Forward pushing type household garbage incinerator grate

A domestic waste incineration and forward push technology, which is applied in incinerators, rotary grate, shaking grate, etc., can solve the problems of increasing slag leakage, destroying refractory materials, and increasing the rate of slag on ignition. To achieve uniform distribution of primary air, ensure the combustion effect, and reduce the effect of burning reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

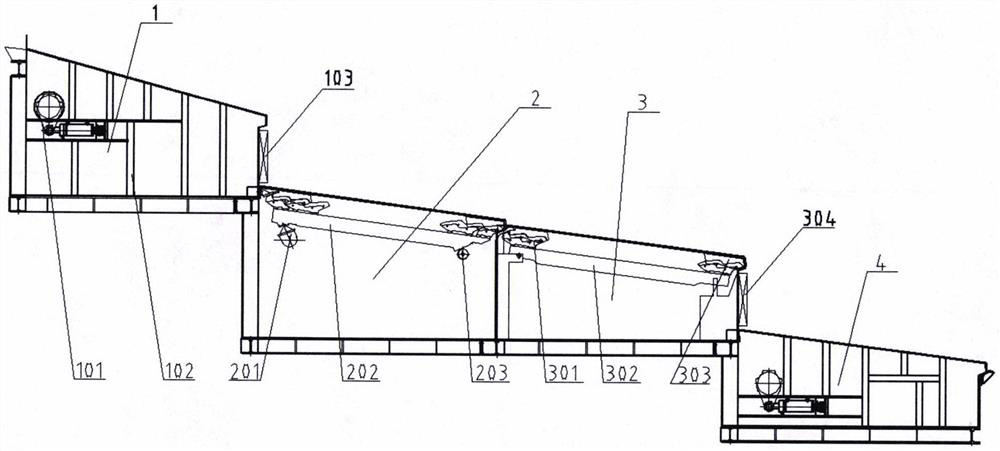

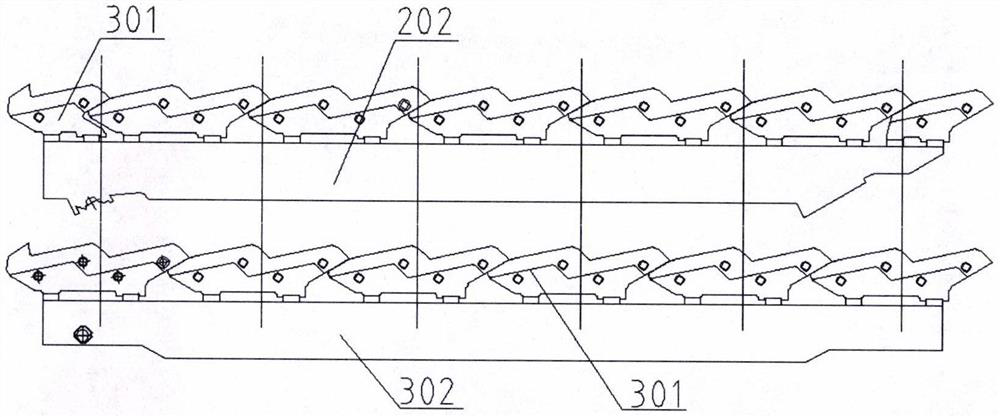

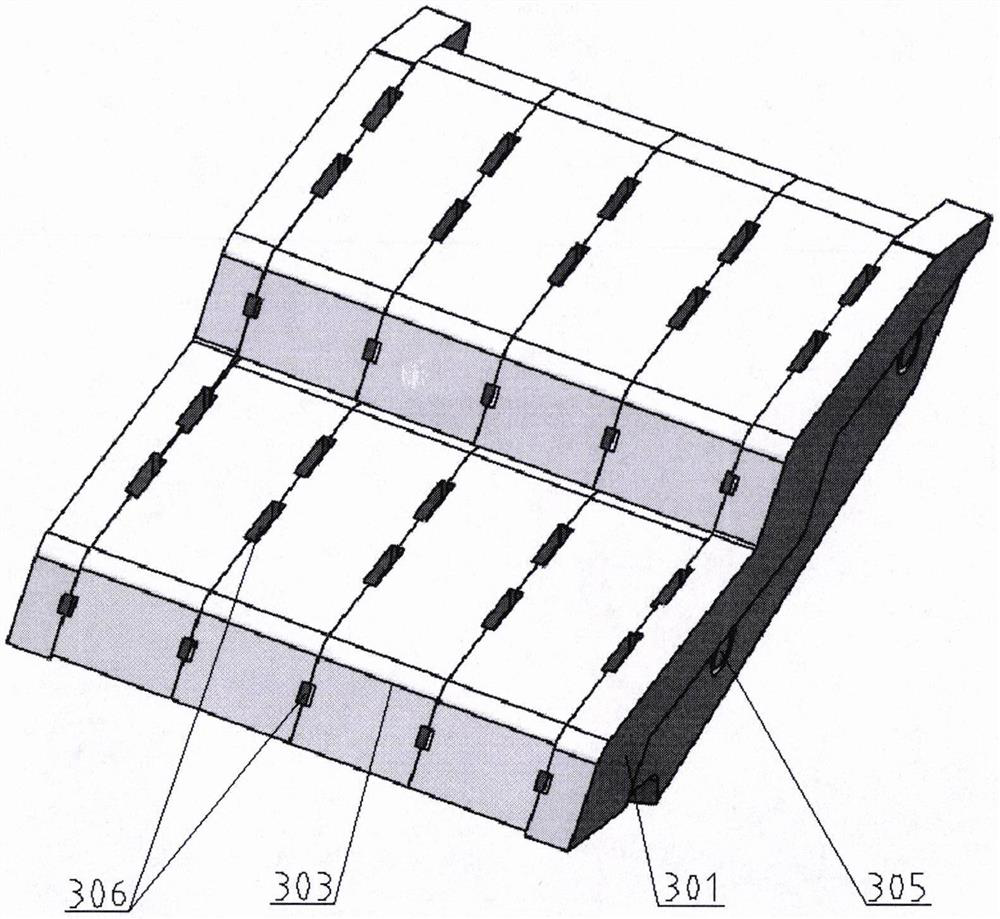

[0031] like figure 1 As shown, the forward-push grate is divided into four sections, which are the drying zone 1, the first combustion zone 2, the second combustion zone 3 and the burning zone 4, among which the drying zone and the burning zone, the burning zone and the burning zone Set the drop between zones. Each section of grate is provided with a swing device 201, a moving beam 202, a support roller 203, a grate piece support 301, a static beam 302 and a fire grate piece 303, wherein the moving beam 202 and the static beam 302 are alternately arranged in a row. The driving devices of each section of the grate are set independently. Taking the drying area 1 as an example, it drives the moving beam 202 to reciprocate along the garbage conveying direction under the action of the side driving device 101 and the swinging device 201 of the grate. The front end of the moving beam 202 is in the The swing device 201 swings back and forth under the action of the moving beam 202. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com