Combined type large household garbage incinerator

A domestic waste incineration and combined technology, which is applied in the field of combined large-scale domestic waste incinerators, can solve problems such as being unsuitable for large cities and centralized treatment of domestic waste, easy blockage of the compensation gap of grate pieces, and unstable operation of feeding equipment. Achieve the effect of reducing equipment maintenance costs, avoiding sudden pressure surges, and controlling the on-site operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

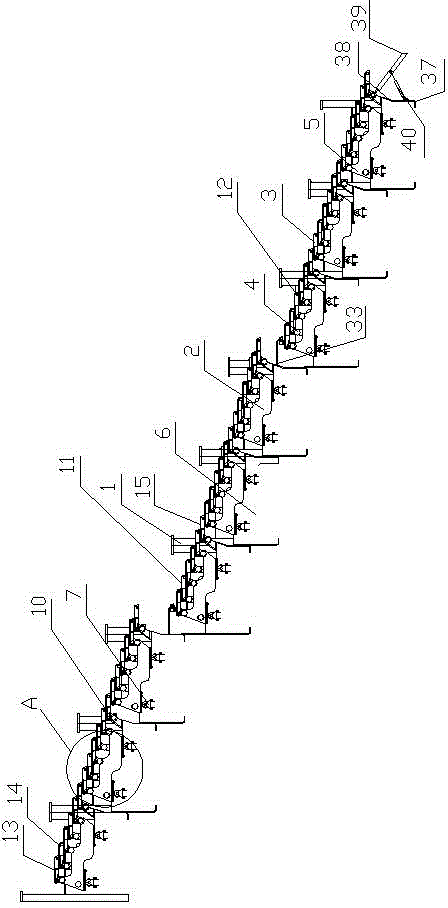

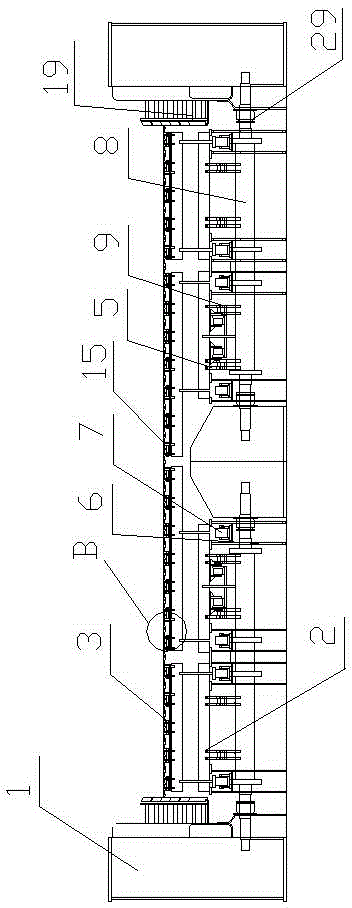

[0031] Such as figure 1 Shown in -5, the present invention comprises main frame 1, and fire grate frame 2 is installed in the main frame 1, and fire grate frame 2 is equipped with fire grate 3.

[0032] The grate frame 2 includes a fixed frame 4, a movable frame 5 and a supporting wallboard 6, the fixed frame 4 is connected with the main frame 1 through the supporting wallboard 6, and the movable frame 5 is slidably installed on the fixed frame 4 through a supporting guide device 7,

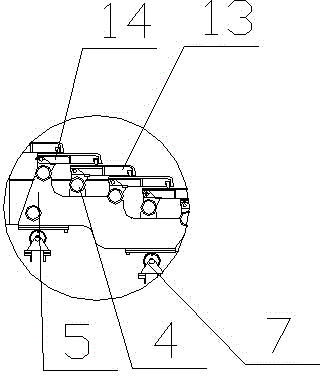

[0033] The fire grate 3 includes a drying section fire grate 10, a combustion section fire grate 11 and a burnout section fire grate 12. With the movable grate 14, the fixed grate 13 and the movable grate are arranged at intervals along the length direction of the grate 14. The fixed grate 13 and the movable grate 14 have the same structure, and are all connected by a plurality of grate pieces 15 along the width direction of the grate 3. As a whole, the ends of adjacent fire grate pieces 28 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com