Spray mist film sulphonation reactor

A sulfonation reactor and mist membrane technology, which is applied in the field of spray mist membrane sulfonation reactor, can solve the problems of restricting the improvement of product quality and output, many side reactions, long production cycle, etc., and achieves the depth and breadth of the reaction. Moderately adjustable, controllable reaction time, less residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

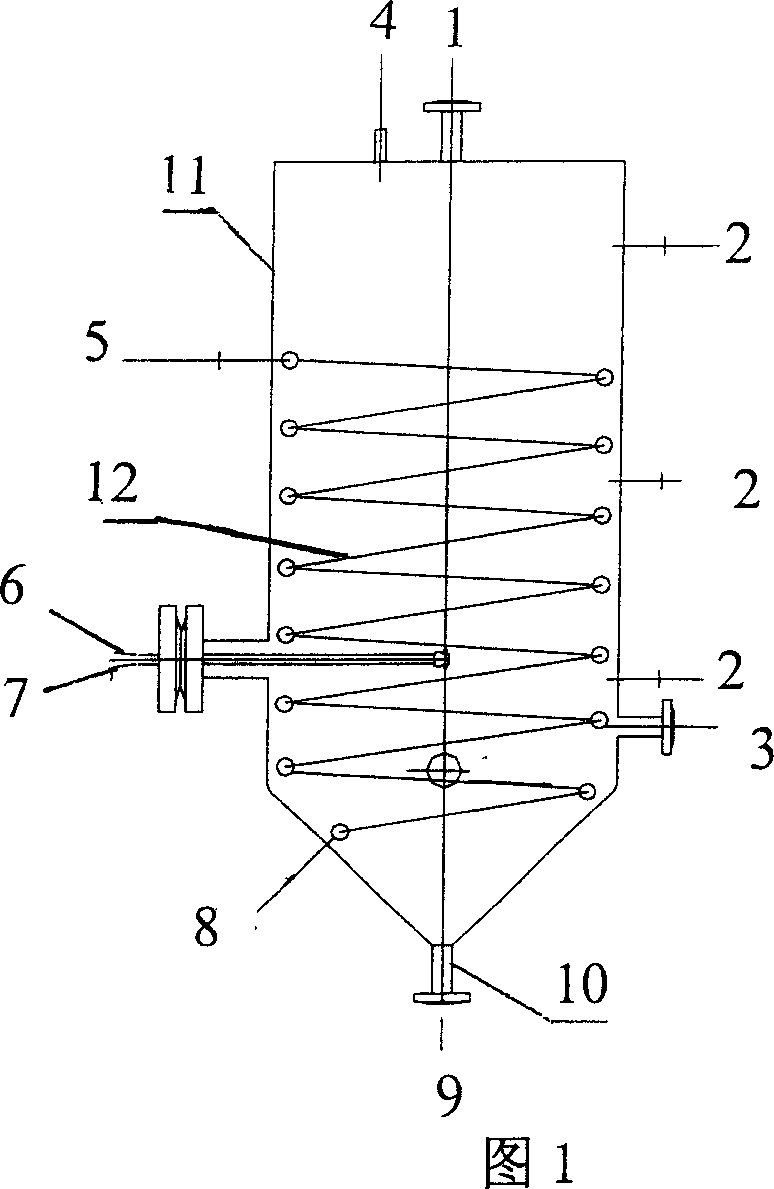

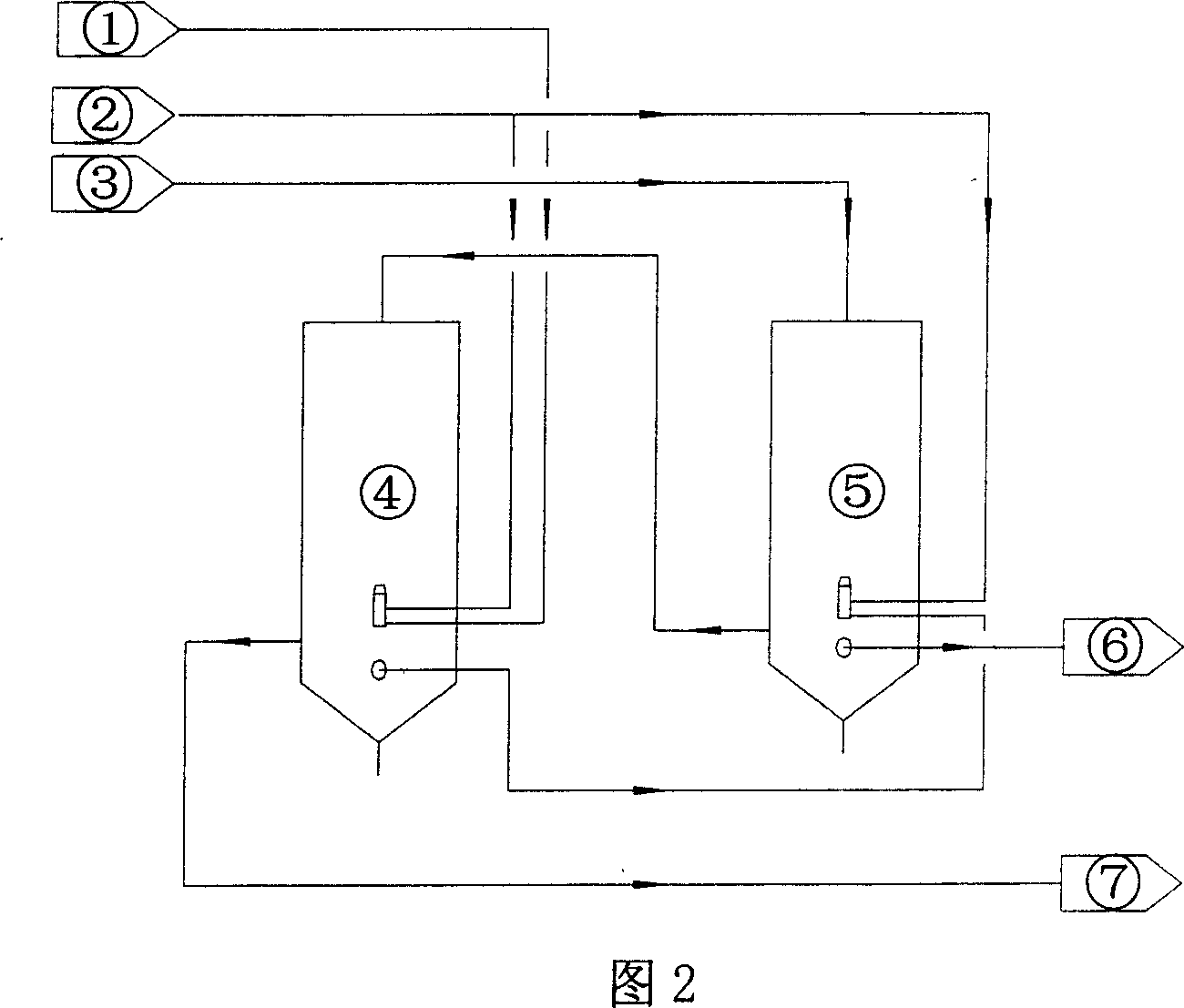

[0019] The principle of the spray film reactor is that the raw oil is atomized by the upward nozzle 10 under a certain pressure to form oil vapor, and micron-sized droplets (oil vapor) are formed in the space inside the reaction tank 11, and the SO 3 The gas is fully exposed to the reaction. The residence time of the reaction is controlled by controlling the length of the reaction tank 11 and the installation height of the nozzle 10; the heat extraction and temperature rise of the system are realized through the inner coil of the reaction tank 11 to ensure the heat balance of the reaction system; through the reaction tank 11 To control the acid value of the target product——petroleum sulfonic acid by cascading and controlling the feeding ratio of materials, to achieve the purpose of controlling the depth of reaction, to reduce the occurrence of side reactions, the yield of the target product has been improved, and the side reactions have been reduced. The loss rate has also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com