Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Guaranteed combustion quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

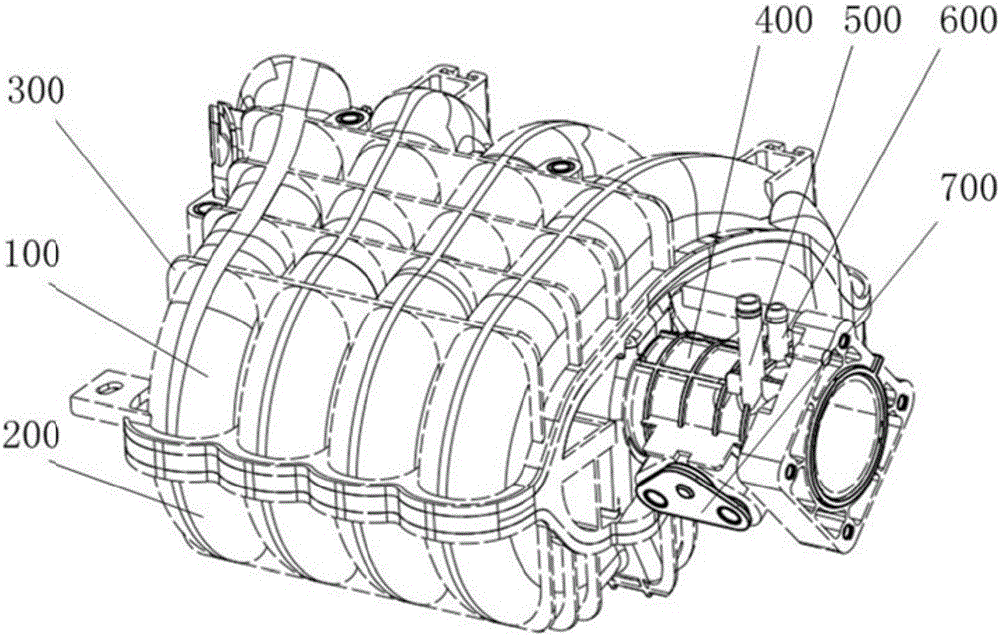

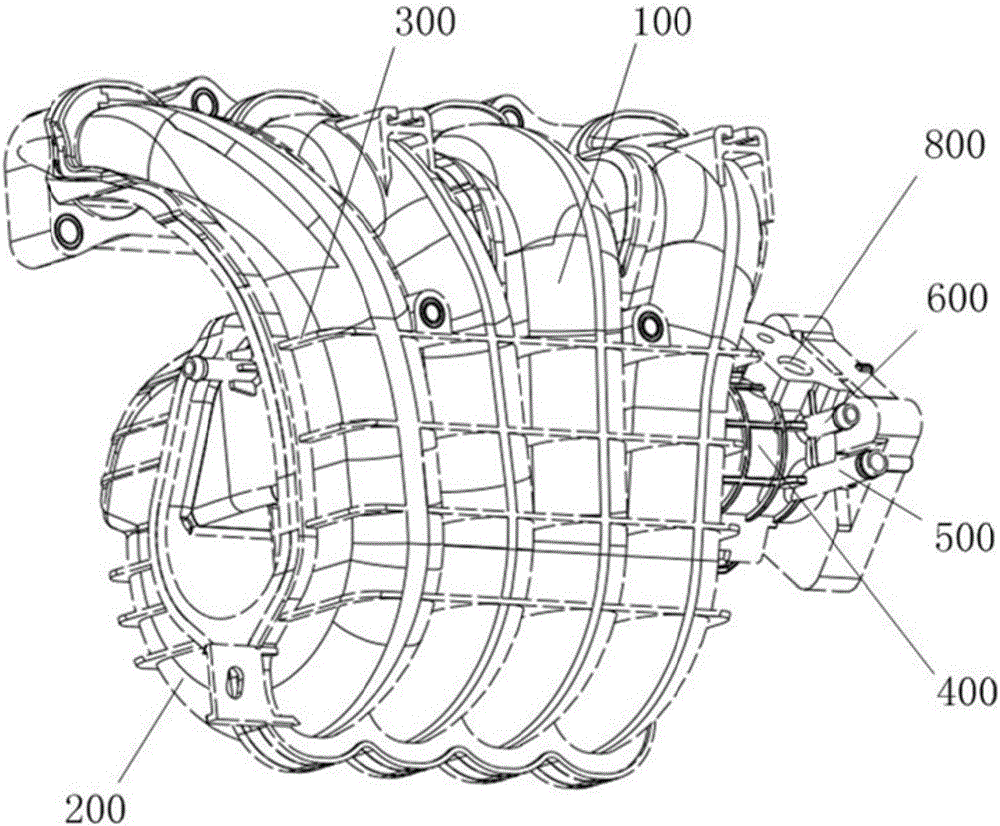

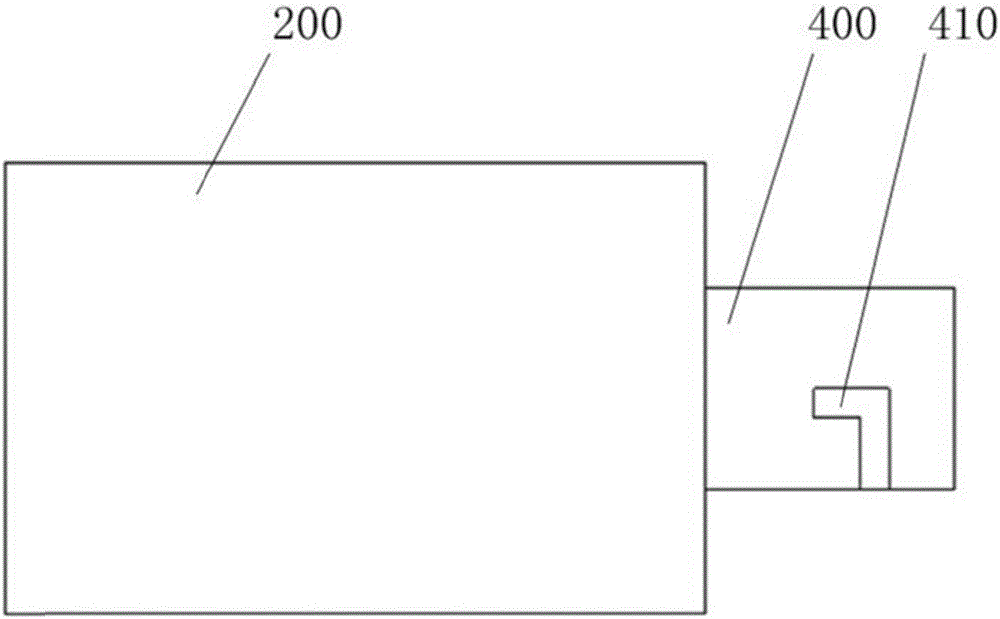

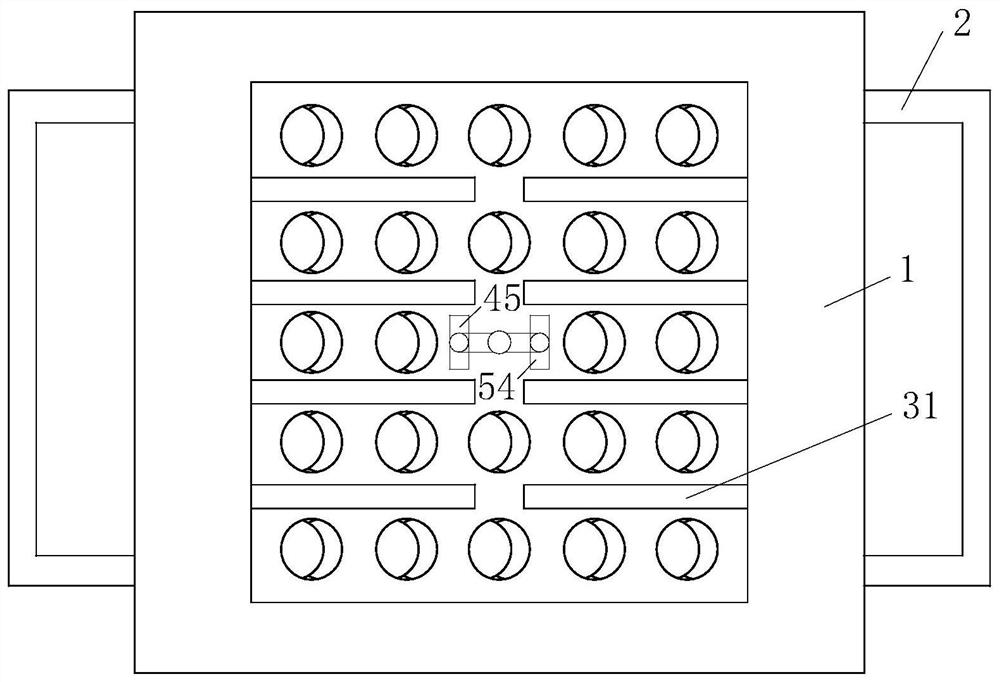

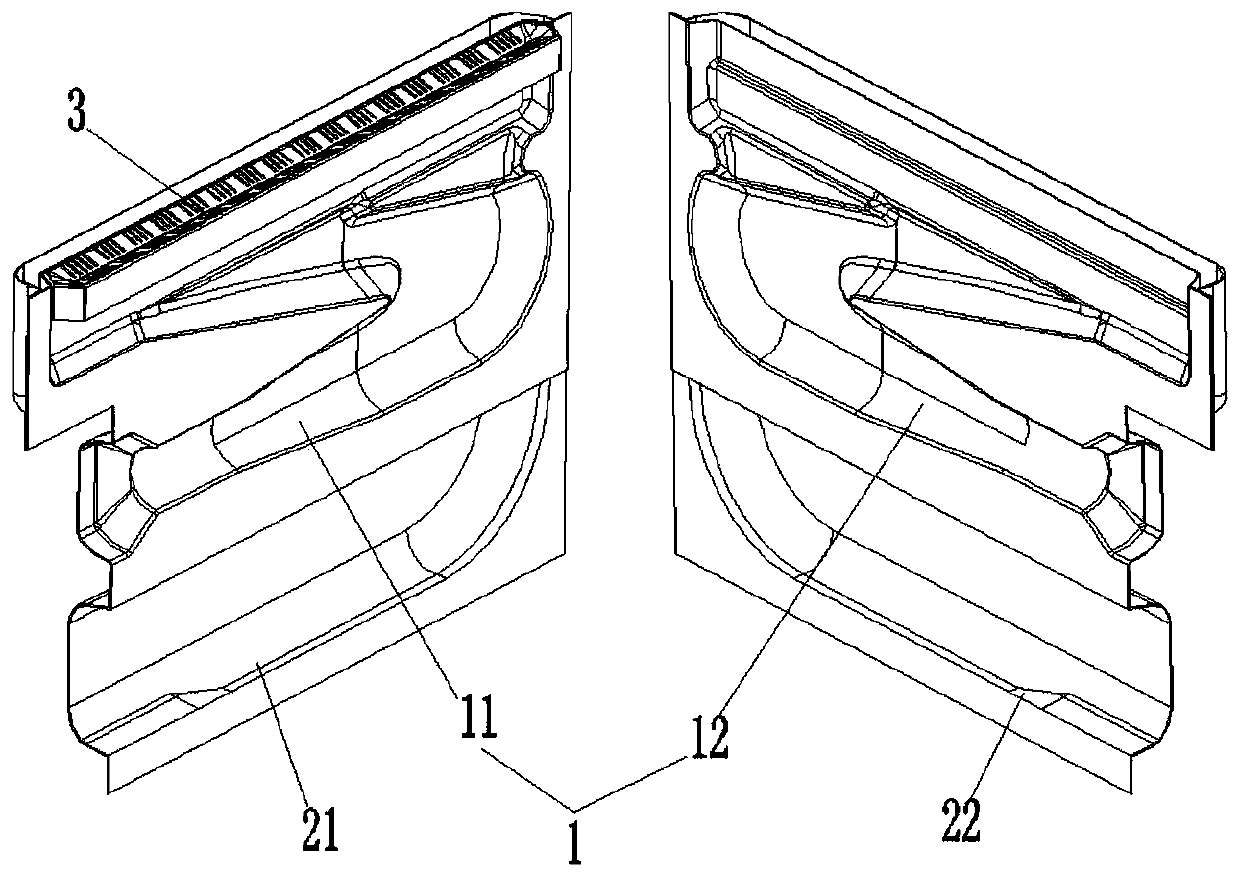

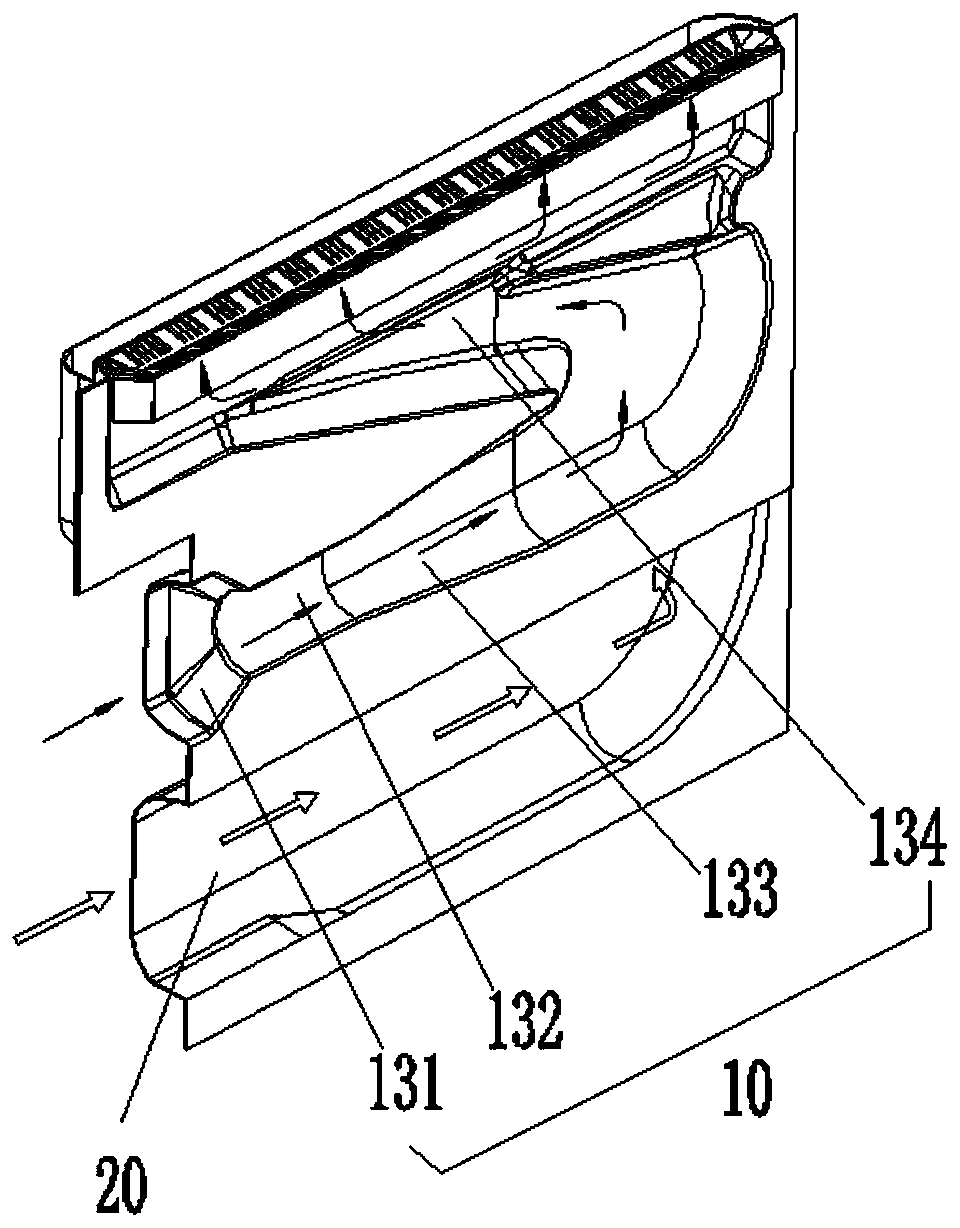

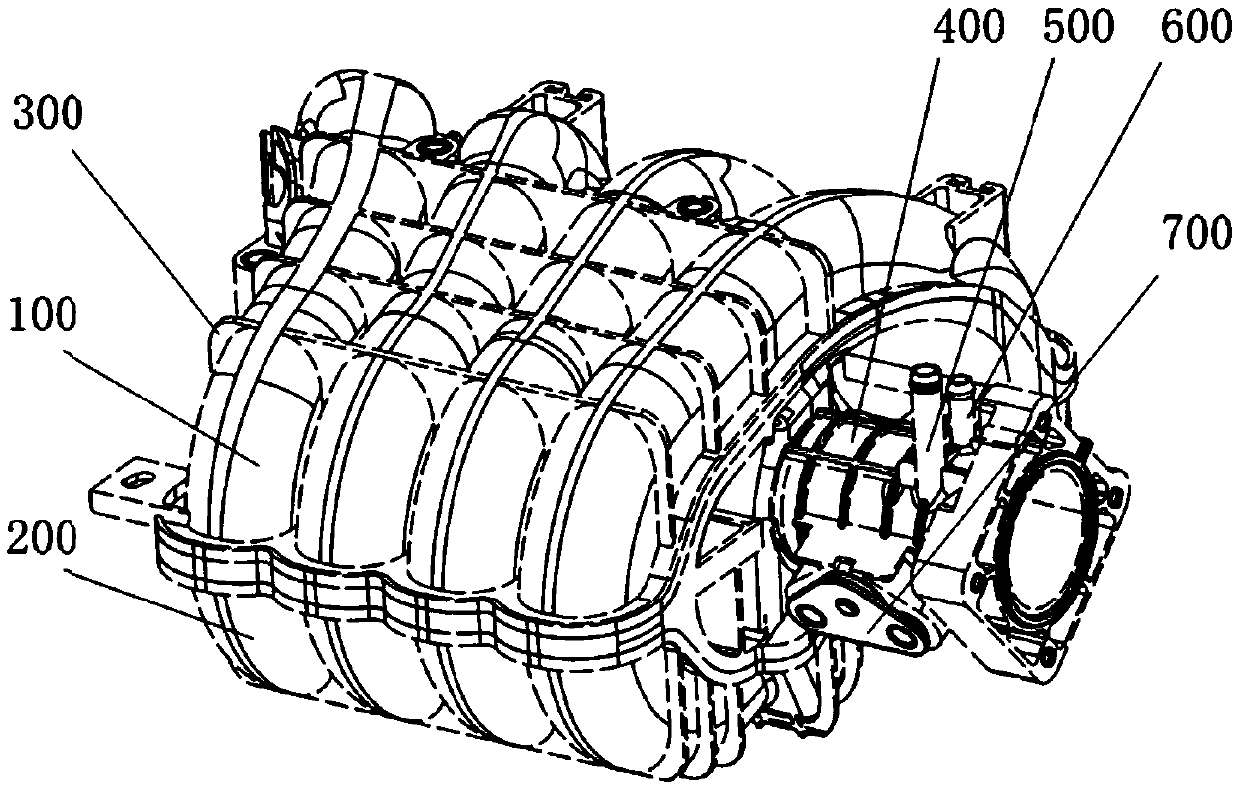

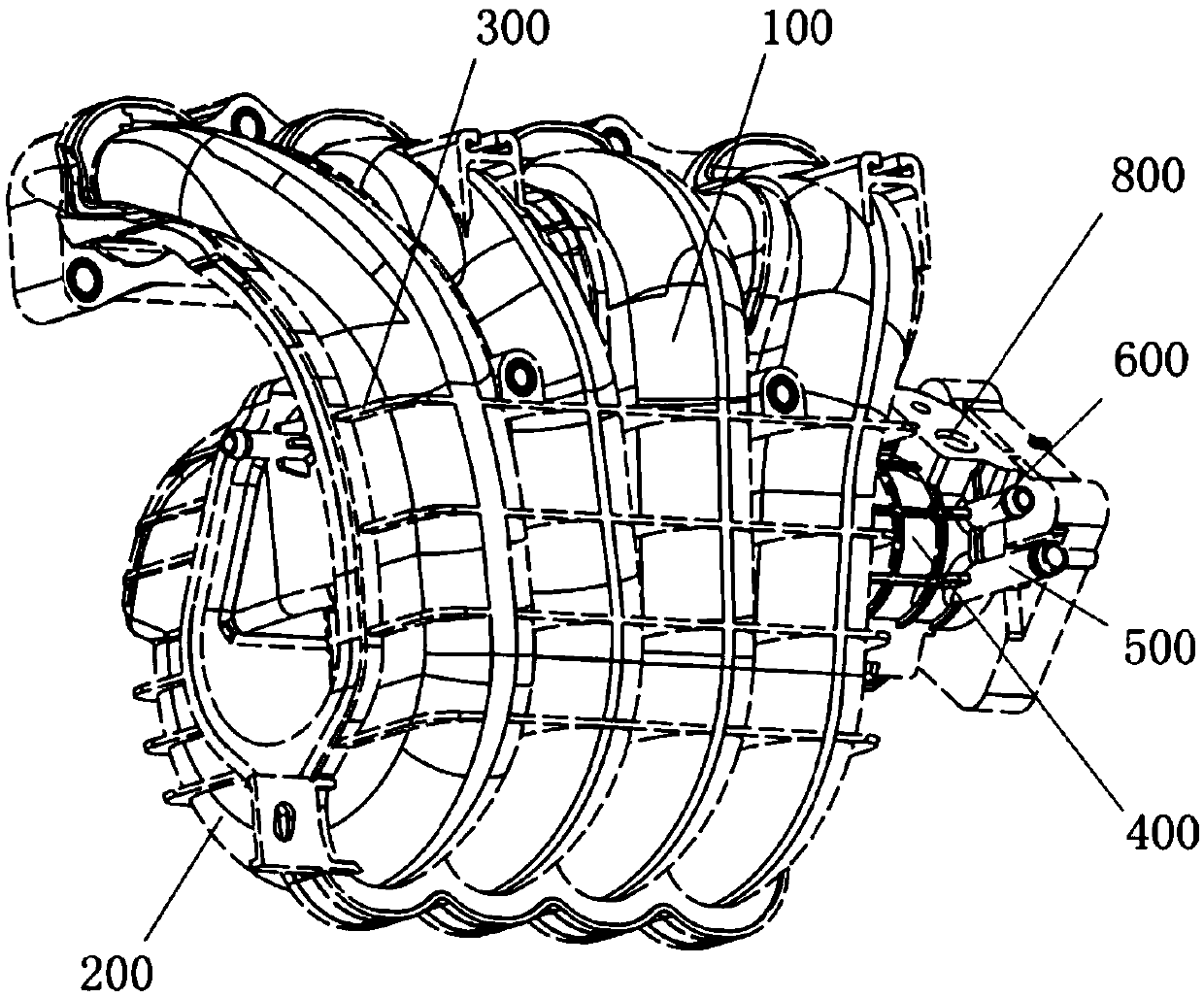

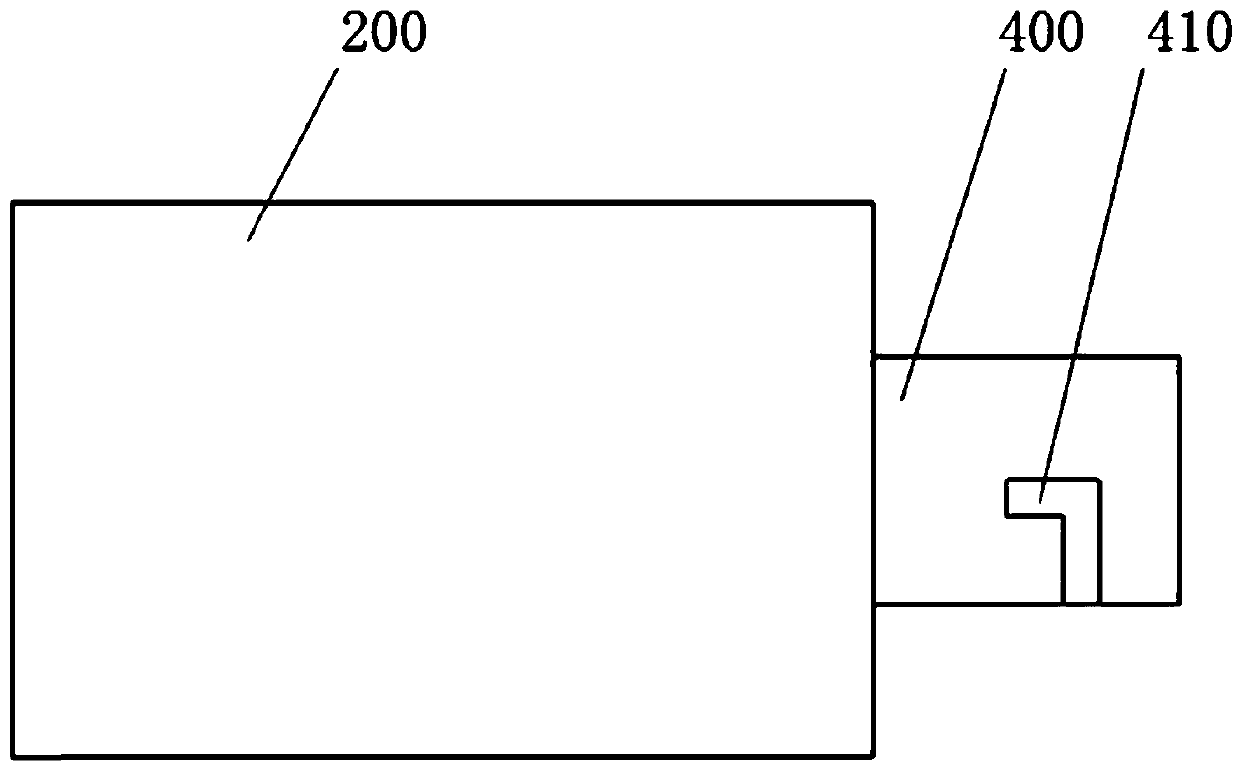

Engine intake manifold

ActiveCN106286044AEmission reductionSolve the problem of uneven air intakeInternal combustion piston enginesCombustion-air/fuel-air treatmentCombustionInlet manifold

The invention discloses an engine intake manifold. The engine intake manifold comprises an intake main pipe, an intake branch pipe and a pressure stabilizing cavity; the intake main pipe is communicated with the pressure stabilizing cavity; and an intake port of the intake branch pipe is communicated with the pressure stabilizing cavity. The engine intake manifold further comprises a waste gas recirculating system and a guide plate, wherein the waste gas recirculating system includes a waste gas pipe; the waste gas pipe is fixed on the intake main pipe, and is communicated with the intake main pipe; the guide plate is perpendicular to the axis direction of the pressure stabilizing cavity; and one end of the guide plate is fixed on the inner wall of the pressure stabilizing cavity near the intake main pipe, and the other end of the guide plate keeps a set distance from the inner wall of the pressure stabilizing cavity. The engine intake manifold realizes the purposes of reduction of oil consumption and waste gas discharge through setting of the waste gas pipe and the guide plate, solves the problem of nonuniform intake quantity of each intake branch pipe, and guarantees the combustion quality in a cylinder.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

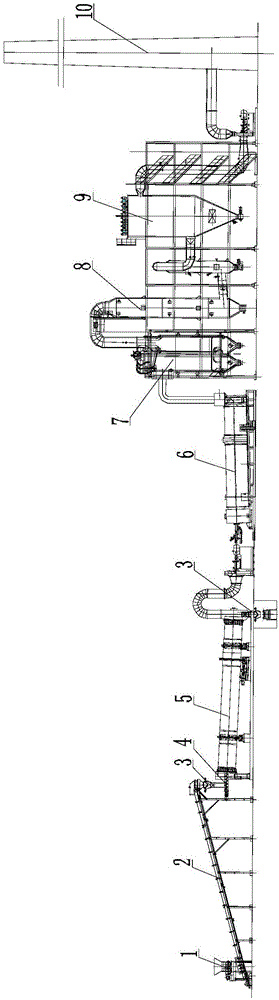

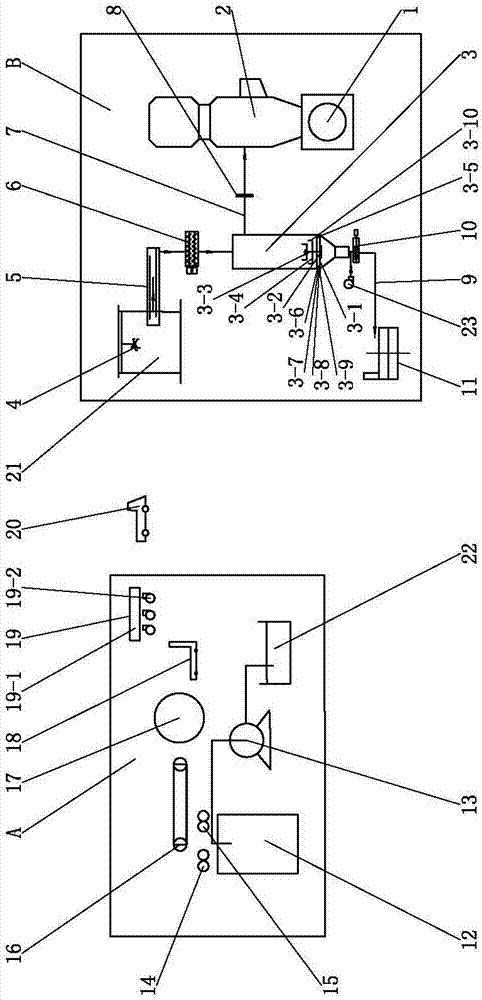

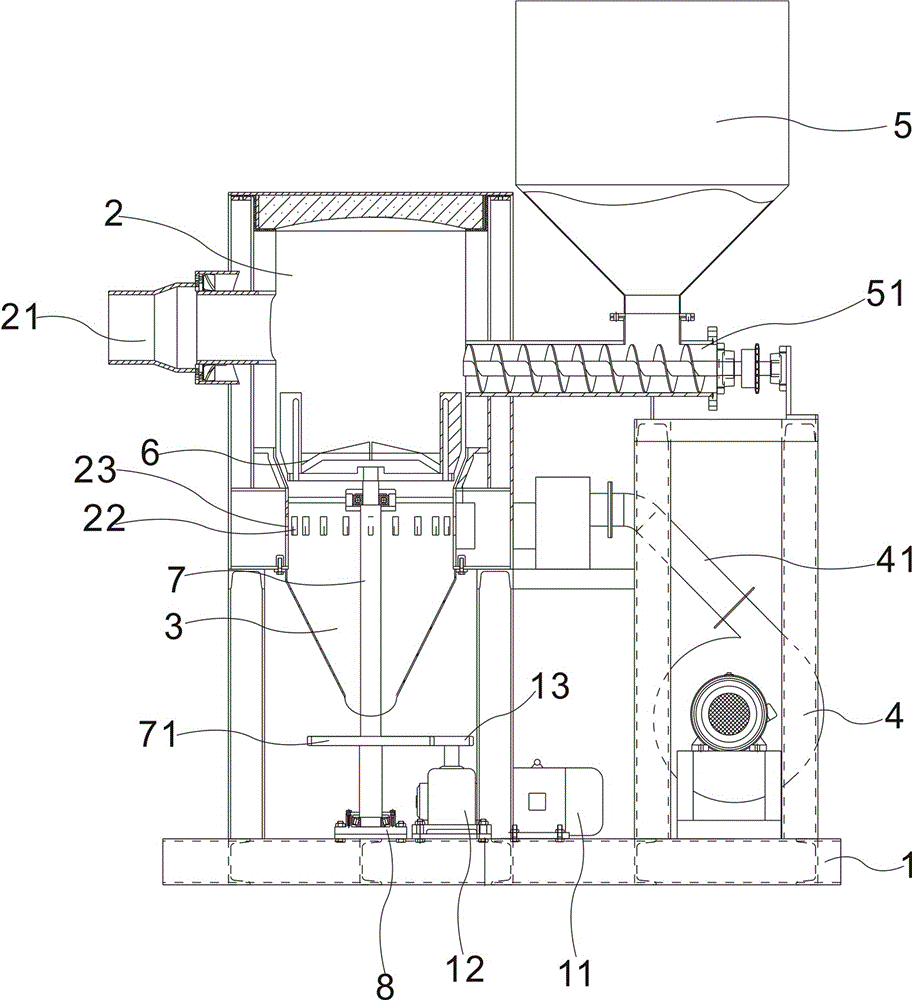

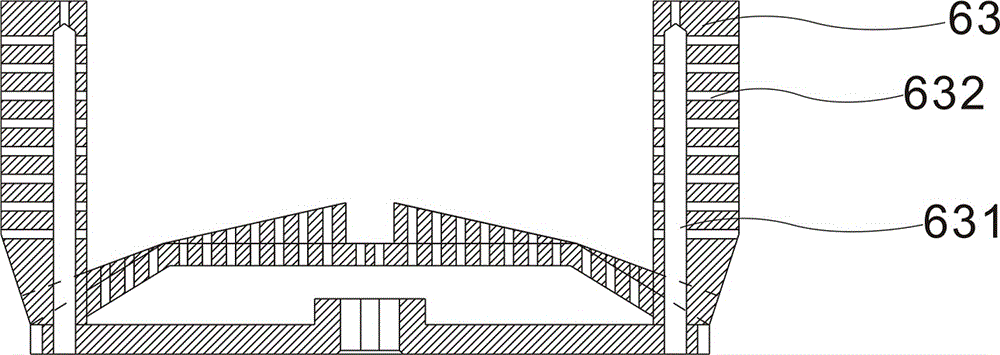

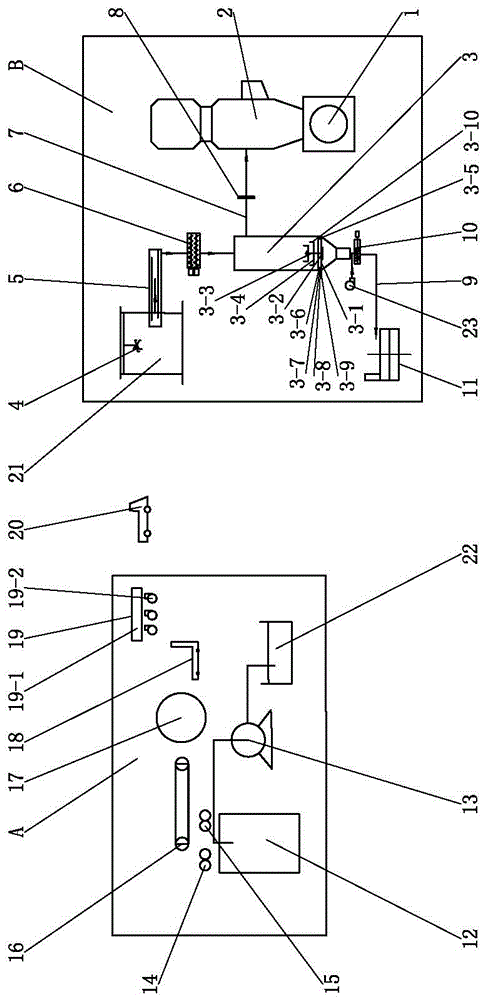

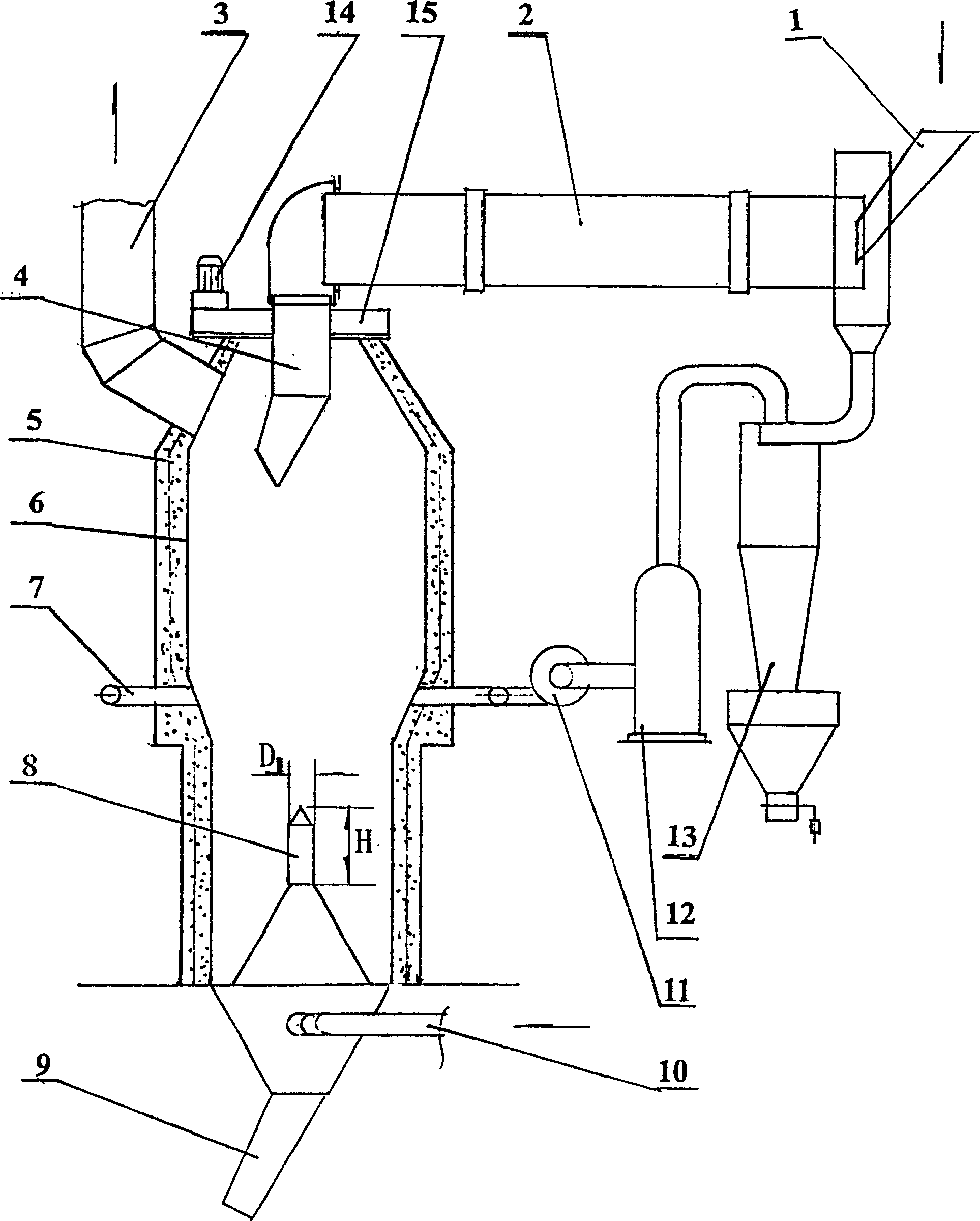

Harmless treatment system for oil field sludge

InactiveCN106196107AStable combustion temperatureGuaranteed combustion qualitySludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCatalytic pyrolysisSludge

The invention discloses a harmless treatment system for oil field sludge, and relates to a harmless treatment device for mixed sludge, which contains complex chemical compositions and is high in content of pollutants, in oil field exploitation. The harmless treatment system comprises a feeding device, a rotating drying machine, a catalytic pyrolysis furnace, a waste heat boiler, a quench tower, an absorption tower and a chimney. The feeding device is located at the inlet end of the rotating drying machine. The outlet end of the rotating drying machine is connected with the inlet end of the catalytic pyrolysis furnace. The outlet end of the catalytic pyrolysis furnace is connected with the inlet end of the waste heat boiler. The number of the outlet ends of the waste heat boiler is two, wherein one outlet is a flue gas outlet connected with the inlet end of the absorption tower to collect dust in flue gas particles, and the other outlet is a hot water outlet connected to a domestic water or production water pipeline through a pipeline. The outlet end of the absorption tower is connected with the chimney. The harmless treatment system has the characteristics of novel structure, mature technology, high waste heat utilization rate, relatively thorough harmless treatment, environmental protection and energy conservation.

Owner:朝阳重型机器制造有限公司

Method for producing liquid fuel by using biomass

ActiveCN110467940AImprove combustion qualityFully convertedLiquid hydrocarbon mixture productionHydrocarbon oils treatmentFiberLiquid fuel

The invention provides a method for producing a liquid fuel by using biomass. The liquid fuel is obtained by performing pretreatment, a pyrolytic reaction and a catalytic cracking reaction on the biomass. The biomass is composed of pine needles, bamboo wood, tung tree branches, ginger stems and leaves, Chinese toon branches, sweet potato seedlings, Enteromorpha prolifera, leftovers from a slaughterhouse and the like, wherein the pine needles, the bamboo wood, the tung tree branches, the ginger stems and leaves, the Chinese toon branches and the sweet potato seedlings contain volatile oil, grease, cellulose, lignin and the like; Enteromorpha prolifera contains a large amount of carbohydrates, proteins, crude fibers, fatty acids and the like; and the leftovers from the slaughterhouse are rich in grease. The above biomass raw materials are subjected to the pyrolysis reaction and the catalytic cracking reaction for sufficient conversion, and the obtained liquid fuel is excellent in combustion quality.

Owner:台州镘霓电子商务有限公司

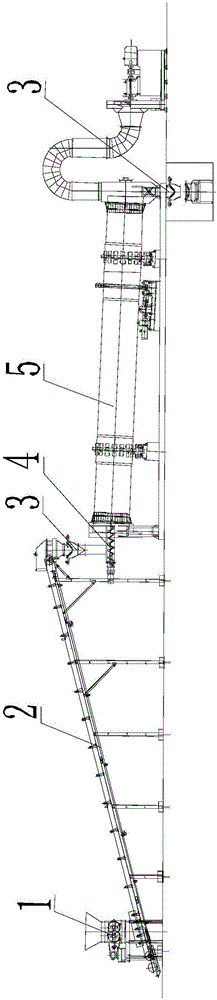

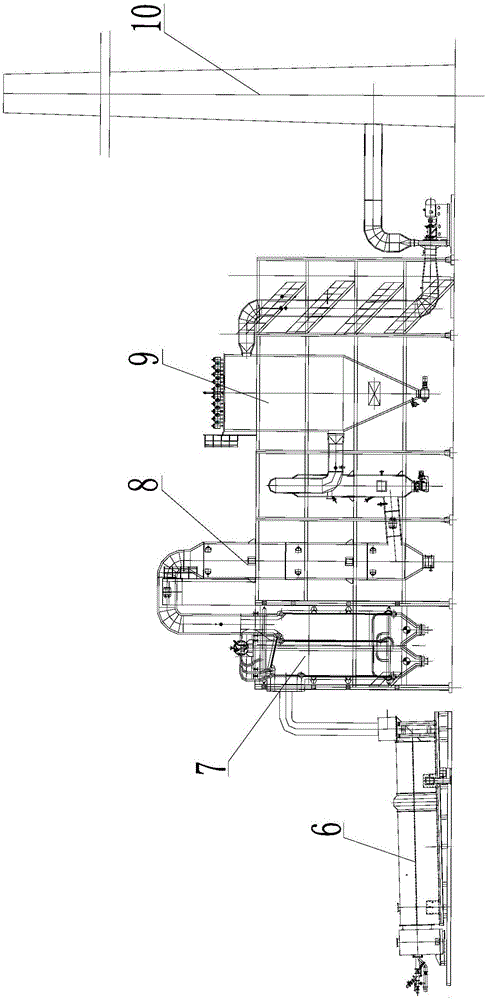

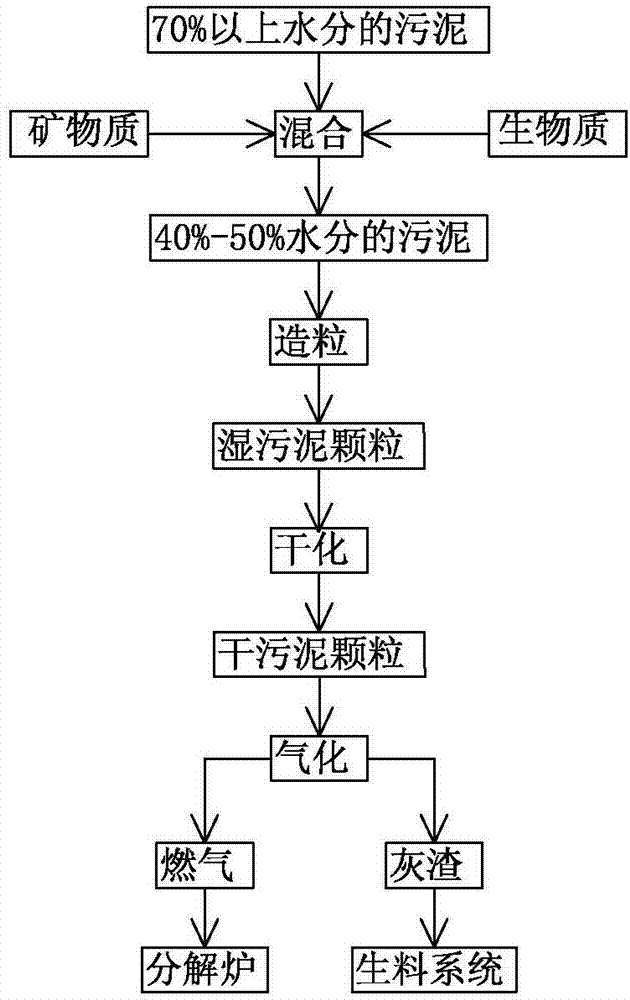

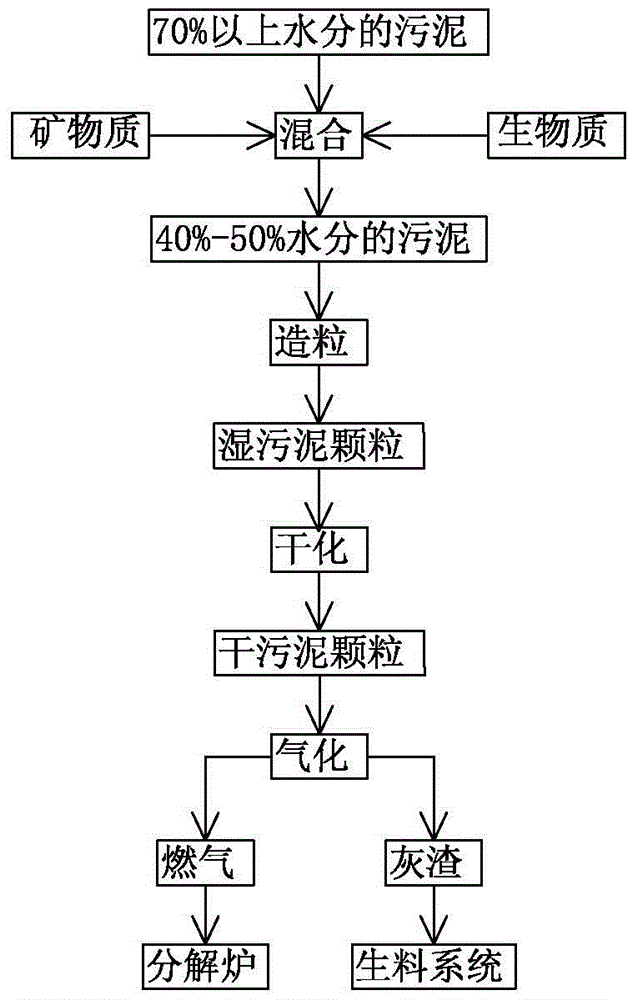

Method for treating sludge by using cement kiln, and sludge gasifying cement kiln system

ActiveCN104496135AReduce moistureTransportSludge treatment by de-watering/drying/thickeningClinker productionSludgeSlag

The invention discloses a method for treating sludge by using a cement kiln, and a sludge gasifying cement kiln system. The method for treating sludge by using the cement kiln comprises the following steps: making wet sludge into dry sludge particles, then gasifying the dry sludge particles, sending the fuel gas obtained after gasification into a decomposing furnace, and sending ash obtained after gasification into a crude material system. The sludge gasifying cement kiln system comprises a cement kiln and a decomposing furnace, wherein an inlet of the cement kiln is communicated with an outlet of the decomposing furnace, and a gas inlet of the decomposing furnace is communicated with a gas outlet of a gasifying furnace through a fuel gas pipeline; a feed opening of the gasifying furnace is communicated with a warehouse through a conveying system, and a slag outlet of the gasifying furnace is communicated with the crude material system through a slagging system. According to the method and the sludge gasifying cement kiln system provided by the invention, the treatment scale of sludge can be greatly improved; the difference between the form of solid sludge directly sent to the kiln and the fineness of coal dust as well as a cement raw material is reduced, and the mass and heat transfer effect is increased.

Owner:BBMG CORP +2

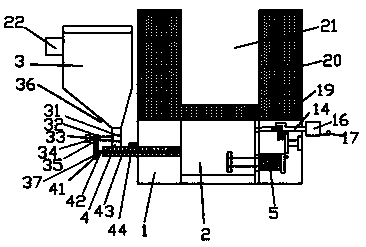

Small process for generating gas through light hydrocarbon gas generating

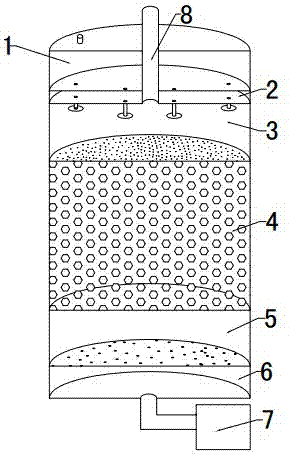

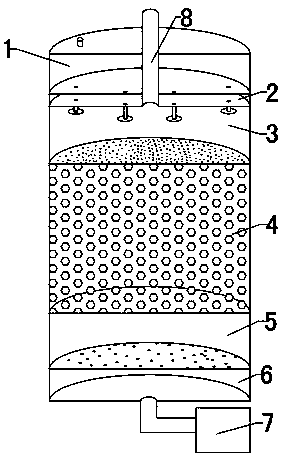

InactiveCN107327868AThe production ofAvoid taking awayLiquid fuel feeder/distributionLiquid fuel pretreatmentAir blowerPorous ceramics

The invention discloses a small process for generating gas through light hydrocarbon gas generating, and belongs to the technical field of gas generating equipment. The process is characterized in that a light hydrocarbon raw material chamber (1), a control chamber (2), a spray chamber (3), a porous ceramic material chamber (4), a flow stabilizing chamber (5) and a rectifying chamber (6) are sequentially arranged in a tank body from top to bottom, wherein the height of the porous ceramic material chamber (4) is 45cm-55cm; the bottom opening of the rectifying chamber (6) is connected with a hot air blower (7); and an upward gas output pipe (8) is arranged at the spray chamber (3). Liquid light hydrocarbon raw materials are added to the light hydrocarbon raw material chamber (1), the hot air blower (7) is started to supplying air 8s-15s after the oil injection of a nozzle, and the hot air and the liquid light hydrocarbon are volatilized and gasified to produce mixed air gas. The independent and small light hydrocarbon gas generating equipment and the gas generating process can be used independently by a family with stable gas quality.

Owner:SHANDONG UNIV OF TECH

Compound anti-oxidization anti-gelling agent for oil product and preparation method of compound anti-oxidization anti-gelling agent

ActiveCN105219456AImprove performancePrevent discolorationLiquid carbonaceous fuelsPhosphoric Acid EstersPolymer science

The invention relates to a compound anti-oxidization anti-gelling agent for an oil product and a preparation method of the compound anti-oxidization anti-gelling agent and belongs to the technical field of oil gas additives. The compound anti-oxidization anti-gelling agent for the oil product is prepared from the following components in parts by weight: 1 to 2 parts of butylated hydroxyanisole, 0.5 to 1.5 parts of alkyl glycoside, 2 to 5 parts of stearic acid, 0.1 to 0.2 parts of triethylene glycol bi[beta-(3-tertiary butyl-4-hydroxy-5-methyl phenyl)propionate, 0.1 to 0.2 parts of bi(2,4-bitertiary butyl phenyl)pentaerythritol biphosphite, 1 to 2 parts of diosmetin, 1 to 3 parts of nano calcium carbonate, 15 to 19 parts of ethanol and 5 to 10 parts of glycerol. The compound anti-oxidization anti-gelling agent for the oil product has good stability; the performance of the compound anti-oxidization anti-gelling agent is not influenced after the compound anti-oxidization anti-gelling agent is stored for a long period; the oil product is prevented from color change when the oil product is stored; original colloid in the oil product can be completely removed and the formation of colloids is inhibited; the quality of the oil product is effectively improved.

Owner:重庆索银新能源科技有限公司

Combustion organization method and system for inhibiting gasoline engine knocking

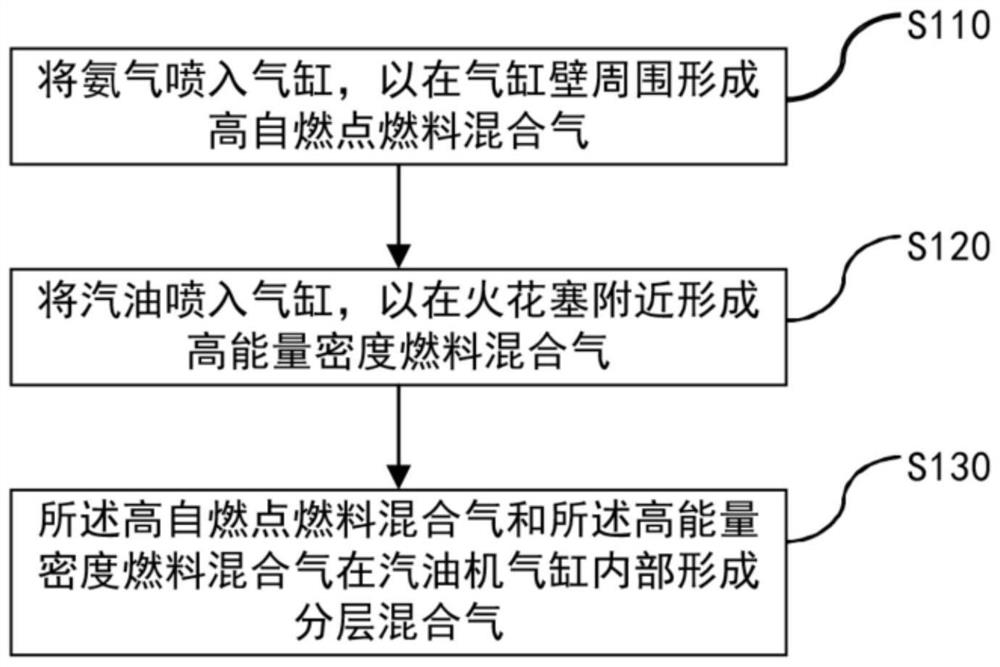

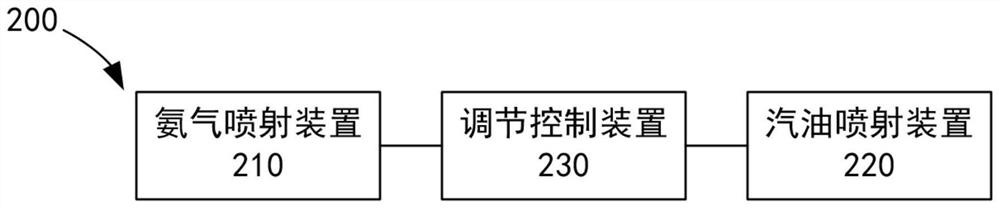

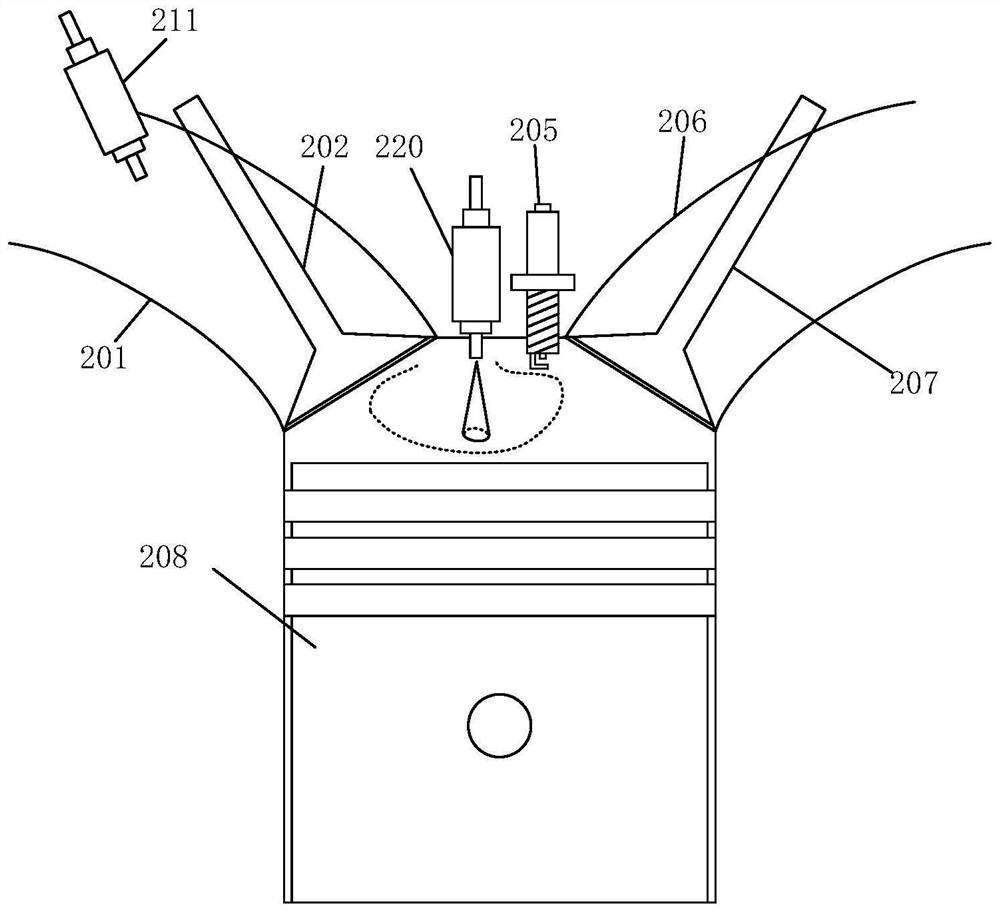

PendingCN114412648AReduced propensity to spontaneous combustionKnock suppressionEngine controllersMachines/enginesSpontaneous combustionHigh energy

The invention relates to the field of engines, in particular to a combustion organization method and system for restraining gasoline engine knocking. A combustion organization method for restraining gasoline engine knocking comprises the steps that ammonia gas is sprayed into an air cylinder, so that high-spontaneous-ignition-point fuel mixed gas is formed around the wall of the air cylinder; gasoline is injected into the air cylinder, so that high-energy-density fuel mixed gas is formed near a sparking plug; the high-spontaneous-ignition-point fuel mixed gas and the high-energy-density fuel mixed gas form layered mixed gas in a gasoline engine cylinder; wherein the high-spontaneous-ignition-point fuel is ammonia gas, and the high-energy-density fuel is gasoline. According to the combustion organization method and system, the gasoline-ammonia layered mixed gas is formed in the gasoline engine air cylinder, the gasoline-air mixed gas is distributed in the peripheral area of the spark plug, the ignition process and the development of fire cores are facilitated, and therefore the combustion quality is guaranteed; in the tail end high-temperature unburned area where spontaneous combustion is prone to occurring, the spontaneous combustion tendency of mixed gas is reduced due to the existence of ammonia gas, and therefore knocking is restrained.

Owner:南昌济铃新能源科技有限责任公司

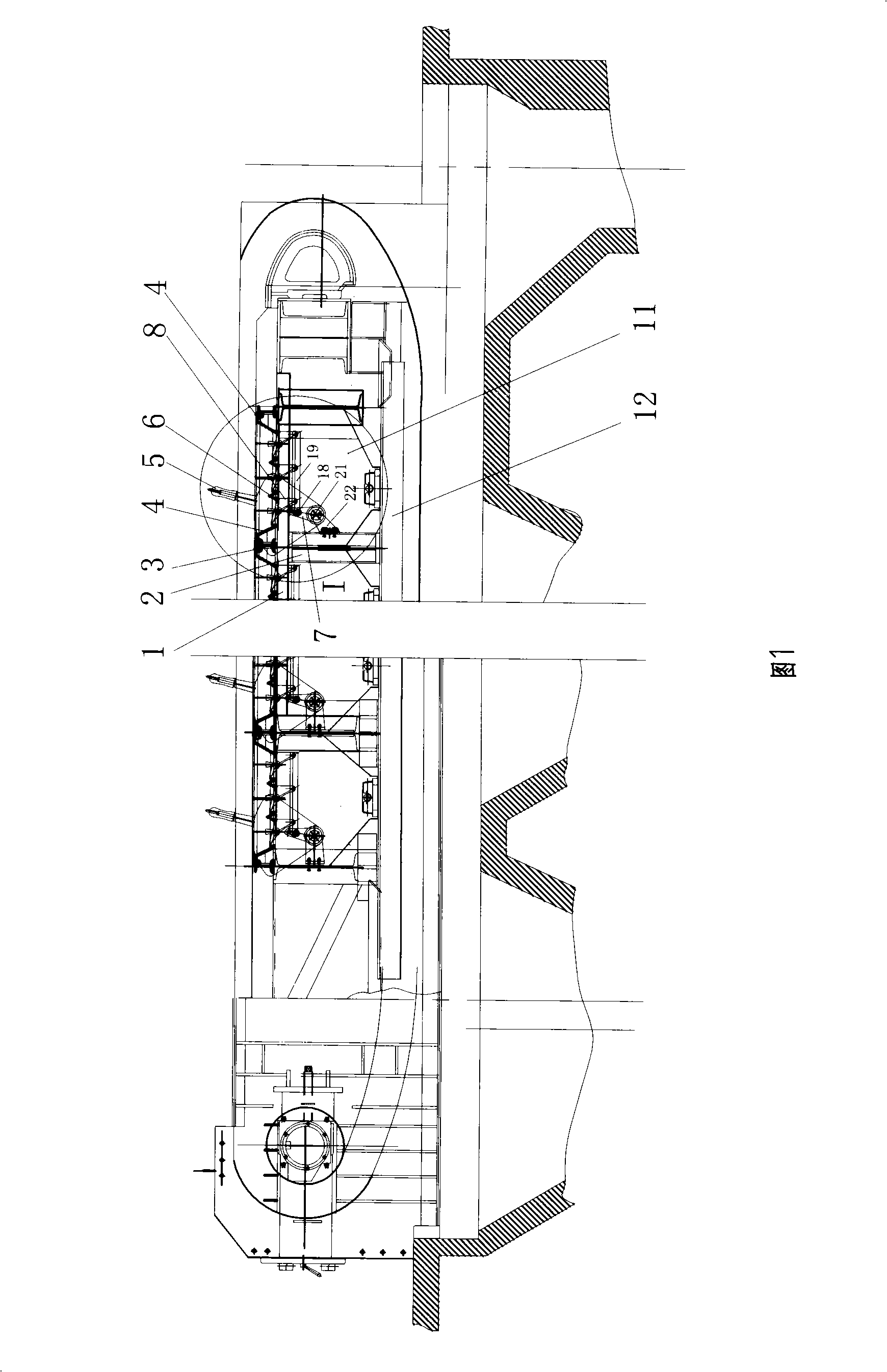

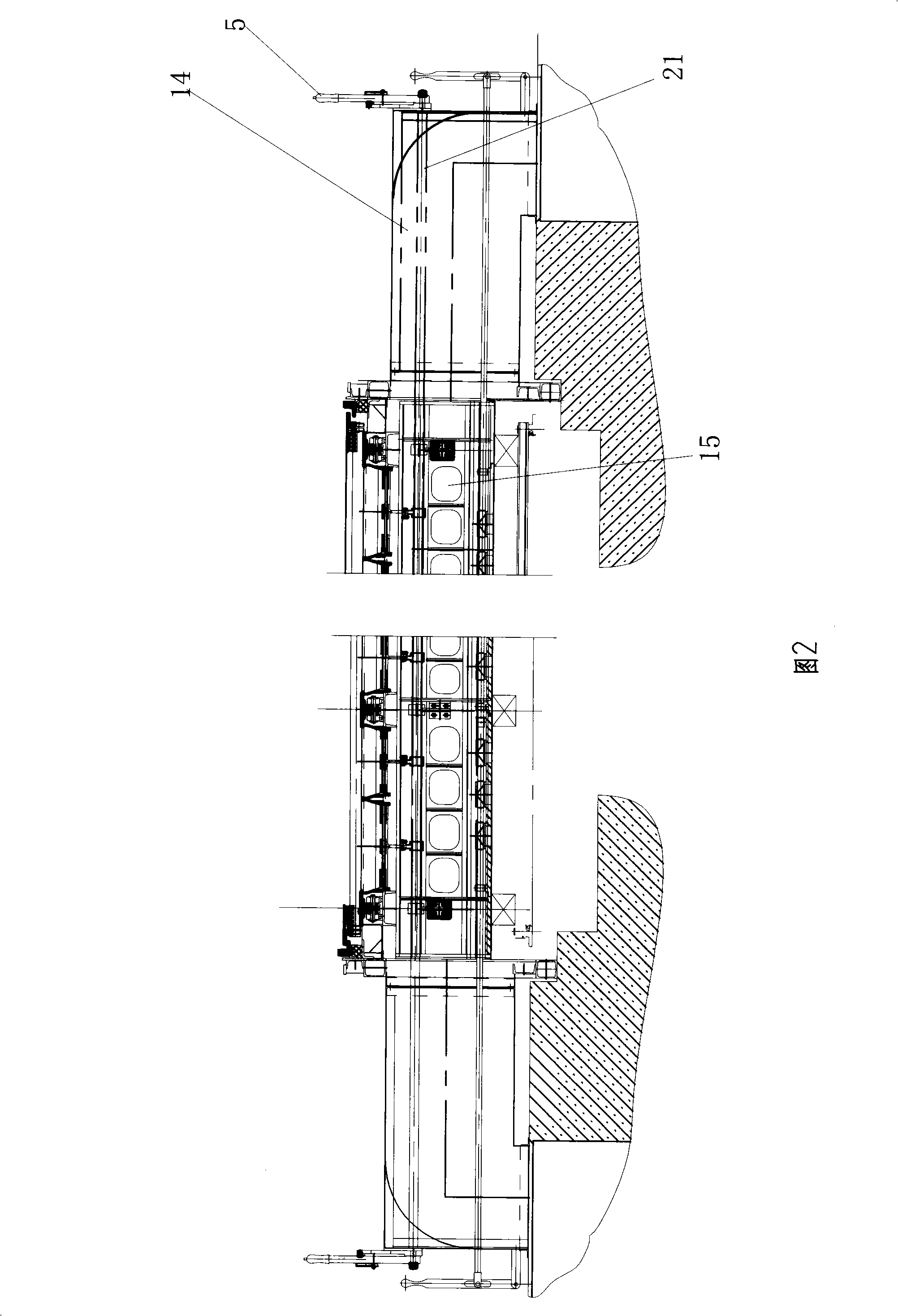

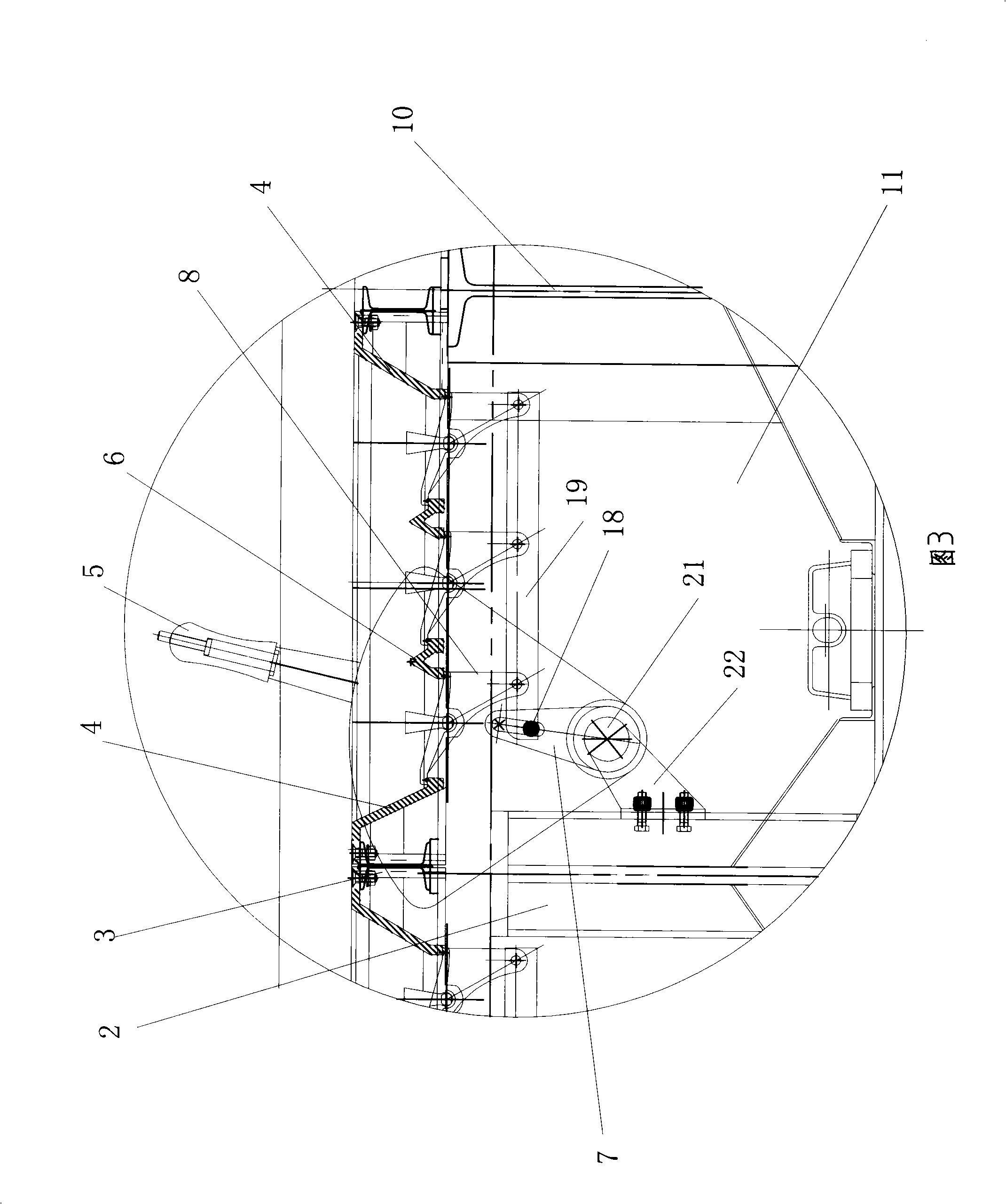

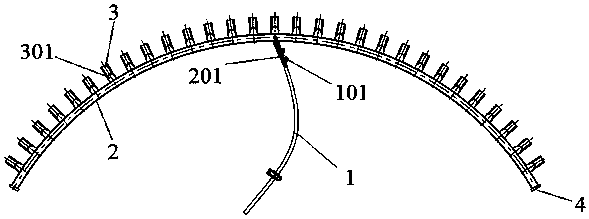

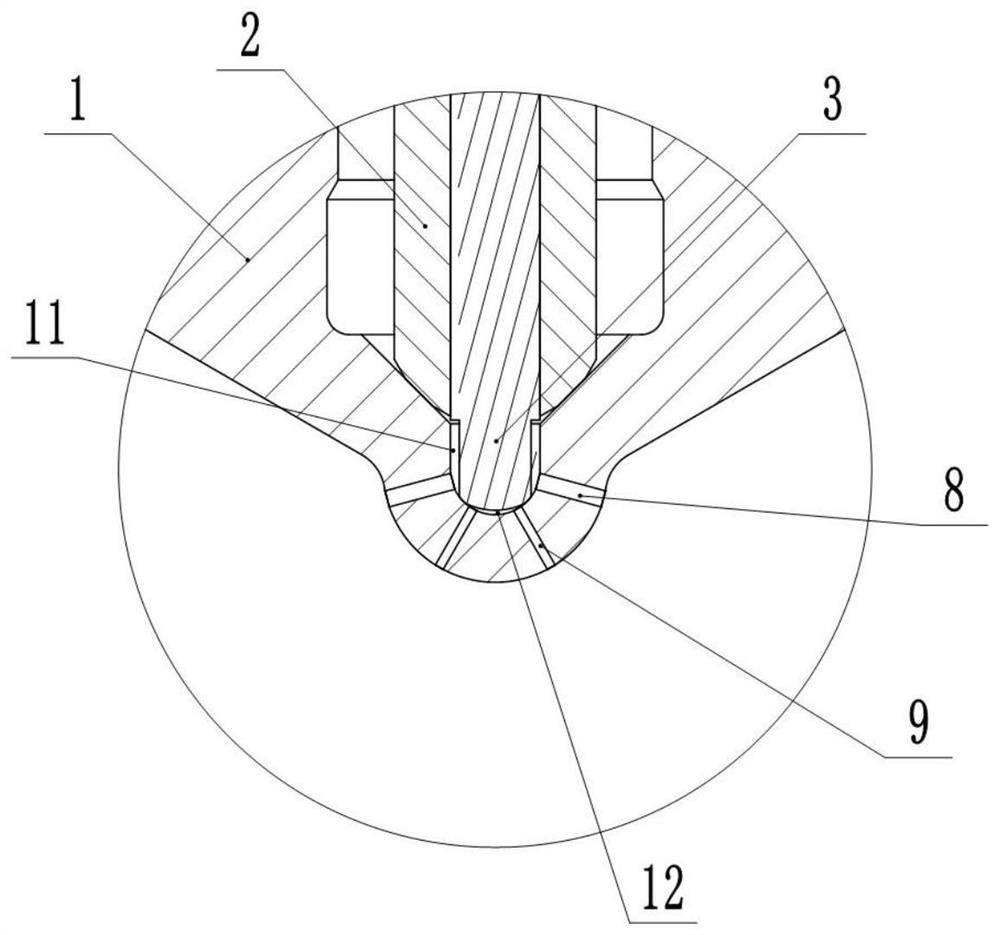

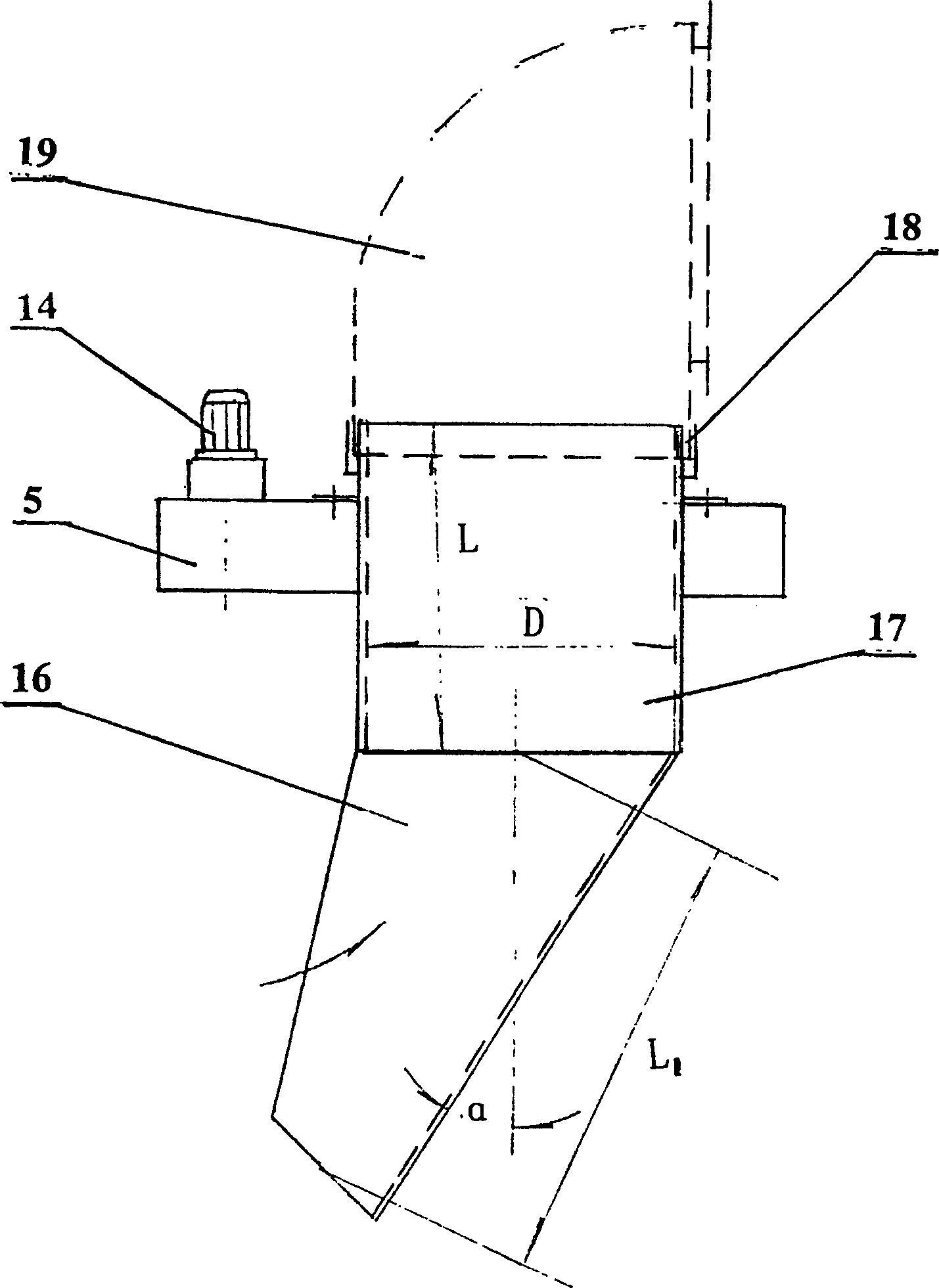

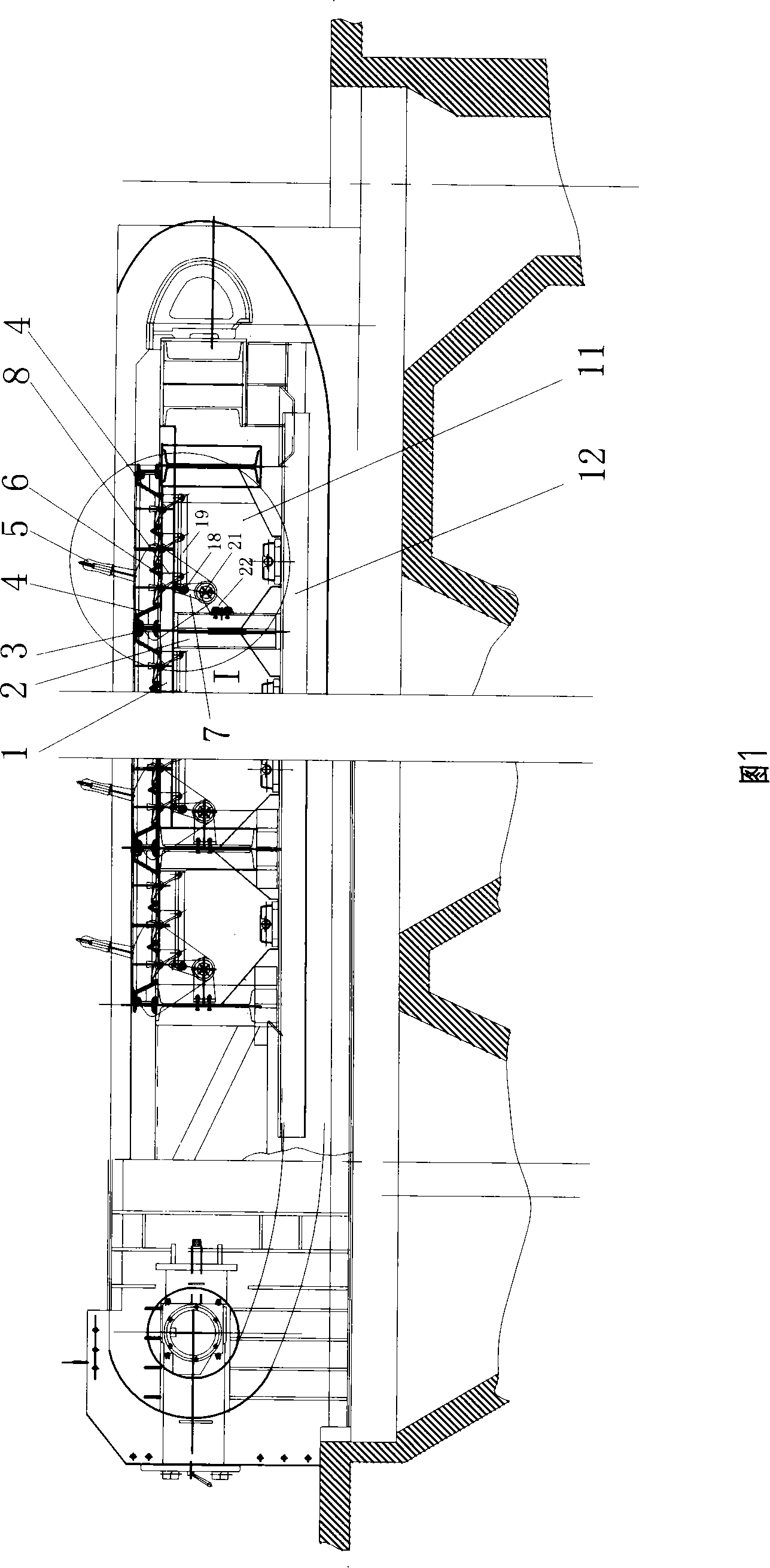

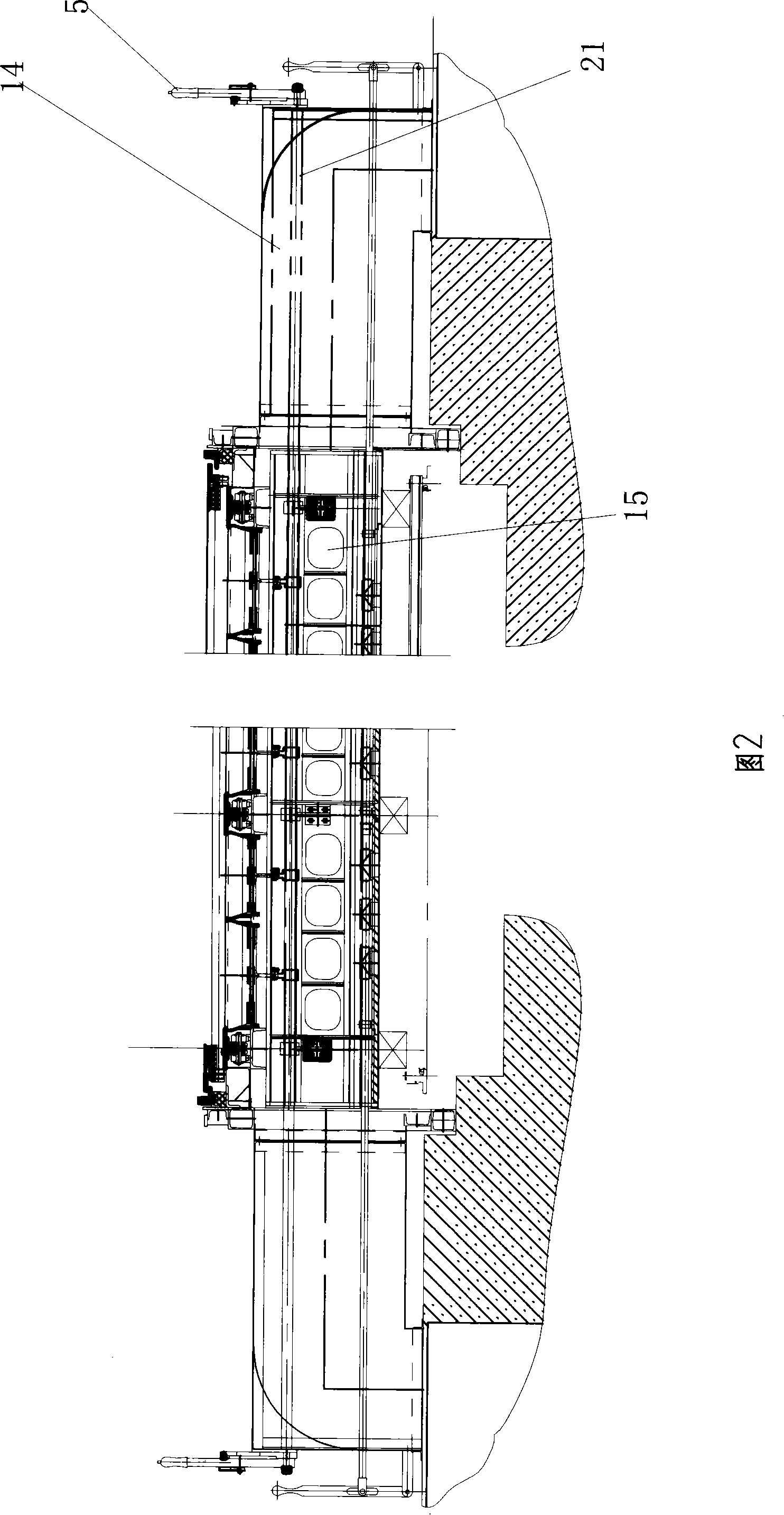

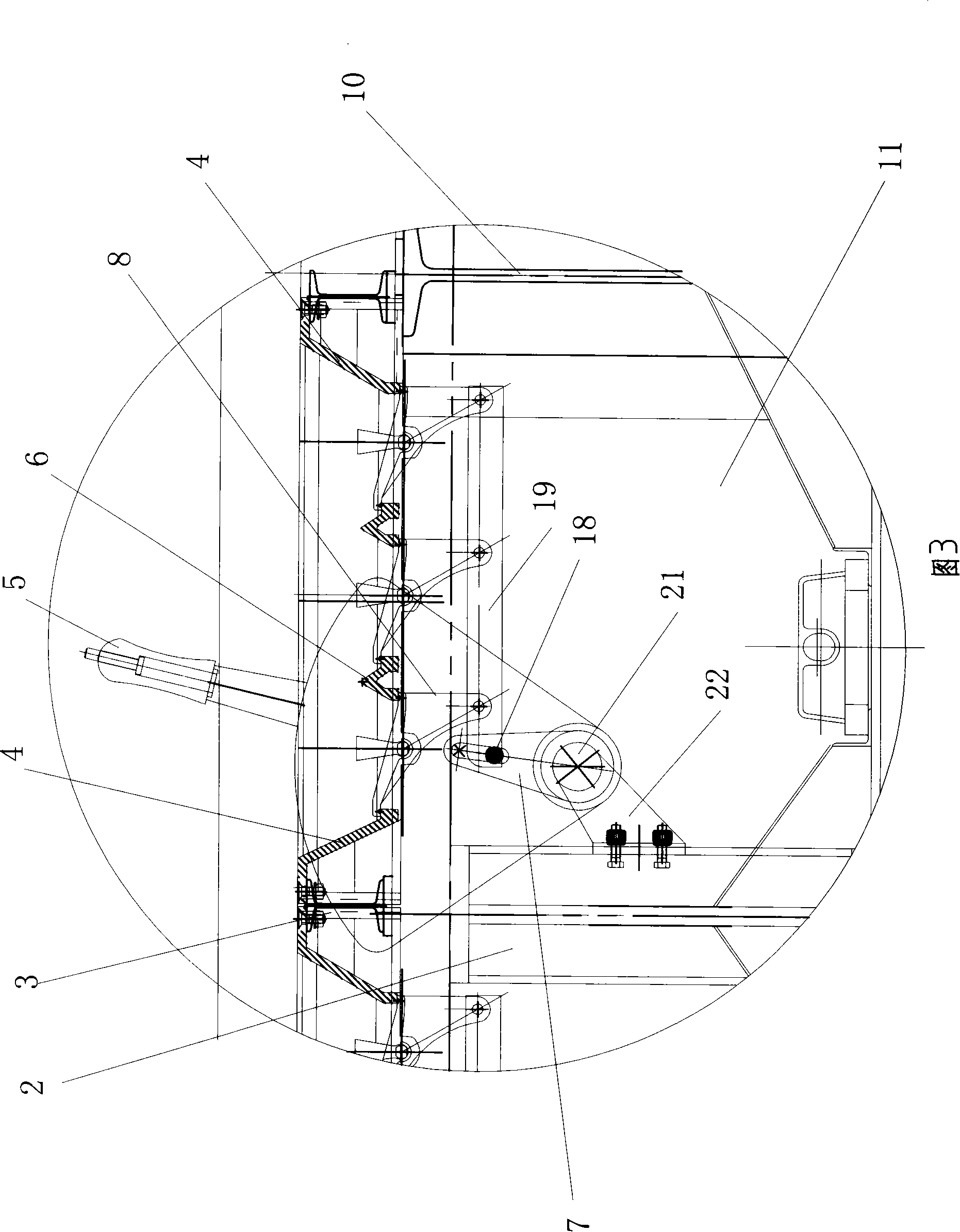

Large wind barn small air scoop crossbeam type chain-grate

InactiveCN101290122AImprove combustion qualityReduce wind speedTravelling grateEngineeringWind speed

The invention discloses an endless grate, in particular to a big wind bin and small wind catcher crossbeam-type endless grate. The endless grate comprises a frame consisting of a middle beam (2), an upper lead rail (1) and a lower lead rail (12); a furnace chain connected with a drive device is arranged on the frame; the endless grate is characterized in that: the lower part of the furnace chain on the upper part is provided with a wind bin (11) communicated with the furnace chain; a wind chest (14) communicated with the wind bins (14) is arranged on the whole side of the grate; the wind chest (14) is connected with a wind supply device. The endless grate changes the mode that each wind chamber respectively supplies wind in the prior art, thereby greatly reducing wind speed, stabilizing wind pressure, ensuring the even wind supply to the furnace chain, improving the burning quality of fuel and saving energy.

Owner:瓦房店市永宁机械厂

New-energy biomass energy smelting furnace capable of uniformly supplying energy

InactiveCN108627014APromote combustionBurn fasterCharge treatment typeCrucible furnacesCombustion chamberNew energy

The invention provides a new-energy biomass energy smelting furnace capable of uniformly supplying energy. The new-energy biomass energy smelting furnace comprises a furnace body, a combustion chamberand a feeding device, wherein a rotary feeding roller is arranged under the feeding device; a conveying box is arranged under the feeding device and is connected with the combustion chamber; a reverse rotation device is arranged on one side of the combustion chamber; the upper end of the reverse rotation device is rotatably connected with a first rotating disc; the first rotating disc is connected with a fifth connecting rod by a gear; a stop block is arranged on the fifth connecting rod; the fifth connecting rod is connected with a fixed block; an opening is formed in the fixed block and corresponds to the stop block; the fixed block is fixed to a second gas inlet pipe; one end of the second gas inlet pipe is connected with a first gas inlet pipe; the other end of the second gas inlet pipe is connected with a third gas inlet pipe; the third gas inlet pipe is connected with a combustion chamber; a coconut-dimensional carbon frame is arranged at the upper end of the combustion chamber;a diamond slot is formed in the coconut-dimensional carbon frame; and a smelting pot is arranged on the diamond slot. According to the new-energy biomass energy smelting furnace disclosed by the invention, by utilizing the rotary feeding roller, the quantity of materials is controlled, the gas intake quantity is controlled by the stop block, turning of the reverse rotation device is carried out,and uniform heat transfer with high velocity is carried out by utilizing diamonds.

Owner:南京陶卓信息技术有限公司

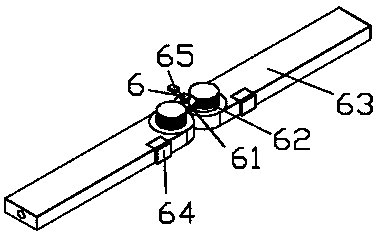

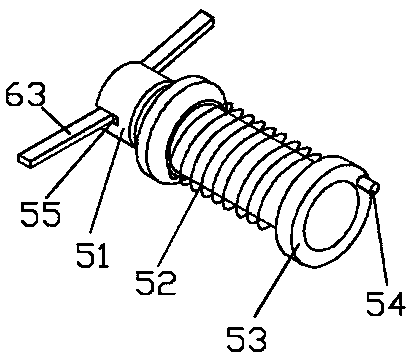

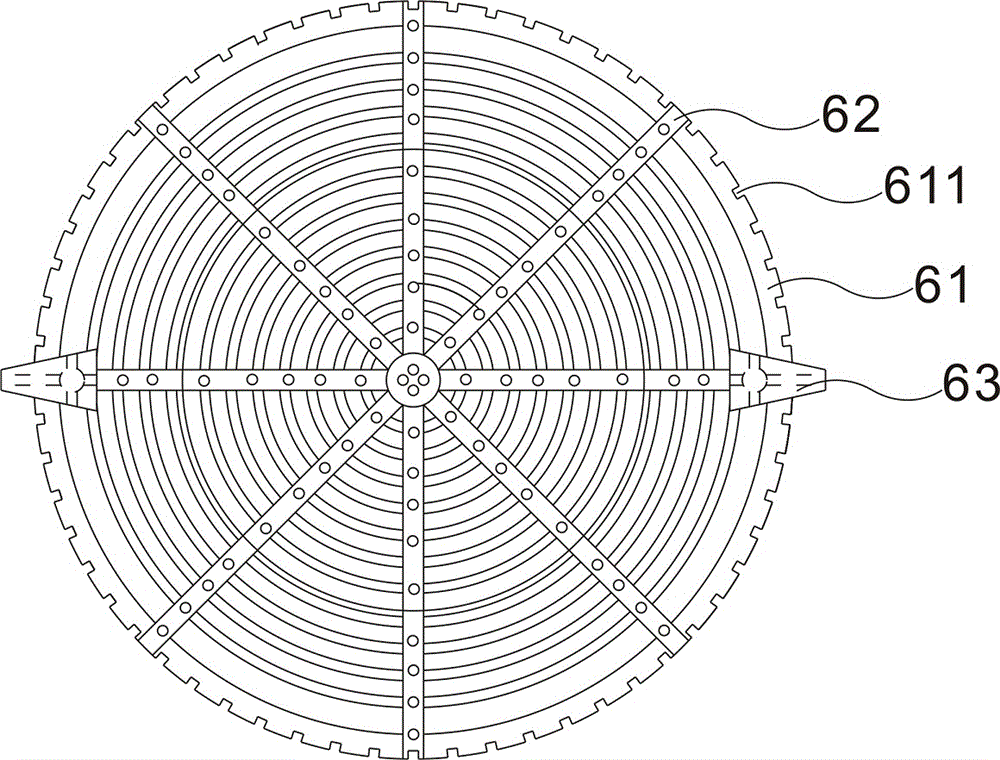

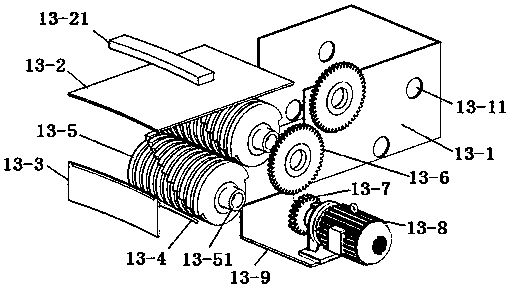

Turntable type automatic slag-crushing combustion machine

InactiveCN105546518AGuaranteed to continueGuaranteed combustion qualitySolid fuel combustionAir/fuel supply for combustionCombustion chamberSlag

A turntable type automatic slag-crushing combustion machine comprises a machine frame, a hearth, an air supply device, a feeding device and a deslagging device. The hearth, the air supply device, the feeding device and the deslagging device are arranged on the machine frame, the hearth consists of a cylindrical combustion chamber at the upper portion and a conical discharging chamber at the lower portion, a flame spraying port is formed in the combustion chamber, a discharging port is formed in the bottom of the discharging chamber, the feeding device is formed by connecting a lower hopper with a spiral feeder, and a discharging port of the spiral feeder is communicated with the combustion chamber. The deslagging device is arranged in the hearth and comprises a deslagging disc and a rotary shaft, wherein the bottom of the deslagging disc is connected with the rotary shaft, the lower end of the rotary shaft extends out of the hearth, a bearing seat is arranged on the machine frame, the lower end of the rotary shaft is installed on the bearing seat, and a large gear is arranged on the rotary shaft. The deslagging disc adopted by the deslagging device can conduct deslagging and cleaning on the inner wall of the hearth, cleaning while working is achieved, continuous combustion work and combustion quality are ensured, slagging can be further prevented from being produced at the bottom of the hearth, and the service life is prolonged.

Owner:ZHENGZHOU HENGJI WEAR-RESISTANT PROD CO LTD

A method of treating sludge with a cement kiln and a sludge gasification cement kiln system

ActiveCN104496135BReduce moistureTransportSludge treatment by de-watering/drying/thickeningClinker productionSludgeSlag

The invention discloses a method for treating sludge by using a cement kiln, and a sludge gasifying cement kiln system. The method for treating sludge by using the cement kiln comprises the following steps: making wet sludge into dry sludge particles, then gasifying the dry sludge particles, sending the fuel gas obtained after gasification into a decomposing furnace, and sending ash obtained after gasification into a crude material system. The sludge gasifying cement kiln system comprises a cement kiln and a decomposing furnace, wherein an inlet of the cement kiln is communicated with an outlet of the decomposing furnace, and a gas inlet of the decomposing furnace is communicated with a gas outlet of a gasifying furnace through a fuel gas pipeline; a feed opening of the gasifying furnace is communicated with a warehouse through a conveying system, and a slag outlet of the gasifying furnace is communicated with the crude material system through a slagging system. According to the method and the sludge gasifying cement kiln system provided by the invention, the treatment scale of sludge can be greatly improved; the difference between the form of solid sludge directly sent to the kiln and the fineness of coal dust as well as a cement raw material is reduced, and the mass and heat transfer effect is increased.

Owner:BBMG CORP +2

Vehicle gasoline additive

InactiveCN106995732AGuaranteed combustion qualityImprove powerLiquid carbonaceous fuelsFuel additivesExhaust gasKerosene

The invention relates to a vehicle gasoline additive. The vehicle gasoline additive is prepared from the following components in parts by weight: 20 to 30 parts of naphthenic oil, 5 to 15 parts of naphtha, 20 to 30 parts of kerosene, 10 to 20 parts of light aromatic hydrocarbon, 5 to 10 parts of polyisobutylene phenol, 5 to 10 parts of cleaning agent, and 1 to 7 parts of anti-blasting agent. The vehicle gasoline additive has the advantages that the engine power can be effectively increased, the accumulated carbon is cleared, the fuel is saved, and the emission of tail gas is reduced; the technology formula is simple, the production cost is low, the application effect is good, and the vehicle gasoline additive is favorable for being popularized and applied.

Owner:HUBEI UNIV OF ARTS & SCI +1

Method for detecting calorific value characteristic of raw material fire coal

InactiveCN108956364AAccurate judgmentComprehensive judgmentWeighing by removing componentChemical analysis using combustionCombustionPulverized fuel ash

A method for detecting a calorific value characteristic of raw material fire coal comprises the following steps: 1. taking a coal pile as a sampling unit to obtain a coal sample with a particle size less than 13mm; 2. adding the air-dried coal sample with the particle size less than 13mm into a combustion boat at 1140-1160 DEG C, and calculating total sulfur content; 3. breaking the air-dried coalsample to a particle size less than 0.2 mm, sending the coal sample to a constant temperature zone of a muffle furnace with temperature less than or equal to 100 DEG C, firing for 40 min at 805-825 DEG C, and measuring an air dry ash component; crushing the coal sample to a particle size of less than 0.2 mm, sending the coal sample to a furnace heated to 920 DEG C for heating for 7 min, and measuring an air dry volatile component; calculating air dry fixed carbon; 4. making burned coal ash into an ash cone, heating the ash cone in the furnace, and measuring ash fusibility by an ash fusibilitytester; and 5. according to the total sulfur, the air-dried fixed carbon and the ash fusibility of the fire coal, determining whether the total sulfur, the air-dried fixed carbon and the ash fusibility of the fire coal meet the calorific value requirements of coal. The method can accurately determine the actual total sulfur content, air-dried fixed carbon and ash fusibility of the fire coal so asto achieve more comprehensive and accurate determination of the calorific value of the coal.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD +1

Production method of liquid fuel

InactiveCN113293022AImprove combustion qualityFully convertedLiquid hydrocarbon mixture productionHydrocarbon oils treatmentCelluloseCrude fibre

The invention provides a production method of liquid fuel. Biomass is used for pretreatment, pyrolytic reaction and catalytic cracking reaction to obtain the liquid fuel, wherein the biomass is composed of pine needles, bamboo wood, tung tree branches, fresh ginger stems and leaves, toona sinensis branches, sweet potato seedlings, enteromorpha, slaughter house leftovers and the like, the pine needles, the bamboo wood, the tung tree branches, the fresh ginger stems and leaves, the toona sinensis branches and the sweet potato seedlings contain volatile oil, grease, cellulose, lignin and the like, enteromorpha contains a large amount of carbohydrates, proteins, crude fibers, fatty acids and the like, the slaughter house leftovers are rich in grease, the biomass raw materials are subjected to pyrolytic reaction and catalytic cracking reaction and are fully converted, and the combustion quality of the obtained liquid fuel is excellent.

Owner:王照云

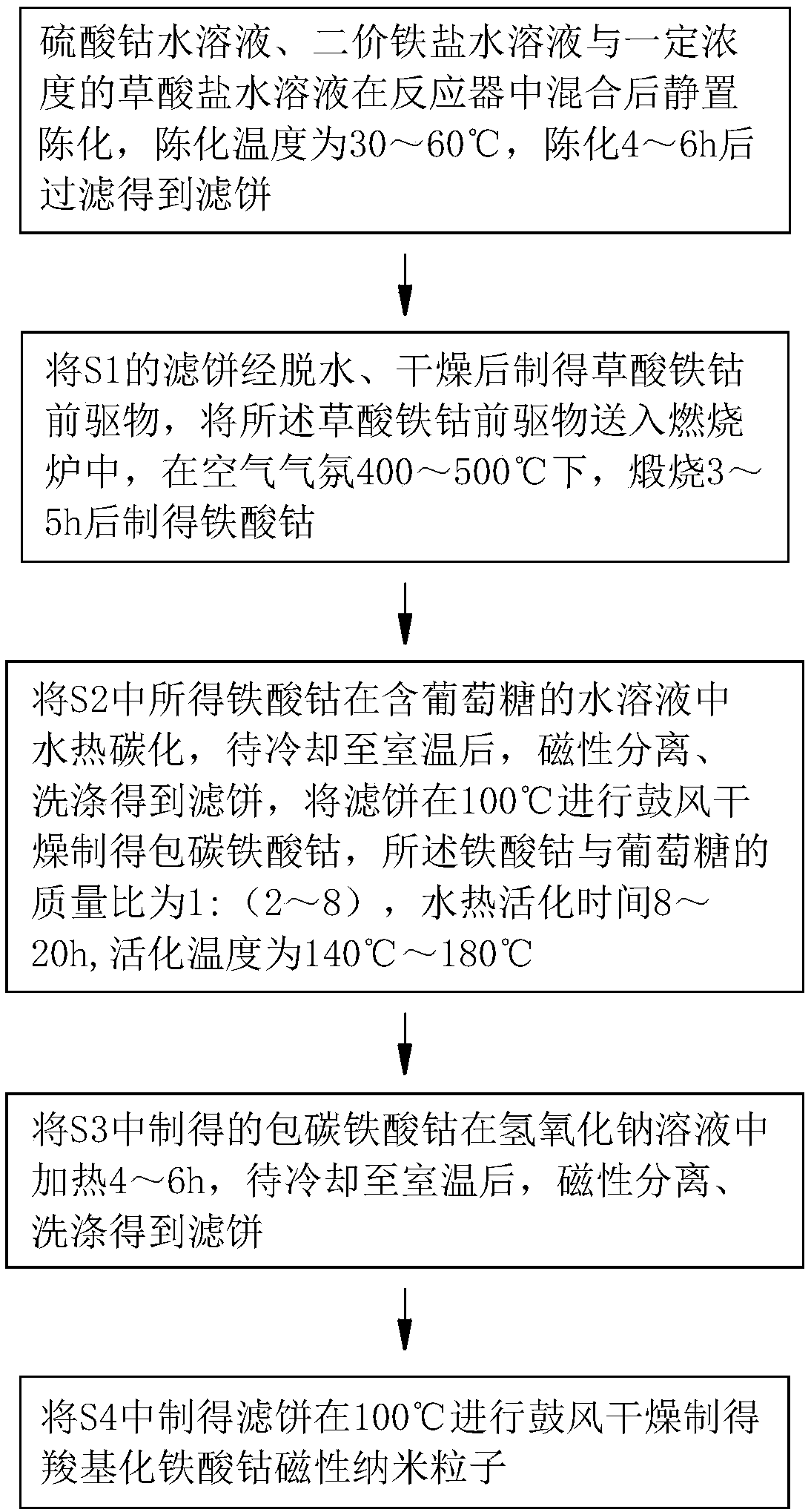

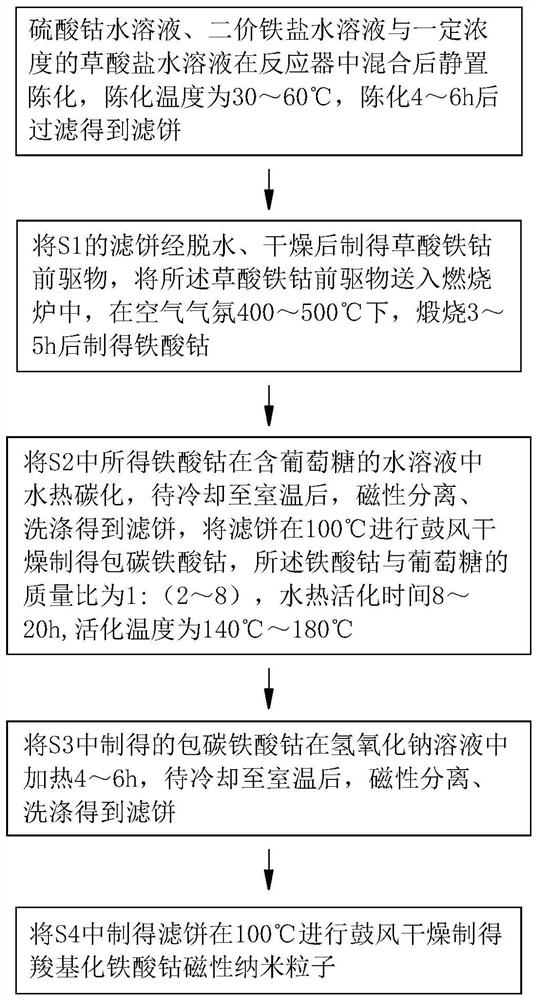

Preparation method of CoFe2O4 nano particle

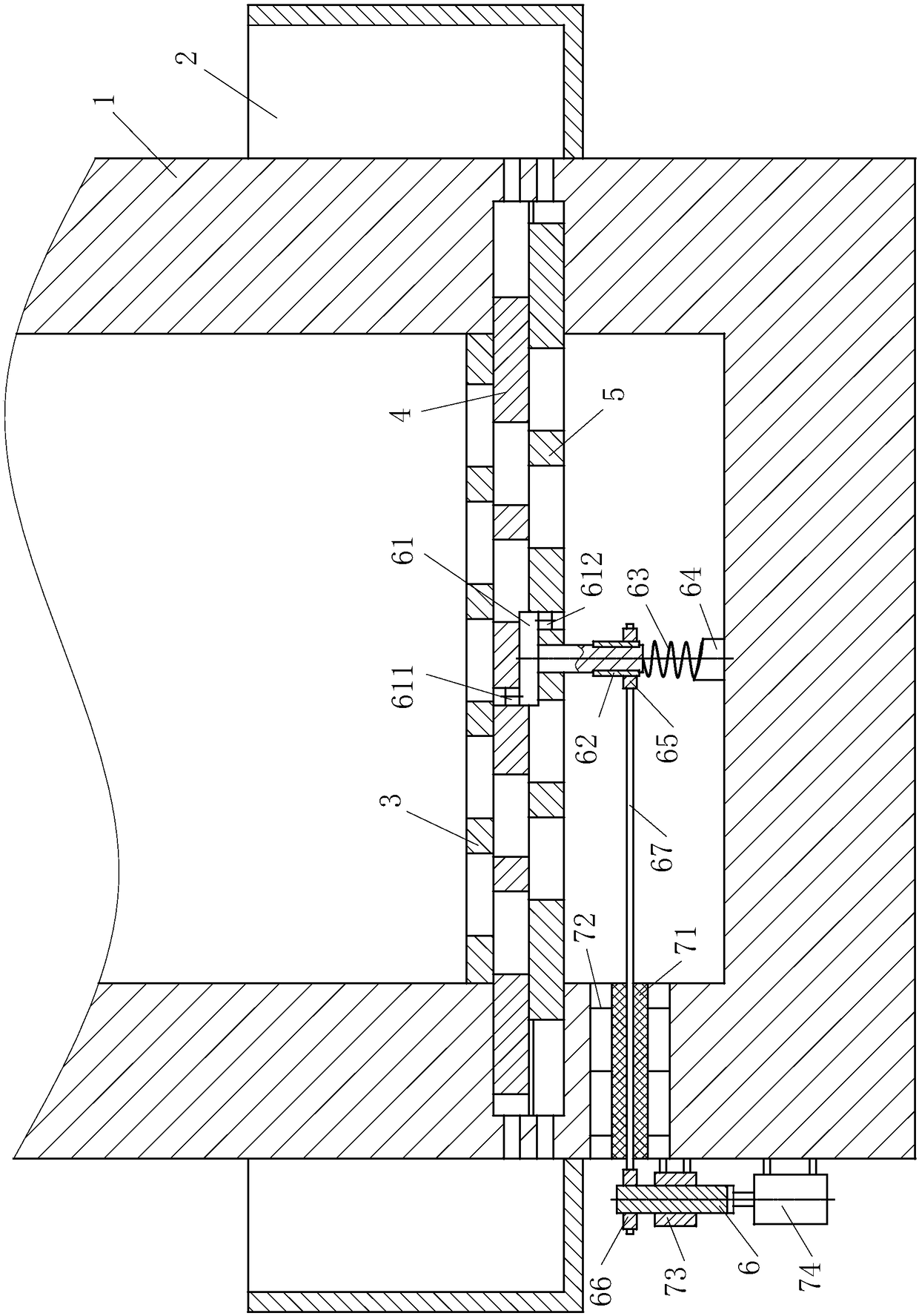

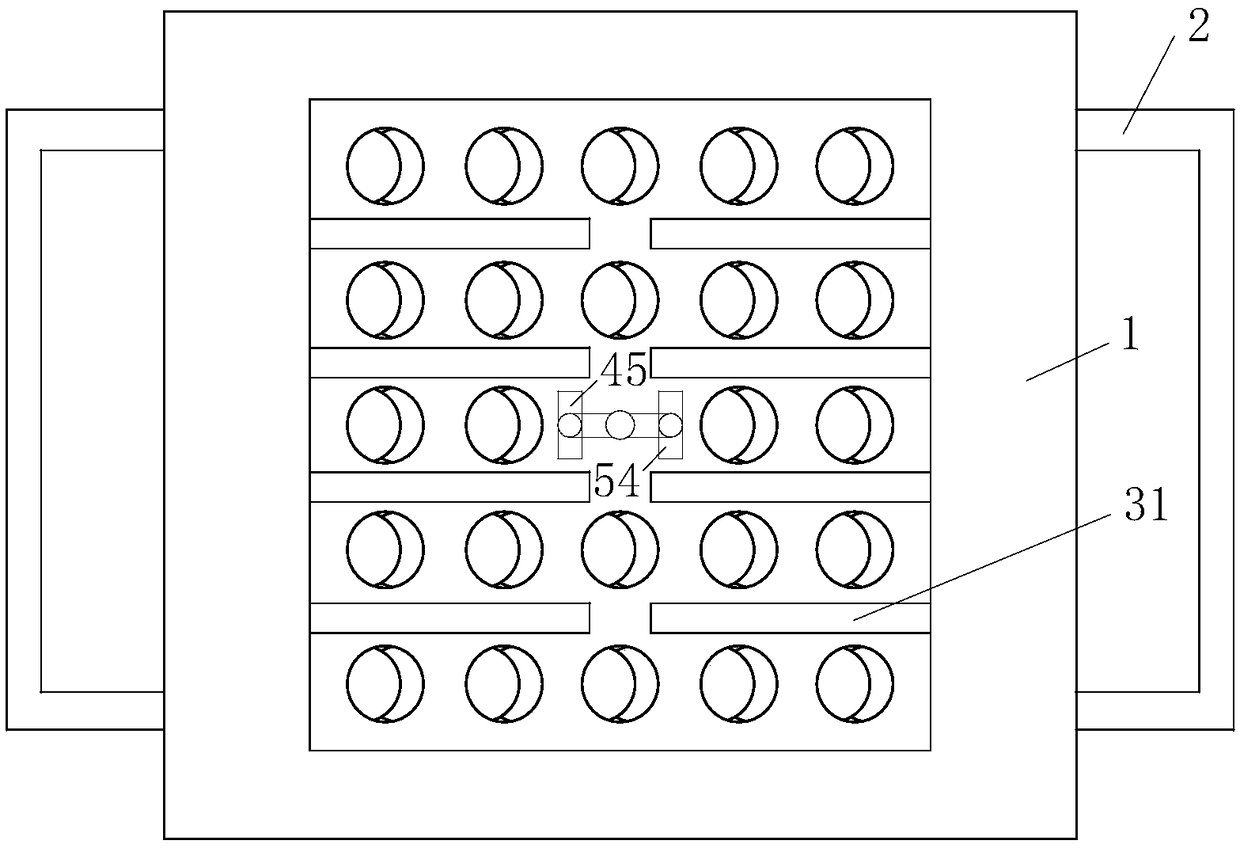

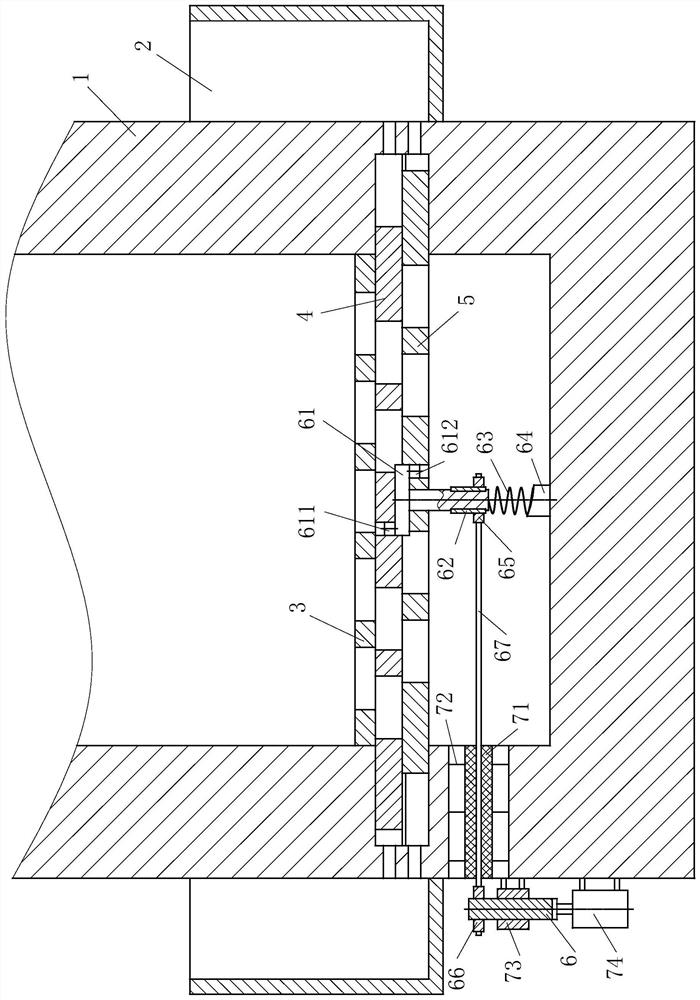

ActiveCN109264792AImprove combustion efficiencyImprove reliabilityMaterial nanotechnologyInorganic material magnetismCombustionDrive shaft

The invention belongs to the technical field of inorganic materials, and particularly relates to a preparation method of a CoFe2O4 nano particle. A combustion furnace in the preparation method comprises a furnace body, a material box, a supporting plate, an upper sliding plate, a lower sliding plate and a driving module, wherein the upper sliding plate is eccentrically provided with a 1# rectangular sliding chute; the lower sliding plate is eccentrically provided with a 2# rectangular sliding chute; a 1# cylindrical bulge is arranged above one end of a driving plate; the 1# cylindrical bulge slides in the 1# rectangular chute; a 2# cylindrical bulge is arranged below the other end of the driving plate; and the 2# cylindrical bulge slides in the 2# rectangular chute. According to the invention, the upper sliding plate and the lower sliding plate are driven to continuously and relatively slide through arranging a driving shaft, so as to realize the effect that a combustion improver is continuously ejected upwards on the left and right sides of the supporting plate; therefore, the combustion efficiency is high; further, the on-off control of the whole combustion furnace is realized through a mechanical structure; therefore, the reliability is high; furthermore, the combustion quality of the combustion furnace is ensured; and furthermore, the preparation efficiency of a carboxylated cobalt ferrite magnetic nano particle is improved.

Owner:东营睿港投资服务有限责任公司

a cofe 2 o 4 Preparation method of nanoparticles

ActiveCN109264792BImprove combustion efficiencyImprove reliabilityMaterial nanotechnologyInorganic material magnetismDrive shaftMagnetite Nanoparticles

The invention belongs to the technical field of inorganic materials, specifically a CoFe 2 o 4 A method for preparing nanoparticles. The combustion furnace in the preparation method includes a furnace body, a material box, a support plate, an upper slide, a lower slide, and a drive module; a No. 1 rectangular chute is set eccentrically on the upper slide; Rectangular chute; No. 1 cylindrical protrusion is set above one end of the driving plate, and the No. 1 cylindrical protrusion slides in the No. 1 rectangular slot. Sliding in a rectangular groove; the present invention drives the upper slide plate and the lower slide plate to continuously slide relative to each other by setting a drive shaft, so that the left and right sides of the support plate are continuously sprayed upward with combustion aid, so the combustion efficiency is high, and the on-off control of the whole device is passed The mechanical structure is realized, so the reliability is high, thereby ensuring the combustion quality of the device, and further improving the preparation efficiency of the carboxylated cobalt ferrite magnetic nanoparticles.

Owner:东营睿港投资服务有限责任公司

Cylinder section circular seam heating mechanism of pressure container

The invention discloses a cylinder section circular seam heating mechanism of a pressure container. Blockage plates are arranged at two end parts of carbon steel heating arc pipes; the center parts ofthe carbon steel heating arc pipes communicate with one end parts of natural gas conveying pipes; the other end parts of the natural gas conveying pipes are connected with a natural gas source; the carbon steel heating arc pipes are suspended to surround the cylinder section circular seam heating inner wall or outer wall of the pressure container; ventilation holes, distributed at intervals, areformed in the outer walls of the carbon steel heating arc pipes; burners are mounted on all the ventilation holes; fire outlet directions of all the burners are perpendicular to cylinder section circular seam heating surfaces in corresponding places; arc gaps are formed in the bottoms of the burners; and two end parts of the arc gaps are welded on the carbon steel heating arc pipes on two sides ofthe corresponding ventilation holes. The cylinder section circular seam heating mechanism of the pressure container guarantees uniform heating effect in each cylinder section circular seam heating place, improves the heating quality, and is simple in structure, easy to realize and excellent in application prospect.

Owner:ERZHONG GROUP ZHANJIANG HEAVY EQUIP FACTORYCO

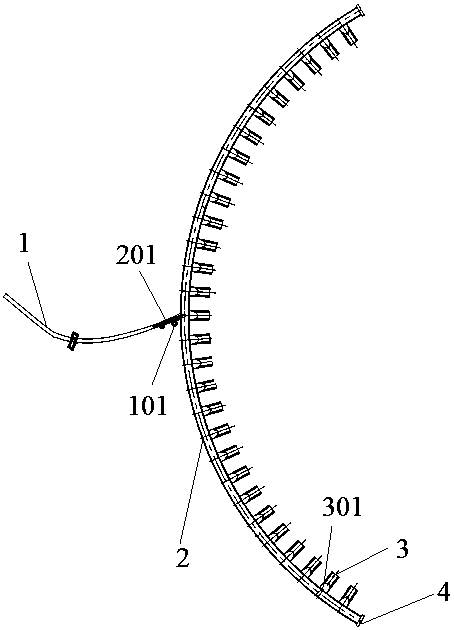

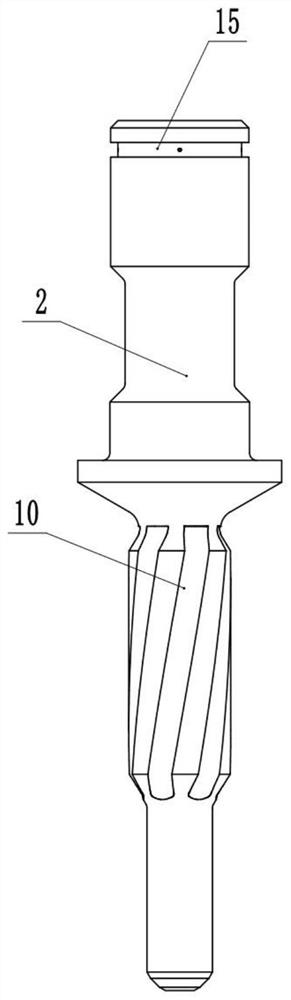

Novel needle valve matching part

ActiveCN114810443AFlexible controlReduce oilFuel injection apparatusMachines/enginesEngineeringInternal combustion engine

The invention relates to the technical field of needle valve matching parts of internal combustion engines, in particular to a novel needle valve matching part which comprises a needle valve body, a first-stage valve element, a second-stage valve element, a pressure adjusting spring, a reset spring, a control sleeve and a plug, the needle valve body is of a hollow structure, the first-stage valve element is installed in the needle valve body, the second-stage valve element is installed in the first-stage valve element, and a pressure storage cavity is formed in the bottom of the needle valve body. A plurality of first-layer spraying holes and a plurality of second-layer spraying holes are formed in the outer side of the pressure storage cavity, the first-level valve element can seal the pressure storage cavity, the bottom of the second-level valve element can stretch into the pressure storage cavity to seal the second-layer spraying holes, and the first-level valve element and the second-level valve element are adopted to independently control the two layers of spraying holes. The second-level valve element can be closed, only the first-level valve element is opened, and therefore only the first-layer spraying holes are opened, and the oil amount is reduced; when high oil quantity is needed, the two-stage valve element can be opened, so that the two layers of spray holes are opened, and the circulation sectional area is increased by increasing the number of the spray holes.

Owner:CHONGQING HONGJIANG MACHINERY

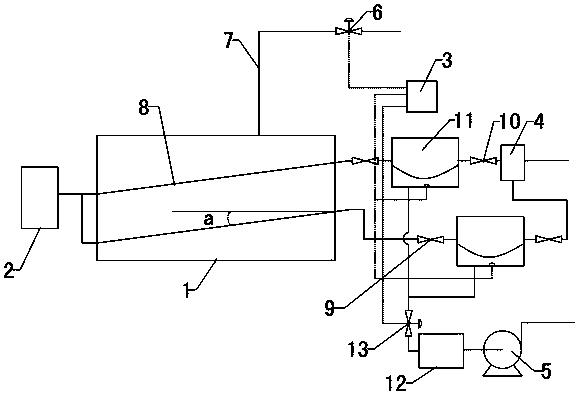

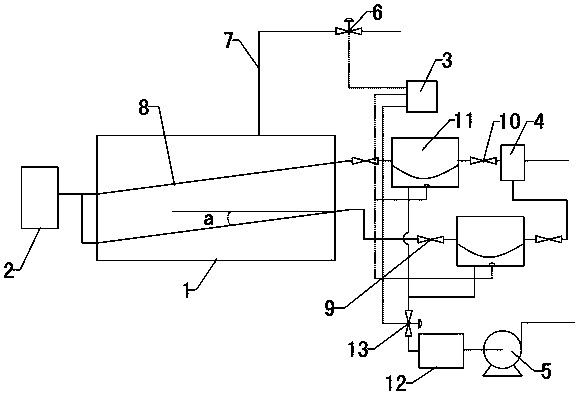

Negative-pressure liquefied gas preparation process

InactiveCN107631171AReduce volumeReduce energy consumptionContainer filling methodsPipeline systemsFuel gasGas mixing

The invention provides a negative-pressure liquefied gas preparation process and belongs to the technical field of liquefied gas preparation. The negative-pressure liquefied gas preparation process ischaracterized in that after a vacuum pump (5) is opened, negative pressure is formed in an oil-gas mixing pipe (8), air is sucked in, meanwhile liquid light hydrocarbons in a constant-liquid-level oil storage tank (1) are sucked into holes in the oil-gas mixing pipe (8), and the liquid light hydrocarbons in the oil-gas mixing pipe (8) are mixed with the air and gasified into air-mixed gas and enters gas chambers of negative-pressure tanks (11); and after the liquid light hydrocarbons in the constant-level oil liquid tank (1) are reduced, the liquid light hydrocarbons are supplemented in realtime so that the center position of the oil-gas mixing pipe (8) can be always in the position 45 cm-55 cm below the liquid light hydrocarbon liquid level. According to the negative-pressure liquefiedgas preparation process, because gasification can be accelerated under both the negative pressure and the air flow, the light hydrocarbons are gasified quickly in the flowing process, the size of thesystem is reduced, the energy consumption is lowered, and the gas preparation efficiency is improved.

Owner:SHANDONG UNIV OF TECH

A negative pressure liquefied gas preparation process

InactiveCN107631171BEasy accessGuaranteed combustion qualityContainer filling methodsPipeline systemsLiquid tankGas chamber

A negative pressure liquefied gas preparation process belongs to the technical field of liquefied gas preparation. It is characterized in that: the gas production process is: after the vacuum pump (5) is turned on, negative pressure is formed in the oil-gas mixing pipe (8) to inhale air, and at the same time, the holes on the oil-gas mixing pipe (8) are sucked into the constant liquid level oil storage tank (1) at the same time The liquid light hydrocarbons are mixed with air in the oil-gas mixing tube (8) and gasified to form mixed air gas, which enters the gas chamber of the negative pressure box (11); the liquid light hydrocarbons in the constant liquid level oil storage tank (1) After the hydrocarbons are reduced, liquid light hydrocarbons are replenished in real time so that the center of the oil-gas mixing pipe (8) is always 45cm-55cm below the liquid light hydrocarbon level. Because the gasification can be accelerated under both the negative pressure and the air flow, the present invention makes the light hydrocarbon gasify rapidly during the flowing process, not only reduces the volume of the system, reduces energy consumption, but also improves the gas preparation efficiency.

Owner:SHANDONG UNIV OF TECH

A small-scale light hydrocarbon gas generation gas production process

InactiveCN107327868BThe production ofAvoid taking awayLiquid fuel feeder/distributionLiquid fuel pretreatmentAir blowerPorous ceramics

The invention relates to a small light hydrocarbon gas generating process for gas production, which belongs to the technical field of gas generating equipment. It is characterized in that: the tank body is composed of a light hydrocarbon raw material chamber (1), a control chamber (2), a spray chamber (3), a porous ceramic material chamber (4), and a steady flow chamber (5) in order from top to bottom. and the rectification chamber (6), the height of the porous ceramic material chamber (4) is 45cm~55cm; the bottom opening of the rectification chamber (6) is connected to the hot air blower (7); the spray chamber (3) ) is provided with an upward gas output pipe (8). Fill the liquid light hydrocarbon raw material into the light hydrocarbon raw material chamber (1), start the hot air blower (7) after the fuel injection nozzle starts to inject oil for 8s~15s and start to send hot air. gas. The invention is an independent, small-sized light hydrocarbon gas generating equipment and a gas-making process that can be used by independent households and have stable gas quality.

Owner:SHANDONG UNIV OF TECH

Domestic garbage continuous incinerator

InactiveCN1282849CGuaranteed combustion qualityBurn fullyIndirect carbon-dioxide mitigationIncinerator apparatusCombustion systemSlag

The present invention relates to a domestic refuse continuous incinerator. It includes the components of rotary drying and combustion system, chimney, rotary distributor system, furnace body, non-sticky furnace wall, air-inducing and air-feeding system, air inlet tube, slag discharge pipe, high-temp. fan, oxygen-enriching device, water-vapour separator and feeding hopper, etc.

Owner:滕清华

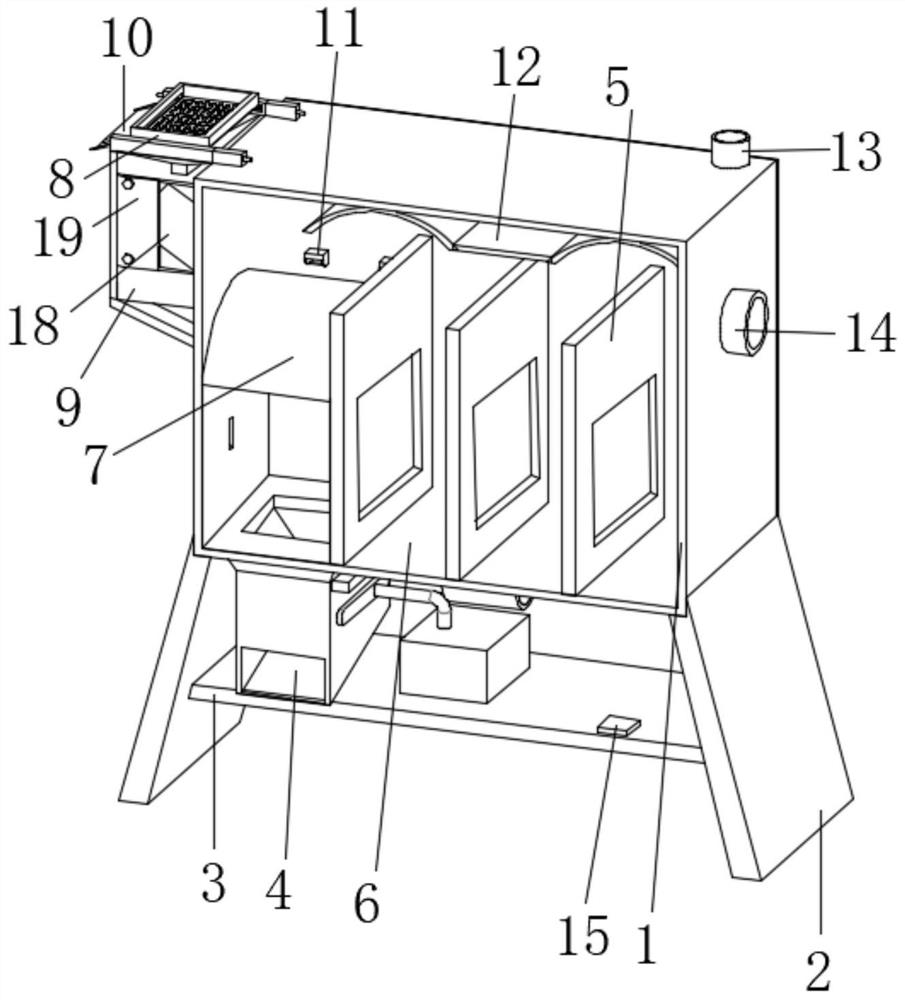

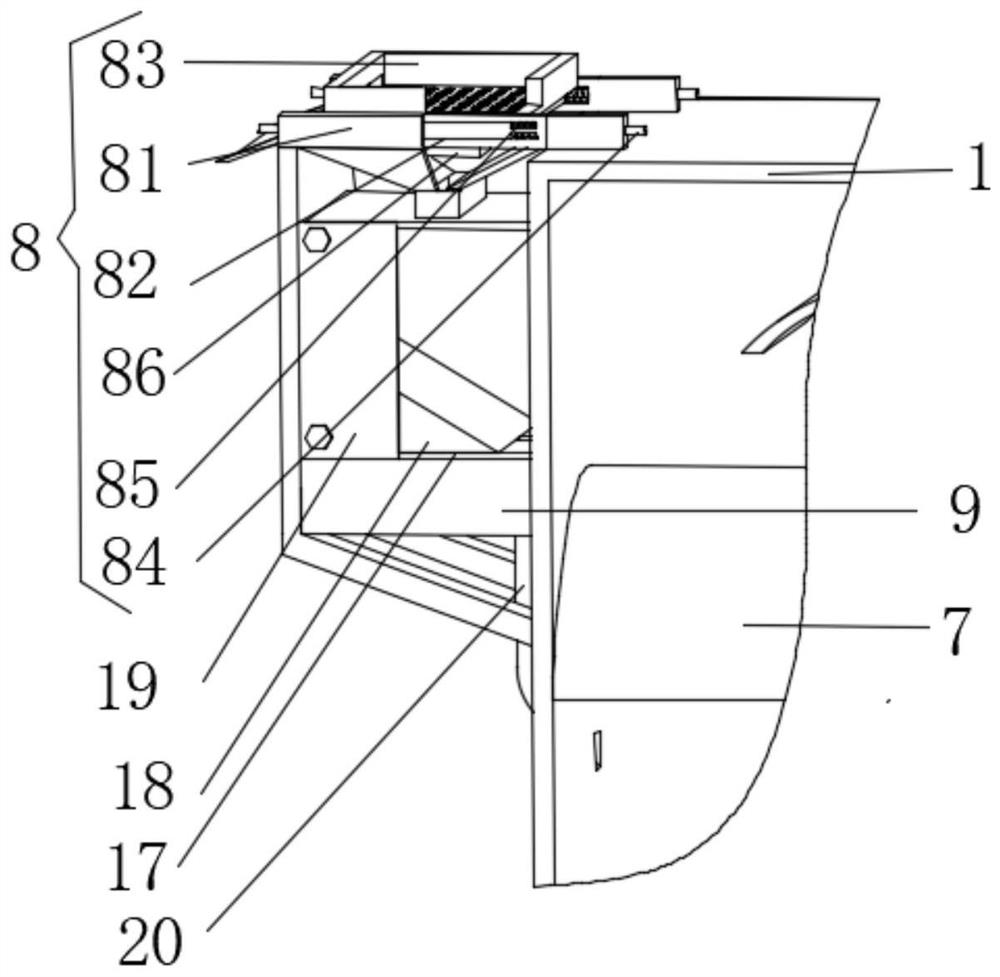

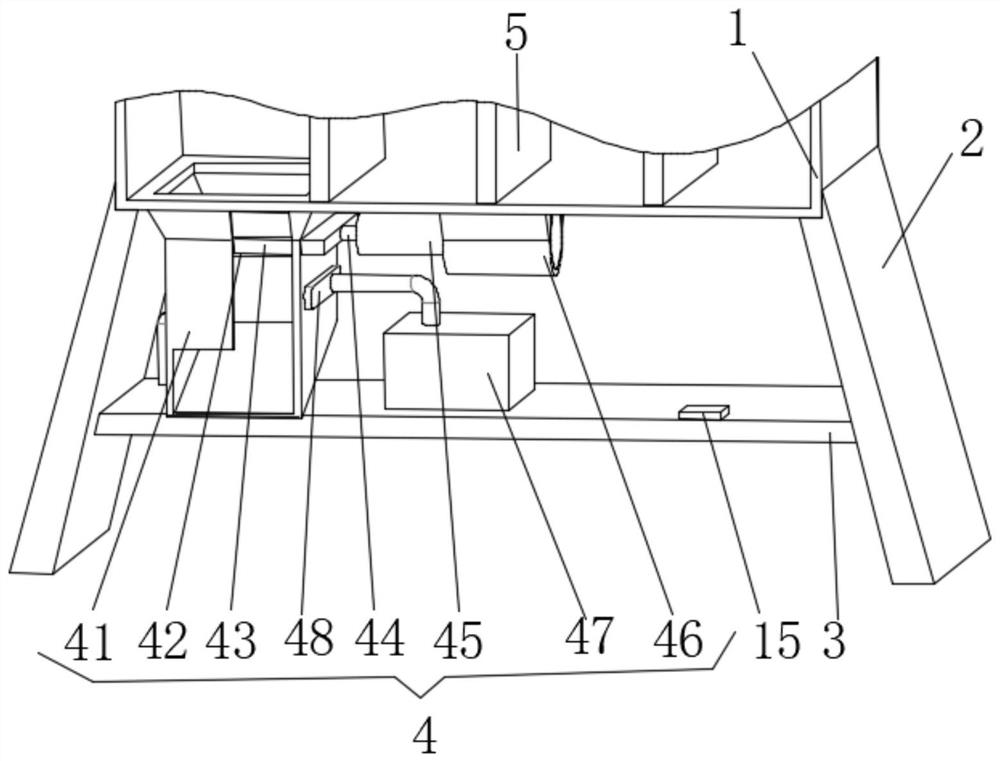

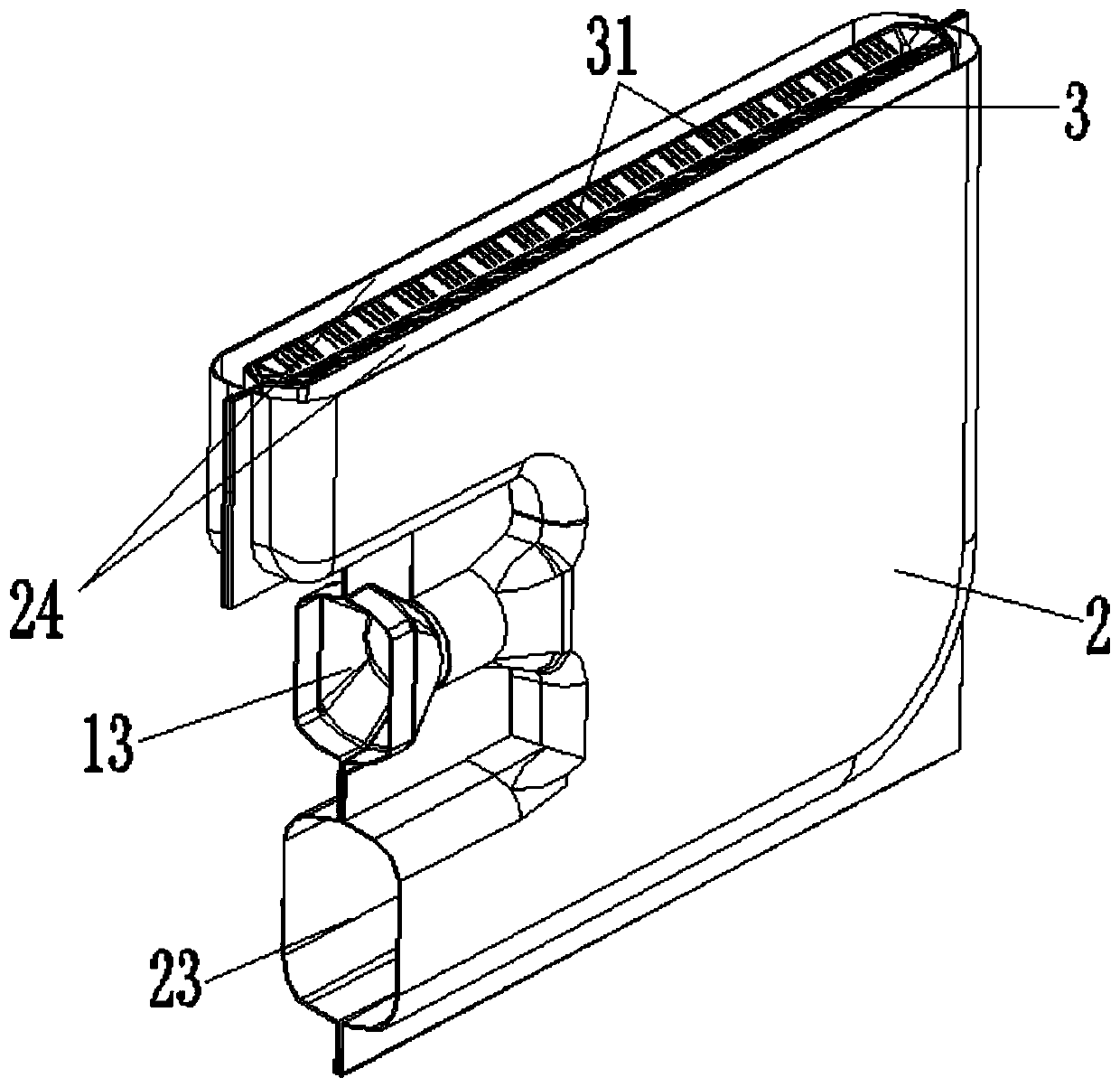

Novel fluidized bed roaster

PendingCN112524602AGuaranteed combustion qualityEfficient combustionSievingFluidized bed combustionCoal briquetteCombustion

The invention discloses a novel fluidized bed roaster. The fluidized bed roaster comprises a box body, a slag tapping structure and a screening structure, wherein supporting legs are symmetrically distributed at the left end and the right end of the lower surface of the box body; a supporting plate is arranged between the two supporting legs; heat insulation plates are evenly distributed in the box body; a boiling chamber is arranged between every two adjacent heat insulation plates; an arc-shaped plate is arranged at the upper end of the boiling chamber at the left end; a heat absorption plate is arranged on the rear wall face of the box body; a support is arranged at the upper end of the left side face of the box body; an air blower is arranged at the rear end of the left side of the upper surface of the supporting plate; the front end of an air outlet pipe arranged at the upper end of the rear side face of the box extends into the box body; the air blower is connected to an air inlet of the air outlet pipe through an air pipe; and the slag tapping structure is arranged at the lower end of the box body and is fixedly connected to the supporting plate. According to the novel fluidized bed roaster, large coal briquettes are blocked, the combustion quality is guaranteed, the balance of heat in the box body is guaranteed, efficient combustion is achieved, humidifying operation isconducted on ash, automatic slag tapping is conducted, and the operation safety is guaranteed.

Owner:HUBEI XINYE THERMAL ENERGY ENG CO LTD

Nozzle sheet, combustor and gas water heater

The invention provides a nozzle sheet, a combustor and a gas water heater. The nozzle sheet comprises a mixed gas flow channel shell, a nozzle sheet outer shell, a mixed gas flow channel is formed inthe mixed gas flow channel shell, the mixed gas flow channel is provided with a first outlet, the first outlet is covered with a nozzle sheet cover, the mixed gas flow channel shell is located in a nozzle sheet shell, a secondary air flow channel is formed between the mixed gas flow channel shell and the nozzle sheet shell, the secondary air flow channel is provided with a second outlet, and the second outlet surrounds the nozzle sheet cover. According to the nozzle sheet, the combustor and the gas water heater, secondary air can surround the nozzle sheet cover, secondary air distribution is more uniform, combustion noise can be lowered, and the gas combustion quality can be improved.

Owner:GREE ELECTRIC APPLIANCES INC

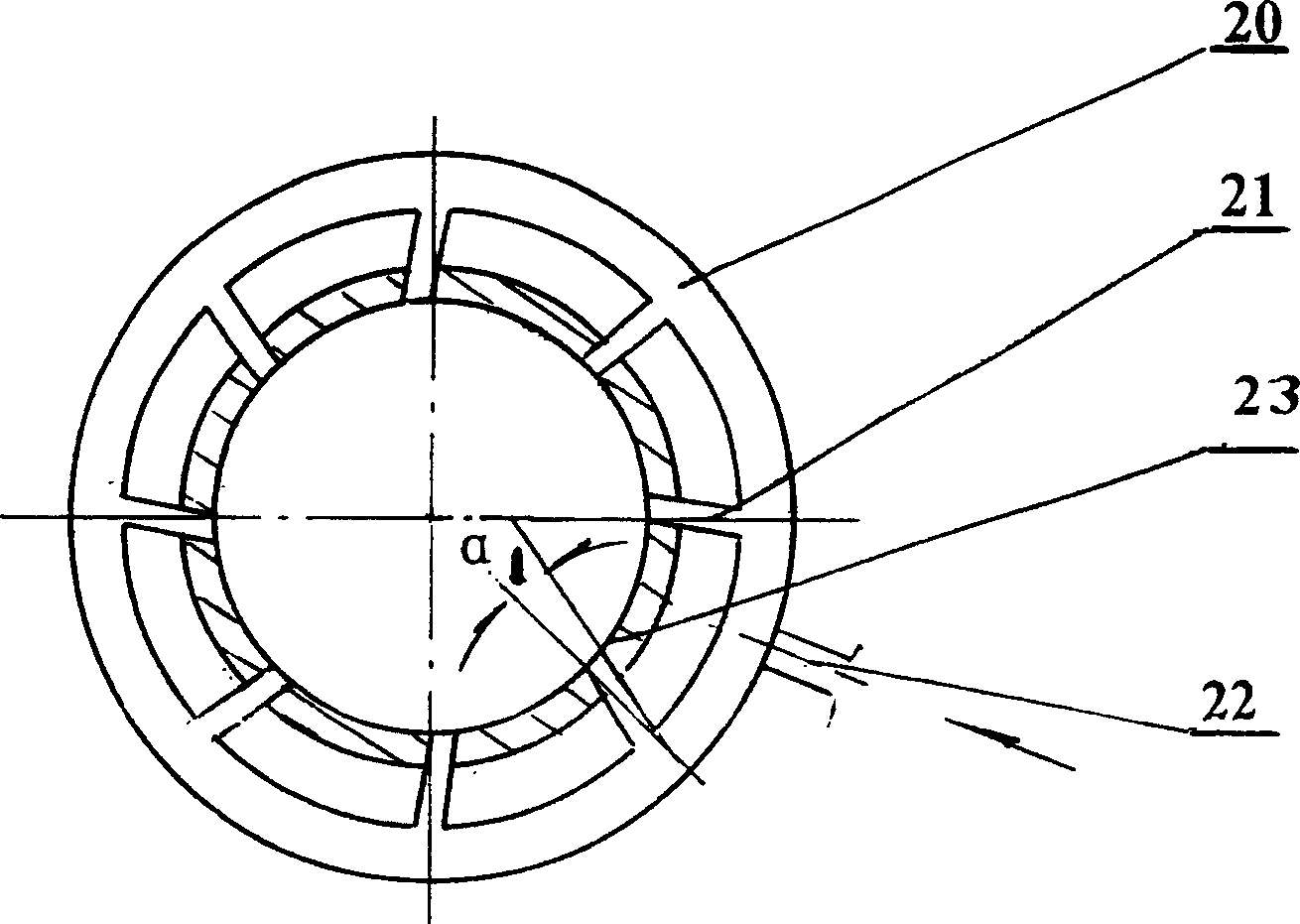

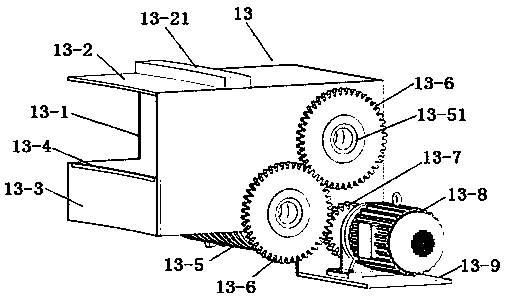

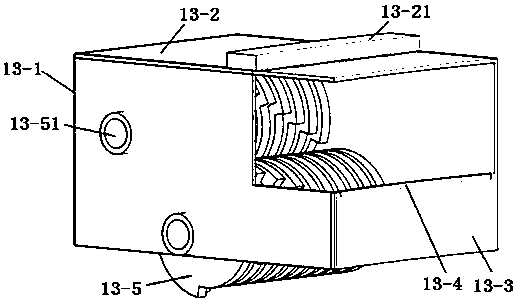

Slag breaking apparatus for biomass combustor and realization method

PendingCN108479928AGuaranteed combustion qualitySolid fuel combustionGrain treatmentsGear driveCombustor

The invention relates to a slag breaking apparatus for a biomass combustor and a realization method. A motor I drives a small gear to rotate, the small gear drives two engaged large gears to rotate, two slag breakers fixedly connected with the two large gears rotate in a face-to-face manner, the slag-bonding biomass fuel successively moves toward the slag breakers by virtue of an ash inlet and anoblique surface of a guide plate, the slag-bonding biomass fuel is driven by two end surfaces of large semicircles of the two slag breakers to enter a plurality of grooves which are arranged correspondingly, a plurality of large semicircles enter the plurality of grooves to crush the slag-bonding biomass fuel, and the crushed biomass fuel is discharged from a lower port of an ash discharging box.The slag breaking apparatus has the beneficial effects that the slag breaker of the slag breaking apparatus is formed by a plurality of eccentric wheels, i.e., concentric cam sheets, and the pluralityof eccentric wheels are divided into two groups and arranged in an intersecting manner on an ash outlet on the tail end of the combustor. By adopting the structural design of the slag breaking apparatus, the reside, i.e., coke fragments generated by the biomass combustor can be crushed in an engagement manner at any time and then is discharged from the lower port of the ash discharging box, so that the combustion quality of the biomass combustor can be ensured.

Owner:天津市星拓科技发展有限公司

A method of using biomass to produce liquid fuel

ActiveCN110467940BImprove combustion qualityFully convertedLiquid hydrocarbon mixture productionHydrocarbon oils treatmentCelluloseOil and grease

The invention provides a method for producing liquid fuel by using biomass, which uses biomass to perform pretreatment, pyrolysis reaction and catalytic cracking reaction to obtain liquid fuel. Among them, biomass is composed of pine needles, bamboo, tung tree branches, ginger leaves, Chinese toon branches, sweet potato seedlings, enteromorpha, slaughterhouse scraps, etc. Seedlings contain volatile oil, grease, cellulose, lignin, etc. Hantai contains a lot of carbohydrates, protein, crude fiber, fatty acids, etc., and the leftovers of slaughterhouses are rich in oil. These biomass raw materials are subjected to pyrolysis and catalytic cracking reactions. Fully converted, the combustion quality of the obtained liquid fuel is excellent.

Owner:台州镘霓电子商务有限公司

Composite antioxidant and anti-adhesive agent for oil products and preparation method thereof

InactiveCN105219456BImprove performancePrevent discolorationLiquid carbonaceous fuelsGlycerolColor changes

The invention relates to a compound anti-oxidization anti-gelling agent for an oil product and a preparation method of the compound anti-oxidization anti-gelling agent and belongs to the technical field of oil gas additives. The compound anti-oxidization anti-gelling agent for the oil product is prepared from the following components in parts by weight: 1 to 2 parts of butylated hydroxyanisole, 0.5 to 1.5 parts of alkyl glycoside, 2 to 5 parts of stearic acid, 0.1 to 0.2 parts of triethylene glycol bi[beta-(3-tertiary butyl-4-hydroxy-5-methyl phenyl)propionate, 0.1 to 0.2 parts of bi(2,4-bitertiary butyl phenyl)pentaerythritol biphosphite, 1 to 2 parts of diosmetin, 1 to 3 parts of nano calcium carbonate, 15 to 19 parts of ethanol and 5 to 10 parts of glycerol. The compound anti-oxidization anti-gelling agent for the oil product has good stability; the performance of the compound anti-oxidization anti-gelling agent is not influenced after the compound anti-oxidization anti-gelling agent is stored for a long period; the oil product is prevented from color change when the oil product is stored; original colloid in the oil product can be completely removed and the formation of colloids is inhibited; the quality of the oil product is effectively improved.

Owner:重庆索银新能源科技有限公司

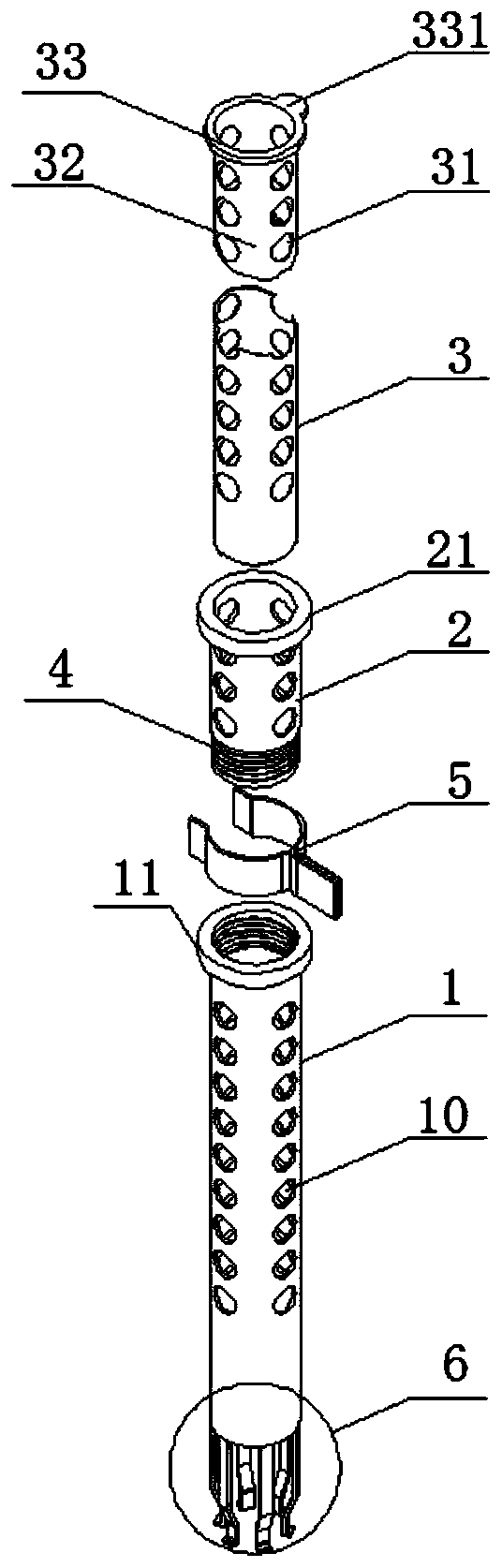

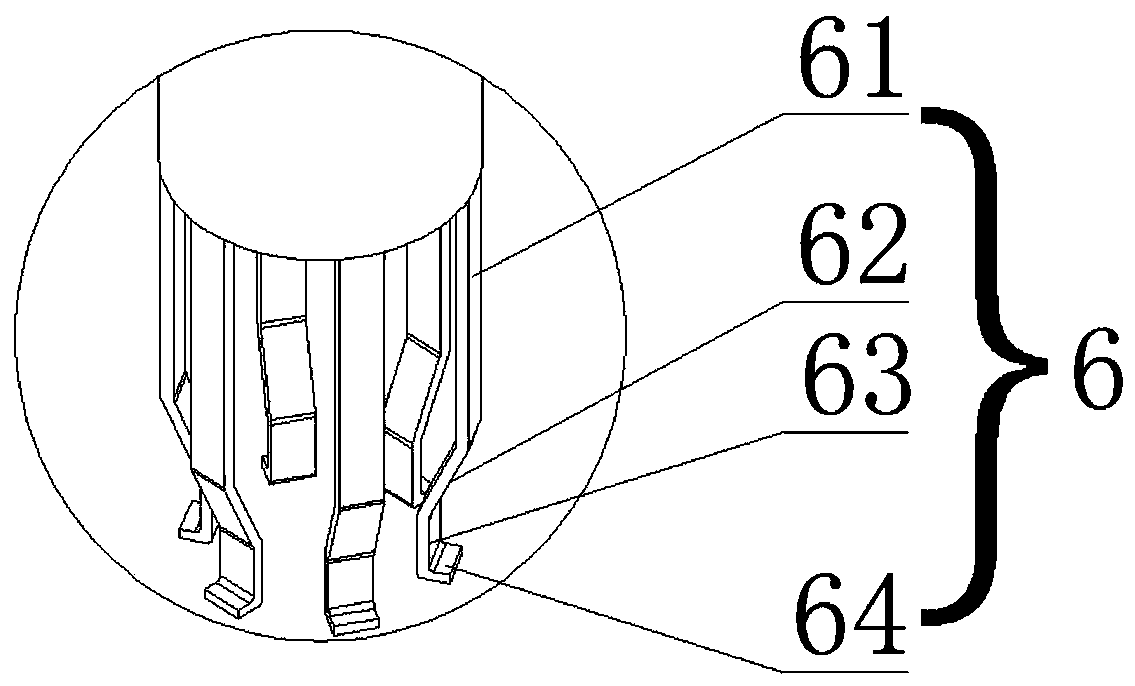

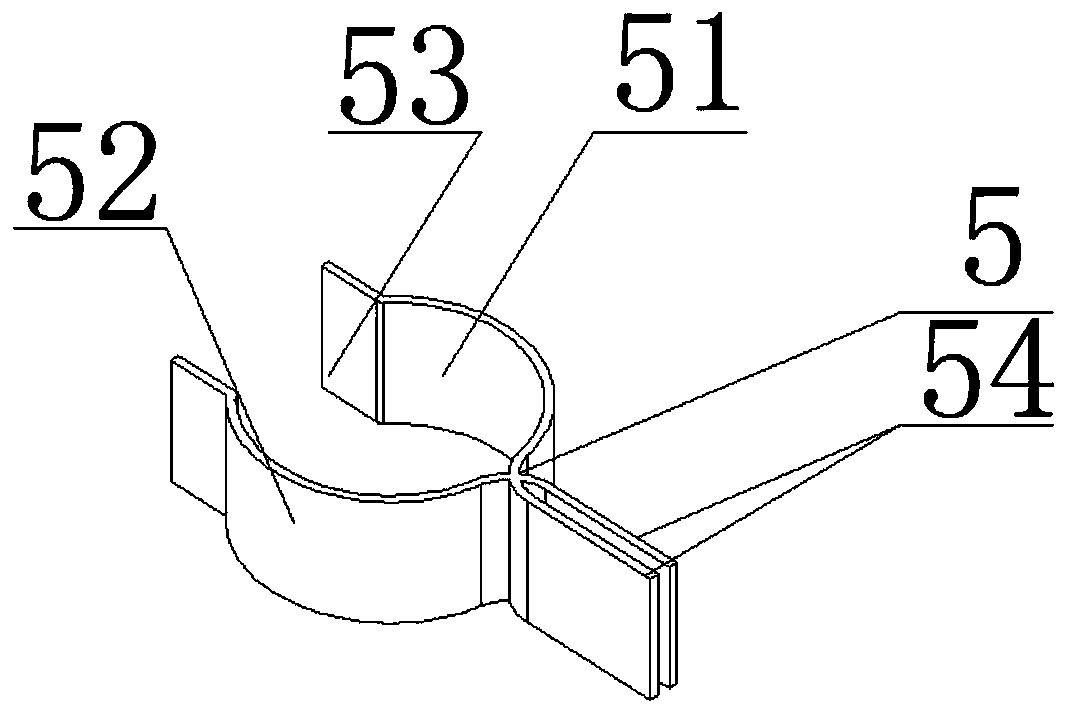

Improved moxa support for traditional Chinese medical science acupuncture and moxibustion physiotherapy

ActiveCN110522633AImprove the accuracy of useQuality assuranceDevices for heating/cooling reflex pointsAcupunctureTreatment effectEngineering

The invention discloses an improved moxa support for traditional Chinese medical science acupuncture and moxibustion physiotherapy. The improved moxa support comprises a moxa support body, wherein themoxa support body consists of a moxa support outer housing and a moxa support inner housing; the moxa support inner housing is arranged in the moxa support outer housing in a sleeving connecting manner; and the moxa support housing is used for limiting the moxa support inner housing. According to the improved moxa support for traditional Chinese medical science acupuncture and moxibustion physiotherapy disclosed by the invention, under the premise that the using quality of the moxa support is guaranteed, real-time adjustment of the position of moxa relative to the moxa support is convenient for an operator to perform according to practical using requirements, so that the using quality of the improved moxa support is effectively guaranteed; and in addition, a third cylinder body is arranged to be used as a medium for supporting the moxa, so that the position of the moxa in the moxa support is convenient to guarantee, the situation that the moxa is displaced during the needle moving operation of acupuncture and moxibustion needles is effectively avoided, and the treatment effect of moxibustion treatment is reduced.

Owner:瑞安市职业中等专业教育集团学校

engine intake manifold

ActiveCN106286044BEmission reductionSolve the problem of uneven air intakeInternal combustion piston enginesCombustion-air/fuel-air treatmentCombustionInlet manifold

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Large wind barn small air scoop crossbeam type chain-grate

InactiveCN101290122BImprove combustion qualityReduce wind speedTravelling grateEngineeringWind speed

The invention discloses an endless grate, in particular to a big wind bin and small wind catcher crossbeam-type endless grate. The endless grate comprises a frame consisting of a middle beam (2), an upper lead rail (1) and a lower lead rail (12); a furnace chain connected with a drive device is arranged on the frame; the endless grate is characterized in that: the lower part of the furnace chain on the upper part is provided with a wind bin (11) communicated with the furnace chain; a wind chest (14) communicated with the wind bins (14) is arranged on the whole side of the grate; the wind chest (14) is connected with a wind supply device. The endless grate changes the mode that each wind chamber respectively supplies wind in the prior art, thereby greatly reducing wind speed, stabilizing wind pressure, ensuring the even wind supply to the furnace chain, improving the burning quality of fuel and saving energy.

Owner:瓦房店市永宁机械厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com