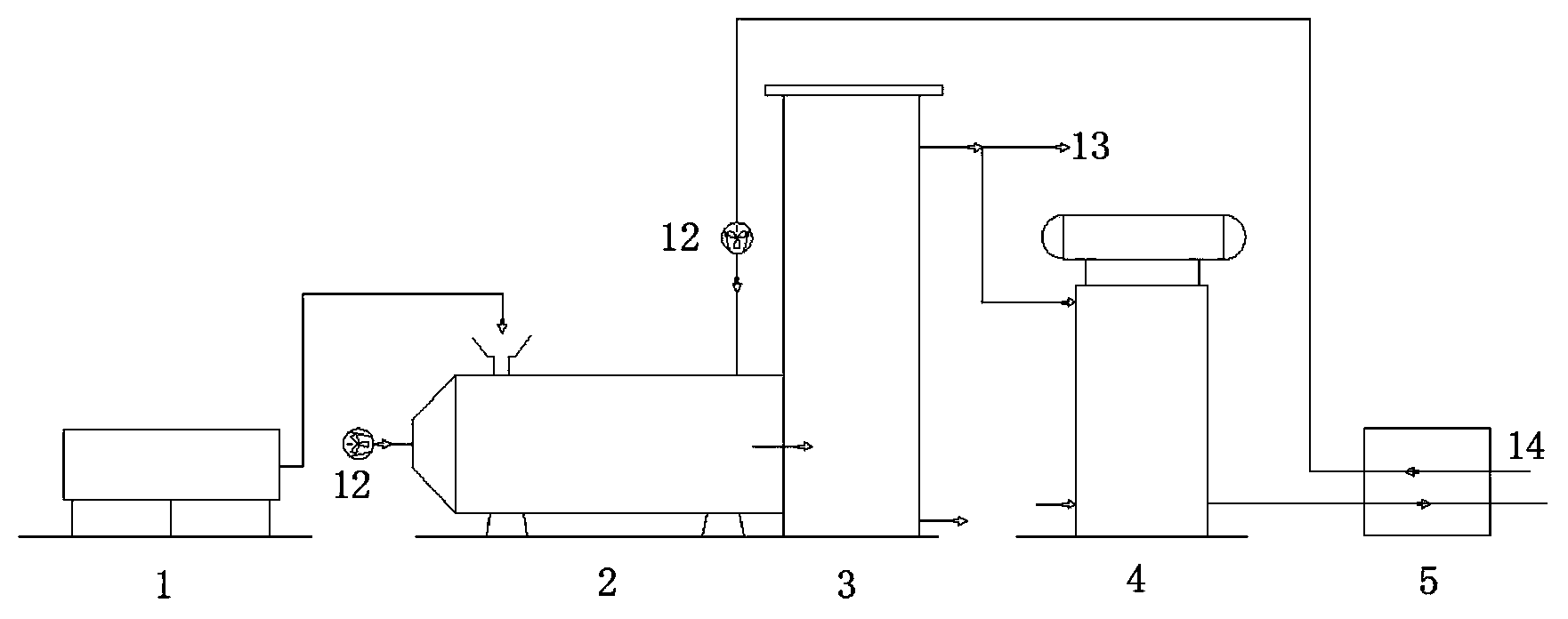

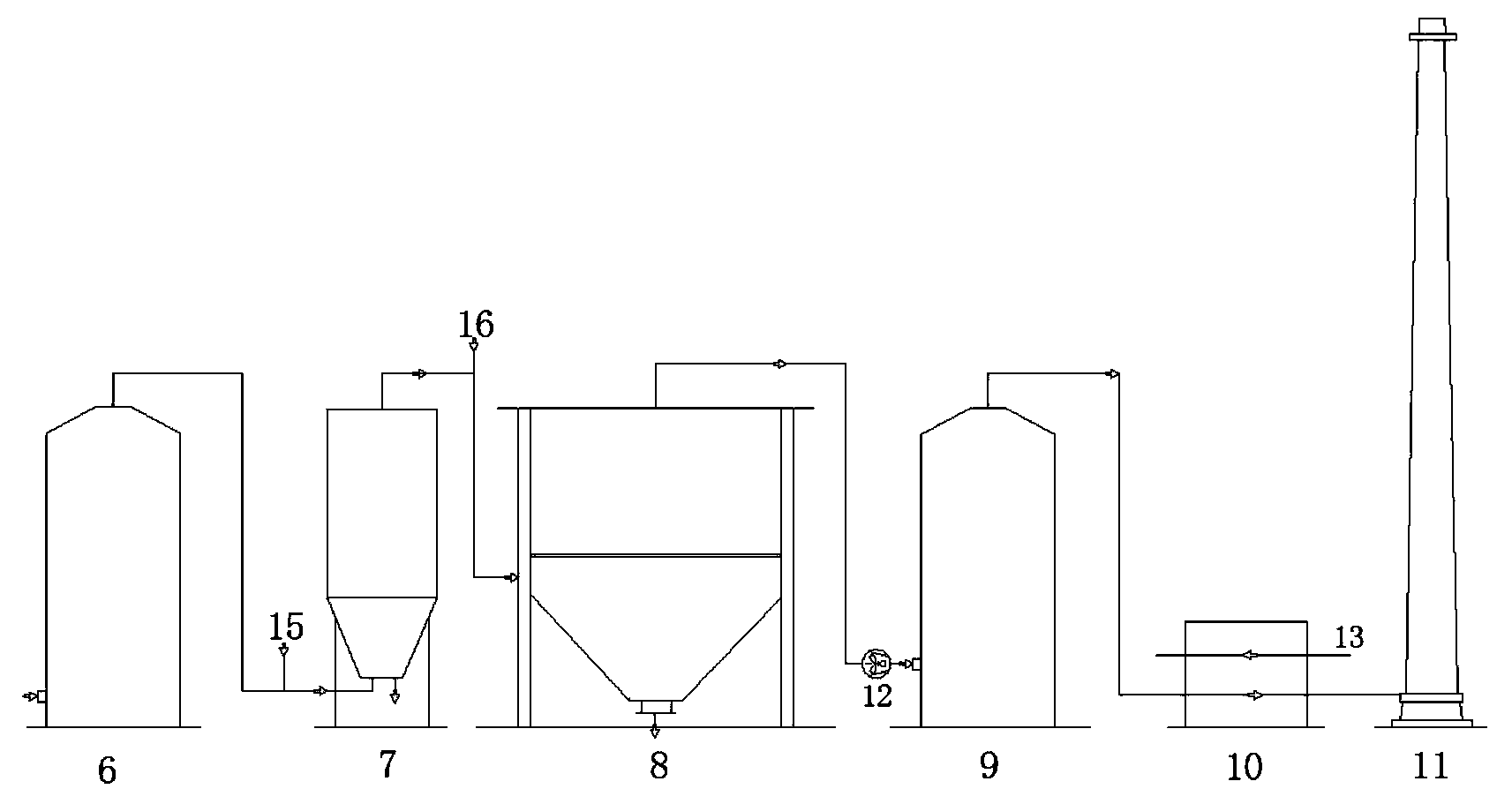

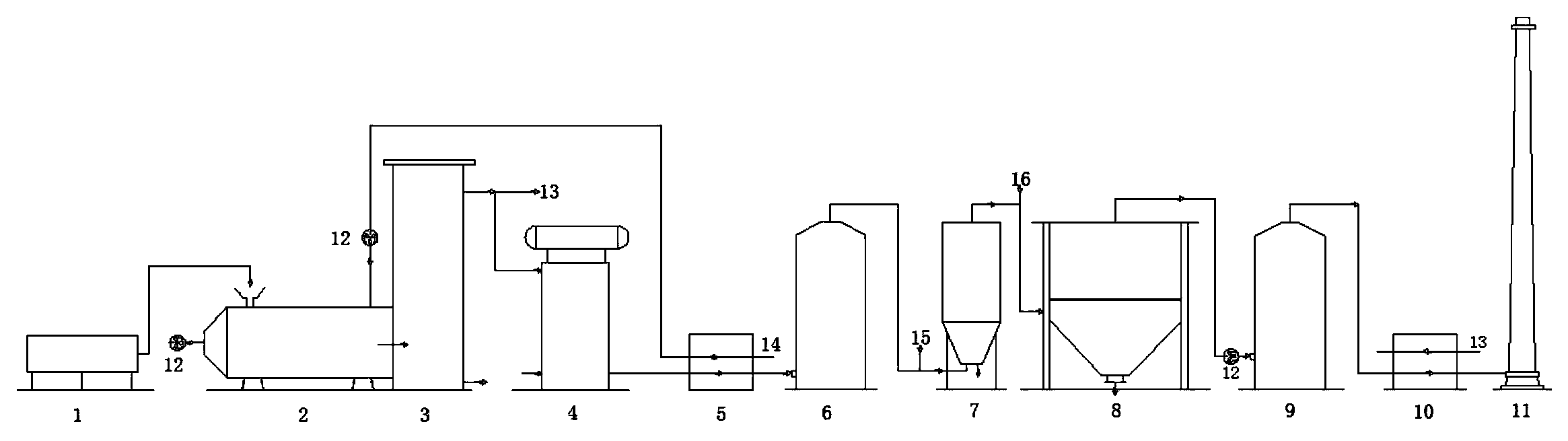

Gas, solid and liquid integrated combustion system

A gas-solid-liquid and incinerator technology, applied in the environmental field, can solve the problems of inability to stably reach the standard operation, difficult waste liquid treatment, and high one-time investment, and achieve the effect of facilitating granulation, reducing the rate of hot ignition and reducing investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The pulverizer breaks up the coal and solid waste, and the mixer dilutes the viscous waste liquid and mixes it evenly. The coal-solid waste-waste liquid is in a specific mass ratio of (1-12):(2-7):(1-4) It is made into a regular shape in the granulator and is hydraulically pushed to the kiln head of the rotary furnace.

Embodiment 2

[0035] The crusher breaks up the coal and solid waste, and the mixer dilutes the viscous waste liquid and mixes it evenly. The coal-solid waste-waste liquid has a specific mass ratio of (1-12):(7-13):(4-7) It is made into a regular shape in the granulator and is hydraulically pushed to the kiln head of the rotary furnace.

Embodiment 3

[0037] The pulverizer breaks up the coal and solid waste, and the mixer dilutes the viscous waste liquid and mixes it evenly. The coal-solid waste-waste liquid has a specific mass ratio of (1-12):(13-19):(7-10) It is made into a regular shape in the granulator and is hydraulically pushed to the kiln head of the rotary furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com