Novel needle valve matching part

A coupling and needle valve technology, which is applied in the direction of engine components, charging systems, fuel injection devices, etc., can solve the problem of reducing the service life of the needle valve coupling, can not solve the problem of oil volume under high and low working conditions, and the atomization effect of the needle valve coupling Poor problems, to achieve the effect of prolonging service life, improving atomization effect and quality, and improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

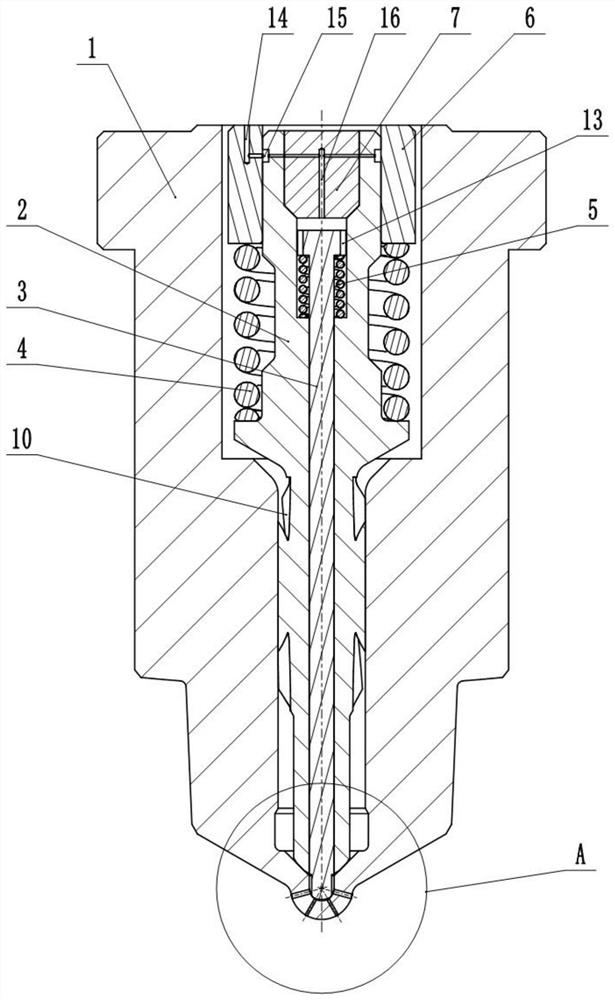

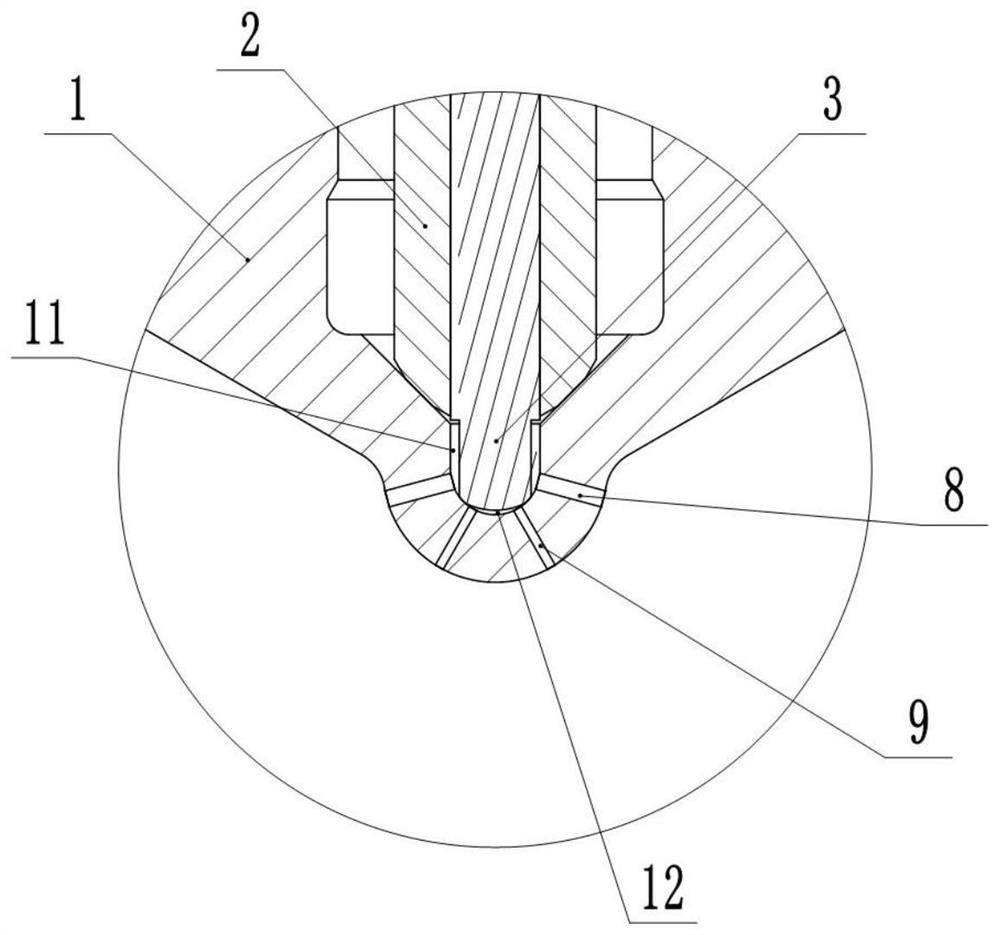

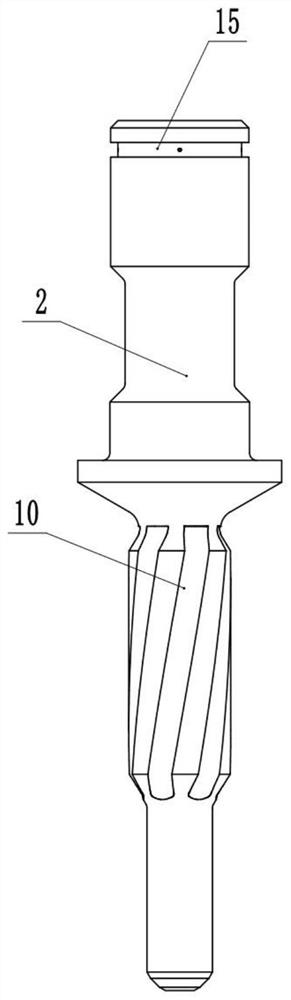

[0027] basically as attached figure 1 Shown: a new type of needle valve coupler, including needle valve body 1, primary valve core 2, secondary valve core 3, pressure regulating spring 4, return spring 5, control sleeve 6 and plug 7, needle valve The body 1 is a hollow structure, the primary valve core 2 is installed in the needle valve body 1, the secondary valve core 3 is installed in the primary valve core 2, the needle valve body 1 and the primary valve core 2, the primary valve core 2 and the primary valve core 2 are installed. The matching pair gap of the secondary valve core 3 is 3 μm to 5 μm. figure 2 As shown in the figure, the bottom of the needle valve body 1 is provided with a pressure accumulating cavity, and there are several first-layer nozzle holes 8 and several second-layer nozzle holes 9 on the outside. The valve core 2 can close the pressure accumulating cavity, and the bottom of the secondary valve core 3 can extend into the pressure accumulating cavity t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com