Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Reduce heat burn rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

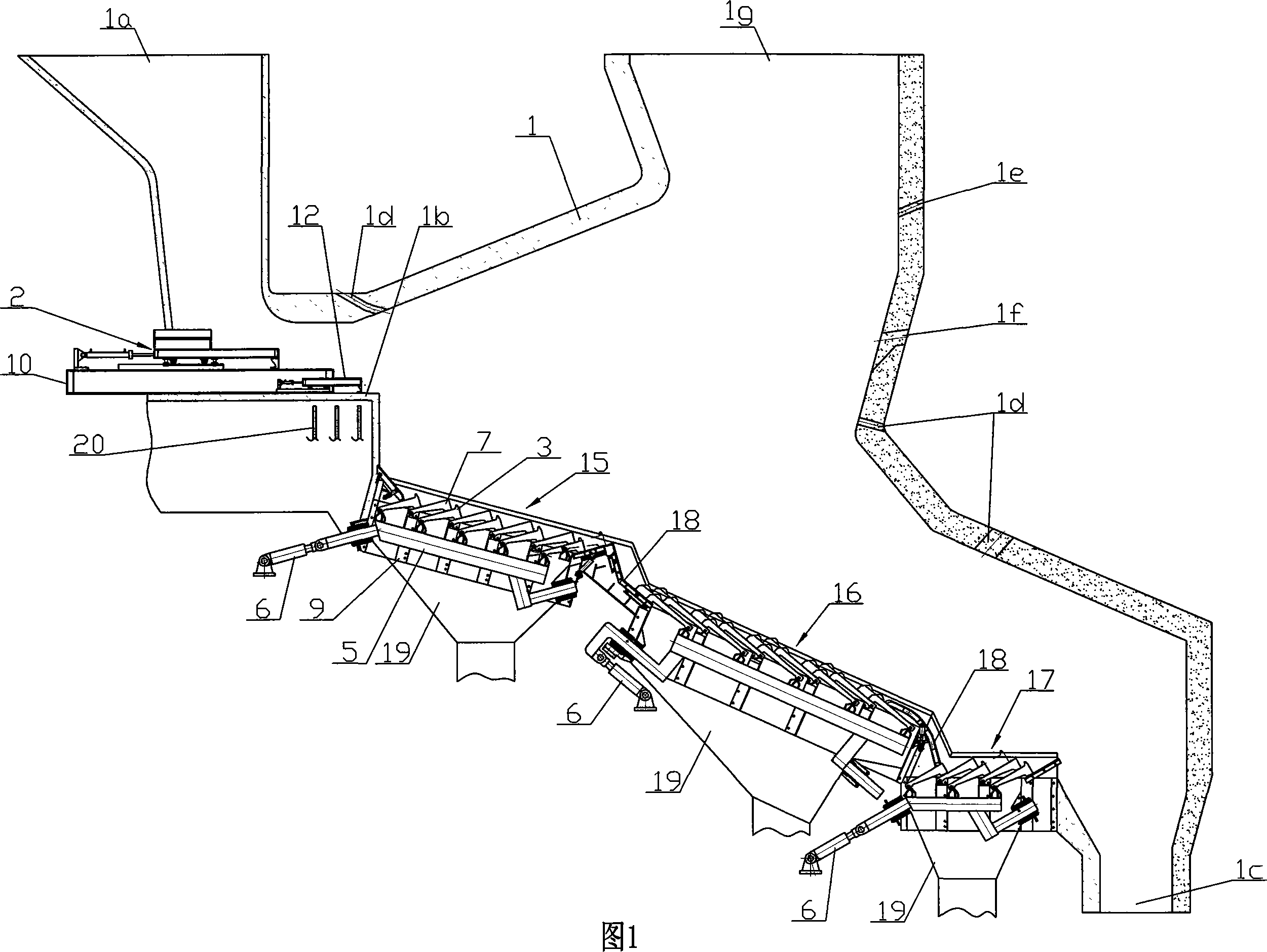

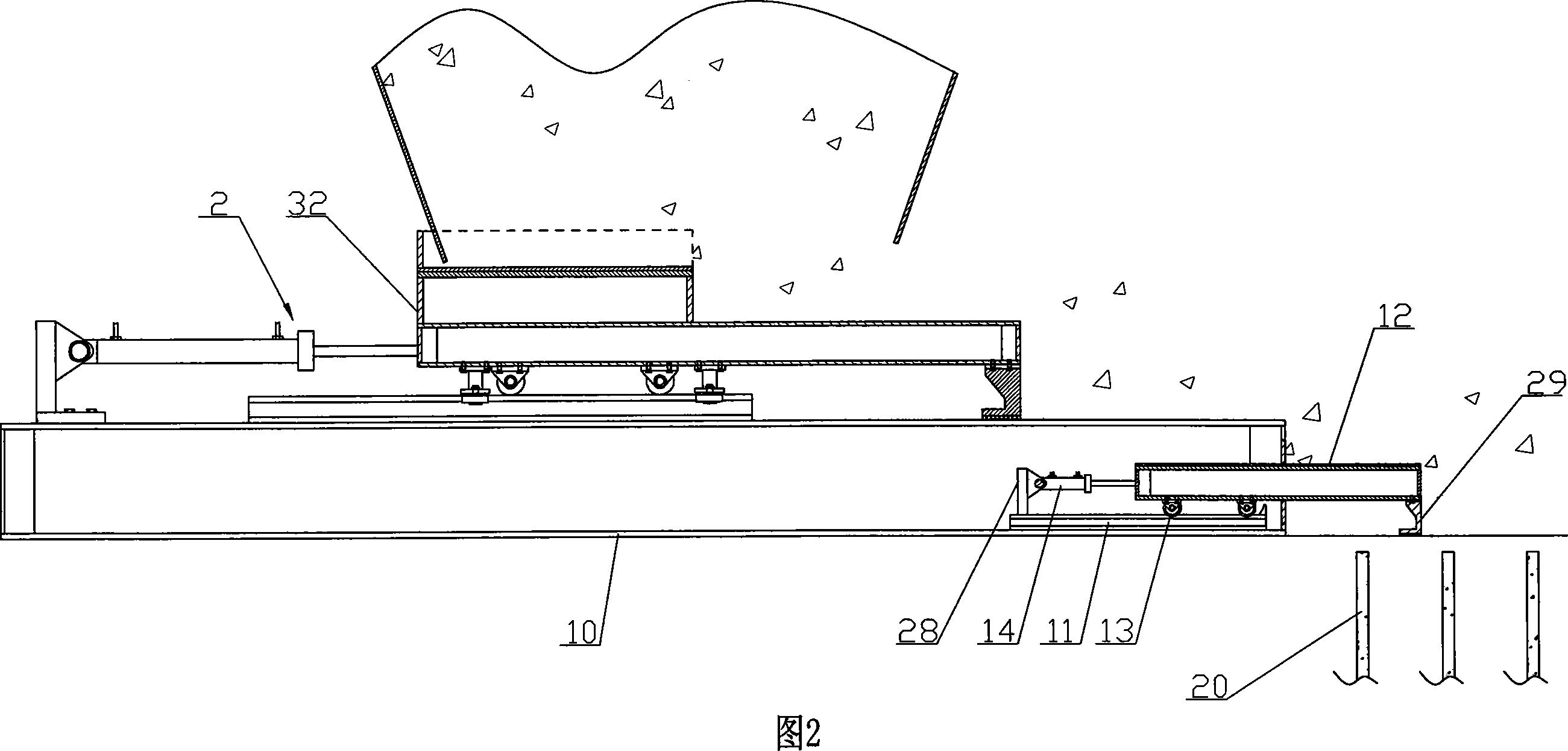

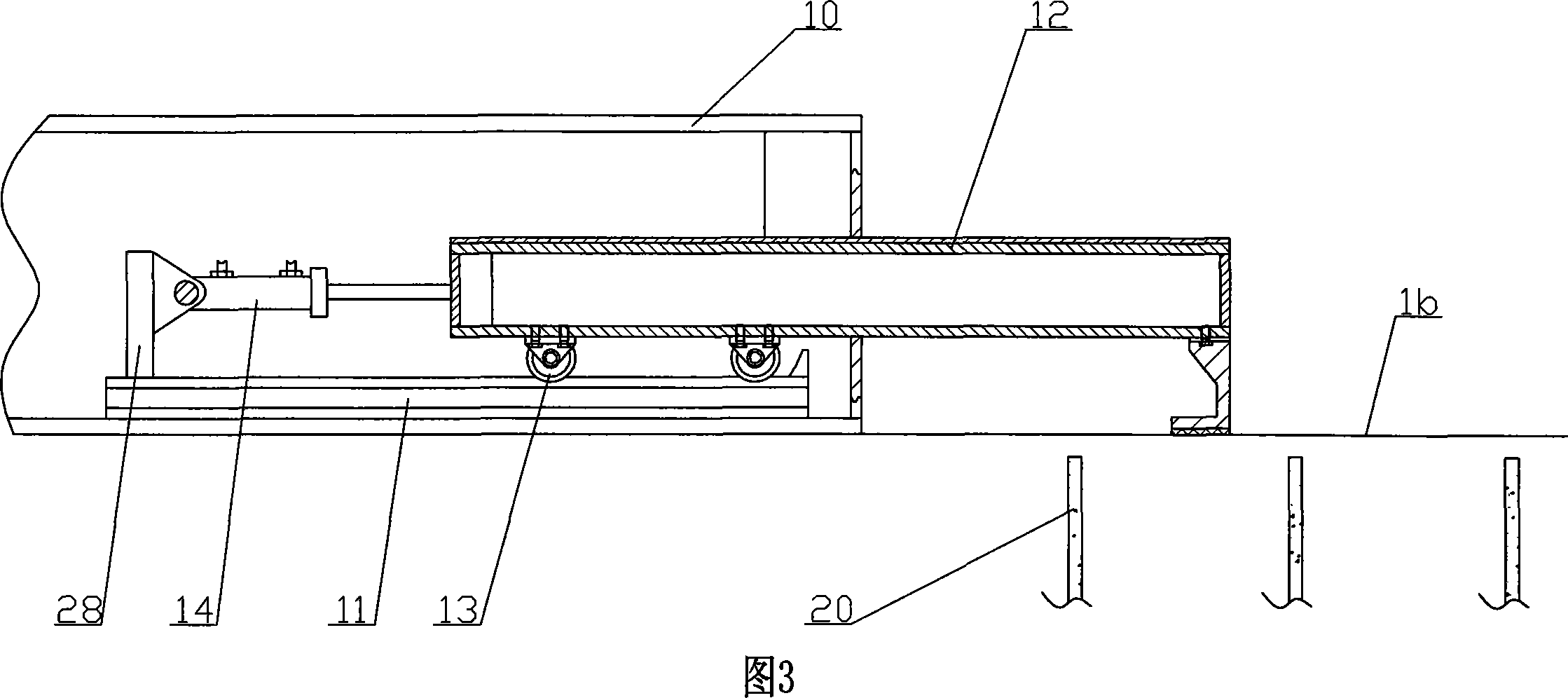

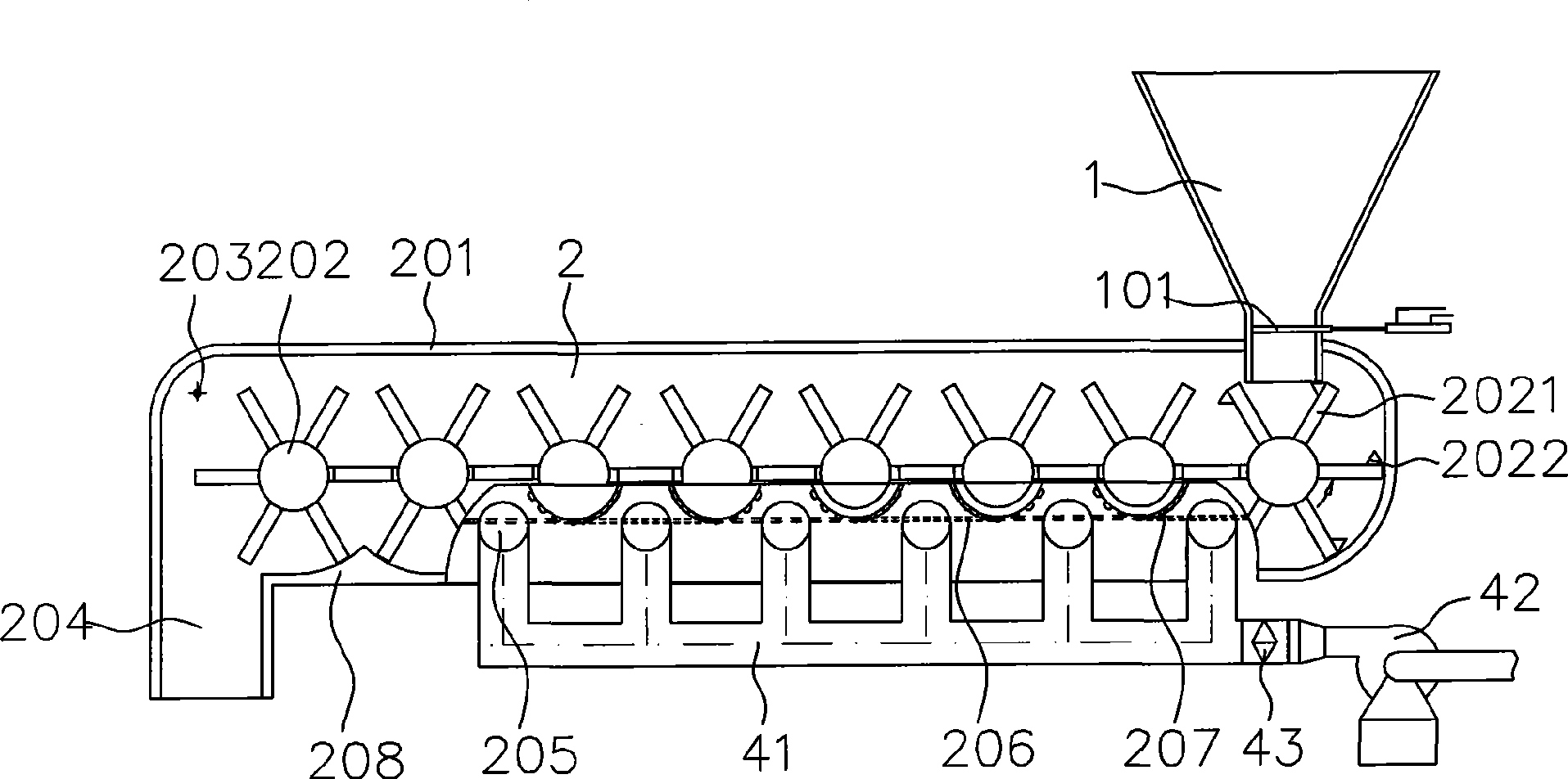

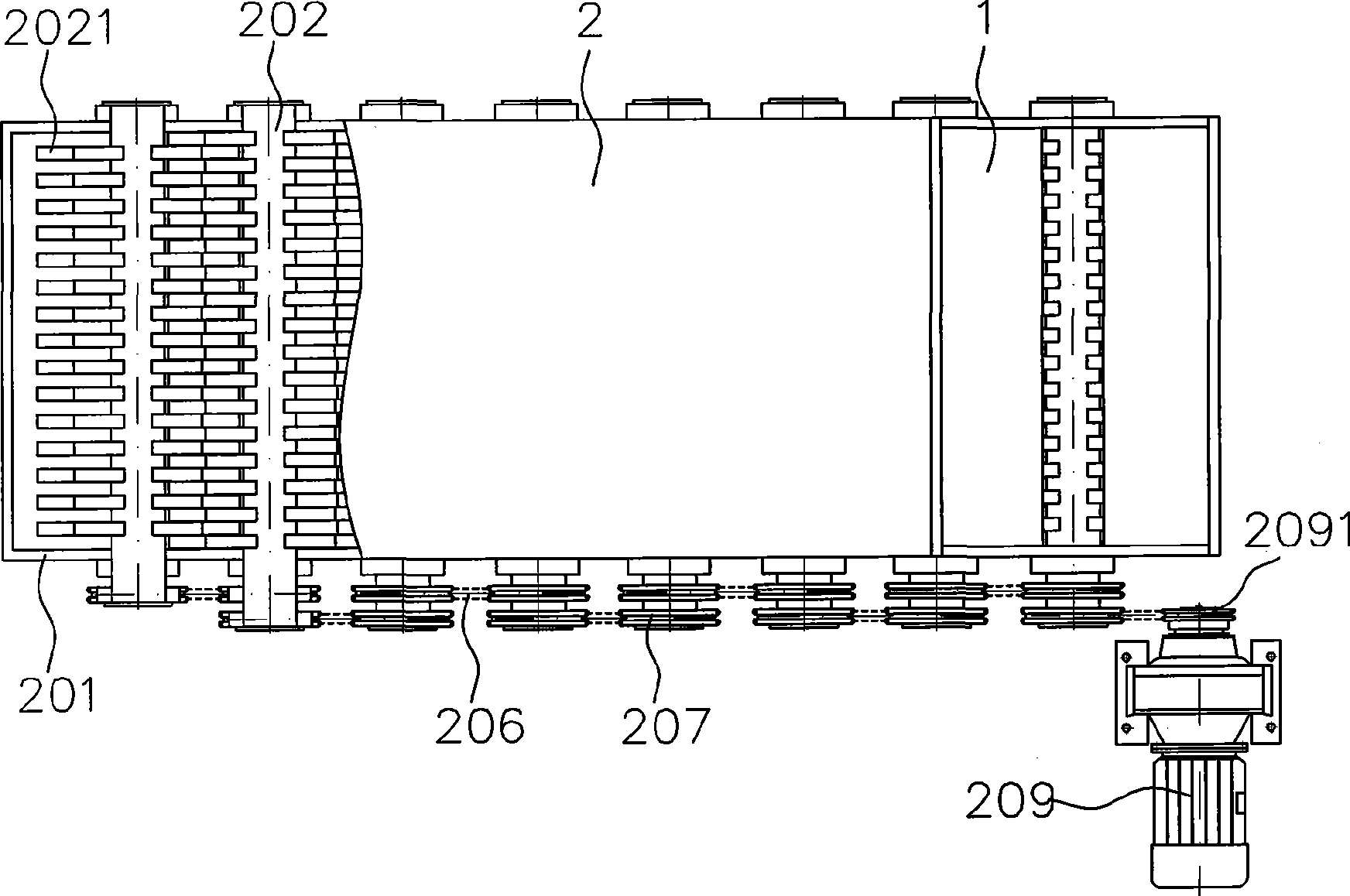

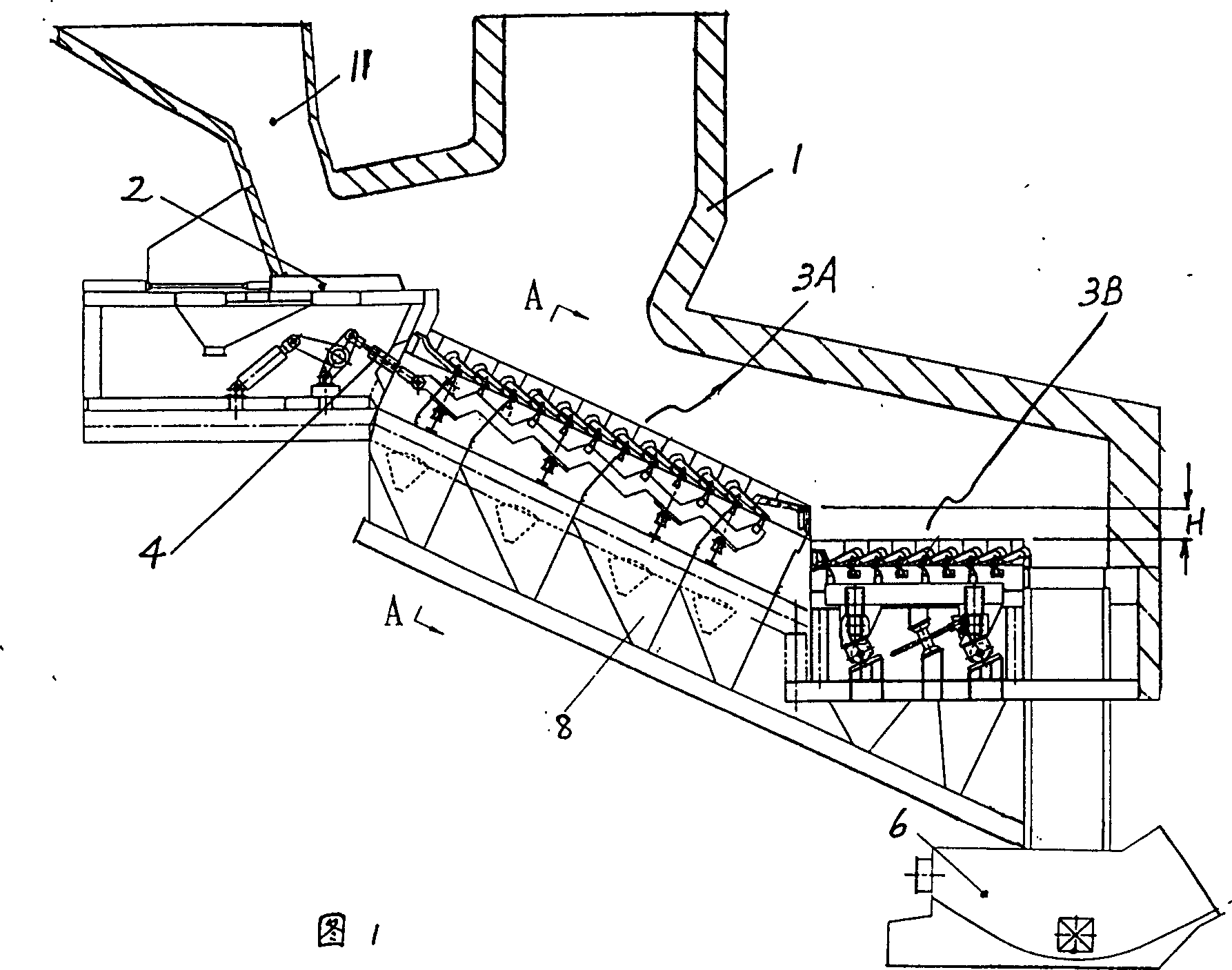

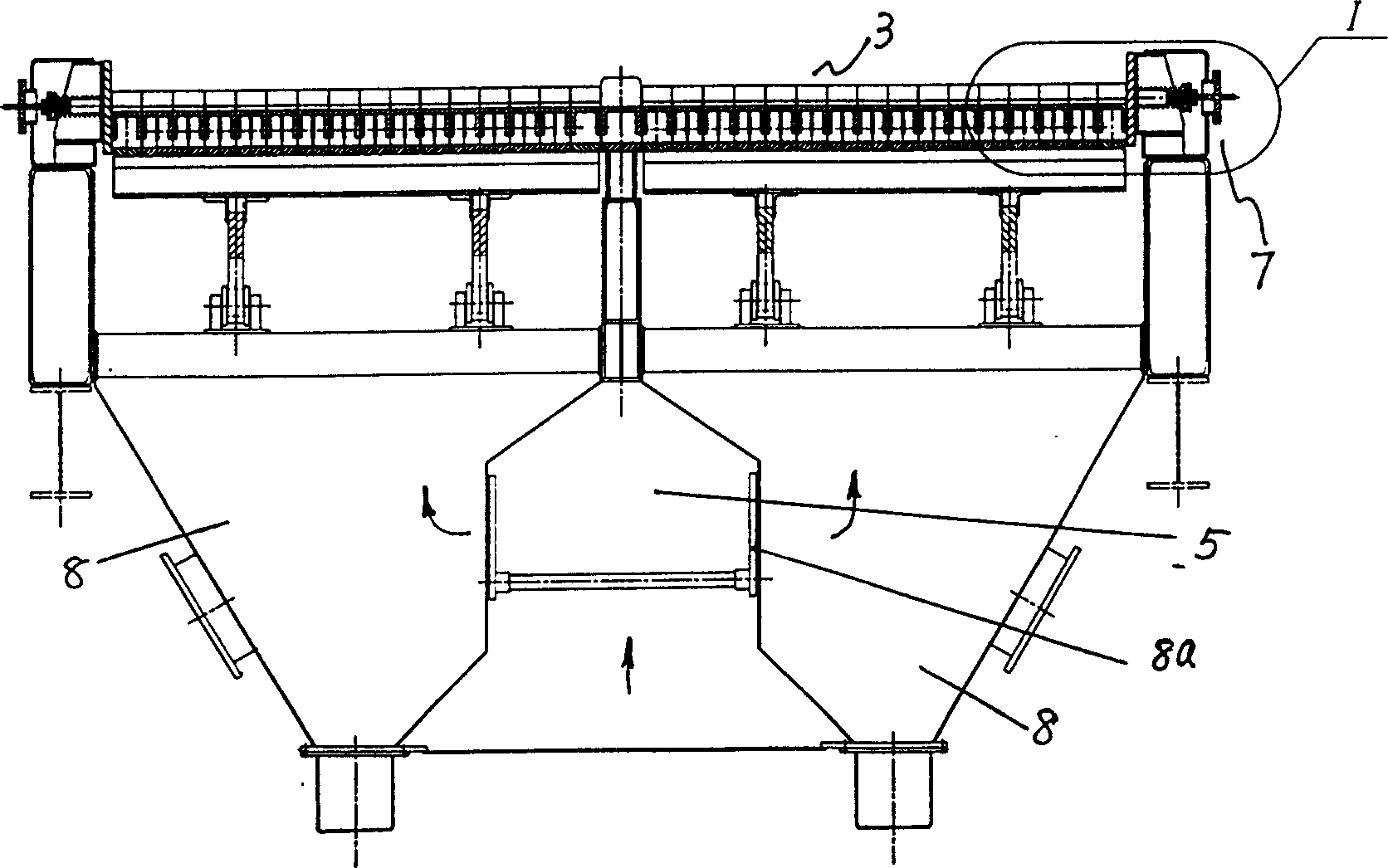

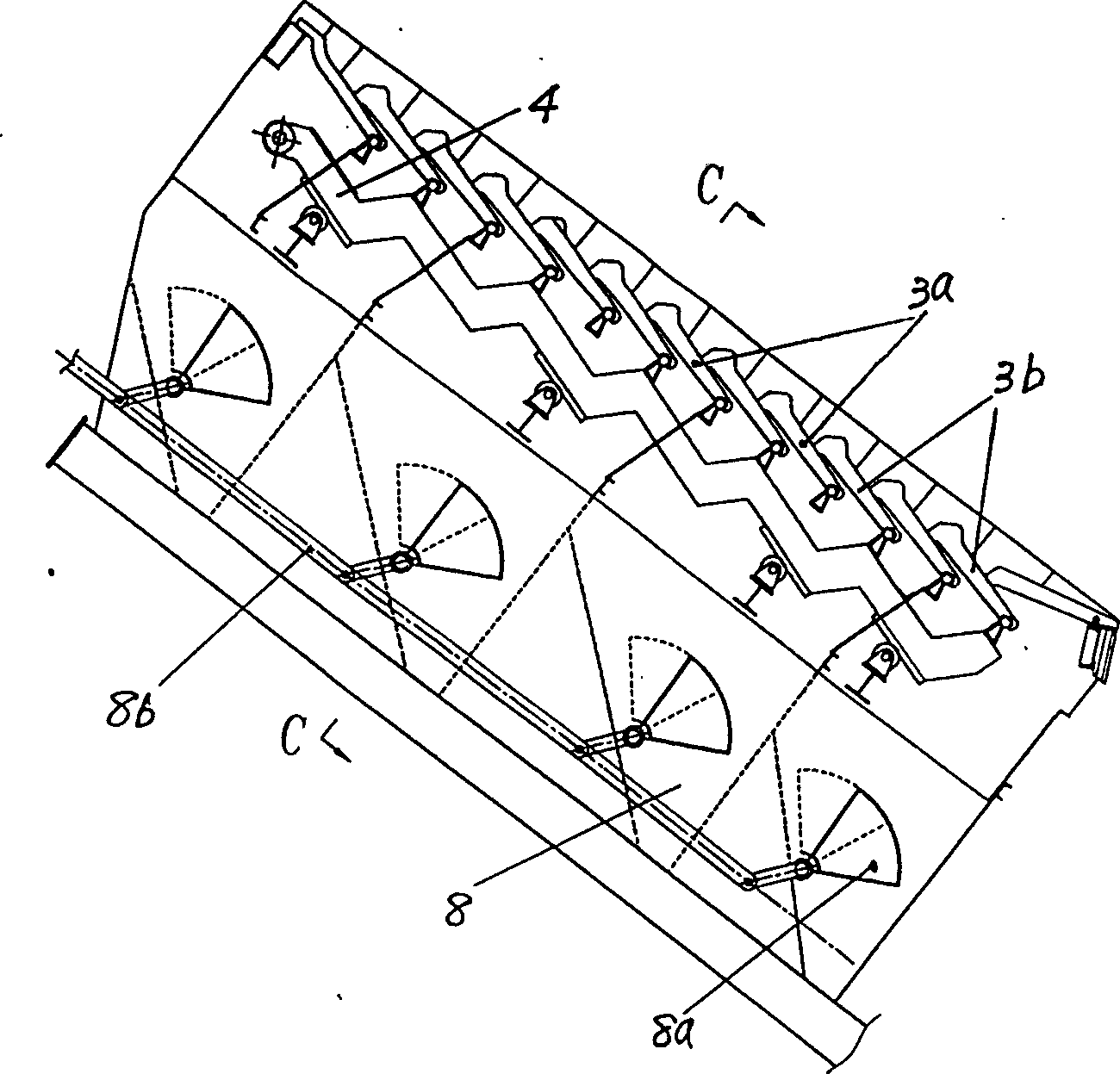

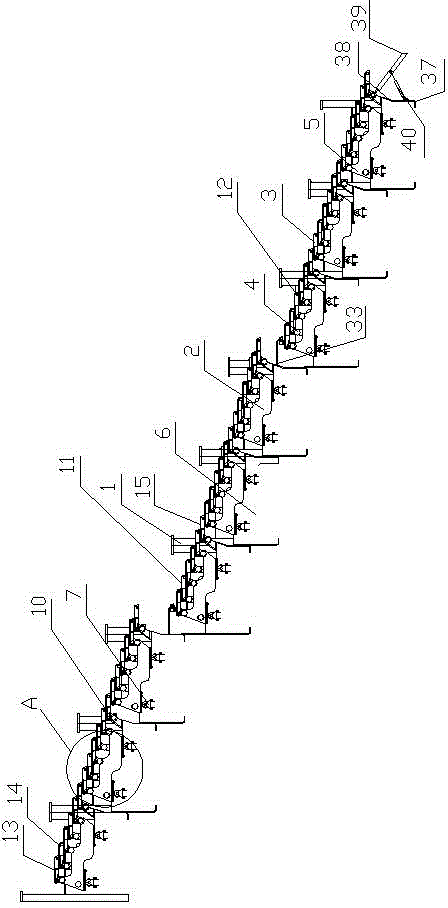

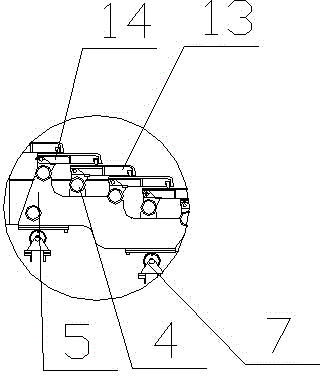

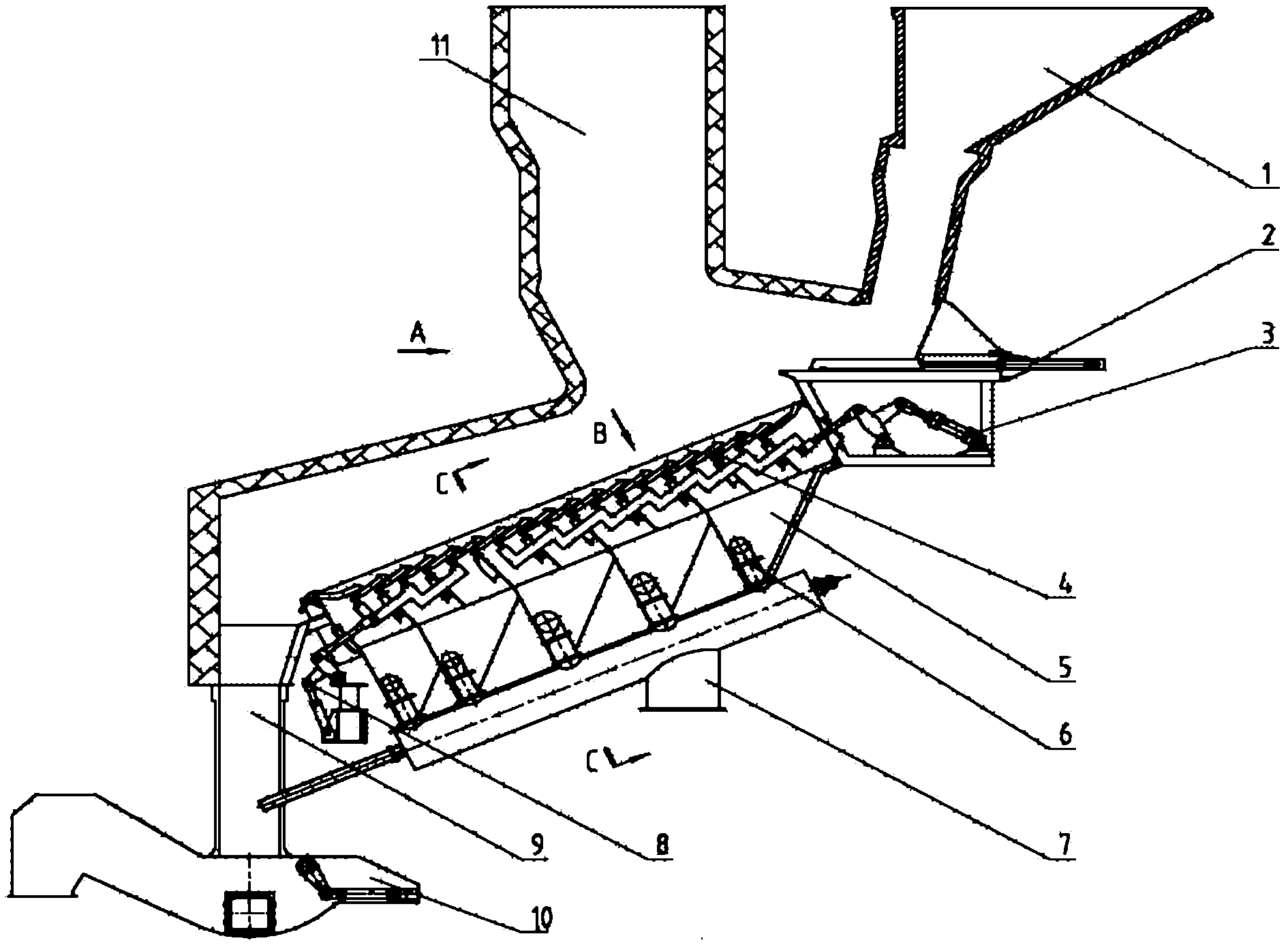

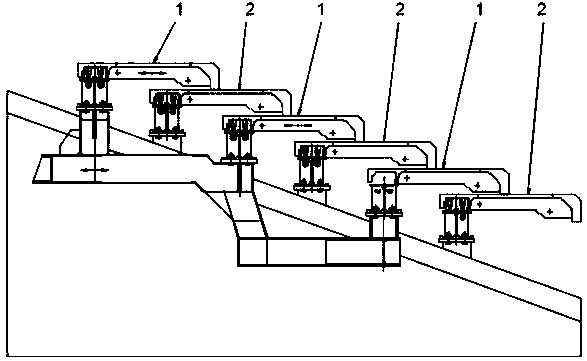

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

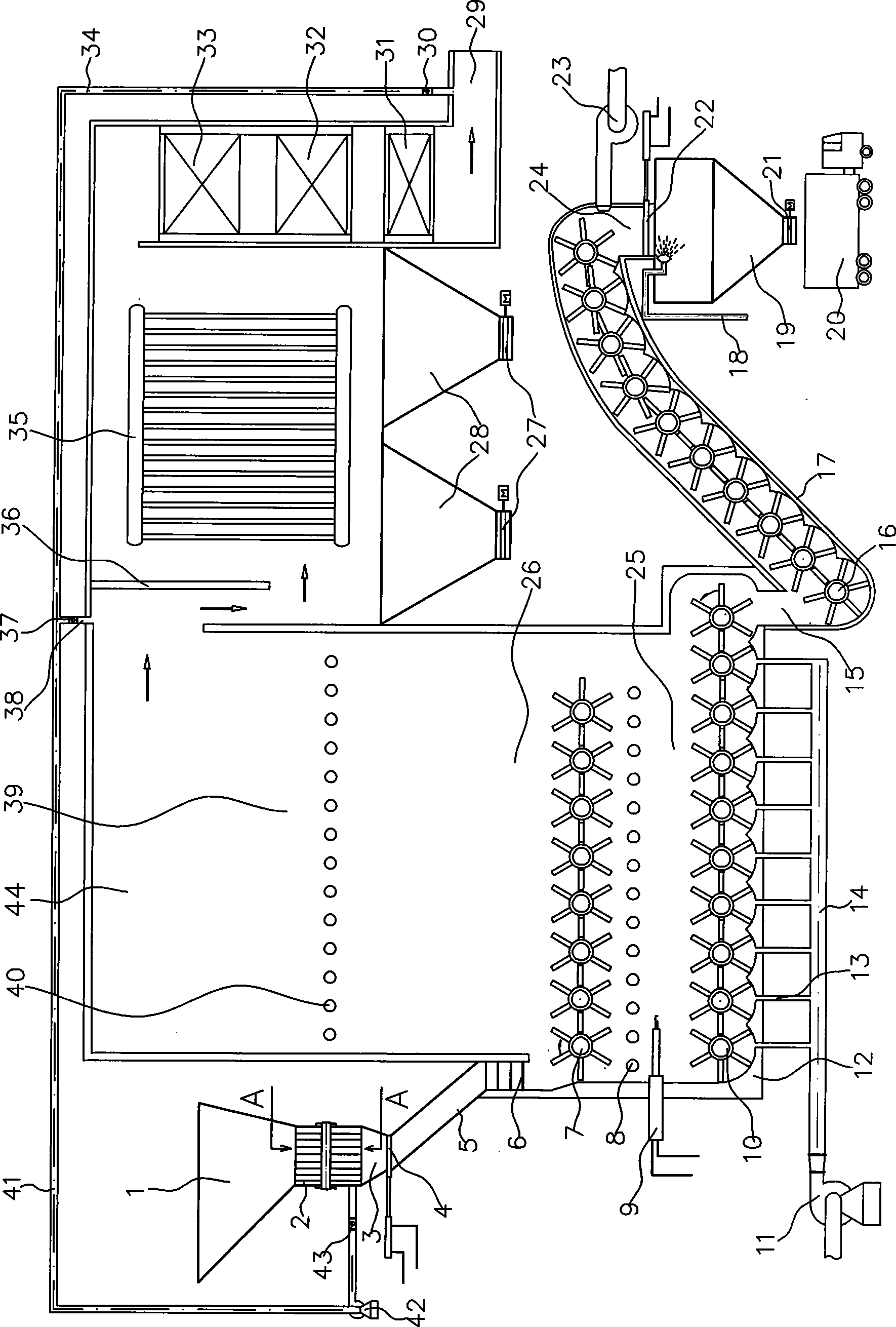

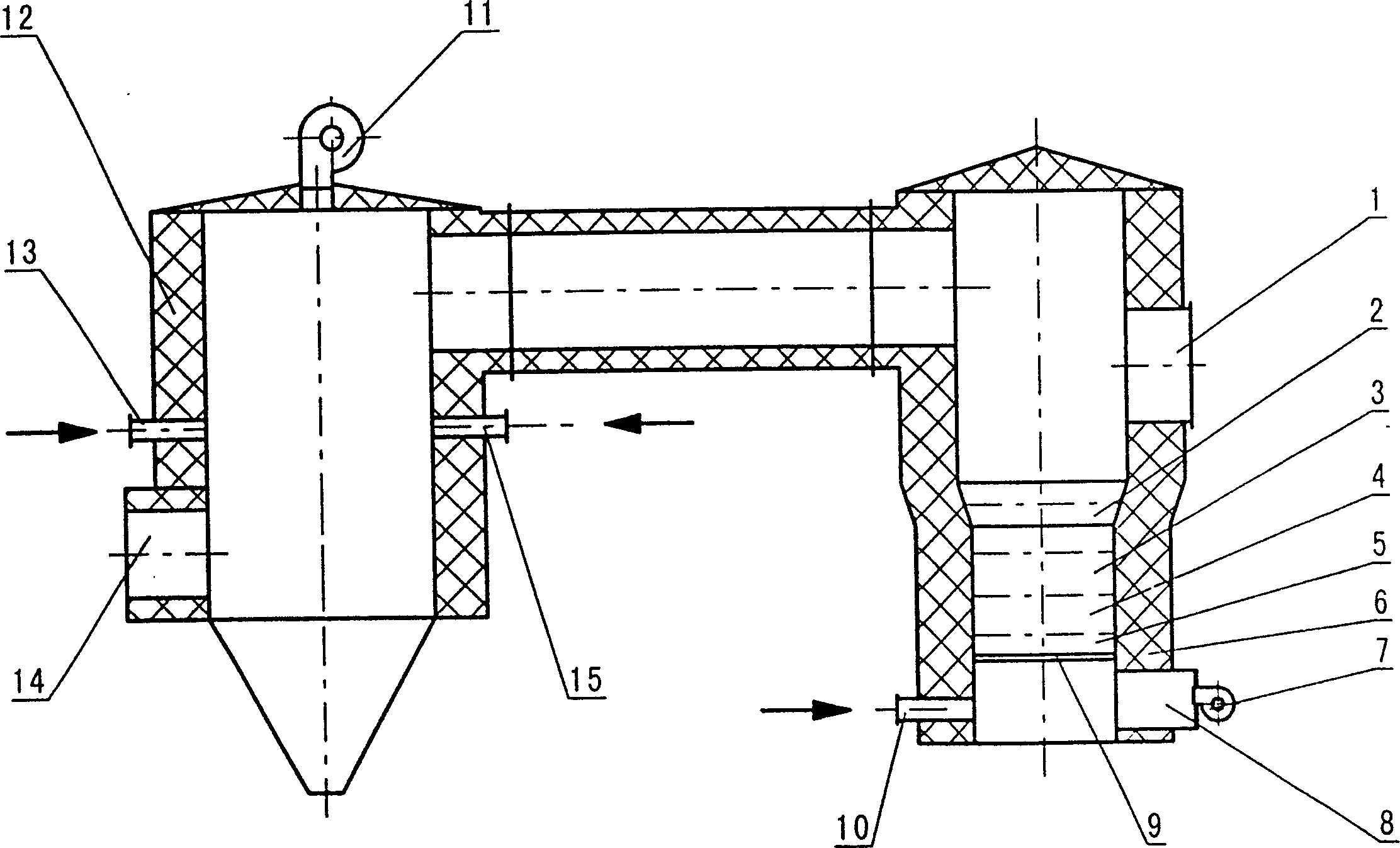

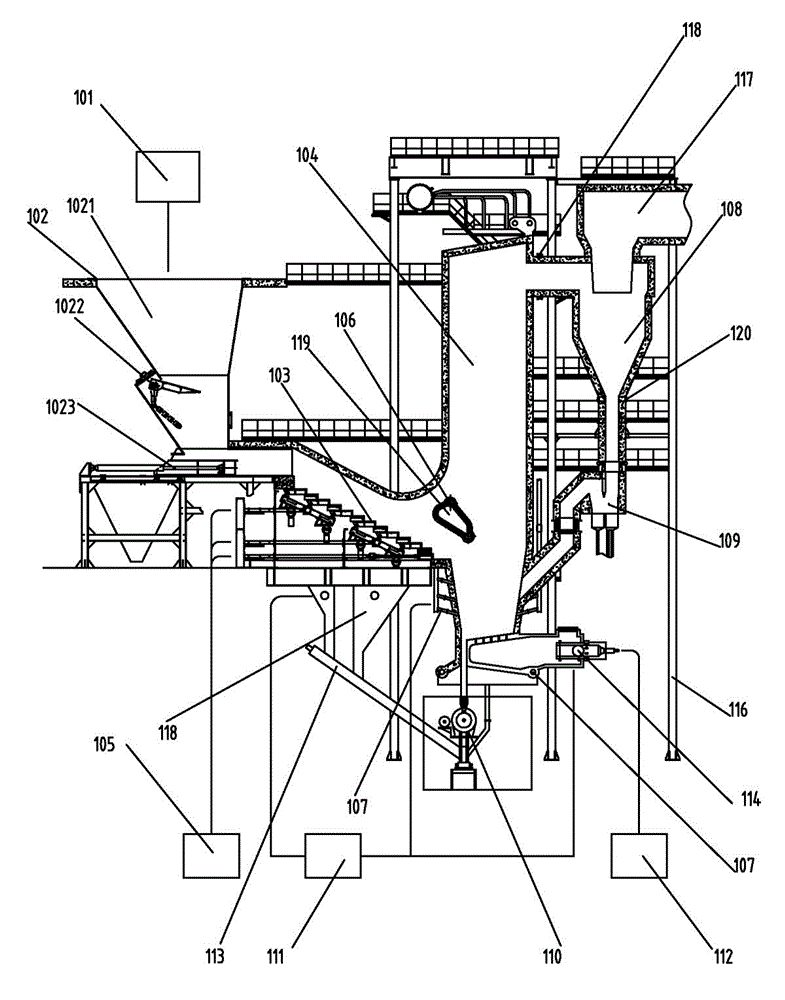

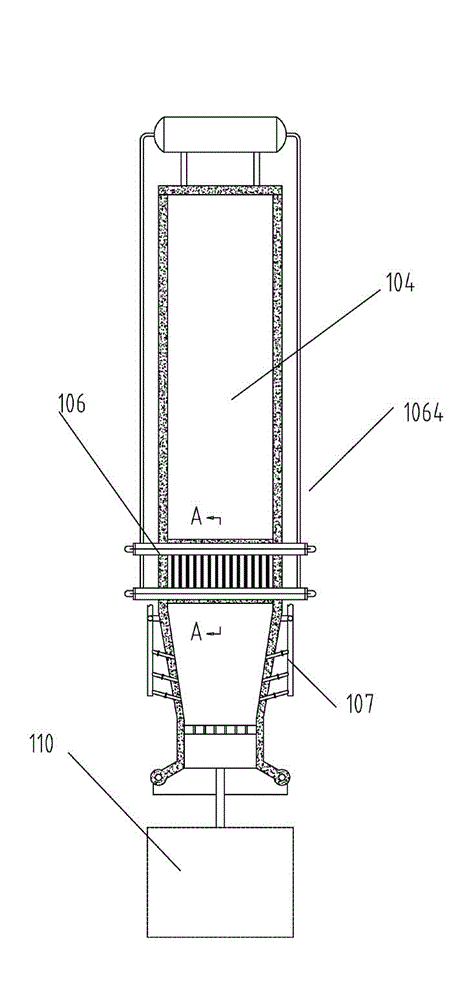

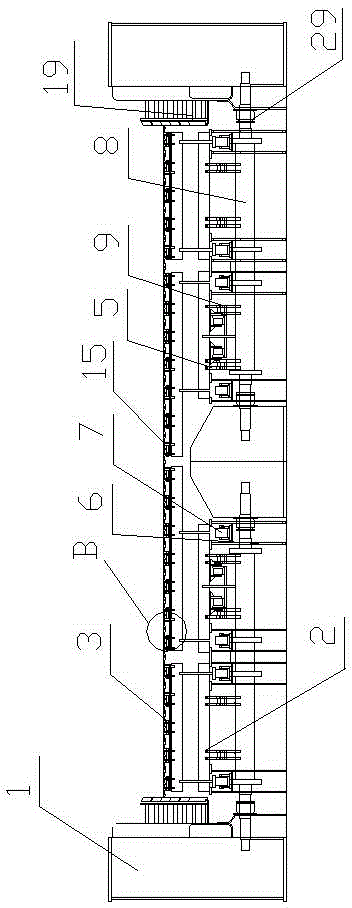

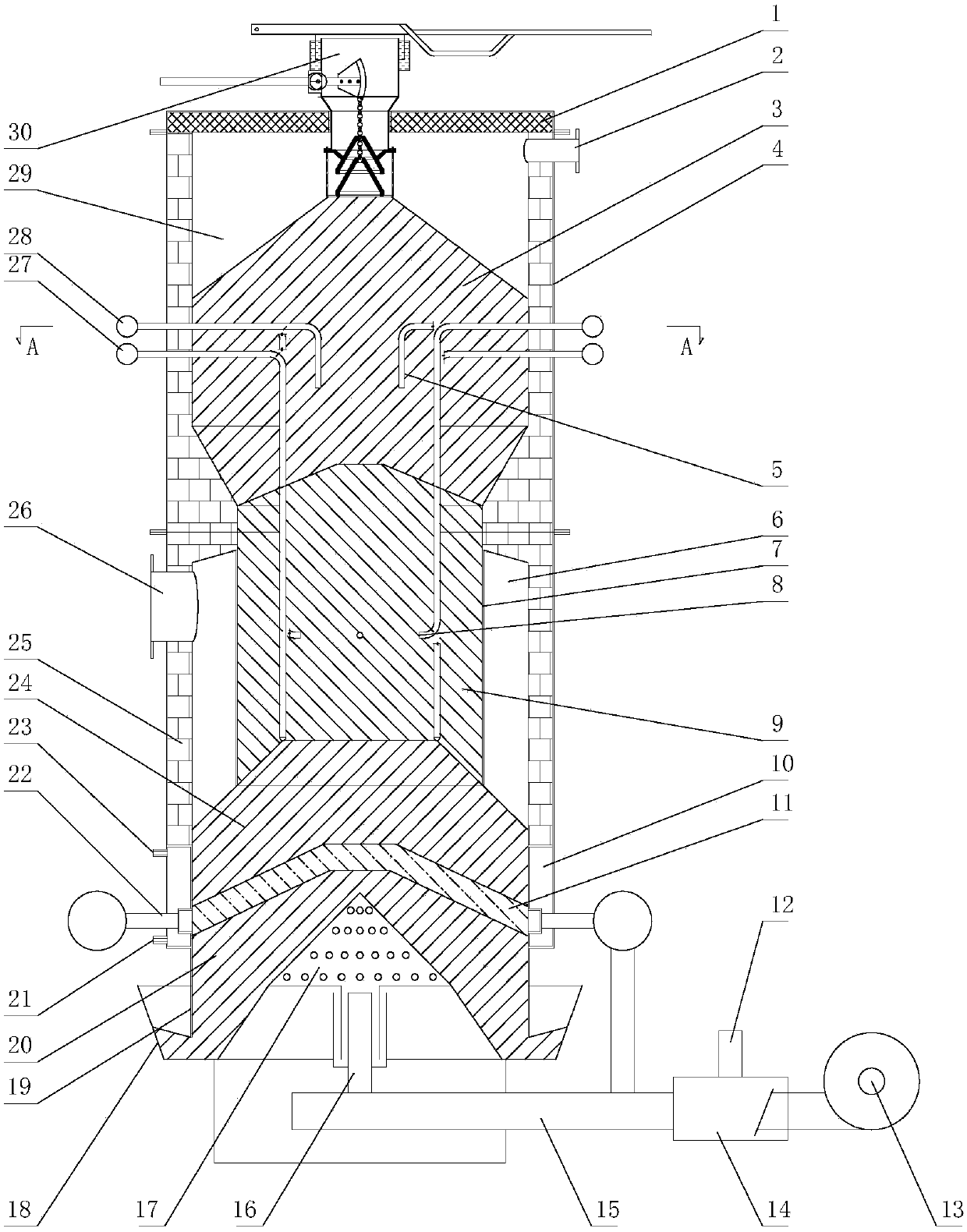

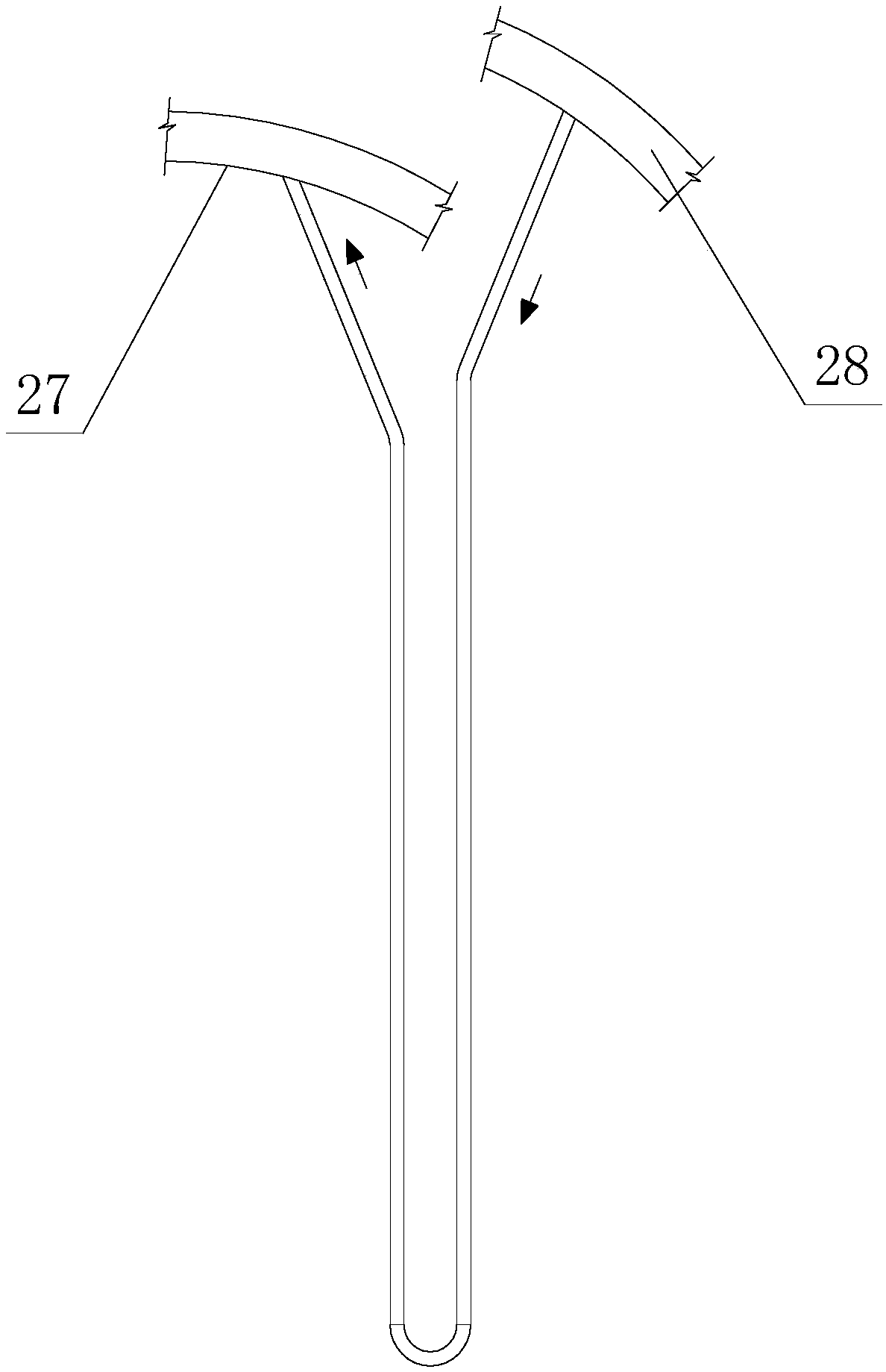

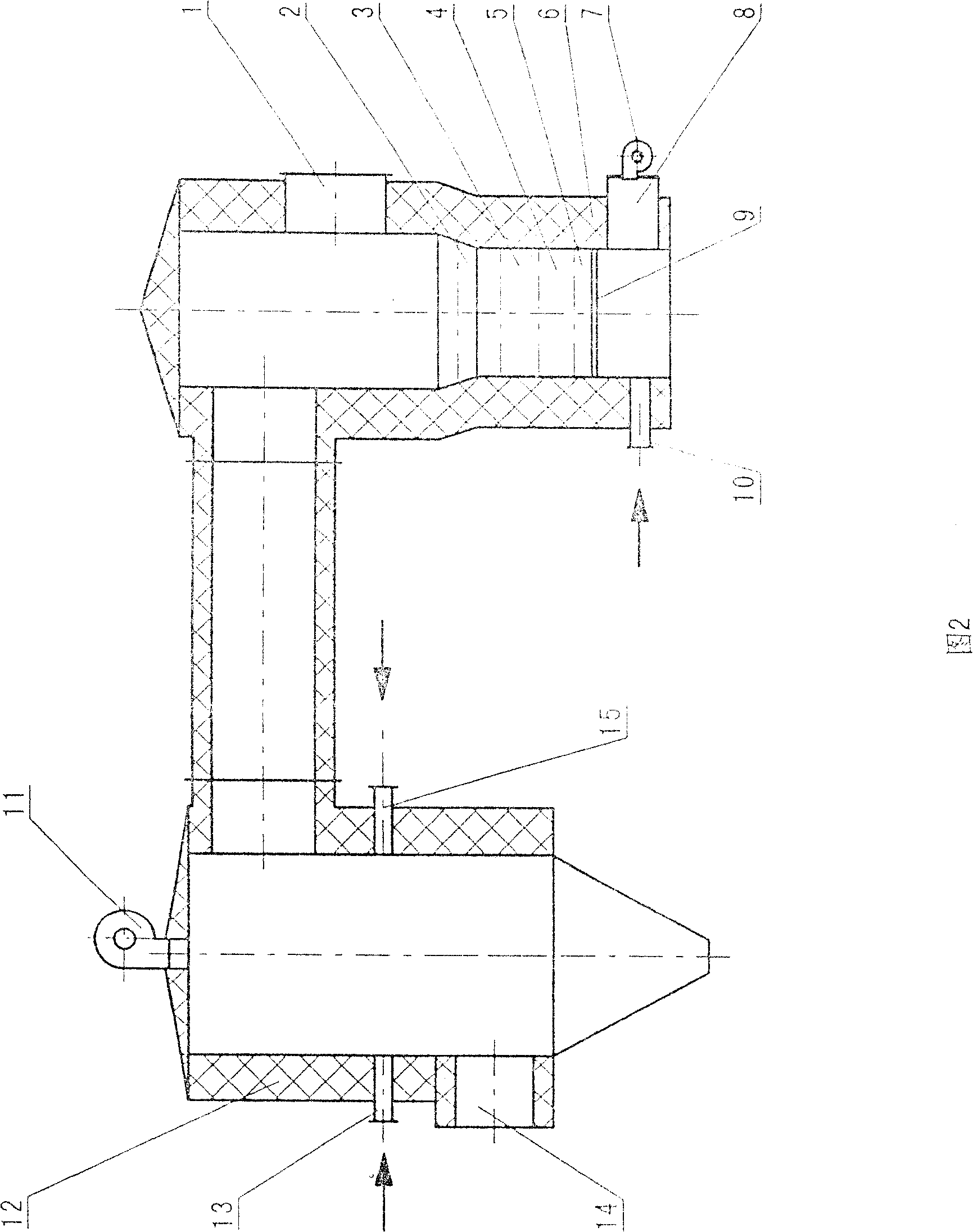

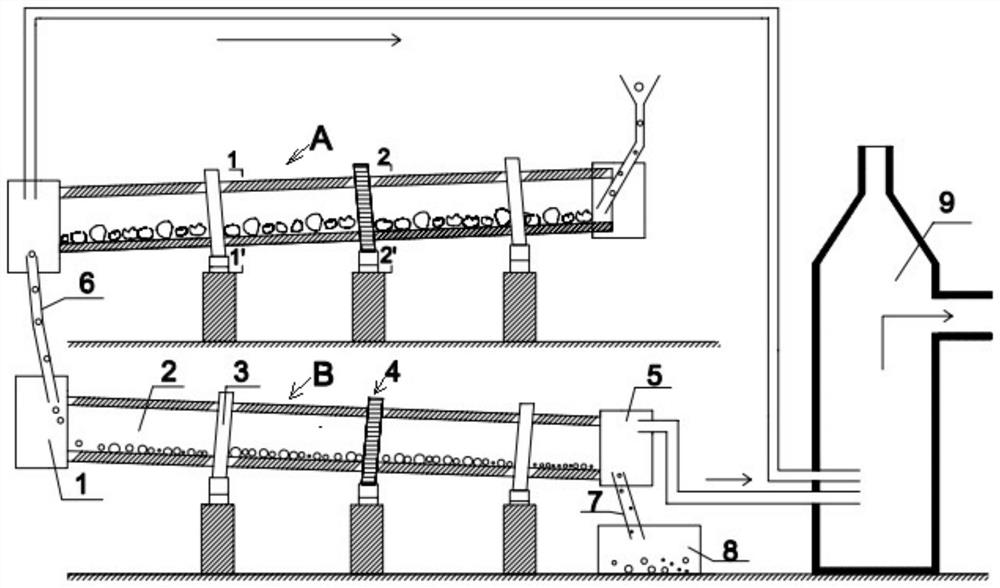

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

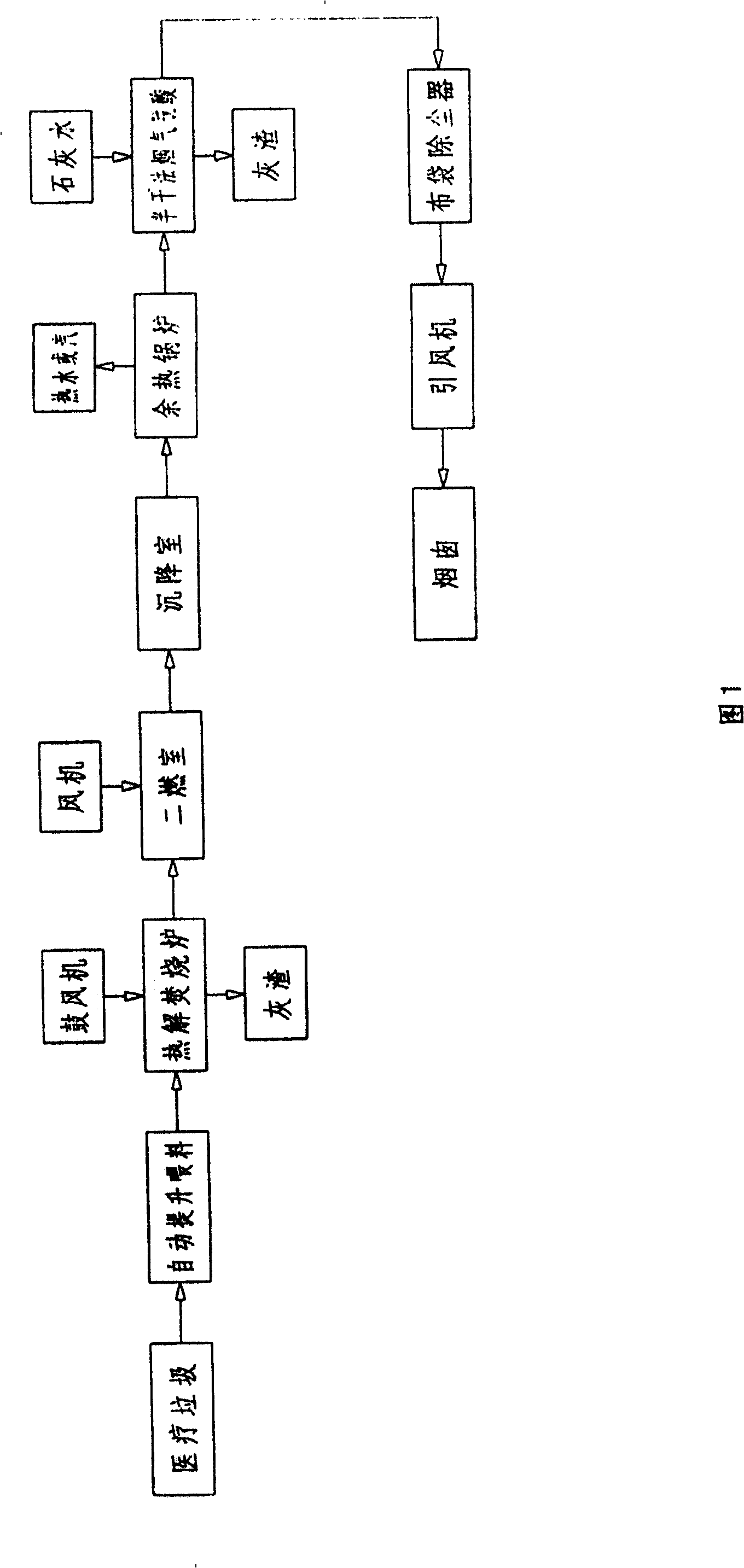

Process for burning medical refuse

ActiveCN1667315AReduce investment and operating costsBurn completelyIncinerator apparatusProduct gasEngineering

The invention relates to a medicine garbage burning technology. The medicine garbage is transferred to the material casting entrance by sealed special transport vehicle and casting equally, quantificatioally into the burning furnace by automatic lifting material feeding device. And the process of dehydration and drying, pyrolysis and gasification, burning, second burning, smoke sedimentation, waste heat recovery and smoke dealing with would be taken. Thus, the content reduce quantity would reach 99%. The invention can effectively avoid the produce of poisonous substance.

Owner:ZHENGCHANG GROUP JIANGSU

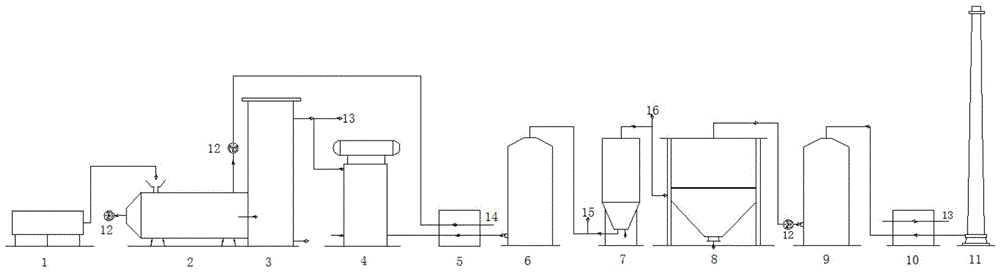

Gas, solid and liquid integrated combustion system

The invention relates to a gas, solid and liquid integrated combustion system, and belongs to the technical field of the environment. The system is composed of a waste gas collection system, a granulation system, a feeding system, a rotating furnace, a combustion furnace, a waste heat boiler, a heat exchanger, a rapid quenching tower, a smoke dry type washing system, a cloth bag dust removal device, a spray tower, a reheater and a chimney. Coal, solid waste and liquid waste are evenly mixed according to the mass ratio (1-12):(2-30):(1-16) in the granulation system for granulation; after collected waste gas is preheated, part of the waste gas enters the rotating furnace, and the other part of the waste gas enters the combustion furnace to be processed through high temperature combustion; high temperature tail gas of the combustion furnace enters the rapid quenching tower, the dry type washing system, the cloth bag dust removal device and the spray tower after heat energy recovery, and is sent to the chimney by a draught fan after the tail gas is cooled and fly ash, dioxin and acid gas are removed, so that emission reaching the standard is completed. Liquid waste produced in the running process of the system is recycled in the granulation system, solid waste such as activated carbon is fed into the rotating furnace to be combusted, and therefore harmless treatment is achieved while running cost of the system is reduced.

Owner:JIANGSU ANQIER WASTE GAS PURIFICATION

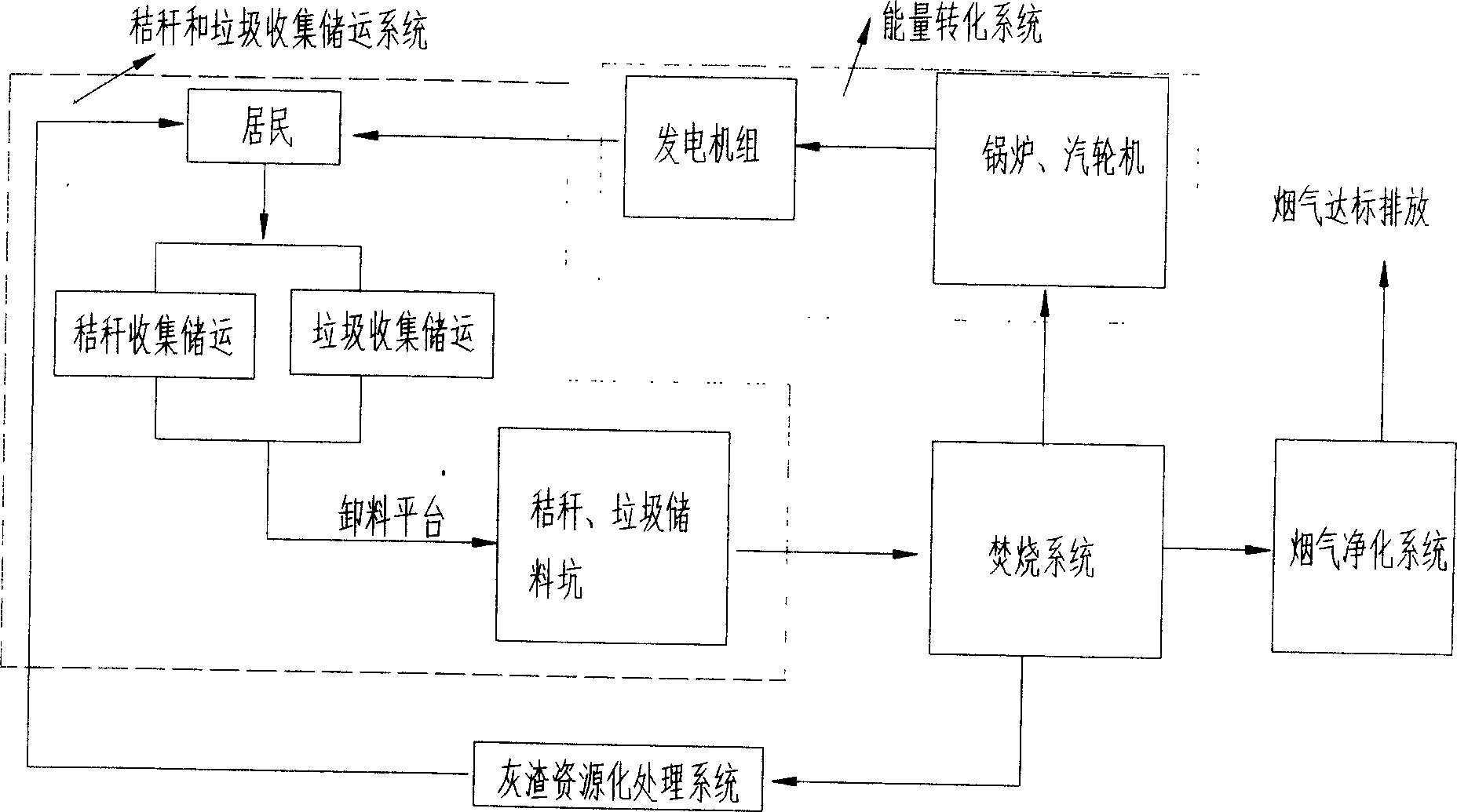

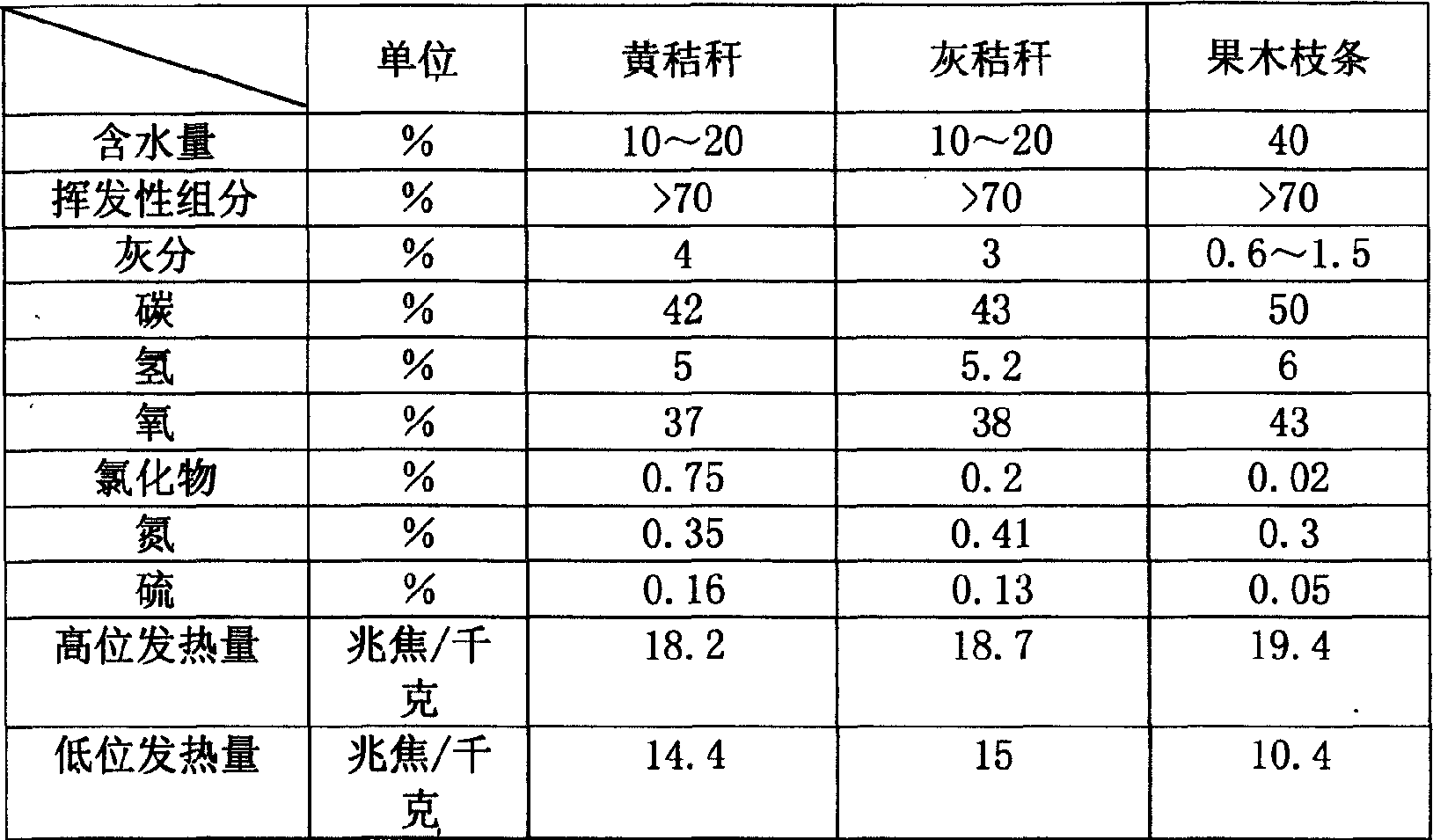

Method for electric generating utilizing stalks mixed burned with city life refuses

The invention relates a method of generating by using mixed combustion of stalks and municipal house refuse. The heat energy produced by the mixed combustion of the stalks and the municipal house refuse in the refuse burner is coverted into the generating energy by a boiler, a turbine and a generator, so as to supply the power for cities. The proportion of the stalks and the house refuse in their mixed combustion must be adjusted continually according to the differences of refuse water ratio and dust composition. When the combustion temperature in the burner is in the range of 870-1200 deg. C, the combustion can be fully burned and the combustion product can be discharged up to the standard.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION

Domestic refuse incinerator

InactiveCN1162646CImprove mashing effectChange the ventilation sectionTravelling grateIncinerator apparatusAir volumeLitter

The domestic refuse incinerator is characterized by that two-stage reciprocating grate, it is suitable for incinerating low-calority high water content and non-sorted domestic refuse, it comprises furnace body with bunker, feeding machine, fire grate, air chamber positioned under the grate and ash-discharge hole, in which said fire grate comprises fixed grate segments fixed on the furnace body and movable grate segments connected on the reciprocating bar. Said fire grate can be divided into two portions of front-stage grate and rear-stage grate, between them there is a position head with a certain height, said fire grate can make refuse automatically be turned, stirred and crushed, and its air intake can be regulated conveniently, and the refuse can be fully incinerated.

Owner:屠柏锐 +2

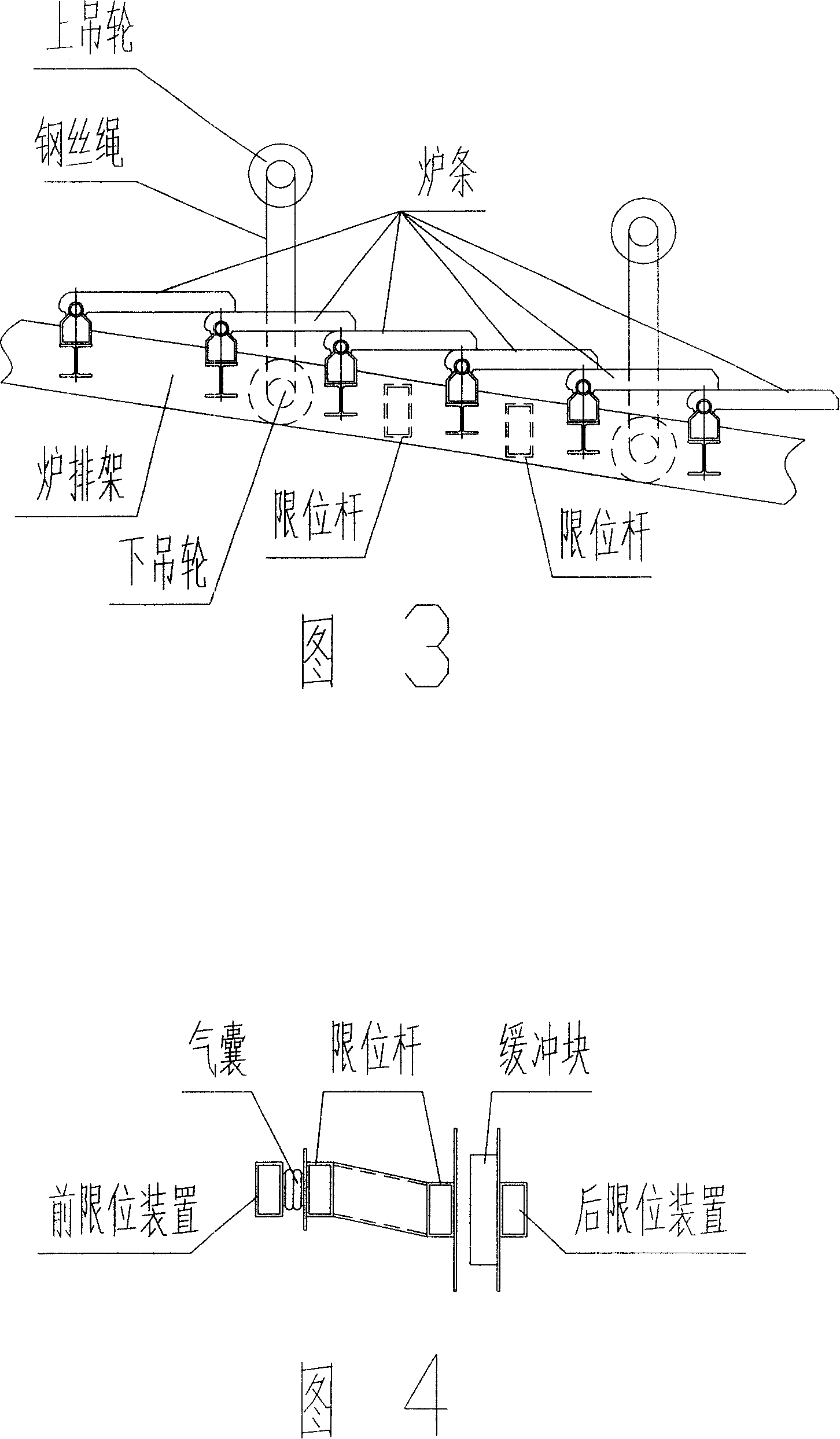

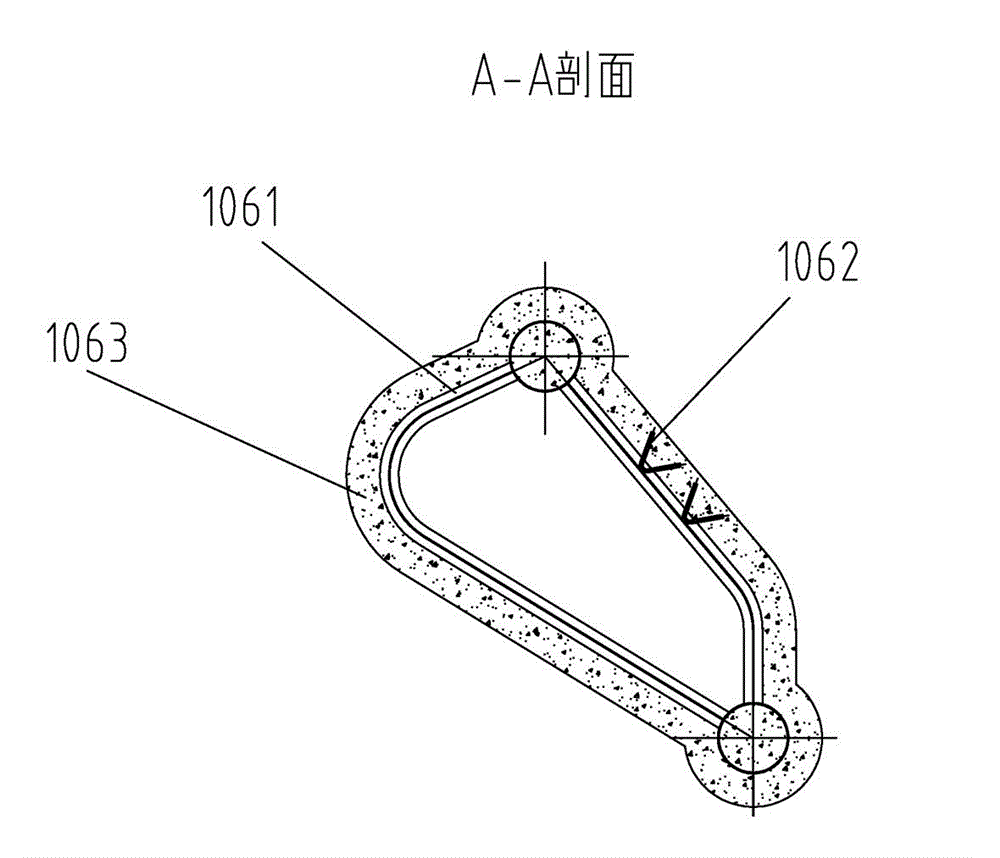

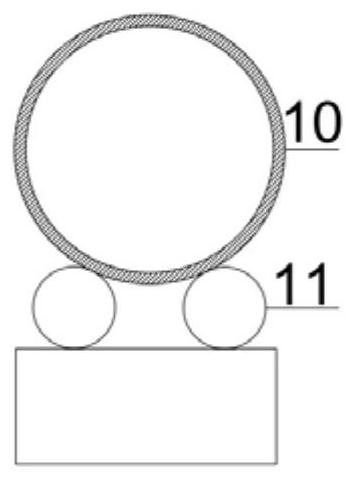

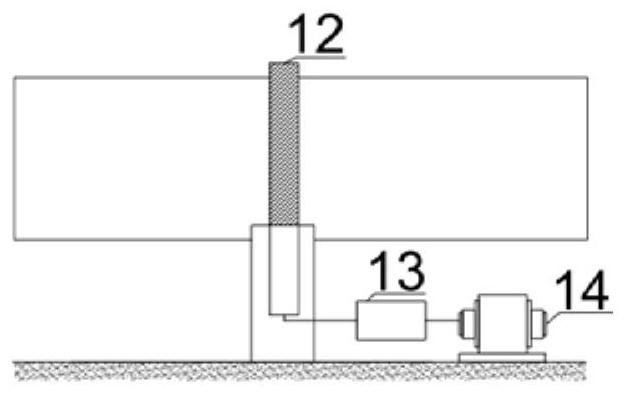

Vibrating high burn-out grate

InactiveCN101149152AReduce gapImprove combustion efficiencyRevolving grateTravelling grateCombustion chamberSlag

This invention is a vibrating high burnout grate. The fire bar is fixed at the grate surface. The grate is suspended on the furnace wall through steel wire and can move a little backwards. The air chamber in vibration device provides driving force for grate to move. The anterior end of grate is material feeding opening. The posterior end is slag-off opening. The superior end is combustion chamber. The inferior end is air chamber. This invention has high combustion efficiency and long life span.

Owner:刘沪滨

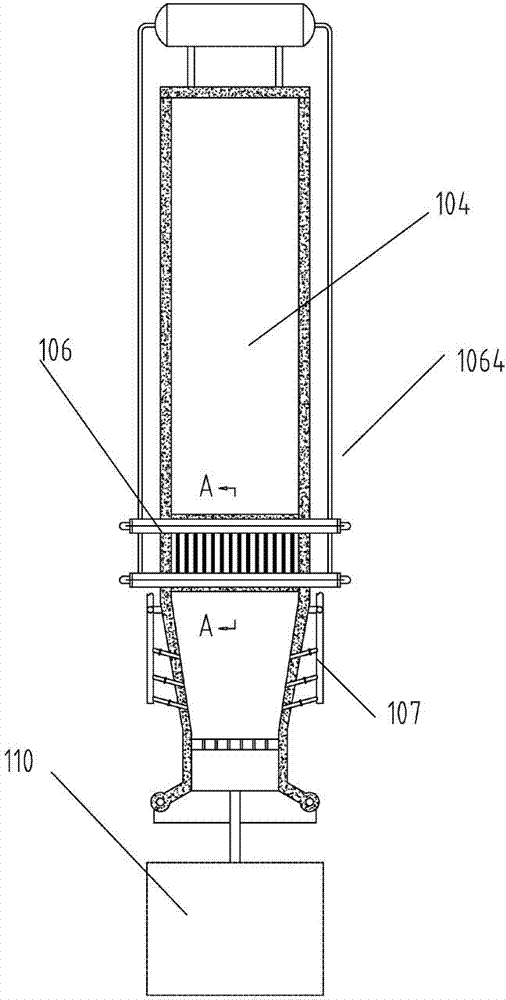

Moving grate drying bed-circulating fluidized bed boiler-compounded incineration equipment

InactiveCN102913916AKeep dryGood incineration efficiencyIncinerator apparatusFluidized bedProcess engineering

The invention provides moving grate drying bed-circulating fluidized bed boiler-compounded incineration equipment, which comprises a moving grate drying bed and a circulating fluidized bed boiler, wherein the moving grate drying bed comprises a feed system arranged on the moving grate drying bed; the circulating fluidized bed boiler comprises a dreg outlet formed in the bottom of a furnace of the circulating fluidized bed boiler; and the moving grate drying bed is connected with the circulating fluidized bed boiler in a dense phase zone of the moving grate drying bed. The moving grate drying bed-circulating fluidized bed boiler-compounded incineration equipment realized by the invention is reasonable and scientific in design, can be used for processing dregs with the characteristics of low heat value, high moisture content and poor air permeability, and can be further used for processing municipal solid wastes with the similar characteristics.

Owner:福建省丰泉环保控股有限公司

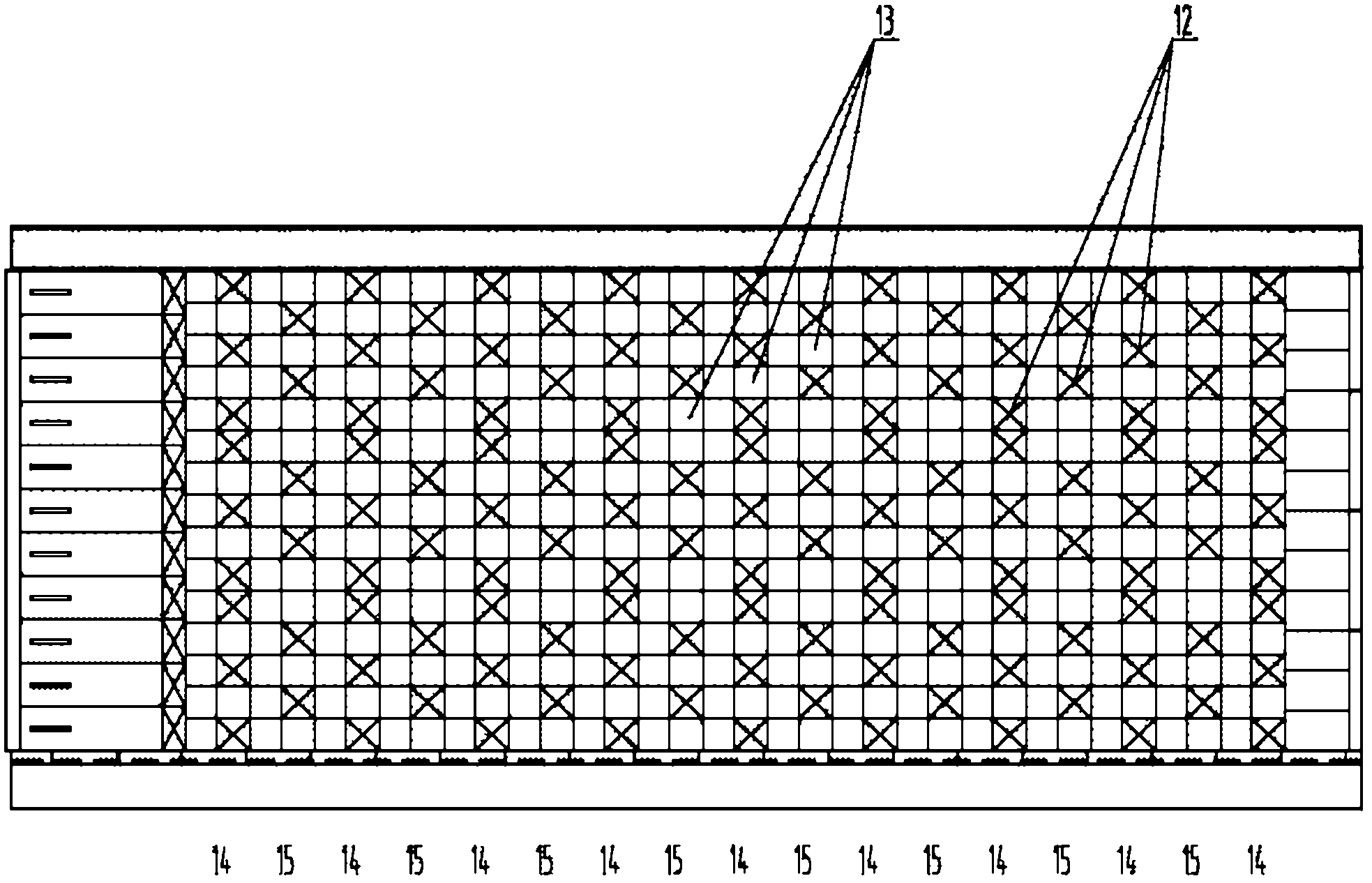

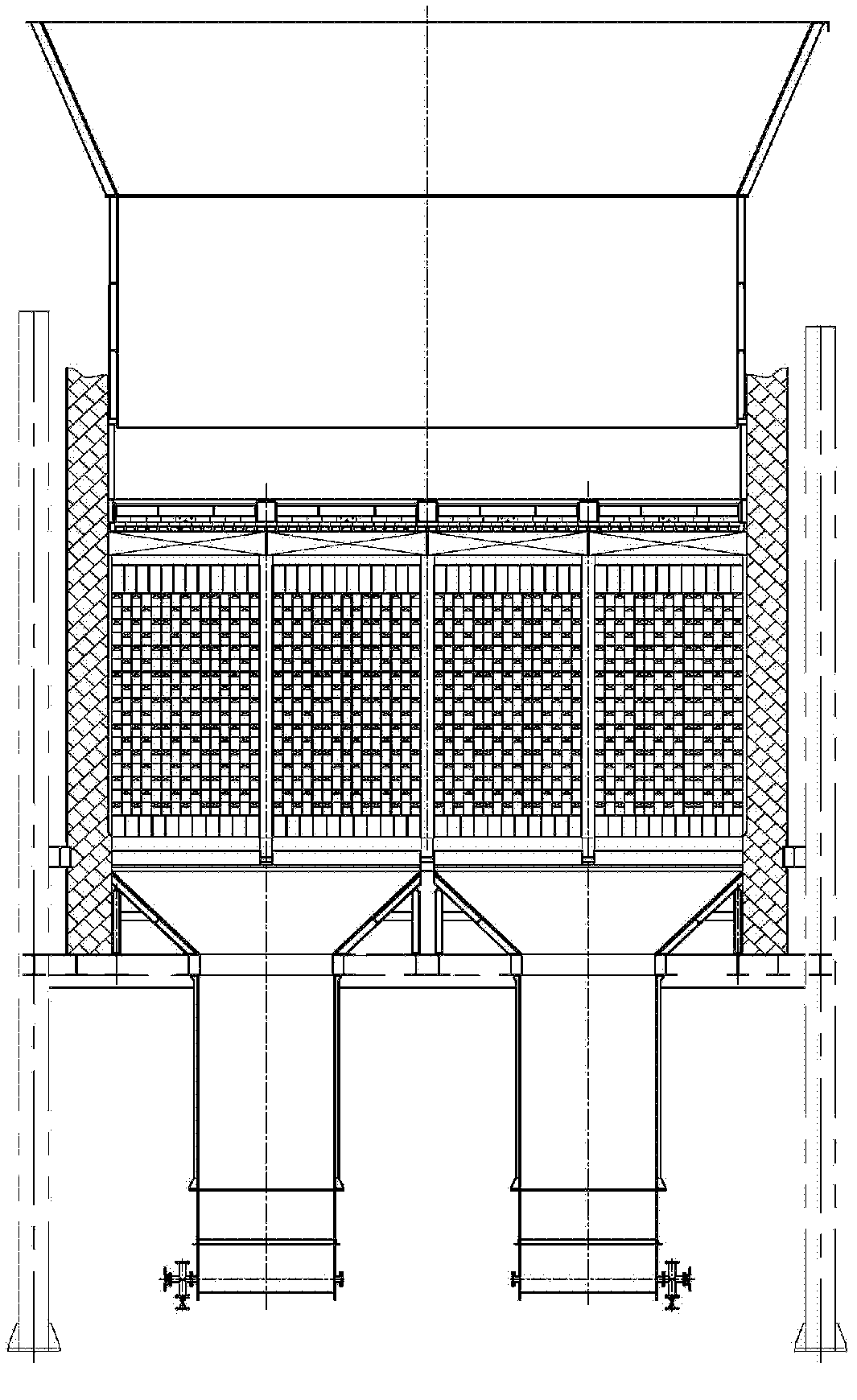

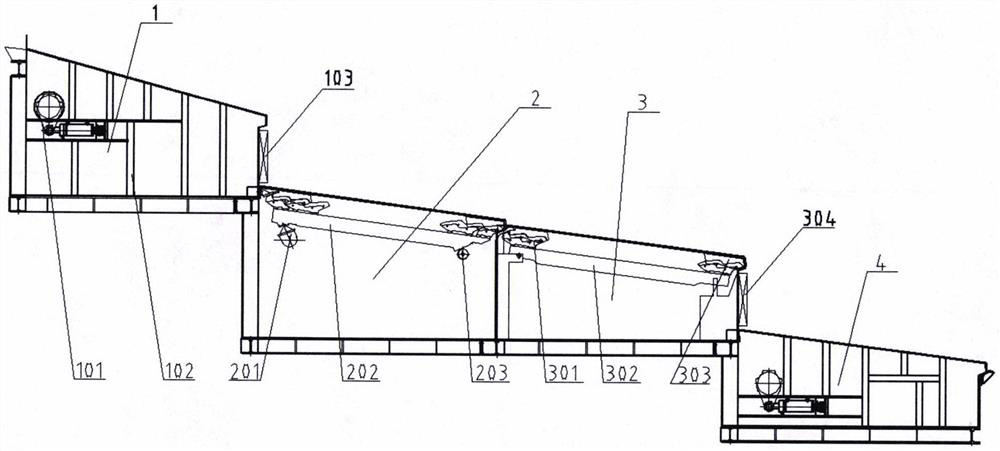

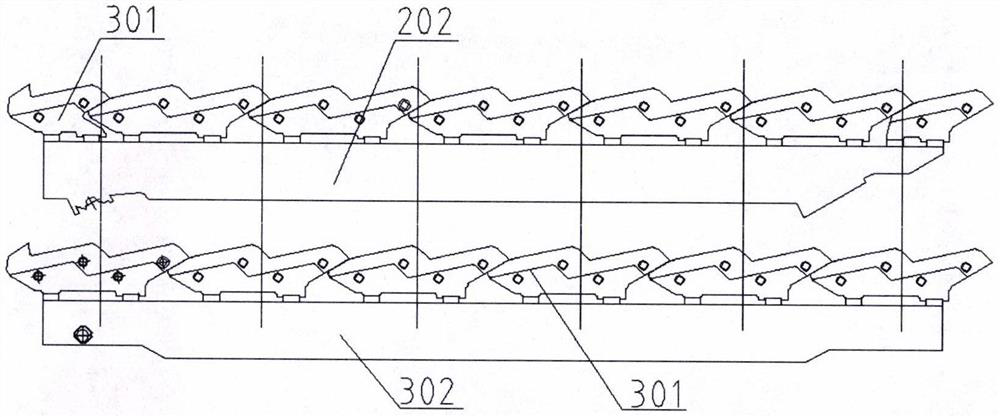

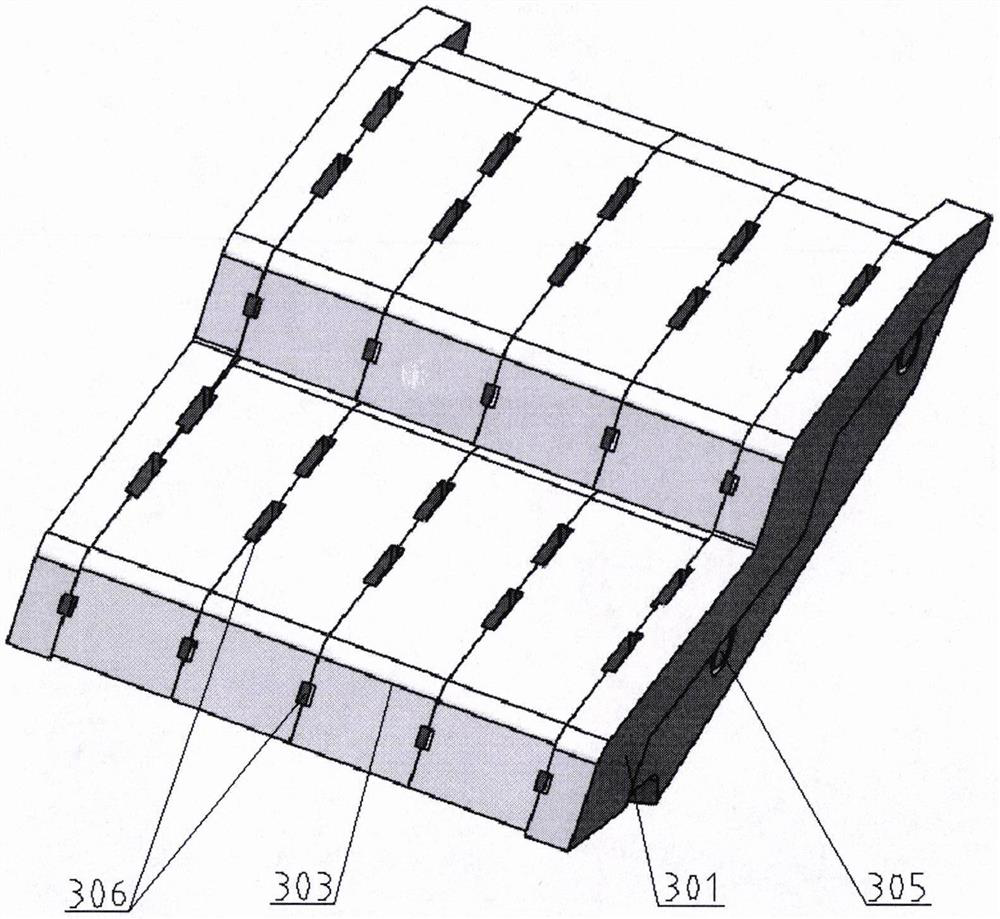

Combined type large household garbage incinerator

The invention discloses a combined type large household garbage incinerator, and relates to a garbage incinerating device. The combined type large household garbage incinerator comprises a main frame, a fire grate frame is installed in the main frame, is provided with a fire grate and comprises a fixed frame, a movable frame and a supporting wall plate, the fixed frame is connected with the main frame through the supporting wall plate, and the movable frame is installed on the fixed frame in a sliding mode through a supporting guide device. The fire grate comprises a fixed fire grate body and a movable fire grate body which are the same in structure, the fixed fire grate body and the movable fire grate body are each formed in the mode that a plurality of fire grate sheets are connected into a whole in the width direction of the fire grate, the ends of the adjacent fire grate sheets are connected in a lap joint mode, the fire grate sheets are provided with pin holes respectively, the fire grate sheets of the fixed fire grate body are connected with the fixed frame through hinge pins, the fire grate sheets of the movable fire grate body are connected with the movable frame through hinge pins, and spring pins are arranged at the two ends of the hinge pins respectively for limiting. The fire grate of the combined type large household garbage incinerator is in the combined mode, the incinerators different in processing capacity are rapidly designed easily, most parts are the same in structure, the number of the types of the parts is small, the interchangeability is good, and the manufacturing cost and the maintenance cost are low.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Garbage pyrolysis gasification and secondary combustion chamber integrated device

ActiveCN108758639ASolve the problem of continuous and stable gas productionStable incineration pyrolysis gasificationIncinerator apparatusReduction rateCombustion chamber

The invention discloses a garbage pyrolysis gasification and secondary combustion chamber integrated device. The garbage pyrolysis gasification and secondary combustion chamber integrated device comprises a gasification furnace, a secondary combustion chamber, a conical barrel and a slag box. A feeding device is arranged on the top of the gasification furnace, and a smoke outlet is formed in the side wall of the gasification furnace. The secondary combustion chamber is arranged below the gasification furnace and fixedly connected with the gasification furnace. A smoke inlet is formed in the side wall of the secondary combustion chamber, the smoke inlet communicates with the smoke outlet through a flue, and the flue is provided with a first draught fan and a spraying combustion furnace. Theconical barrel is arranged in the secondary combustion chamber and communicates with the gasification furnace. The slag box communicates with the conical barrel through a slag falling pipeline, and the slag falling pipeline is provided with a flap valve. According to the main characteristics of the device, the gasification furnace and the secondary combustion chamber are integrated, the problem that continuous and stable gas generation cannot be achieved during garbage gasification is solved, accordingly, garbage incineration pyrolysis gasification is relatively stable, the garbage treatmentspeed is increased, it is guaranteed that the secondary combustion chamber conducts continuous incineration and fire is not stopped, the temperature is guaranteed, the garbage hot burning reduction rate and the slag amount are reduced, energy is saved, and the occupied area is saved.

Owner:江苏金煌环境工程有限公司

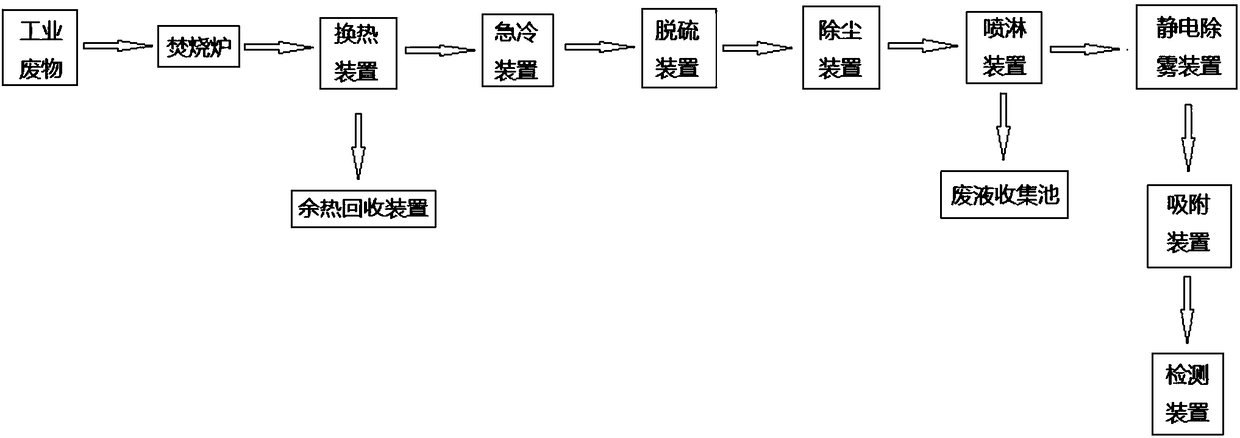

Industrial waste high-temperature incineration flue gas purification treatment process

InactiveCN108151023AEasy to handleReduce the temperatureEmission preventionCombustion technology mitigationLiquid wasteFlue gas

The invention discloses an industrial waste high-temperature incineration flue gas purification treatment process. The treatment process comprises the following steps that (1), industrial waste is pretreated; (2), the waste is loaded into an incinerator, and the temperature in the incinerator is controlled to burn the waste; (3), the flue gas temperature is lowered through a heat exchange device;(4), the flue gas temperature is lowered again through a quick cooling device; (5), acid gas in the flue gas is removed through a deacidification device; (6), solid smoke particles in the flue gas areremoved through a dedusting device; (7), the acid gas and the water-soluble tiny dust particles in the flue gas are washed with a spray device and collected into a waste liquid collection pool; (8),the tiny dust particles and the water mist obtained after spray washing are removed through an electrostatic demisting device; (9), harmful gases such as dioxin in the flue gas are removed through anadsorption device; (10), the flue gas can be discharged when the flue gas is detected to meet the standards through a detection device. The process is simple, high in operability and obvious in flue gas purification effect, and automated operation is facilitated.

Owner:南通润启环保服务有限公司

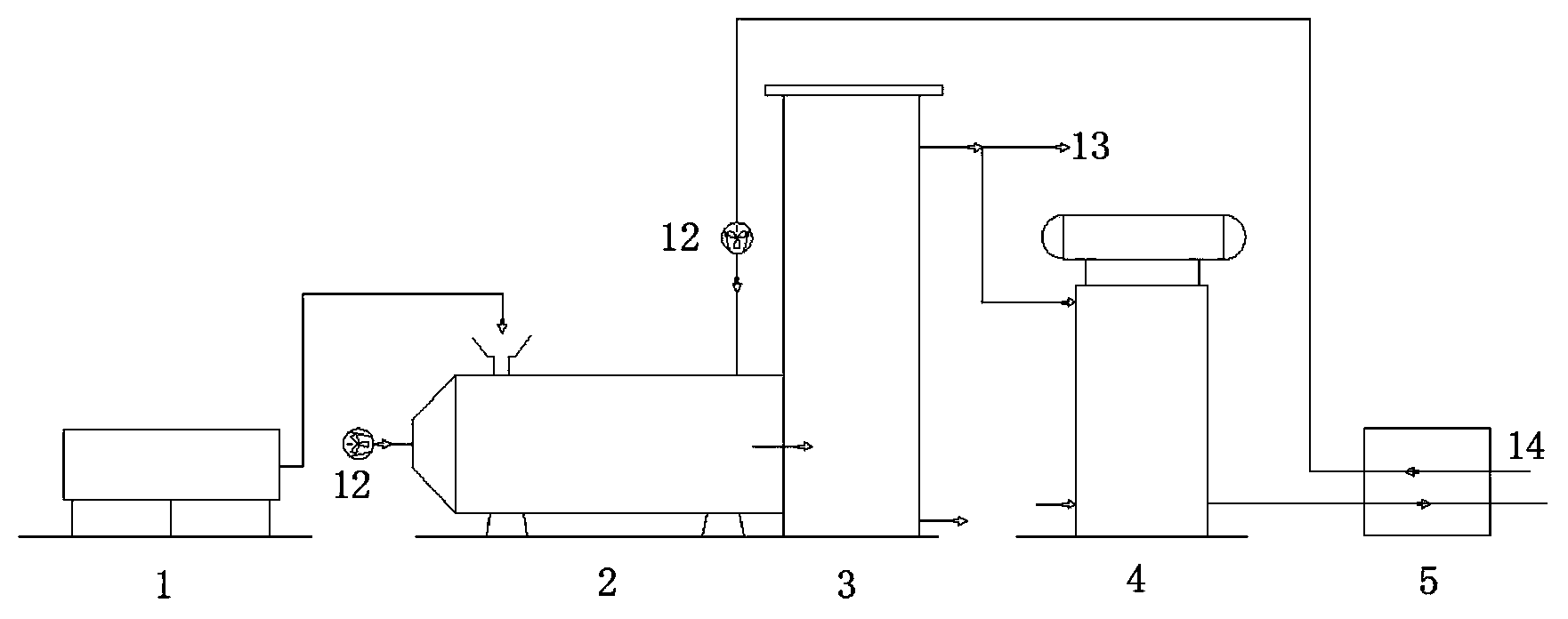

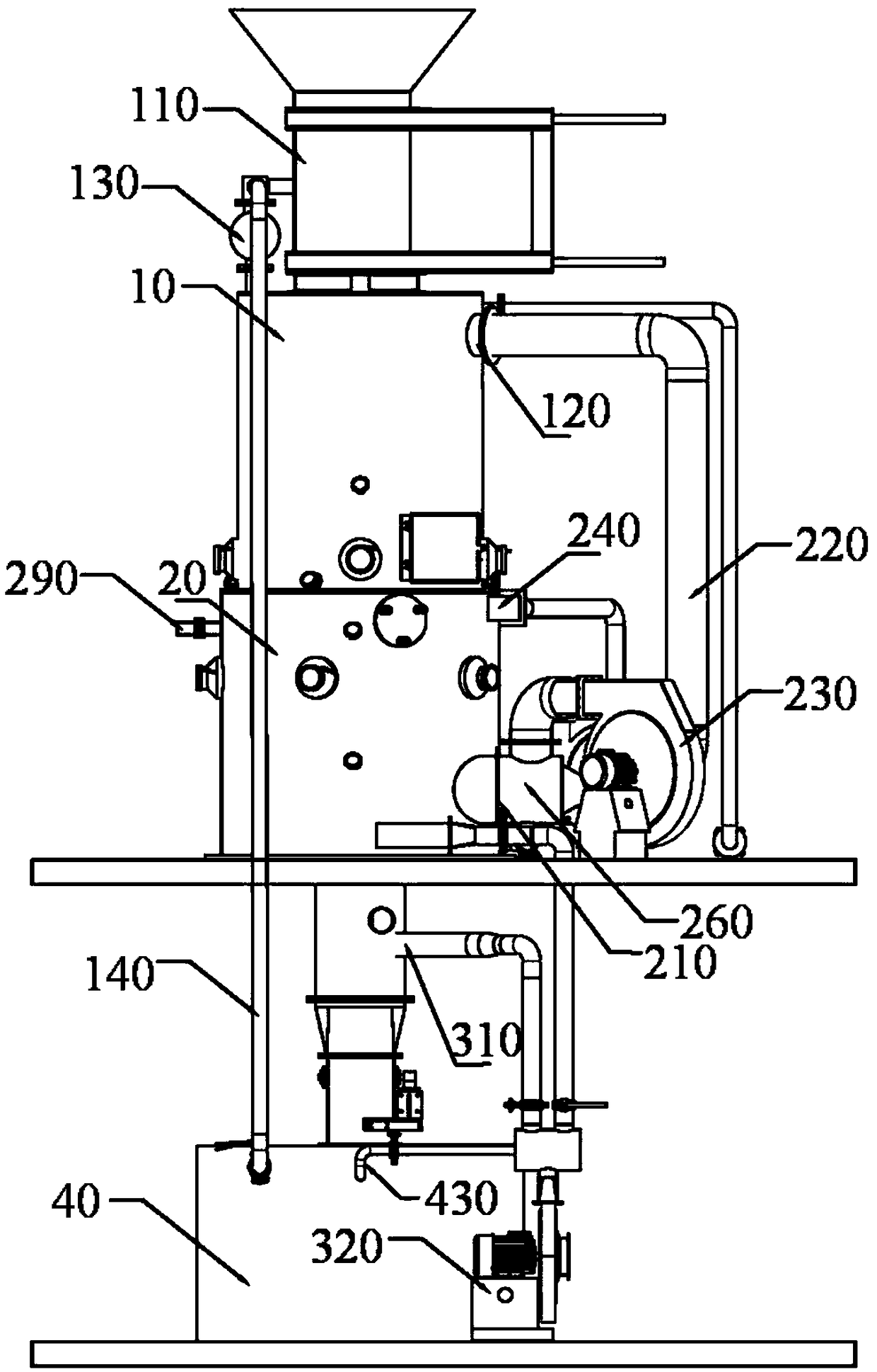

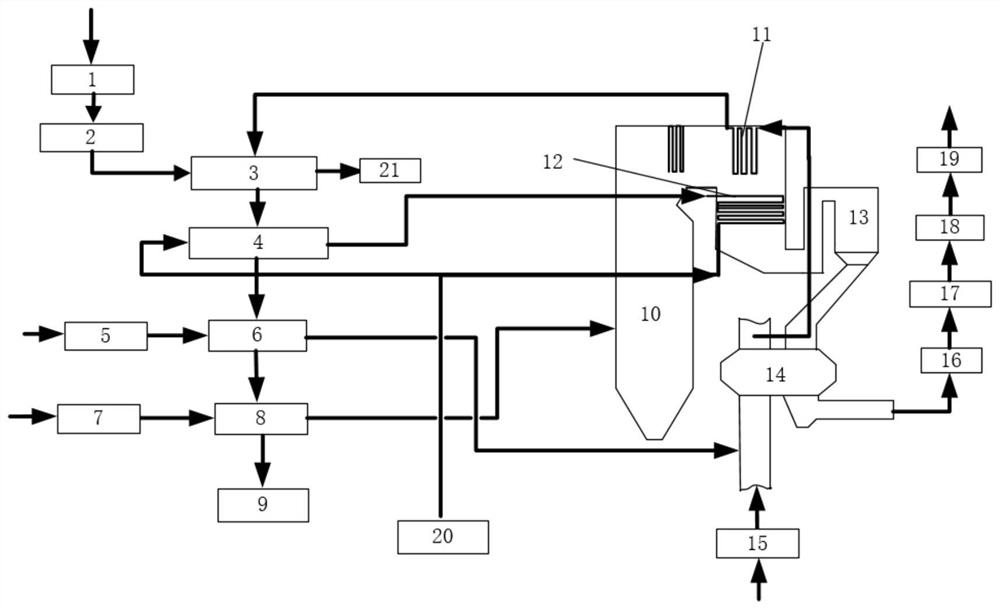

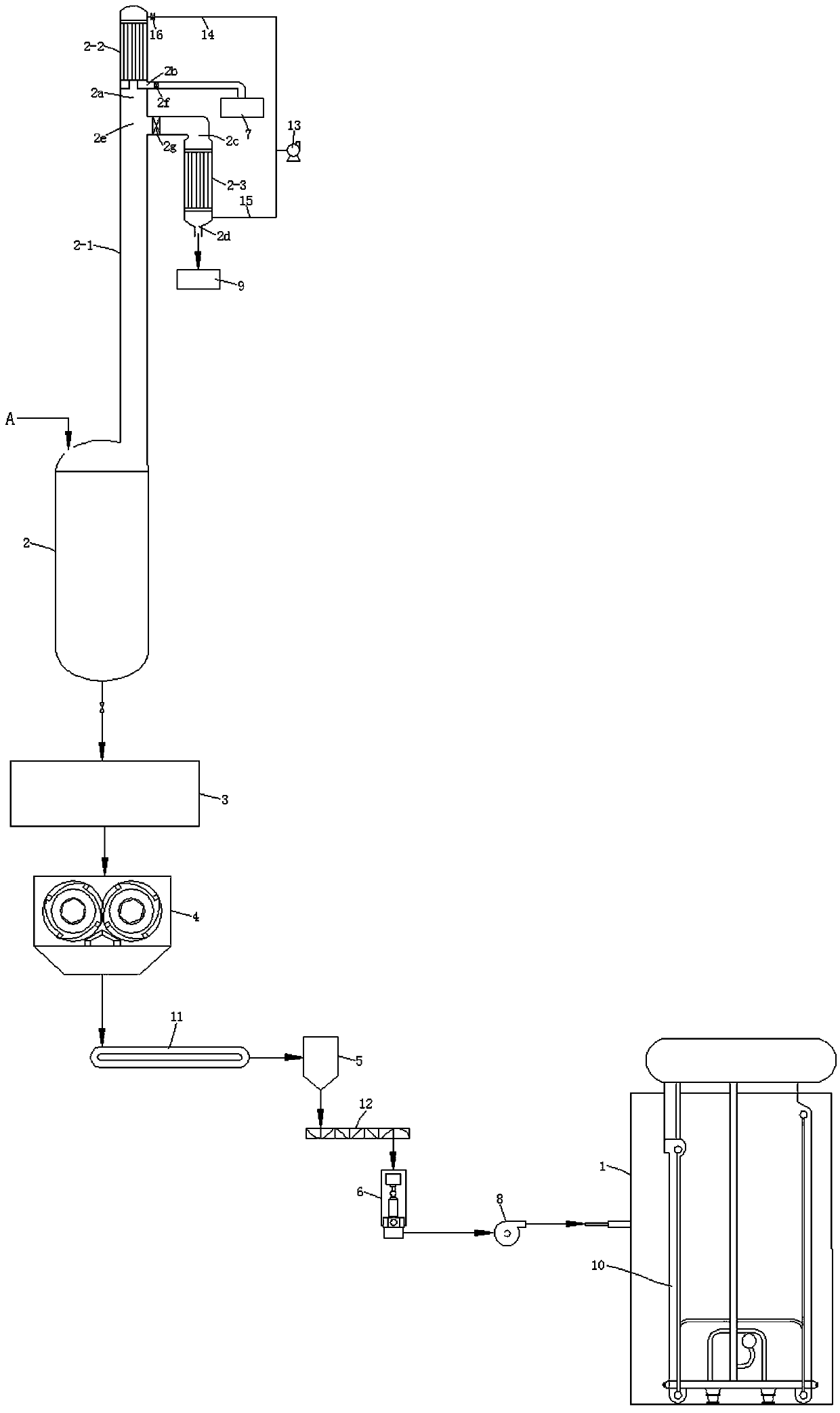

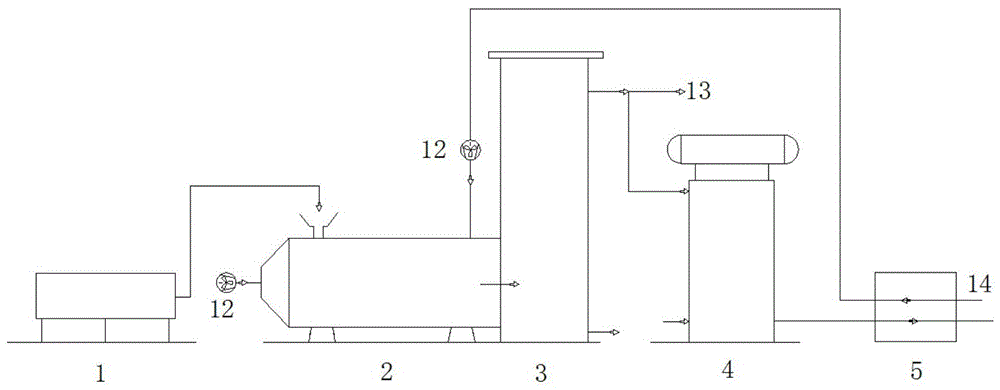

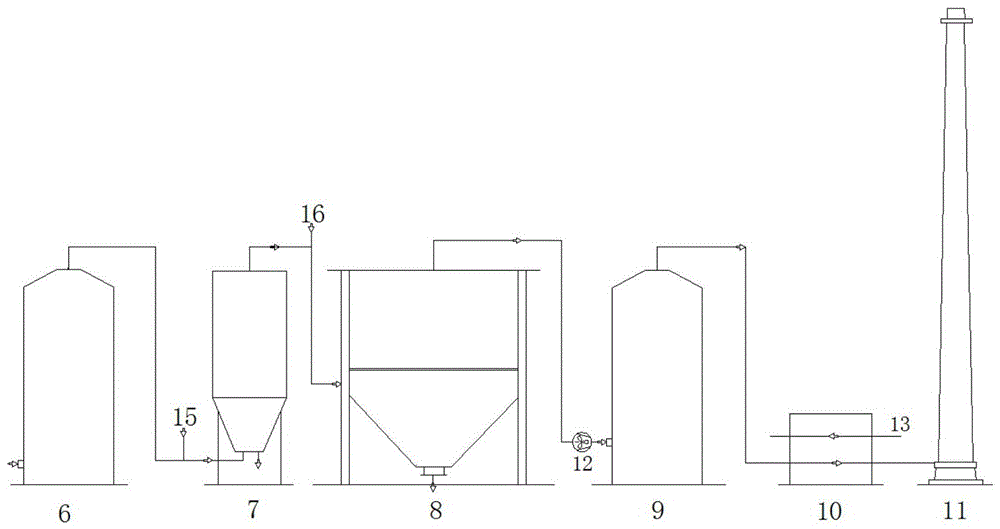

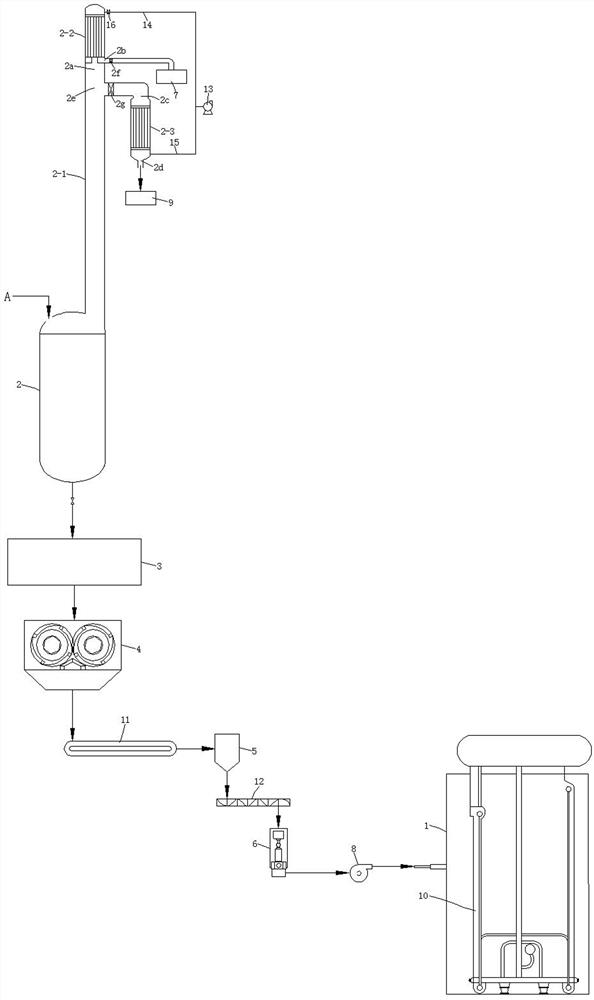

Garbage disposal and generator set coupling power generation system

PendingCN111895424AEasy to handleReduce heat burn rateIndirect carbon-dioxide mitigationSteam engine plantsDust controlRefuse Disposals

The invention belongs to the technical field of energy utilization and discloses a garbage disposal and generator set coupling power generation system which comprises a garbage disposal system and a thermal power generation system; the garbage disposal system comprises a garbage incinerator and a dust remover communicating with each other; the thermal power generation system comprises a boiler, afirst air pre-heater and a first heat exchanger; the first heat exchanger is arranged in a reversal chamber of the boiler and communicates with the garbage incinerator; the first air pre-heater communicates with the first heat exchanger; the dust remover communicates with the boiler; the flue gas through dedusting by the dust remover enters the boiler to burn; and the air enters the first heat exchanger via the first air pre-heater and is heated by heat generated through combustion in the boiler to enter the garbage incinerator. Compared with a conventional waste incineration power station, heat generated through garbage decomposition can be directly absorbed by a boiler system, and after the boiler treats waste incineration flue gas at the high temperature, dioxin and other exhaust gas inwaste incineration flue gas can reach the discharge standard of pollutants.

Owner:YANTAI LONGYUAN POWER TECH +1

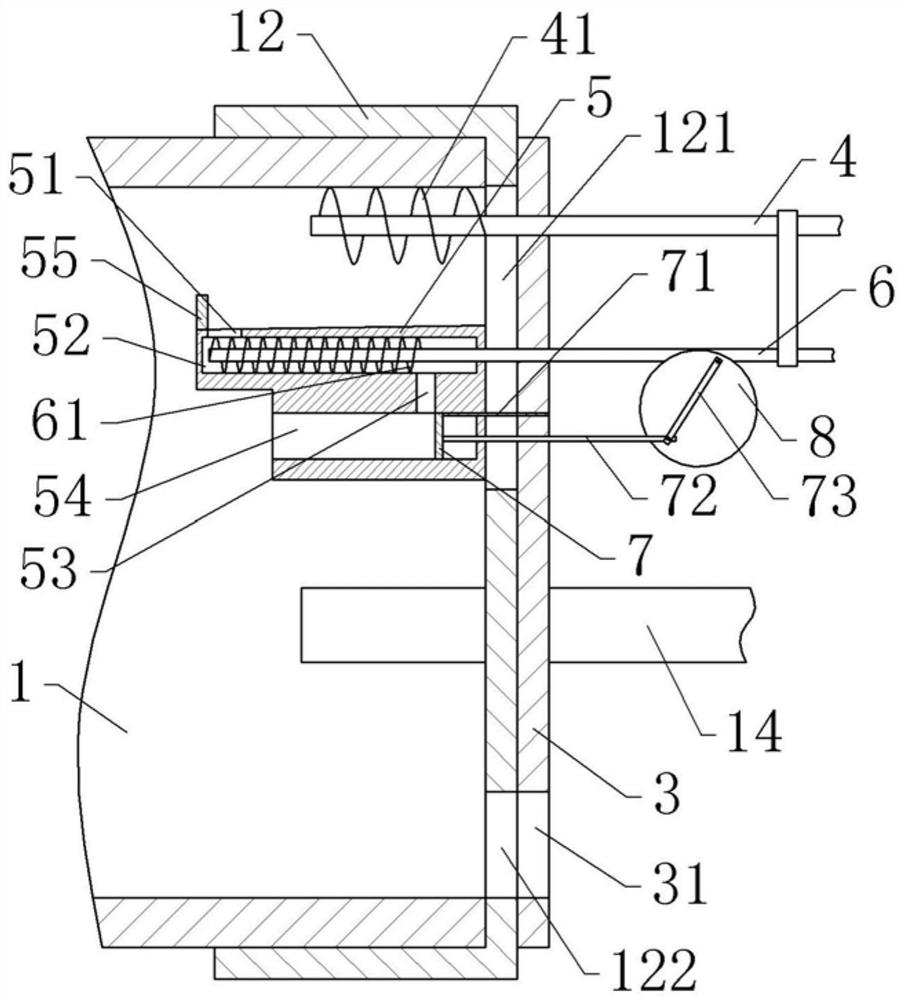

Hazardous waste rotary kiln incineration process

The invention belongs to the technical field of hazardous waste incineration, and discloses a hazardous waste rotary kiln incineration process which is realized by adopting a hazardous waste rotary kiln. The hazardous waste rotary kiln comprises a cylinder body, the two ends of the cylinder body are respectively provided with a kiln head cover and a kiln tail cover in a rotatably and hermeticallyconnected manner, the lower part of the kiln tail cover is provided with a slag outlet, and the kiln head cover is cylindrical; a main air hole and an auxiliary air hole are formed in the side wall ofthe kiln head cover, the main air hole is located in the top of the kiln head cover, the main air hole and the auxiliary air hole are not located in the same circumferential line of the kiln head cover, the main air hole is formed close to the cylinder body, and the auxiliary air hole is formed in the side away from the cylinder body; hazardous waste is thrown into the cylinder body to be incinerated, after the temperature in the cylinder body rises to 1000-1150 DEG C, air is supplied into the kiln head cover from the main air hole and the auxiliary air hole, and the air speed of the main airhole and the air speed of the auxiliary air hole are consistent; and after the hazardous waste is incinerated, ash slag is guided out from the slag outlet. By means of the hazardous waste rotary kilnincineration process, it can be guaranteed that the ignition loss rate is low after hazardous waste is incinerated, and the excess air coefficient is low, so that the hazardous waste can be fully incinerated, and heat losses in the incineration process can be reduced.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

Solid waste gasifying system and solid waste gasifying method

PendingCN107723030AHeating up fastDehydration fastGasification processes detailsGasification with fuel pre-distillationSlagSpray nozzle

The invention discloses a solid waste gasifying system and a solid waste gasifying method. Currently, solid wastes are disposed mainly by incineration so as to cause secondary environmental pollutioneasily. According to the solid waste gasifying system, an air distribution mechanism is arranged at the bottom part of a furnace body; a primary air inlet of the air distribution mechanism is communicated with a gasifying fan by a one-way mixer, and a secondary air inlet of the air distribution mechanism is communicated with an inner cavity of the furnace body by a ring-shaped air duct, and is also communicated with an air outlet of the one-way mixer; a mixed steam inlet of the one-way mixer is communicated with a high-temperature steam outlet; the inner part of the furnace body is divided into an upper empty layer, a drying cavity, a dry distillation cavity, a lower empty layer, a reducing cavity, an oxidizing cavity and an ash slag cavity; dry steam spraying nozzles communicated with a high-temperature steam inlet are distributed in the drying cavity; dry distillation steam spraying nozzles communicated with the high-temperature steam inlet are distributed in the dry distillation cavity; high-temperature steam coils are distributed in the drying cavity and the dry distillation cavity and are communicated with the high-temperature steam inlet and the high-temperature steam outlet;and a dry distillation gas outlet is formed in the upper empty layer and a reducing gas outlet is formed in the lower empty layer. The solid waste gasifying system and the solid waste gasifying method disclosed by the invention have the advantages that the solid waste can be continuously transformed into combustible gas and cured furnace slag for high-temperature sintering, so that the harmless purpose is achieved.

Owner:马加德

Multiple row sectional drive combined type domestic garbage incinerator

The invention relates to multi-column sectional drive combined type domestic incinerator. It is set three fire-grates that drying section, burning section, and firing section. The middle fire grate is connected between them. There is altitude fall between them that the drying section is the highest point; the firing one is the lowest point. The primary air chamber is respectively set under them. The incinerator fire grate system of the invention has independent drive mechanism, air supply system, and air chamber for each section which is convenient for controlling technical parameter that traveling speed, air quantity, air temperature, air pressure etc to realize full drying and burning for whole garbage layer.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

Moving grate drying bed-circulating fluidized bed boiler-compounded incineration equipment

InactiveCN102913916BKeep dryGood incineration efficiencyIncinerator apparatusFluidized bedProcess engineering

The invention provides moving grate drying bed-circulating fluidized bed boiler-compounded incineration equipment, which comprises a moving grate drying bed and a circulating fluidized bed boiler, wherein the moving grate drying bed comprises a feed system arranged on the moving grate drying bed; the circulating fluidized bed boiler comprises a dreg outlet formed in the bottom of a furnace of the circulating fluidized bed boiler; and the moving grate drying bed is connected with the circulating fluidized bed boiler in a dense phase zone of the moving grate drying bed. The moving grate drying bed-circulating fluidized bed boiler-compounded incineration equipment realized by the invention is reasonable and scientific in design, can be used for processing dregs with the characteristics of low heat value, high moisture content and poor air permeability, and can be further used for processing municipal solid wastes with the similar characteristics.

Owner:福建省丰泉环保控股有限公司

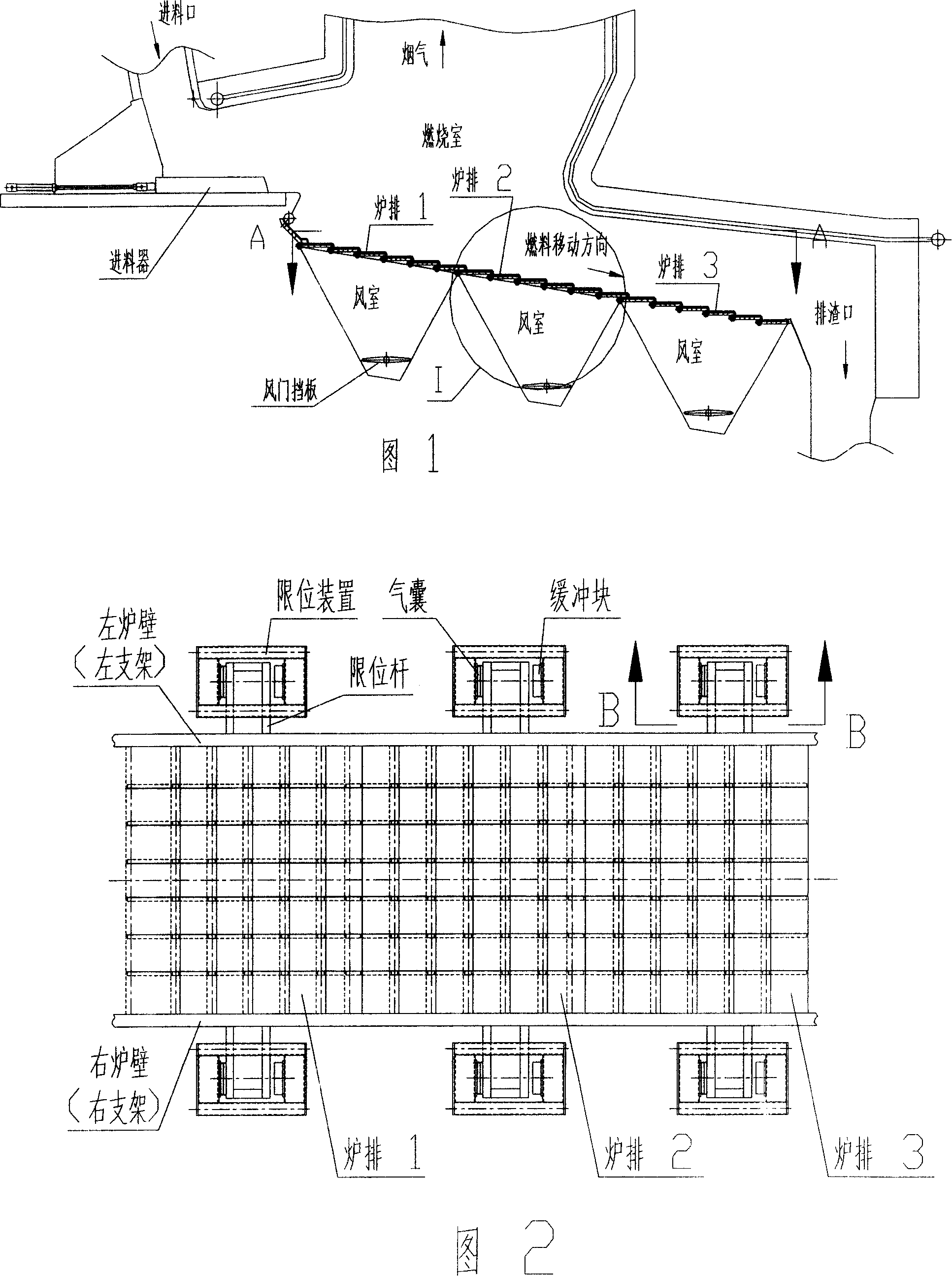

Pull up and down push driven reverse push garbage incinerator

ActiveCN102278763AAdjust the speed of movementExtension of timeIncinerator apparatusBurn treatmentSlag

The invention discloses a pull-up push-down driven reverse push garbage incinerator, which comprises a feed hopper, a feeding mechanism, grates, a heath, a grate lee chamber, a slag falling well and a slag discharger, wherein the grates are divided into static grates and dynamic grates, the static grates and the dynamic grates are arranged alternately up and down to form a column, a dynamic gratedrive consists of an upper section and a lower section, the driving mechanism of the upper section is arranged at the upper end of the grates, and the driving mechanism of the lower section is arranged at the lower end of the grates; and an air chamber is formed below the grates, and an electric air door is arranged on an air inlet pipeline of the air chamber. The garbage incinerator has the advantages that: the movement speed of the grates of each section is adjustable, and the grates can be properly lengthened, so that the burning treatment time is prolonged; the incinerator of different capacity can be combined; and the grates of each column are independently driven and do not interfere with one another, so the incinerator has simple structure and can be modularized. The intertwined garbage cluster is easily scattered, and the garbage is mixed uniformly and burnt stably; the incinerator is provided with a heat expansion absorption device, so that the grate sheets are not blocked due to expansion; and the air quantity of the air chamber can be adjusted, so that the garbage can be stably burnt.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Purified terephthalic acid residue recycling and incineration treatment method

ActiveCN110836378AAchieve reductionReduce processing costsIncinerator apparatusFractional distillationBenzoic acidProcess engineering

The invention discloses a purified terephthalic acid residue recycling and incineration treatment method. An incinerator serves as an incineration treatment device, a reaction kettle is adopted as a resource recycling treatment device, the reaction kettle is provided with a rectifying tower, a first condenser and a second condenser, the first condenser is provided with a gas inlet and a liquid outlet, the second condenser is provided with a gas inlet and a liquid outlet, and the gas inlet of the first condenser and the gas inlet of the second condenser communicate with a gas outlet of the rectifying tower. The method comprises the following steps of feeding, dewatering, benzoic acid recycling, waste residue crushing, waste residue grinding and waste residue incineration. According to the method, useful resources in residues can be effectively extracted, resource recycling is achieved, and waste recycling is carried out on the residues. Besides, compared with the prior art, the incineration amount is improved by more than three times, the incineration amount is greatly improved, combustion of the residues is more sufficient, harmless treatment is more thorough and more environmentally friendly, the energy consumption during treatment is low, the process is simple and feasible, and the residue treatment cost is lower.

Owner:沈福昌

Process for burning medical refuse

The invention relates to a medicine garbage burning technology. The medicine garbage is transferred to the material casting entrance by sealed special transport vehicle and casting equally, quantificatioally into the burning furnace by automatic lifting material feeding device. And the process of dehydration and drying, pyrolysis and gasification, burning, second burning, smoke sedimentation, waste heat recovery and smoke dealing with would be taken. Thus, the content reduce quantity would reach 99%. The invention can effectively avoid the produce of poisonous substance.

Owner:ZHENGCHANG GROUP JIANGSU

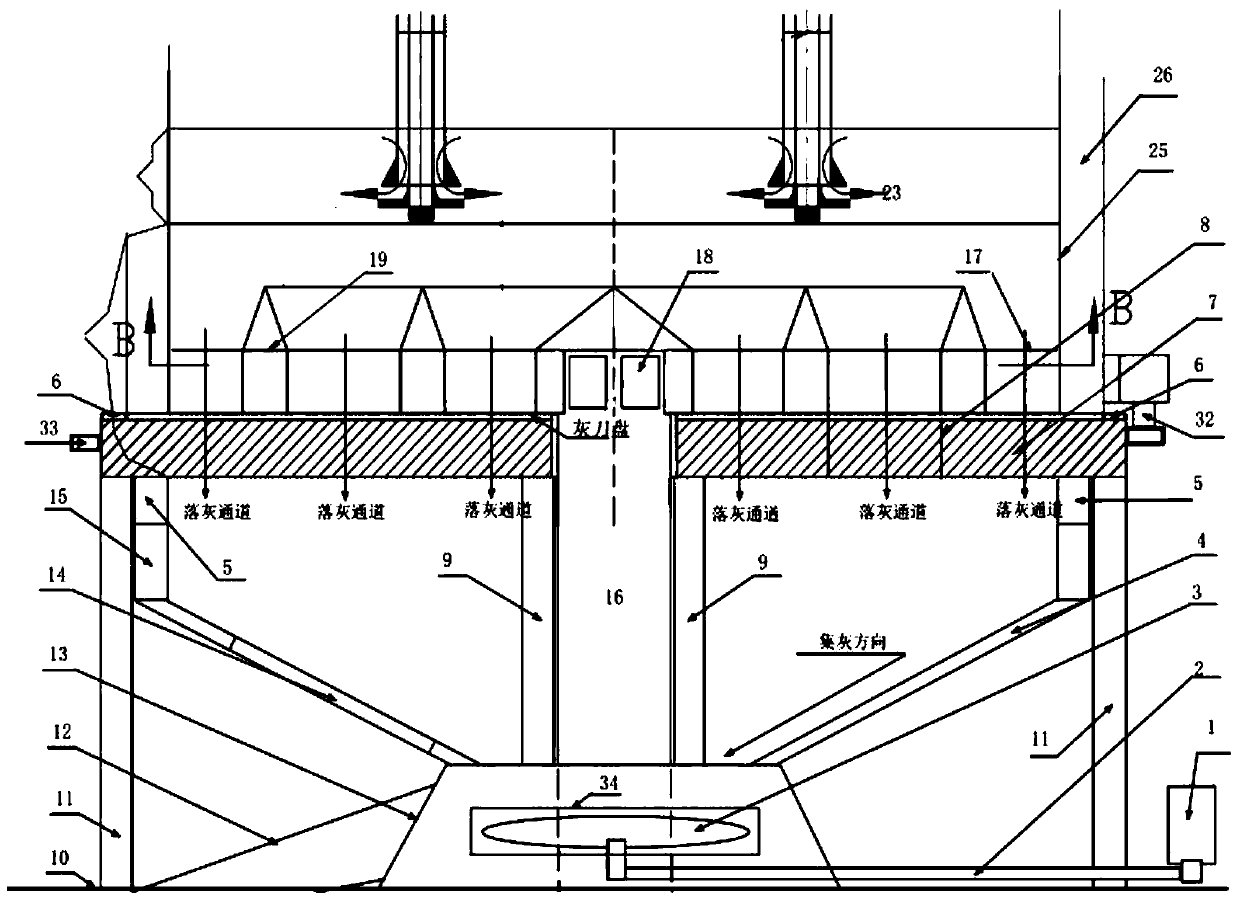

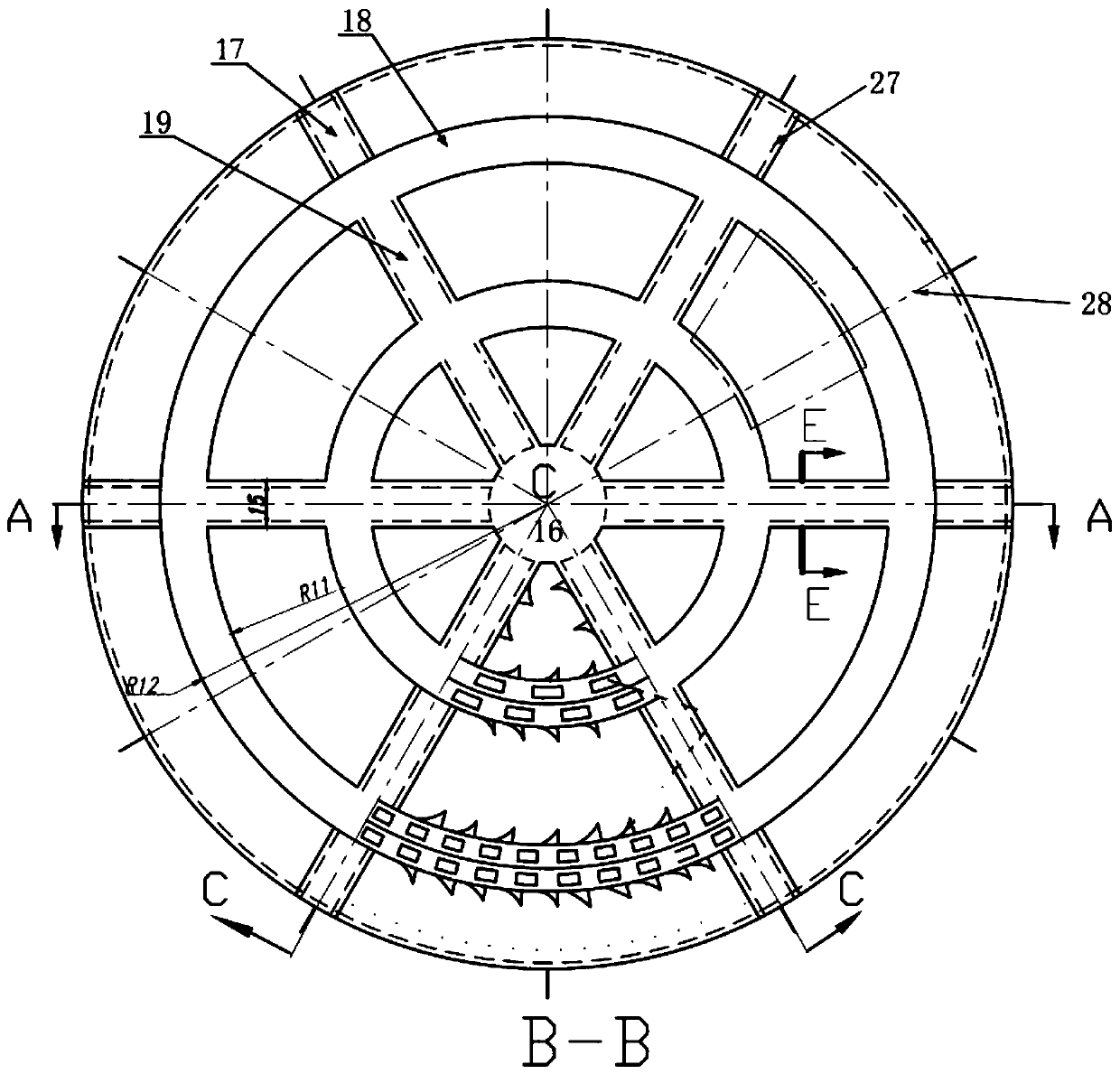

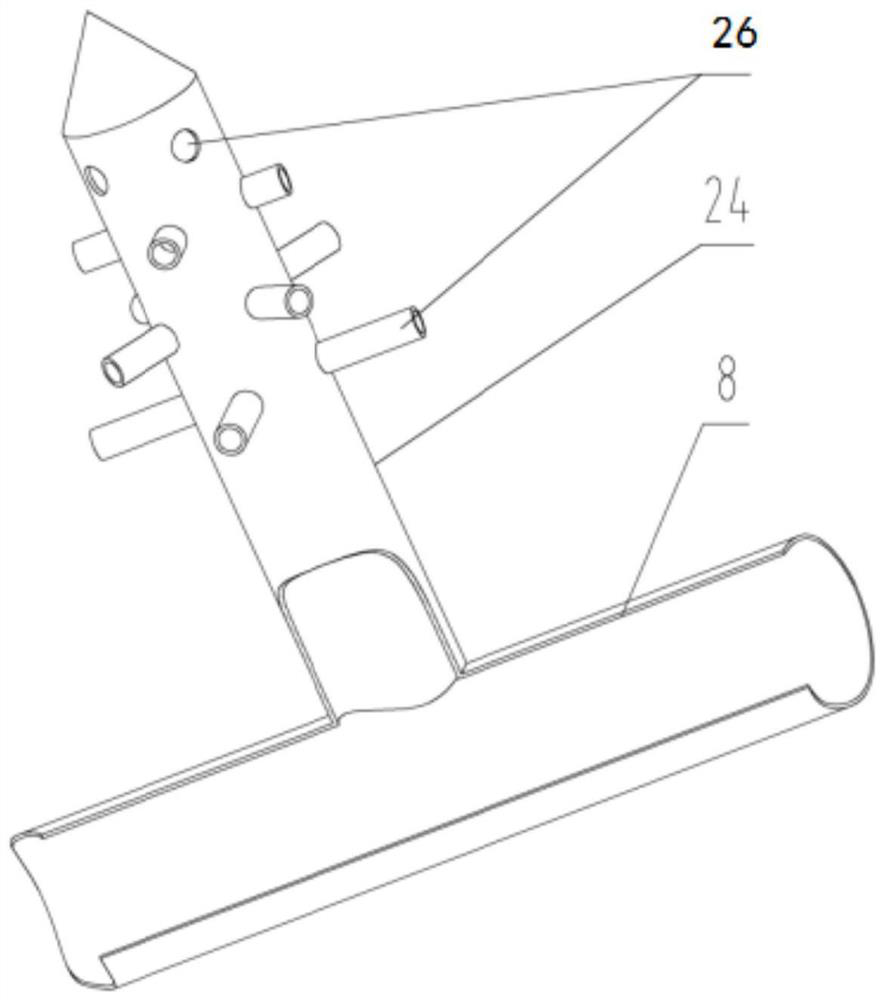

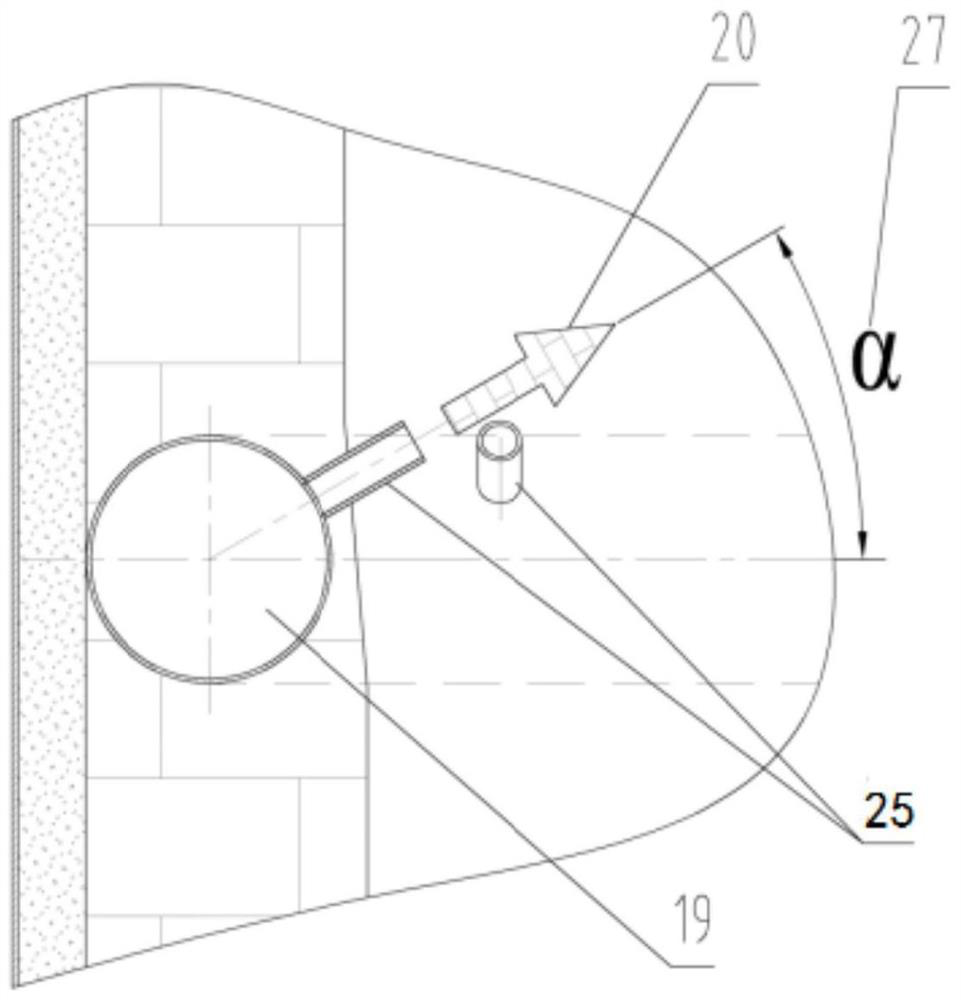

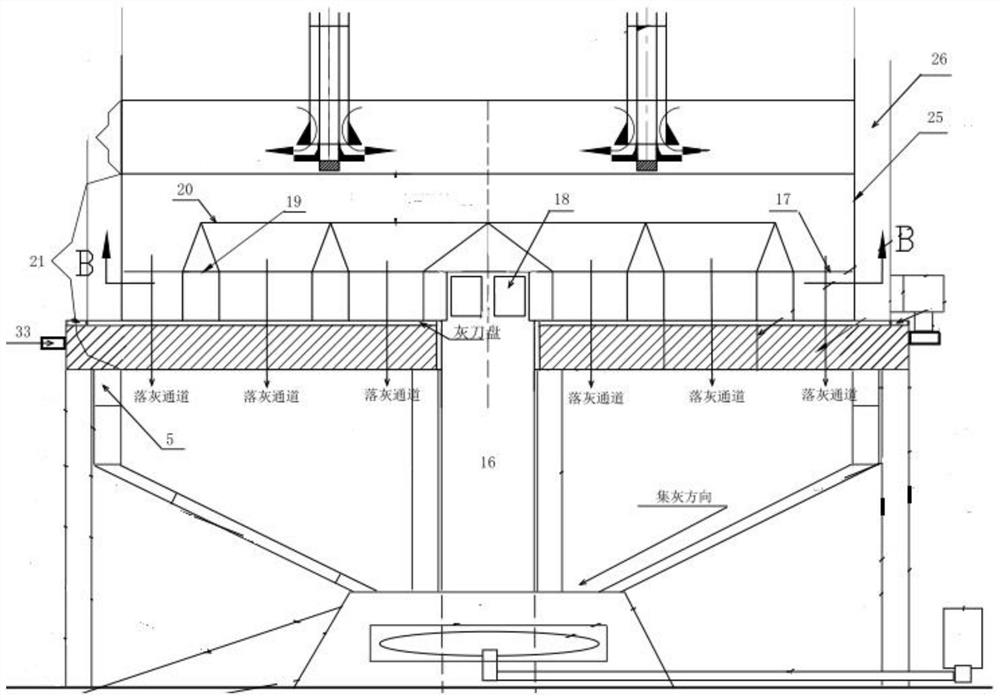

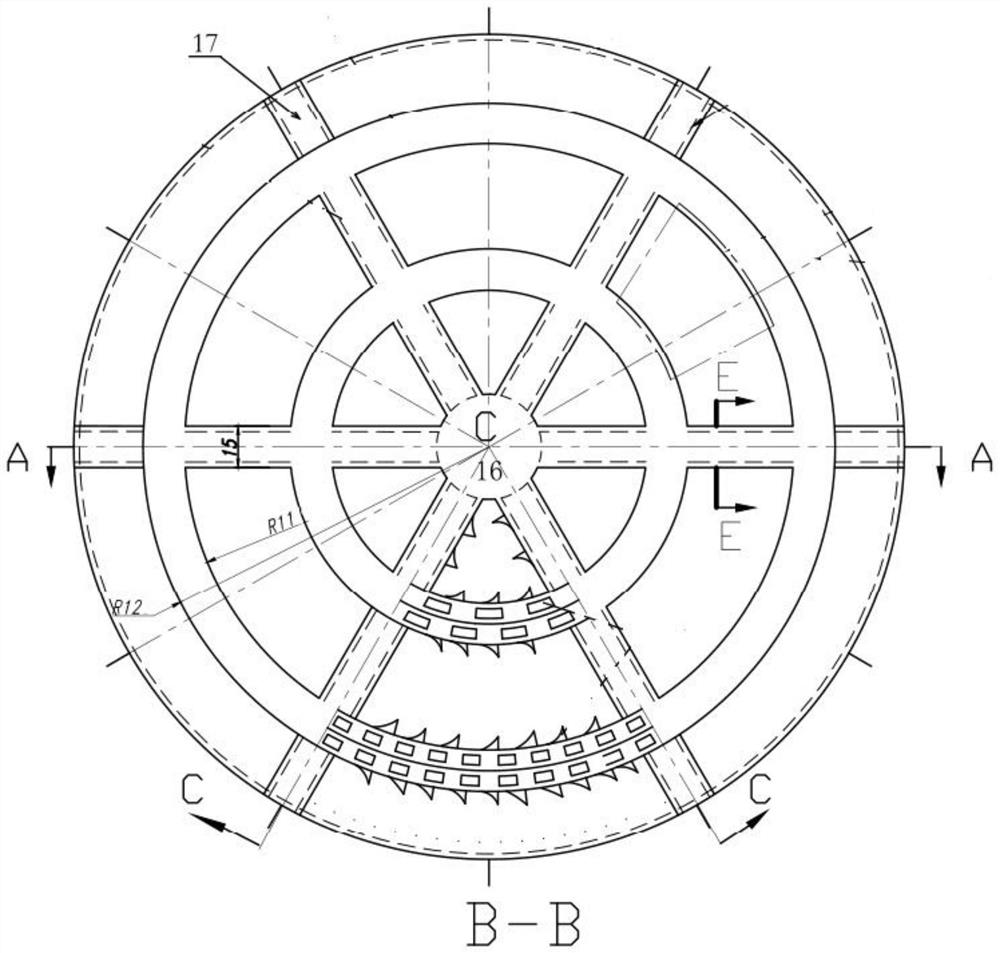

Ash discharge system of biomass gasification furnace

ActiveCN111253982AIncrease effective volumeReduce volumeGasification processes detailsCombustible gas productionCombustionSlag

The invention discloses an ash discharge system of a biomass gasification furnace, which sequentially comprises an ash channel system, an ash falling system, an ash collecting system and an ash outputsystem from top to bottom. The ash channel system is arranged in a furnace body, and the ash falling system, the ash collecting system and the ash output system are arranged at the bottom of the furnace body. The ash channel system is a dish-shaped grate. The ash falling system is arranged on the lower side of the ash channel system and can rotate to open and block the ash falling channel to enable ash to fall. The ash collecting system is arranged below the ash falling system, and the ash output system is connected with the ash collecting system. The dish-shaped grate is uniform in air outlet, the number of ash falling channels is increased, the ash falling section is increased, ash falling is more uniform, collapse of a fixed carbon combustion layer is more uniform, the probability thatthe grate bar body is burnt out by non-uniformly collapsed scorching carbon is reduced, the ignition loss rate is reduced, and the physical and chemical properties of ash slag are more stable. The combustion speed and the gasification speed of the RDF can be effectively increased, so that the unit consumption of the biomass waste is increased.

Owner:刘跃伟

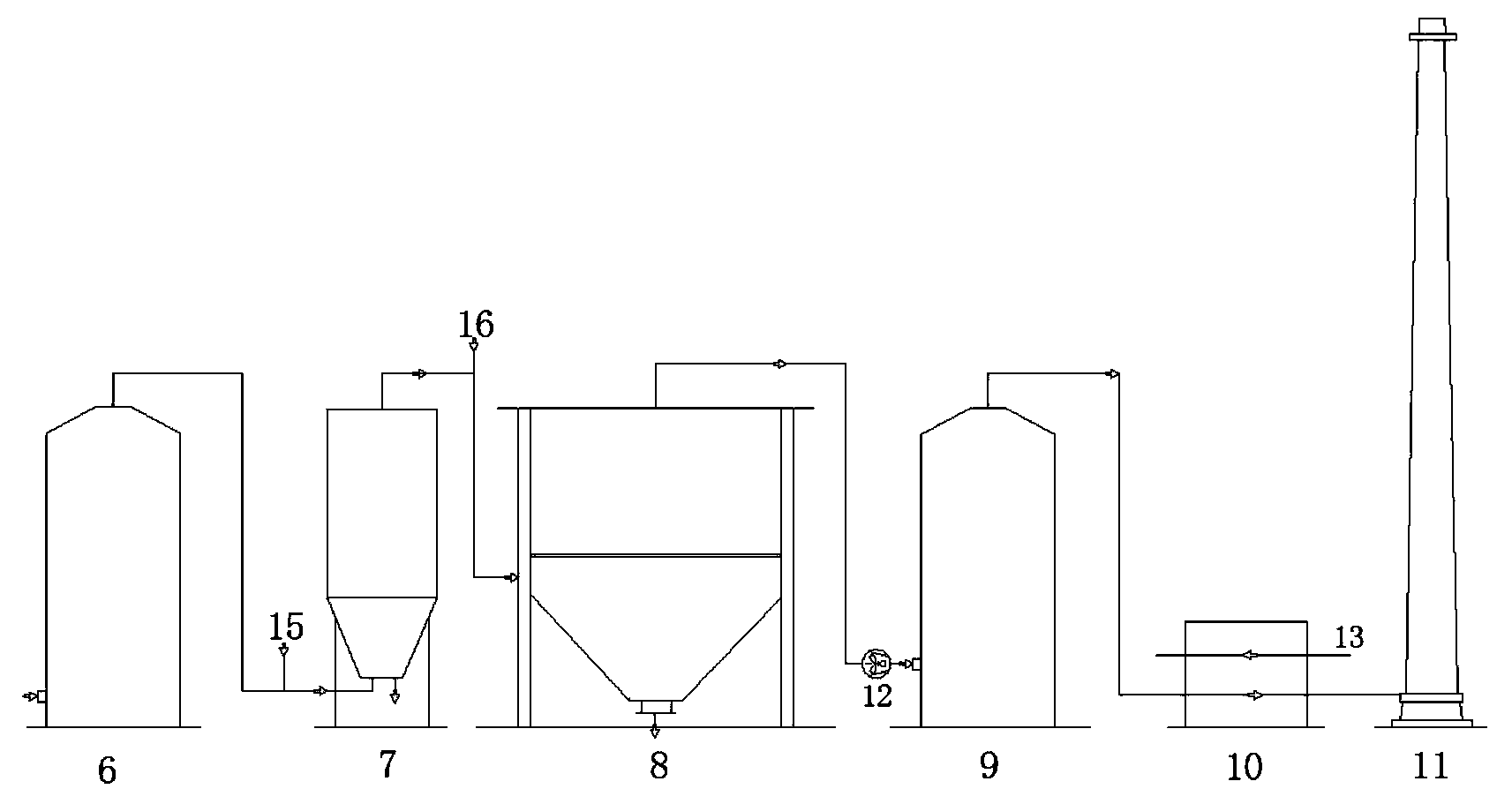

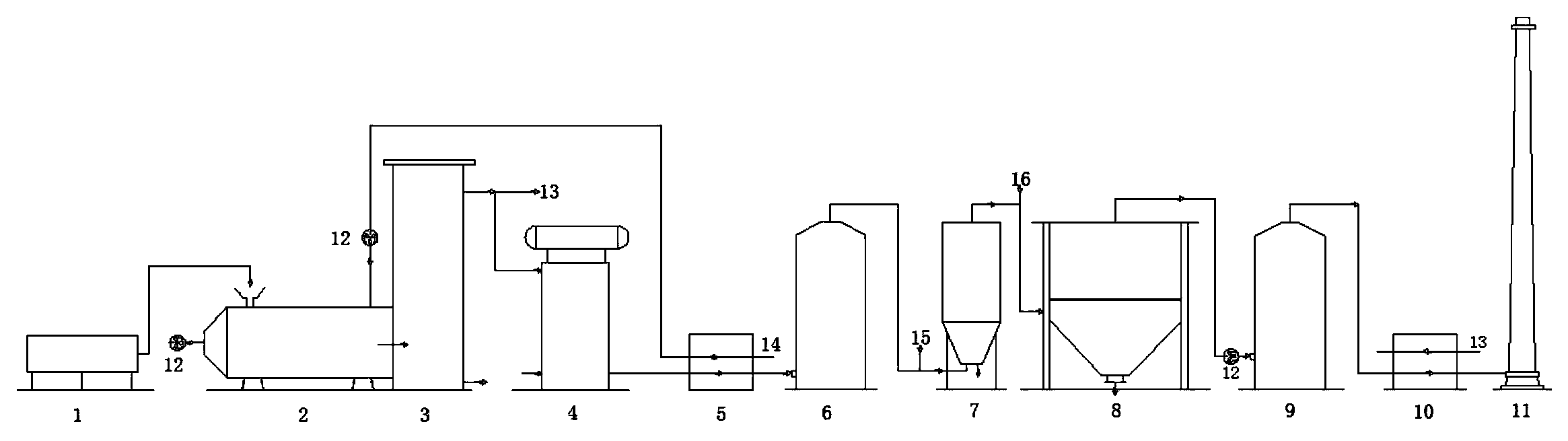

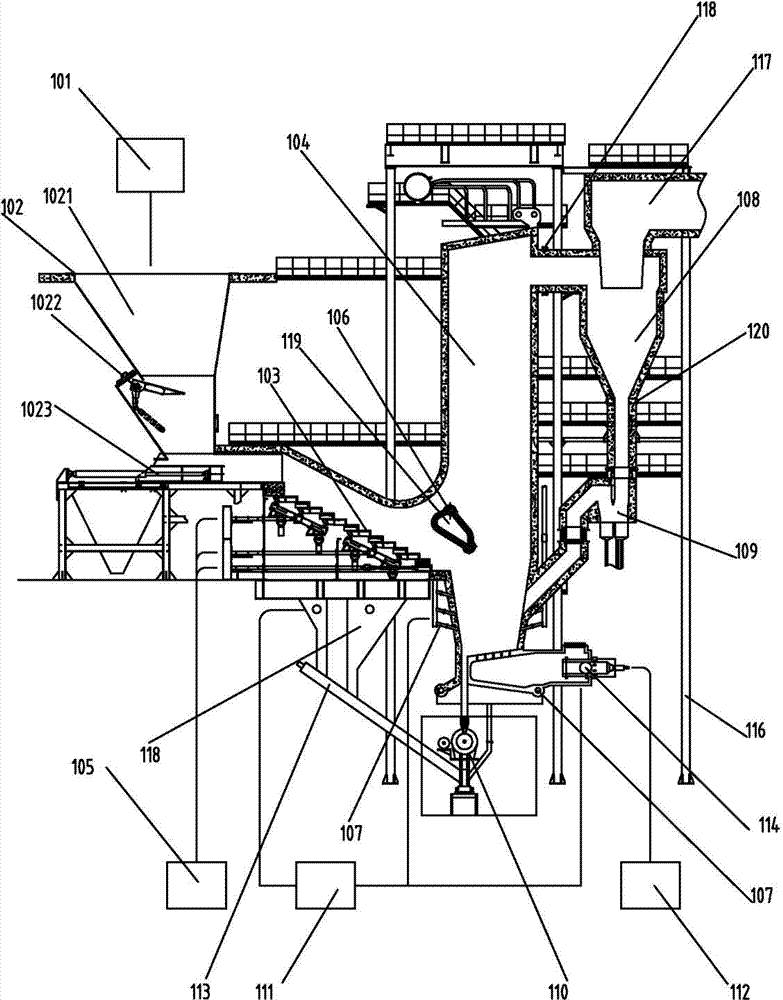

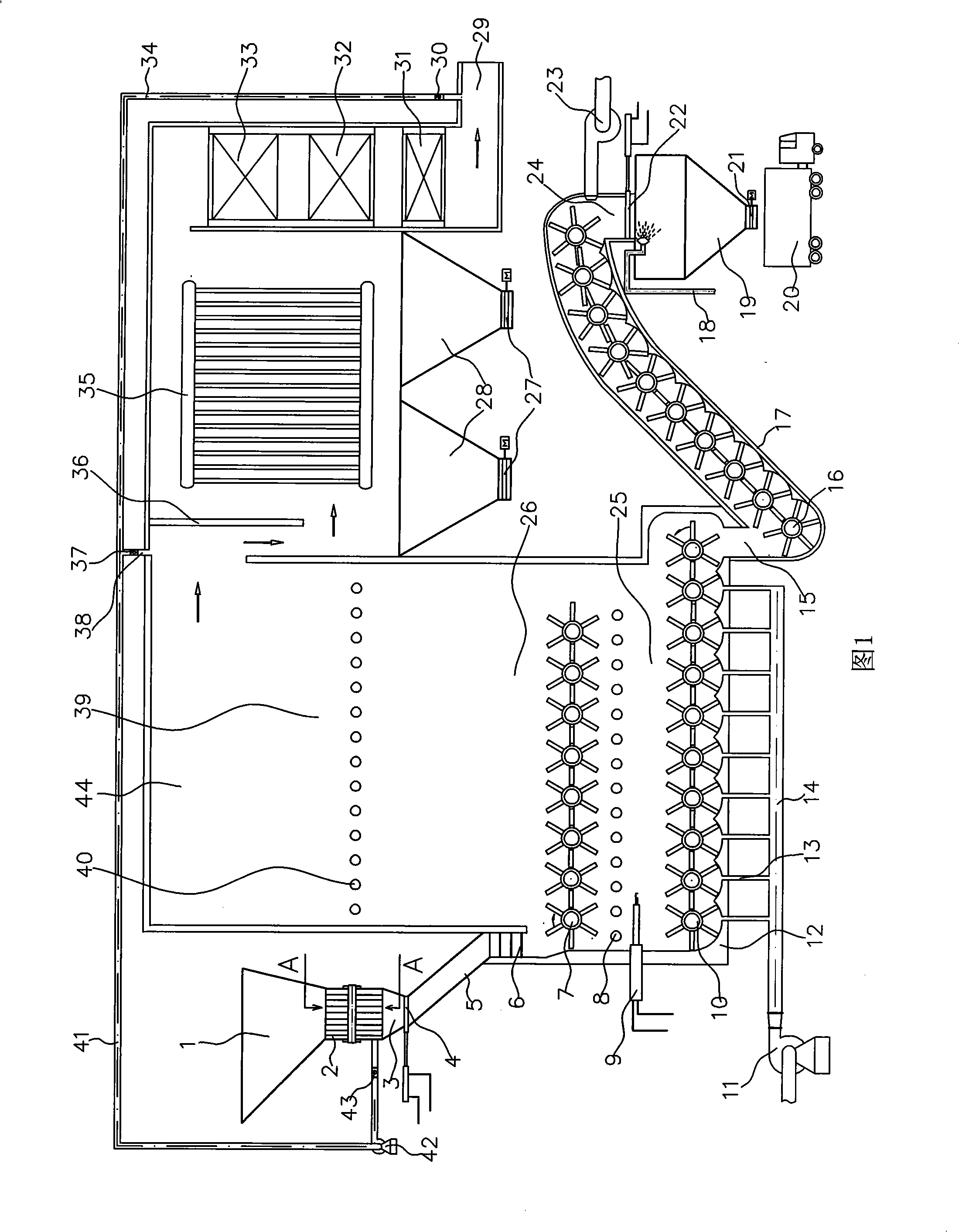

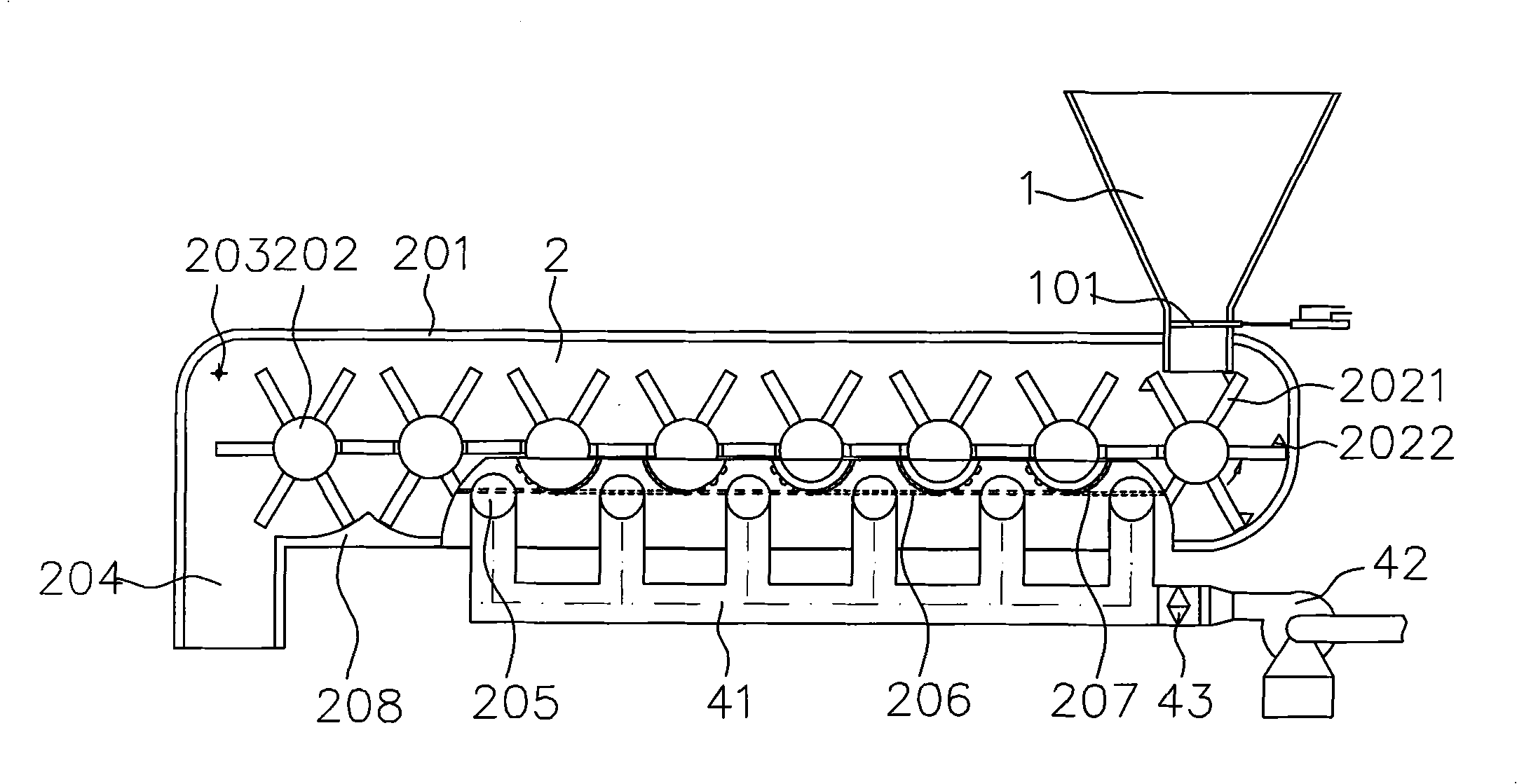

Efficient burning furnace with rotary fluidization grate

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consistsof a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

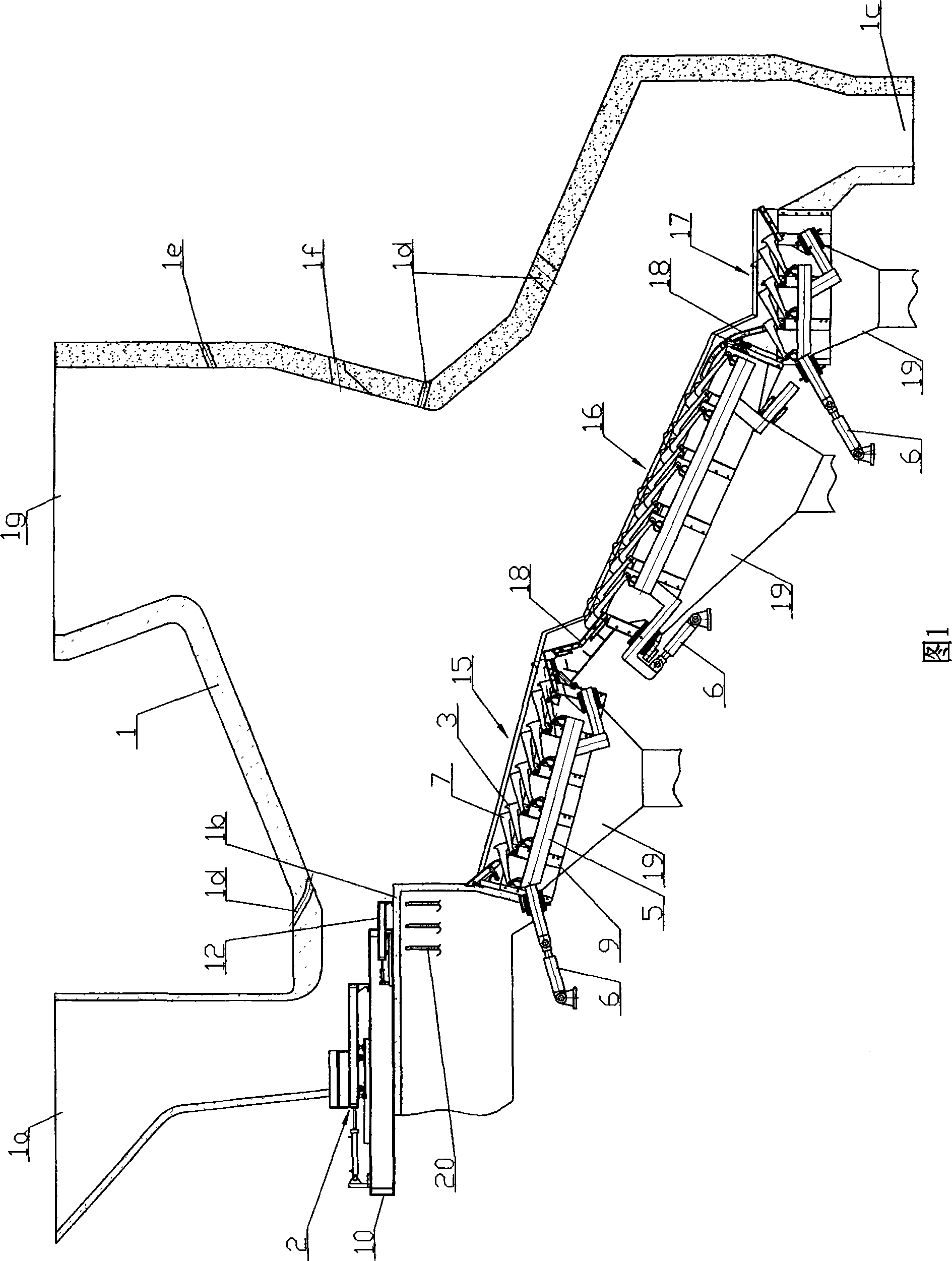

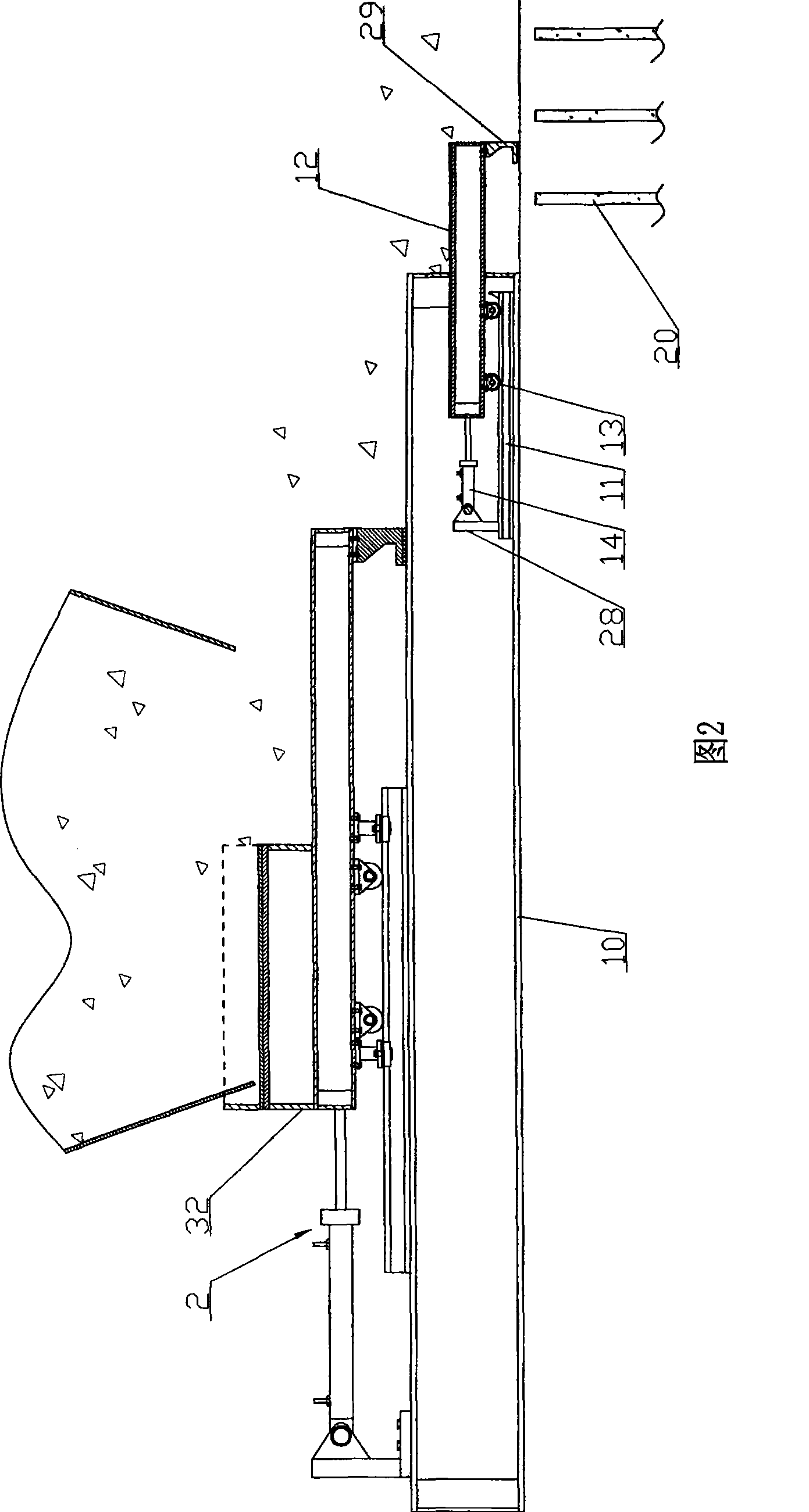

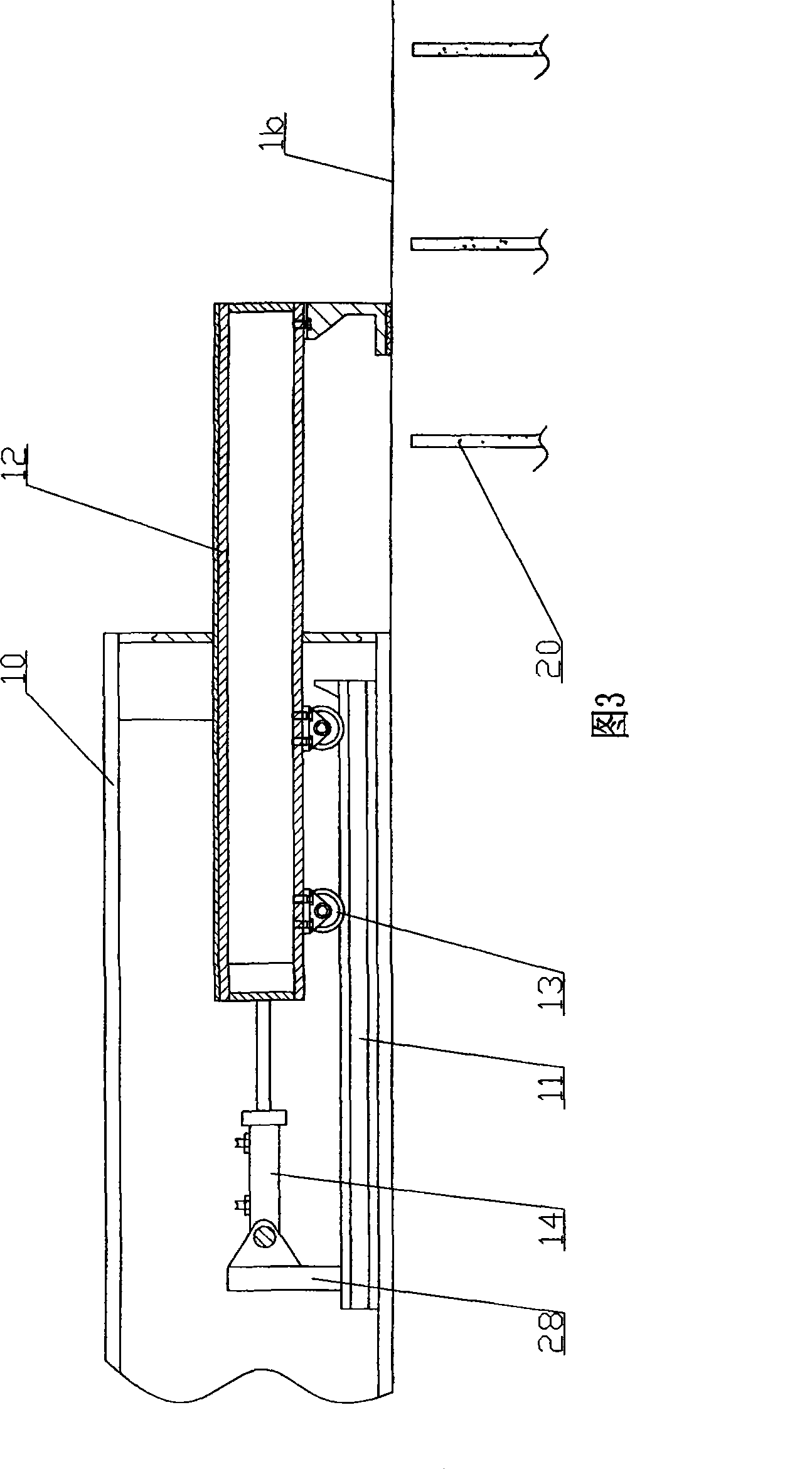

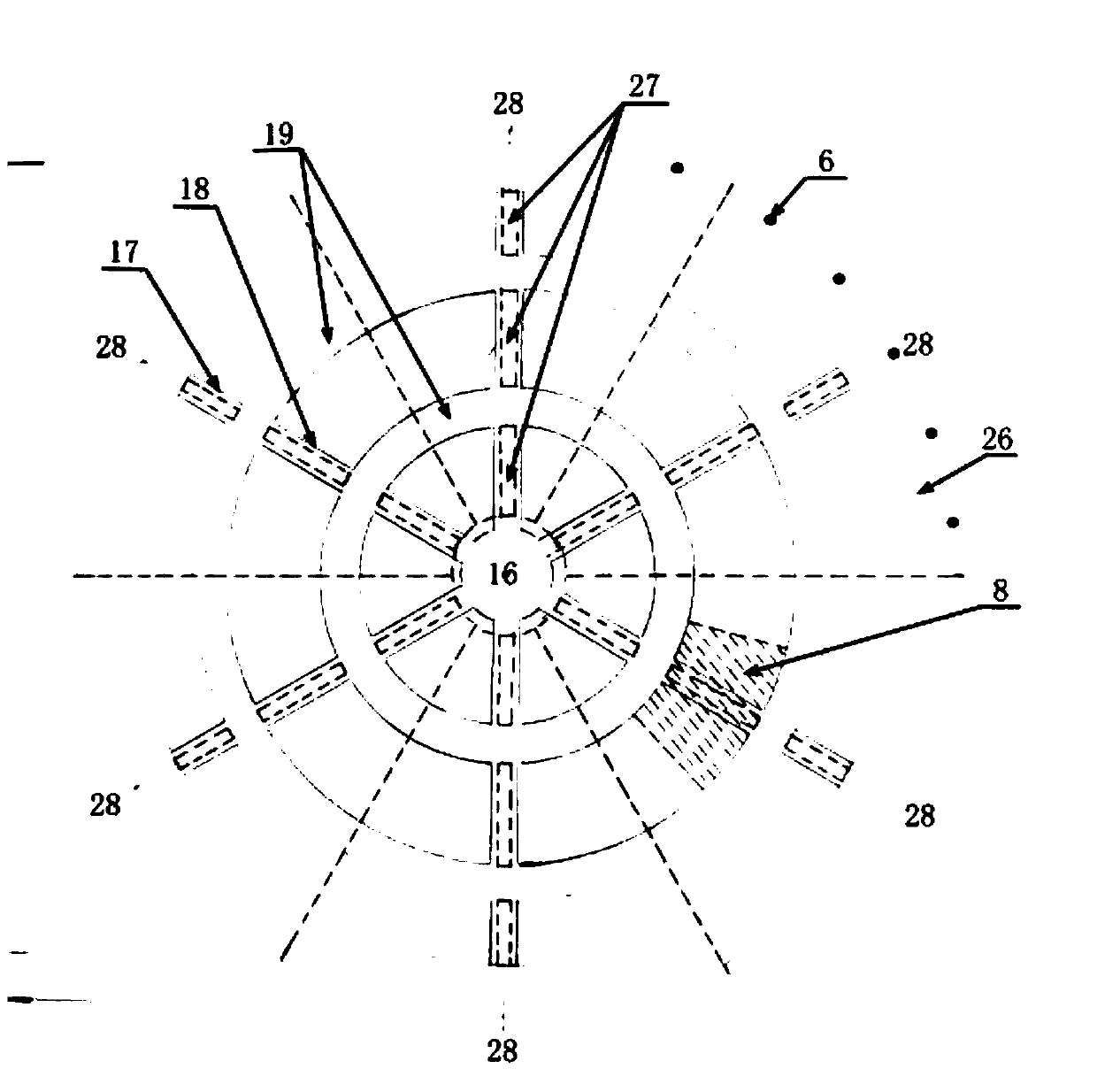

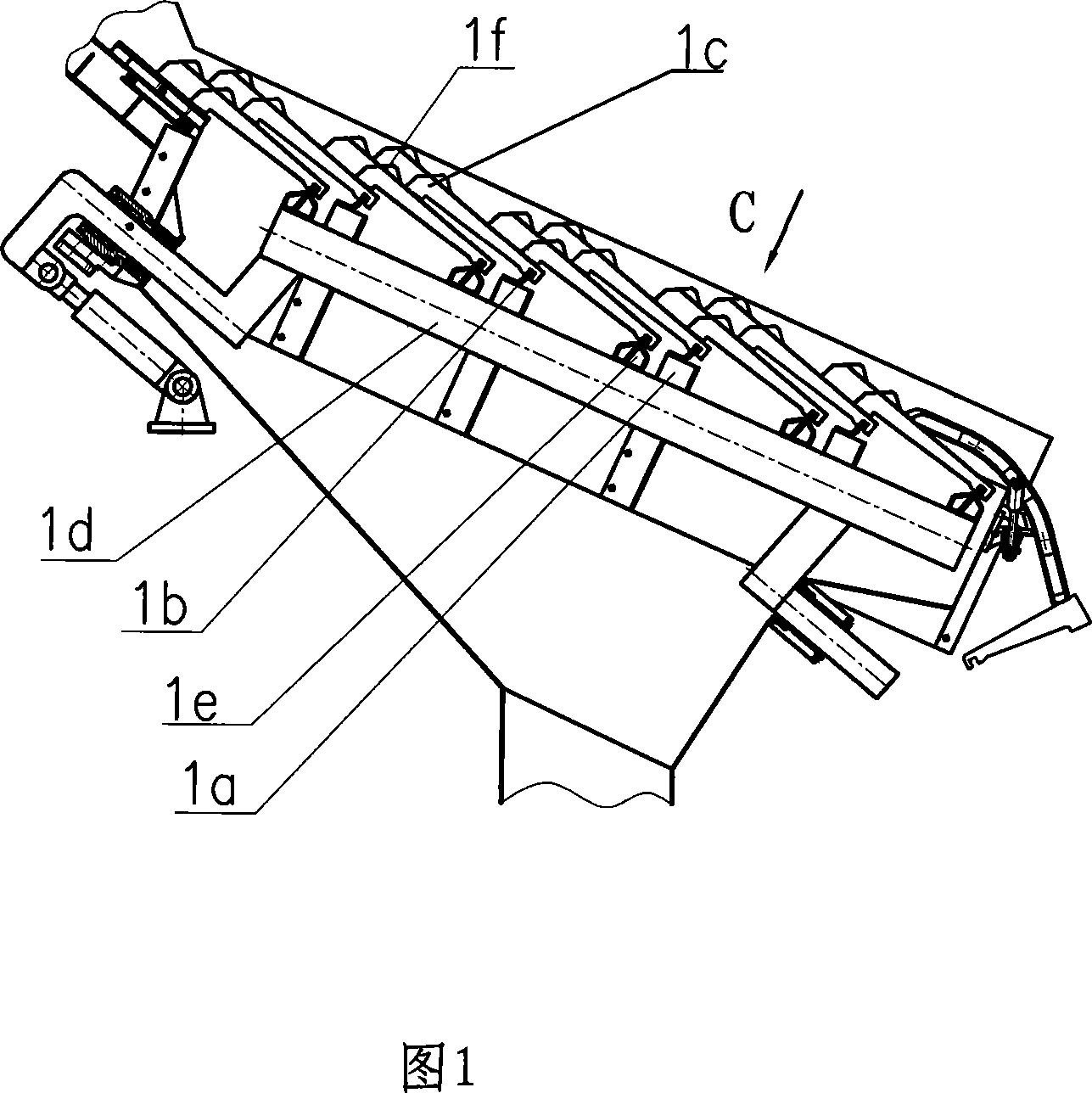

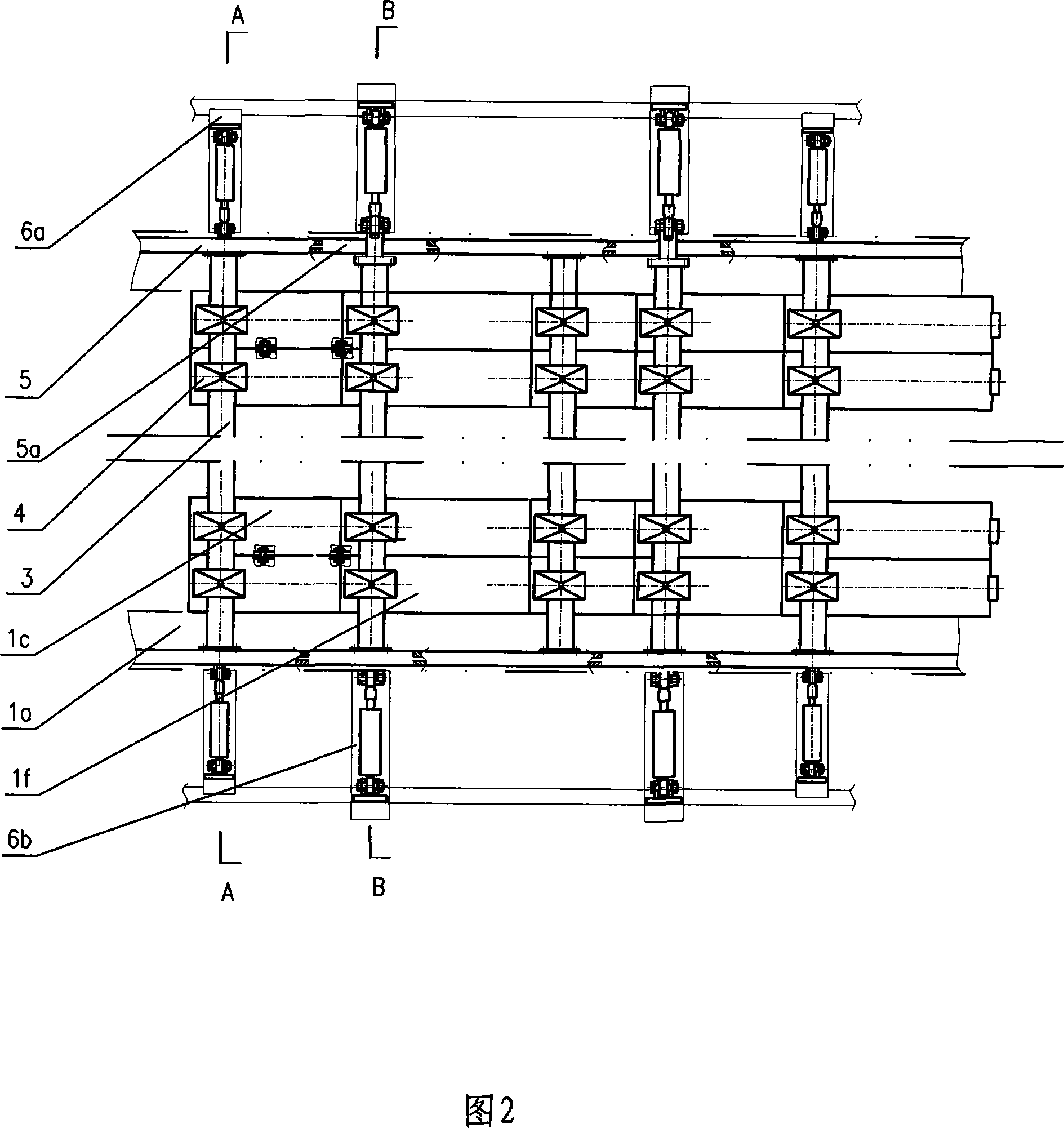

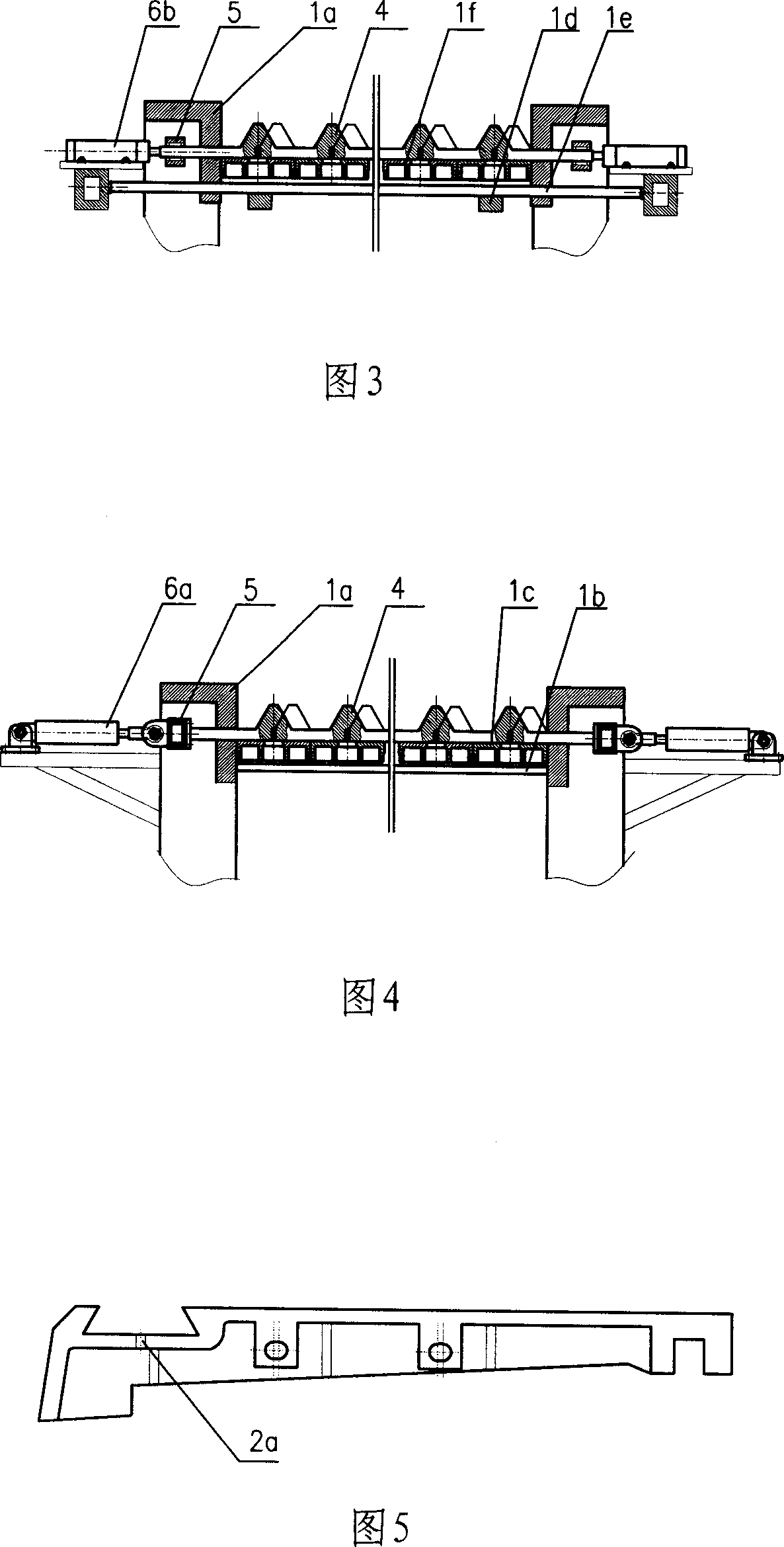

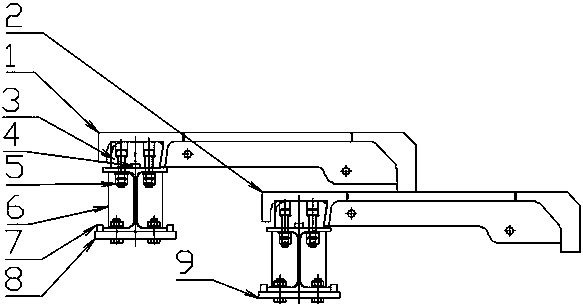

Lateral motion reciprocating fire grate system

InactiveCN101122390AImprove drying efficiencyImprove combustion efficiencyTravelling grateIncinerator apparatusCombustionPiston rod

The invention is a reciprocating furnace grate system provided with a transverse movement. The heat section of the furnace grate is equipped with a dovetail through-groove (2). A connecting rod (3) goes through the same row of dovetail through-groves, and is equipped with bosses (4), the number of which is the same as that of the dovetail through-grooves, and which corresponds to the grooves one by one. Two ends of a connecting rod on a fixed furnace grate plate (1c) are fixed on a push rod (5). A support lug (3a) at the external side of the push rod is connected with a piston rod of a fixed oil cylinder (6), and the fixed oil cylinder (6a) is fixed on a middle beam (1a). Two ends of a connecting rod on a flexible furnace grate plate (1f) go through a bar through-hole (5) respectively and are connected directly with a piston rod of a flexible oil cylinder (6b), which is arranged on a pull rod of the flexible furnace grate. The invention is a reciprocating furnace grate system provided with the transverse movement, and is favorable for breaking up, loosening and mixing of a rubbish layer in an incinerator. Thus, the drying and combustion of rubbish is promoted.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

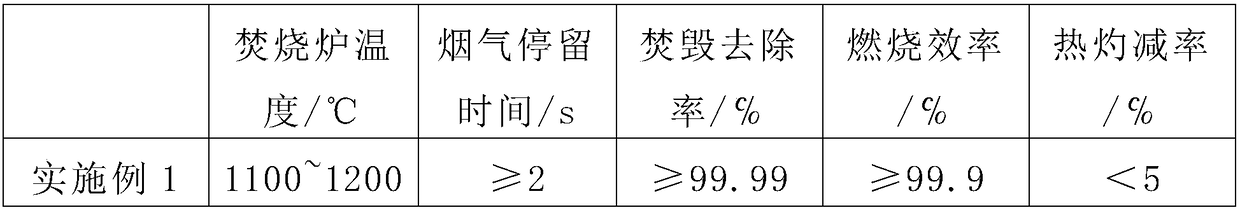

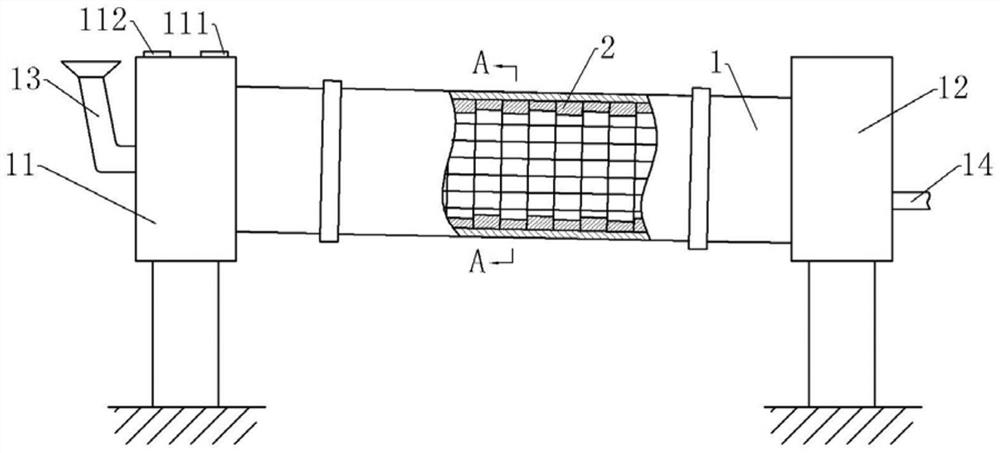

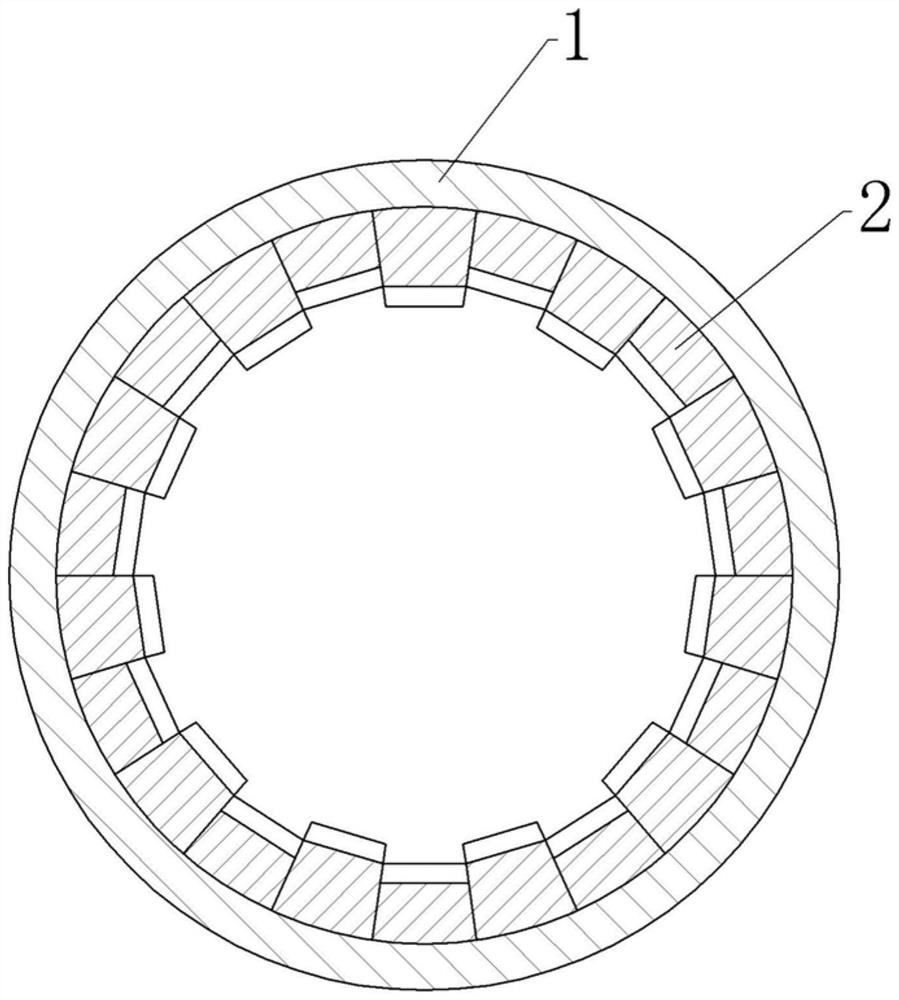

Device for reducing ignition loss rate of incineration residues of hazardous waste incineration rotary kiln

The invention discloses a device for reducing the ignition loss rate of incineration residues of a hazardous waste incineration rotary kiln. The device comprises the hazardous waste incineration rotary kiln, a special carbon residue incineration rotary kiln and a secondary combustion chamber, and the hazardous waste incineration rotary kiln and the special carbon residue incineration rotary kiln have the same structure and each comprise a feeding cover, an inner chamber, a supporting device, a transmission device and a discharging cover, wherein the inner chamber is supported on the supportingdevice, the transmission device drives the inner chamber to rotate, the feeding cover is arranged at the feeding port end of the inner chamber in a sleeving manner, and the discharging cover is arranged at the discharging port end of the inner chamber in a sleeving manner. The discharging cover of the hazardous waste incineration rotary kiln is communicated with the feeding cover of the special carbon residue incineration rotary kiln through a feeding chute; and the discharging covers of the hazardous waste incineration rotary kiln and the special carbon residue incineration rotary kiln are provided with flue gas outlets, and the flue gas outlets of the discharging covers of the hazardous waste incineration rotary kiln and the special carbon residue incineration rotary kiln are communicated with a flue gas inlet of the secondary combustion chamber through flue gas channels. The device is high in waste disposal adaptability, the incineration removal rate is larger than 99.99%, and theslag ignition loss rate is smaller than 5%.

Owner:杭州顶峰环保工程有限公司

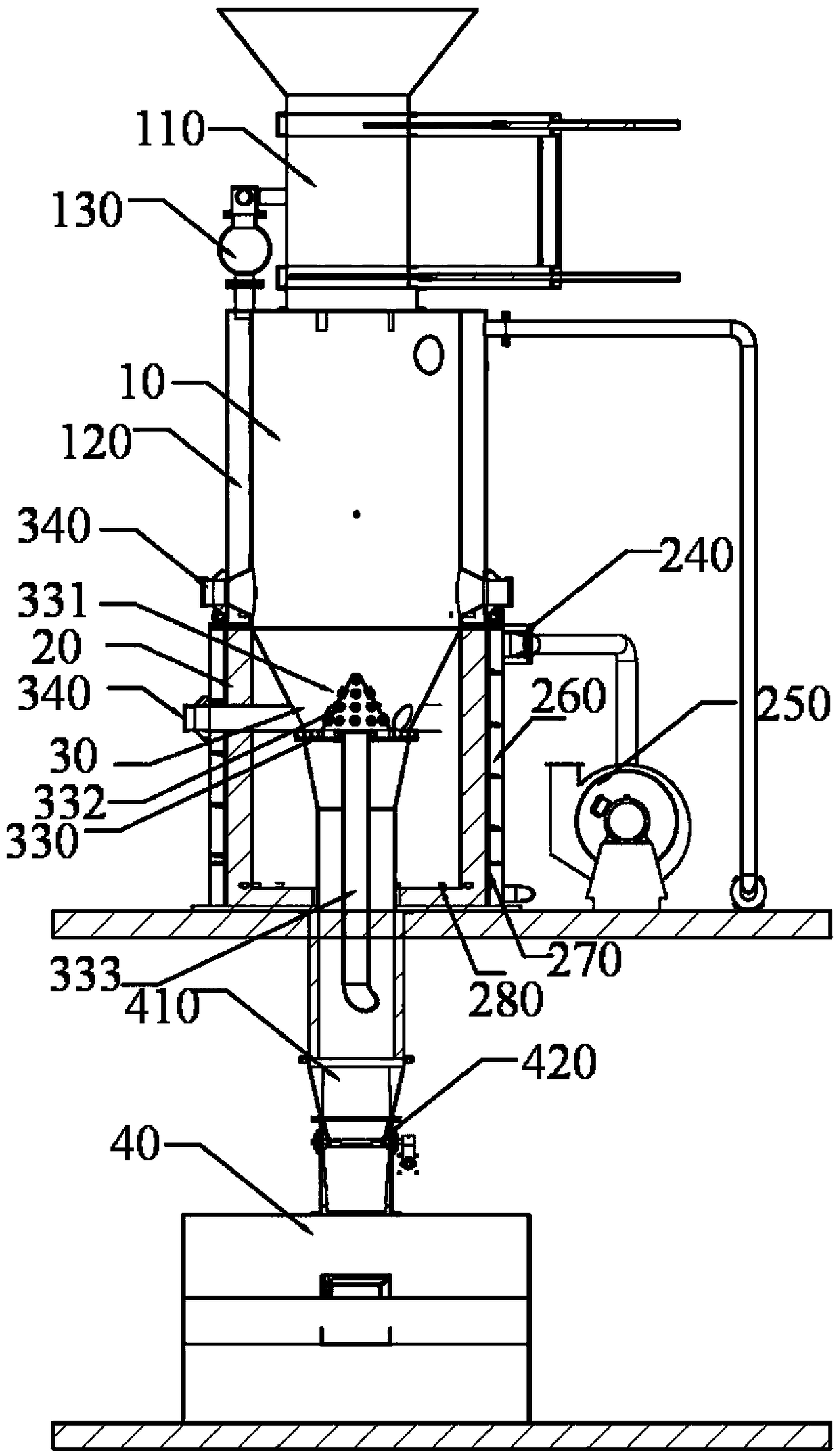

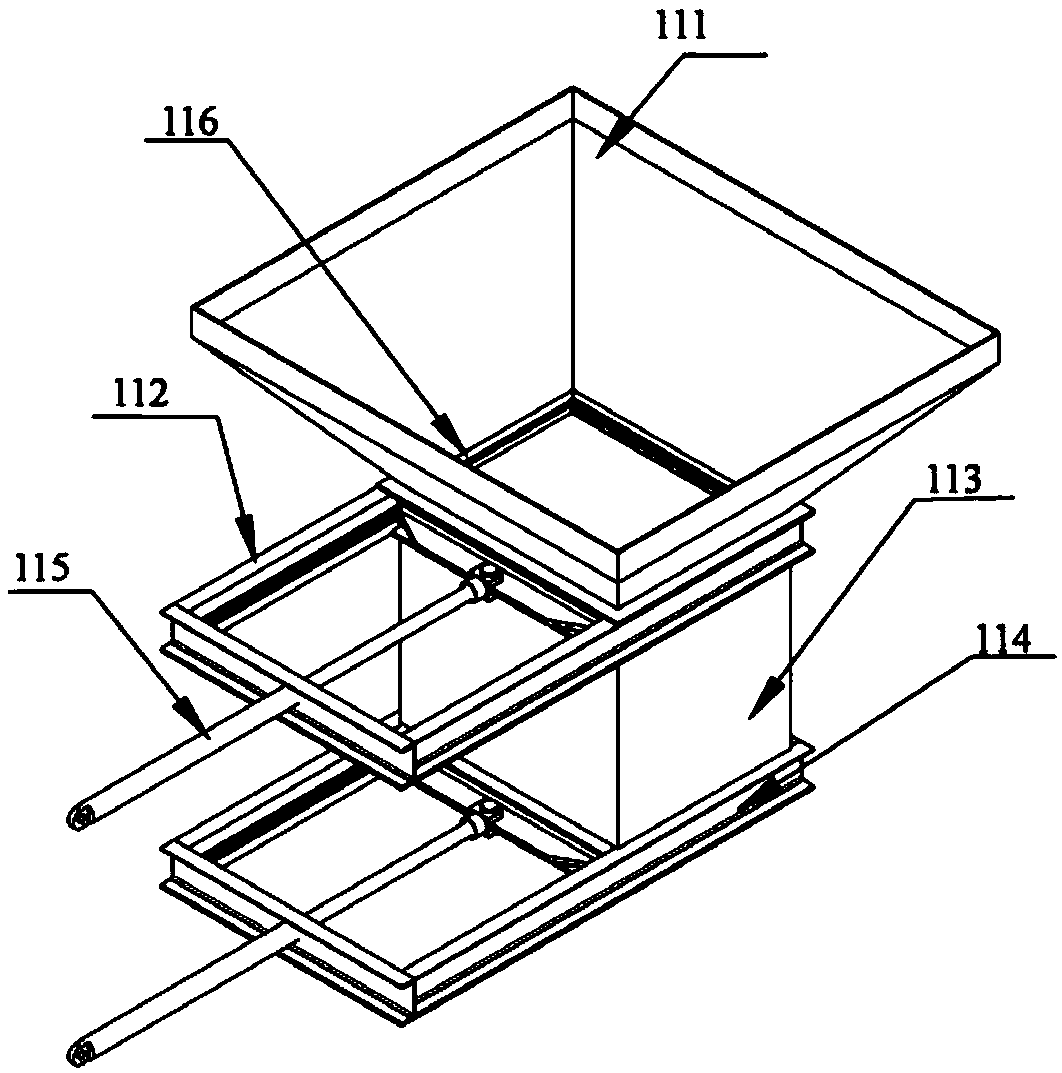

Gas-solid-liquid integrated incineration system

The invention relates to a gas, solid and liquid integrated combustion system, and belongs to the technical field of the environment. The system is composed of a waste gas collection system, a granulation system, a feeding system, a rotating furnace, a combustion furnace, a waste heat boiler, a heat exchanger, a rapid quenching tower, a smoke dry type washing system, a cloth bag dust removal device, a spray tower, a reheater and a chimney. Coal, solid waste and liquid waste are evenly mixed according to the mass ratio (1-12):(2-30):(1-16) in the granulation system for granulation; after collected waste gas is preheated, part of the waste gas enters the rotating furnace, and the other part of the waste gas enters the combustion furnace to be processed through high temperature combustion; high temperature tail gas of the combustion furnace enters the rapid quenching tower, the dry type washing system, the cloth bag dust removal device and the spray tower after heat energy recovery, and is sent to the chimney by a draught fan after the tail gas is cooled and fly ash, dioxin and acid gas are removed, so that emission reaching the standard is completed. Liquid waste produced in the running process of the system is recycled in the granulation system, solid waste such as activated carbon is fed into the rotating furnace to be combusted, and therefore harmless treatment is achieved while running cost of the system is reduced.

Owner:JIANGSU ANQIER WASTE GAS PURIFICATION

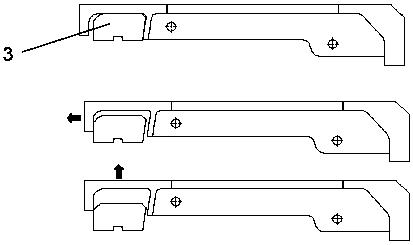

Forward pushing type household garbage incinerator grate

PendingCN112013403AReduce emission concentrationSimple structureDomestic cooling apparatusRevolving gratePollutant emissionsSlide plate

A forward pushing type household garbage incinerator grate comprises a drying area, a first combustion area, a second combustion area and a burnout area. The inclination angle of the portion, in the drying area, of the incinerator grate is 12 degrees to 18 degrees, the inclination angles of the portions, in the combustion areas and the burnout area, of the incinerator grate are 5 degrees to 10 degrees. Each area of the incinerator grate is divided into 1-3 sections in the length direction, is divided into 1-2 air chamber areas in the width direction and is formed by a plurality of driving units. A fall of being about 1m is arranged between every two adjacent sections of incinerator grate, and cooling air is arranged at the fall. Each incinerator grate module comprises a fixing frame, movable beams, static beams, a driving system, a supporting roller, an incinerator grate segment, an incinerator grate segment support and the like. The movable beams and the static beams are alternately arranged in columns, the movable beams are driven by a swing device at the front end to move, and abrasion-resistant sliding plates at the rear ends of the movable beams roll on the supporting rollers.The front ends of the static beams are fixed through hooks, and the rear ends of the static beams are supported and fixed. Each incinerator grate module is independently driven, and a driving deviceis arranged on the outer side of a furnace wall. The forward pushing type household garbage incinerator grate is simple in structure, the primary air distribution is uniform, the combustion process isfully automatically controlled, the long-time continuous stable operation can be achieved, the heat efficiency is improved, and the emission concentration of secondary pollutants is reduced.

Owner:张波

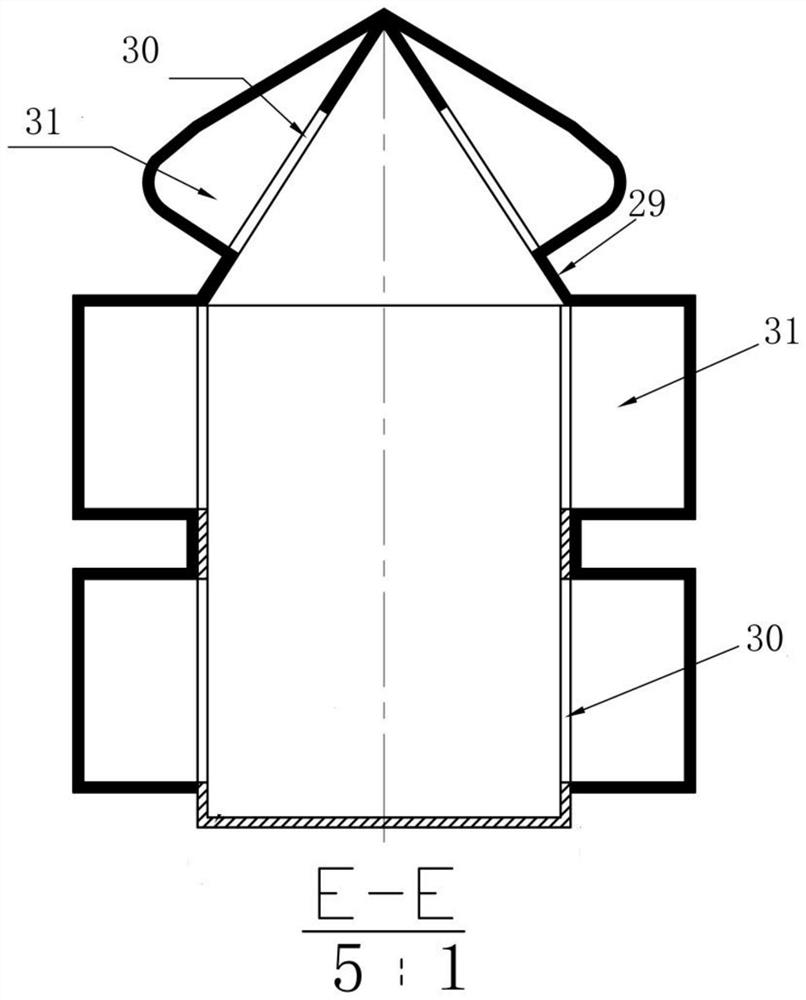

High pressure loss fire grate segment structure device for garbage incinerator

PendingCN107388257ANot easy to warpIncrease contact areaGratesIncinerator apparatusCombustionReciprocating motion

The invention relates to a high pressure loss fire grate segment structure device for a garbage incinerator. The device comprises a fixed fire grate segment and a movable fire grate segment. The fixed fire grate segment and the movable fire grate segment each comprise a fire grate segment supporting block, a supporting block check block, supporting structural steel, a structural steel check block and a base, wherein the supporting structural steel and the structural steel check block are mounted on the base and are fixed through a bolt, and the supporting block and the supporting block check block are arranged on the top of the supporting structural steel, and are fixed through a bolt. Dual supporting parts are arranged on the base of each fire grate segment side by side; the fixed fire grate segment and the movable fire grate segment are arranged in a staggered manner, the base of the movable fire grate segment moves front and back through a drive unit, the movable fire grate segment does front-and-back reciprocated motion from bottom to top, waste moving and turnover can be achieved, the fire grate segment fixing manner is changed, the fire grate segment tail structural manner is improved, it is ensured that a fire grate segment body is not prone to tilting, meanwhile, detaching and overhauling are easy, the fire grate segment air inlet manner is changed, transverse air inlet is uniform, high pressure loss characteristics are formed, and combustion efficiency of the fire grate segment incinerator is improved.

Owner:SHANGHAI ENVIRONMENTAL ENG DESIGN & RES INST CO LTD +1

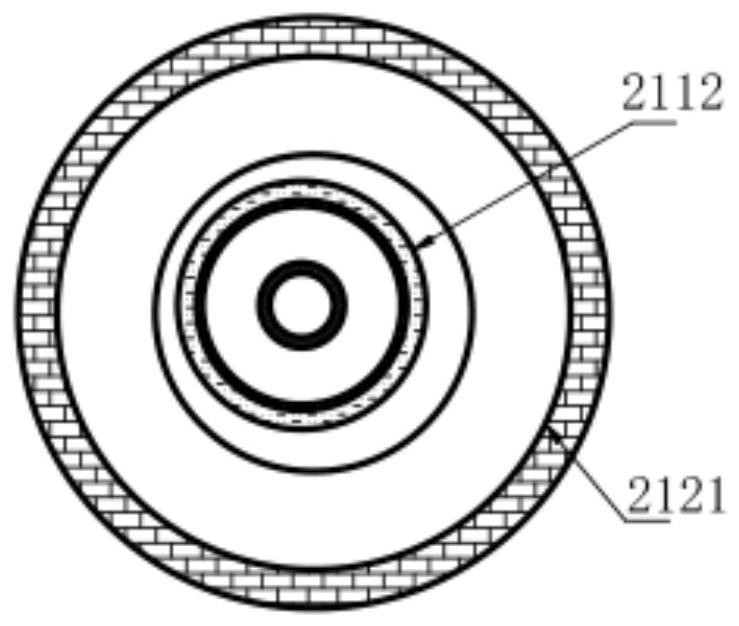

Enamel material resistant to high and low temperature corrosion, its preparation method, application and high temperature boiling rotary grate furnace device

ActiveCN110615615BBurn quicklyIncrease reaction rateIncinerator apparatusAir preheaterCombustion chamber

The invention belongs to the technical field of solid waste incineration engineering for environmental protection and resource utilization, and specifically relates to a high- and low-temperature corrosion-resistant enamel material, its preparation method, application and a high-temperature boiling rotary grate furnace device. The high-temperature boiling rotary grate furnace device of the present invention comprises: a fluidized bed, a garbage feeder is connected to the upper part of one side of the fluidized bed; three combustion chambers and a rotary grate roller are respectively connected to the upper part of the other side of the fluidized bed, and the rotary grate roller is located in the upper part of the fluidized bed. The lower part of the third combustion chamber is connected up and down with the third combustion chamber to reduce the fixed carbon content in the ash entering the rotary grate; the air preheater communicated with the upper part of the third combustion chamber away from the fluidized bed, The air preheater has a flue gas to the aftertreatment port. In the present invention, the boiling section belongs to the fluidized bed, the material can be fully turbulent, the boiling section is high temperature at the temperature of the hot air, the reaction rate is accelerated, the inflammables are rapidly burned, and the inflammable ash residue carbon stays in the rotary grate for a long time. sufficient, reduce carbon residues in ash, and eliminate harmful gas emissions such as dioxins.

Owner:广东生活环境无害化处理中心有限公司

Air distribution system for small household garbage pyrolysis and gasification incinerator and incinerator thereof

PendingCN114508757AImprove responseReduce external energy consumptionIndirect carbon-dioxide mitigationAir/fuel supply for combustionDistribution systemExternal energy

The invention provides an air distribution system for a small household garbage pyrolysis and gasification incinerator. The air distribution system comprises an annular air pipe and an air supply header pipe, and the air supply header pipe is provided with a first air pipe, a second air pipe and a third air pipe. According to the air distribution system for the small household garbage pyrolysis and gasification incinerator, blending combustion air is divided into three paths of air to be actively conveyed to different reaction areas of the hearth so as to maintain garbage reaction, the flow field in the incinerator is actively controlled, and the oxygen supply amount of the corresponding areas can be actively controlled according to the aerobic rule of garbage in the different reaction areas; the stability of a hearth flow field is improved, the reaction process of garbage is optimized, the external energy consumption of various reactions of the garbage and the ignition loss of ash are reduced, the component stability of pyrolysis gas and the operation stability of a secondary combustion chamber are improved, and further treatment of the pyrolysis gas is facilitated; and favorable conditions are created for the incinerator to achieve a better emission level.

Owner:尊峰环保科技有限公司

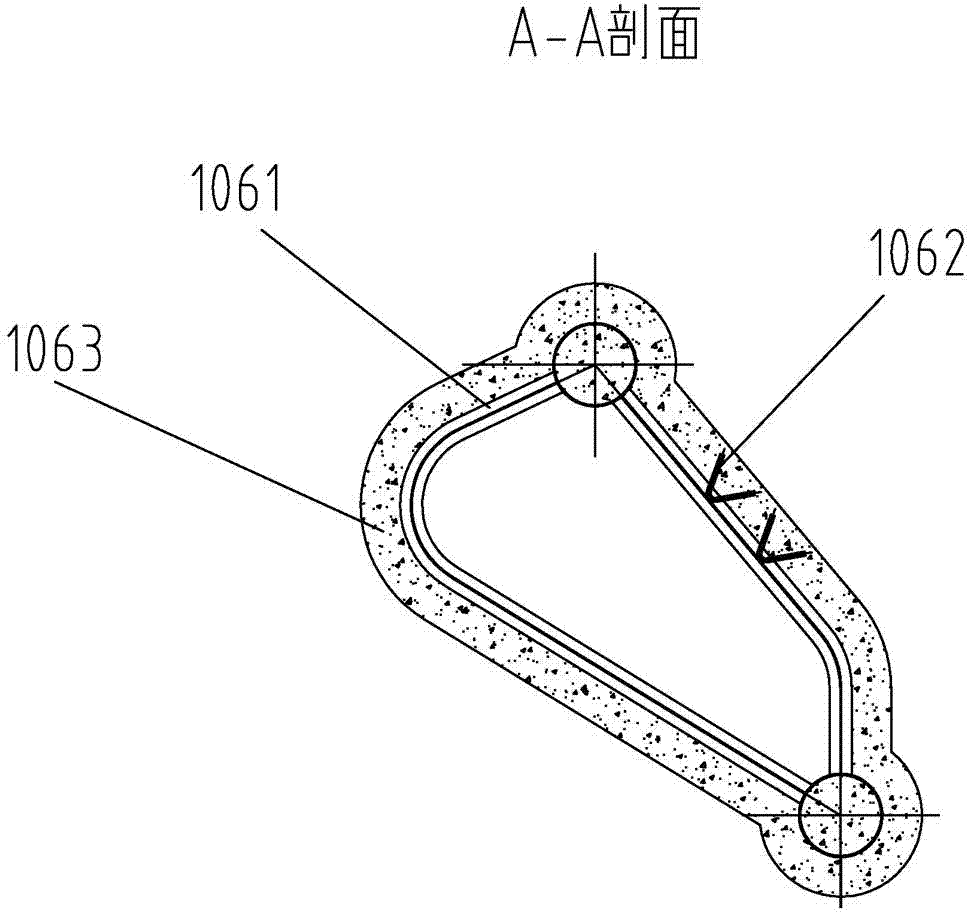

A biomass gasifier grate system

ActiveCN111253981BIncrease effective volumeReduce volumeGasification processes detailsCombustible gas productionThermodynamicsCombustion

Owner:刘跃伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com