Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

290results about "Liquid fuel pretreatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

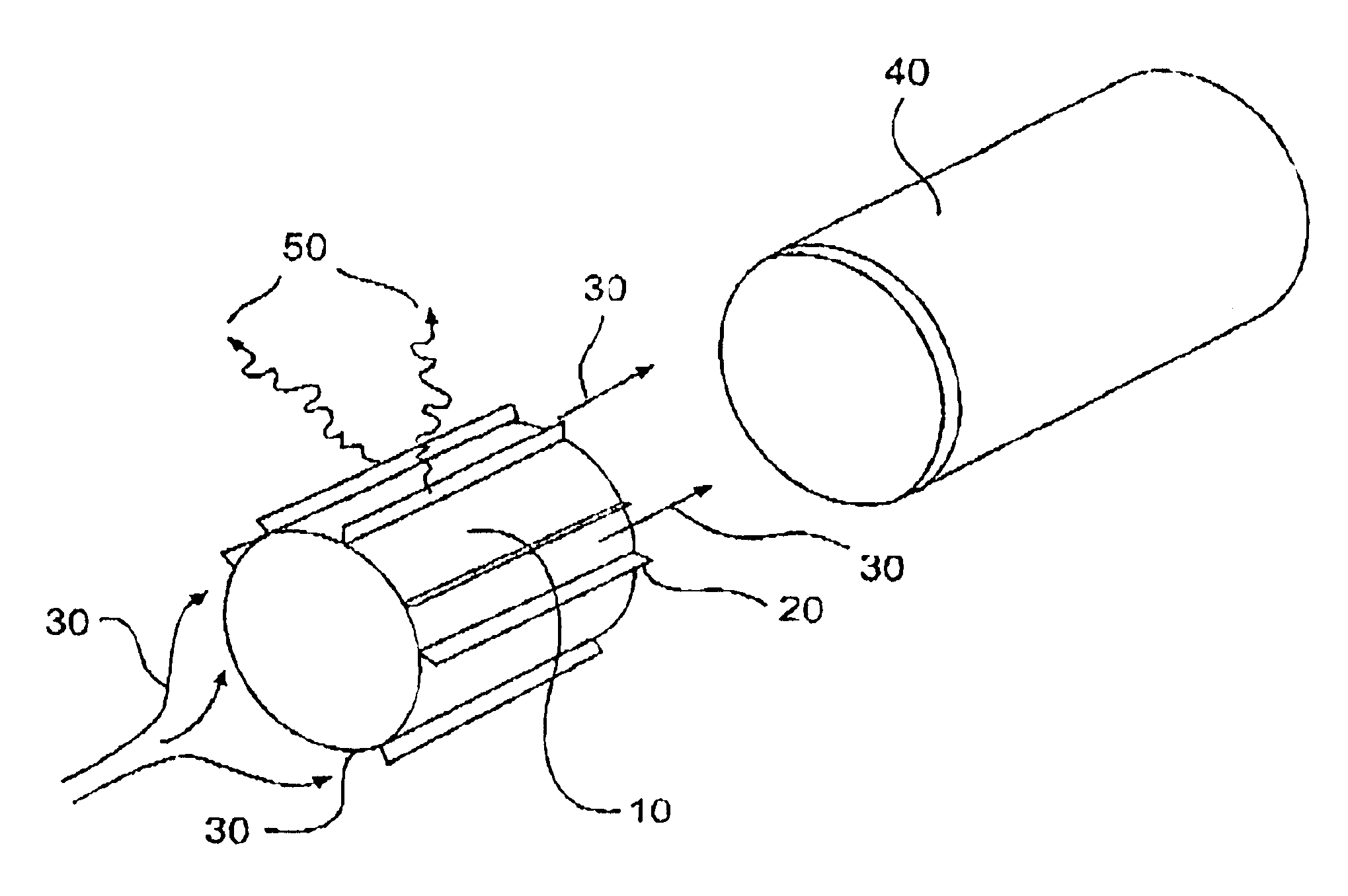

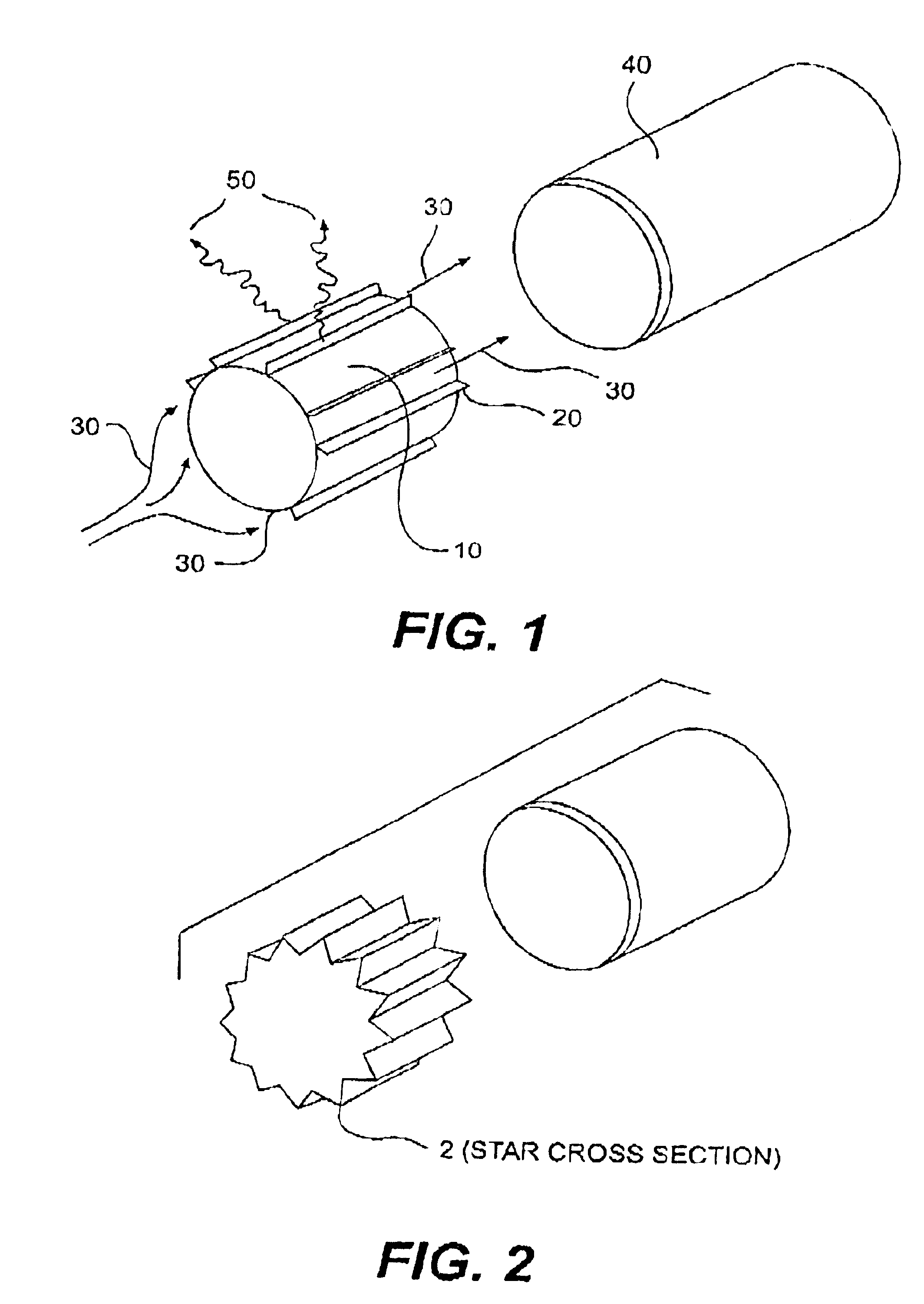

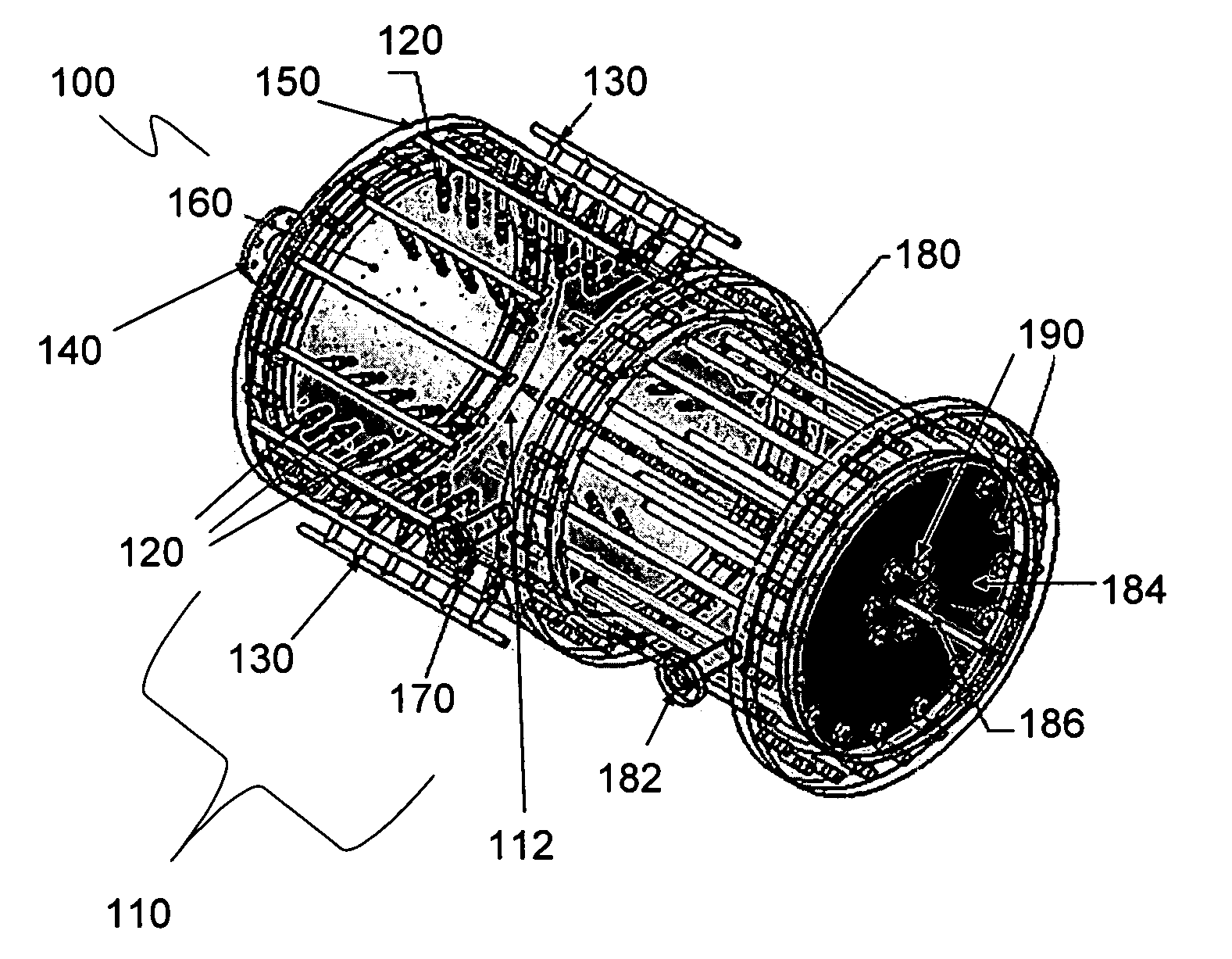

Method and apparatus to increase combustion efficiency and to reduce exhaust gas pollutants from combustion of a fuel

InactiveUS6851413B1Improve combustion efficiencyFacilitate fuel combustionBurnersLiquid fuel feeder/distributionCombustorExhaust fumes

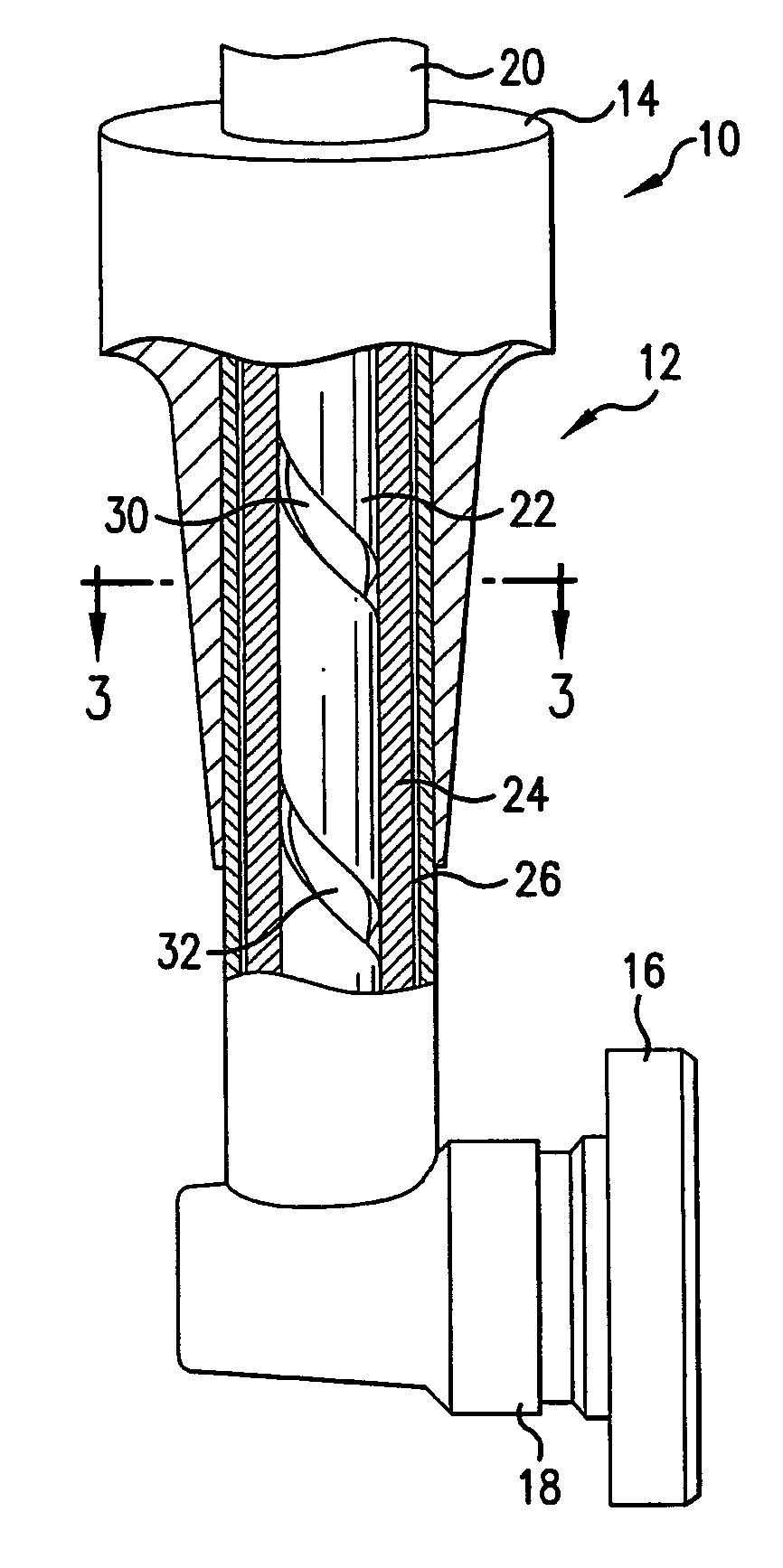

A method and apparatus is disclosed for increasing combustion efficiency in internal combustion engines and external combustors resulting in increased fuel economy and reduced exhaust pollutants. The same principles and apparatus of the invention are used in the exhaust stream to further reduce pollutants.

Owner:RONNELL

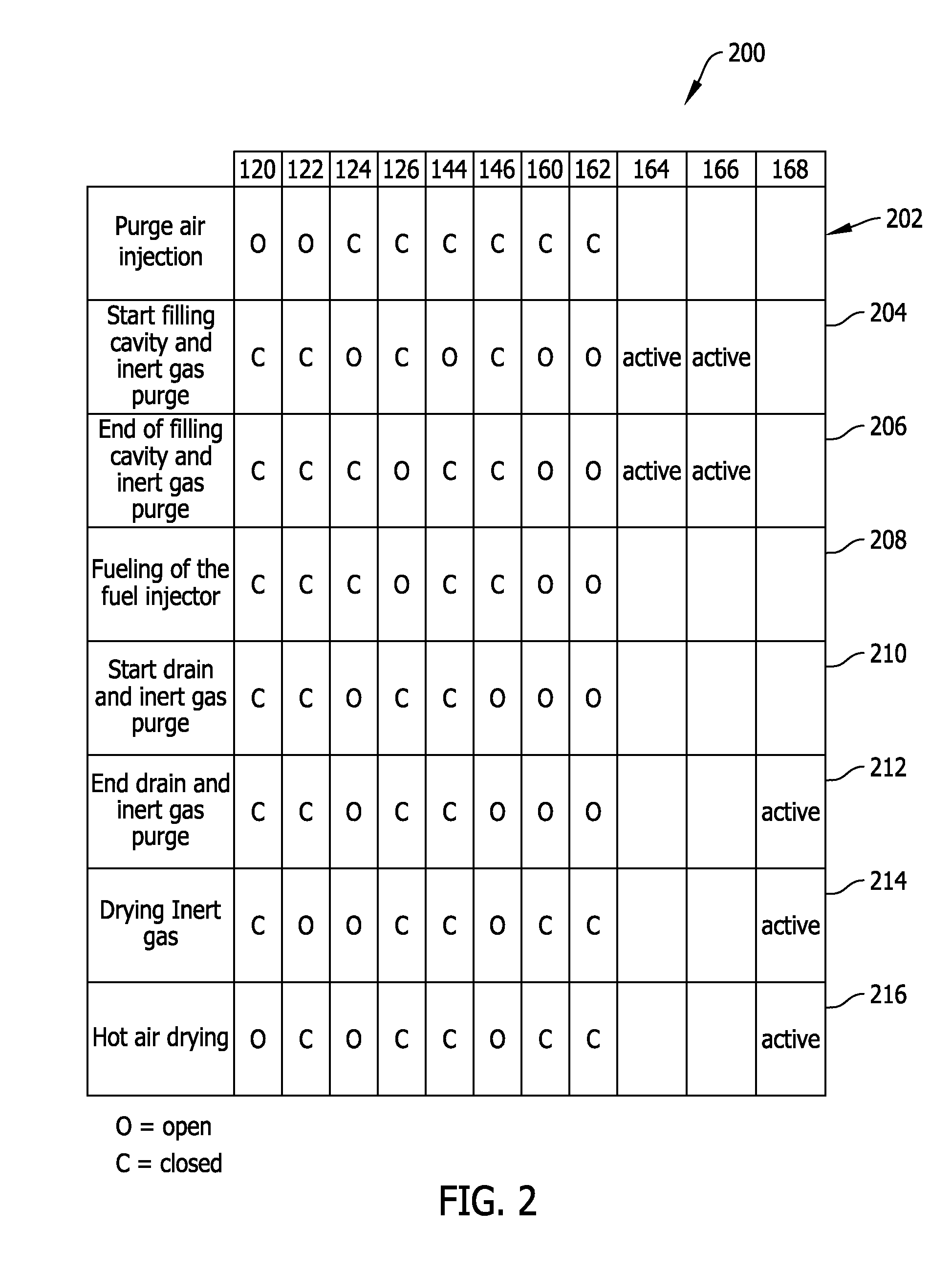

Methods and apparatus for a combustion turbine nitrogen purge system

ActiveUS7730711B2Reduce formationEasy to disassembleLiquid fuel feeder/distributionEngine fuctionsParticulatesCombustion

Owner:GE INFRASTRUCTURE TECH INT LLC

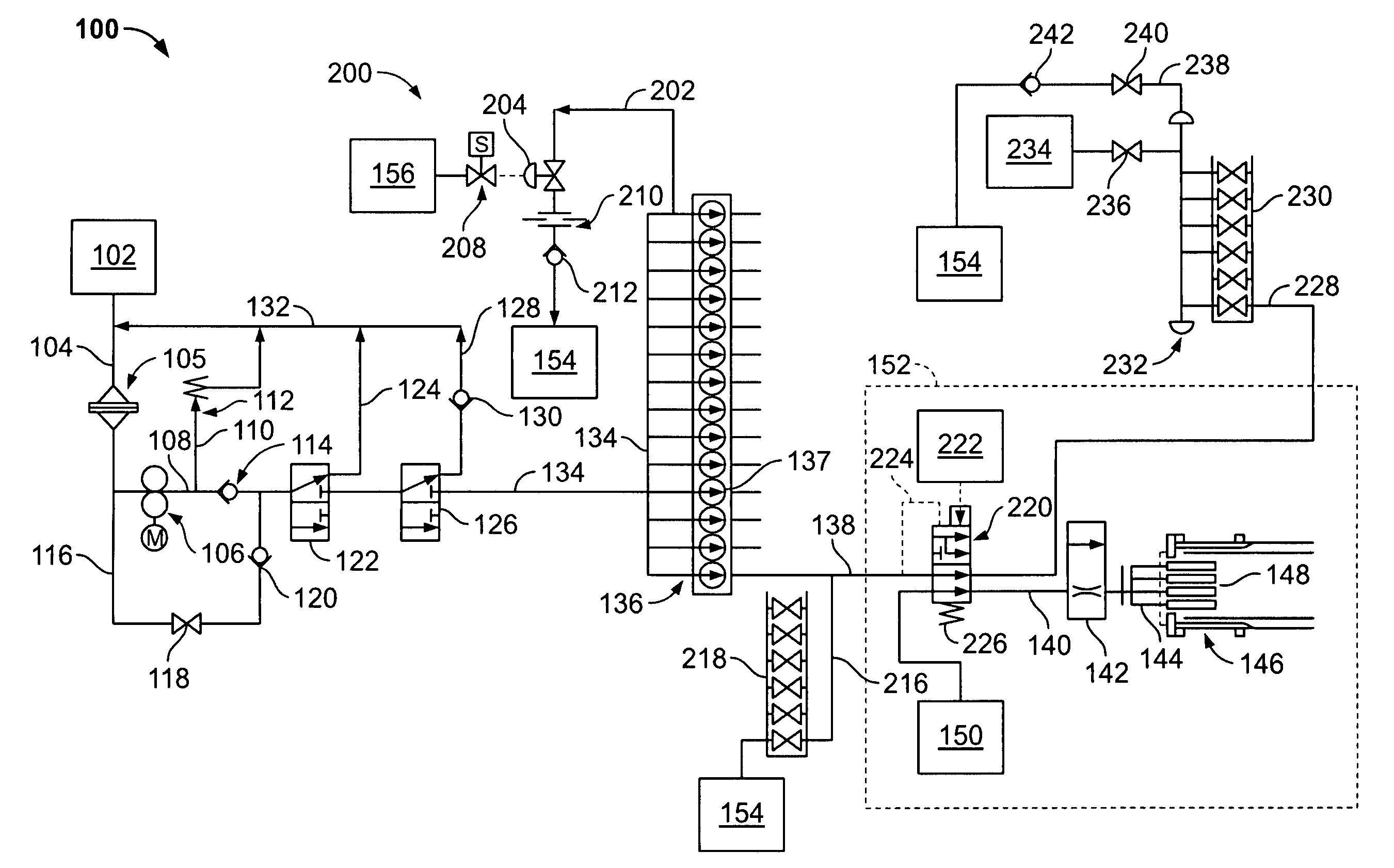

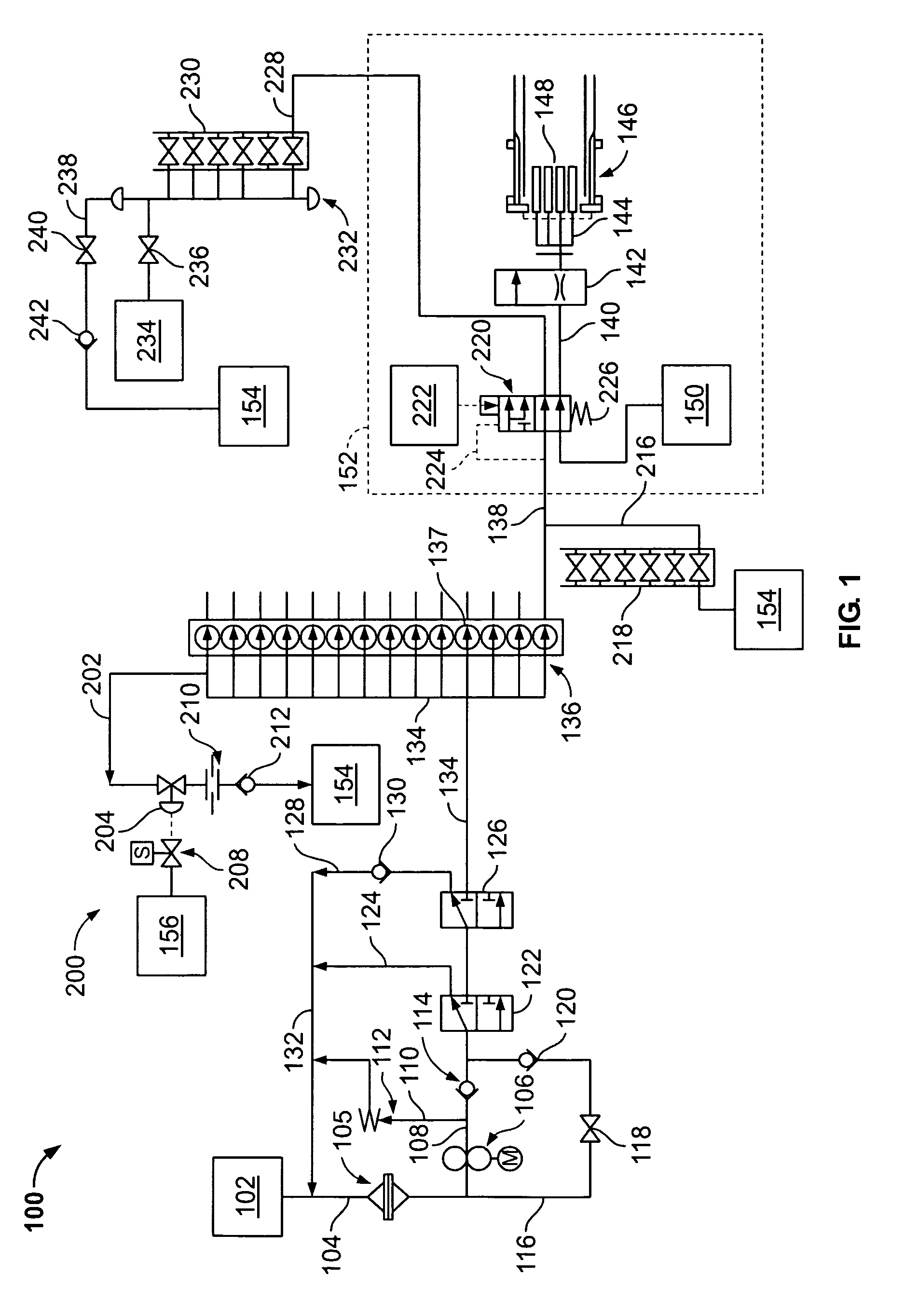

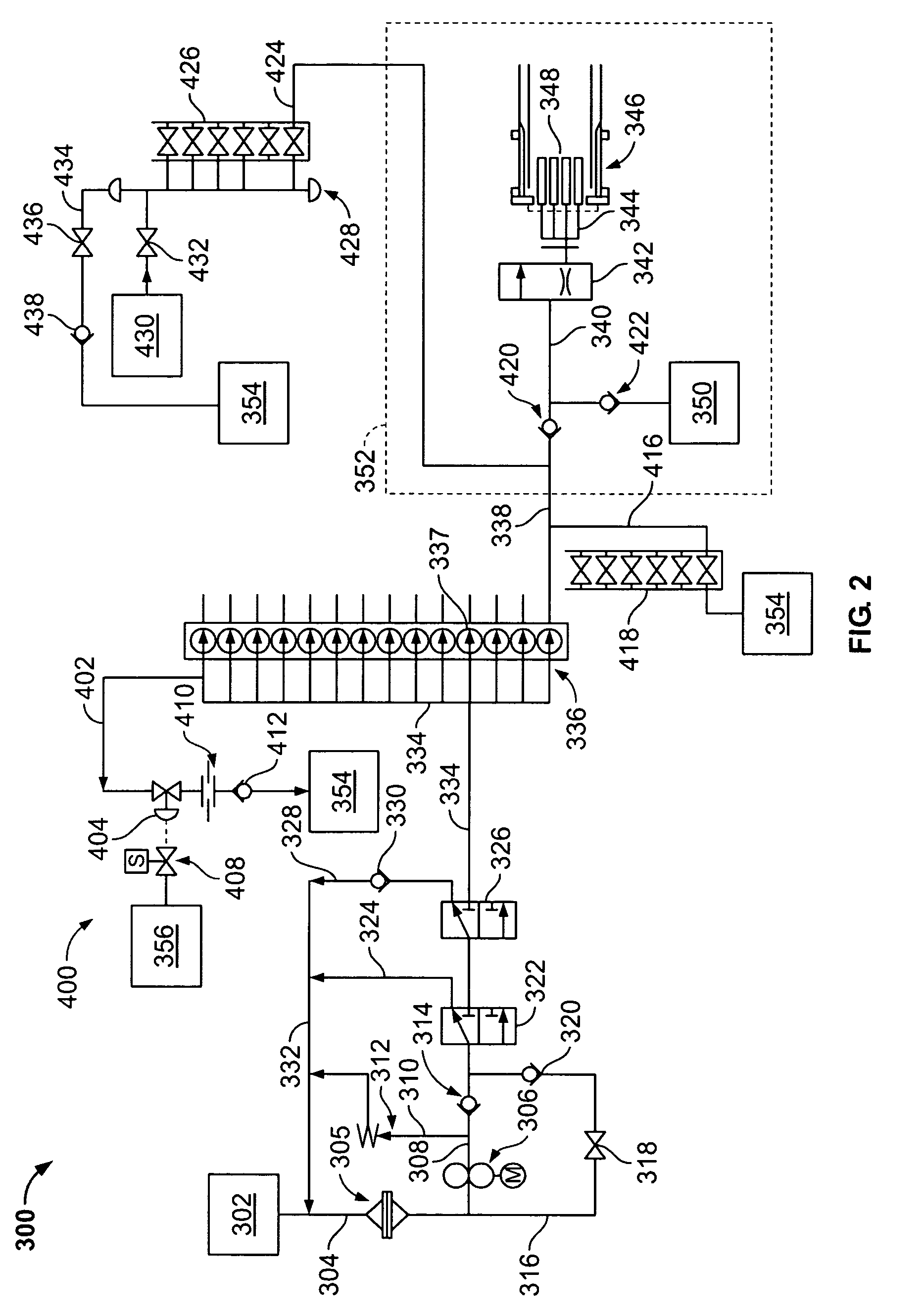

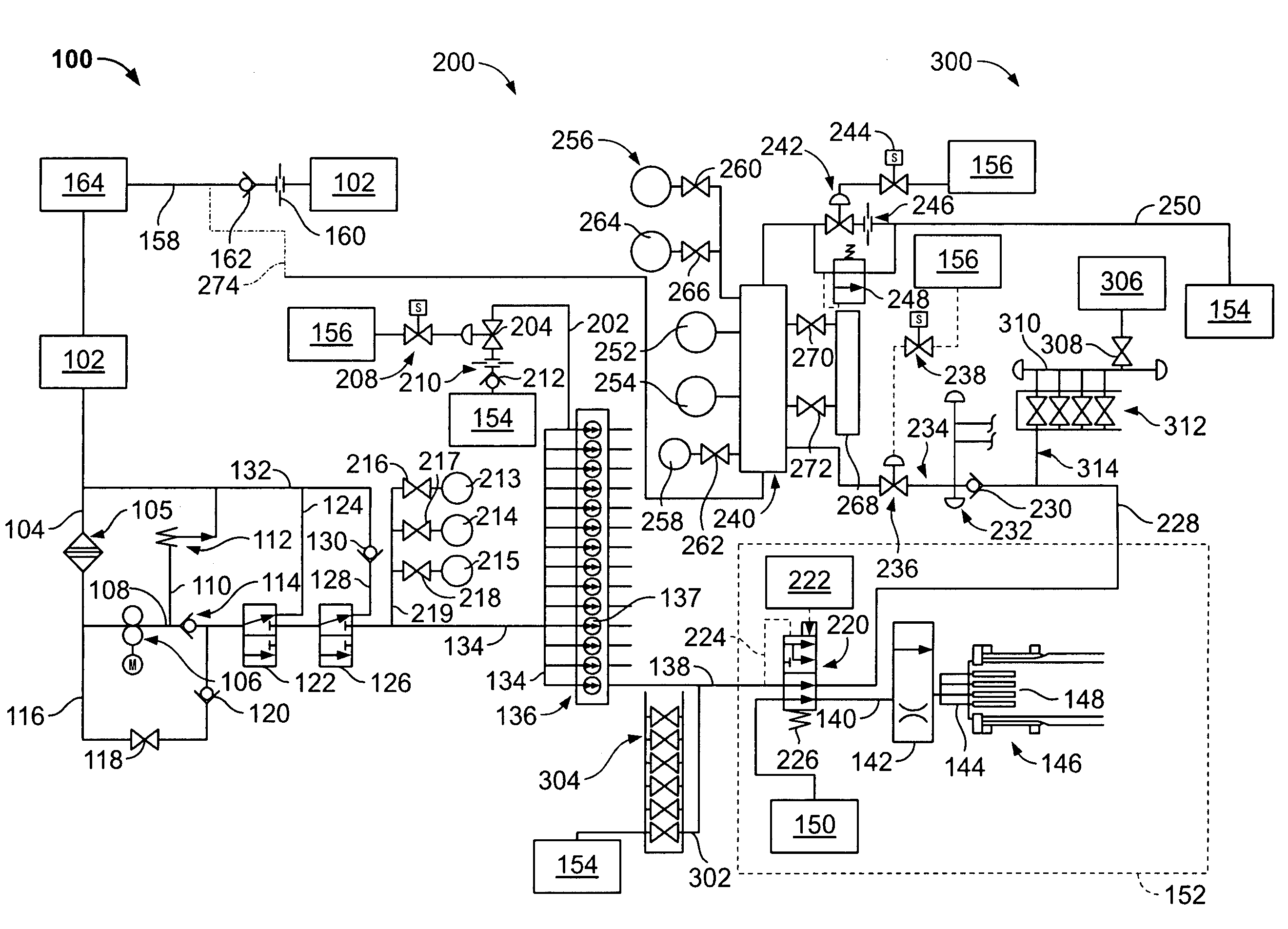

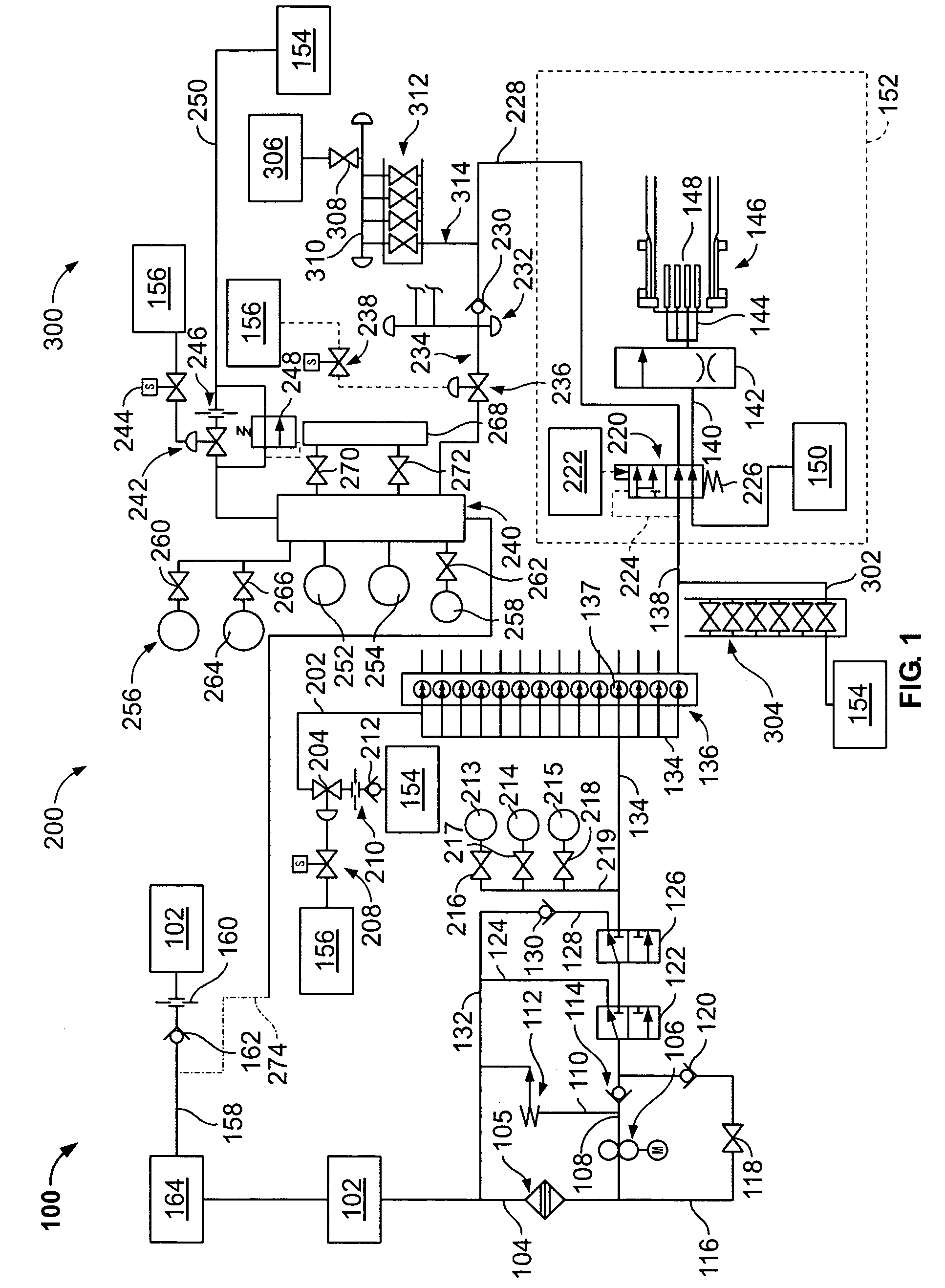

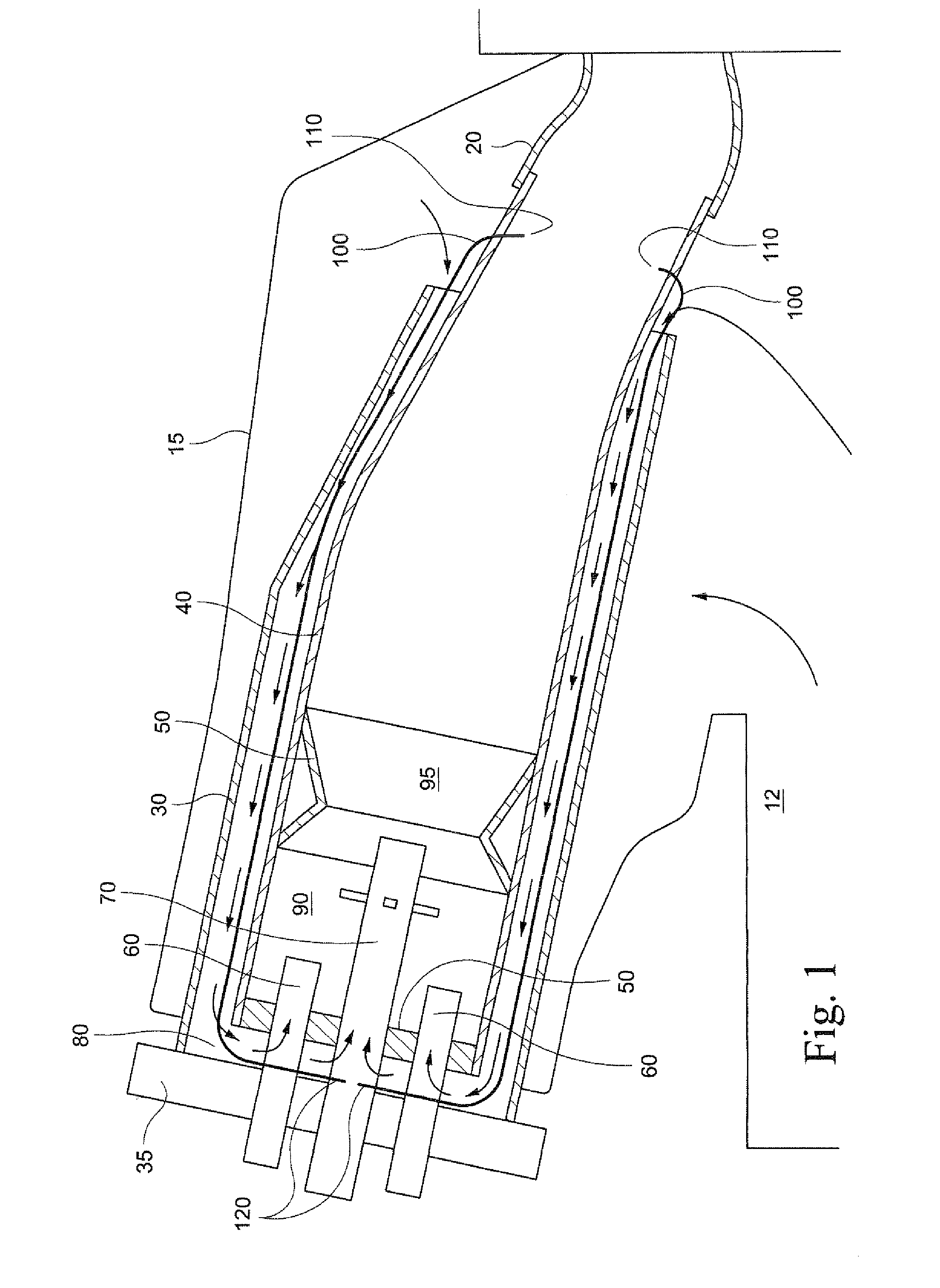

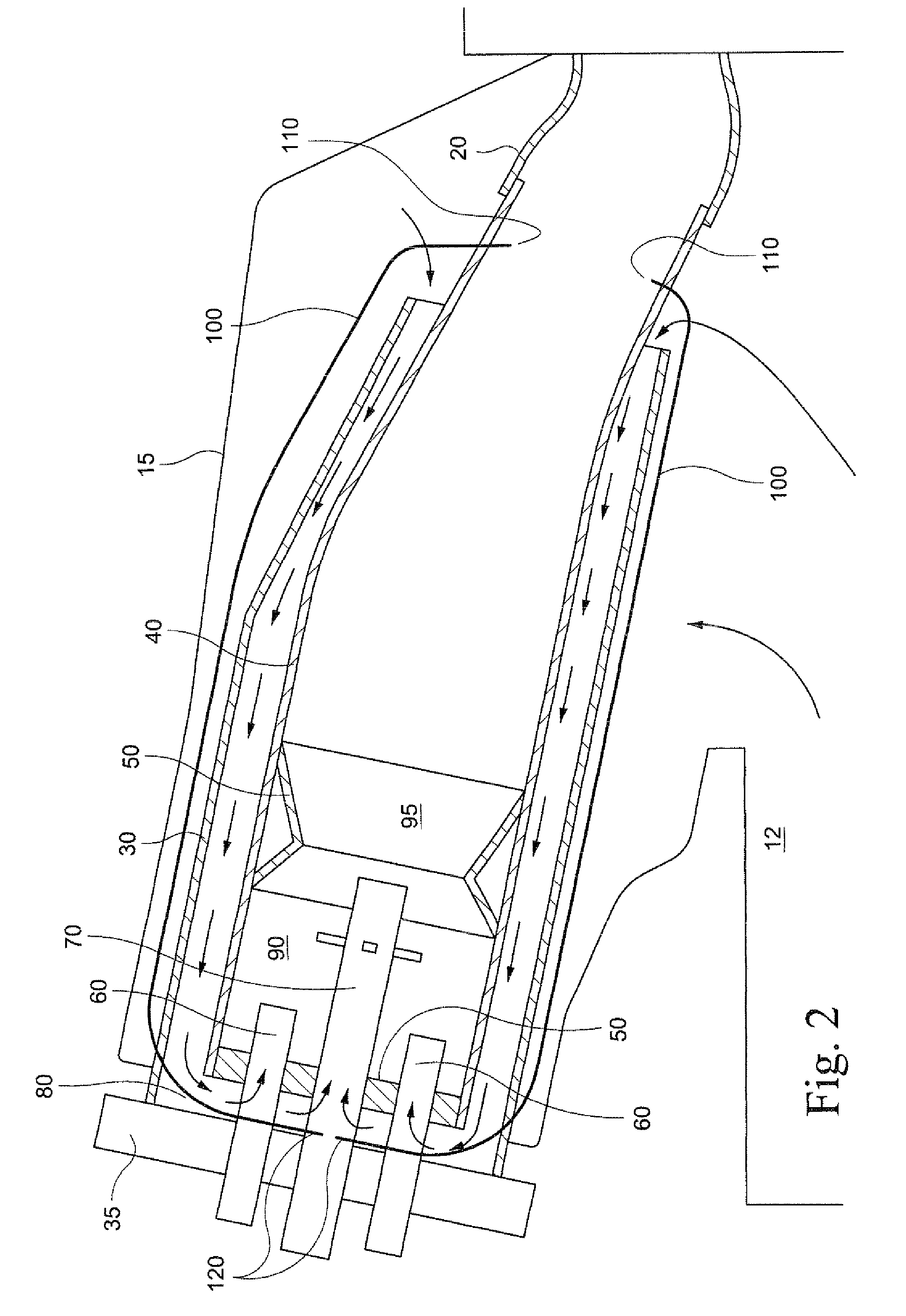

Methods and apparatus for a combustion turbine fuel recirculation system and nitrogen purge system

ActiveUS7721521B2Reduce formationEasy transferLiquid fuel feeder/distributionContinuous combustion chamberParticulatesCombustion

A method of operating a fuel system is provided. The method includes removing fuel from at least a portion of the fuel system using a gravity drain process. The method also includes channeling nitrogen into at least a portion of the fuel system to facilitate removing air and residual fuel from at least a portion of the fuel system, thereby mitigating a formation of carbonaceous precipitate particulates. The method further includes removing air and nitrogen from at least a portion of the fuel system during a fuel refilling process using a venting process such that at least a portion of the fuel system is substantially refilled with fuel and substantially evacuated of air and nitrogen. The method also includes removing air from at least a portion of the refilled fuel system using a venting process. The method further includes recirculating fuel within at least a portion of the fuel system, thereby removing heat from at least a portion of the fuel system and facilitating a transfer of operating fuel modes.

Owner:GENERAL ELECTRIC CO

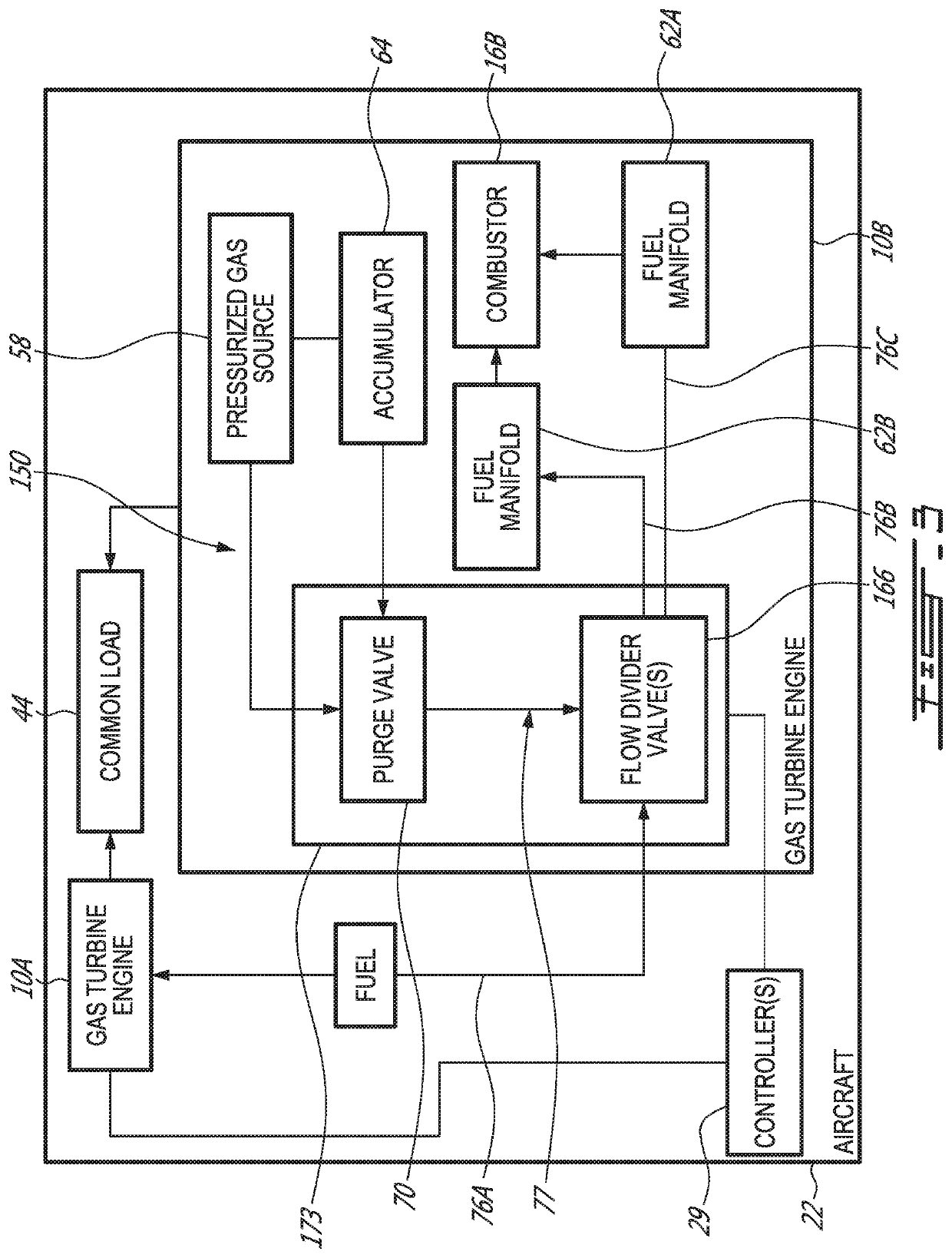

System and method for purging a fuel manifold of a gas turbine engine using a flow divider assembly

Methods and systems of operating a gas turbine engine in a low-power condition are provided. In one embodiment, the method includes supplying fuel to the combustor by supplying fuel to the first fuel manifold via a first flow divider valve and supplying fuel to the second fuel manifold via a second flow divider valve. While supplying fuel to the combustor by supplying fuel to the first fuel manifold, the method includes stopping supplying fuel to the second fuel manifold and supplying pressurized gas to the second fuel manifold via the second flow divider valve to flush fuel in the second fuel manifold into the combustor and hinder coking in the second fuel manifold and associated nozzles.

Owner:PRATT & WHITNEY CANADA CORP

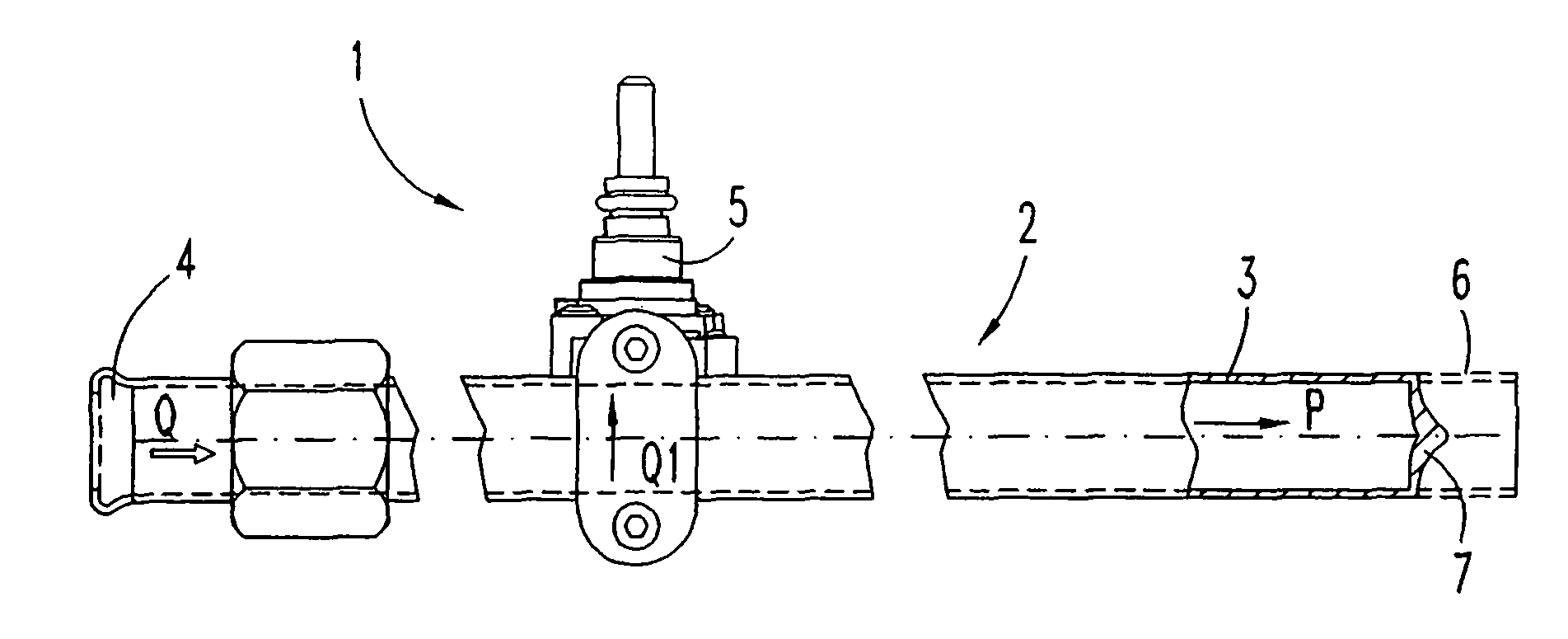

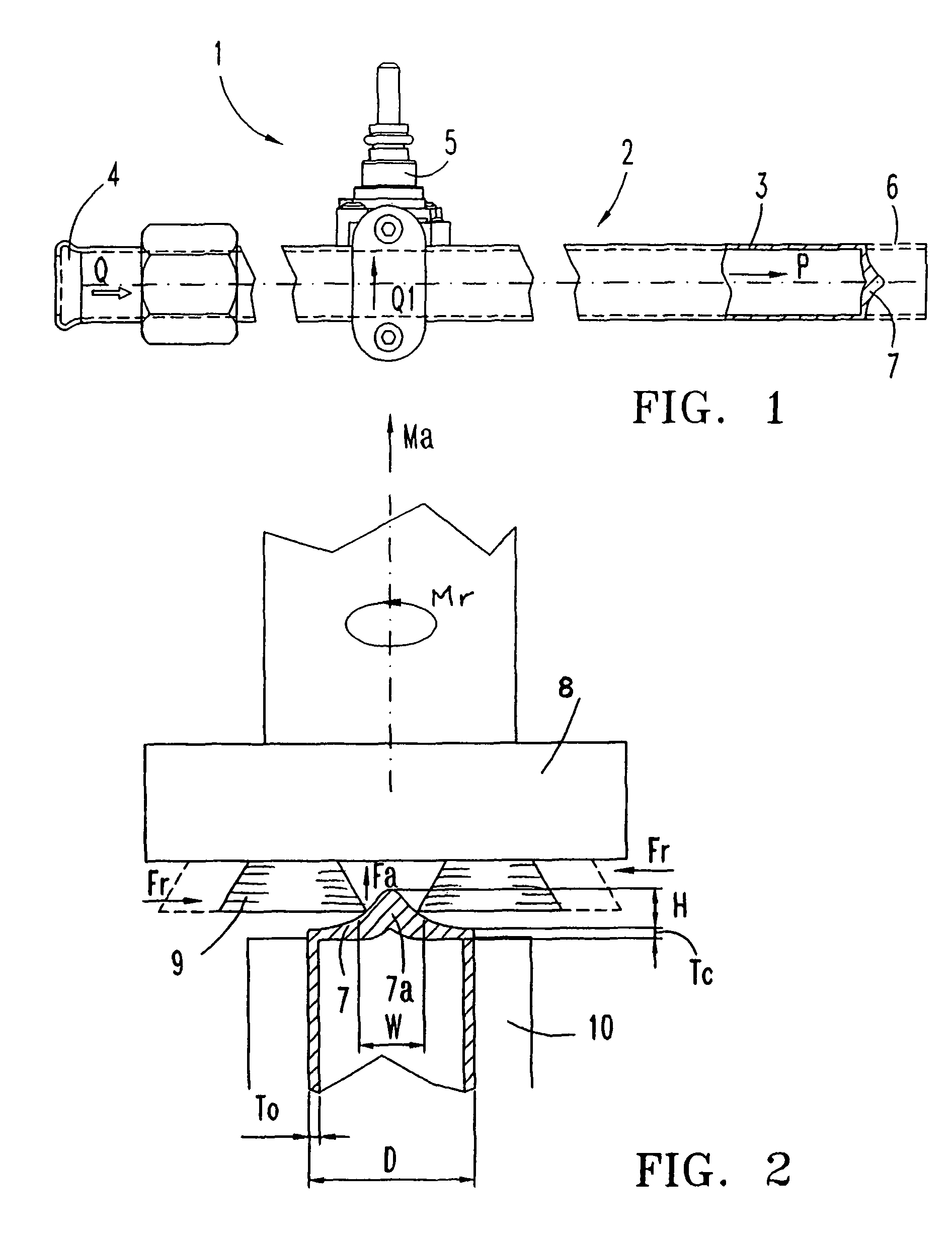

Gas manifold for a cooking range, with a pipe closure

InactiveUS7861706B2Guaranteed tightnessDomestic stoves or rangesStoves/ranges topsFriction weldingEngineering

The gas manifold (1) adapted for installation on a cooking range includes a conduit (2) for distribution of a flow (Q) at a pressure “P”, with a number of regulating taps (5) fixed to the conduit (2). The conduit is made from a metal pipe (3) with a thin cylindrical wall To and the pipe end (6) is sealed without cracks by means of friction welding with no addition of material, with a sealing wall (7) formed by means of a thickening in the form of a tip (7a) in the axial direction of an enlargement or height “H” greater than the original thickness To of the pipe. For making the gastight closure a rotary tool (8) is used that includes at least two rotary rollers (9) for the compaction of the metallic mass between two counterposed centripetal forces (Fr), in combination with an axial stretching force (Fa).

Owner:COPRECITEC

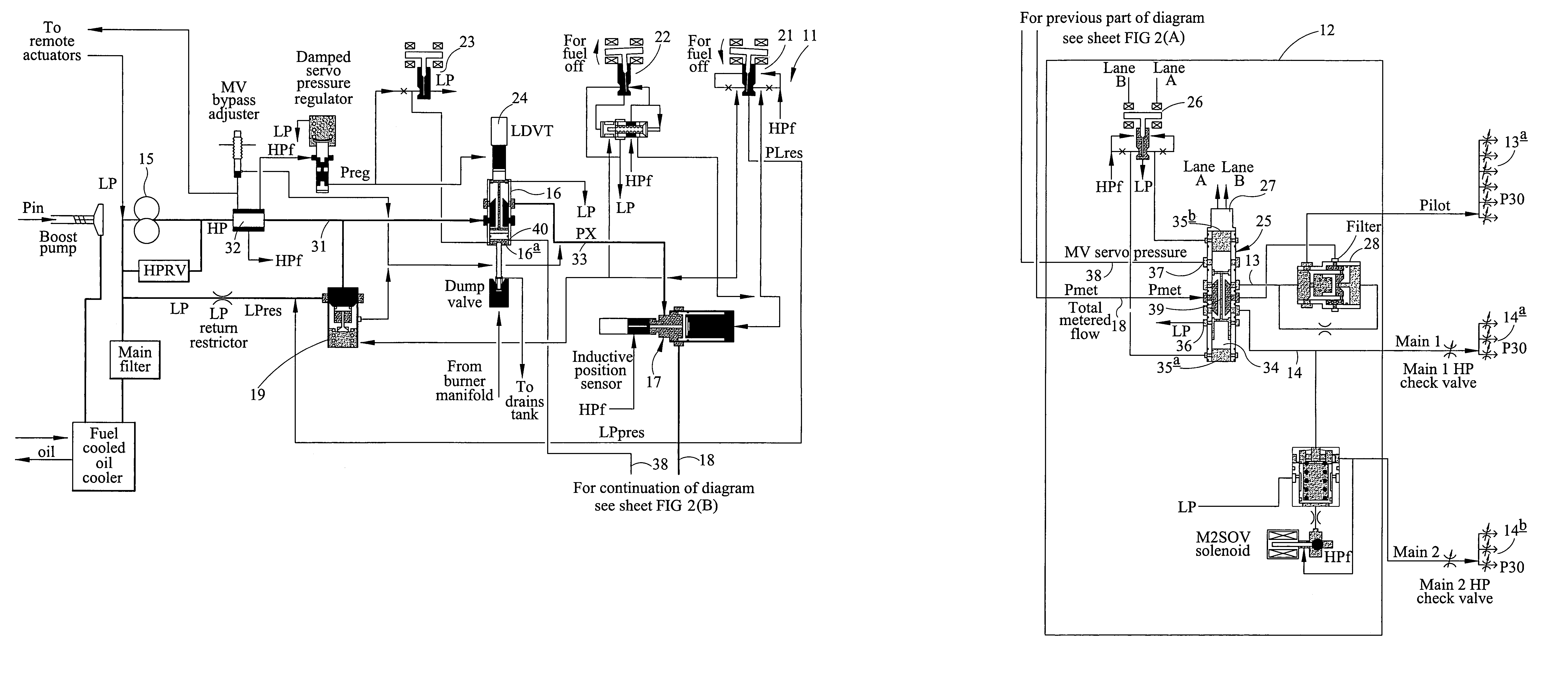

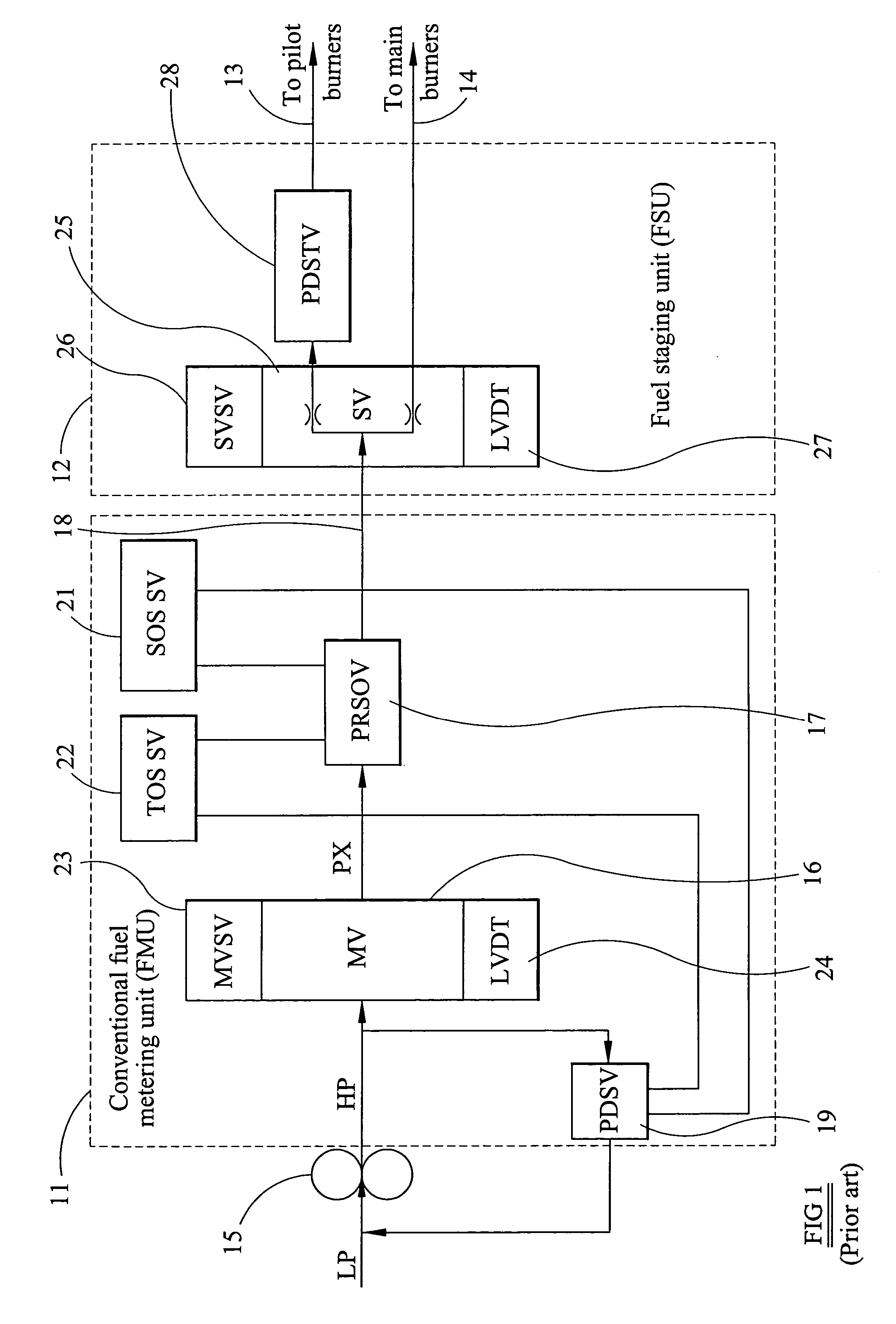

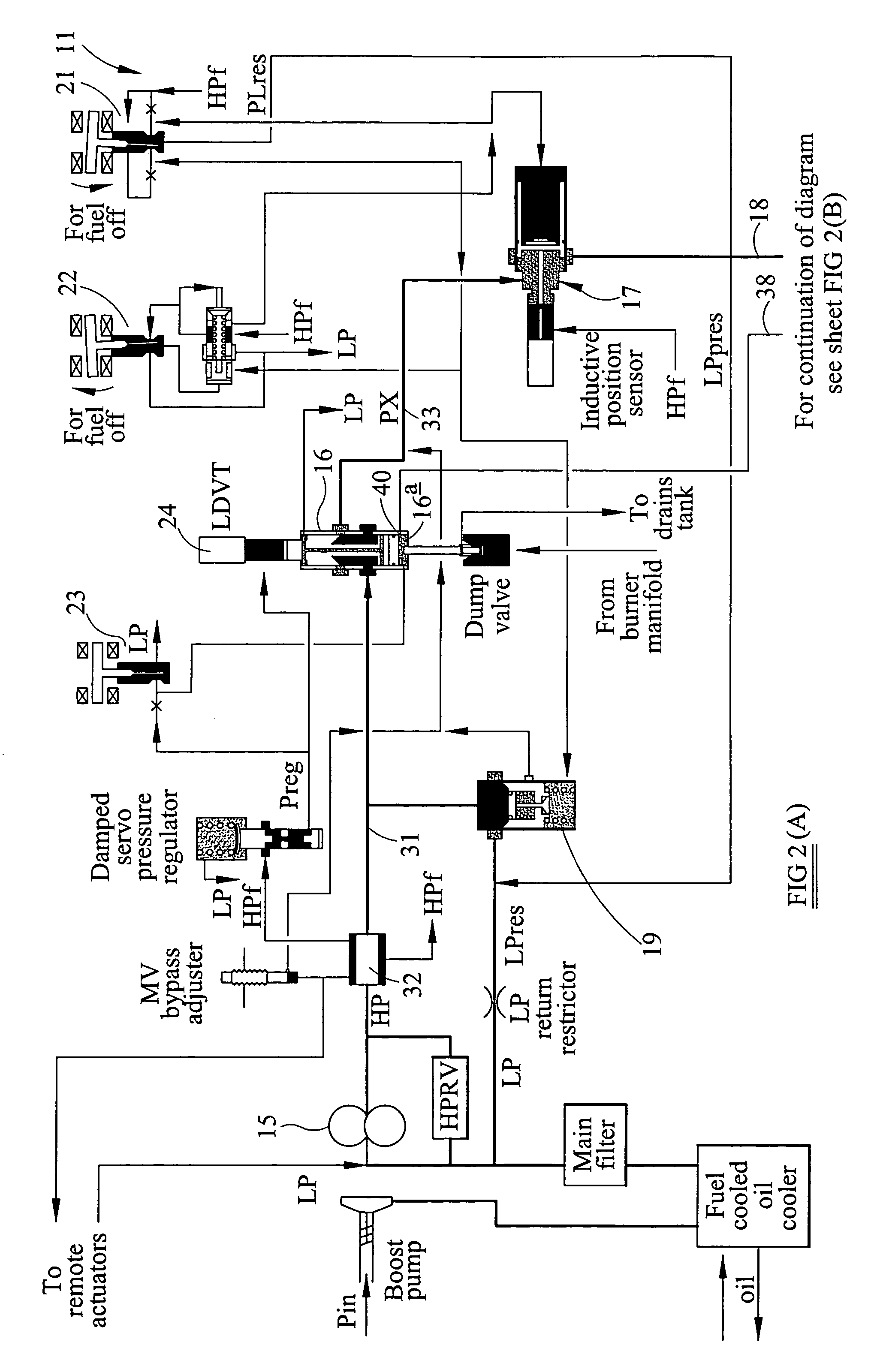

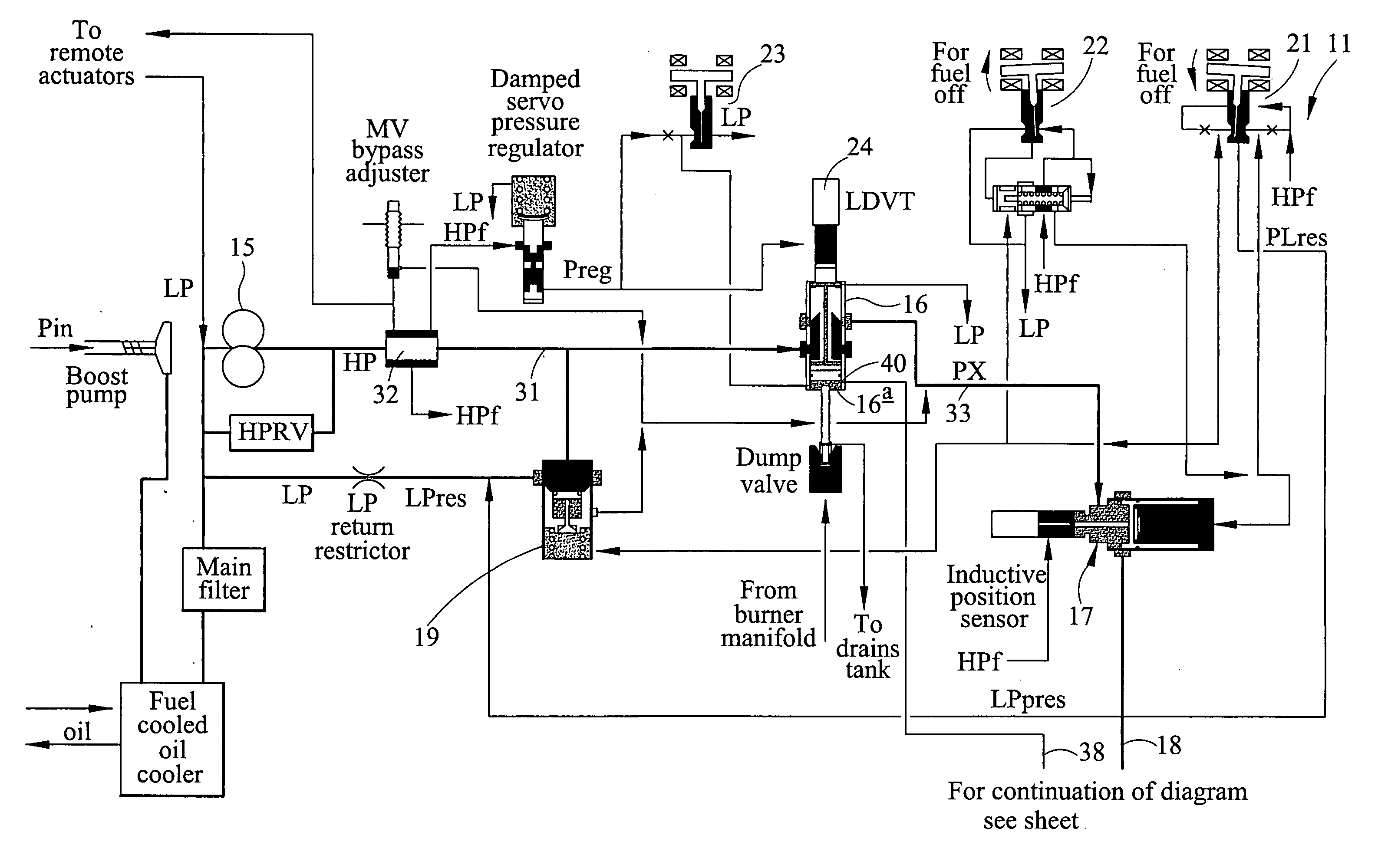

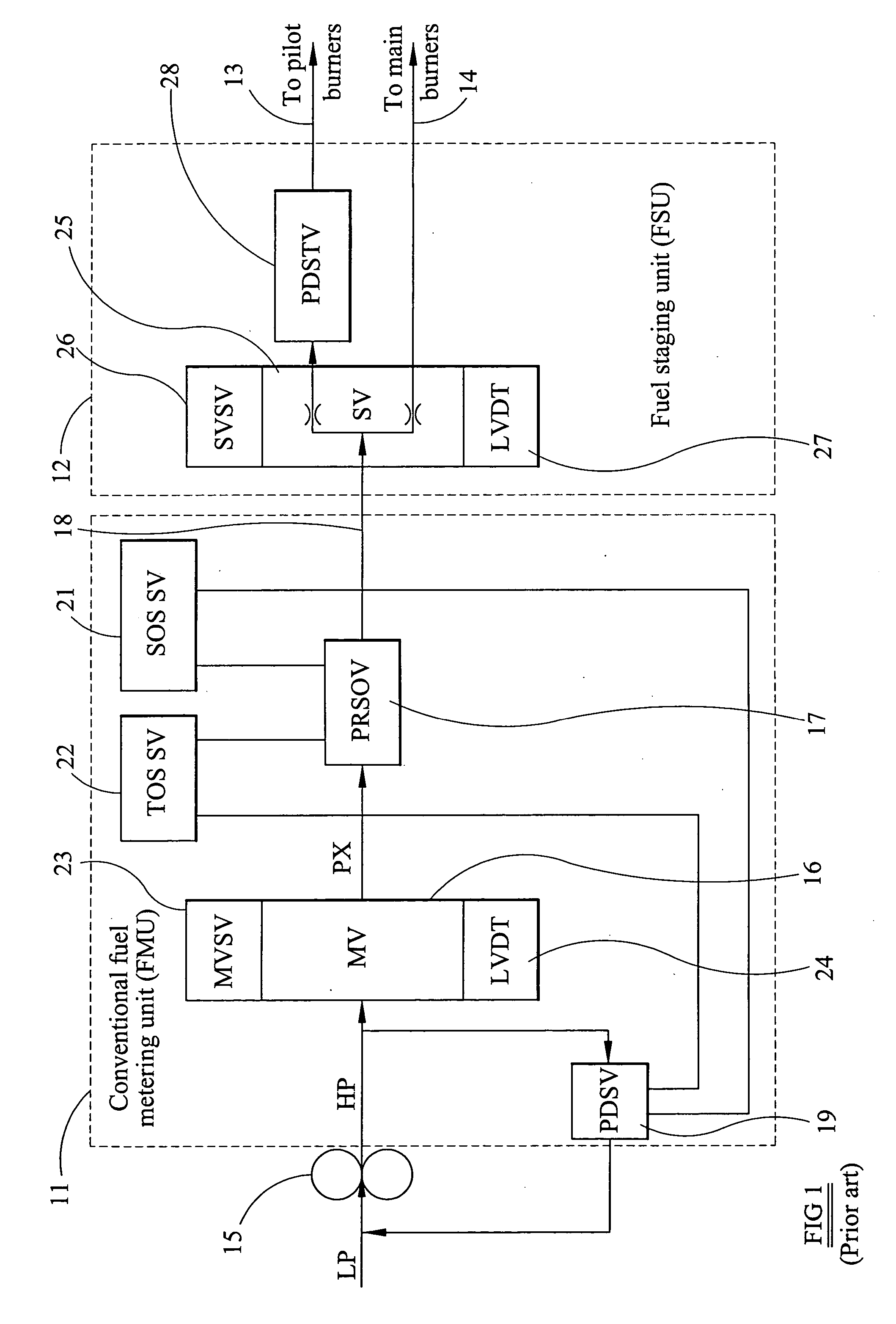

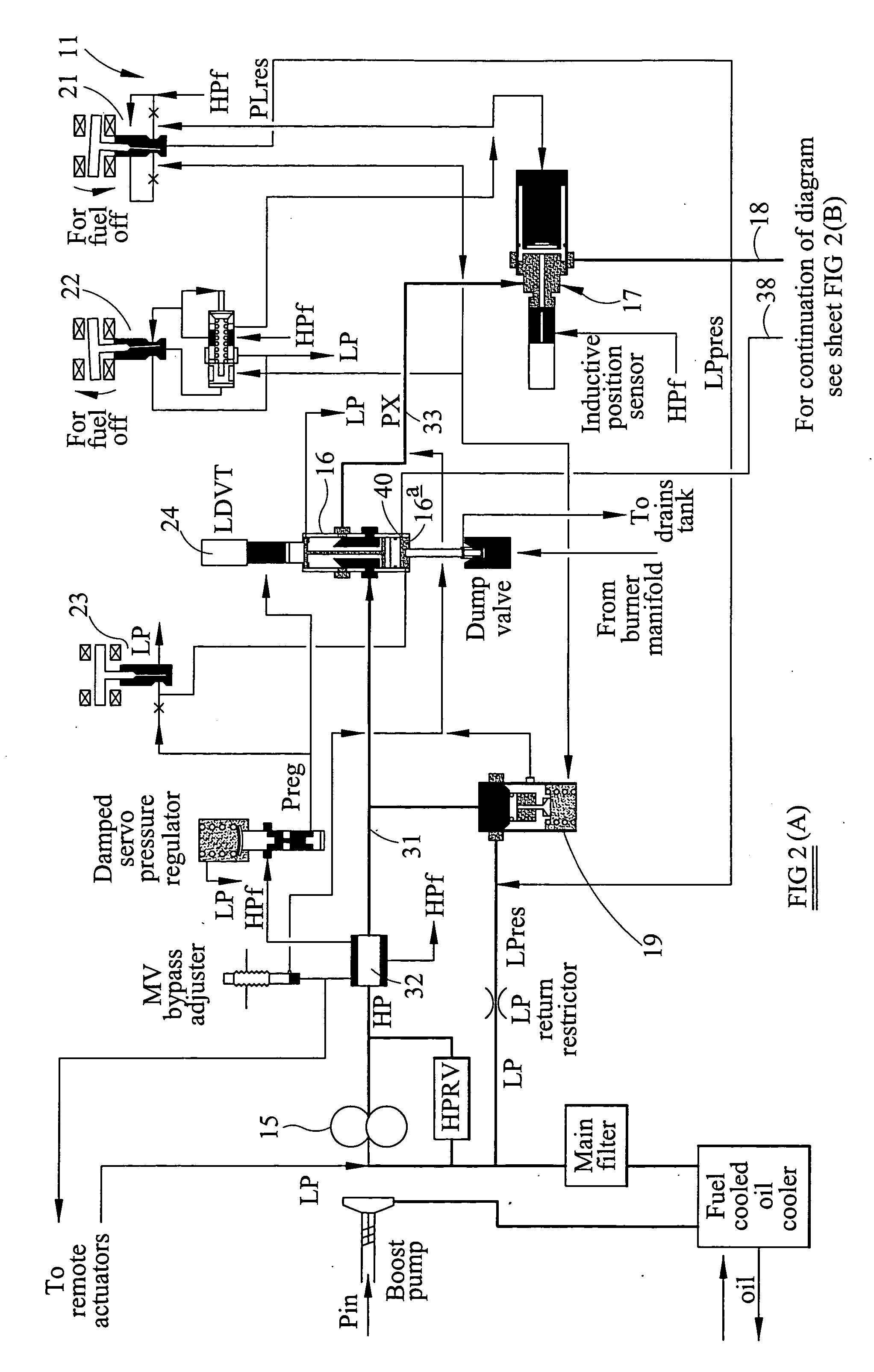

Fuel system

InactiveUS7137242B2Reduce the amount requiredFuel supply regulationLiquid fuel feeder/distributionCombustorControl system

A fuel control system for a staged combustion engine comprising, a fuel metering unit including a fuel metering valve having a fuel metering orifice the opening of which is varied to meter the flow of fuel through the metering valve in use, a fuel staging unit receiving fuel from the metering valve of the fuel metering unit and incorporating a staging valve for dividing the flow of fuel from the fuel metering unit to pilot burner and main burner output lines, a connection between a fuel pressure region of said fuel metering unit and a port of said staging valve, and, overthrust detection means causing said staging valve, in response to overthrust detection, to connect said port of said staging valve to low pressure, whereby to drain fuel under pressure from said pressure zone of said fuel metering unit to low pressure to limit or reduce the fuel supplied from the fuel metering unit to the fuel staging unit and thus to the engine in use.

Owner:GOODRICH CONTROL SYST LTD

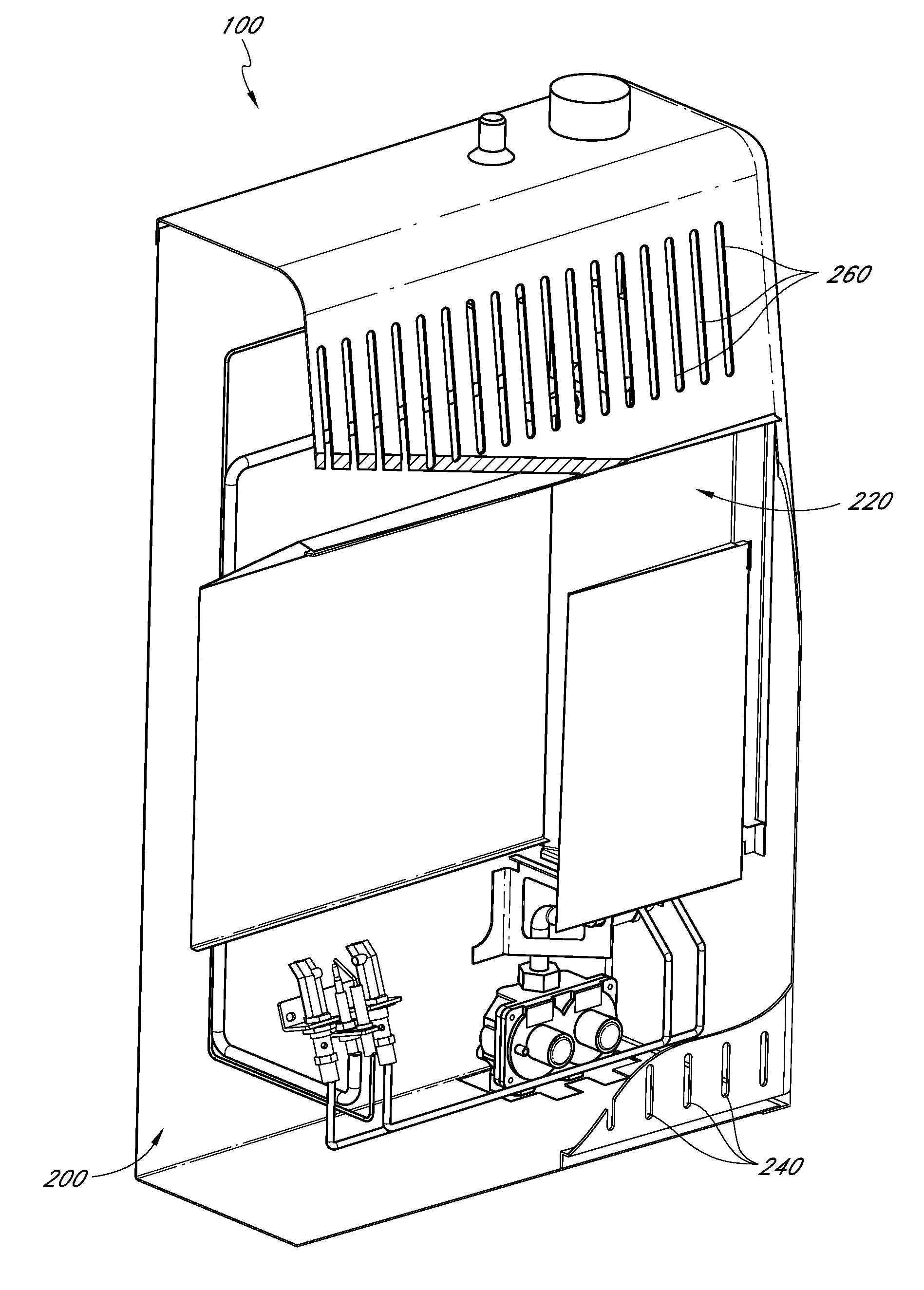

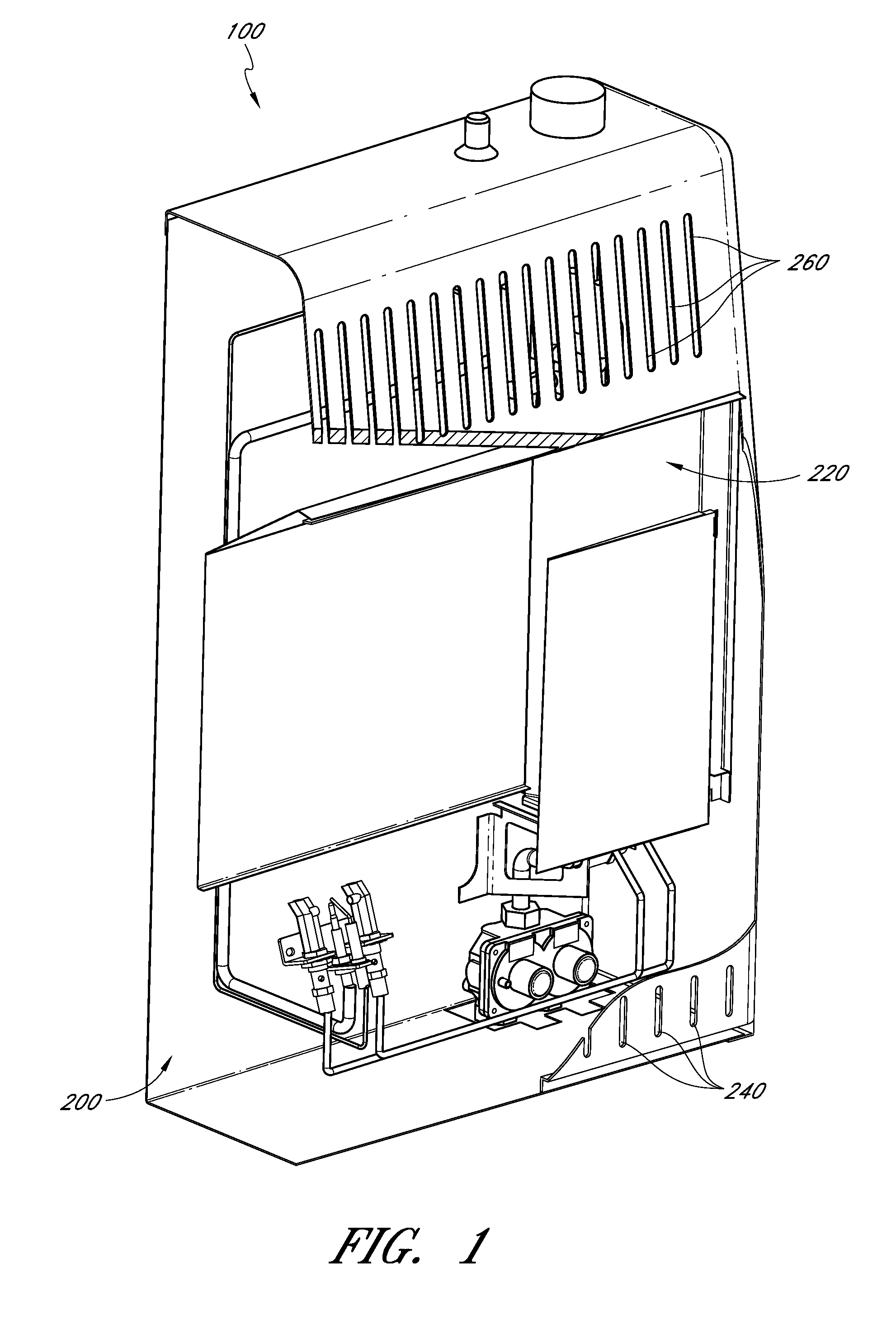

Dual fuel heating source with nozzle

A dual fuel heating source can have a burner and a nozzle. The heating source can be configured to use one of two different fuels flowing at different pressures. The nozzle can have a body, the body defining an outlet opening, an inlet, and an inner chamber. The nozzle can be configured for the first fuel in a first position of said nozzle, and can be configured for a second fuel in a second position.

Owner:DENG DAVID

Method and apparatus to increase combustion efficiency and to reduce exhaust gas pollutants from combustion of a fuel

InactiveUS20050016507A1Improve combustion efficiencyFacilitate fuel combustionBurnersLiquid fuel feeder/distributionCombustorExhaust fumes

A method and apparatus is disclosed for increasing combustion efficiency in internal combustion engines and external combustors resulting in increased fuel economy and reduced exhaust pollutants. The same principles and apparatus of the invention are used in the exhaust stream to further reduce pollutants.

Owner:RONNELL

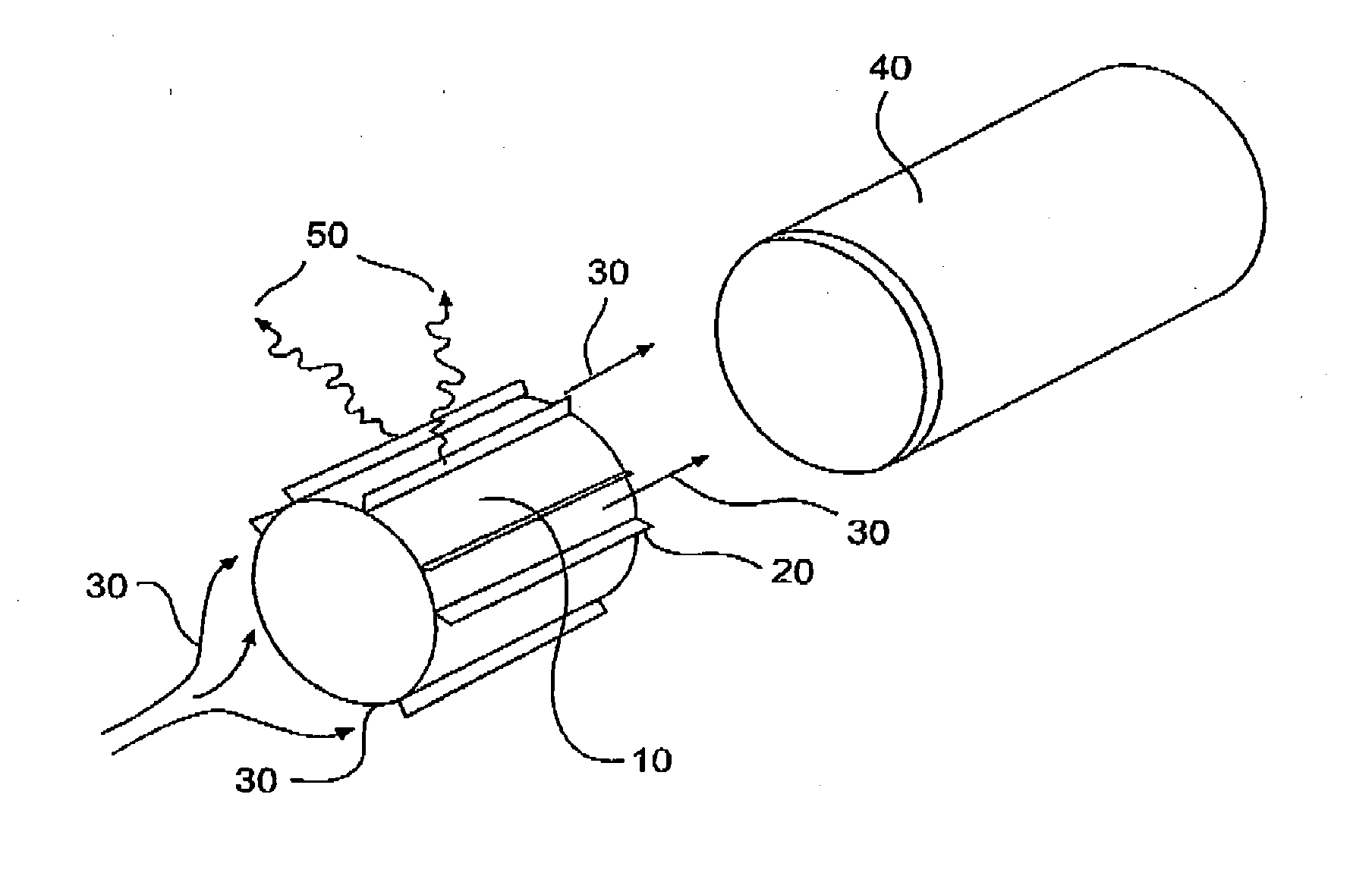

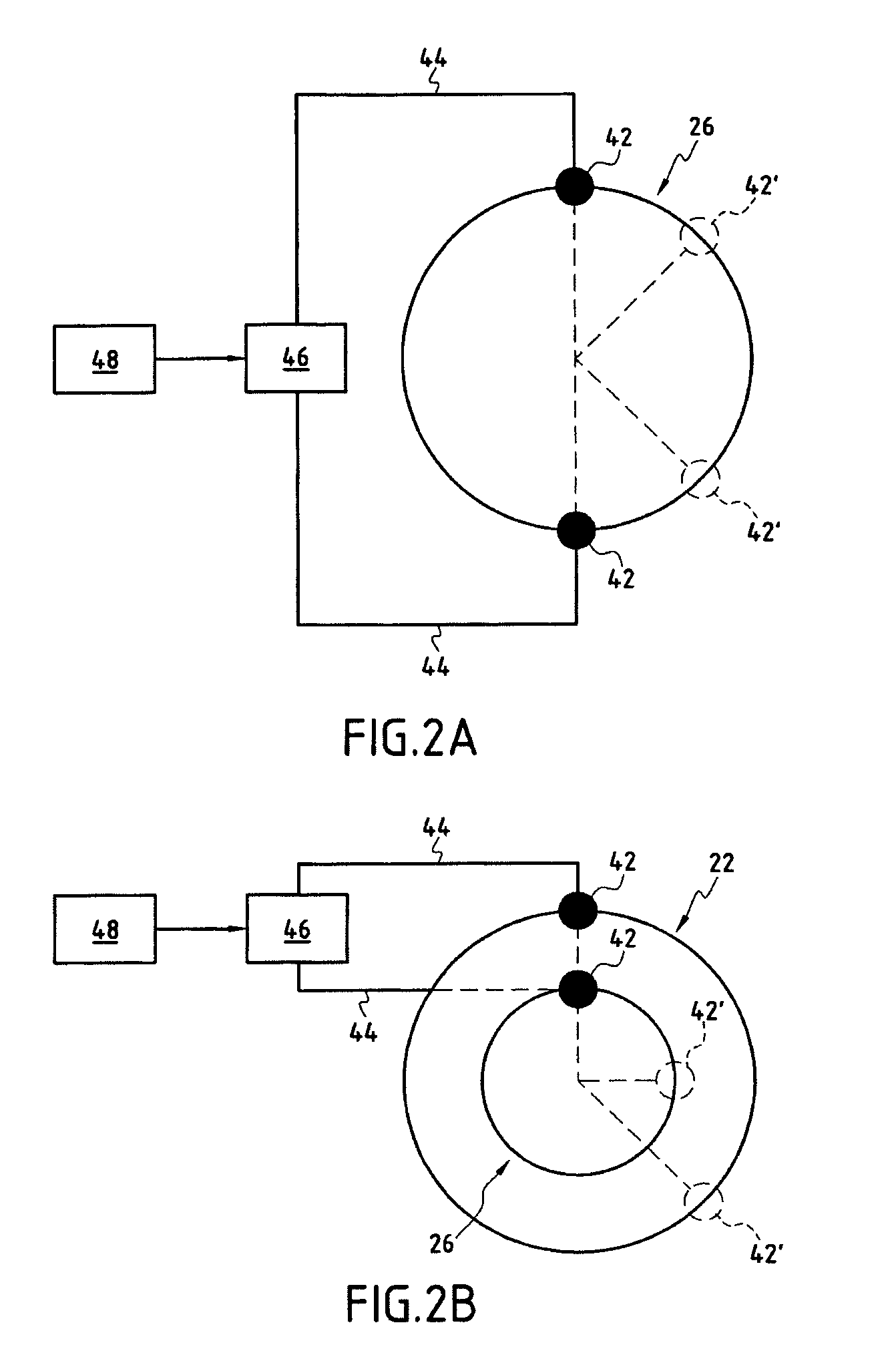

Air/fuel injection system having cold plasma generating means

ActiveUS7114337B2Improve the immunityMitigate such drawbackContinuous combustion chamberLiquid fuel pretreatmentCombustion chamberPlasma generator

A system for injecting an air / fuel mixture into a turbomachine combustion chamber, including a hollow tubular structure for the flow of the air / fuel mixture into the combustion chamber; a fuel injection device placed at an upstream end of the hollow tubular structure, and an air injection device placed downstream of the fuel injection device. The system also includes a cold plasma generator placed downstream of the air injection device so as to generate active species in the flow of the air / fuel mixture and to cause prefragmentation of the molecules of the air / fuel mixture. The system further includes a device for controlling the cold plasma generator depending on the speed of operation of the turbomachine.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

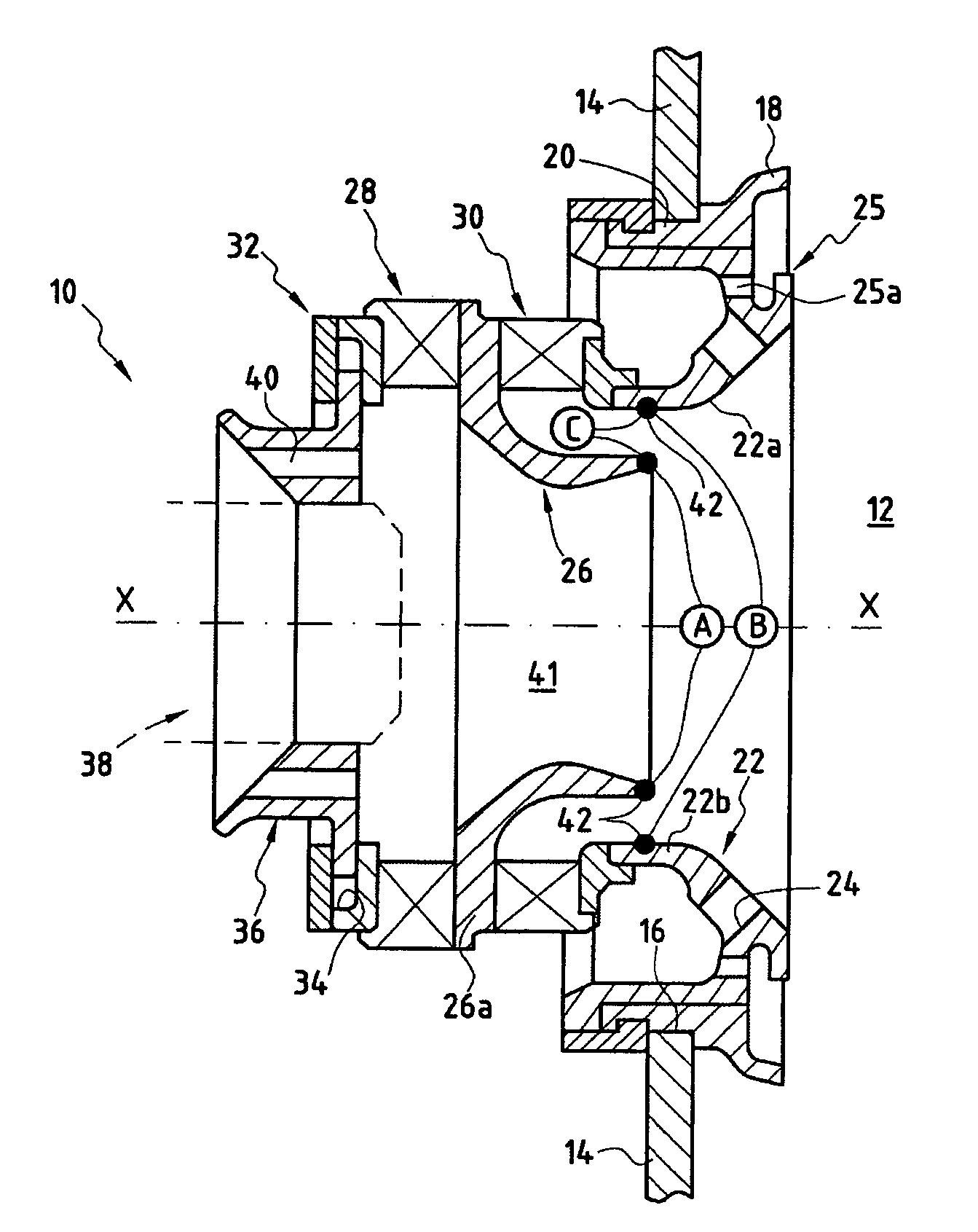

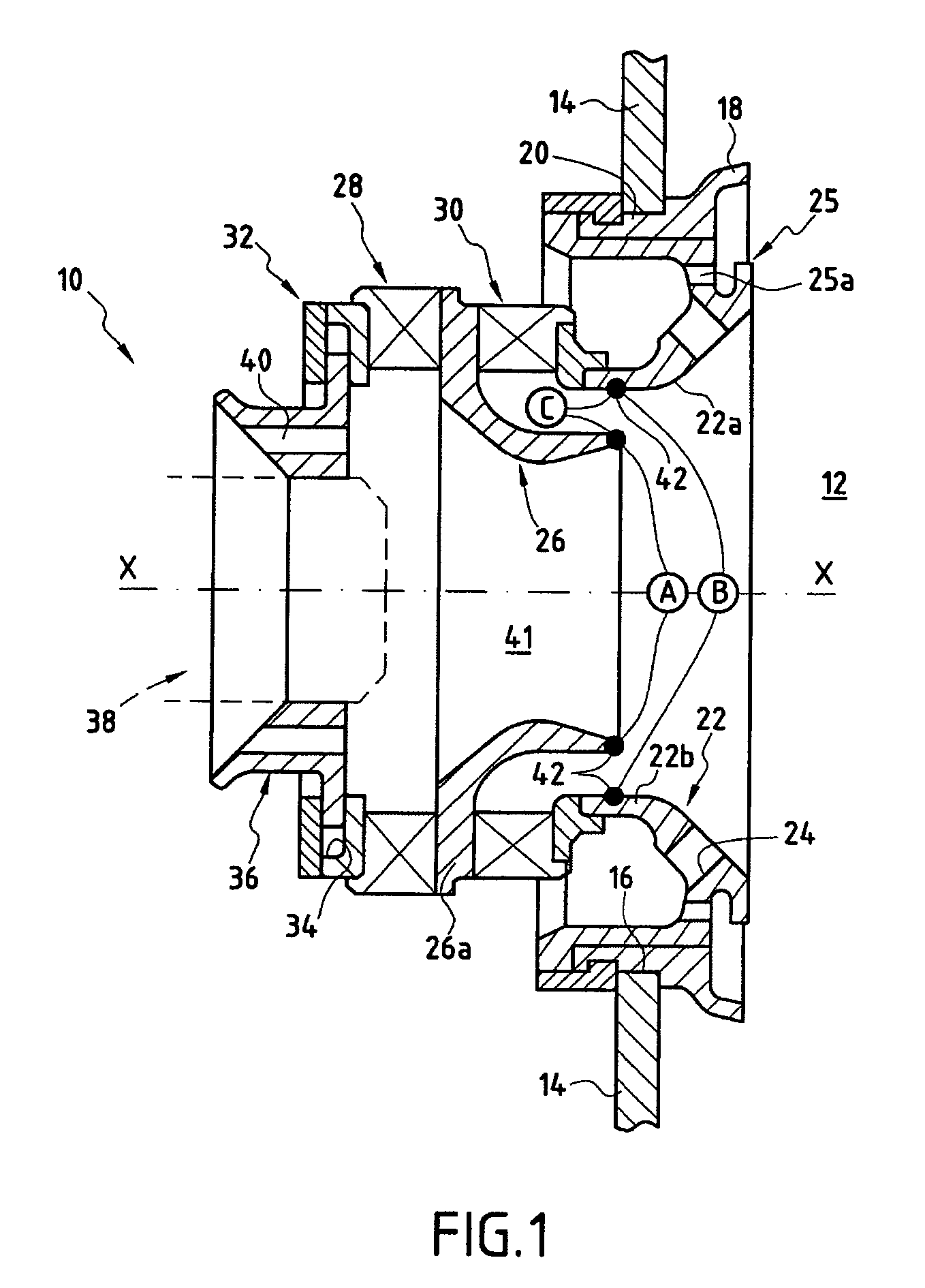

Fluid divider valves

ActiveUS8469059B1Continuous combustion chamberOperating means/releasing devices for valvesEngineeringMechanical engineering

Owner:COLLINS ENGINE NOZZLES INC

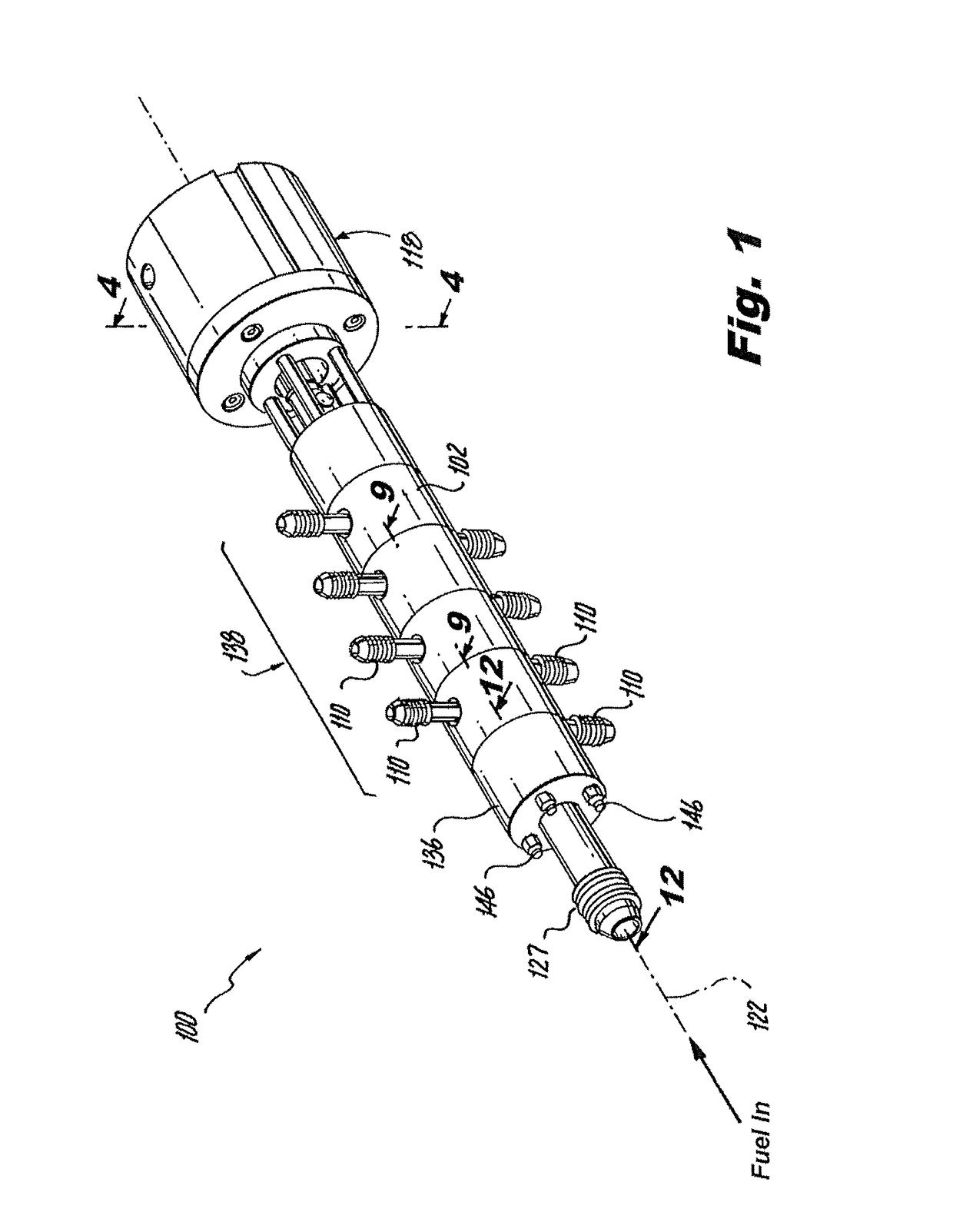

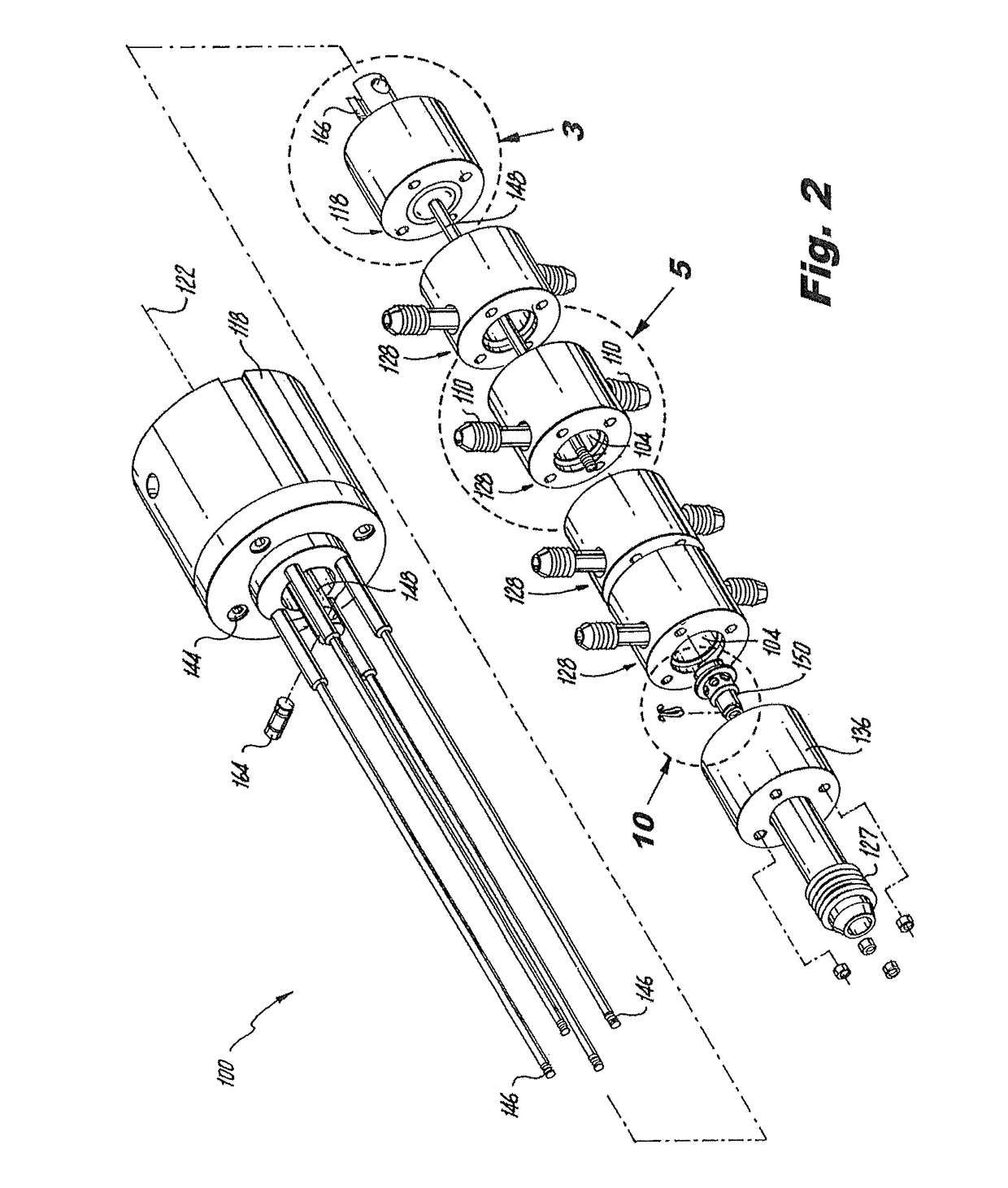

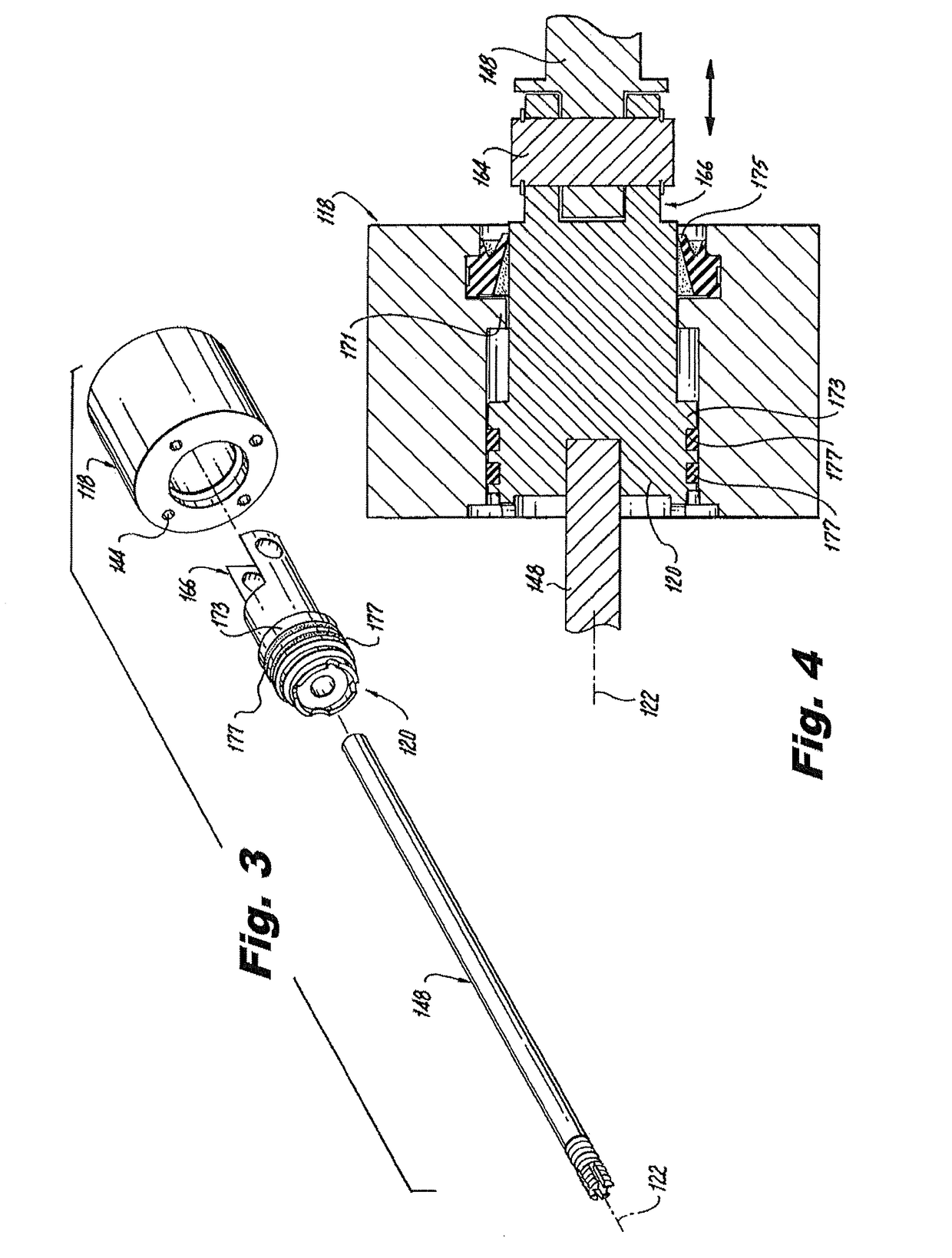

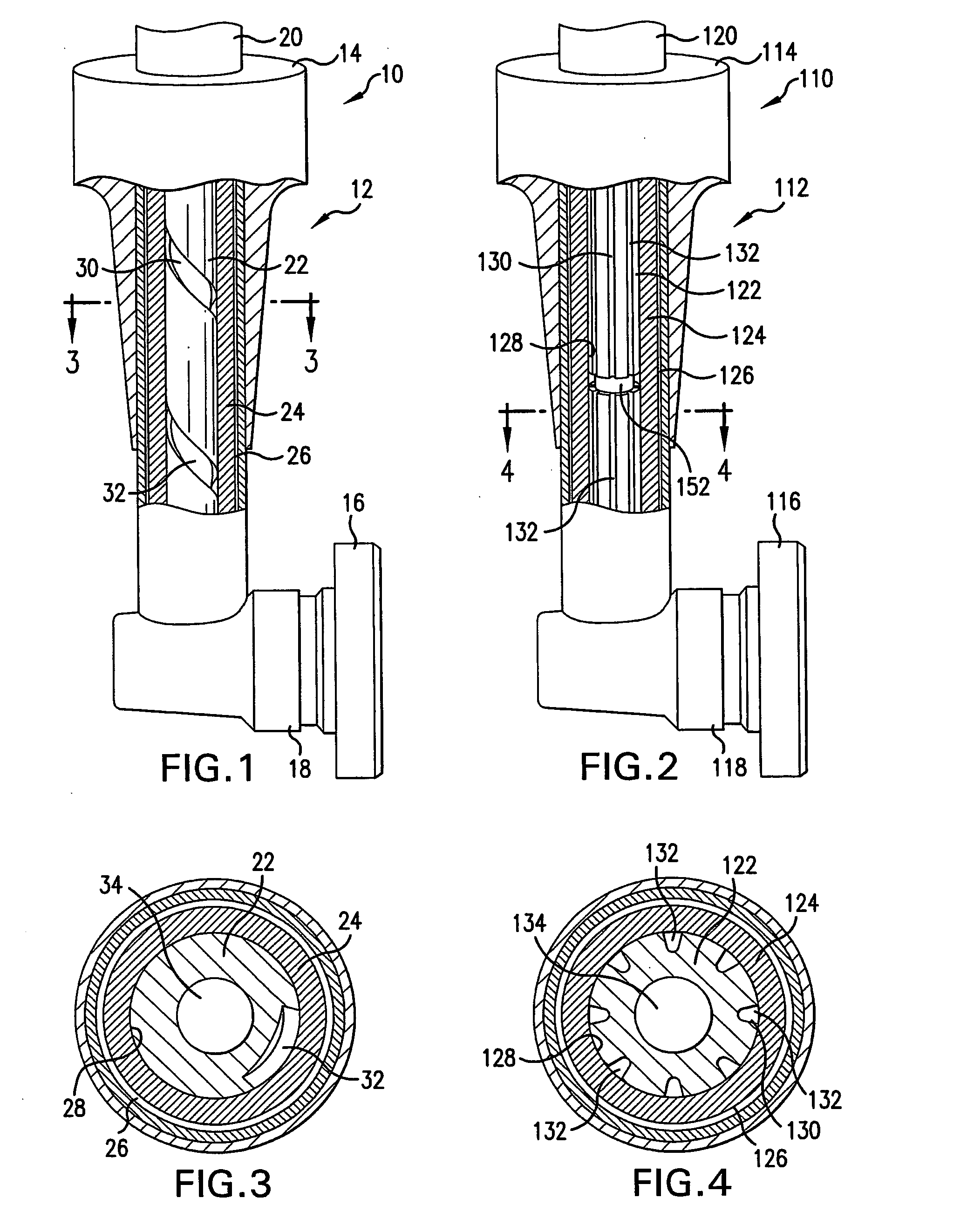

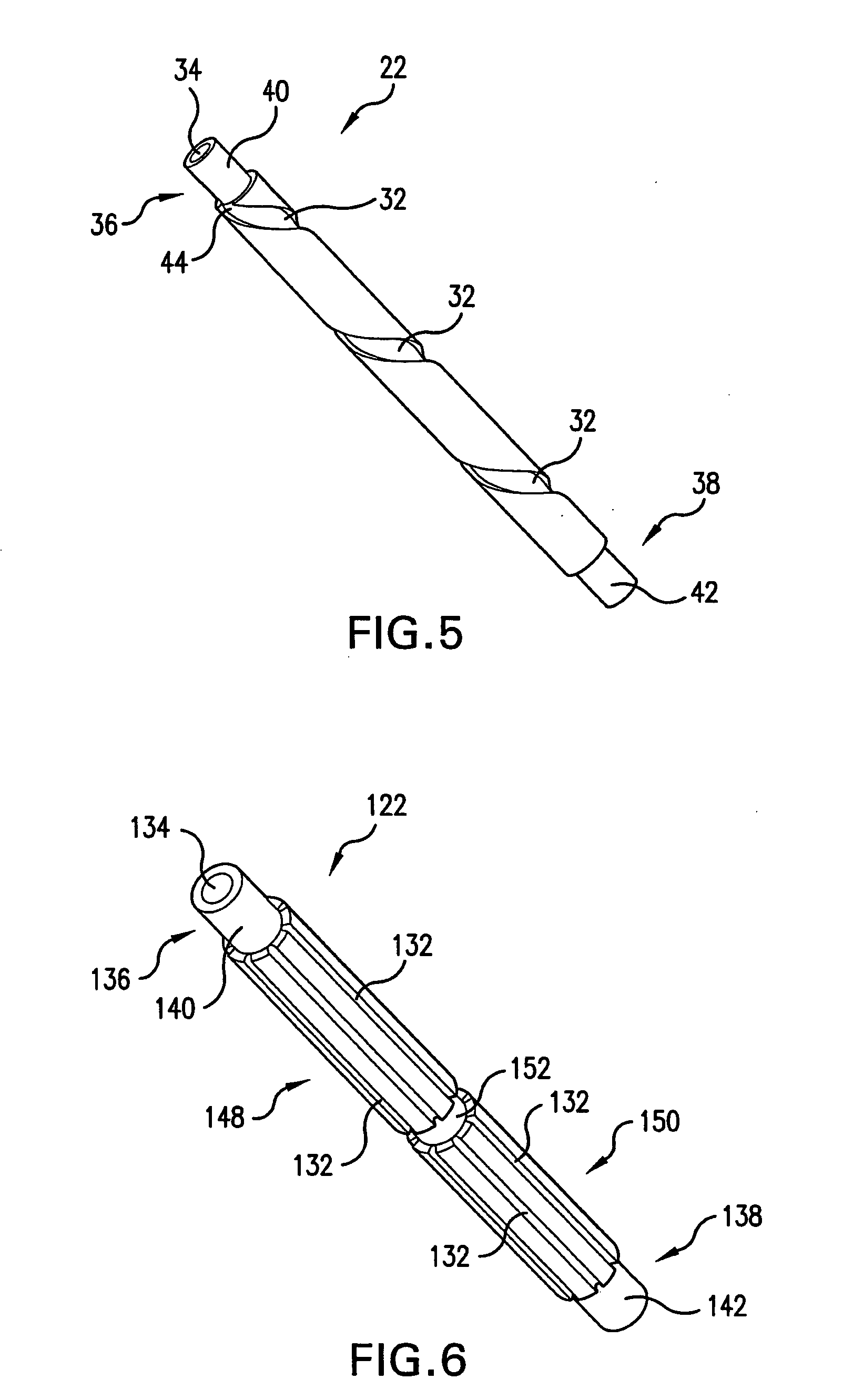

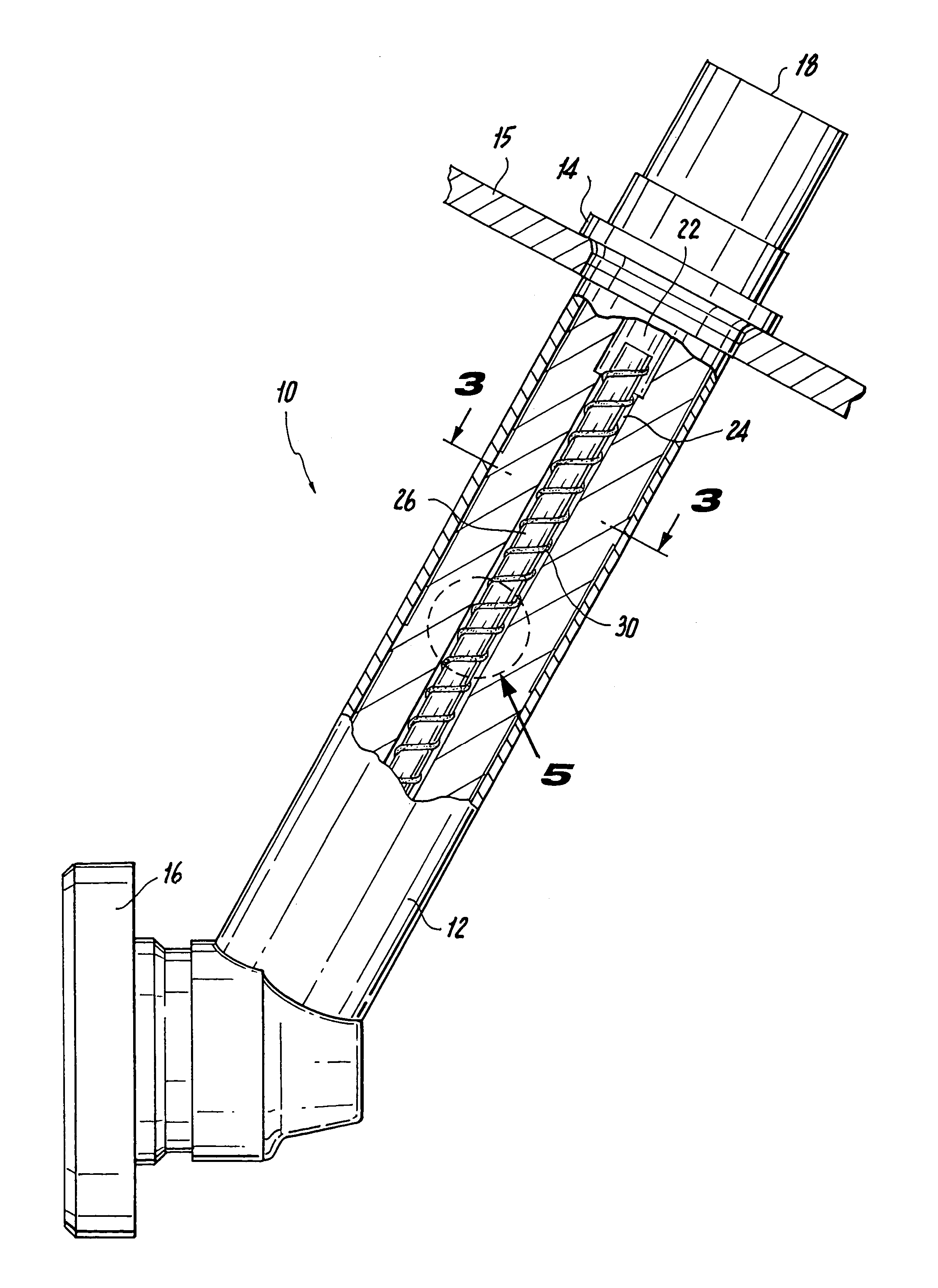

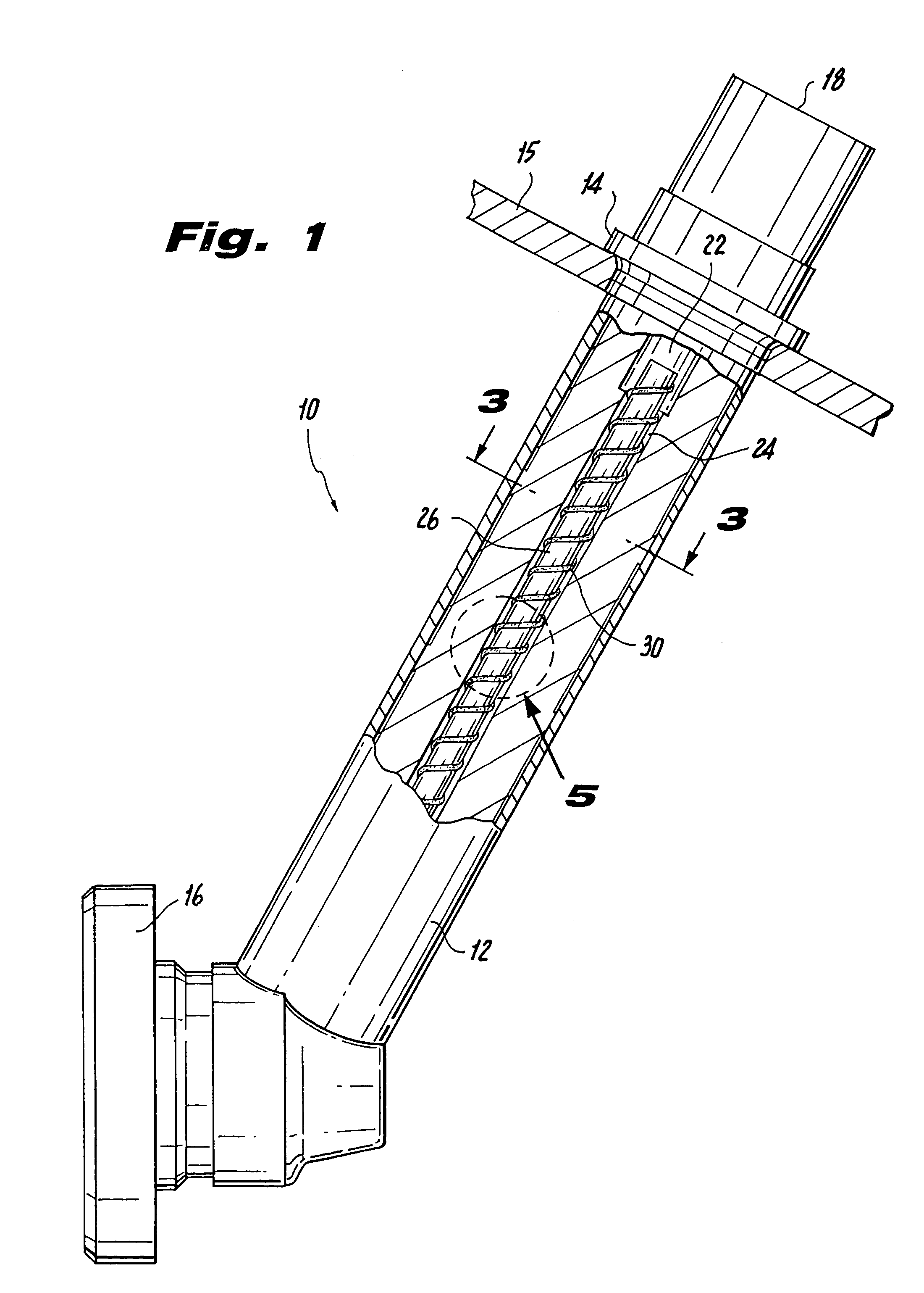

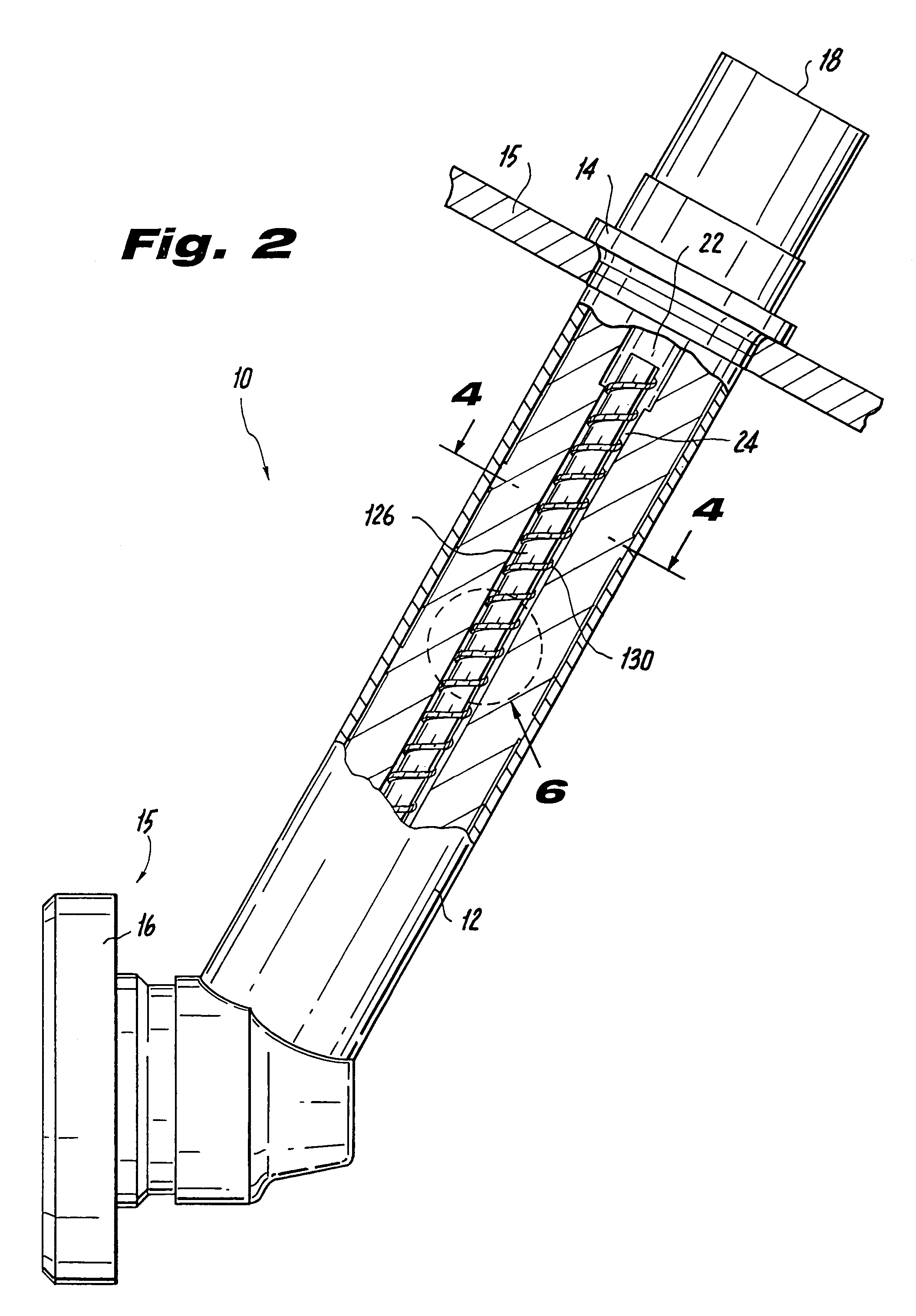

Feed arm for a multiple circuit fuel injector

A feed arm for a multiple circuit fuel injector of a gas turbine engine. The feed arm includes an elongated tubular sleeve having a central bore with an interior wall defining an inner diameter, and an elongated fuel tube positioned within the bore of the tubular sleeve. The fuel tube includes a tubular wall defining an outer diameter, which is substantially equal to the inner diameter of the central bore. A primary fuel flow passage is formed within the tubular wall of the fuel tube and bounded by the interior wall of the tubular sleeve, and the primary fuel flow passage circumferentially extends around the fuel tube at least once along the axial length of the fuel tube. A secondary fuel flow passage extends through a central portion of the fuel tube, and the fuel tube is configured to facilitate heat transfer by conduction and / or convection.

Owner:COLLINS ENGINE NOZZLES INC

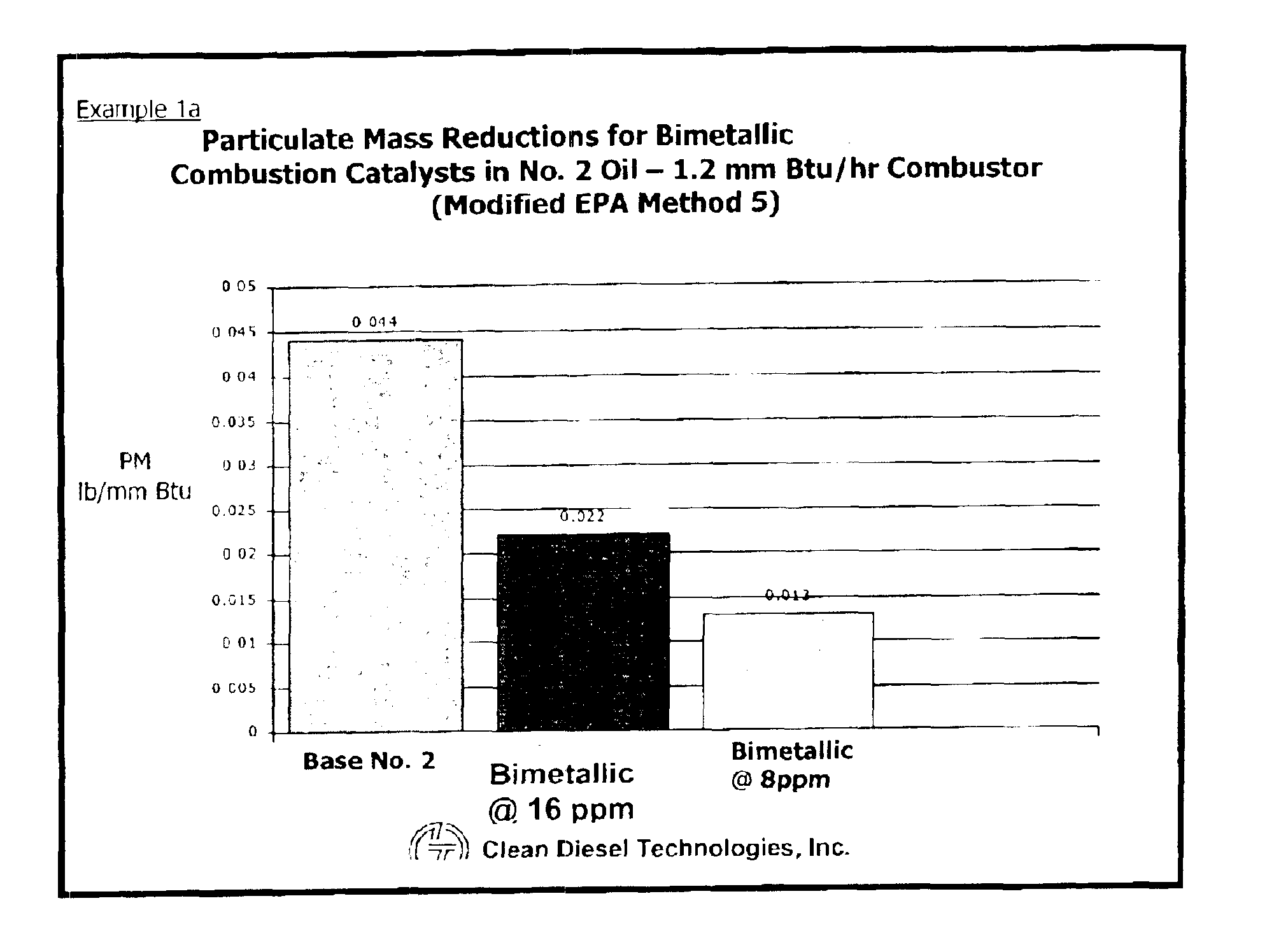

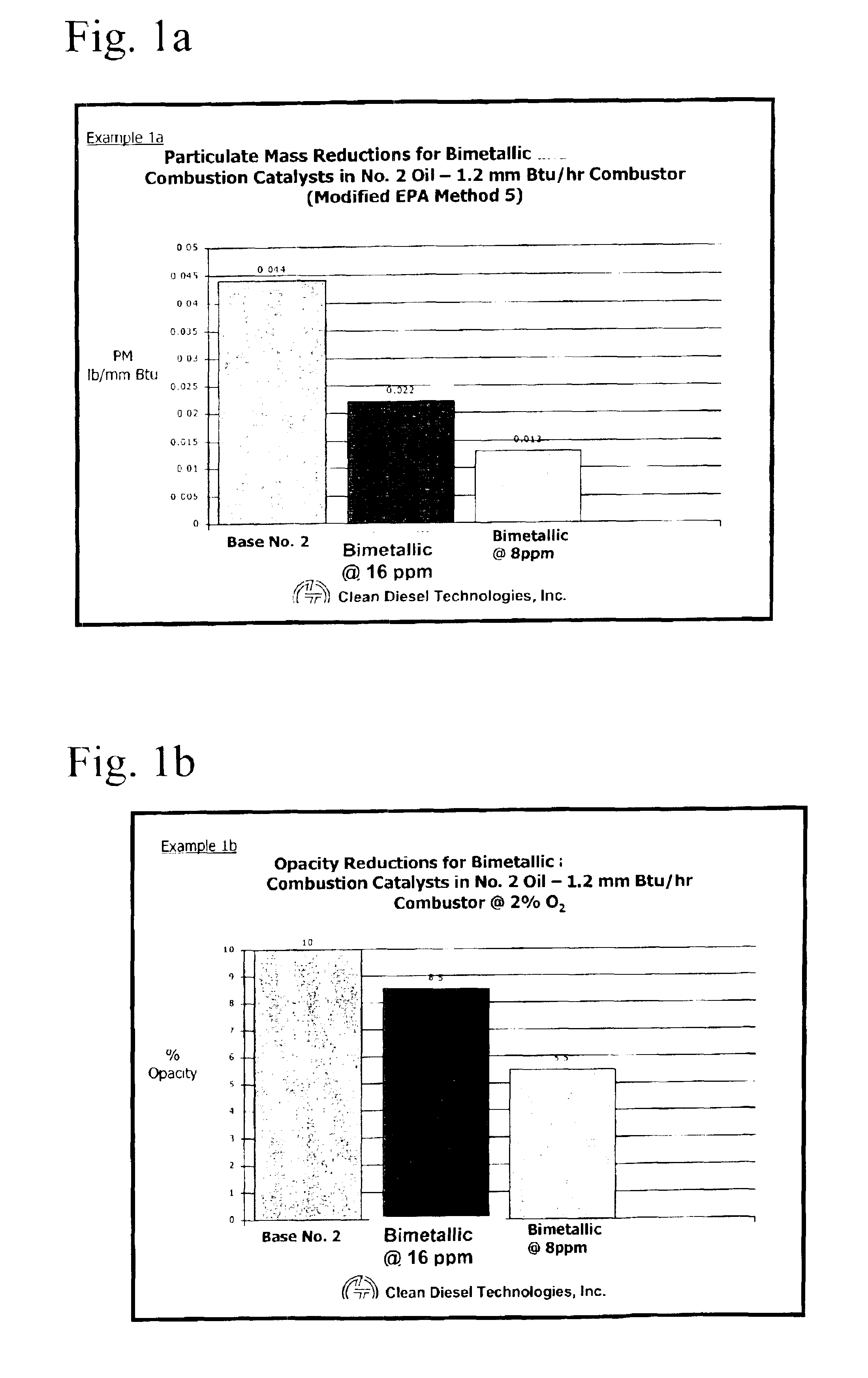

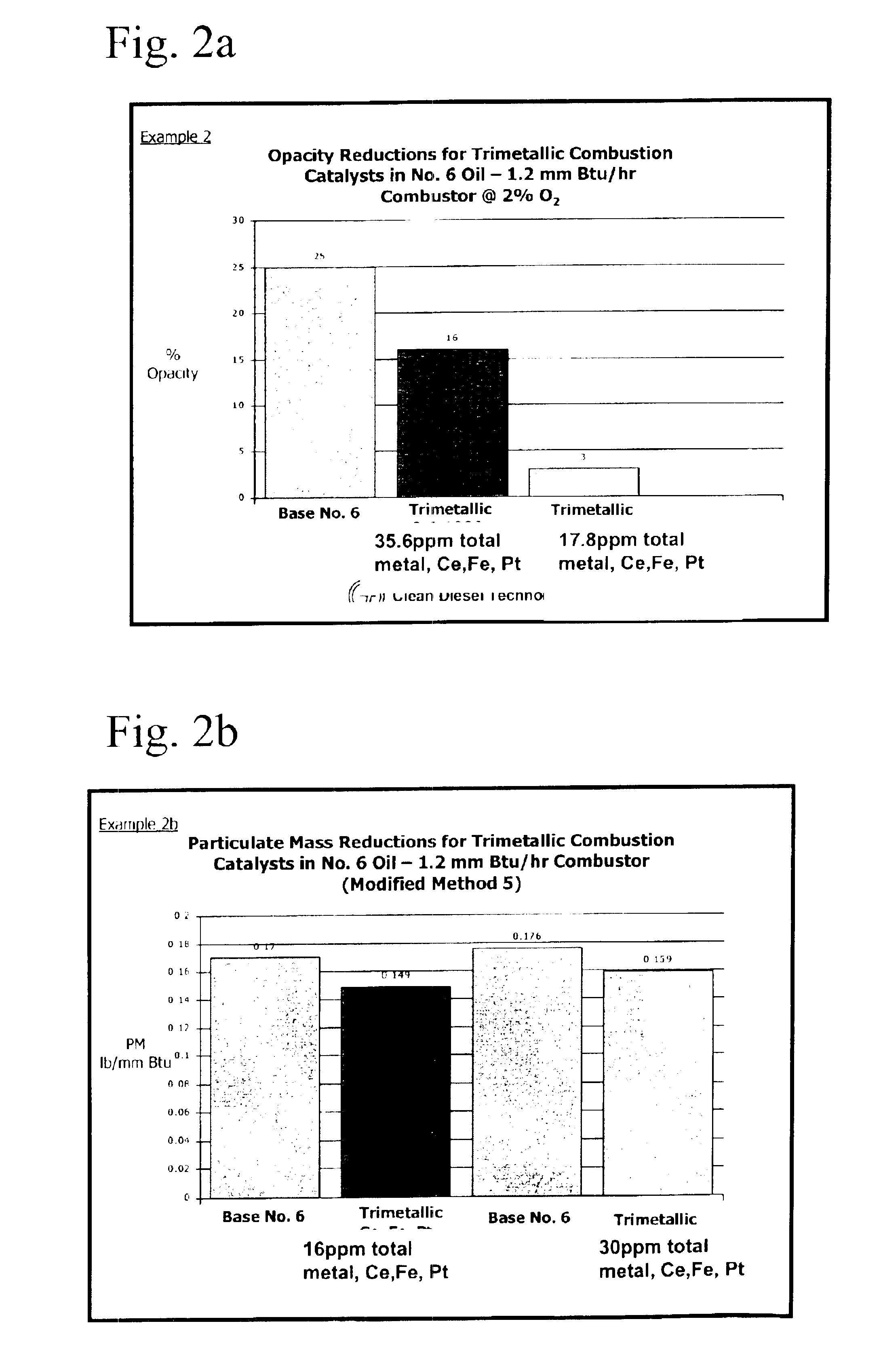

Reduced-emissions combustion utilizing multiple-component metallic combustion catalyst

InactiveUS6948926B2Increase dosePromote combustionLiquid fuel feeder/distributionExhaust apparatusParticulatesCerium

Residual fuels, as well as lighter distillate fuels, are combusted with greater efficiency by utilizing low concentrations of specific bimetallic or trimetallic fuel-borne catalysts. The catalysts reduce fouling of heat transfer surfaces by unburned carbon while limiting the amount of secondary additive ash which may itself cause overloading of particulate collector devices or emissions of toxic ultra fine particles when used in forms and quantities typically employed. By utilizing a fuel containing a fuel-soluble catalyst comprised of platinum and at least one additional metal comprising cerium and / or iron, production of pollutants of the type generated by incomplete combustion is reduced. Ultra low levels of nontoxic metal combustion catalysts are able to be employed for improved heat recovery and lower emissions of regulated pollutants.

Owner:CLEAN DIESEL TECHNOLOGIES

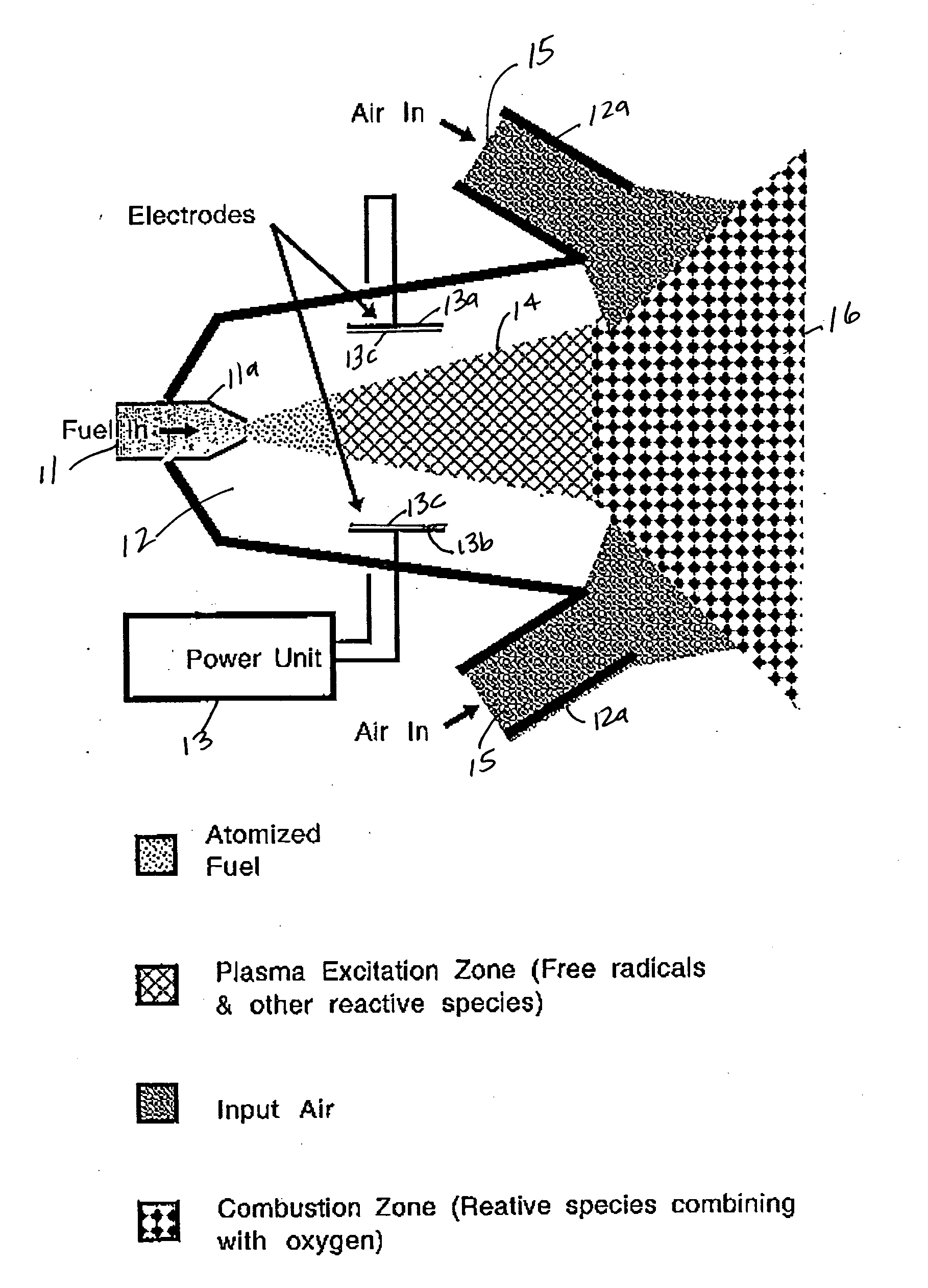

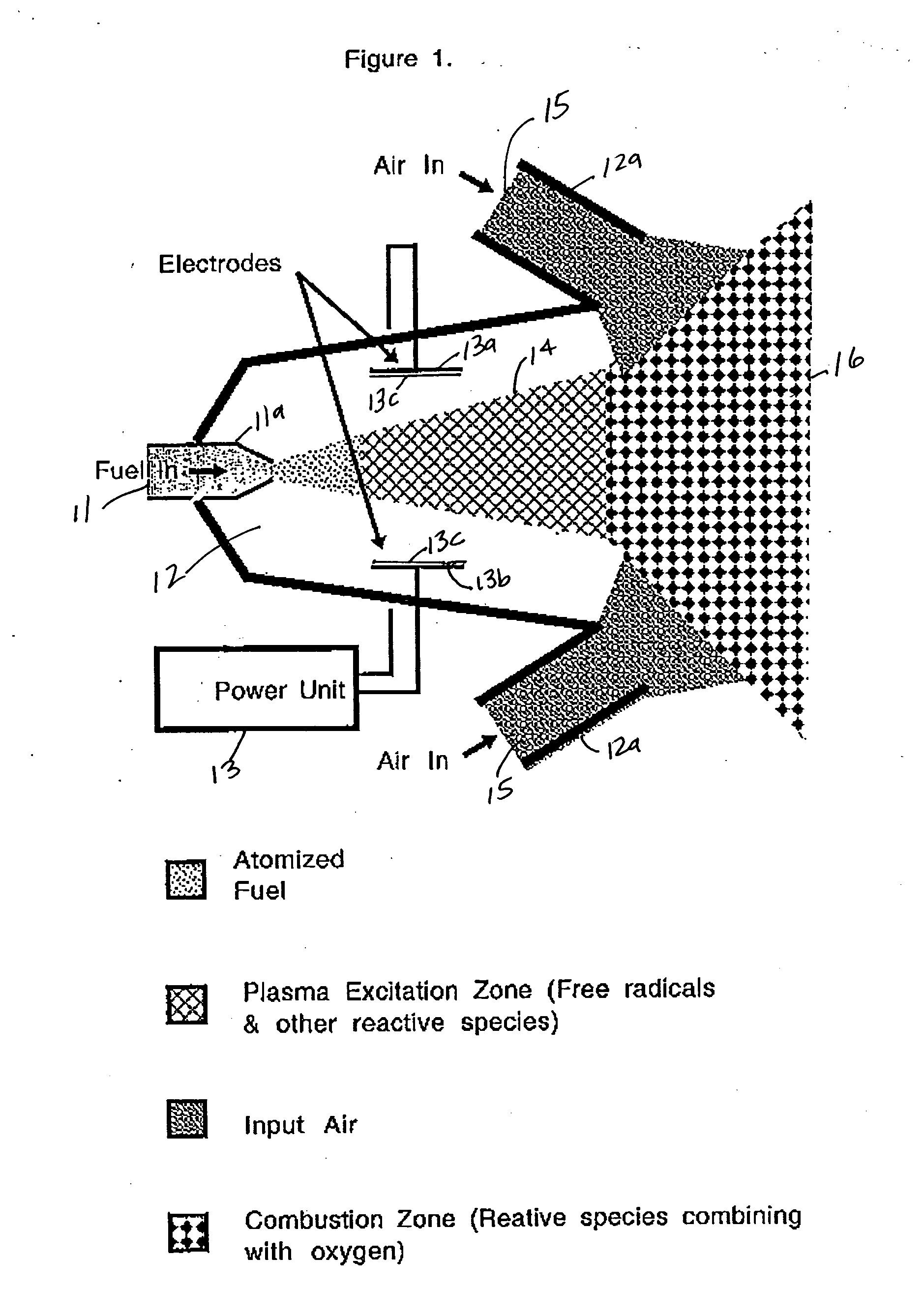

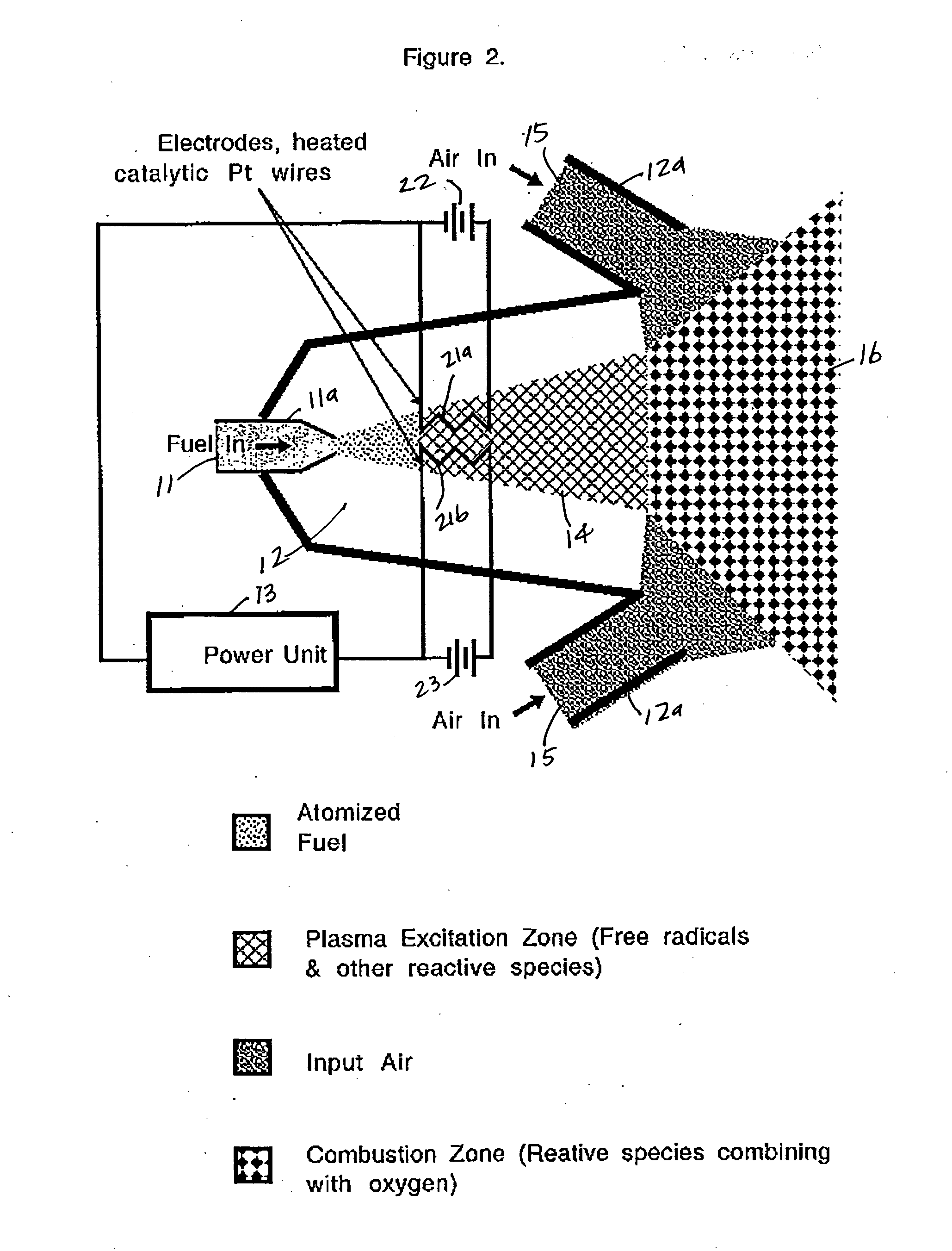

Plasma catalytic fuel injector for enhanced combustion

InactiveUS20050019714A1Improve efficiencyPromote combustionLiquid fuel feeder/distributionGaseous fuel feeder/distributionEngineeringElectric power

Apparatus and method for enhancing combustion comprises an enclosure defining an opening for introduction of a gas and openings for the introduction of air, with a nozzle in the opening for introduction of a fuel gas into the enclosure. First and second electrodes are located in the enclosure, the first and second electrodes being coated with dielectric material, and being connected to an electrical power supply. With electrical power applied to the first and second electrodes and with the fuel gas sprayed into the enclosure, an atmospheric pressure plasma created by a dielectric barrier discharge is produced in the enclosure that cracks the fuel gas prior to its mixing with air introduced through the openings for the introduction of air.

Owner:RGT UNIV OF CALIFORNIA

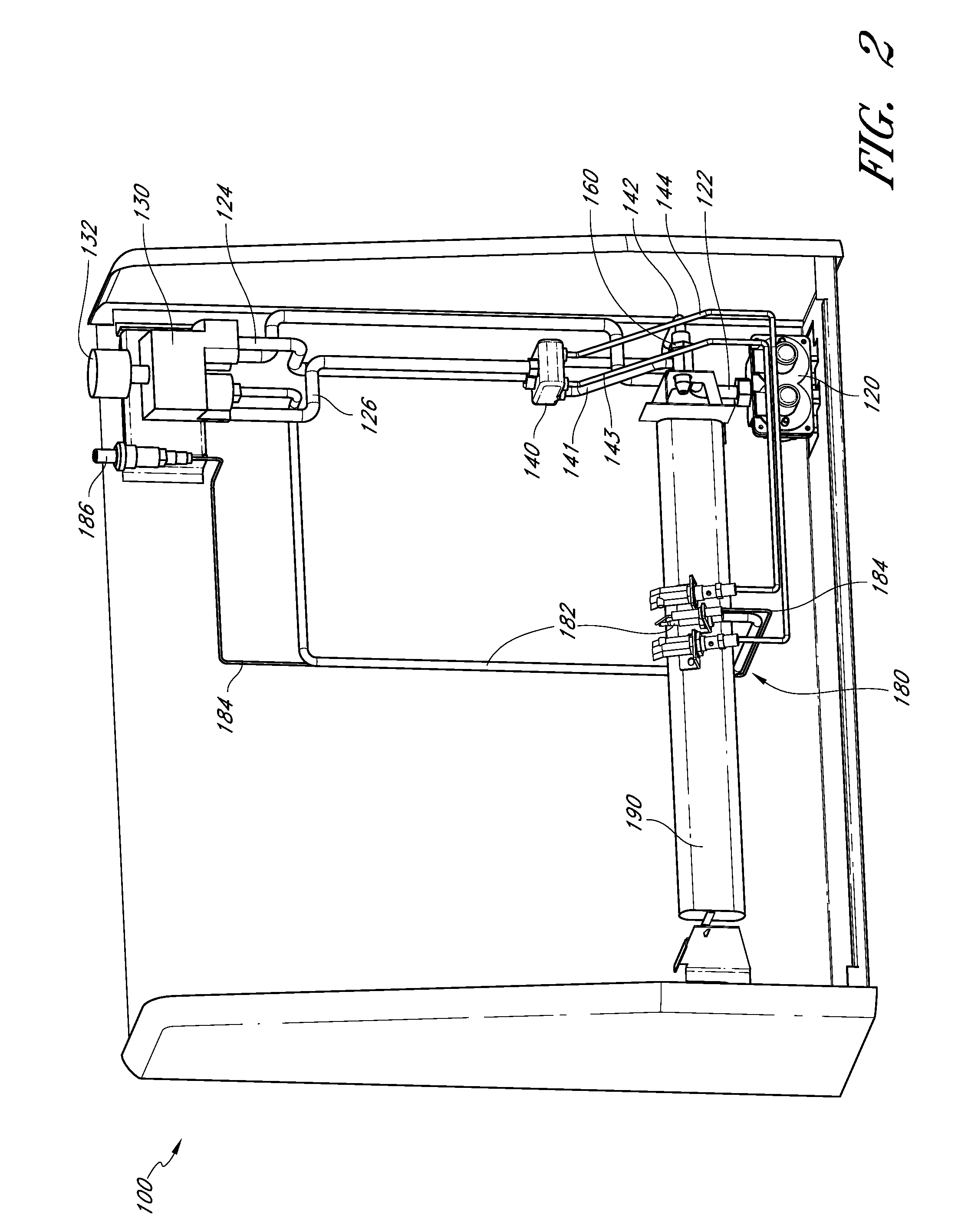

Fuel supply component purging system

A method of purging fuel supply components for a combustion chamber of a regeneration assembly is disclosed. A regeneration cycle is performed during which fuel is supplied from a fuel source to the combustion chamber with fuel supply components including a fuel supply circuit and at least one fuel injector unit. At least a first purging cycle is initiated to purge residual fuel from the fuel supply components. During the purging cycle, a flow of purging gas is directed to the at least one fuel injector unit to purge residual fuel from the at least one fuel injector unit. Also during the purging cycle, a flow of purging gas is directed to the fuel supply circuit to purge at least a portion of the fuel in the fuel supply circuit toward the fuel source.

Owner:CATERPILLAR INC

Method and apparatus for burning oils of varying viscosity

InactiveUS6132203AEfficient combustionPrevents possibility of fire and explosionLiquid fuel feeder/distributionSpraying apparatusHeating oilCombustor

Disclosed is an oil burning system that is capable of burning oils of varying viscosities, including high viscosity waste oils and low viscosity heating oils. Suitable as a new installation or a retrofit modification, the present invention incorporates the use of a variable rate, high-pressure oil delivery system, along with an oil pre-heater, in conjunction with a modified high-pressure atomizing nozzle. Installed in a sliding drawer burner arrangement that allows for quick and easy access, the oil burning system also includes a means by which particulate matter and carbonization build-ups are removed from the burner nozzle automatically, thereby eliminating the need for frequent cleaning.

Owner:MASIN RADEK

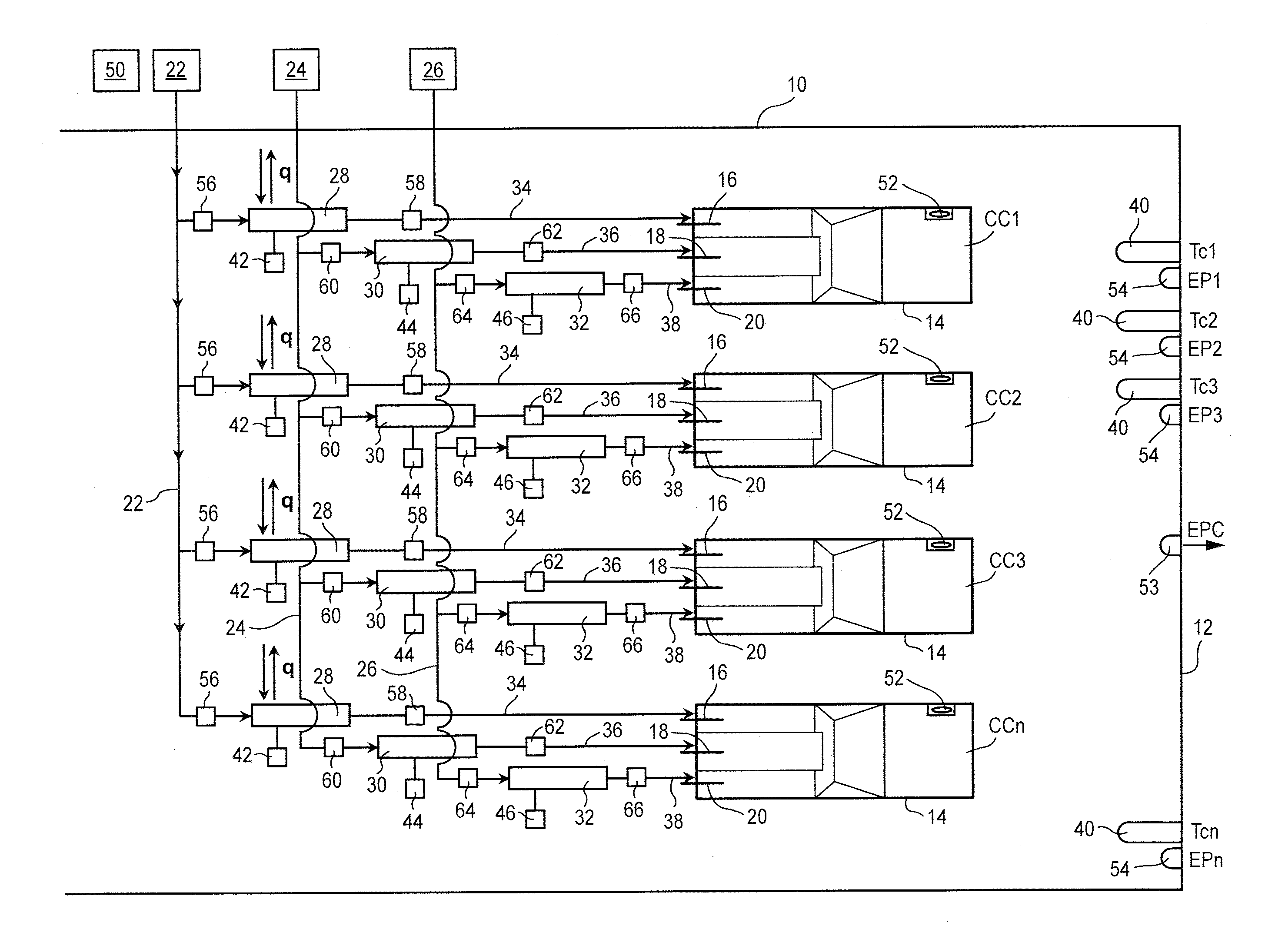

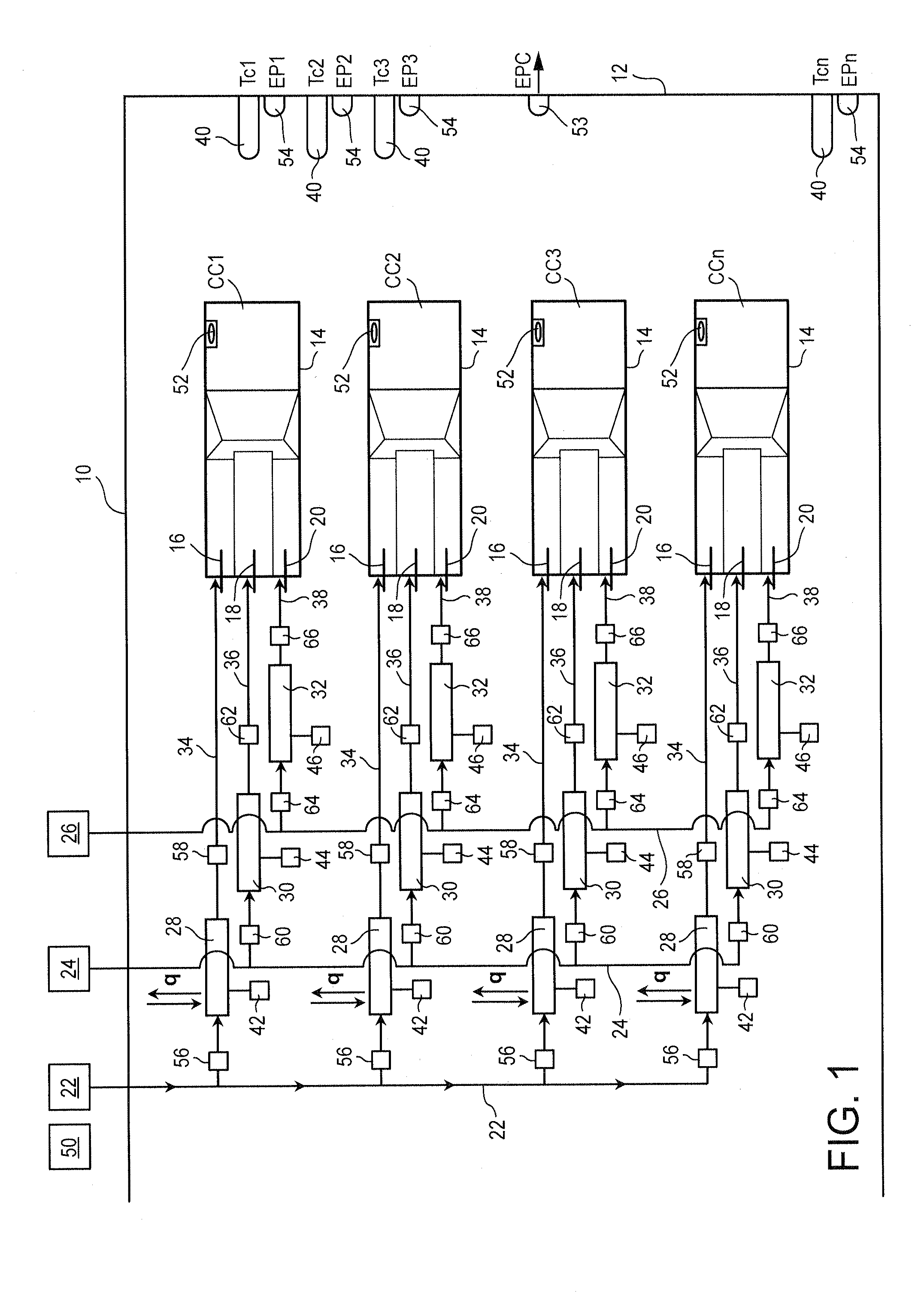

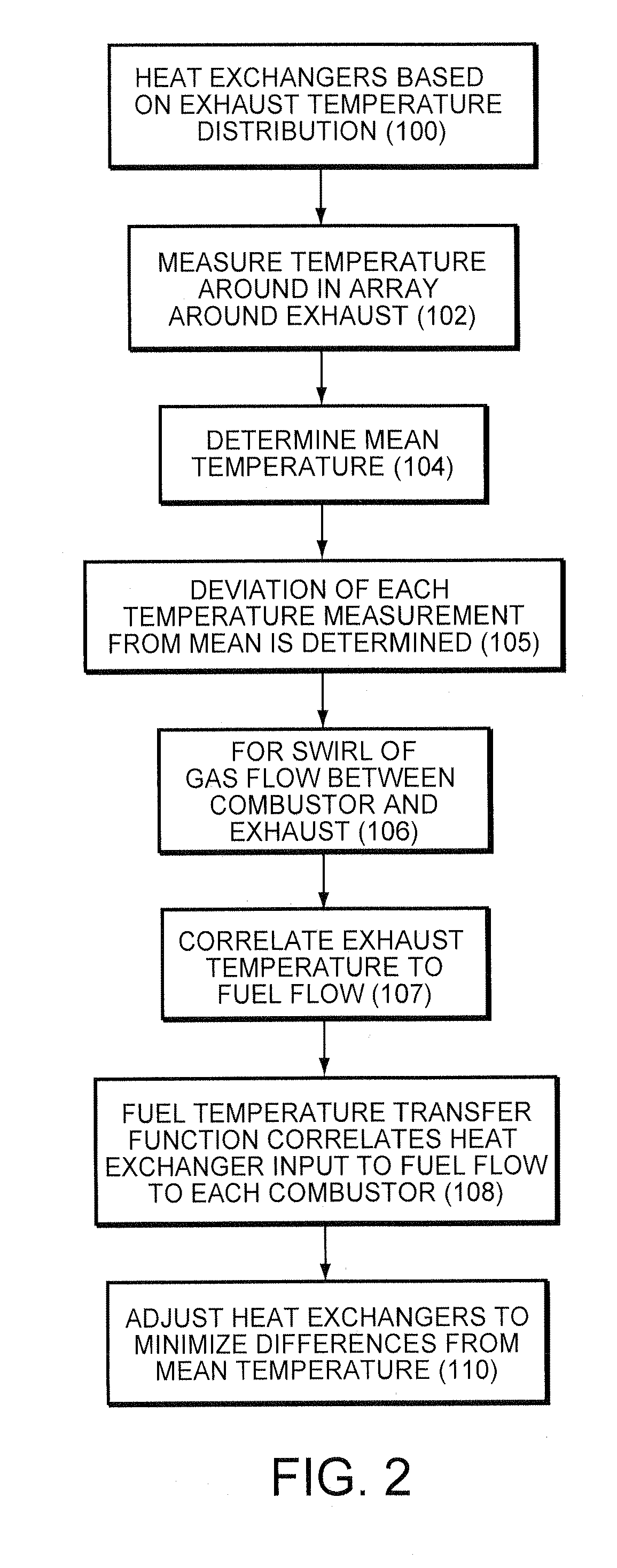

Systems and methods for bulk temperature variation reduction of a gas turbine through can-to-can fuel temperature modulation

InactiveUS20130014514A1Reduce biasReduce variationLiquid fuel feeder/distributionContinuous combustion chamberTemperature controlCombustion chamber

A gas turbine includes a plurality of combustion chambers; at least one fuel nozzle for each of the combustion chambers; at least one fuel line for each fuel nozzle in each of the combustion chambers; at least one heat exchanger for each fuel line configured to adjust a temperature of a fuel flow to each fuel nozzle; and a controller configured to control each of the heat exchangers to reduce temperature variations amongst the combustion chambers.

Owner:GENERAL ELECTRIC CO

Reduced-emissions combustion utilizing multiple-component metallic combustion catalyst and lightly catalyzed diesel particulate filter

InactiveUS20050164139A1Reduce system costLower requirementLiquid fuel feeder/distributionLiquid fuel pretreatmentCeriumPt element

An improved, robust diesel emission control system employs a lightly diesel particulate filter (DPF), preferably with a platinum containing fuel borne catalyst (FBC) in the fuel. The DPF is preferably of wire mesh construction and at least partially lightly catalyzed with precious metal catalyst, e.g., platinum group metal, having a metal loading of from about 3 to 15 grams per cubic foot to minimize formation of NO2 in the exhaust gas. Preferred fuel borne catalyst levels will be low, e.g., from 0.05 to 0.5 ppm for platinum and 3 to 8 ppm for cerium and / or iron, thereby providing effective engine out emissions reductions without discharging excessive amounts of NO2 to the atmosphere.

Owner:CLEAN DIESEL TECHNOLOGIES

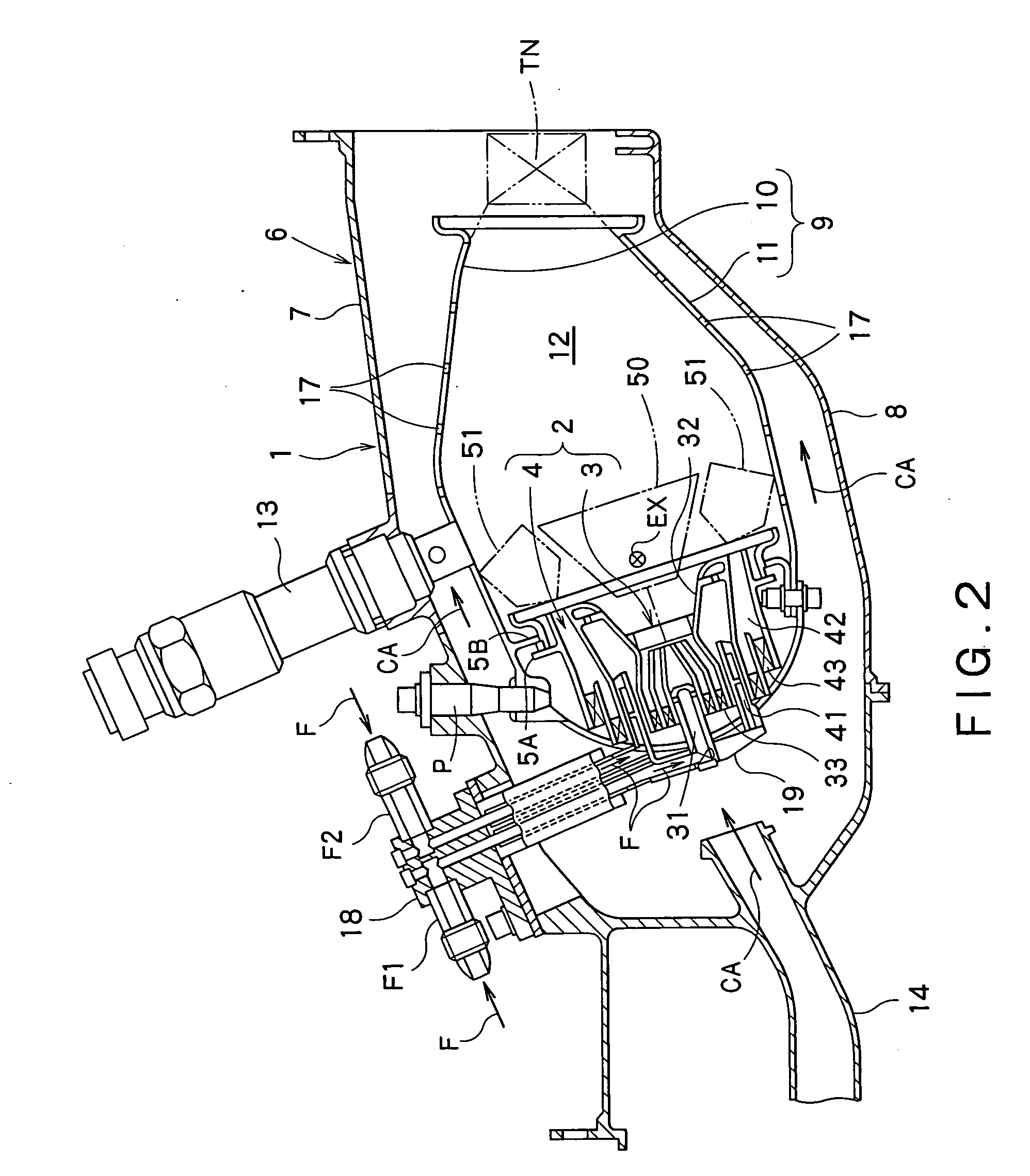

Combustor of a gas turbine engine

ActiveUS20080245074A1Simple structureLow costBurnersLiquid fuel feeder/distributionCombustorDistributor

The present combustor of gas turbine engine includes: a fuel injection unit including a fuel spray part to spray a fuel so that a diffusion combustion region is formed in a combustion chamber, and a pre-mixture supply part to supply a pre-mixture of a fuel and an air so that a pre-mixture combustion region is formed in the combustion chamber; and a fuel supply unit to supply the fuel to the fuel spray part and pre-mixture supply part. The fuel supply unit includes: a pilot fuel passage and a main fuel passage to supply the fuel to the fuel spray part and the pre-mixture supply part, respectively; an assembled fuel passage to supply the fuel to the pilot and main fuel passages; and a fuel distributor disposed at a branch point where the assembled fuel passage is connected to both the pilot and main fuel passages. The fuel distributor is configured to automatically control amounts of the fuel to be distributed to the pilot fuel passage and to the main fuel passage in accordance with the fuel pressure.

Owner:KAWASAKI HEAVY IND LTD

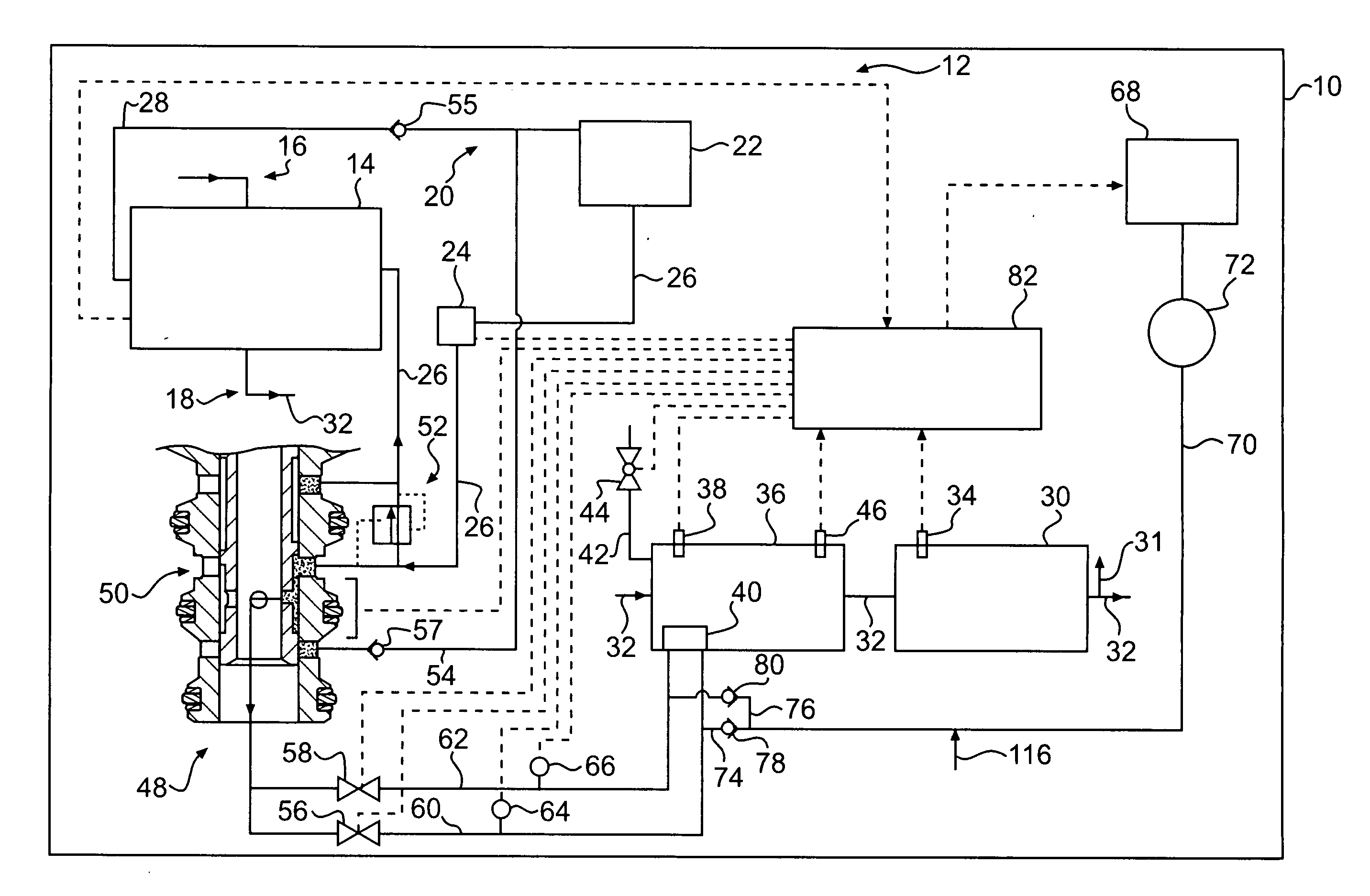

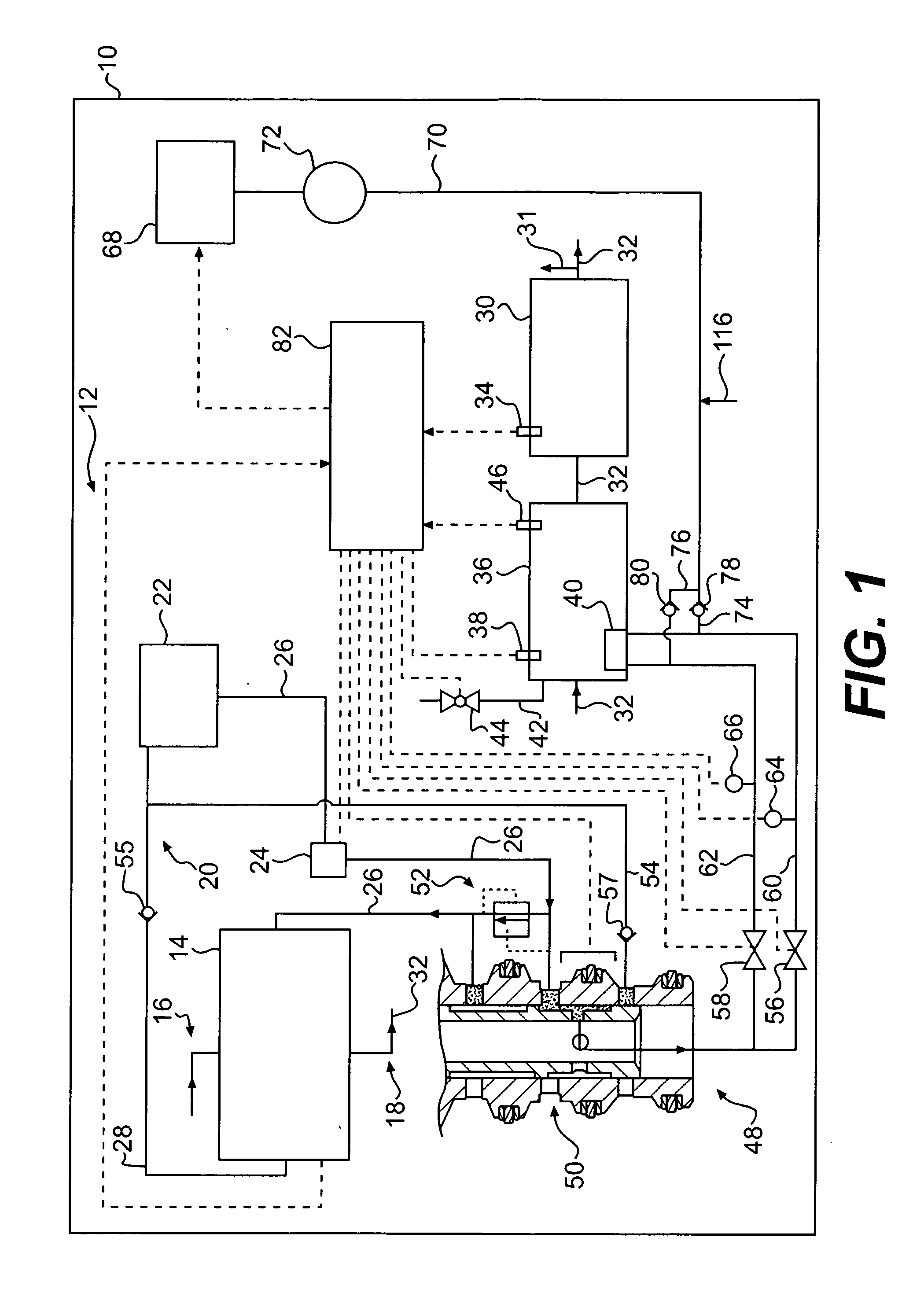

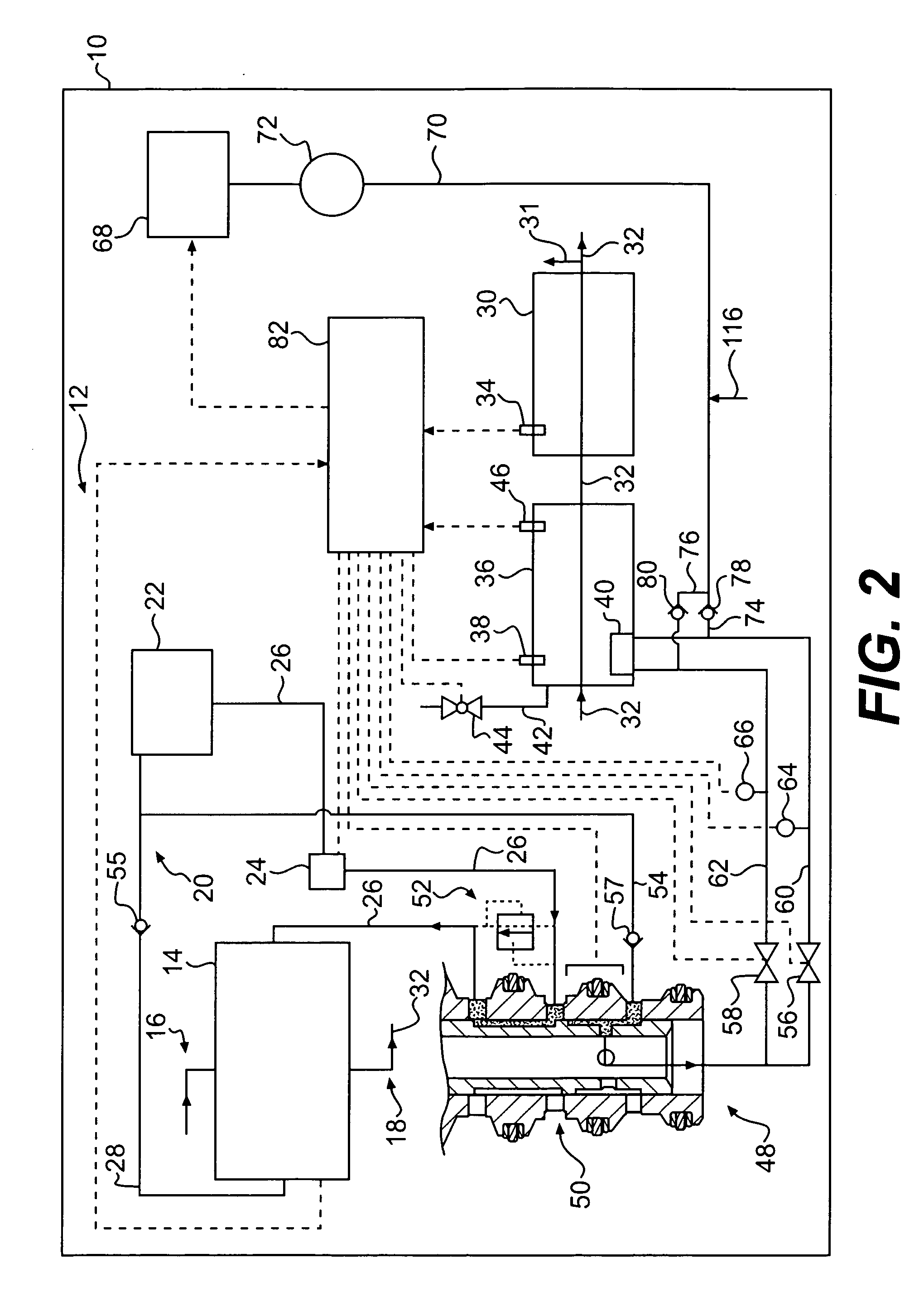

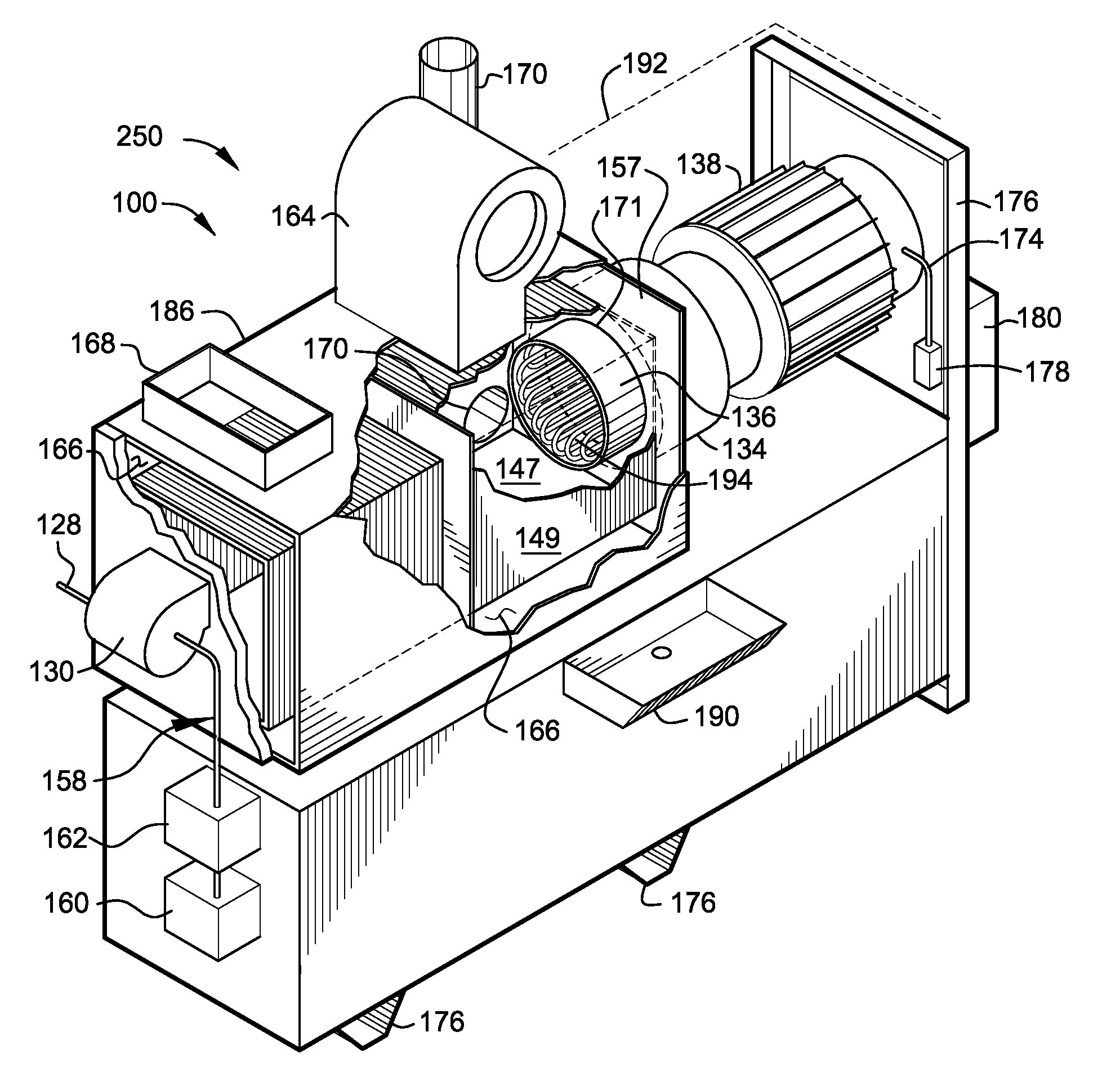

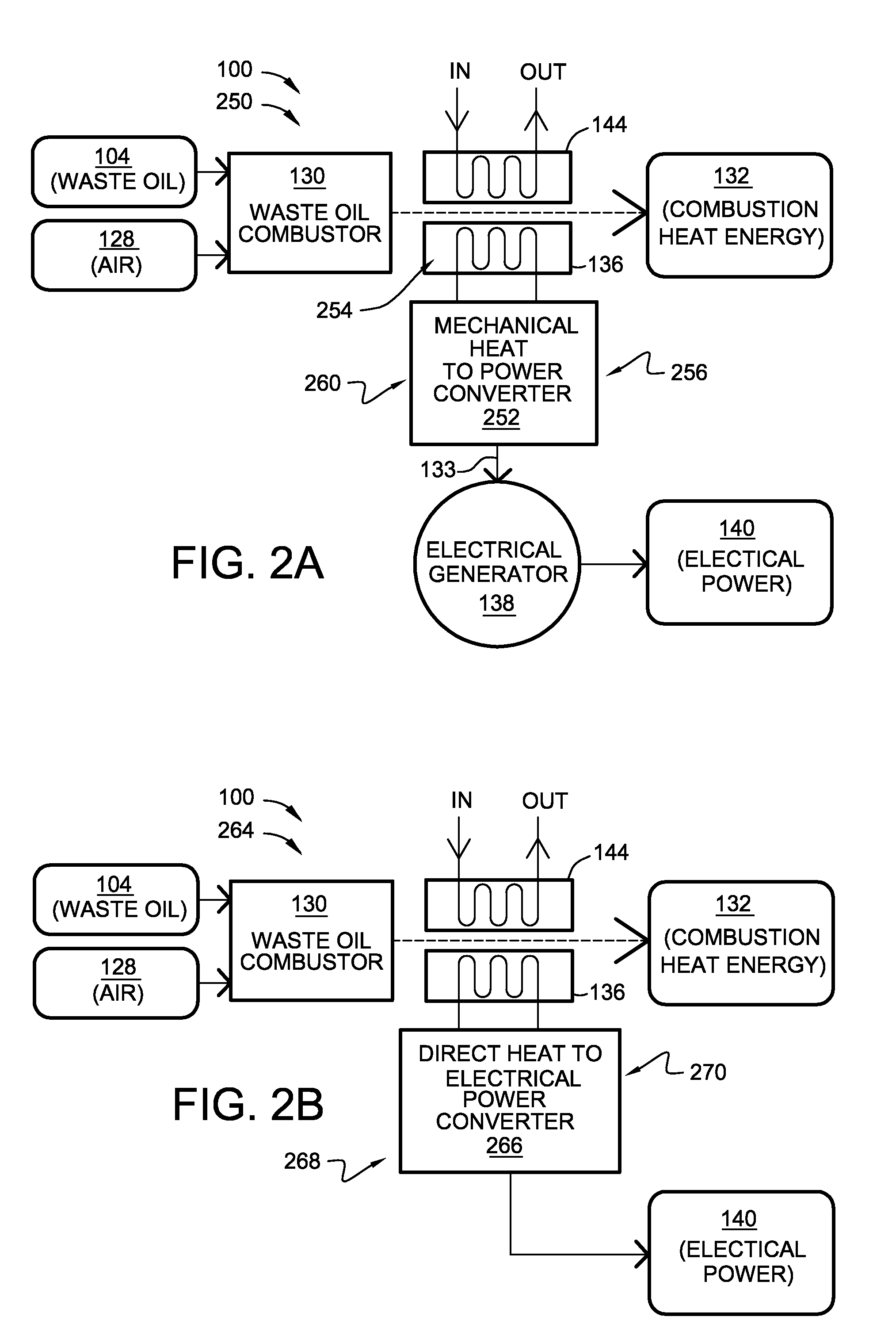

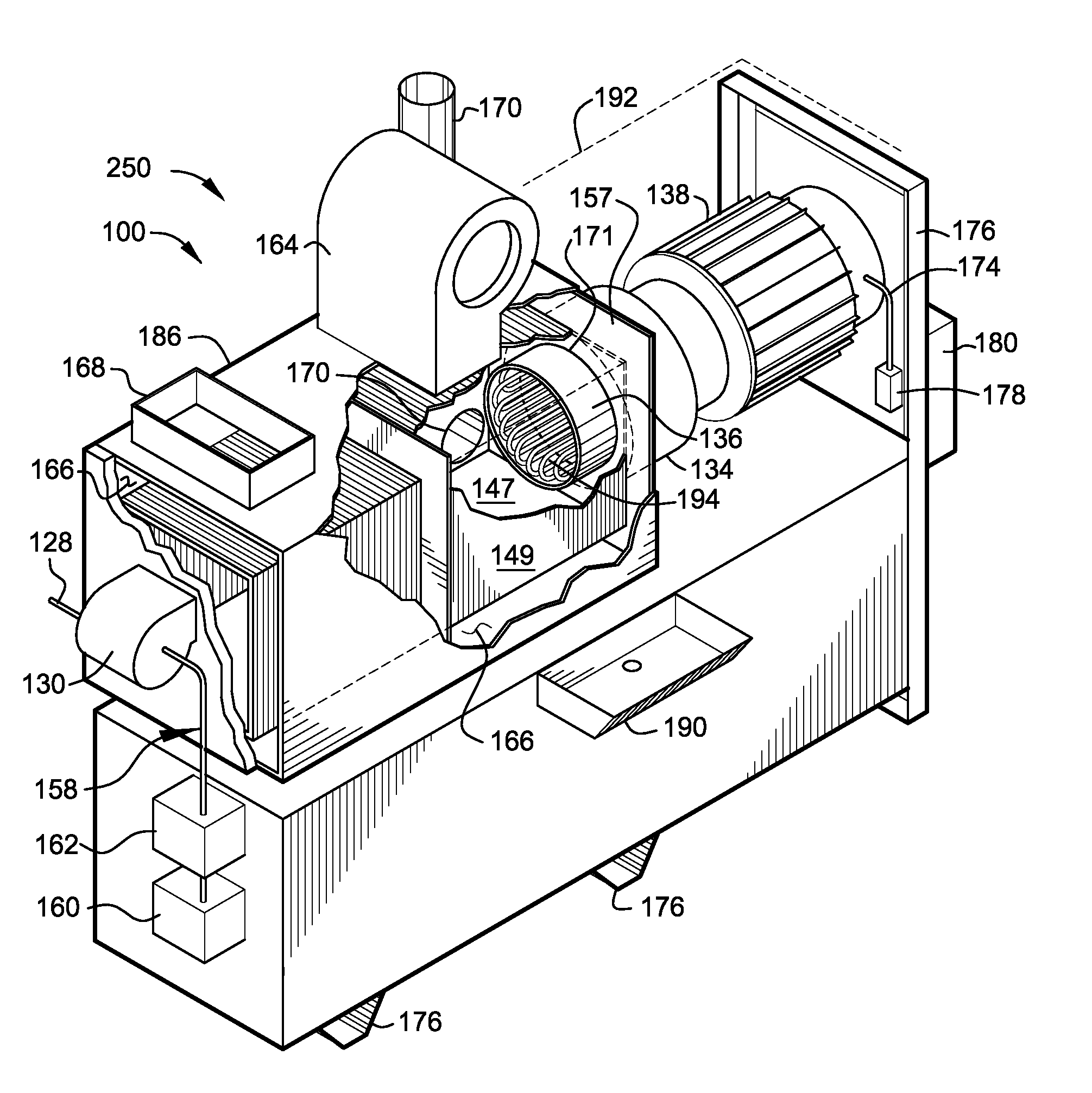

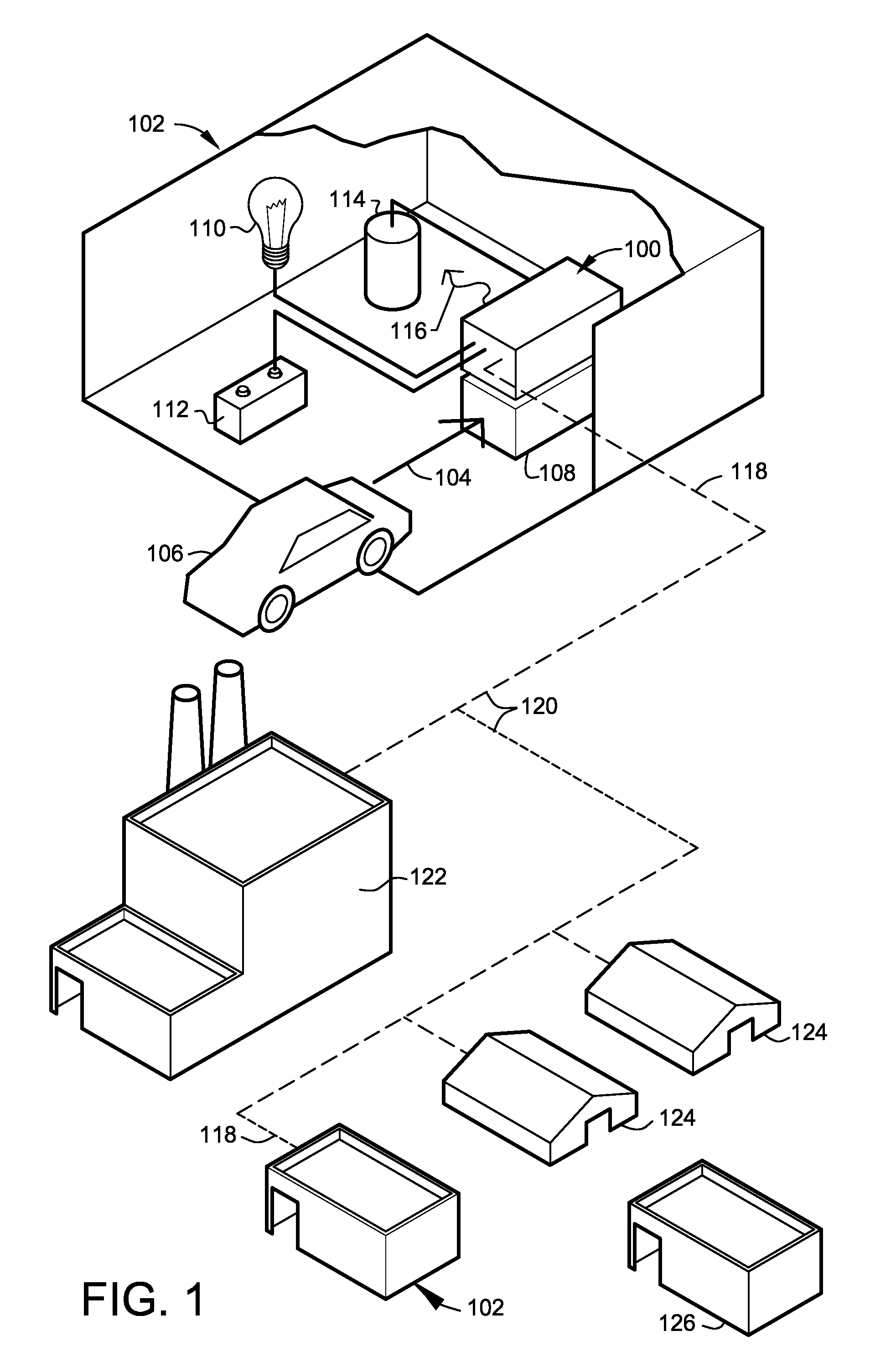

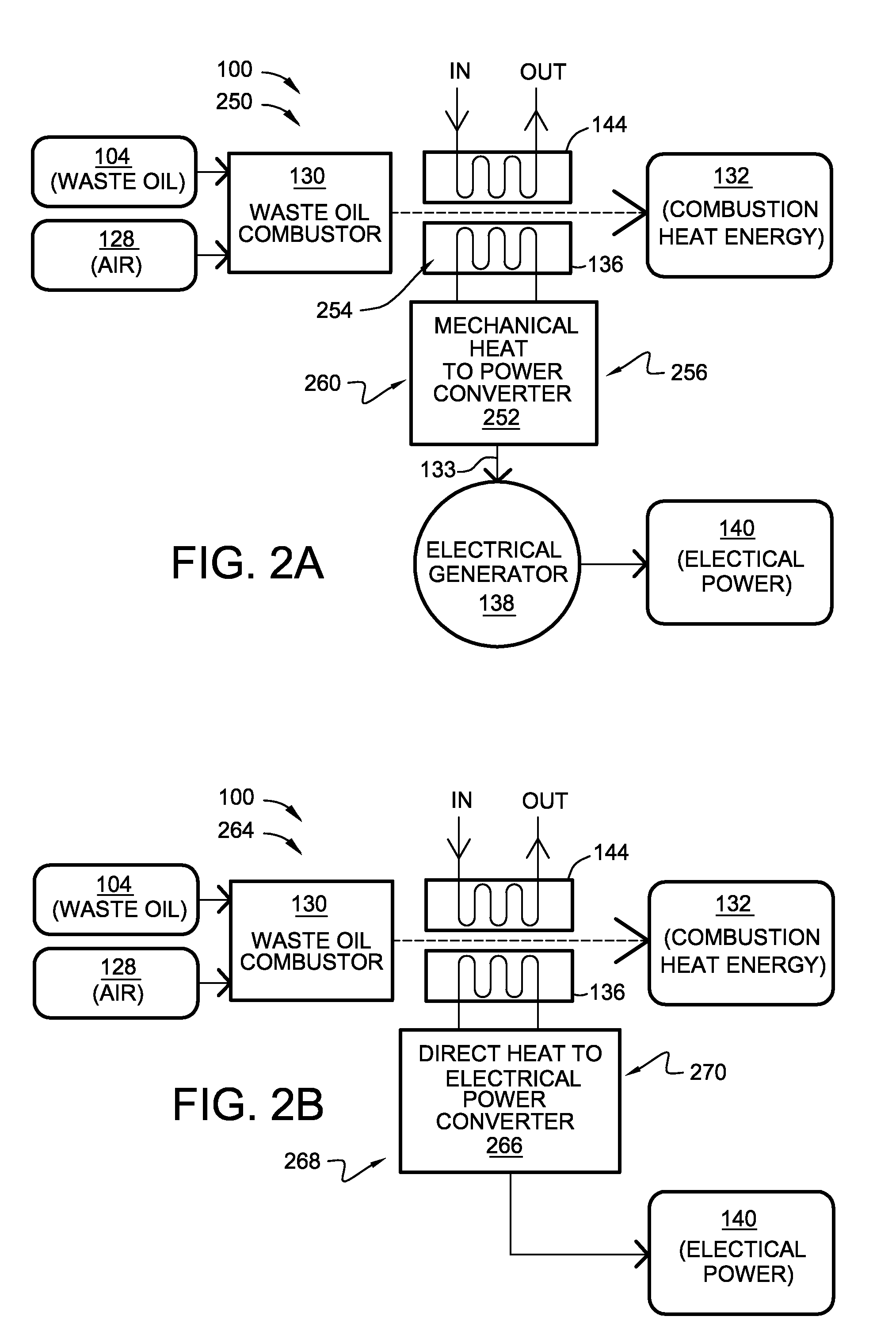

Waste Oil Electrical Generation Systems

An on-site electrical power generation system utilizing environmentally hazardous waste oils as a combustible fuel. The disclosed invention utilizes the combustion of environmentally hazardous waste oils to drive a heat engine and electrical generator. In addition, the system is adapted to provide local space heating and hot water as a byproduct of the combustion process.

Owner:BASSETT TERRY EDGAR

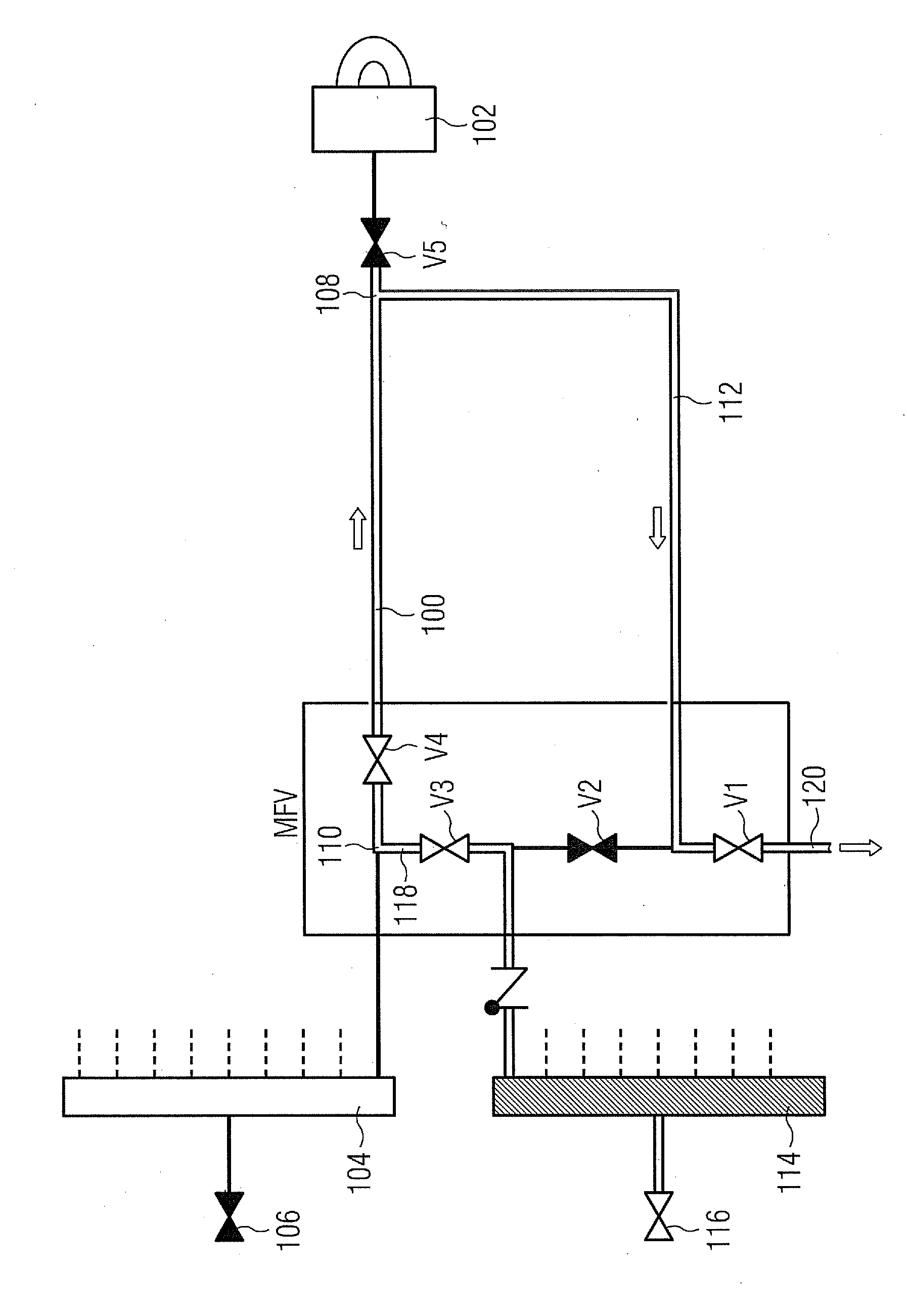

Method for rinsing a fuel system of a gas turbine and associated fuel system

ActiveUS20110146807A1Simple and inexpensive mannerOvercome disadvantagesLiquid fuel feeder/distributionTurbine/propulsion fuel flow conduitsCombustorEngineering

A method for flushing a section of a fuel system of a burner of a gas turbine is provided. The method includes the steps of providing a feed line for feeding fuel from a fuel source to the burner, providing a first feed point close to the burner and a second feed point remote from the burner in the feed line in each case for feeding a medium into the feed line, feeding the medium via the first feed point, and discharging, via the burner, the fuel which is in the feed line between the first feed point and the burner, and also feeding the medium via the second feed point, and discharging, via the first feed point, the fuel which is in the feed line between the second feed point and the first feed point.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Fuel system

InactiveUS20060130455A1Reduce the amount requiredFuel supply regulationLiquid fuel feeder/distributionCombustorControl system

A fuel control system for a staged combustion engine comprising, a fuel metering unit including a fuel metering valve having a fuel metering orifice the opening of which is varied to meter the flow of fuel through the metering valve in use, a fuel staging unit receiving fuel from the metering valve of the fuel metering unit and incorporating a staging valve for dividing the flow of fuel from the fuel metering unit to pilot burner and main burner output lines, a connection between a fuel pressure region of said fuel metering unit and a port of said staging valve, and, overthrust detection means causing said staging valve, in response to overthrust detection, to connect said port of said staging valve to low pressure, whereby to drain fuel under pressure from said pressure zone of said fuel metering unit to low pressure to limit or reduce the fuel supplied from the fuel metering unit to the fuel staging unit and thus to the engine in use.

Owner:GOODRICH CONTROL SYST LTD

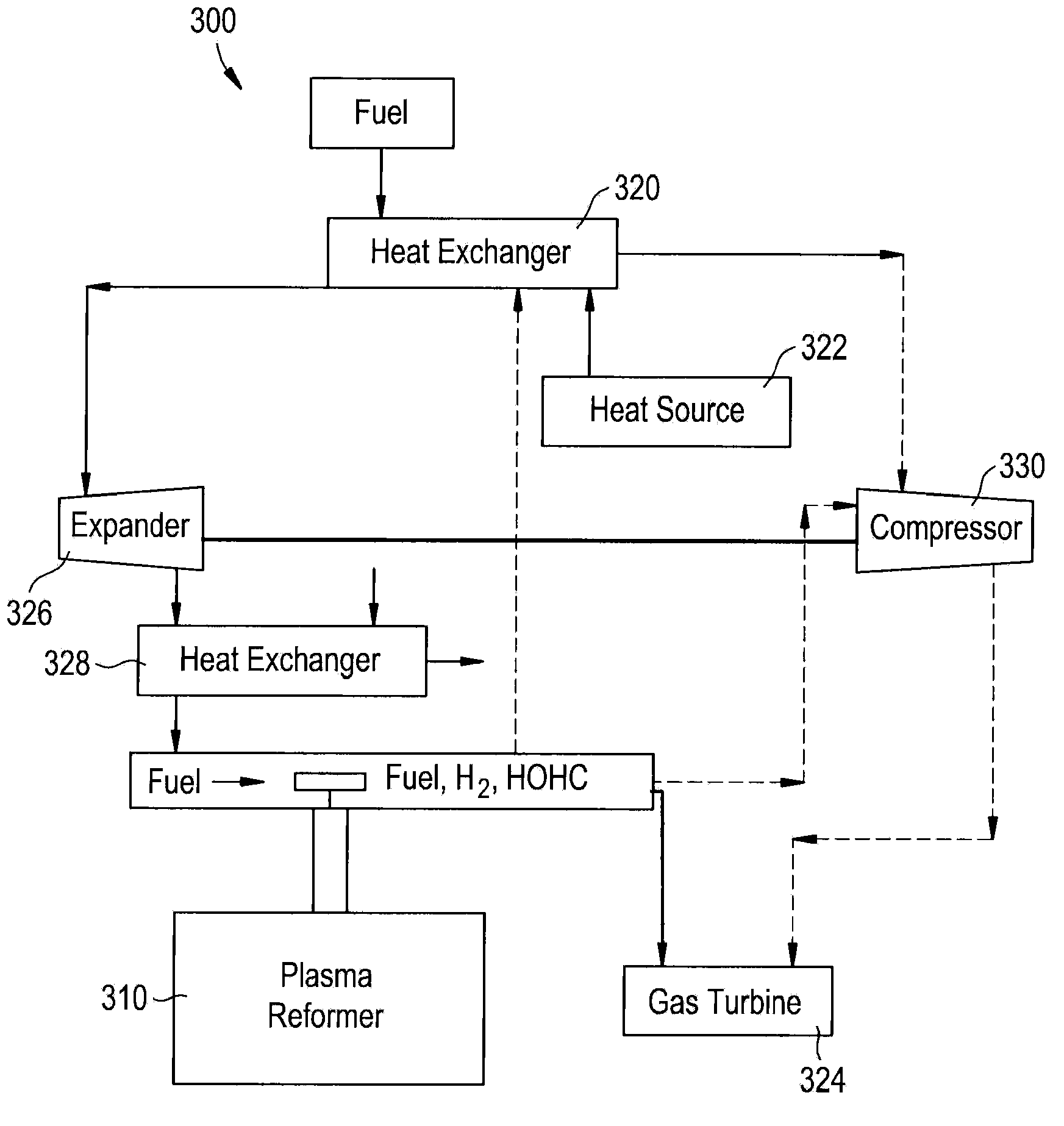

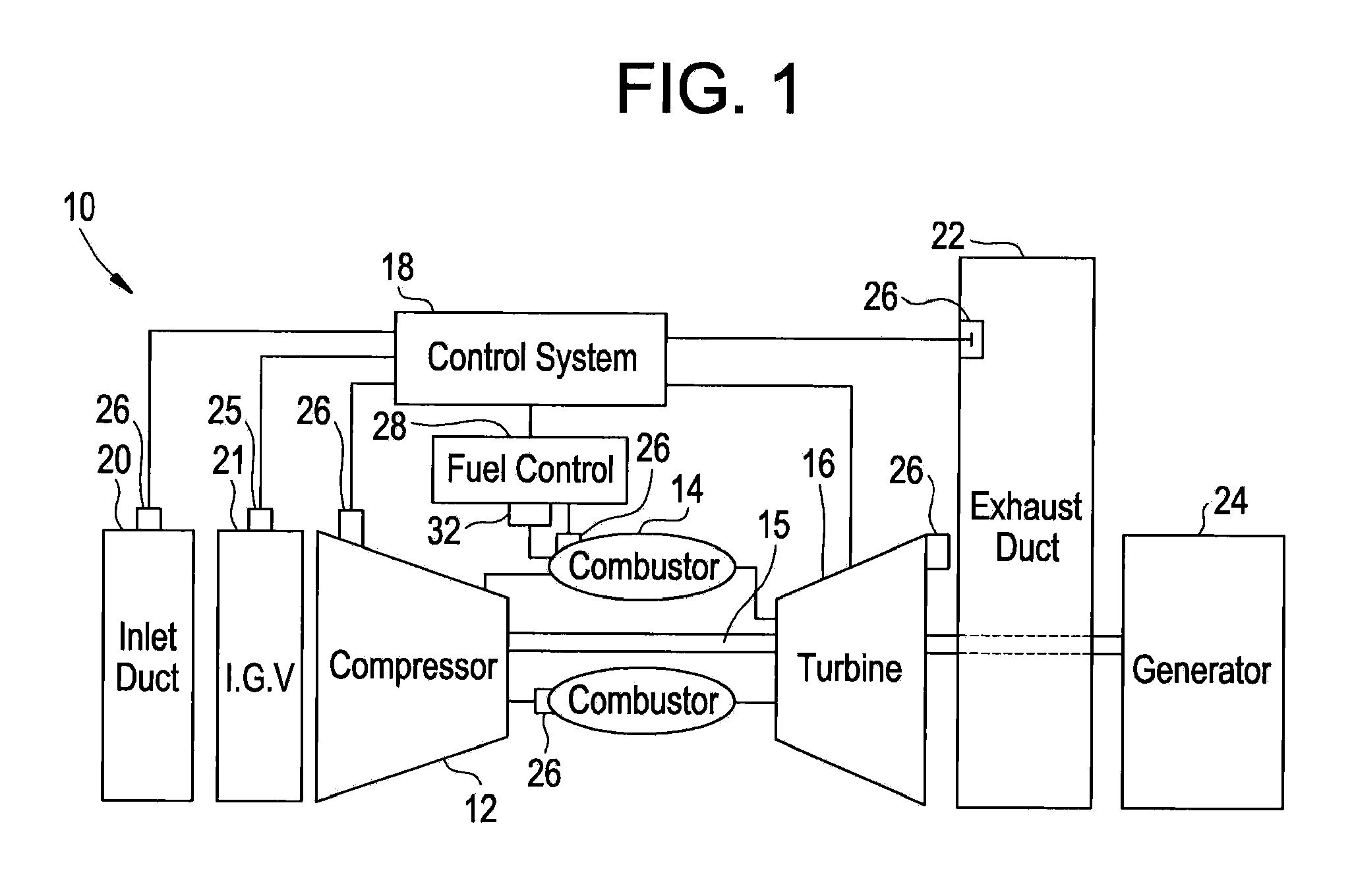

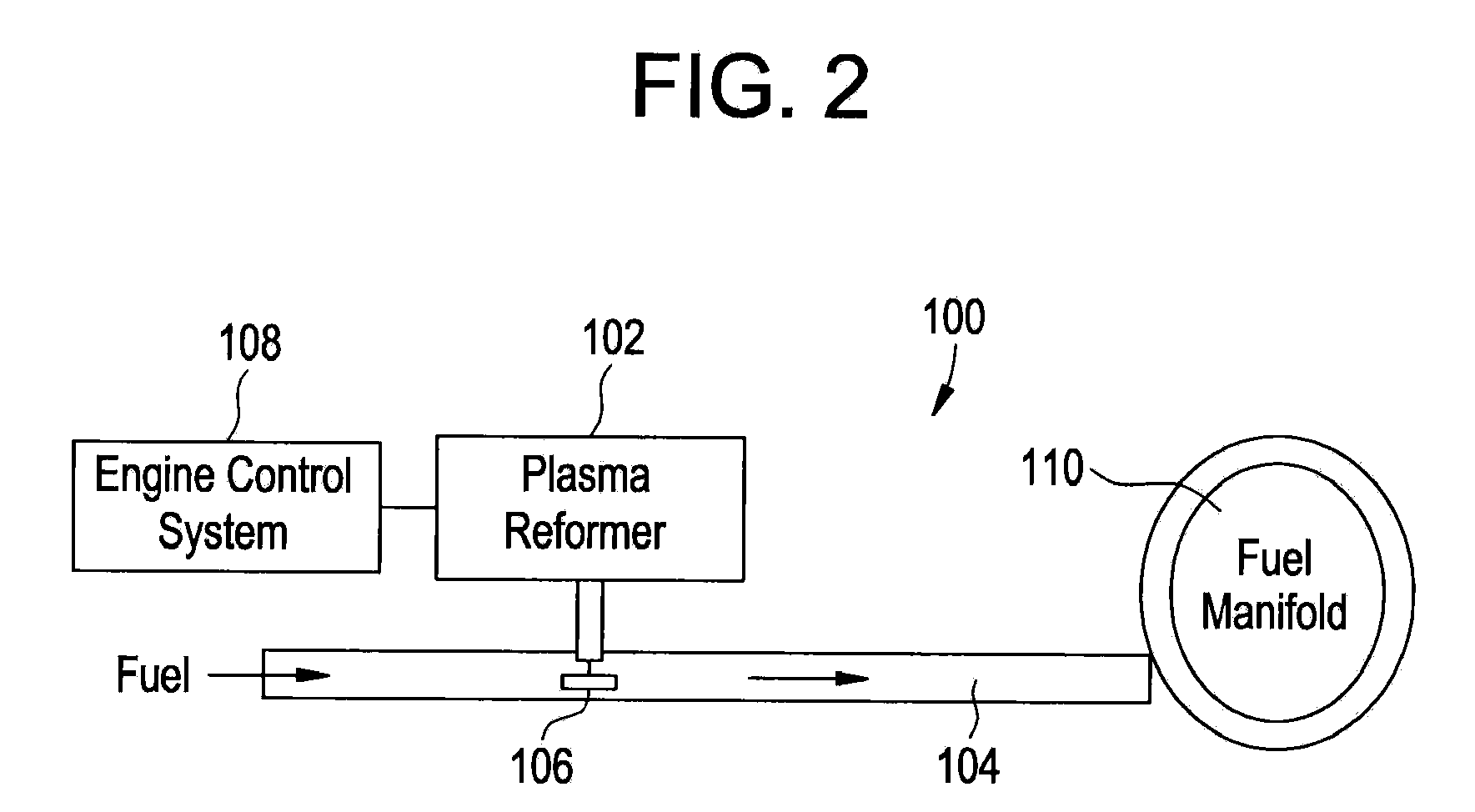

Gas Turbine Combustion System With In-Line Fuel Reforming And Methods Of Use Thereof

InactiveUS20100300110A1Liquid fuel feeder/distributionFuel supply regulationCombustion systemActive feedback

A process for providing a fuel supplied to one or more combustors in a gas turbine engine system, comprising: reforming a fraction of the fuel in one or more fuel circuits of the gas turbine combustion system with a plasma reformer system to form at least one of hydrogen and higher order hydrocarbons to be supplied to the one or more combustors with a remaining fraction of the fuel; and controlling at least one of power and fuel flow to the plasma reformer system with an active feedback control system.

Owner:GENERAL ELECTRIC CO

Waste oil electrical generation systems

An on-site electrical power generation system utilizing environmentally hazardous waste oils as a combustible fuel. The disclosed invention utilizes the combustion of environmentally hazardous waste oils to drive a heat engine and electrical generator. In addition, the system is adapted to provide local space heating and hot water as a byproduct of the combustion process.

Owner:BASSETT TERRY EDGAR

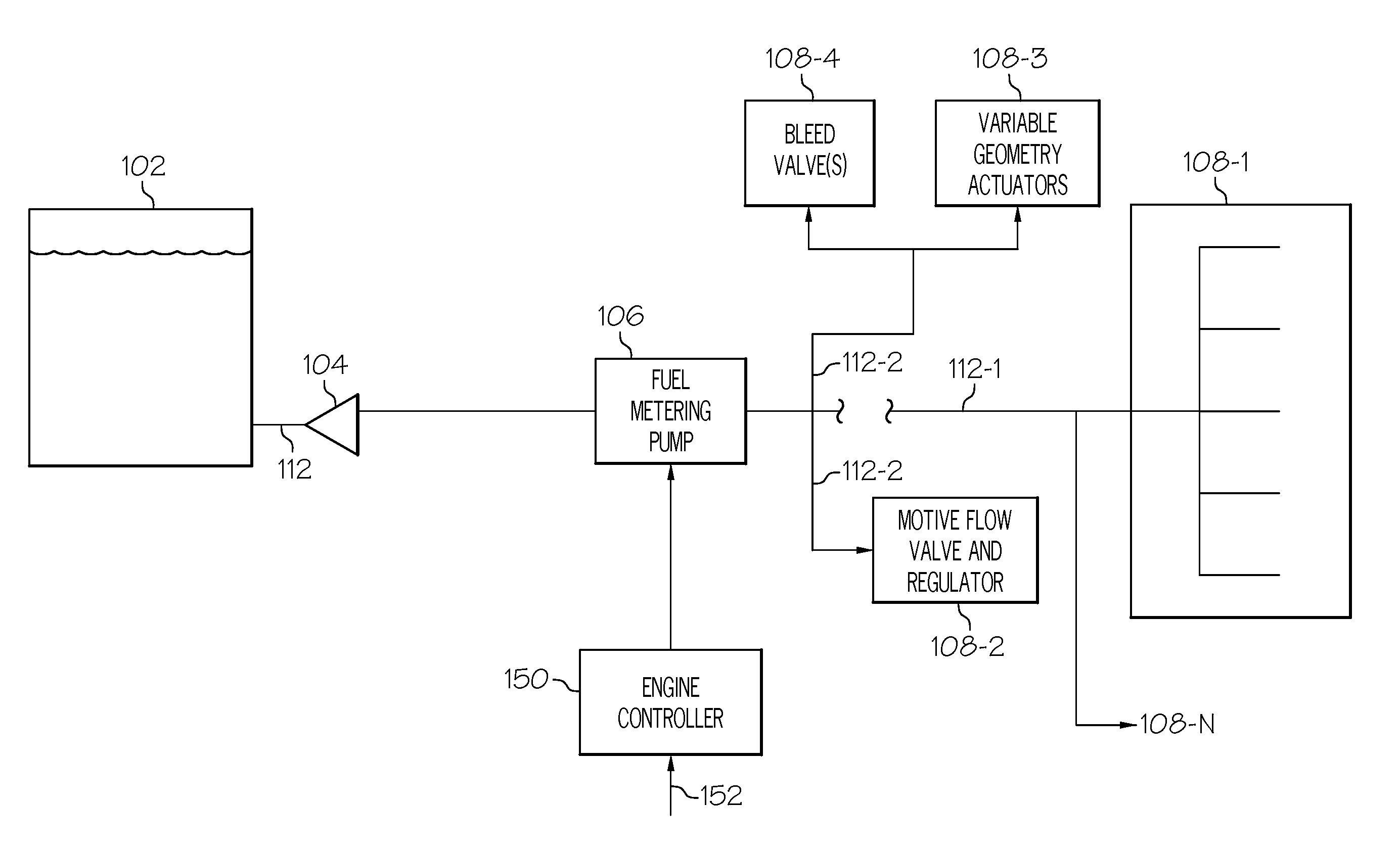

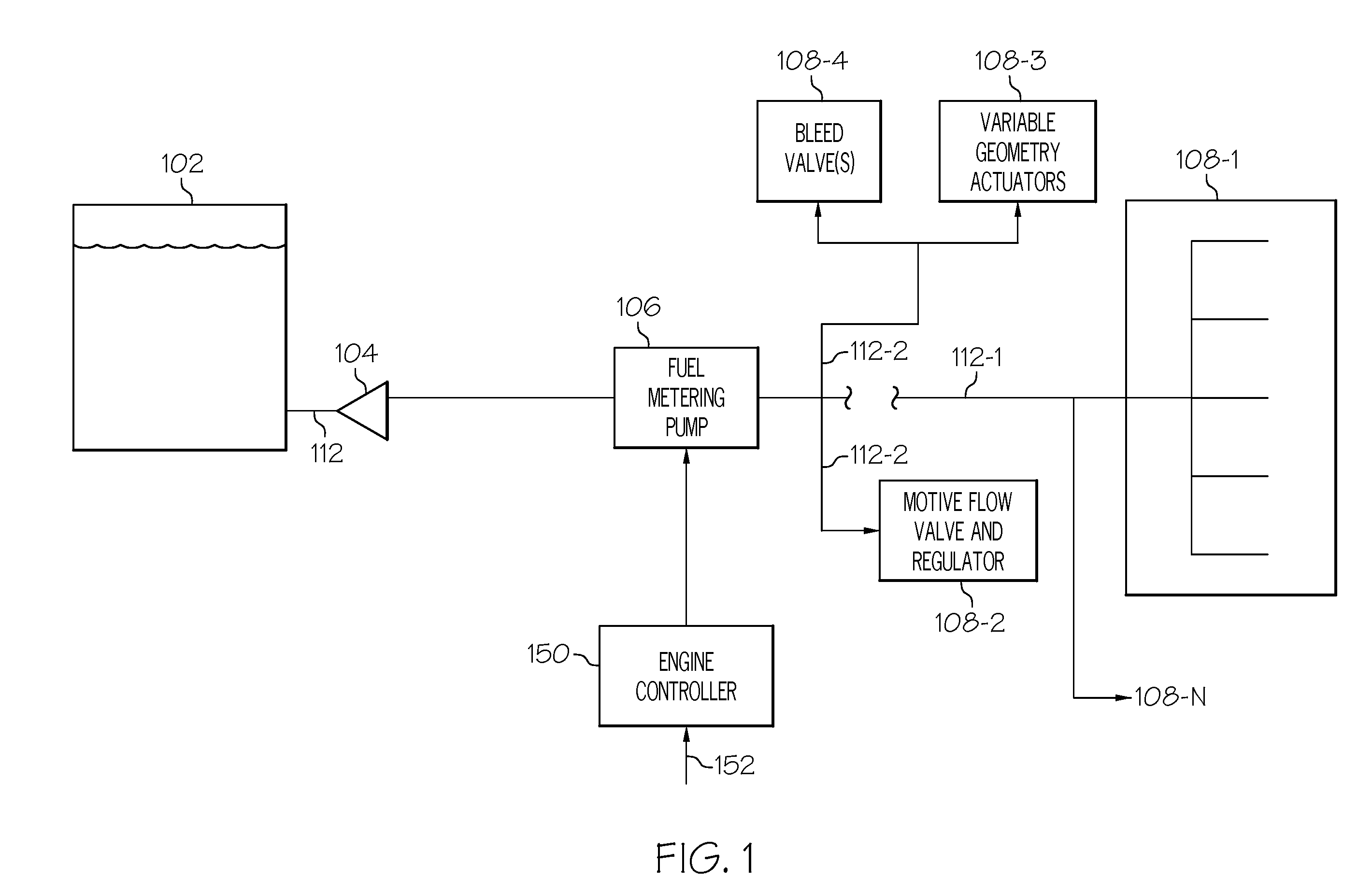

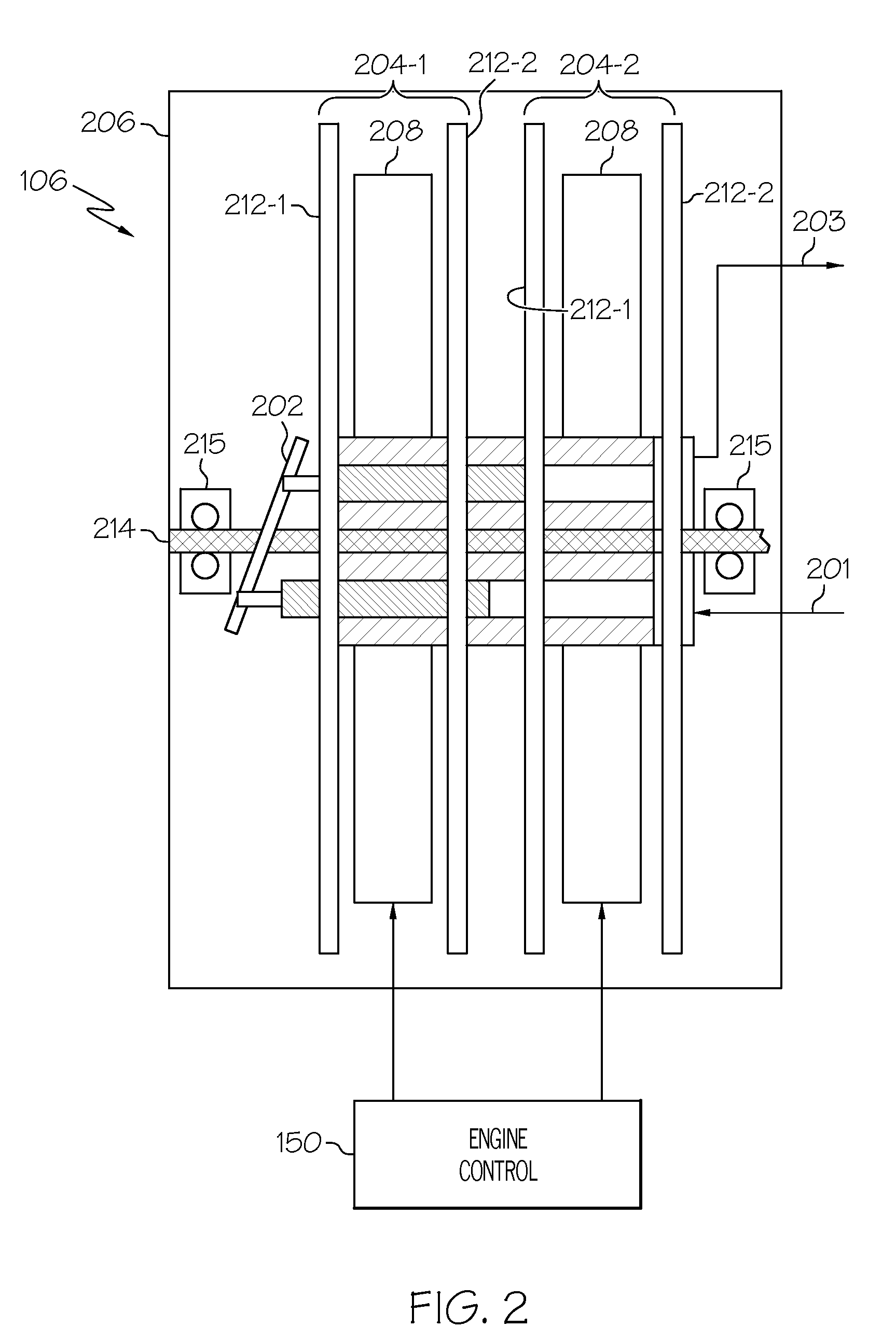

Direct metering fuel system with an integral redundant motor pump

ActiveUS20090071442A1Liquid fuel feeder/distributionPositive displacement pump componentsControl theoryTurbine

A direct metering fuel supply system includes a plurality of axial gap motors, a fixed displacement, variable speed positive displacement piston pump, and a gas turbine engine control. Each axial gap motor is configured to be selectively energized and is operable, upon being energized, to supply a drive torque at a drive speed. The fixed displacement, variable speed positive displacement piston pump is coupled to each of the axial gap motors to receive the drive torque selectively supplied therefrom and is operable, upon receipt of the drive torque, to supply fuel at a flow rate dependent on the drive speed. The gas turbine engine control is adapted to receive fuel flow commands and is operable, in response to the fuel flow commands, to energize one of the plurality of axial gap motors.

Owner:HONEYWELL INT INC

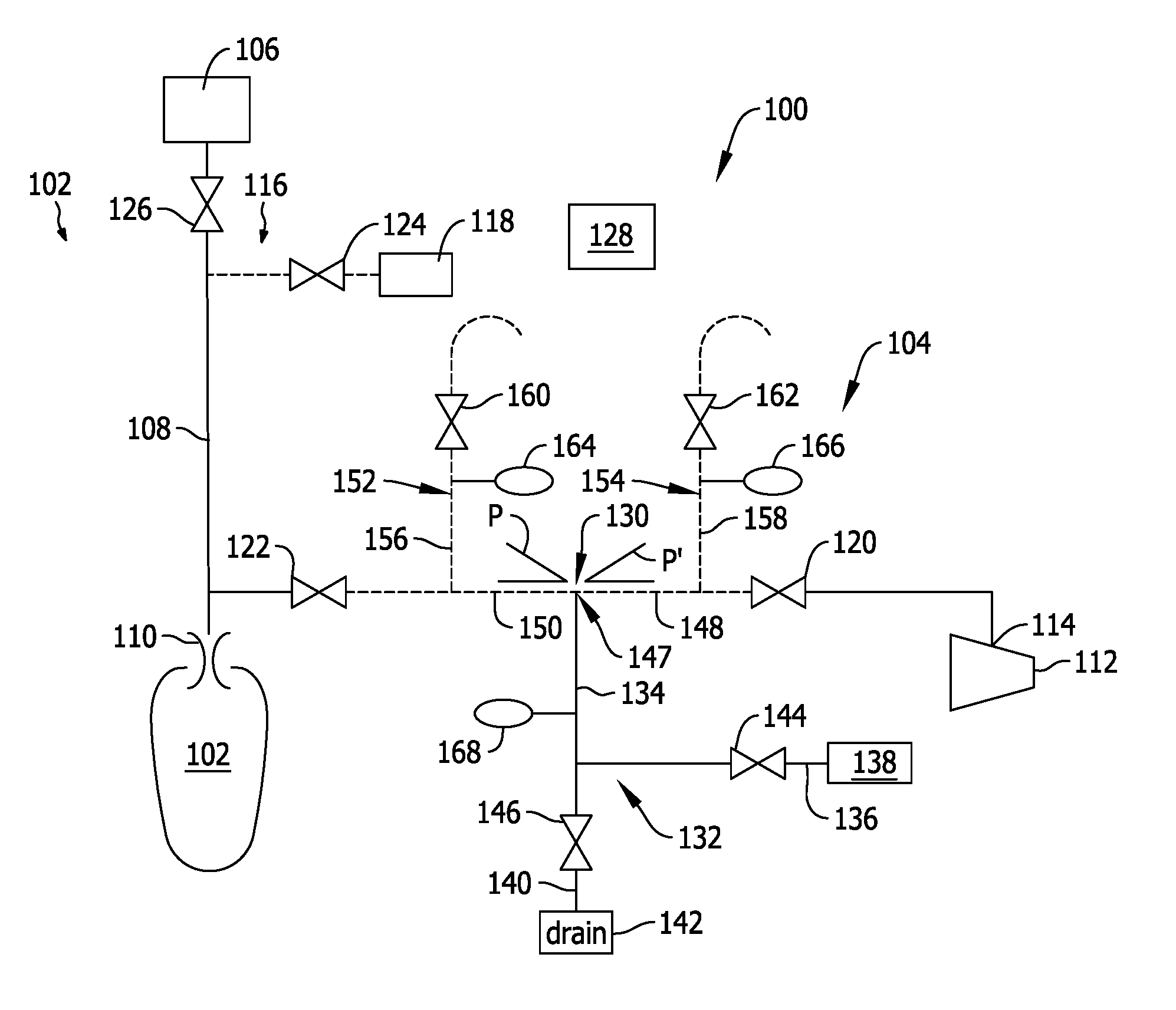

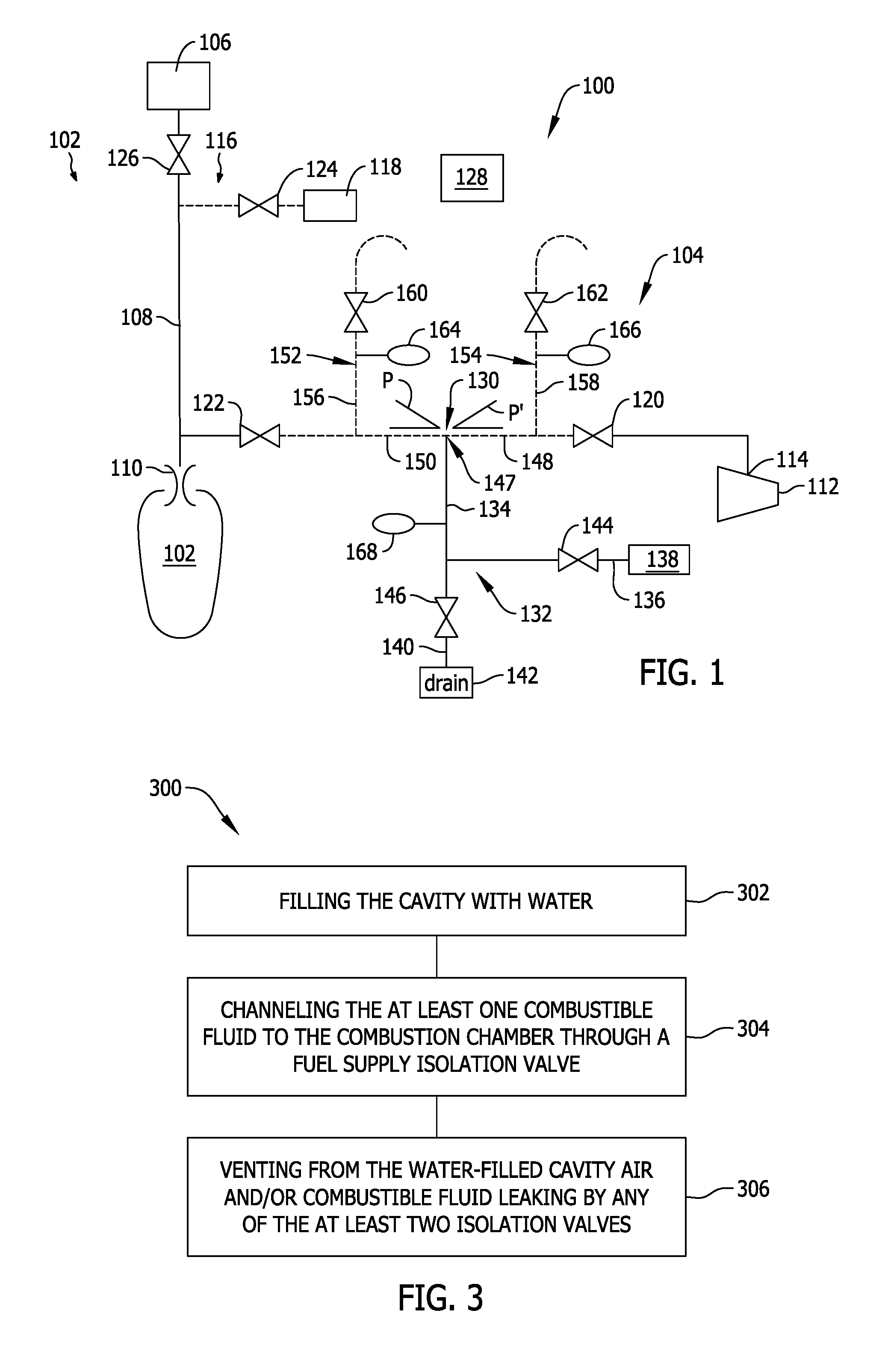

Method and system for a gas turbine engine purge circuit water injection

InactiveUS20160177879A1Liquid fuel feeder/distributionNon-fuel substance addition to fuelCombustion chamberIsolation valve

A method and fuel supply system for supply of a combustion chamber with at least one combustible fluid are provided. The fuel supply system includes a combustion chamber including a fuel injector, at least one supply circuit configured to supply the combustion chamber with a combustible fluid, and at least one purge circuit configured to purge the supply circuit, the purge circuit connected to a purge air source and the at least one supply circuit, the purge circuit including at least two isolation valves defining a cavity between the at least two isolation valves, the purge circuit including a water injection circuit configured to inject water into the cavity, the purge circuit including a cavity draining circuit configured to drain the cavity.

Owner:GENERAL ELECTRIC CO

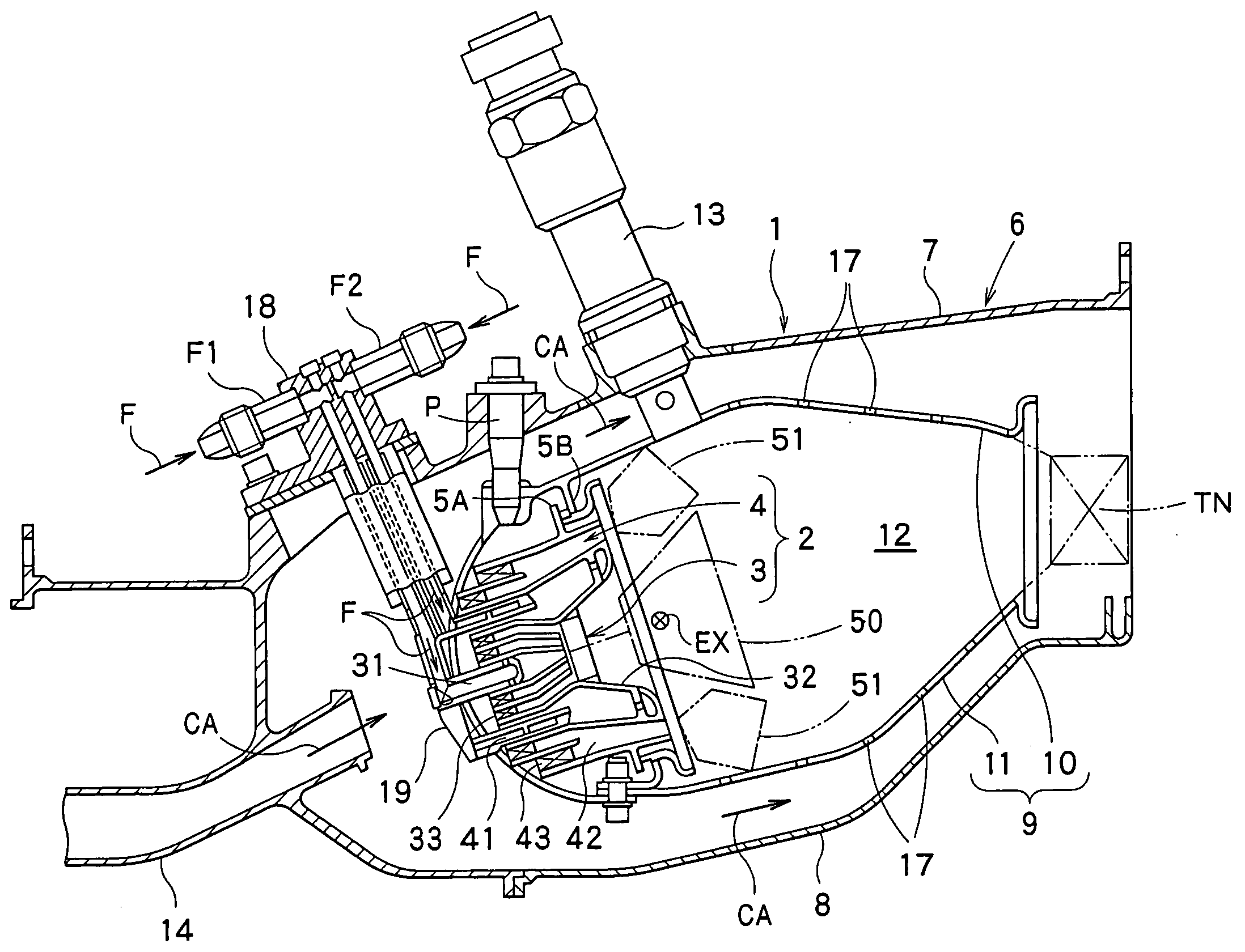

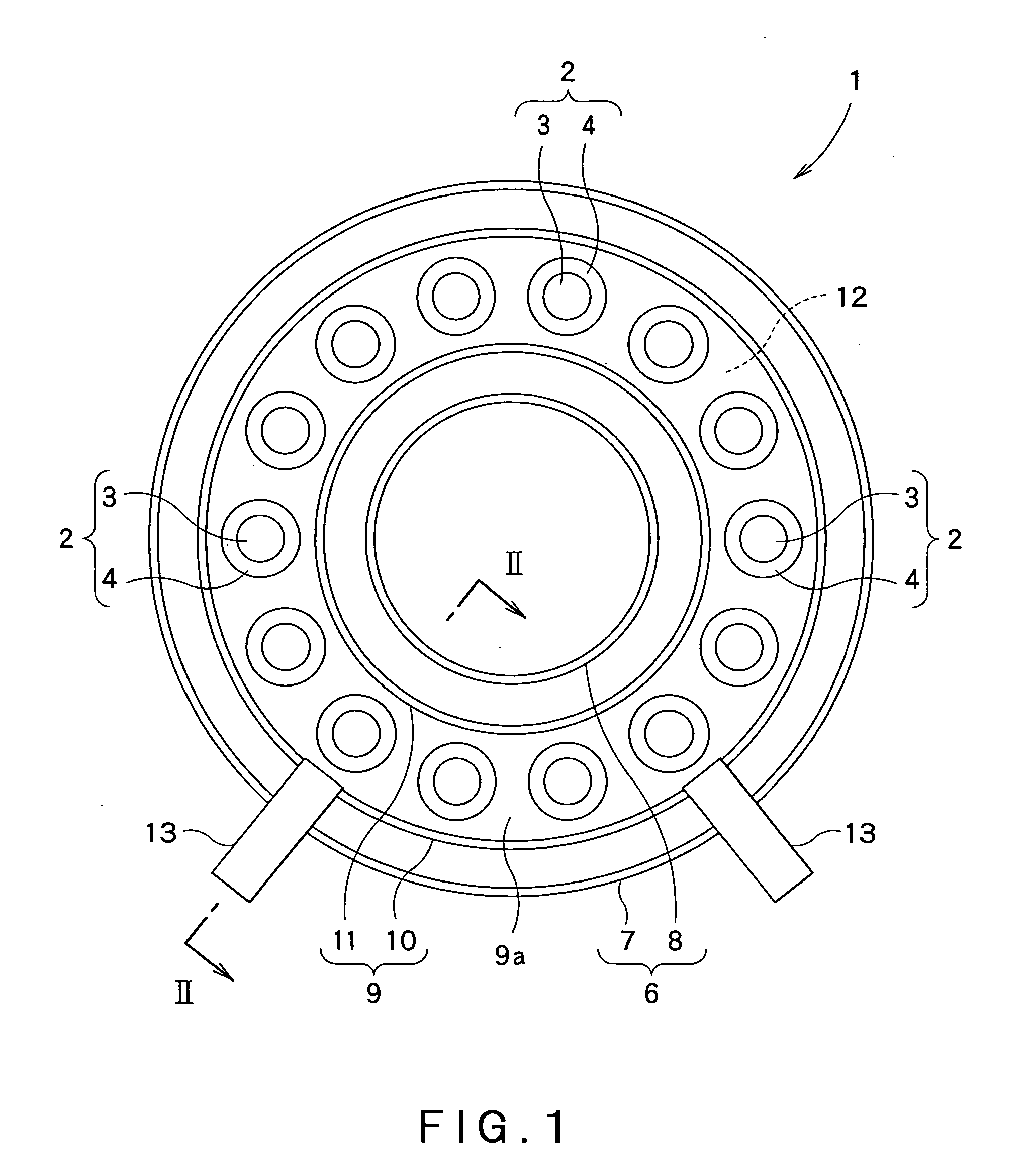

Gas turbine and gas-turbine plant having the same

ActiveUS20130091824A1Prevent burnoutPrevent self-ignition of the fuel remainingBurner safety arrangementsBurnersEngineeringFuel supply

The invention provides a gas-turbine fuel nozzle (1) that includes a plurality of fuel supply channels (3a) to which fuel is supplied, a plurality of fuel / scavenging-fluid supply channels (3b) to which fuel or a scavenging fluid for scavenging the fuel is supplied, and a plurality of injection holes (7a, 7b) that are provided at downstream ends of the fuel supply channels (3a) or the fuel / scavenging-fluid supply channels (3b) and that inject the fuel guided from the fuel supply channels (3a) or the fuel / scavenging-fluid supply channels (3b); a scavenging-fluid supply channel (21) that is connected to the fuel / scavenging-fluid supply channels (3b) to guide the scavenging fluid; and scavenging-fluid cooling means (23) for cooling the scavenging fluid to a temperature lower than a self-ignition temperature of the fuel.

Owner:MITSUBISHI POWER LTD

Method of forming a fuel feed passage in the feed arm of a fuel injector

A method is disclosed for forming a fuel feed passage in the feed arm of a fuel injector. The method includes the steps of providing a fuel feed passage in the feed arm of a fuel injector, whereby the fuel feed passage has an initial cross-sectional flow area that corresponds with an initial fuel flow velocity, an initial convection heat transfer coefficient and initial localized wetted wall temperatures for the fuel feed passage, for a given fuel flow rate and fuel temperature. The method further includes decreasing the initial cross-sectional flow area of the fuel feed passage so as to increase the fuel flow velocity and the convection heat transfer coefficient for the fuel feed passage, while lowering the localized wetted wall temperatures for the fuel feed passage, without varying the given fuel flow rate and fuel temperature.

Owner:DELAVAN

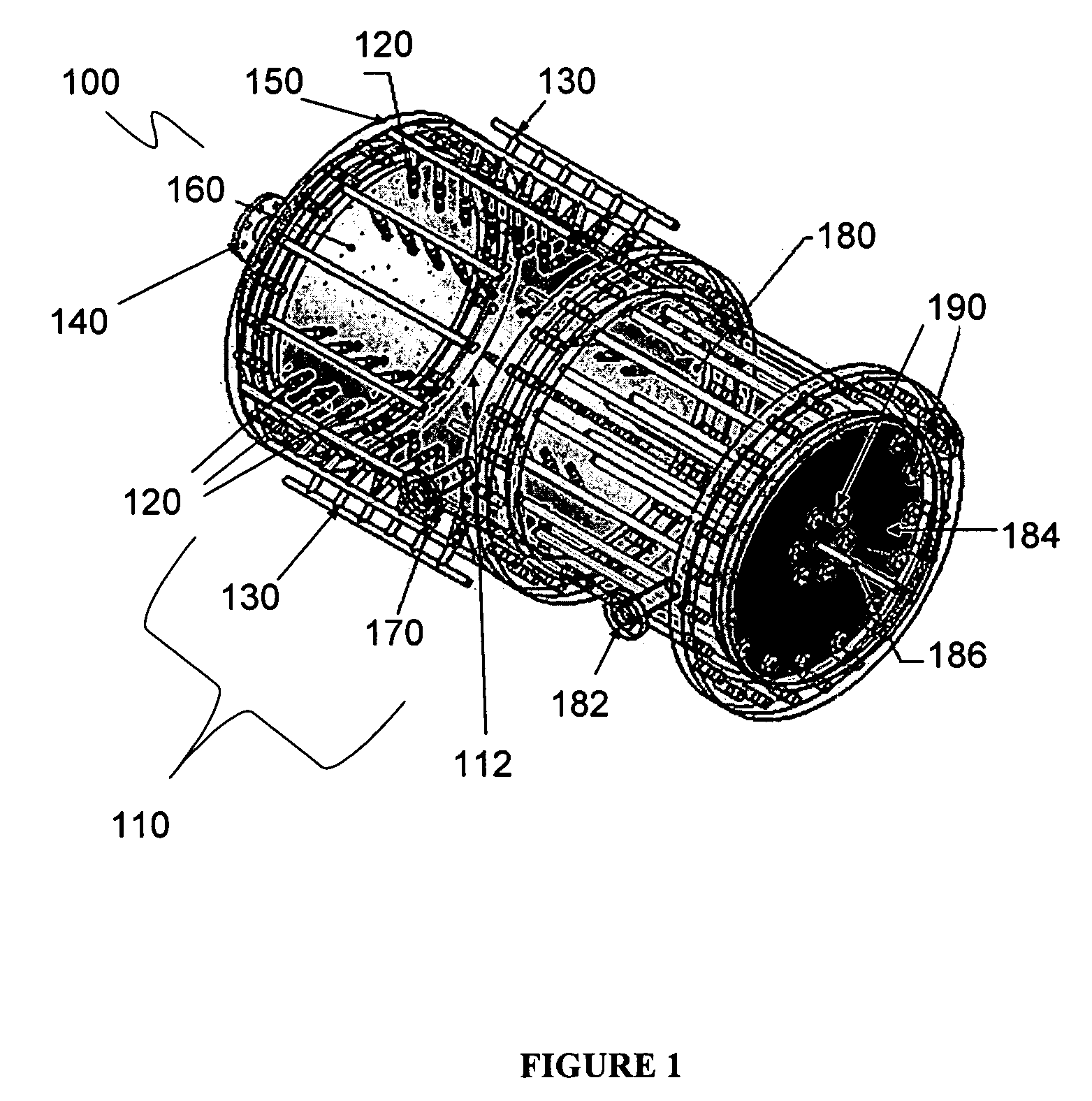

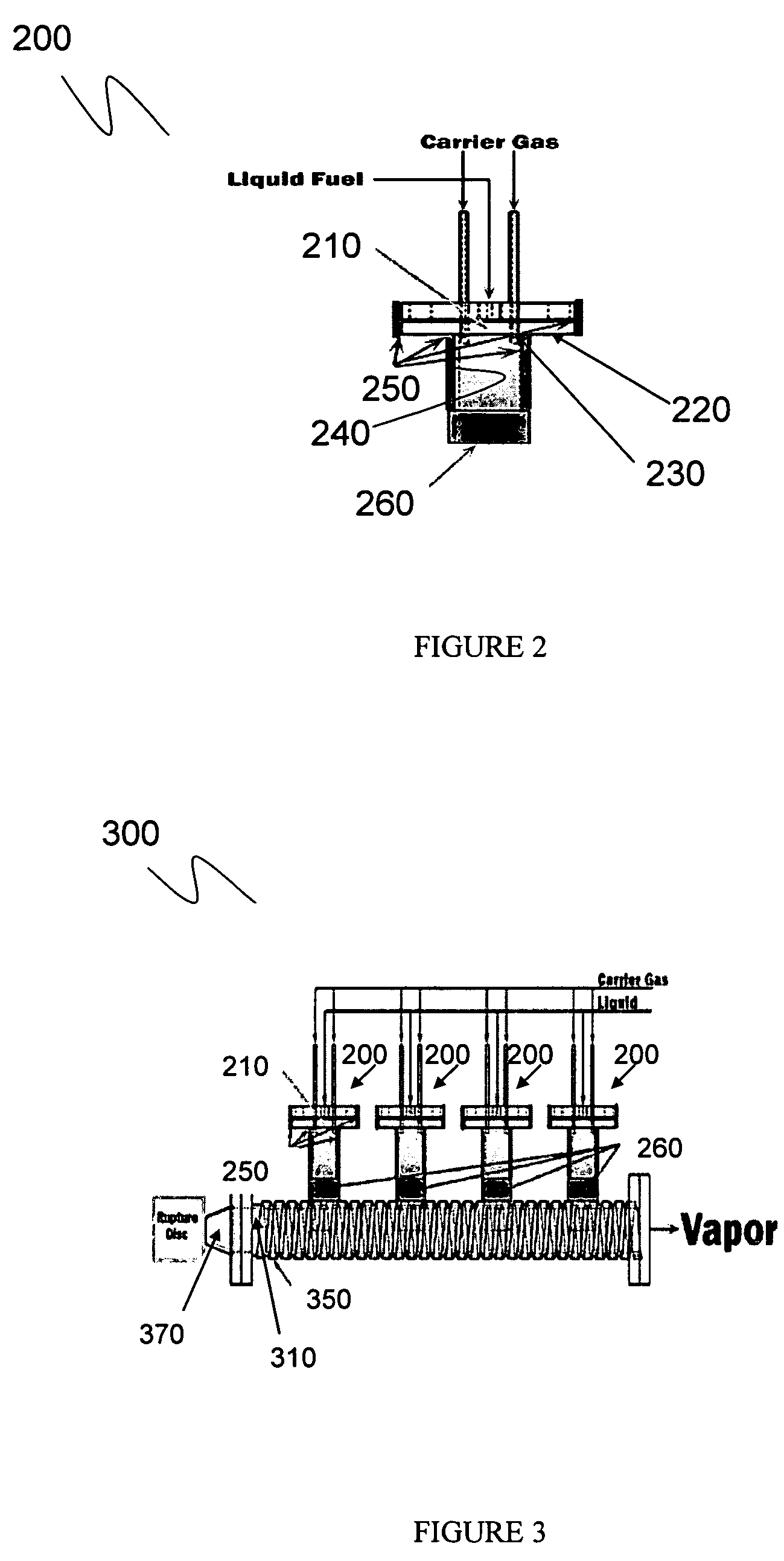

Method and apparatus for conditioning liquid hydrocarbon fuels

ActiveUS20060154189A1Emission reductionPrevent heat lossBurnersLiquid fuel feeder/distributionGas phaseEngineering

In one embodiment of a method for vaporizing liquids such as fuels, the liquid is sprayed into a chamber such that the spray does not impinge on any surface. The energy for vaporization is supplied through the injection of a hot diluent such as nitrogen or oxygen depleted air. Additional heat is added through the surface. In another embodiment, the liquid is sprayed onto a hot surface using a geometry such that the entire spray is intercepted by the surface. Heat is added through the surface to maintain an internal surface temperature above the boiling point of the least volatile component of the liquid. The liquid droplets impinging on the surface are thus flash vaporized. A carrier gas may also be flowed through the vaporizer to control the dew point of the resultant vapor phase mixture.

Owner:LPP COMBUSTION LLC

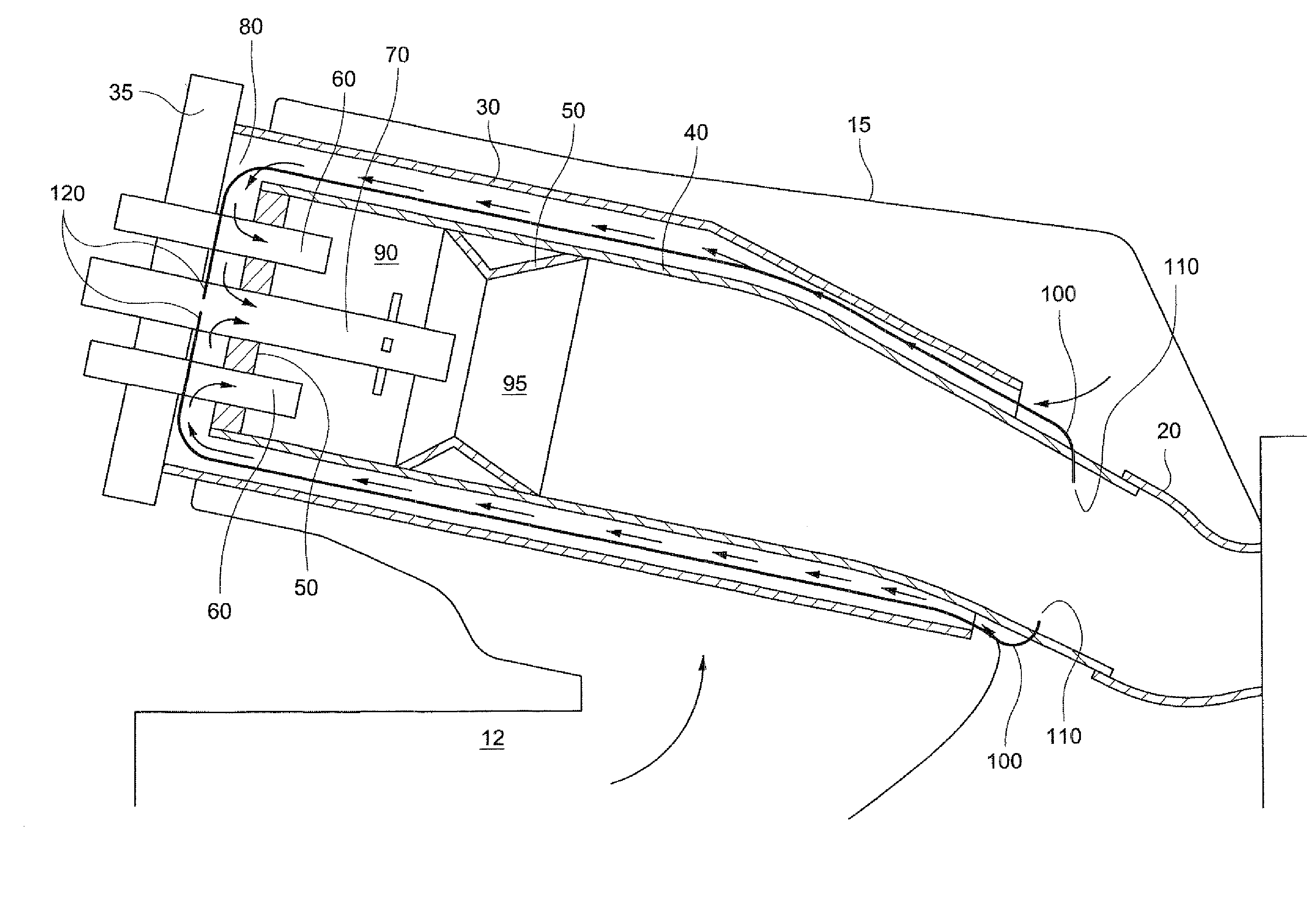

Combustor assembly for a turbine engine that mixes combustion products with purge air

InactiveUS20110167828A1Continuous combustion chamberTurbine/propulsion fuel supply systemsCombustorNitrogen oxides

A combustor assembly for a turbine engine includes a fuel nozzle located at an upstream end of the combustor assembly. The fuel nozzle includes both a fuel delivery passageway and a purge air passageway. The purge air passageway conveys a flow of purge air to cool the fuel nozzle. The combustor assembly also includes a combustion product return line that conveys a flow of combustion products from a position downstream of a combustion zone of the combustor back to the fuel nozzle. The combustion products are mixed with purge air, and the mixture is delivered into a combustion zone located just downstream of the fuel nozzle. The addition of the combustion products into the purge air reduces the amount of oxygen in mixed flow, which helps to reduce the generation of undesirable nitrogen oxide combustion byproducts. Also, the greater heat of the combustion products helps to increase the temperature of the mixture, which helps to maintain the stability of a pilot flame fed by the mixture.

Owner:GENERAL ELECTRIC CO

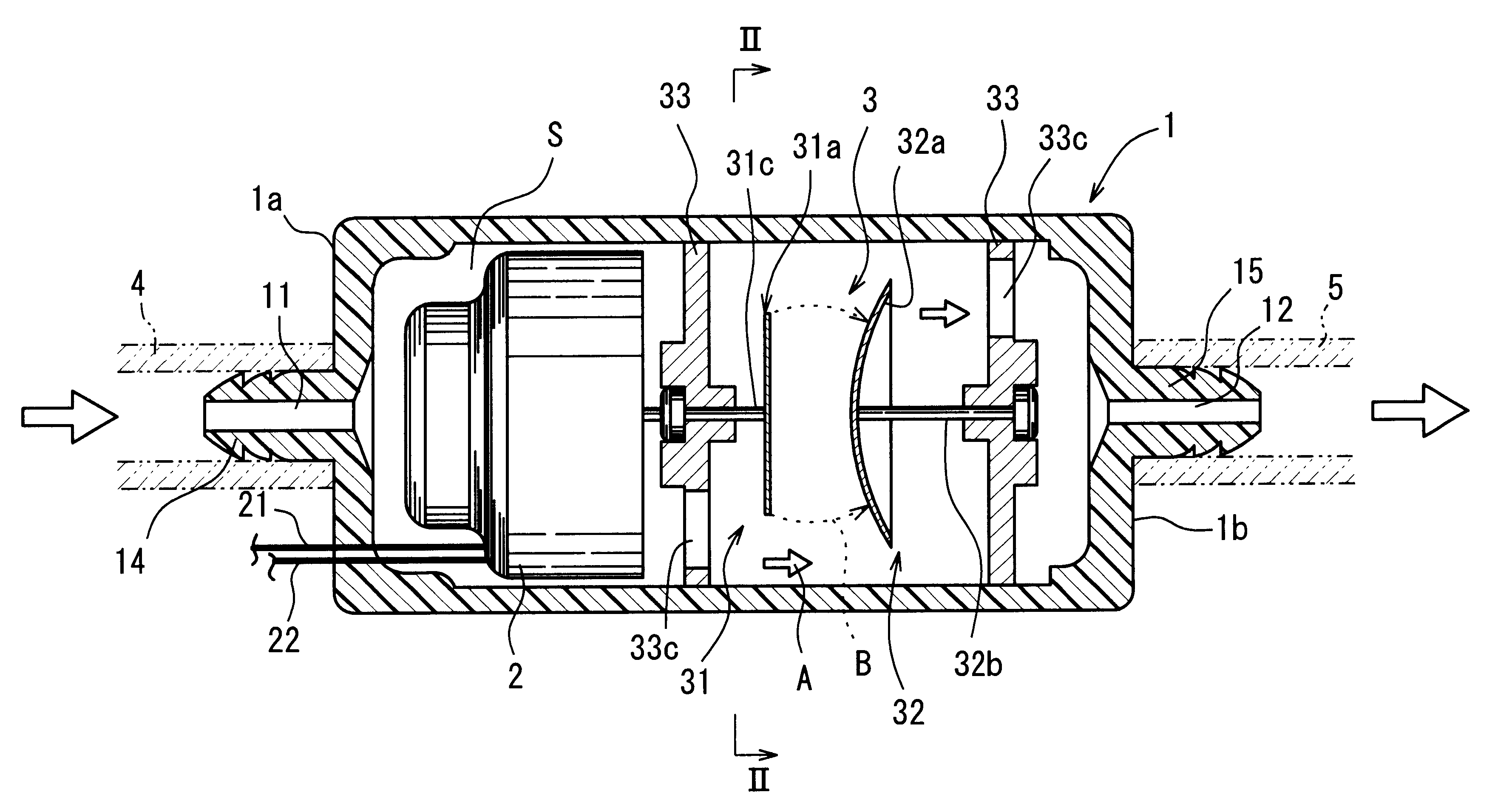

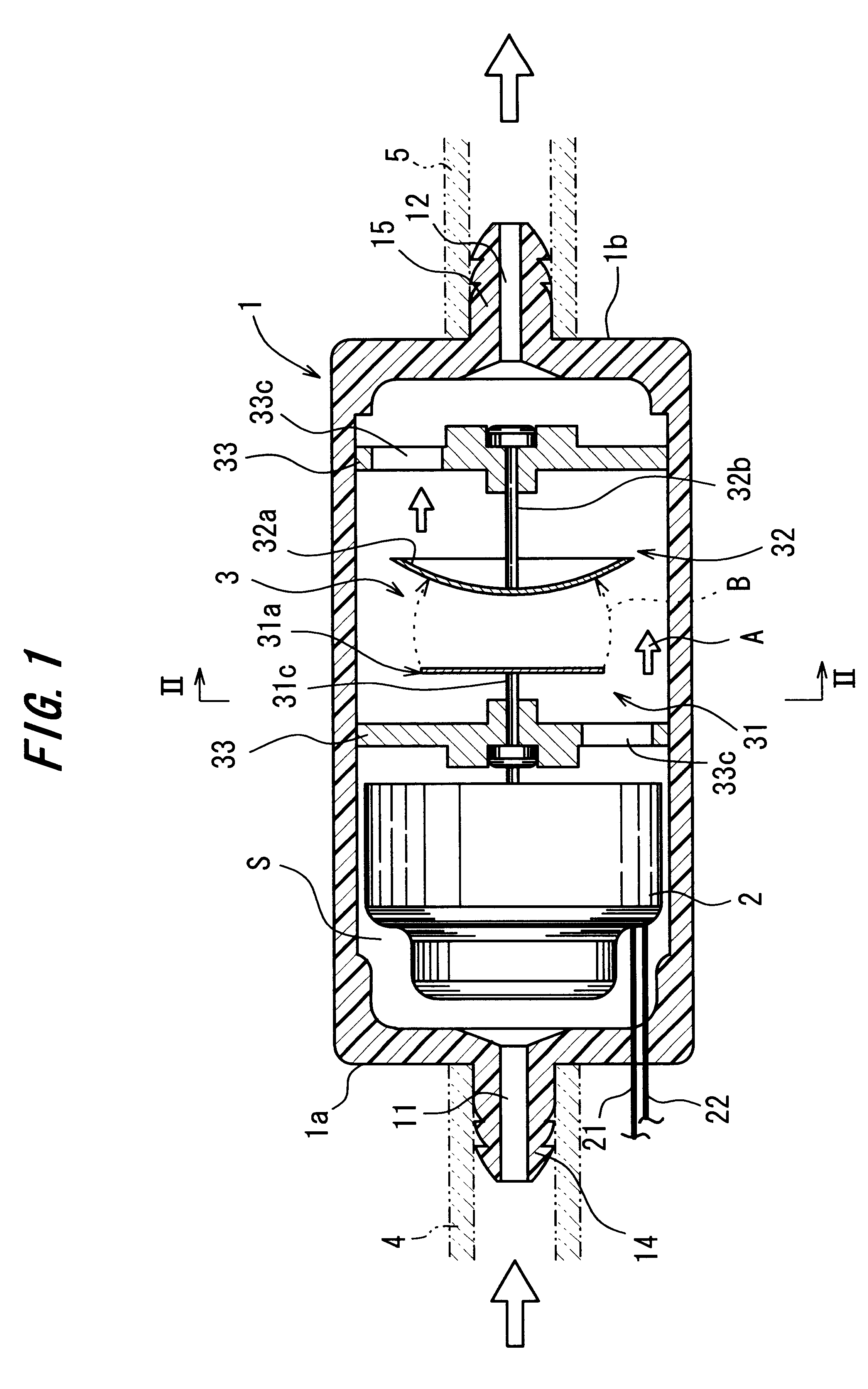

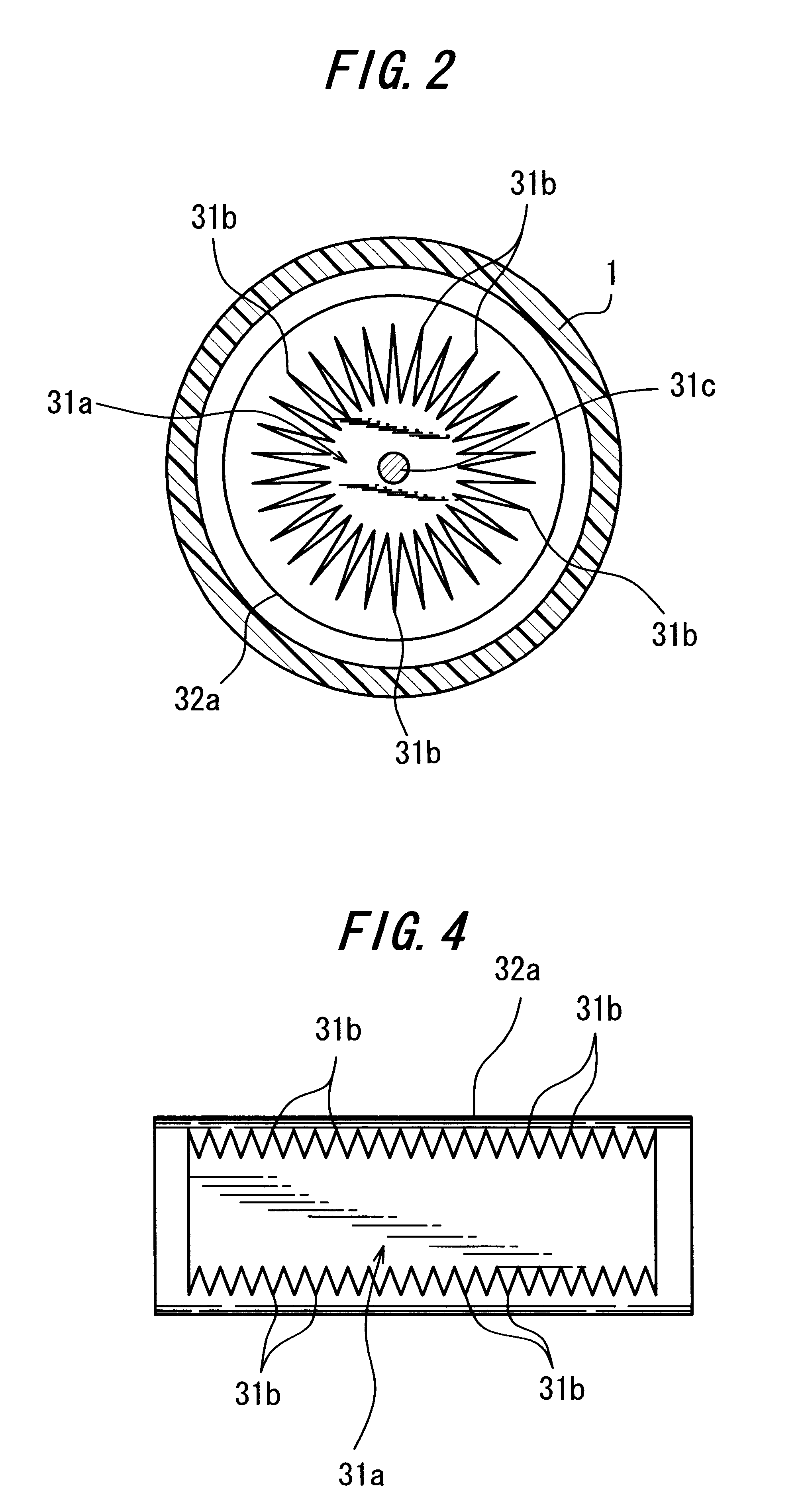

Ionizer

InactiveUS6769420B1Combustion-air/fuel-air treatmentLiquid fuel pretreatmentCorona dischargeIonization

An ionization electrode consists of a plate-like positive pole (31a) formed with plural pointed ends (31b) on its outer edge, and a spheric negative pole (32a) opposing a flat surface of the positive pole (31a). Since the pointed ends (31b) of the positive pole (31a) are not in direct face-to-face relation with the negative pole (32a), corona discharge is prevented from concentrating on some of the pointed ends (31b) that are closer to the negative pole (32b) than the rest due to the working errors or mounting errors of the poles. Therefore, the corona discharge occurs in a stable manner.

Owner:MOTOUCHI KAZUO +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com