Large wind barn small air scoop crossbeam type chain-grate

A technology of chain grate and air bucket, which is applied in the direction of mobile grate, grate, lighting and heating equipment, etc. It can solve the problems of reducing combustion efficiency, uneven air distribution, and affecting combustion, so as to improve combustion quality and supply power. The effect of uniform wind and reduced wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

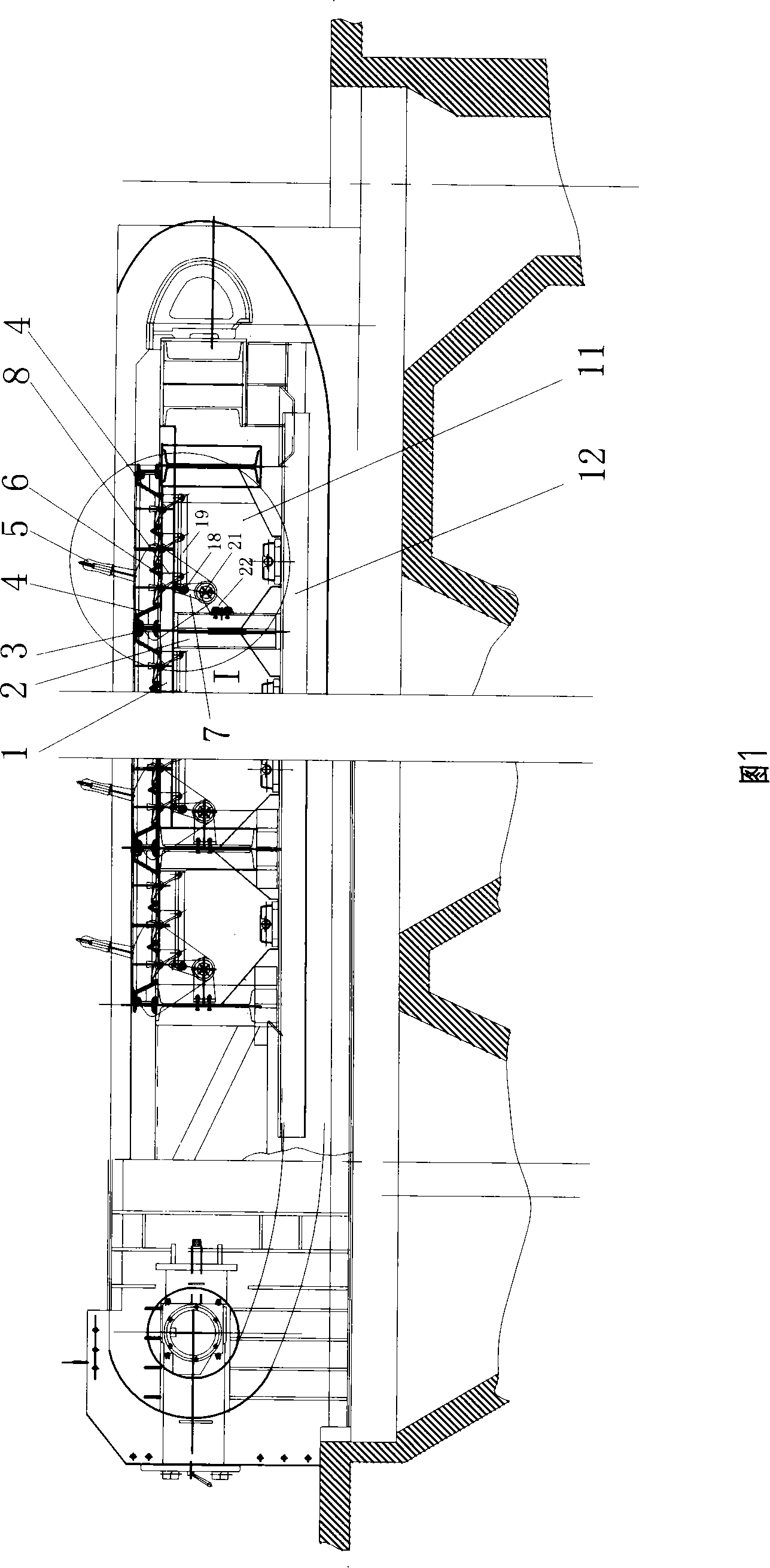

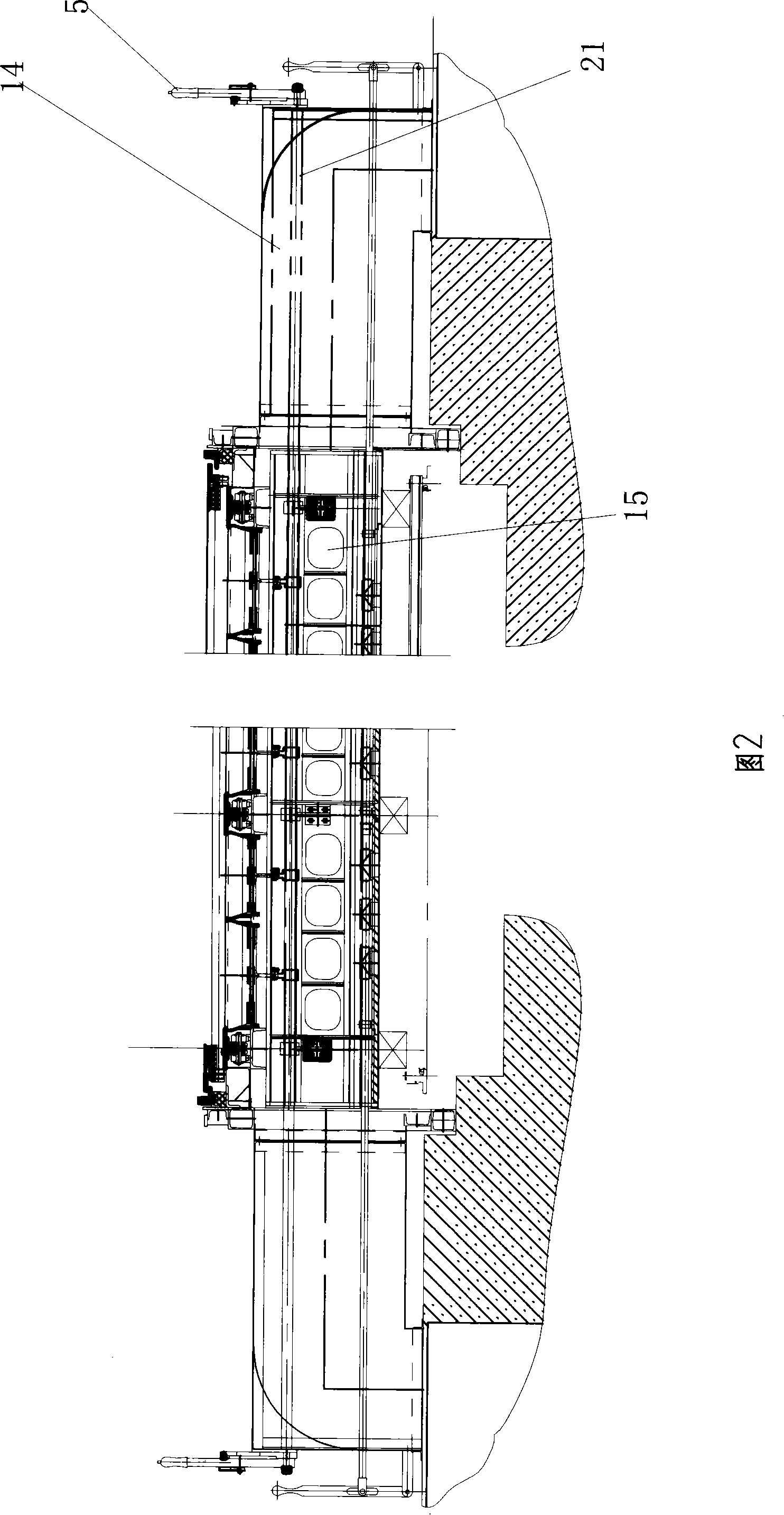

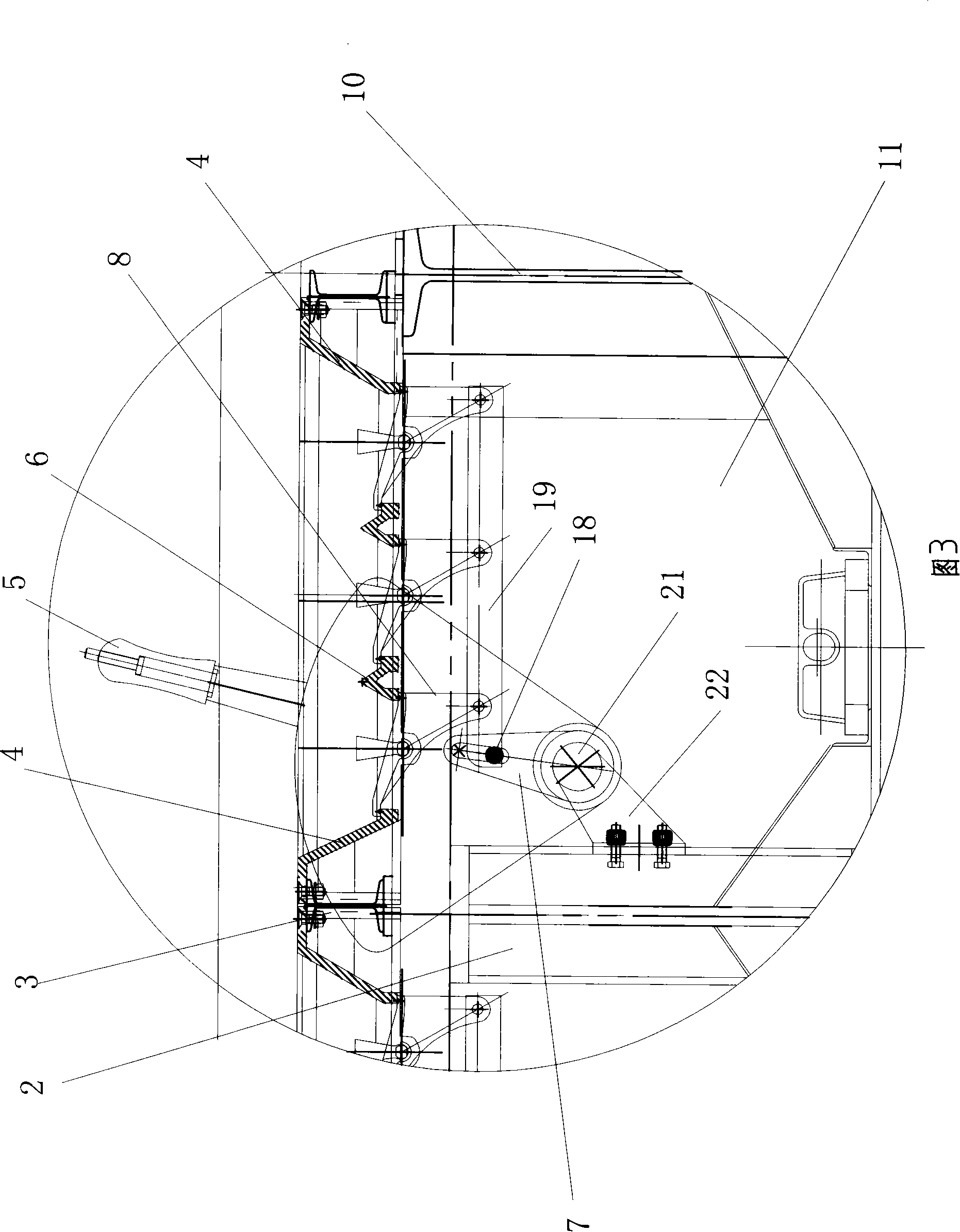

[0014] As shown in the figure: 2 is the middle beam, 1 is the upper guide rail, and 12 is the lower guide rail. The frame is composed of the middle beam 2, the upper guide rail 1 and the lower guide rail 12, and the furnace chain connected with the driving device is installed on the frame. When the furnace chain forms a ring shape and rotates, the fuel is located above the upper furnace chain. Interconnected wind bins 11 are formed under the upper furnace chain, that is, each center beam 2 is processed with a through hole 15, and the area between adjacent center beams 2 communicates with each other through the through hole 15, forming a An integral large air chamber 11 is quite different from an independent air chamber formed between each center beam 2 in the prior art. There is the bellows 14 that communicates with the wind storehouse 11 on all the sides of both sides of the whole fire grate, and the bellows 14 connects the air supply device. When working, the air supply dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com