Acid residue treatment method and binary oil displacement surfactant

A technology of surfactants and treatment methods, applied in chemical instruments and methods, sulfonic acid preparation, drilling compositions, etc., can solve problems such as the inability to effectively utilize acid slag, and achieve harmless reuse of waste, interface Better tension performance and higher oil displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

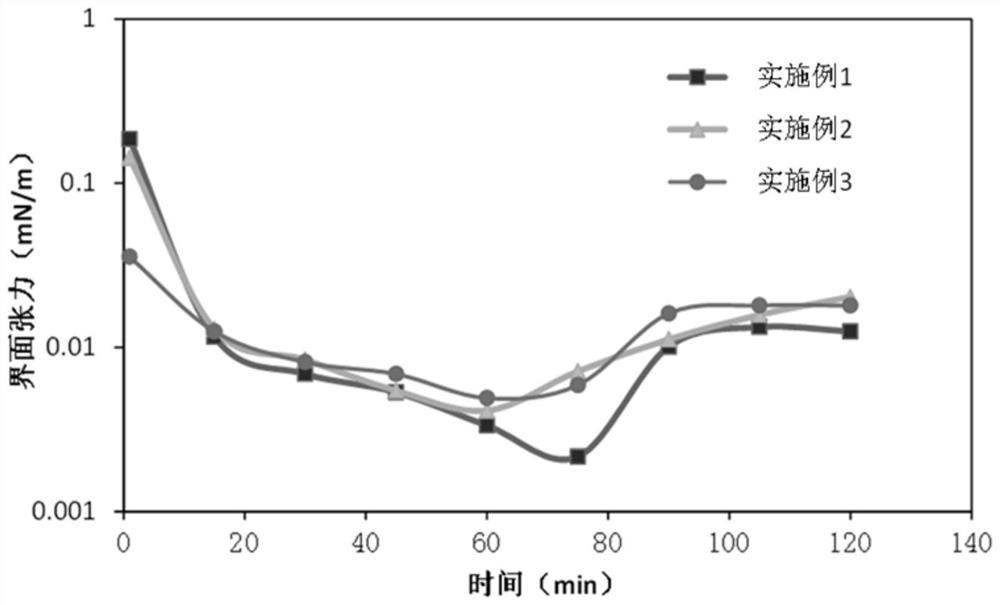

Embodiment 1

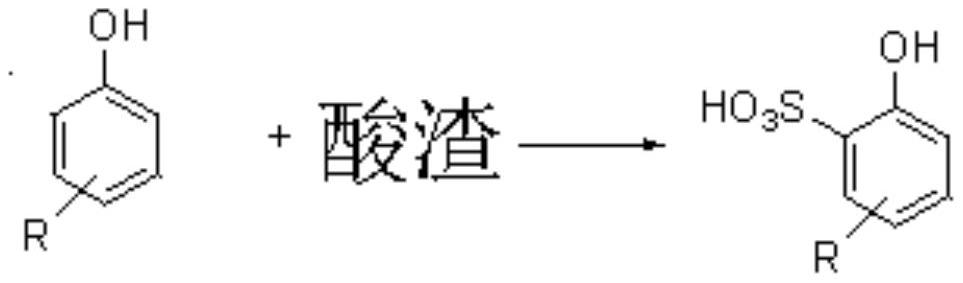

[0049] The acid residue in Xinjiang Oilfield mainly contains unsulfonated oil (30wt%), sulfonic acid (30wt%) and sulfuric acid (40wt%). The aromatic hydrocarbons in the raw oil used in the production of naphthenic petroleum sulfonic acid are highly active and prone to polysulfonate According to the principle of "like dissolves like", a large amount of polysulfonic acid is extracted by sulfuric acid to form a viscous acid slag with a relatively high density similar to solid.

[0050] (1) Weigh 500g of Xinjiang oilfield acid residue, put it in a beaker, heat it, and monitor the temperature of the acid residue in the beaker at all times.

[0051] (2) When the temperature of the acid slag in the step (1) rises to 50° C., start stirring at a stirring speed of 150 r / min, while continuing to heat up to 80° C., then keep stirring.

[0052] (3) Slowly add lauryl phenol (structure is C) in above-mentioned beaker 12 h 25 C 6 h 4 OH, Cas number is 210555-94-5) 300g, the dropping speed...

Embodiment 2

[0058] The difference with embodiment 1 only lies in main component and content difference. The acid residue mainly contains unsulfonated oil (28wt%), sulfonic acid (31wt%) and sulfuric acid (41wt%).

Embodiment 3

[0060] The difference with embodiment 1 only lies in main component and content difference. The acid residue mainly contains unsulfonated oil (32wt%), sulfonic acid (33wt%) and sulfuric acid (35wt%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com