Composite gas hydrate accelerant and application method thereof

A hydrate accelerator and gas hydrate technology, which is applied in the direction of gas fuel, chemical instruments and methods, and other chemical processes, can solve the problems of reduced gas storage density of hydrate, increased investment and operation costs, and shortened induction time. Achieve the effect of reducing generation time, reducing energy consumption, and promoting the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

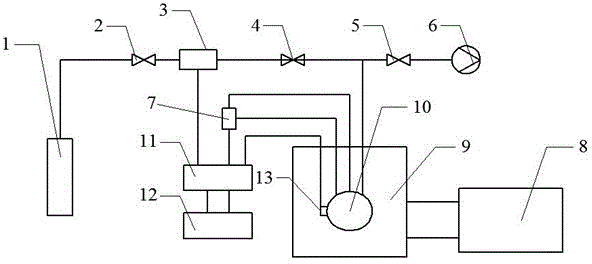

Method used

Image

Examples

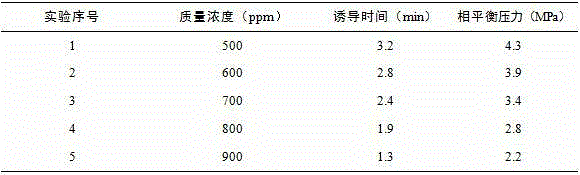

Embodiment 1

[0031] The composition of the selected composite accelerator is as follows: the surfactant is 1.2% petroleum sulfonate, 3% alkyl ammonium oxide and 1% betaine acetate. After mixing, stir at 50°C for 60 minutes to make a hydrate accelerator ;The hydrate formation experiment was done with methane gas in the range of 500ppm~900ppm, and the experimental temperature was 6.7°C; the experimental results are shown in Table 1, and the experimental procedure is the same as above. Under the above conditions, the induction time of hydrate formation is 2.5~3.8min, and the higher the mass concentration of compound accelerator, the shorter the induction time.

[0032] Table 1 Experimental results

Embodiment 2

[0035] Table 2 Experimental results

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com