Method for quantitatively detecting naphthenic sulfonate components and residual oil sulfonate components in petroleum production liquid

A technology of naphthenic sulfonate and alkylsulfonate is applied in the field of quantitative detection of naphthenic sulfonate components and residual oil sulfonate components in petroleum production fluid, and can solve the problem that the sulfonic acid cannot be accurately detected. acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] (1) Preparation of naphthene sulfonate standard mixture

[0095] ①Weigh 50g of naphthenic sulfonate (the product obtained by sulfonation of naphthenic crude oil) and fully dissolve it in 600ml of hot absolute ethanol (60°C) on a water bath, wash with 80ml of hot absolute ethanol, collect and wash Clear liquid, remove absolute ethanol at 110°C to obtain a sulfonate system without asphaltenes and inorganic salts (ie, the first naphthenic sulfonate);

[0096] ②Add 30g of the above sulfonate system to 400ml of isopropanol / water (1:1 volume ratio) to fully dissolve in a water bath at 60°C. When the temperature of the solution drops to 30°C, transfer the solution to a 1000ml separating funnel In, extract repeatedly (4 times) with 400ml n-hexane, until the upper phase is slightly yellow;

[0097] ③ Collect the aqueous phase of isopropanol and dry it in an oven at 110°C to constant weight to obtain the standard mixture of naphthene sulfonates.

[0098] (2) Preparation of resi...

Embodiment 2

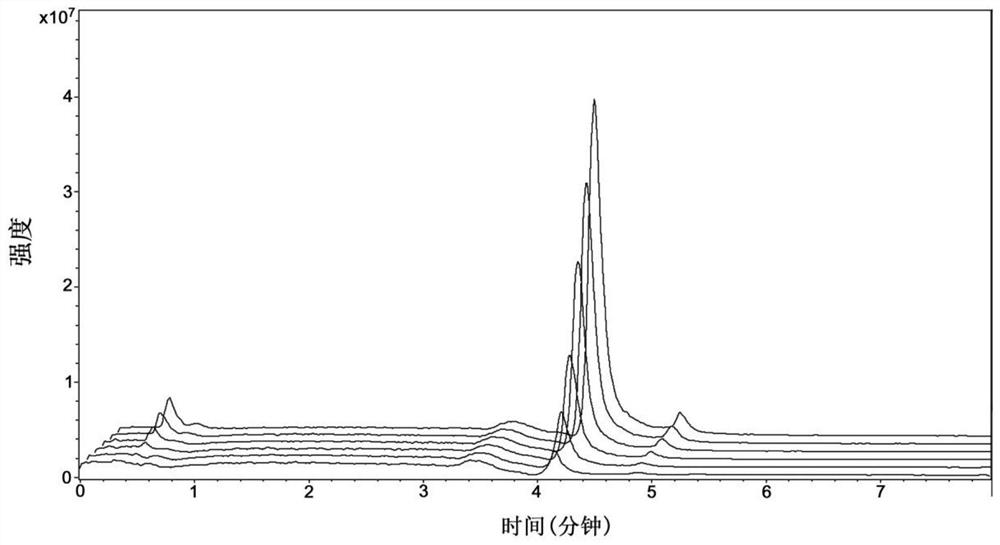

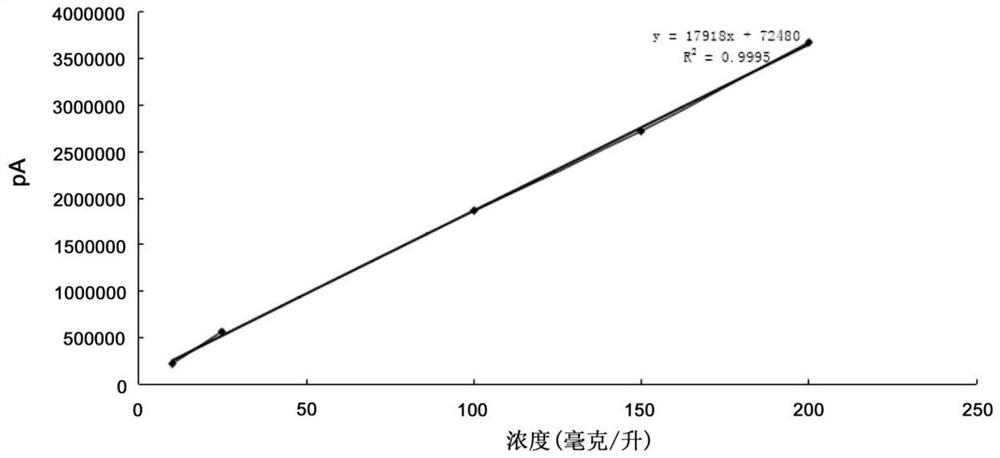

[0124] (1) according to the method described in embodiment 1, preparation concentration is the naphthene sulfonate test sample of 100mg / L, under the liquid chromatography-mass spectrometry analysis condition in above-mentioned embodiment 1, this sample Injection analysis, get spectrum. The naphthene sulfonate sample spectrogram that obtains, according to the naphthene sulfonate standard curve that embodiment 1 establishes, obtains its concentration detection result.

[0125] The above samples were repeated 6 times under the same conditions, and the results are shown in Table 1.

[0126] Table 1: Repeatability test results of 100mg / L naphthene sulfonate samples

[0127]

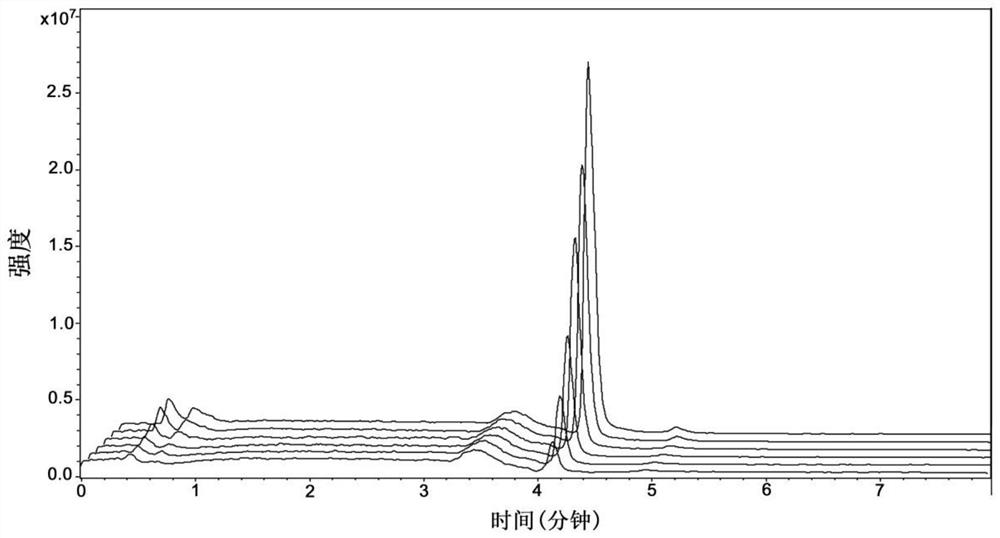

[0128](2) according to the method described in embodiment 1, preparation concentration is the residual oil sulfonate test sample of 250mg / L, under the liquid chromatography-mass spectrometry analysis condition in above-mentioned embodiment 1, this sample is carried out Analyze the sample and get the spect...

Embodiment 3

[0134] In this embodiment, the measurement parameter of sample addition recovery rate is used to determine and evaluate the accuracy of the analytical method and measurement system of the present invention.

[0135] The same sample (this sample has contained naphthene sulfonate and residual oil sulfonate) is taken in two parts: one of them is added with quantitative standard substance (i.e. two kinds of sulfonates) to obtain the spiked sample; No standard substance was added to the sample, which was an unspiked sample.

[0136] A total of 5 groups of samples were configured, which involved different concentration combinations. The “actual spiked concentration” of the spiked samples in each group is shown in Table 3. Specifically, in sample group 1, 55 mg / L naphthene sulfonate and 50 mg / L residue sulfonate were added to the spiked sample; Alkane sulfonate and 12.5 mg / L residual oil sulfonate; in sample group 3, 25 mg / L naphthene sulfonate and 50 mg / L residual oil sulfonate we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com