Solid waste gasifying system and solid waste gasifying method

A technology of waste gas and furnace body, which is applied in the solid waste gasification system and its gasification field based on the enhanced reaction of high temperature superheated steam, can solve the problems of pollution, heavy metal and fly ash discharge secondary environment, etc. The effect of increasing the rate and strengthening the dry distillation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

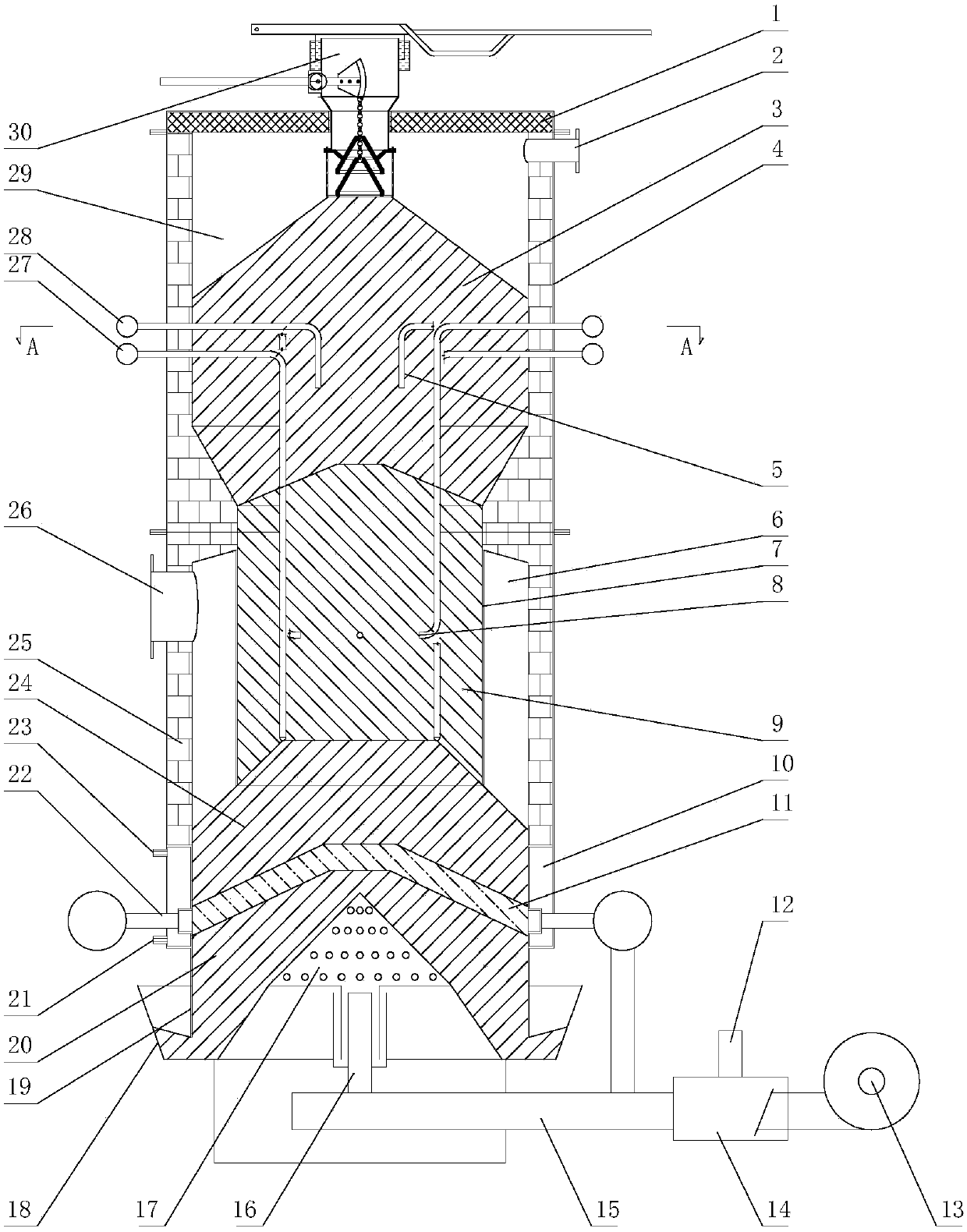

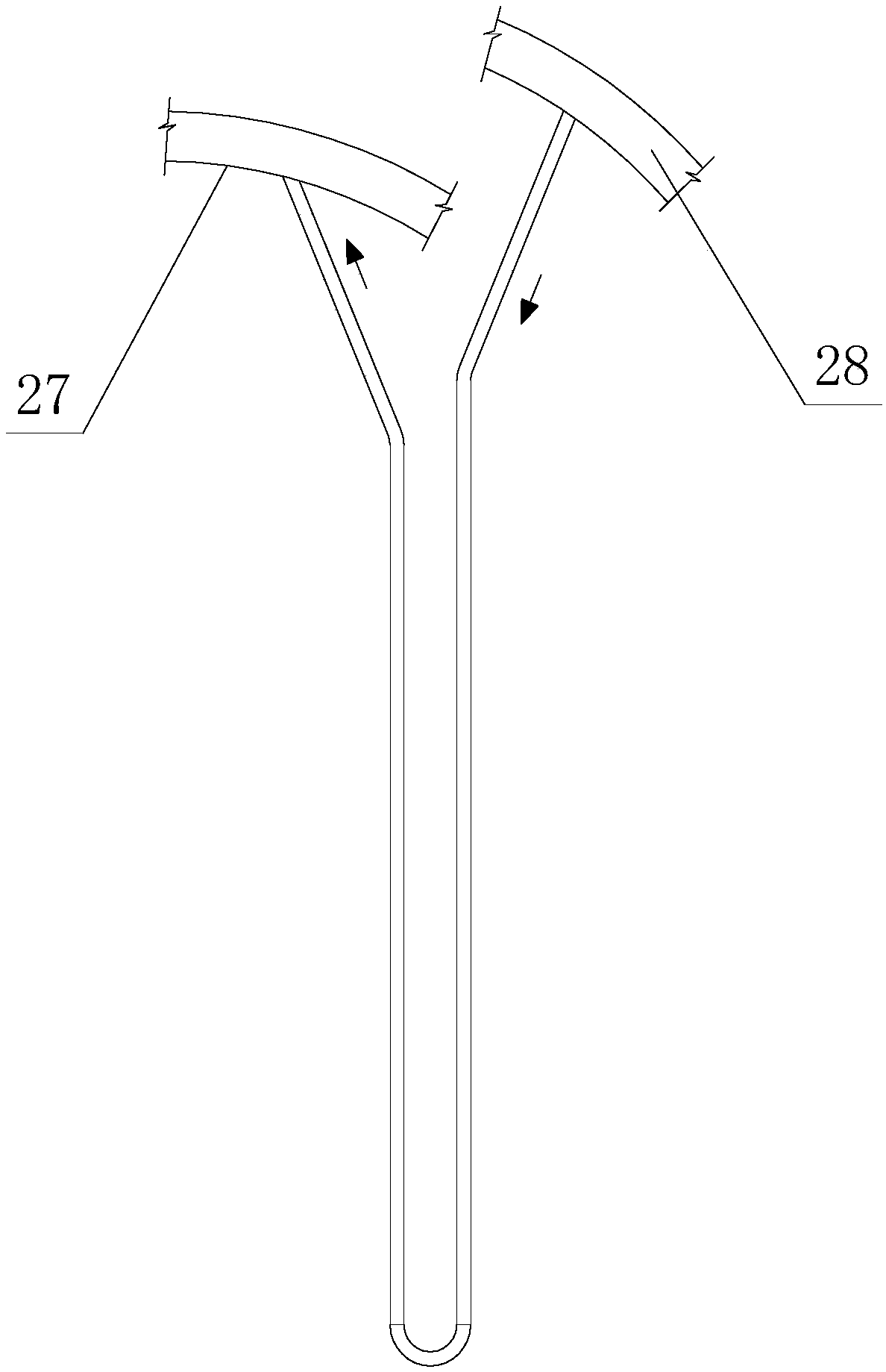

[0046] Such as figure 1 , 2 As shown in and 3, a solid waste gasification system includes a top cover 1, a furnace body 4, a water jacket 10, a furnace skirt 19, a sealed feed mechanism 30, an air distribution mechanism 17, a slag discharge mechanism 18, a retort gas outlet 2, Reducing gas outlet 26, primary air inlet 16, secondary air inlet 22, downcomer connection 21, steam rising pipe connection 23, dry distillation cylinder 7, furnace wall 25, high-temperature steam outlet 27 and high-temperature steam inlet 28; furnace wall 25 masonry Inside the furnace body 4, it belongs to the furnace building process category of known technology in the industry. The top of the furnace body 4 is provided with a top cover 1, and the bottom and the ash tray of the slag discharge mechanism 18 form a rotating pair; a sealed feeding mechanism 30 is arranged on the top cover 1; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com