Mahogany petroleum sulfonate preparation method for oil exploitation

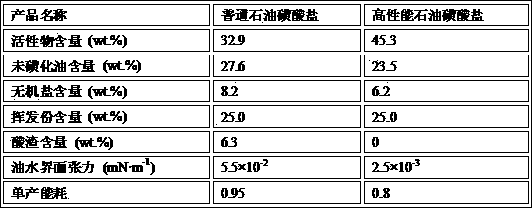

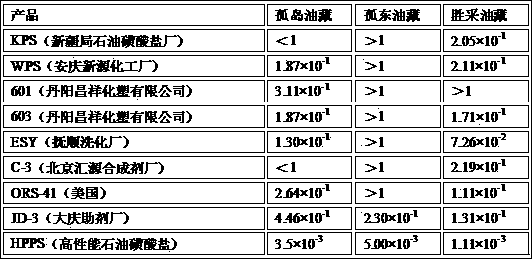

A technology of petroleum sulfonate and petroleum, which is applied in the directions of sulfonate preparation, chemical instrument and method, drilling composition, etc., to achieve the effects of high oil washing efficiency, high active substance content, and enhanced oil recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

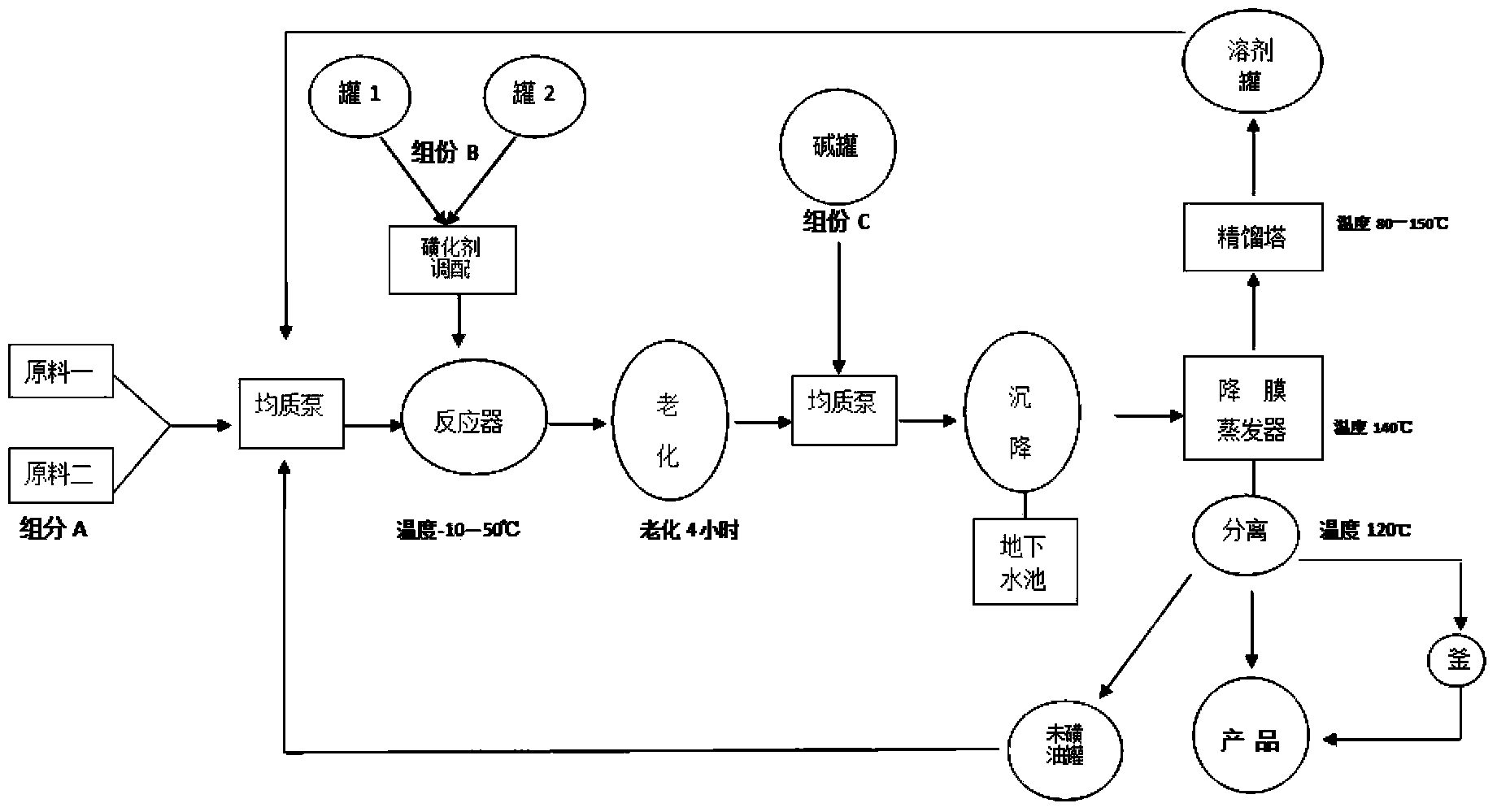

Method used

Image

Examples

Embodiment 1

[0015] Petroleum development adopts a high-performance petroleum sulfonate preparation method. The raw materials are: crude oil distillate oil (mixture) in the 240°C~590°C fraction section and halogenated hydrocarbons are mixed in a mass ratio of 1:0.1 to form A component; sulfur trioxide and Halogenated hydrocarbons are mixed in a mass ratio of 1:2 as component B; ammonia water is component C; the halogenated hydrocarbons are dichloromethane; components A and B are mixed in a mass ratio of 1:0.2 and added to the rotary Packed bed sulfonation reactor, the temperature is 0°C, the continuous outflow is petroleum sulfonic acid, the petroleum sulfonic acid is aged in the aging reactor for 4 hours, and then the aged petroleum sulfonic acid and component C are mixed in a ratio of 1: The mass ratio of 0.5 is mixed and added to the homogeneous neutralization reactor, the temperature is 60°C, and the continuous effluent is crude petroleum sulfonate; the crude petroleum sulfonate enters ...

Embodiment 2

[0017] Petroleum development adopts a high-performance petroleum sulfonate preparation method. The raw materials are: crude oil distillate oil (mixture) in the 240°C~590°C fraction section and halogenated hydrocarbons are mixed in a mass ratio of 1:0.6 to form A component; sulfur trioxide and Halogenated hydrocarbons are mixed into component B at a mass ratio of 1:3; ammonia water is component C; the halogenated hydrocarbons are dichloroethane; components A and B are mixed and added at a mass ratio of 1:1 Rotating packed bed sulfonation reactor, the temperature is 20°C, the continuous outflow is petroleum sulfonic acid, the petroleum sulfonic acid is aged in the aging reactor for 4 hours, and then the aged petroleum sulfonic acid and C component are mixed with 1 The mass ratio of :1 is mixed and added to the homogeneous neutralization reactor, the temperature is 80°C, and the continuous effluent is crude petroleum sulfonate; the crude petroleum sulfonate enters the settling tan...

Embodiment 3

[0024] Petroleum development adopts a high-performance petroleum sulfonate preparation method. The raw materials are: crude oil distillate oil (mixture) in the 240°C~590°C fraction section and halogenated hydrocarbons are mixed in a mass ratio of 1:1 to form A component; sulfur trioxide and Halogenated hydrocarbons are mixed into component B at a mass ratio of 1:4; ammonia water is component C; the halogenated hydrocarbon is dichloroethane; components A and B are mixed at a mass ratio of 1:2 and added Rotating packed bed sulfonation reactor, the temperature is 60°C, the continuous outflow is petroleum sulfonic acid, the petroleum sulfonic acid is aged in the aging reactor for 4 hours, and then the aged petroleum sulfonic acid and C component are mixed with 1 : The mass ratio of 2 is mixed and added to the homogeneous neutralization reactor, the temperature is 120 ° C, and the continuous effluent is petroleum sulfonate crude product; the petroleum sulfonate crude product enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com