PE composite modified asphalt waterproof coil material and preparation method thereof

A technology of composite modified asphalt and modified asphalt, which is applied in the direction of asphalt material adhesives, adhesive types, adhesive additives, etc., can solve the problems of poor water resistance and aging resistance, and achieve good high and low temperature performance and storage stability, improved service life, improved water repellency and anti-aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

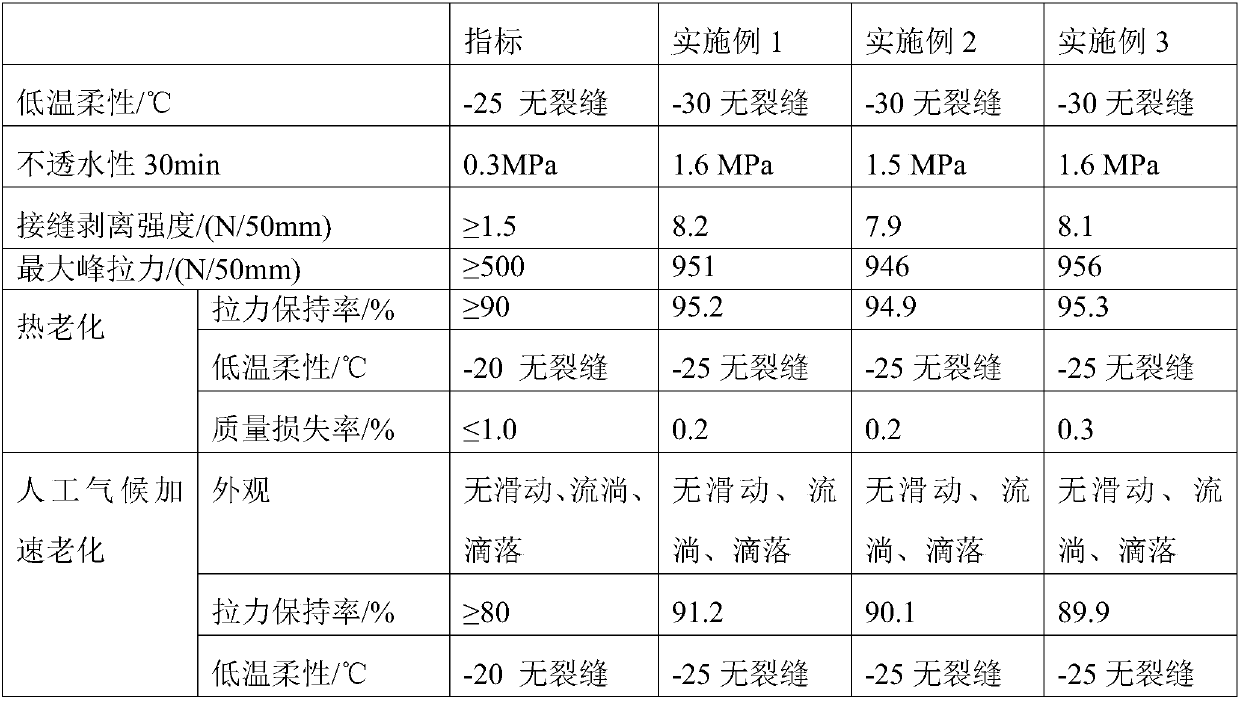

Embodiment 1

[0018] A PE composite modified asphalt waterproofing membrane, from top to bottom: an upper surface isolation layer, an upper polymer modified asphalt layer, a base layer, a lower polymer modified asphalt layer and a lower surface isolation layer; The upper surface isolation layer is a layer of mineral particles, fine sand is used in this embodiment; the lower surface isolation layer is one of PE film, PET film or PVC film. This embodiment adopts PE film. The base layer of the tire is glass fiber felt.

[0019] The upper polymer-modified asphalt layer and the lower polymer-modified asphalt layer are made of PE composite modified asphalt, and the PE composite modified asphalt, in parts by weight, includes 70 parts of petroleum asphalt, 25 parts of polyethylene, 15 parts of SBS rubber, 13 parts of bark resin, 3 parts of pentaerythritol stearate, 0.1 part of graphene, 3 parts of sodium dodecylbenzene sulfonate, 1 part of sodium oleate, 5 parts of paraffin, 2 parts of ethyl pheny...

Embodiment 2

[0025] A PE composite modified asphalt waterproofing membrane, from top to bottom: an upper surface isolation layer, an upper polymer modified asphalt layer, a base layer, a lower polymer modified asphalt layer and a lower surface isolation layer; The upper surface isolation layer is a layer of mineral particles, fine sand is used in this embodiment; the lower surface isolation layer is one of PE film, PET film or PVC film. This embodiment adopts PE film. The base layer of the tire is glass fiber felt.

[0026] The upper polymer-modified asphalt layer and the lower polymer-modified asphalt layer are made of PE composite modified asphalt, and the PE composite modified asphalt, in parts by weight, includes 75 parts of petroleum asphalt, 20 parts of polyethylene, 13 parts of SBS rubber, 15 parts of furan resin, 4 parts of pentaerythritol stearate, 0.2 parts of graphene, 2 parts of sodium dodecylbenzene sulfonate, 2 parts of sodium oleate, 6 parts of paraffin, 2 parts of ethyl ph...

Embodiment 3

[0032] A PE composite modified asphalt waterproofing membrane, from top to bottom: an upper surface isolation layer, an upper polymer modified asphalt layer, a base layer, a lower polymer modified asphalt layer and a lower surface isolation layer; The upper surface isolation layer is a layer of mineral particles, fine sand is used in this embodiment; the lower surface isolation layer is one of PE film, PET film or PVC film. This embodiment adopts PE film. The base layer of the tire is glass fiber felt.

[0033]The upper polymer-modified asphalt layer and the lower polymer-modified asphalt layer are made of PE composite modified asphalt, and the PE composite modified asphalt, in parts by weight, includes 80 parts of petroleum asphalt, 30 parts of polyethylene, 10 parts of SBS rubber, 10 parts of furan resin, 5 parts of pentaerythritol stearate, 0.3 parts of graphene, 1 part of sodium dodecylbenzene sulfonate, 3 parts of sodium oleate, 8 parts of paraffin, 2 parts of ethyl phen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com