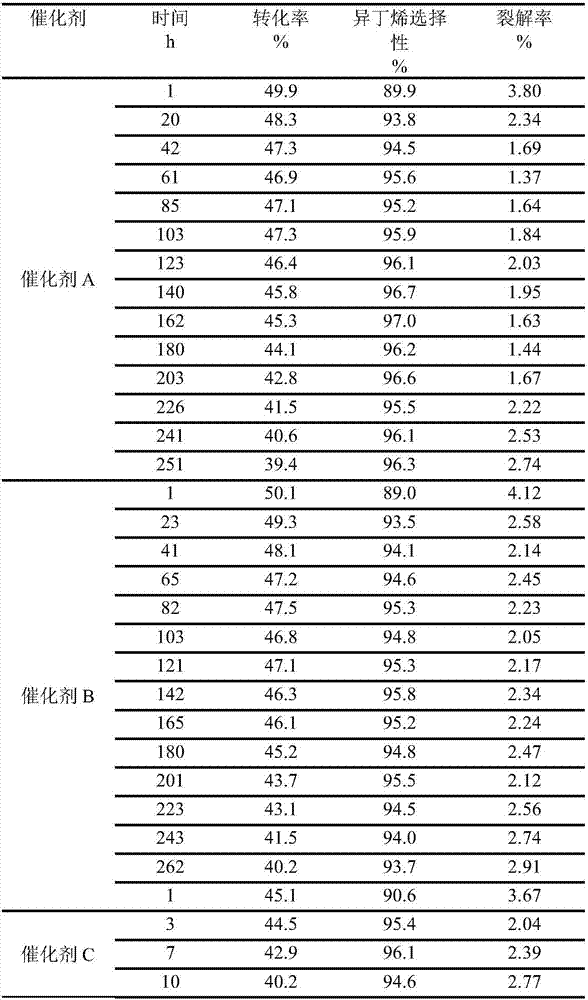

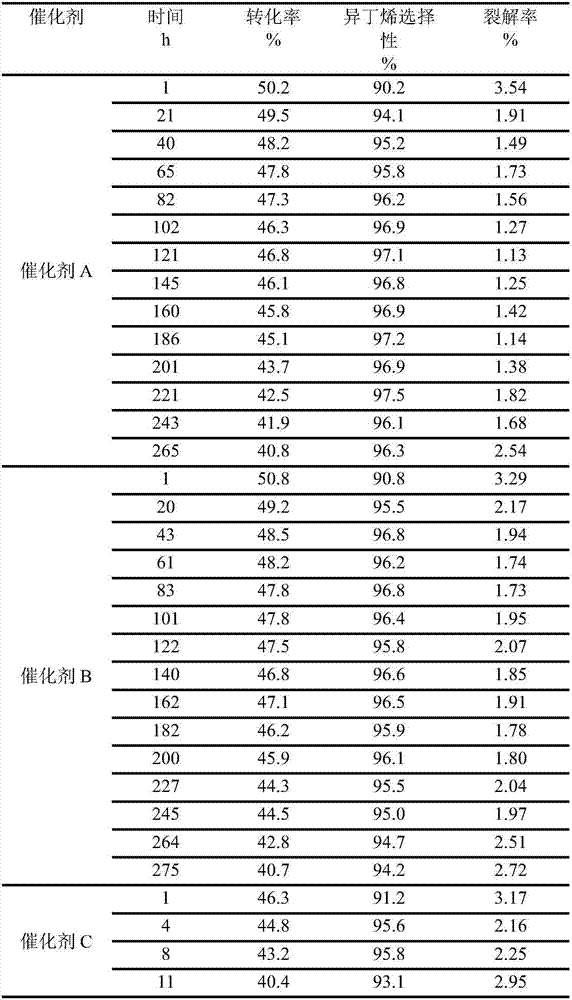

Catalyst for preparation of isobutene by isobutene dehydrogenation as well as preparation process and dehydrogenation process thereof

InactiveCN102000593BGood dispersionImprove uniformityPhysical/chemical process catalystsHydrocarbonsPtru catalystHalogen

The invention relates to a catalyst for the preparation of isobutene by isobutene dehydrogenation as well as a preparation process and a dehydrogenation process thereof. In the catalyst, a heat-resistant oxide is used as a carrier, a platinum group metal element is used as a main catalyst, an IVA group metal element is used as a first assistant, an alkali metal element is used as a second assistant, and a halogen element is used as a modifier. The catalyst is prepared by loading a solution containing the active components onto the heat-resistant oxide carrier in one step by adopting an isopyknic immersion method, has higher isobutene conversion rate, better isobutene selectivity and favorable stability by using a mixture of hydrogen and water vapor as a diluent, and is suitable for the application in industrialized production.

Owner:BEIJING UNIV OF CHEM TECH +1

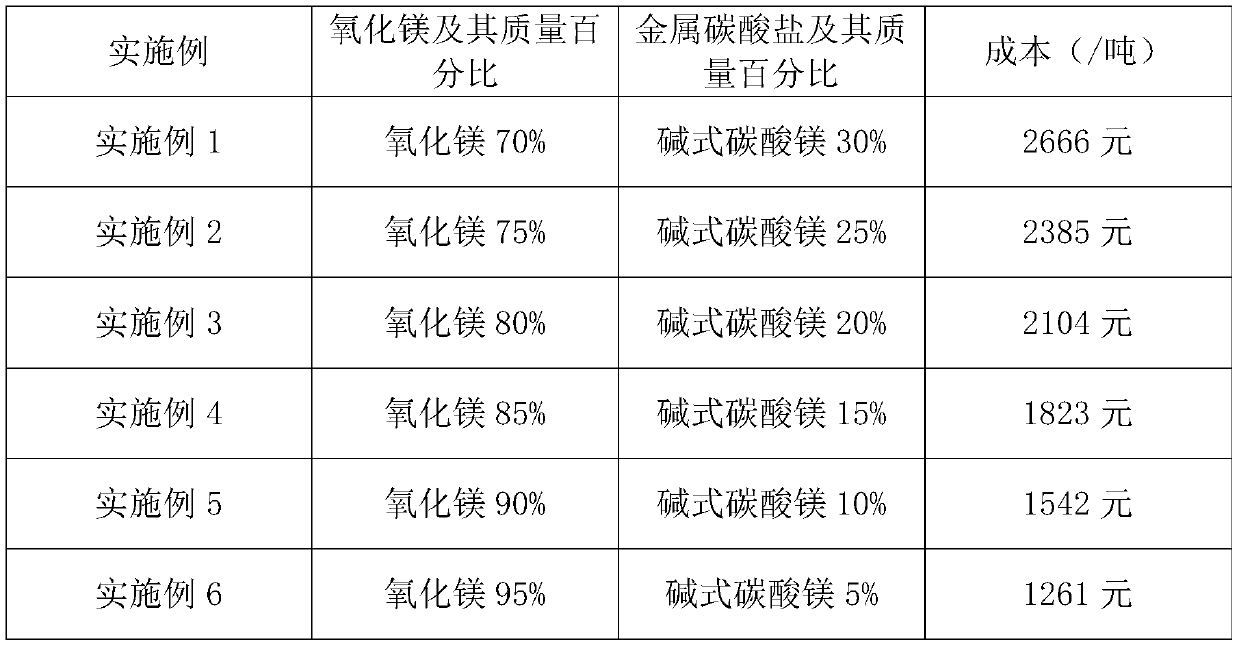

Coking inhibitor special for hazardous waste incinerator and preparation method and application thereof

InactiveCN111548840AReduce the probability of being in focusReduce the difficulty of clearing focusSolid fuelsDirect carbon-dioxide mitigationCombustion chamberPhysical chemistry

The invention relates to a coking inhibitor special for a hazardous waste incinerator and a preparation method and application thereof, and belongs to the technical field of chemistry. The coking inhibitor is simple in component, the melting point of fly ash generated by incineration is increased in the hazardous waste incineration process of magnesium oxide, the number of fly ash molten at the high temperature adhering to the tail of a rotary kiln, a fire grate, a secondary combustion chamber necking opening, the side wall of a horizontal flue and the heated surface is reduced to a certain degree, and therefore the coking rate of an incinerator is reduced. The carbon dioxide generated by the metal carbonate destroys the compact structure of the coke block to form a porous fragile structure, so that the coke block is loose and is in a sandwich shape, the decoking is time-saving and labor-saving, and the influence on equipment and refractory materials is small.

Owner:宁波市北仑环保固废处置有限公司

Method for inhibiting coking of hydrocarbon cracking furnace tube during on-line coke burning process

ActiveCN102807886BReduce cokingReduce pyrolysis cokingThermal non-catalytic crackingProcess engineeringAtmospheric pressure

Owner:CHINA PETROLEUM & CHEM CORP +1

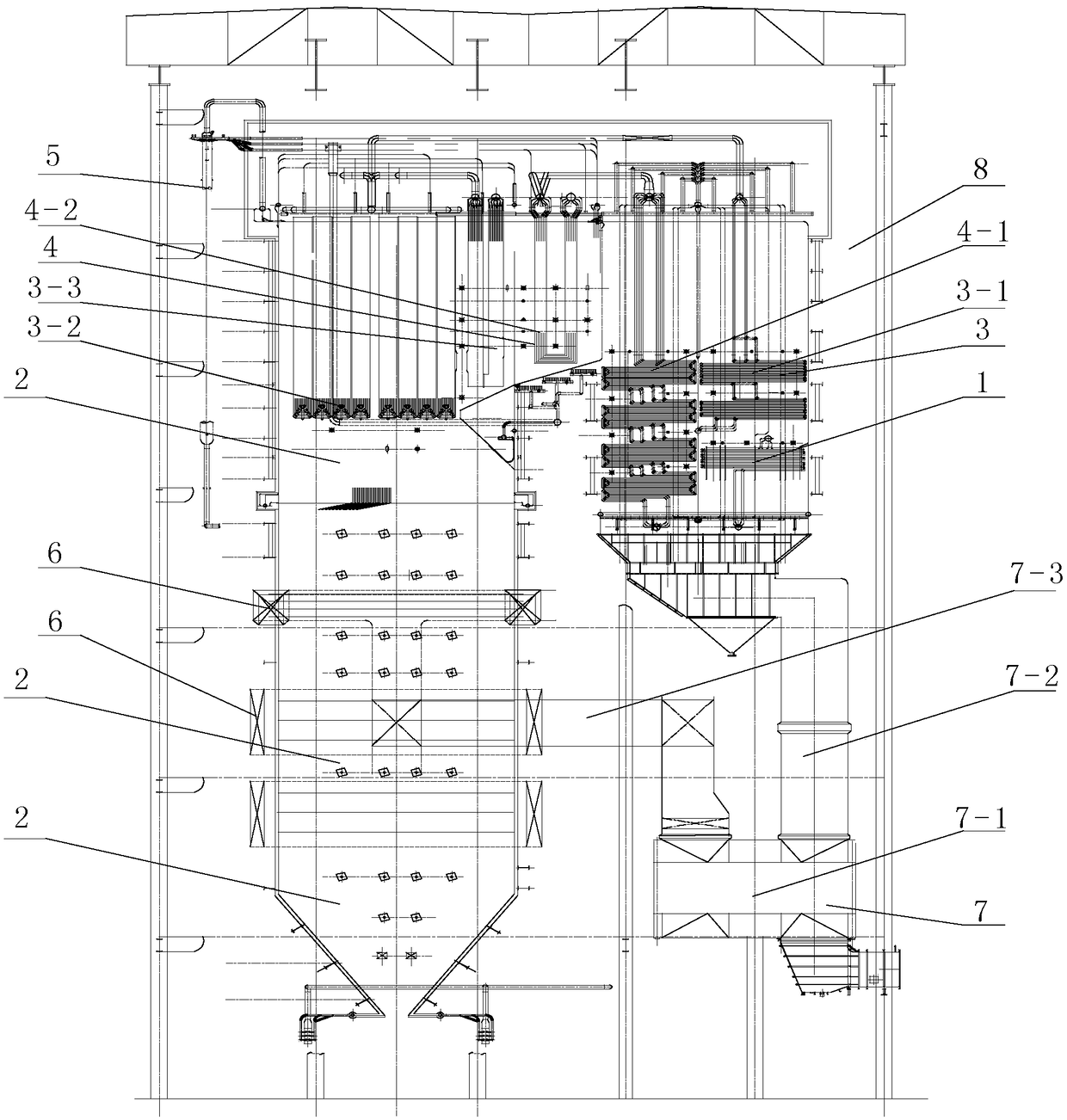

660MW tangential firing ultra-supercritical boiler burning Xinjiang Zhundong coal

PendingCN108692305AReduce heat loadReduced coking tendencySteam superheatersSteam boilersSupercritical steam generatorCombustion system

The invention relates to ultra-supercritical boilers, in particular to a 660MW tangential firing ultra-supercritical boiler burning Xinjiang Zhundong coal, and belongs to the field of boiler equipment. The problem that the phenomena of tube burst and blowing out can occur to whole parts of an existing boiler is solved. The 660MW tangential firing ultra-supercritical boiler comprises an economizer,a water cooling wall, a superheater system, a reheater system, a starting system and a flue gas and air system. The starting system is mounted at the top of a hearth; the economizer, the superheatersystem, the reheater system and a combustion system are mounted on the upper portion of the hearth; the combustion system is mounted in the middle of the hearth; the water cooling wall is mounted on the inner wall of the hearth; the smoke gas and air system is mounted on the lower portion of the hearth; the combustion system is distributed at the corner, defined by a water cooling wall system, ofthe hearth; and flames form corner tangential firing in the hearth.

Owner:HARBIN BOILER

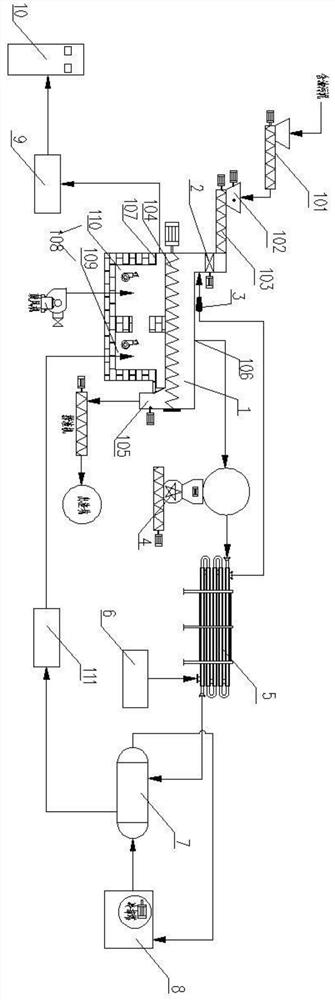

Mineral oil-containing waste comprehensive utilization system and method

PendingCN111646666AImprove heat transfer efficiencyGood effectSpecific water treatment objectivesSludge treatment by pyrolysisSludgeFlue gas

The invention discloses a mineral oil-containing waste comprehensive utilization system and method. The system comprises a feeding part and a main body reaction device, a crushing assembly and an airflow impact assembly are arranged between the main body reactor and the feeding part, and oily sludge enters the main body reaction device after being crushed by the crushing assembly and the airflow impact assembly from the feeding part; a flue gas dust collection device and an energy saver are arranged on the rear side of the main body reaction device; one end of the energy saver is connected tothe airflow impact assembly, one end of the flue gas dust collection device is connected to the main body reactor, the other end of the flue gas dust collection device is connected to the energy saver, an inert gas generation device and an oil-water recovery device are arranged on the rear side of the energy saver, a flue gas circulation device is arranged on the rear side of the oil-water recovery device, and the flue gas circulation device is in through connection with the main body reaction device; by means of the energy-saving device, while tail gas is condensed, heat is exchanged to inertgas, and materials are crushed and heated.

Owner:四川深蓝环保科技有限公司

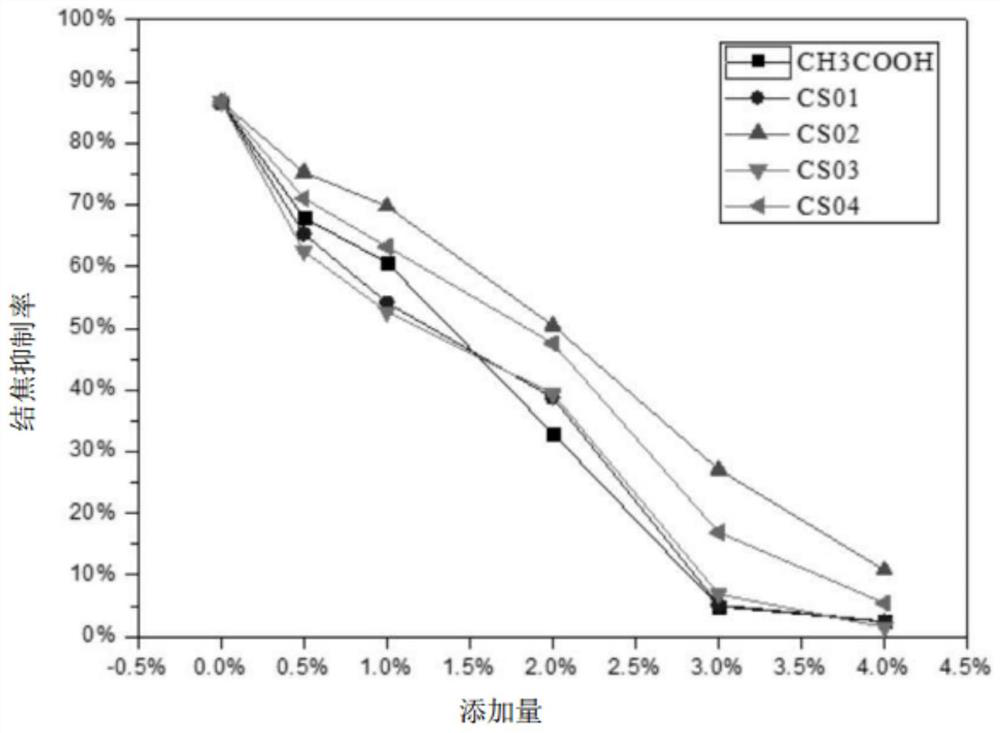

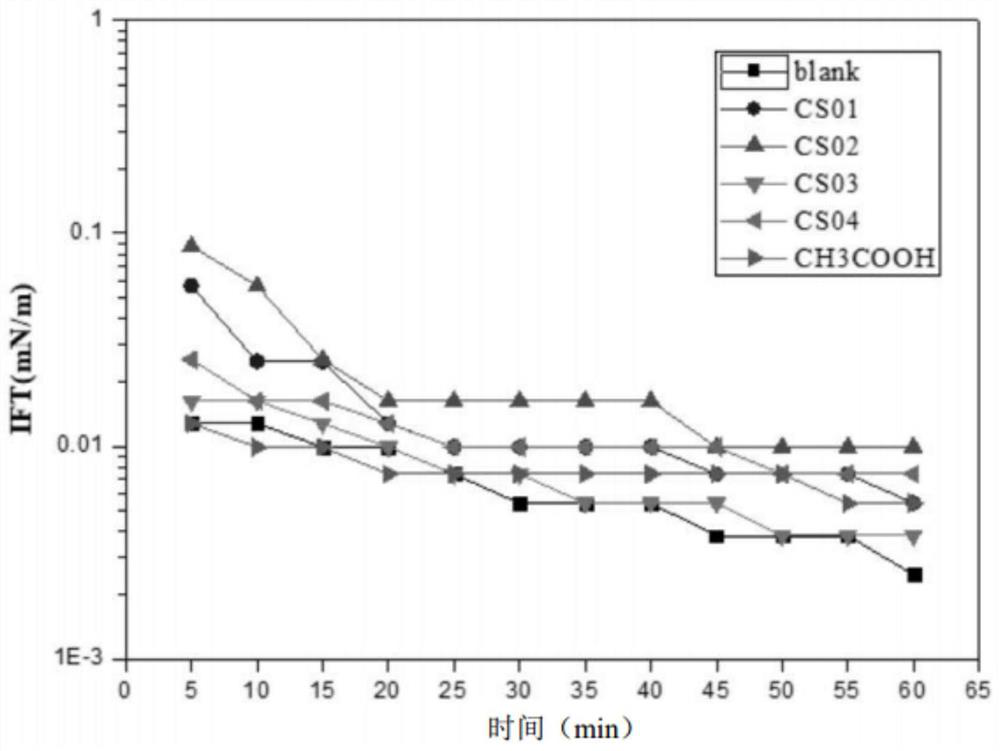

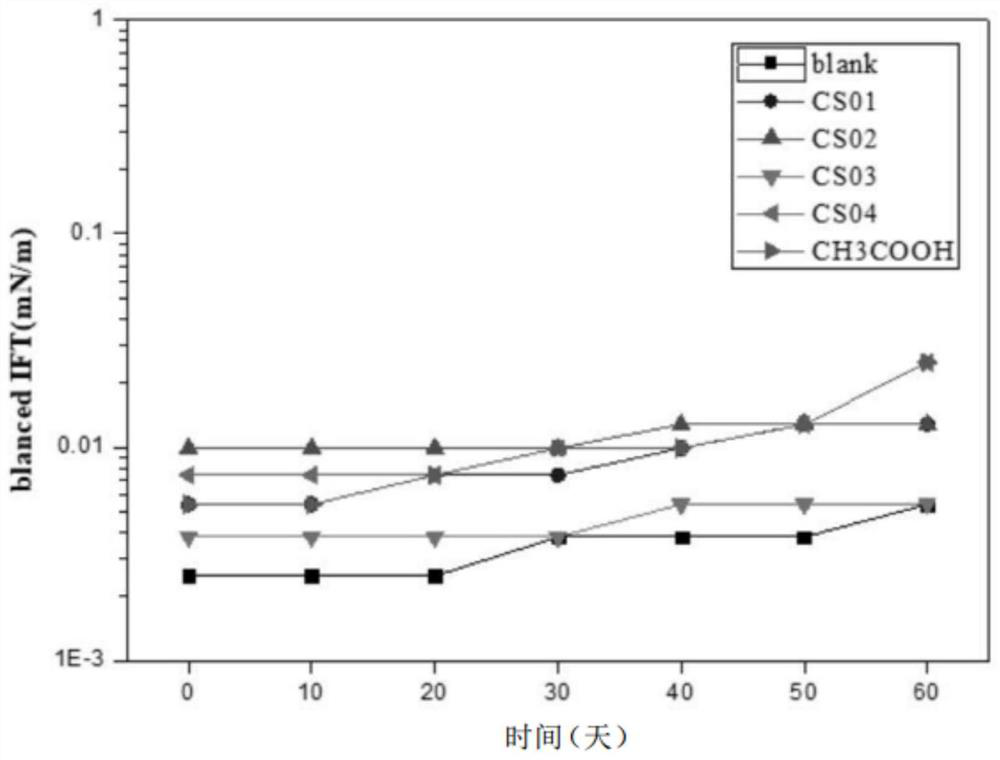

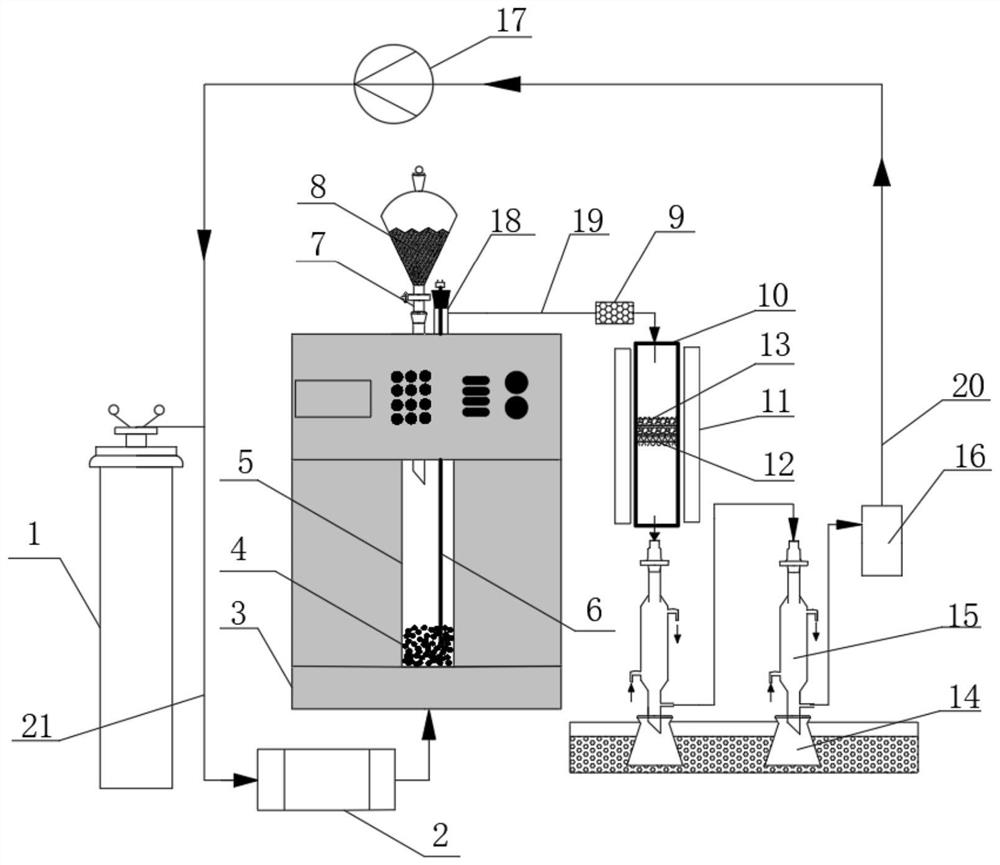

A kind of inhibitor and application thereof for inhibiting the coking of petroleum sulfonate sulfonation reaction

ActiveCN112250602BExtended continuous reaction cycleReduce the amount of cokingSulfonic acids salts preparationSulfonic acid preparationSulfolaneSulfonate

The invention provides an inhibitor for inhibiting the coking of petroleum sulfonate sulfonation reaction and application thereof. Wherein, the coking inhibitor includes organic oxygen-containing compounds with a molecular weight below 150, specifically, the organic oxygen-containing compounds include one or more of maleic anhydride, methyl isobutyl ketone, sulfolane and dioxane . Compared with the existing sulfonation process, adding the coking inhibitor of the present invention can reduce the amount of coking by more than 80%, which can effectively alleviate the decrease in product interface activity caused by excessive coking amount; meanwhile, it can prolong the sulfonation process The continuous reaction cycle reduces the energy consumption and production efficiency reduction caused by shutdown maintenance.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com