Antirust paint used for electrical equipment

A technology for power equipment and anti-rust paint, applied in the field of anti-rust paint, can solve problems such as power equipment damage, danger, and influence on the operation of power equipment in the casing, and achieve the effect of enhancing rust resistance and oxygen resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

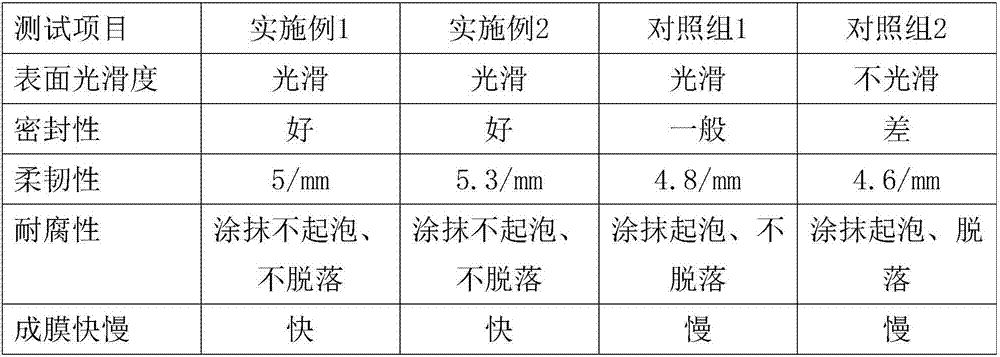

Examples

Embodiment 1

[0020] An antirust paint for electric equipment, made of the following components by weight: 20 parts of modified alkyd resin, 8 parts of polyurethane modified acrylic emulsion, 10 parts of polyether modified siloxane, petroleum sulfonate 5 parts, xylene 4 parts, oily wax 7 parts, polyphosphate 8 parts, chlorinated polyvinyl chloride 2 parts, C5 hydrogenated petroleum resin 5 parts, silicon dioxide 1 part, rust inhibitor 4 parts.

[0021] The antirust agent is made of the following components by weight: 5 parts of dicyclohexylamine, 3 parts of soda ash, 2 parts of ceramic micropowder, 1 part of nano-zinc oxide, 2 parts of nano-calcium carbonate, 3 parts of ascorbyl palmitate .

[0022] The preparation method of the above-mentioned antirust paint for electric equipment is as follows:

[0023] a. Mix the modified alkyd resin, polyether modified siloxane, and petroleum sulfonate, heat to a molten state, and carry out stirring reaction, and the stirring time is 20 minutes;

[00...

Embodiment 2

[0029] An antirust paint for electric equipment, made of the following components by weight: 30 parts of modified alkyd resin, 15 parts of polyurethane modified acrylic emulsion, 15 parts of polyether modified siloxane, petroleum sulfonate 10 parts, xylene 8 parts, oily wax 15 parts, polyphosphate 12 parts, chlorinated polyvinyl chloride 4 parts, C5 hydrogenated petroleum resin 10 parts, silicon dioxide 3 parts, rust inhibitor 6 parts.

[0030] The antirust agent is made of the following components by weight: 10 parts of dicyclohexylamine, 6 parts of soda ash, 4 parts of ceramic micropowder, 2 parts of nano-zinc oxide, 3 parts of nano-calcium carbonate, 5 parts of ascorbyl palmitate .

[0031] The preparation method of the above-mentioned antirust paint for electric equipment is as follows:

[0032] a. Mix the modified alkyd resin, polyether modified siloxane, and petroleum sulfonate, heat to a molten state, and carry out stirring reaction, and the stirring time is 30 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com