Method for displaying M/A island structures inside pipeline steel

A display method and technology for pipeline steel, which are applied in measuring devices, instruments, and optical devices, etc., can solve the problems of complicated operation and expensive microscope, and achieve the effect of simple operation and shortened corrosion time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Step 1, pipeline steel sample preparation

[0054] Use 120#, 360#, 600#, 800#, 1000# metallographic water sandpaper for rough grinding and fine grinding for X70 samples respectively. After replacing the fine sandpaper, the grinding direction should be 90° to the previous direction until the previous grinding marks are worn off. Afterwards, the samples were polished with 2.5 μm and 1.5 μm diamond spray polishing agents for 3 minutes respectively. At this time, the test surface of the sample becomes a mirror surface without scratches.

[0055] Step 2, preparation of coloring reagent

[0056]在烧杯中将100ml蒸馏水中加入0.95g偏重亚硫酸钠;100ml无水乙醇中加入3.6g苦味酸和0.6g氢氧化钠。将两种溶液3:2混合并加热至50℃,保温2min。在加热过程中用玻璃棒进行搅拌使其完全溶解且充分反应,所得溶液即为着色试剂。

[0057] 步骤三,M / A岛的腐蚀显示

[0058] 将试样采用2%的硝酸酒精溶液腐蚀5s左右后用酒精洗净吹干。此时金相观察应为轻度腐蚀。将步骤二中所制备的着色试剂加热至50℃,将试样放入其中浸泡200s后用酒精洗净吹干。

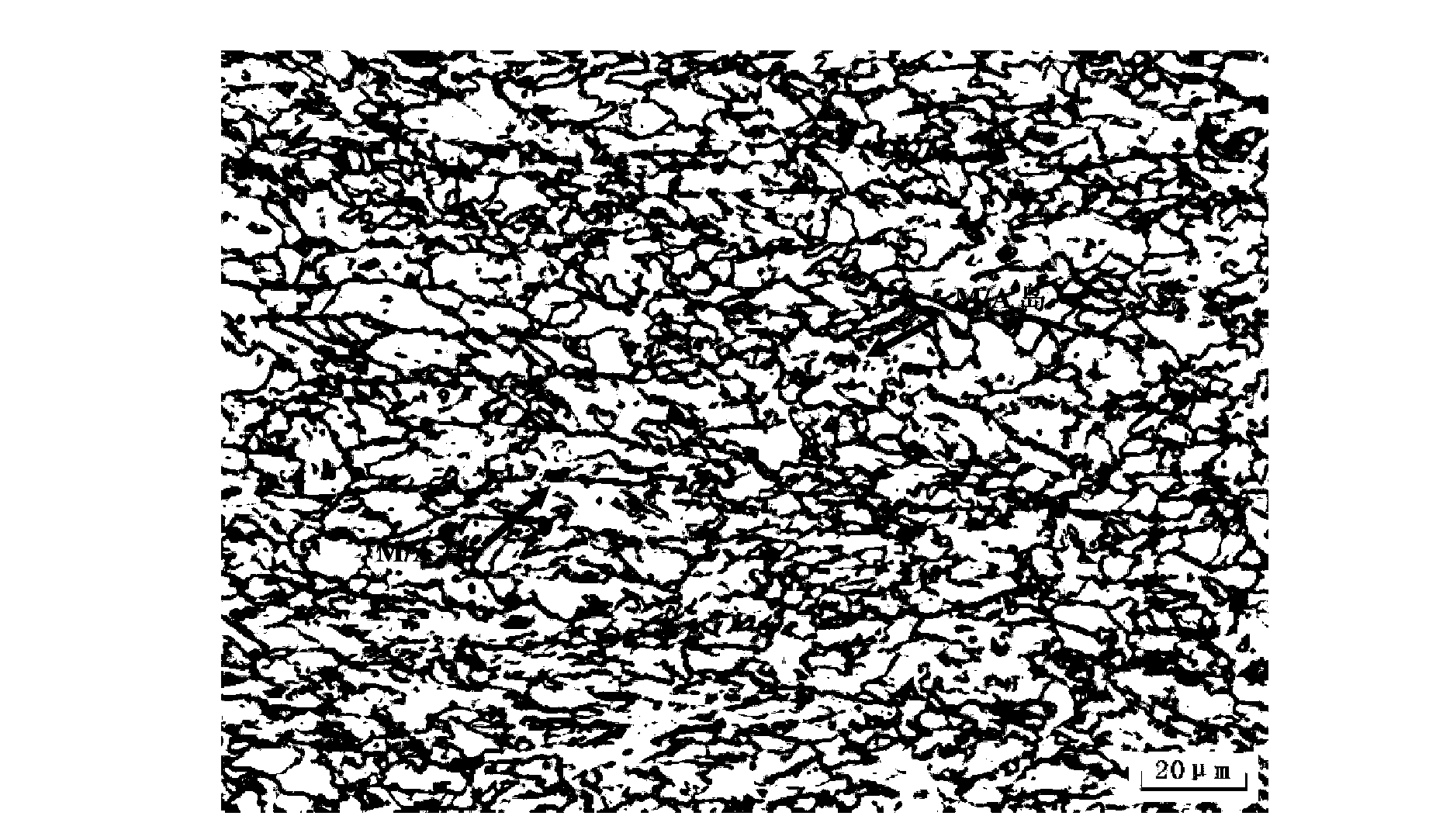

[0059] 经上述对管线钢试样进行处理后,将其放置金相显微镜下进行观察,如 figure 2 所示,M / A岛呈现出亮白色M / A岛,与周围组织灰度差明显。

Embodiment 2

[0061] 步骤一,管线钢试样制备

[0062] 对X80试样分别使用120#、360#、600#、800#、1000#金相水砂纸进行粗磨、细磨。更换细砂纸后的打磨方向要与上道方向成90°,直到上道磨痕磨掉为止。之后对试样分别使用2.5μm、1.5μm的金刚石喷雾抛光剂各抛光5min。此时试样的检验面成镜面且无划痕。

[0063] 步骤二,着色试剂的制备

[0064] 在烧杯中将100ml蒸馏水中加入1g偏重亚硫酸钠;100ml无水乙醇中加入3.65g苦味酸和0.65g氢氧化钠。将两种溶液3:2混合并加热至50℃,保温3min。在加热过程中用玻璃棒进行搅拌使其完全溶解且充分反应,所得溶液即为着色试剂。

[0065] 步骤三,M / A岛的腐蚀显示

[0066] 将试样采用2%的硝酸酒精溶液腐蚀5s左右后用酒精洗净吹干。此时金相观察应为轻度浸蚀。将步骤二中所制备的着色试剂加热至50℃,将试样放入其中浸泡180s后用酒精洗净吹干。

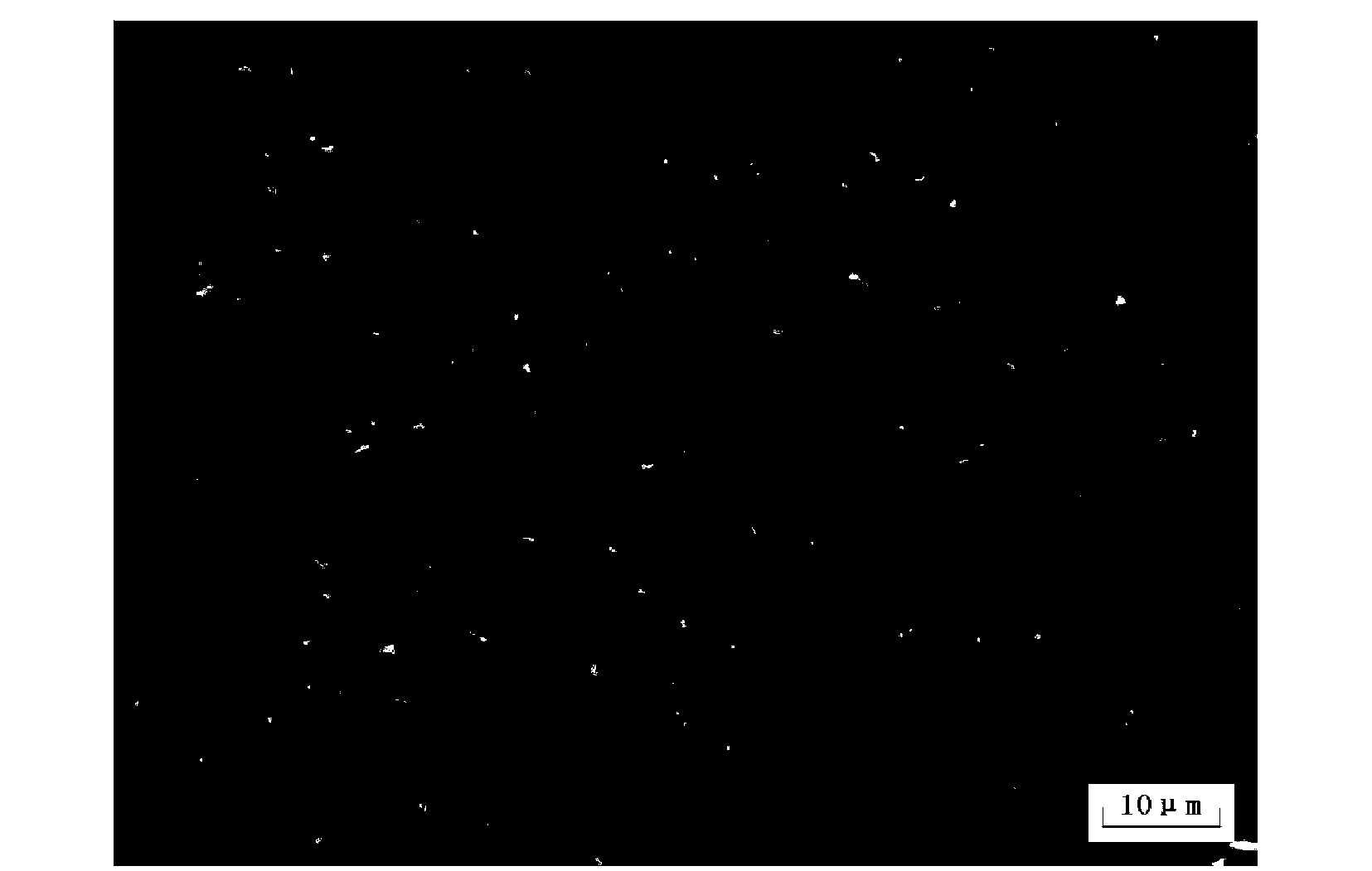

[0067] 经上述对管线钢试样进行处理后,将其放置金相显微镜下进行观察,如 image 3 所示,M / A岛呈现出亮白色M / A岛,与周围组织灰度差明显。

Embodiment 3

[0069] 步骤一,管线钢试样制备

[0070] 对X80试样分别使用120#、360#、600#、800#、1000#金相水砂纸进行粗磨、细磨。更换细砂纸后的打磨方向要与上道方向成90°,直到上道磨痕磨掉为止。之后对试样分别使用2.5μm、1.5μm的金刚石喷雾抛光剂各抛光5min。此时试样的检验面成镜面且无划痕。

[0071] 步骤二,着色试剂的制备

[0072] 在烧杯中将100ml蒸馏水中加入1.05g偏重亚硫酸钠;100ml无水乙醇中加入3.7g苦味酸和0.7g氢氧化钠。将两种溶液3:2混合并加热至50℃,保温3min。在加热过程中用玻璃棒进行搅拌使其完全溶解且充分反应,所得溶液即为着色试剂。

[0073] 步骤三,M / A岛的腐蚀显示

[0074] 将试样采用4%的硝酸酒精溶液腐蚀5s左右后用酒精洗净吹干。此时金相观察应为轻度浸蚀。将步骤二中所制备的着色试剂加热至55℃,将试样放入其中浸泡240s后用酒精洗净吹干。

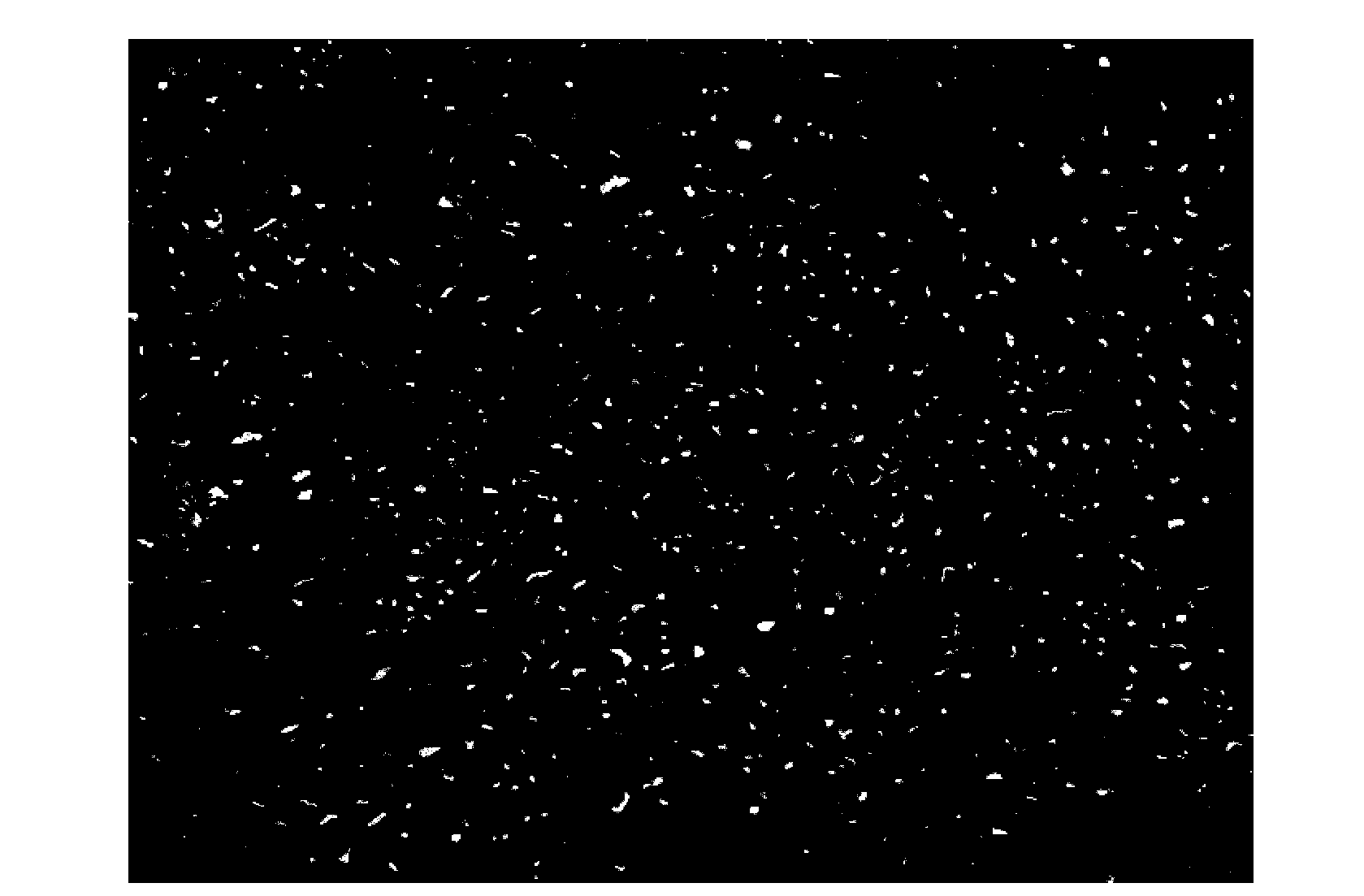

[0075] 经上述对管线钢试样进行处理后,将其放置金相显微镜下进行观察,如 Figure 4 所示,M / A岛呈现出亮白色M / A岛,与周围组织灰度差明显。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com