Surfactant, composition and preparation method for amphiphilic gamma type oil displacement

A technology of surfactant and composition, which is applied in the field of surfactants for oil displacement, can solve the problem that surfactants are difficult to meet the oil production needs of Xinjiang Oilfield Company, and achieve good compatibility, good stability and good salt resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

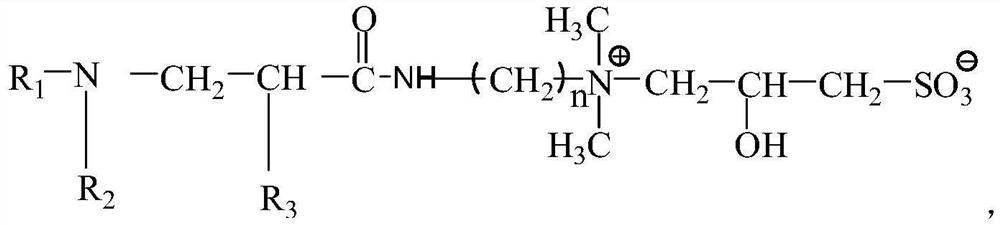

[0034] In another typical embodiment of the present application, a preparation method of any one of the above-mentioned surfactants is provided, the preparation method comprising: Step S1, making R 1 NH 2 and CH 2 =CR 3 -COO(CH 2 ) m CH 3 Carry out a Michael addition reaction to give R 1 NH-CH 2 -CHR 3 COO(CH 2 ) m CH 3 , where R 1 for C 12 ~C 22 Alkyl, cycloalkyl or alkenyl, R 3 Be H or methyl, m is any integer in 0 to 3; Step S2, make R 1 NH-CH 2 -CHR 3 COO(CH 2 ) m CH 3 and X-CH 2 -COOM or X-CH 2 -CH 2 -SO 3 M is reacted to give R 1 NR 2 -CH 2 -CHR 3 COO(CH 2 ) m CH 3 , where R 2 for -CH 2 COOM or CH 2 -CH 2 SO 3 M, M is alkali metal ion, and X is halogen; Step S3, makes R 1 NR 2 -CH 2 -CHR 3 COO(CH 2 ) m CH 3 and react, get and step S4, so that and Y-CH 2 CHOHCH 2 SO 3 M' reacts to get Wherein, Y is a halogen, and M' is an alkali metal ion.

[0035] The above-mentioned reaction processes are all realized according to th...

Embodiment 1

[0050] Add 1 mol of octadecylamine to the four-necked bottle, and heat octadecylamine to a molten state, slowly add 1.1 mol of methyl acrylate dropwise under mechanical stirring, and complete the dropwise addition within 3.5 hours to form the first reaction system; 65 Continue the constant temperature reaction at ℃ for 4 hours. After the reaction is completed, the first product system is obtained. The excess methyl acrylate in the first product system is distilled off at 0.03 MPa to obtain methyl octadecylaminopropionate with a yield of 98.5 %;

[0051] Add 1 mol of methyl octadecylaminopropionate to the four-necked flask, heat at 90°C to a molten state, and add 1.05 mol of sodium chloroacetate to the four-necked flask to form a second reaction system; after reacting for 2 hours, the obtained The third reaction system; in the third reaction system, dropwise add 1 mol of sodium hydroxide solution to control the pH value of the third reaction system between 8 and 9, and react at...

Embodiment 2

[0057] Add 1 mol of octadecylamine to the four-necked bottle, and heat the octadecylamine to a molten state, slowly add 1.2 mol of methyl acrylate dropwise under mechanical stirring, and complete the dropwise addition within 3.5 hours to form the first reaction system; 65 ℃ under constant temperature reaction 4h. After the reaction was completed, the first product system was obtained, and the excess methyl acrylate in the first product system was distilled off at 0.03 MPa to obtain methyl octadecylaminopropionate with a yield of 98%.

[0058] Add 1 mol of methyl octadecylaminopropionate to the four-necked flask, heat at 90°C to a molten state, and add 1.05 mol of sodium chloroacetate to the four-necked flask to form a second reaction system; after reacting for 2 hours, the obtained The third reaction system: 1 mol of sodium hydroxide solution was added dropwise to the third reaction system, and the reaction was carried out at constant temperature for 4 hours to obtain a transe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com