Continuous preparing method for petroleum sulfosalt

A petroleum sulfonate and sulfonating agent technology, applied in organic chemistry and other fields, can solve problems such as heavy fraction of raw oil, uneven reactor wall, and difficult flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

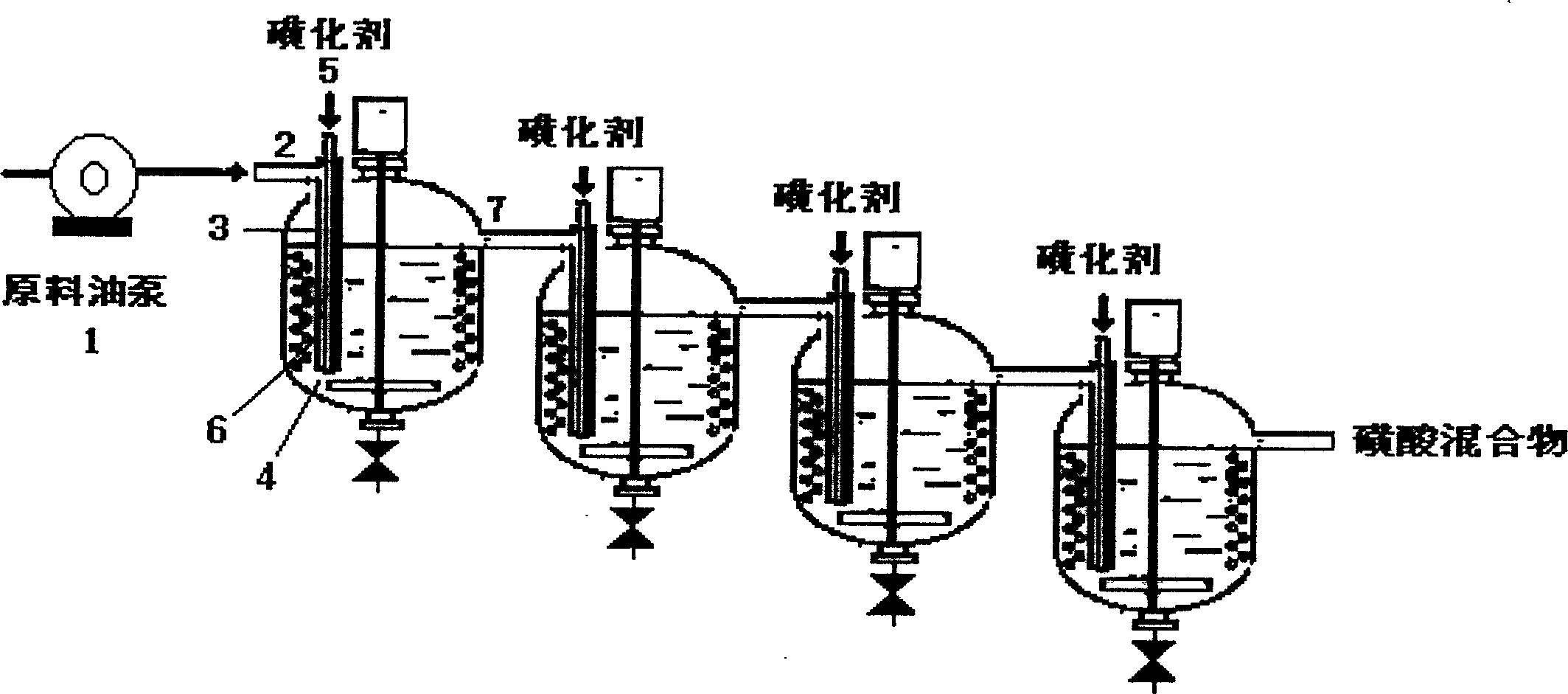

Method used

Image

Examples

example 1

[0019] The raw material oil is straight run oil of Gudao crude oil, the sum of aromatics and colloid content (measured by column separation method) is 41.2%, and the freezing point and boiling point range are shown in Table 1. A 2:1 mixture (weight ratio) of raw oil and dichloroethane is injected into the first sulfonation reactor with a flow rate of 1800 g / hr by a metering pump. The sulfonating agent is a 25% sulfur trioxide solution diluted with dichloroethane, which is sent into the first to the fourth sulfonation reactors with a ratio of 40:25:25:10 with a metering pump, and the total flow is 1296g / h (sulfur trioxide: raw oil=0.27, weight ratio). The temperature of the first to fourth sulfonation reactors is controlled at -5°C, +5°C, +5°C and +15°C respectively, and the total residence time of materials in the four sulfonation reactors is 2hr. After the material flowing out of the device is neutralized with ammonia water to pH = 7, it is distilled at 130°C, the water is ...

Embodiment 2

[0022] The raw material oil is the aromatic fraction extracted from Liaohe crude oil, the sum of aromatic hydrocarbon and colloid content (measured by column separation method) is 75.7%, and the freezing point and boiling point range are shown in Table 1. The mixture of raw oil and dichloroethane (2:1, weight ratio) is injected into the first sulfonation reactor with a metering pump, and the flow rate is 1800g / hr. The sulfonating agent is a 25% sulfur trioxide solution diluted with dichloroethane, which is sent into the first to the fourth sulfonation reactors with a ratio of 40:25:25:10 with a metering pump, and the total flow is 1728g / hr (sulfur trioxide: raw oil = 0.36, weight ratio). The temperatures of the first to fourth sulfonation reactors are all controlled at +5°C. All the other steps obtain the sulfonate product by example 1, and test the oil-water interfacial tension by the steps described in example 1 with the XZD-3 type interfacial tensiometer. The results are...

Embodiment 3

[0024] The feedstock oil is the aromatic fraction extracted from the third-line fraction of Iranian crude oil. The sum of aromatic hydrocarbon and colloid content (measured by column separation method) is 69.1%. The freezing point and boiling point range are shown in Table 1. The mixture of raw oil and dichloroethane (2:1, weight ratio) is injected into the first sulfonation reactor with a metering pump, and the flow rate is 1800g / hr. The sulfonating agent is a 25% sulfur trioxide solution diluted with dichloroethane, which is sent into the first to the fourth sulfonation reactors with a ratio of 50:20:20:10 with a metering pump, and the total flow is 1440g / hr (sulfur trioxide: raw oil = 0.30, weight ratio). All the other steps obtain the sulfonate product by example 1, and test the oil-water interfacial tension by the steps described in example 1 with the XZD-3 type interfacial tensiometer. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com