Polyether polyol for fuel additive, and preparation method and application of polyether polyol

A polyether polyol and additive technology, applied in fuel additives, fuel, petroleum industry, etc., can solve problems such as pollution, affecting the quality of polyether polyol, waste of resources, etc., to improve reaction yield, remove carbon deposits in automobiles, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In a specific embodiment, the present invention provides a kind of preparation method of polyether polyol, and it comprises the steps: a certain amount of starter (monohydric alcohol) is added in the reactor with nitrogen device, Stir evenly, control the temperature between 80-160°C, add a catalyst, and carry out a subsequent reaction to catalyze the addition of a certain proportion of epoxy (propylene oxide, ethylene oxide or a mixture).

[0027] In a specific embodiment, the C 4 -C 18 The monohydric fatty alcohol is n-butanol, octanol, nonanol, n-decyl alcohol, n-hexadecanol, n-stearyl alcohol, or one or more of their respective isomers.

[0028] In a specific embodiment, the participating reactants can be various catalysts conventionally used in this field, preferably one or more of potassium methoxide, sodium methoxide, NaOH, and KOH.

[0029] In a specific embodiment, the epoxides may be various epoxides conventionally used in the art, preferably including one or...

Embodiment 1

[0041] Raw material formula: 500 parts by weight of n-butanol, 2 parts by weight of KOH, and 1600 parts by weight of propylene oxide.

[0042] Preparation method: Add 500 parts by weight of n-butanol into the reaction kettle, replace the air with nitrogen, and raise the temperature to about 140°C after detecting that the oxygen content is ≤200ppm, slowly add 2 parts by weight of KOH, and then pass in 1600 parts by weight of propylene oxide , maintain the pressure at about 0.5MPa, keep the heat and pressure for 2 hours, and then use the phosphoric acid method to neutralize and form phosphate, then dry, filter to remove metals and deionize, and obtain polyether polyols.

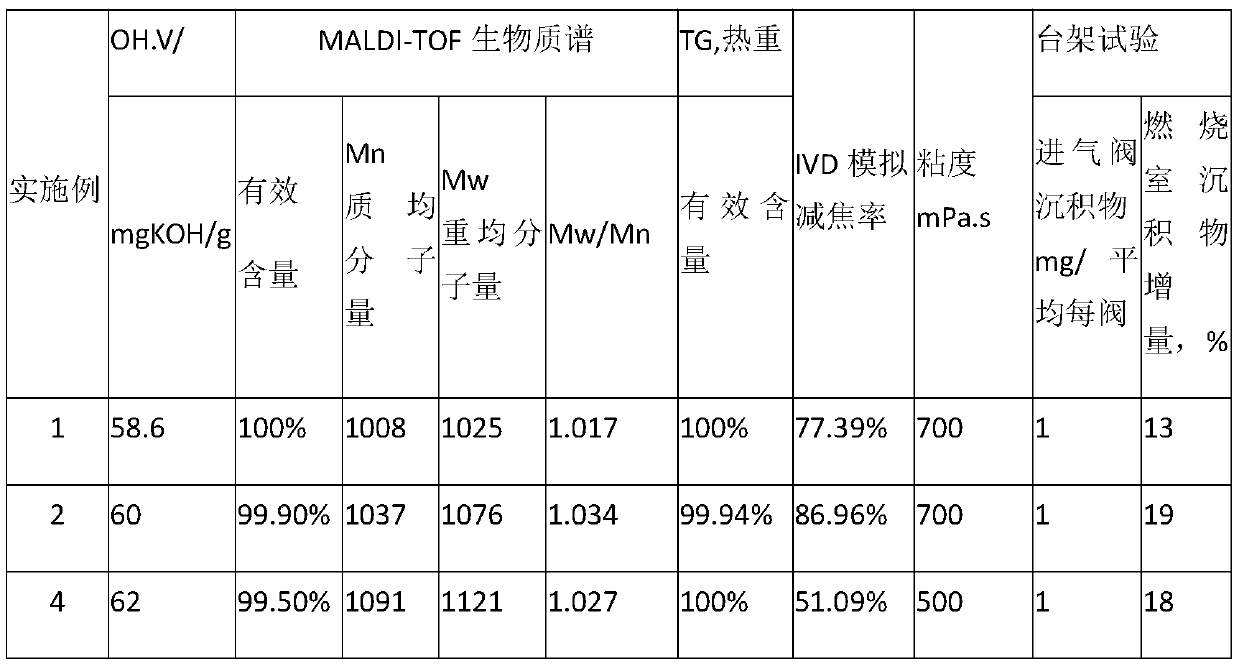

[0043]The hydroxyl value of the polyether polyol obtained in this embodiment is 58.6mgKOH / g, and the yield (specific calculation method: the total mass of the discharged material / the total mass of the input material*100%) is 98.97%, and the appearance is a colorless transparent liquid. The kinematic viscosity a...

Embodiment 2

[0045] Raw material formula: 500 parts by weight of n-decanol, 2.5 parts by weight of KOH, and 1600 parts by weight of propylene oxide.

[0046] Preparation method: Add 500 parts by weight of n-decyl alcohol into the reaction kettle, replace the air with nitrogen, and raise the temperature to about 140°C after detecting that the oxygen content is ≤200ppm, slowly add 2.5 parts by weight of KOH, and then pass in 1600 parts by weight of propylene oxide, Maintain the pressure at about 0.5 MPa, heat and hold the pressure for 2 hours, and then use the phosphoric acid method to neutralize to form phosphate, then dry, filter to remove metals and deionize, and then obtain polyether polyol.

[0047] The hydroxyl value of the polyether polyol obtained in this embodiment is 60 mgKOH / g, and the yield (specific calculation method: total mass of discharged materials / total mass of input materials*100%) is 99.0%, and the appearance is a colorless transparent liquid, 25 The kinematic viscosity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com