Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68 results about "P-Toluic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

P-Toluic acid (4-methylbenzoic acid) is a substituted benzoic acid with the formula CH₃C₆H₄CO₂H. It is a white solid that is poorly soluble in water but soluble in acetone. A laboratory route to p-toluic acid involves oxidation of p-cymene with nitric acid.

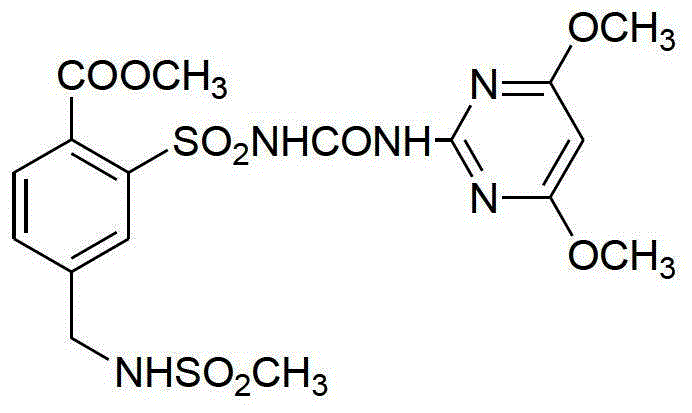

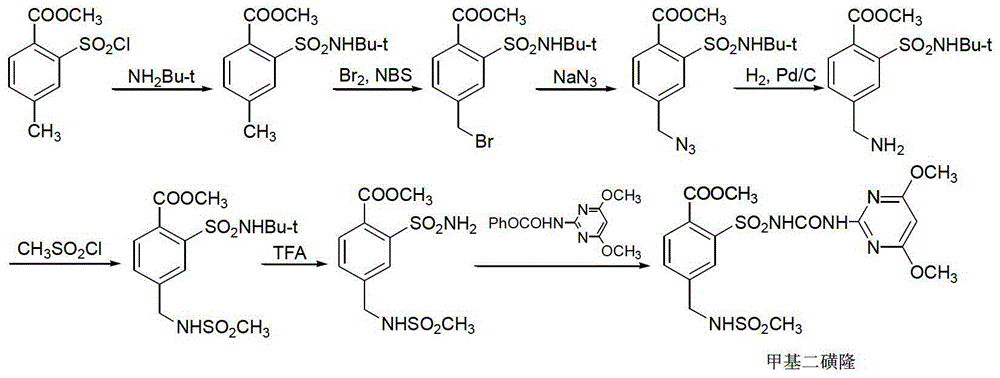

Mesosulfuron-methyl synthetic method

ActiveCN103333120ARaw materials are cheap and easy to getEasy to operateOrganic chemistryMesosulfuron-methylChloride

The invention discloses a mesosulfuron-methyl synthetic method. The mesosulfuron-methyl synthetic method is characterized in that mesosulfuron-methyl is prepared from raw materials such as paratoluic acid by adopting the seven steps of chlorosulfonation-ammonolysis, oxidation, dehydration, reduction, alcoholysis, methyl sulfone chloride acylation and condensation. The mesosulfuron-methyl synthetic method provided by the invention has the advantages of being low in cost of the raw materials, easy in availability of the raw materials, simple in operation and mild in conditions, having low requirements on equipment, high yield and strong practicability and being suitable for industrial production.

Owner:JIANGSU REPONT PESTICIDE FACTORY

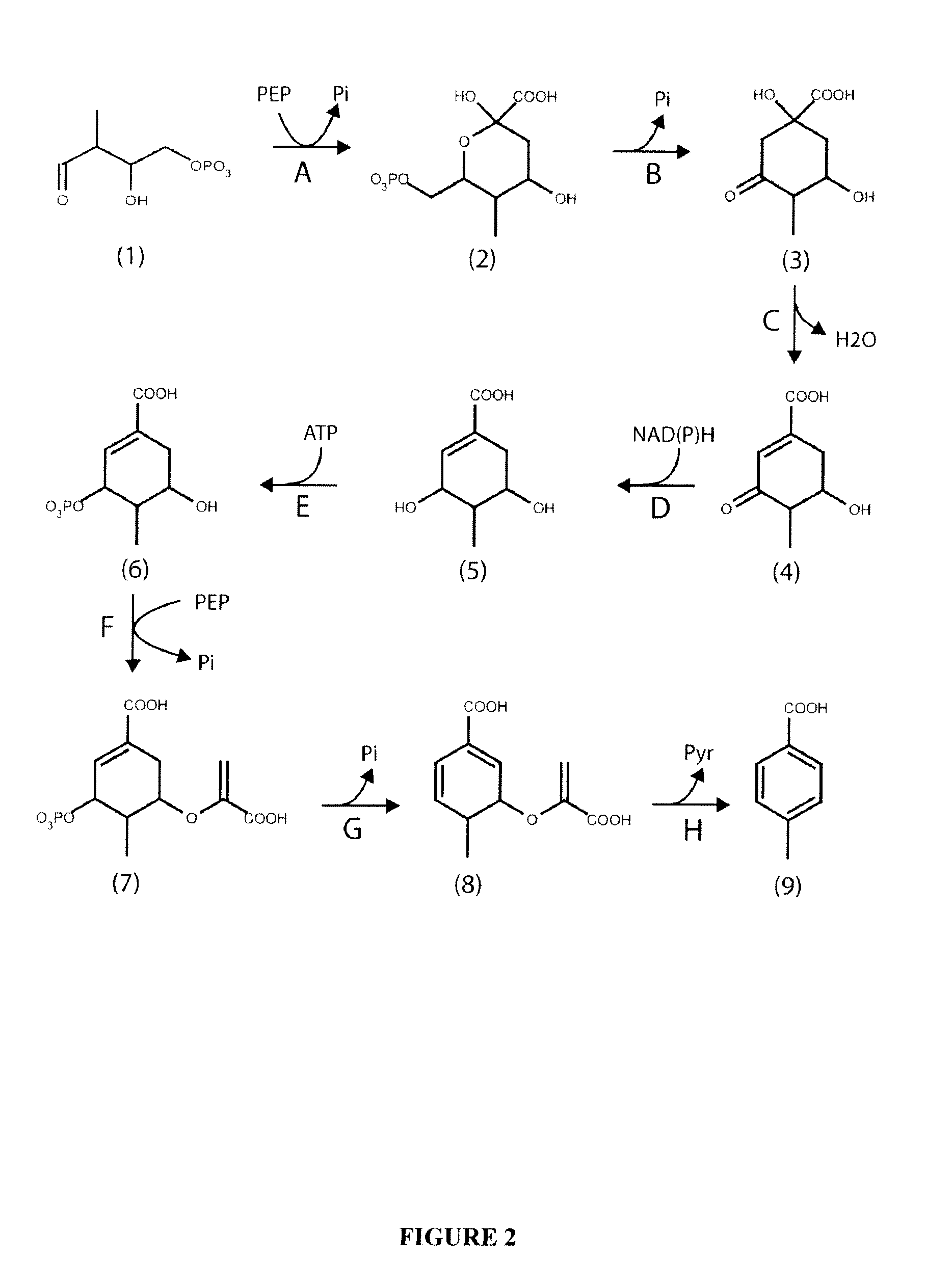

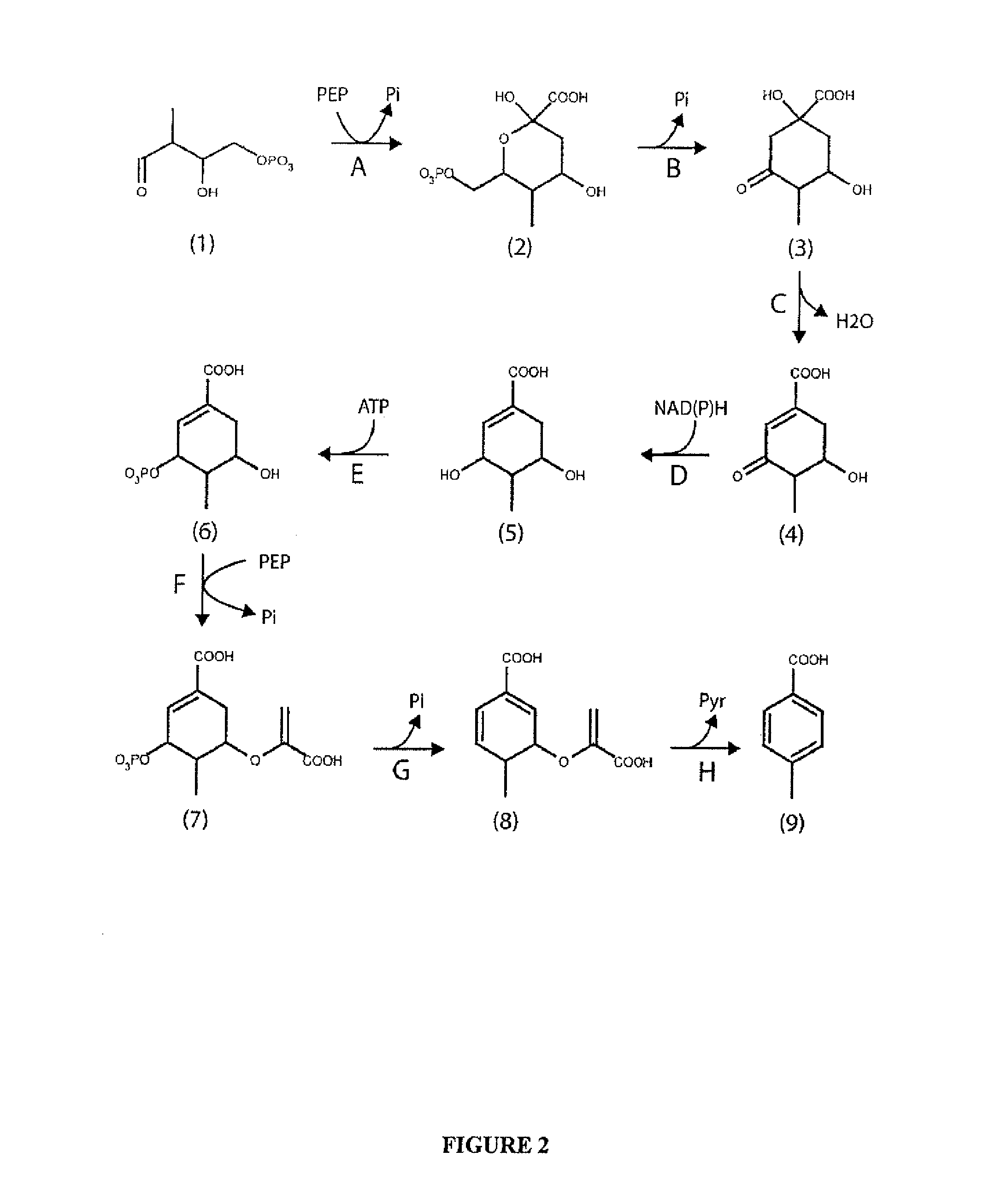

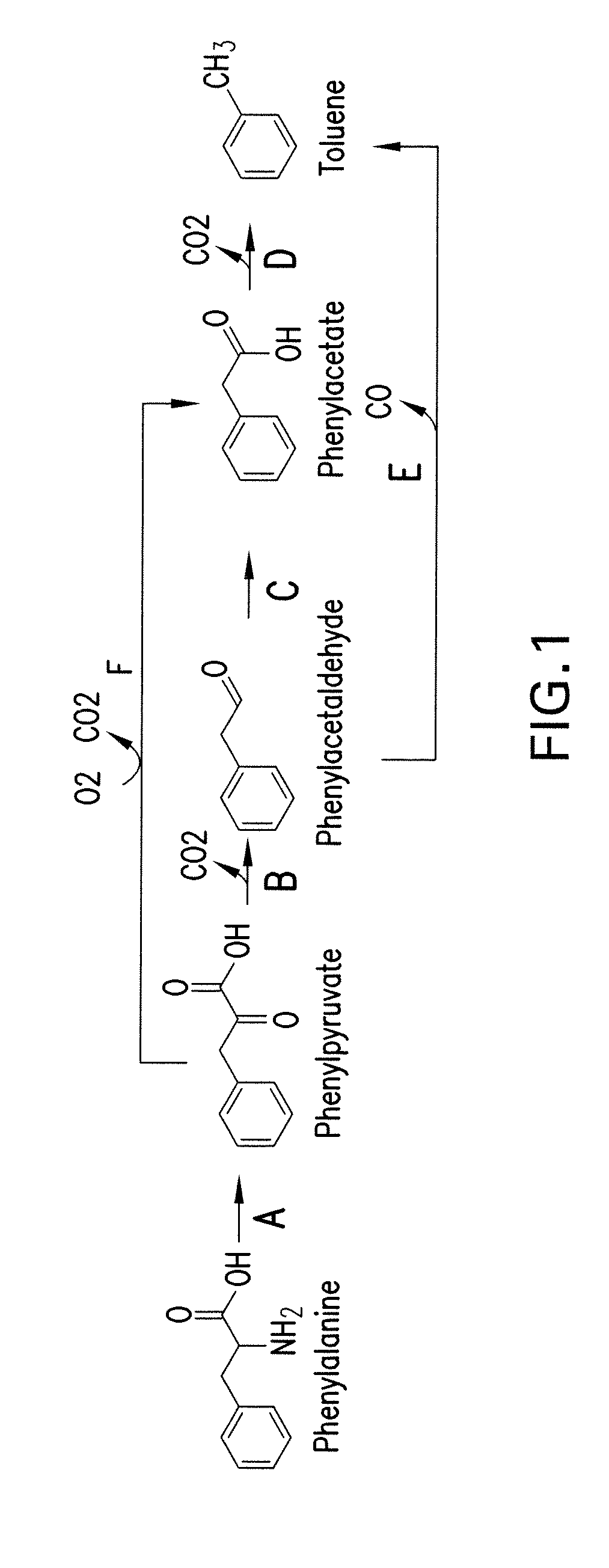

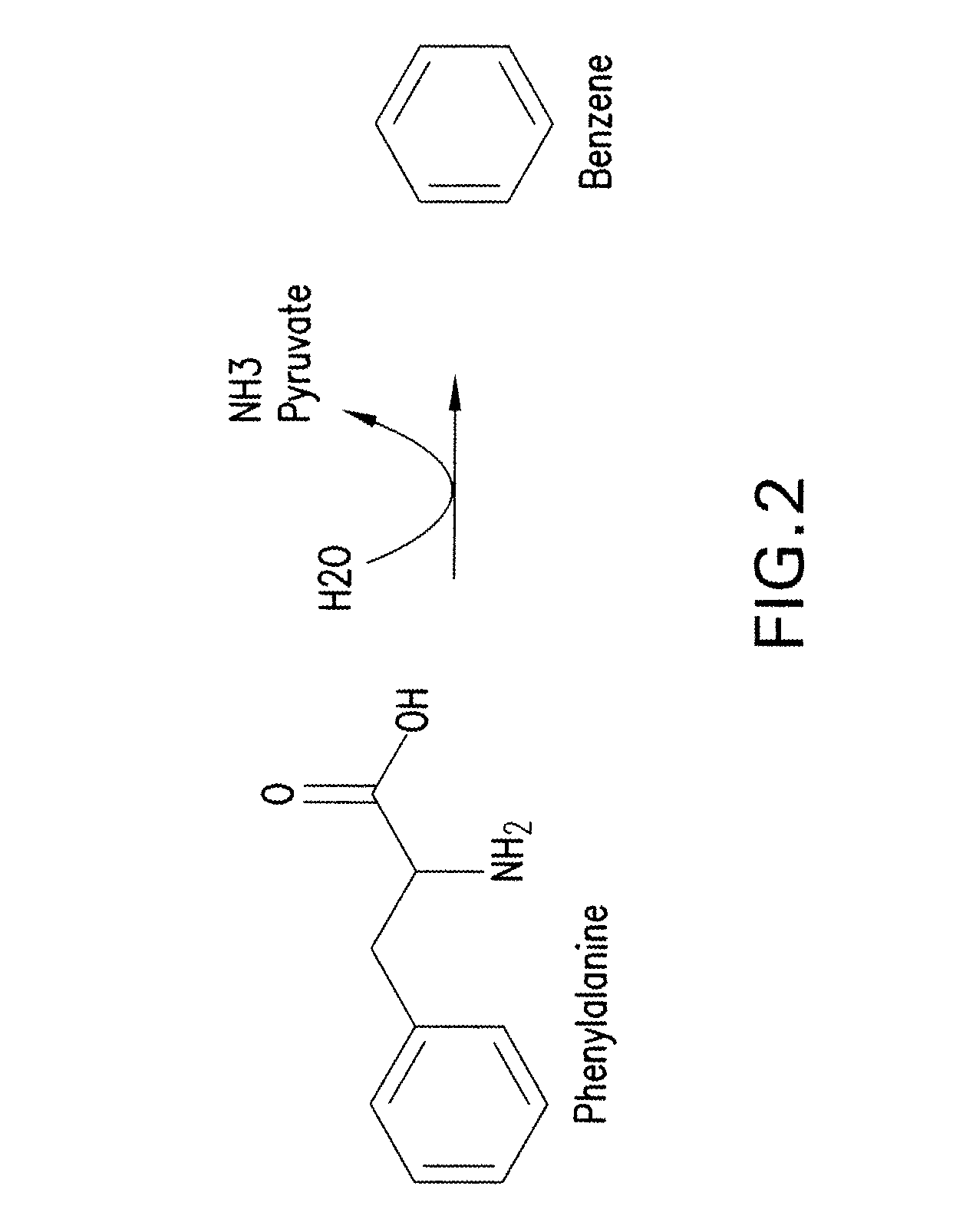

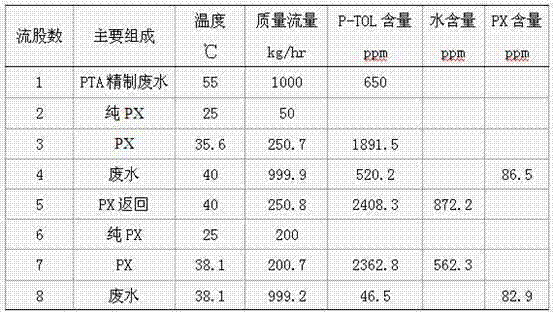

Microorganisms and methods for the biosynthesis of p-toluate and terephthalate

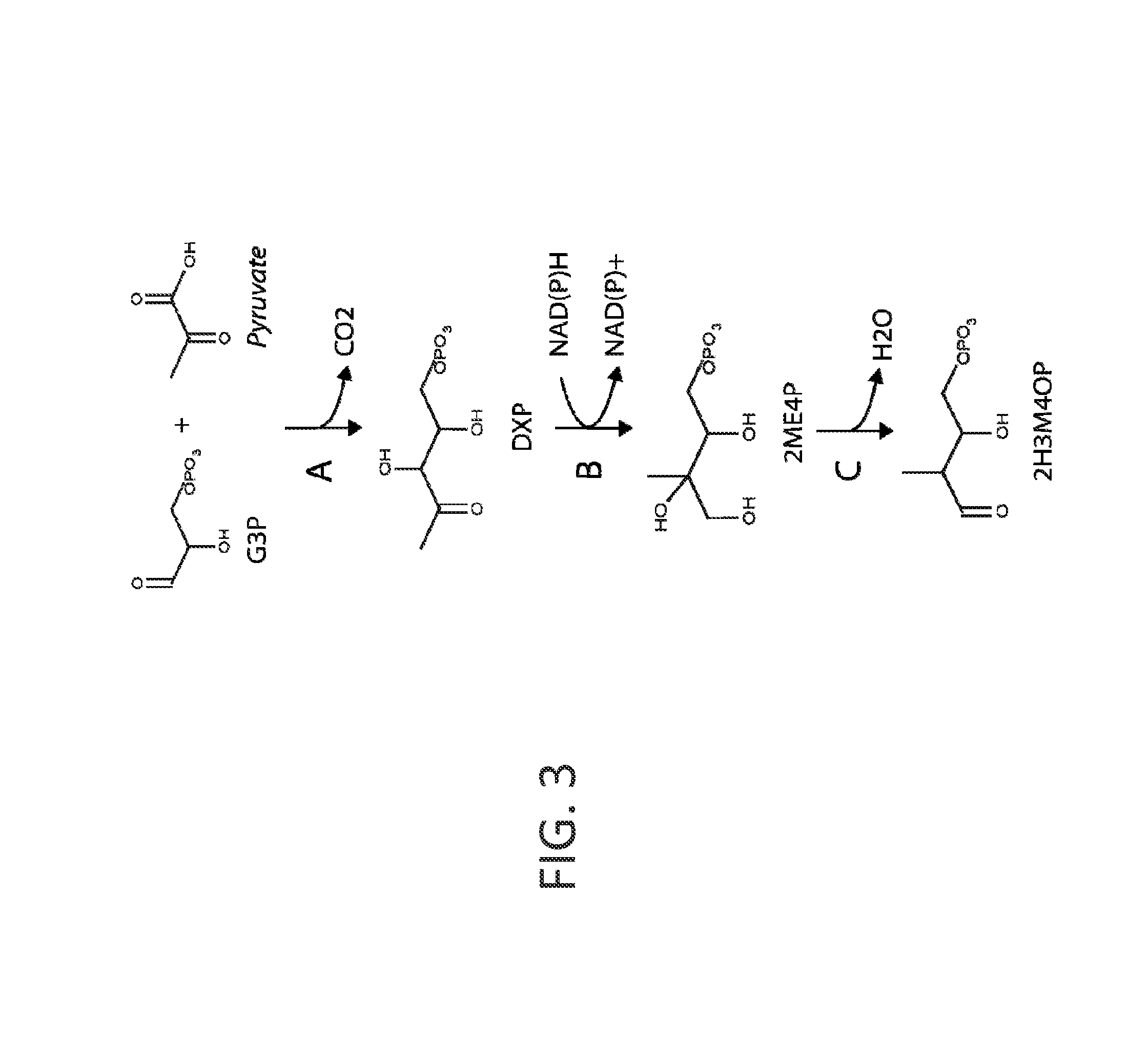

The invention provides non-naturally occurring microbial organisms having a (2-hydroxy-3-methyl-4-oxobutoxy)phosphonate pathway, p-toluate pathway, and / or terephthalate pathway. The invention additionally provides methods of using such organisms to produce (2-hydroxy-3-methyl-4-oxobutoxy)phosphonate pathway, p-toluate pathway or terephthalate pathway.

Owner:GENOMATICA INC

Selective hydrogenation catalyst of aromatic aldehydes for refinement of terephthalic acid

ActiveCN101347737AHigh selectivityImprove hydrogenation activityPreparation by hydrogenolysisMetal/metal-oxides/metal-hydroxide catalystsActivated carbonBenzaldehyde

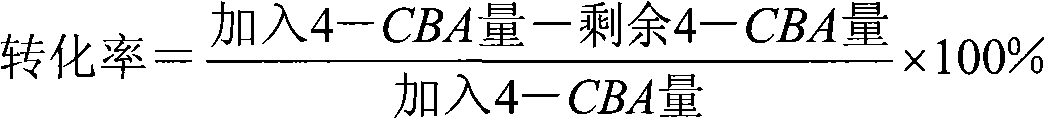

The invention relates to a selective hydrogenation catalyst of aromatic aldehydes for refining of terephthalic acid. The selective hydrogenation catalyst is mainly used for solving the problems that the hydrogenation of 4-carboxy-benzaldehyde (called as 4-CBA for short) in the prior art mainly generates p-toluic acid (referred to as P-TA), the amount of hydrogen consumption is great and the operation cost is high. The selective hydrogenation catalyst adopts activated carbon as a carrier and is supported with one or more metals of palladium, ruthenium, nickel, zinc and copper, and the like; therefore, the technical proposal can better solve the problems and can be used in the industrial production for hydrogenation refining of the terephthalic acid.

Owner:CHINA PETROLEUM & CHEM CORP +1

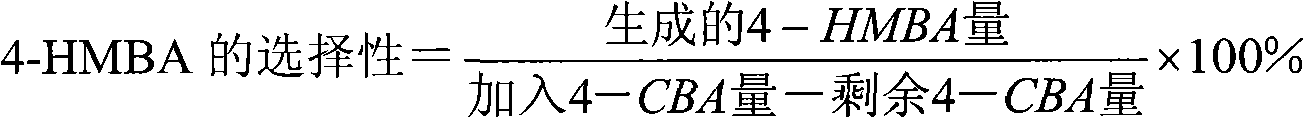

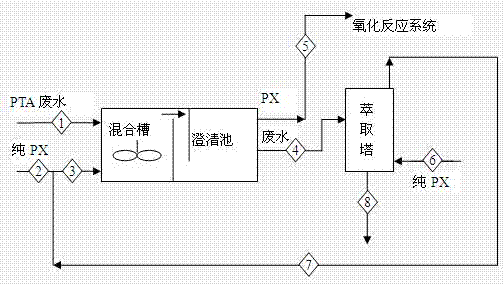

Method for recycling mother solid in PTA-refining wastewater

ActiveCN101941901AAvoid wastingSolve easy blockageMultistage water/sewage treatmentCarboxylic compound separation/purificationRecovery methodSingle stage

The invention discloses a method for recycling mother solid in PTA-refining wastewater, comprises the following steps: mixing PTA-refining wastewater and paraxylene in a prepositioned mixing tank, carrying out single-stage extraction and cooling on the wastewater, dissolving and extracting the solid in mother liquor into a PX phase, returning the extract phase PX discharged from a clarification tank to an oxidizing reaction system, and delivering the wastewater to an extraction tower to be subject to multistage countercurrent extraction; delivering the wastewater discharged from the bottom ofthe extraction tower to be subject to further treatment; and returning the extraction phase discharged from the top of the extraction tower to serve as extract liquor for single-stage extraction. By adopting the method in the invention, most of organic matters, such as p-toluic acid, terephthalic acid and the like in the wastewater can be recycled, thus the purpose of recycling wastes is achieved, and wasting of resources is avoided; and the invention omits the conventional filtering unit, saves the filter cloth-replacing cost, ensures that the extraction tower can operate at appropriate operating temperature, and has the advantages of investment saving, low energy consumption, high resource recovery rate and the like.

Owner:FUZHOU UNIV

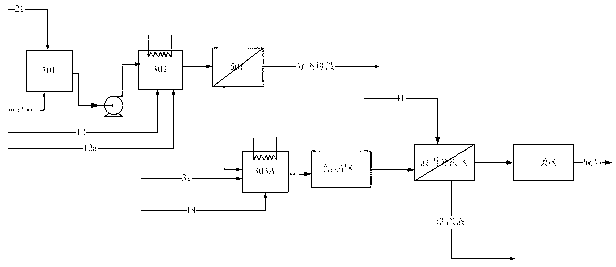

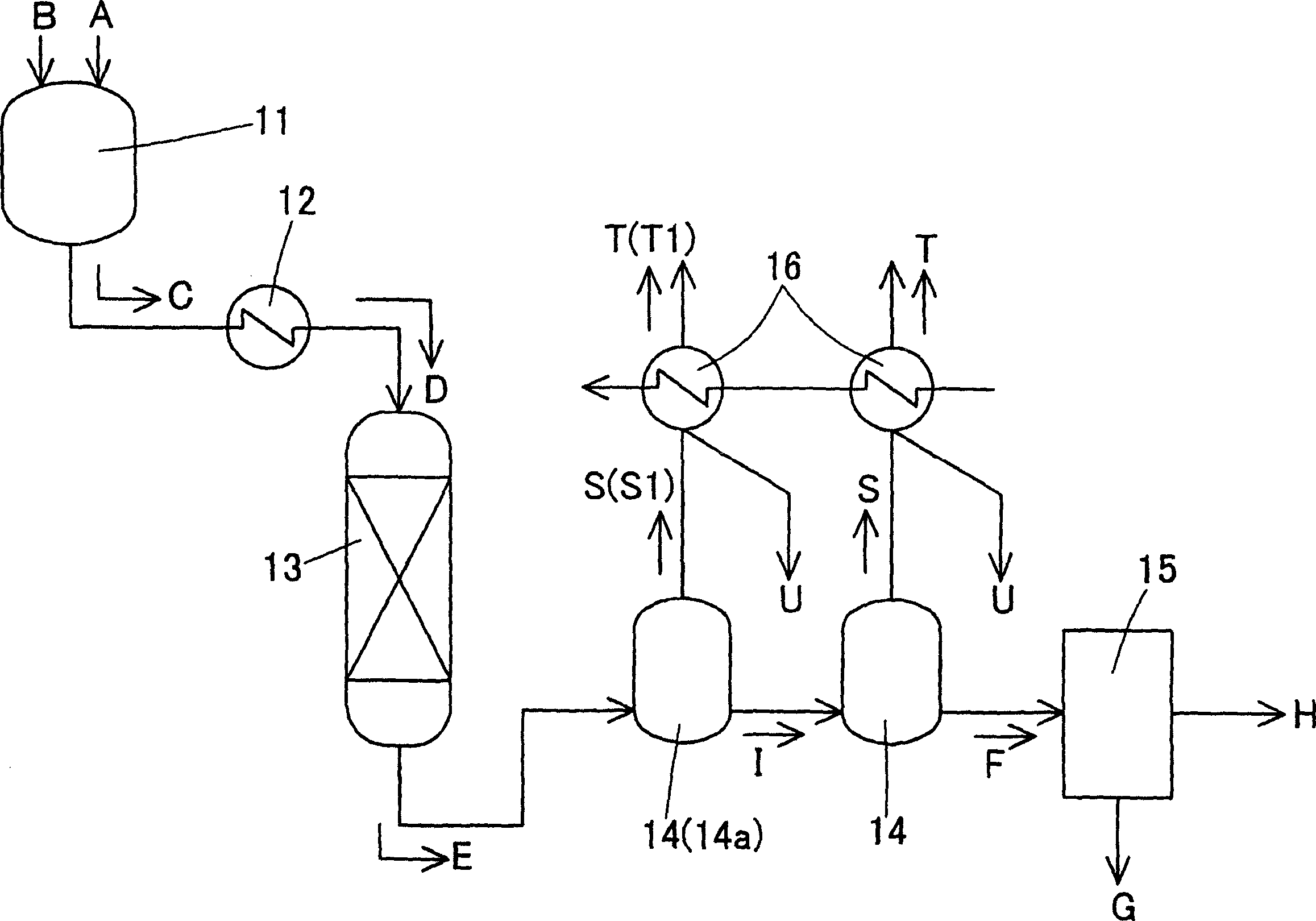

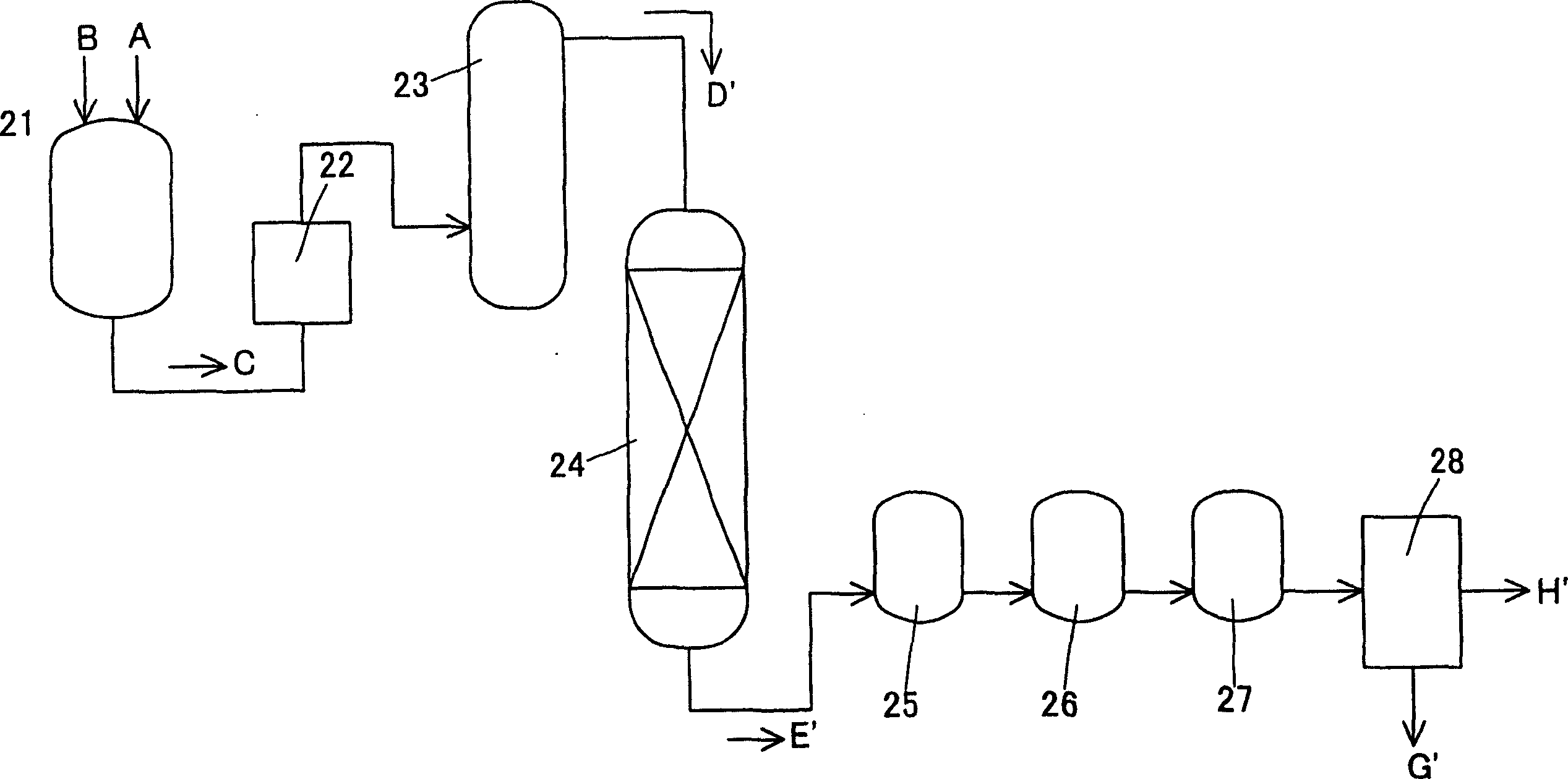

Method and equipment for preparing terephthalic acid by air oxidation of p-xylene

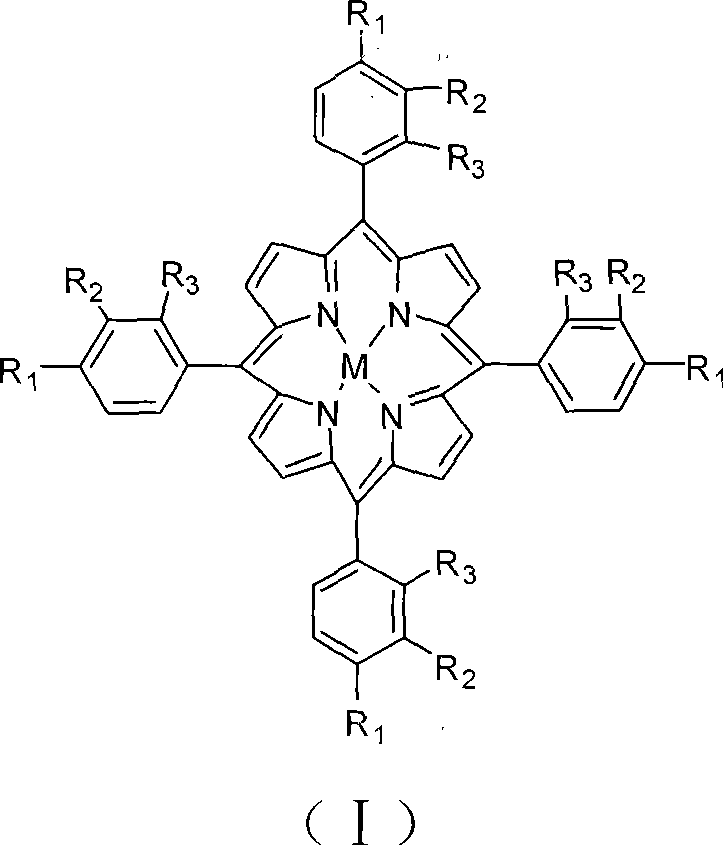

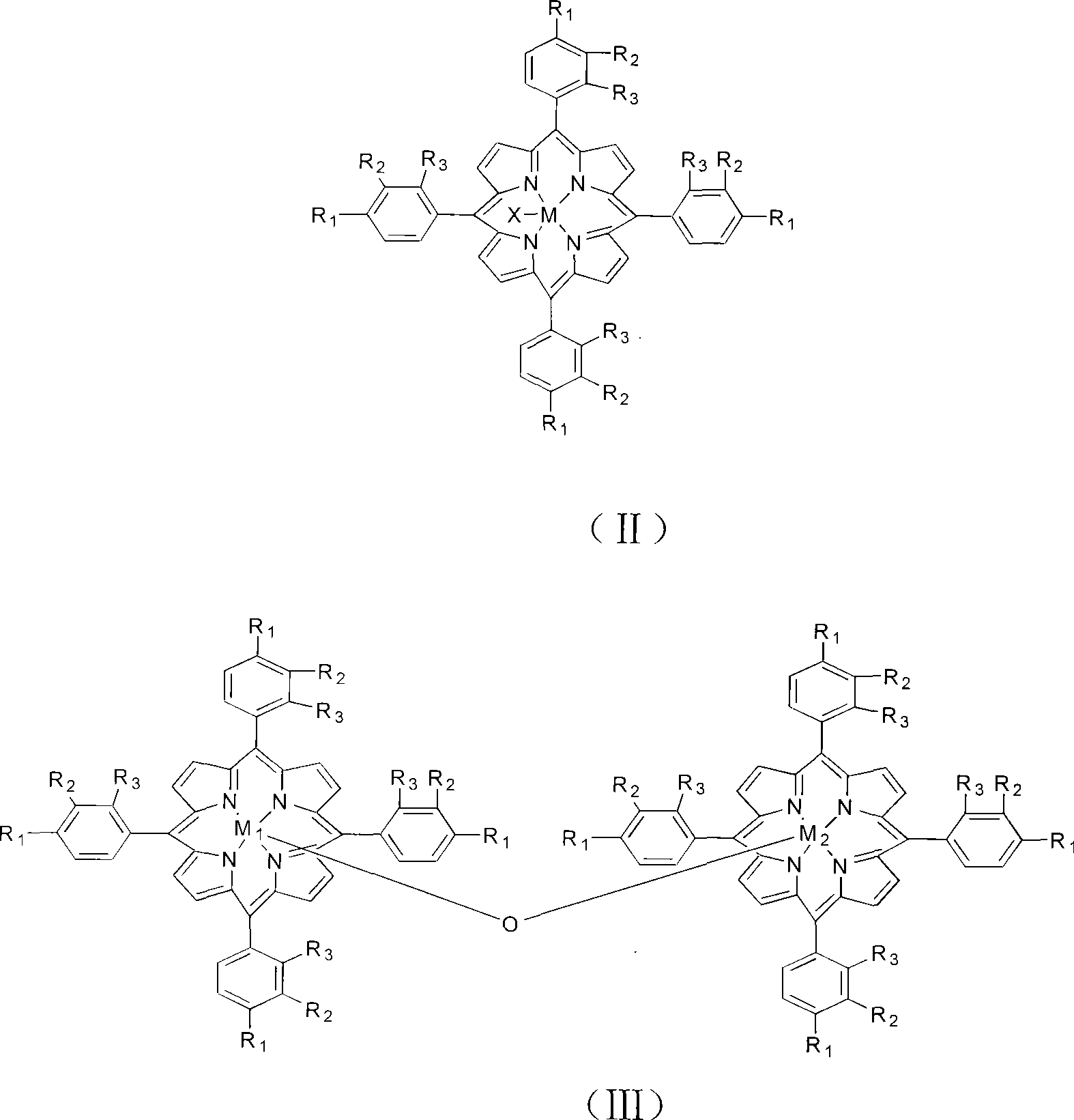

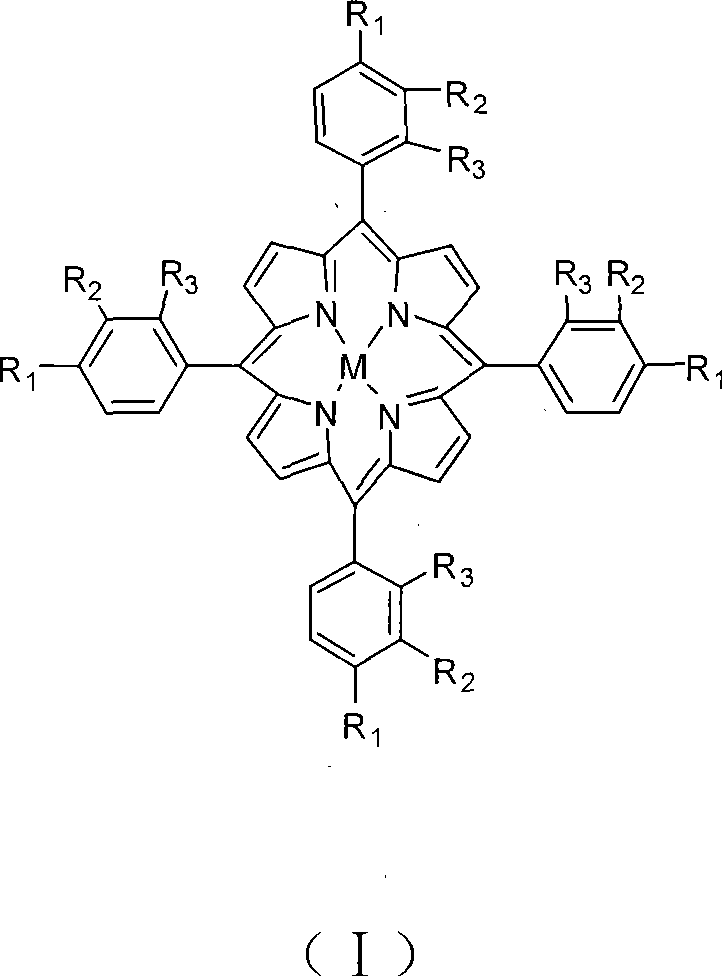

The invention discloses a method and equipment for preparing terephthalic acid by the air oxidation of p-xylene. The method is as follows: in the reaction system in which an oxidation reactor is connected with a crystallization separator in series, p-xylene containing metalloporphyrin catalyst or the mixing catalyst of metalloporphyrin and metal salt, and air, oxygen-diluted air, rich oxygen air or air with carbon dioxide are fed in the oxidation reactor and stay for 70 minutes to 180 minutes in the reactor at the temperature of 140 DEG C to 200 DEG C. The oxidation reaction mixture enters into a crystallizer for crystallization by overflow or pumping. The p-xylene, p-toluic acid and p-methyl benzyl alcohol obtained by separation is pumped into the oxidation reactor to be mixed with the p-xylene containing metalloporphyrin catalyst for secondary oxidation, and the fine terephthalic acid is obtained by purification after crystallization. The invention has the advantages that the p-xylene is directly oxidized into terephthalic acid by air, the energy consumption is low, the production efficiency is high, and the conversion rate of p-xylene and the yield of terephthalic acid can achieve more than 95 percent.

Owner:HUNAN UNIV +1

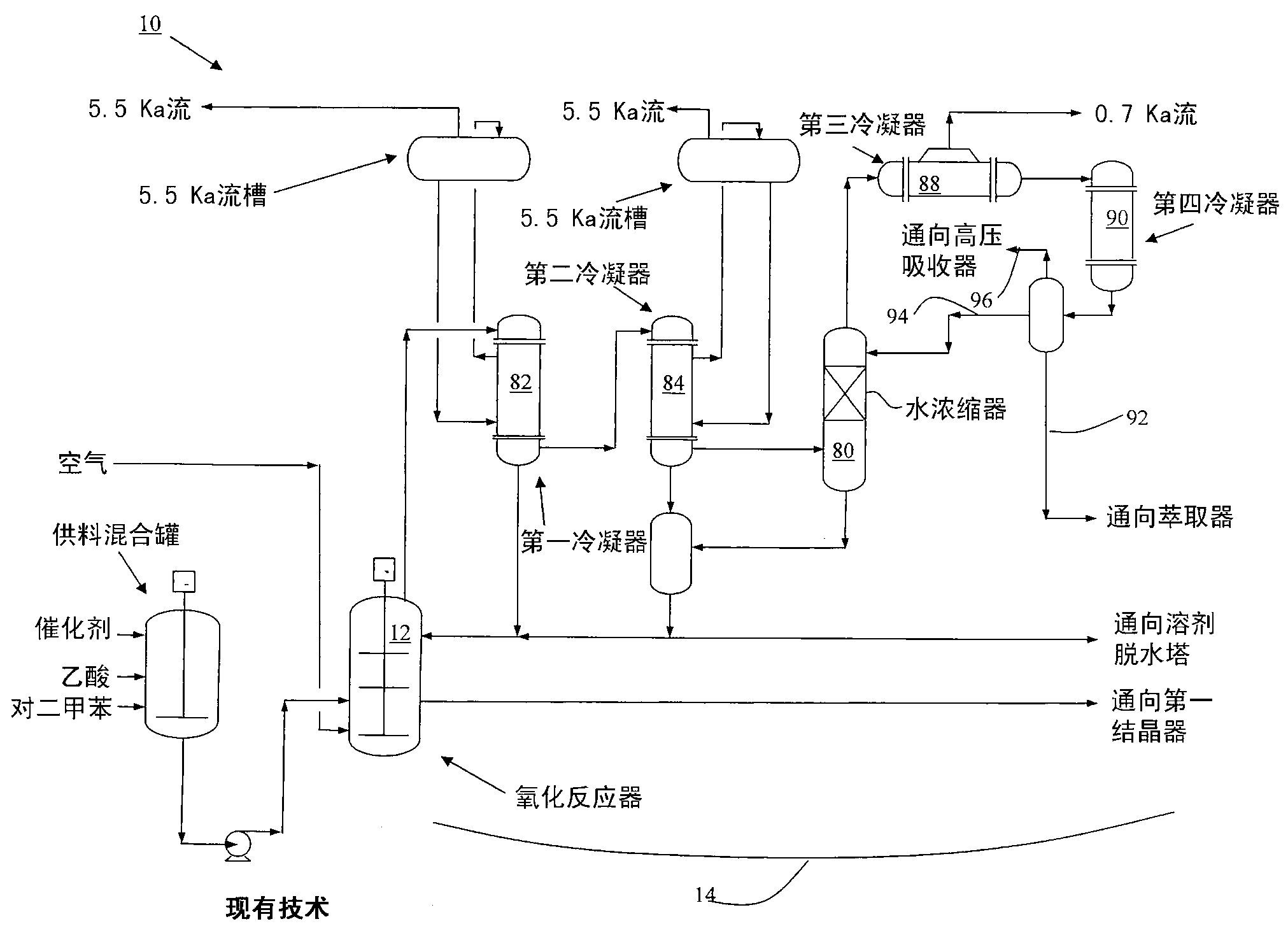

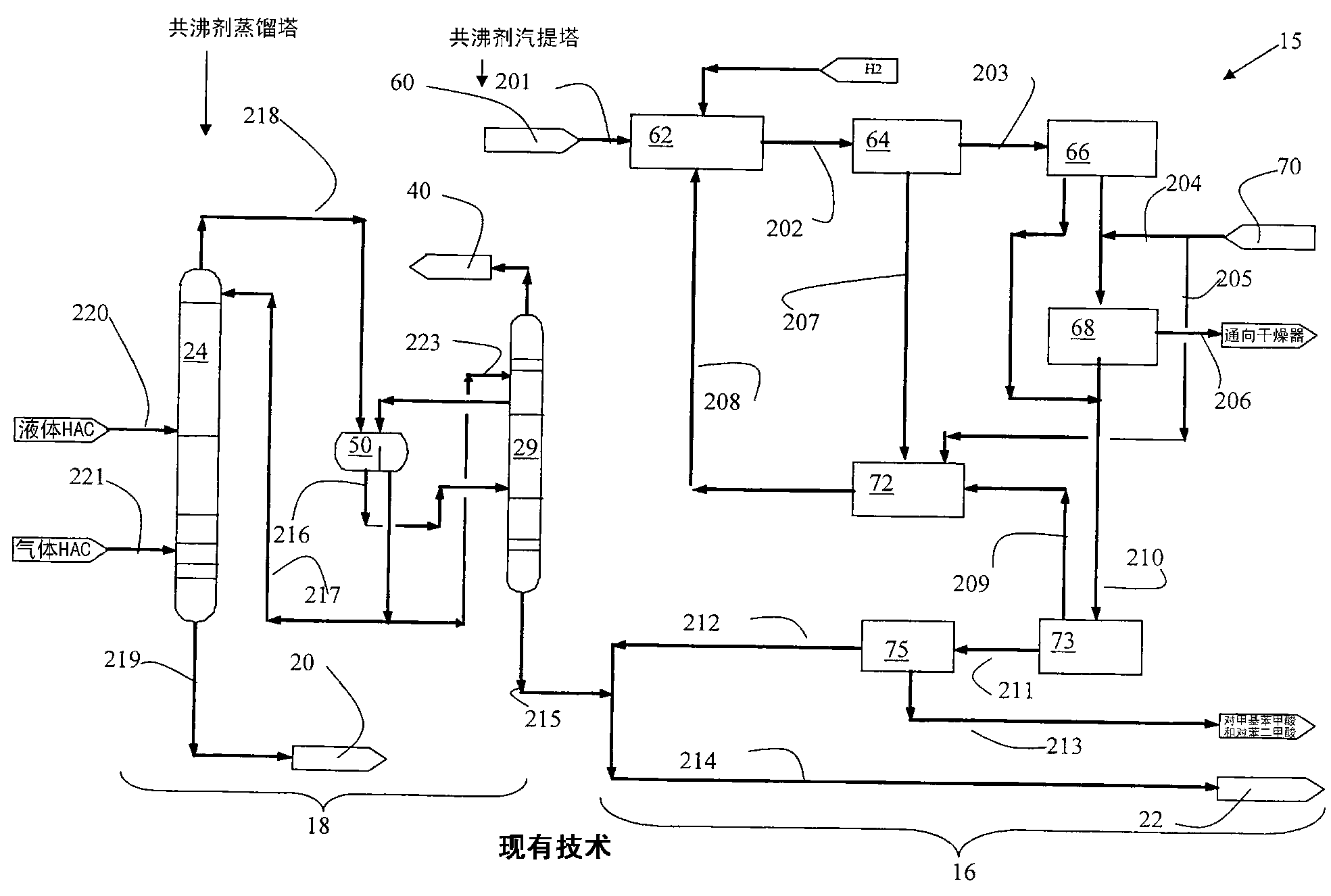

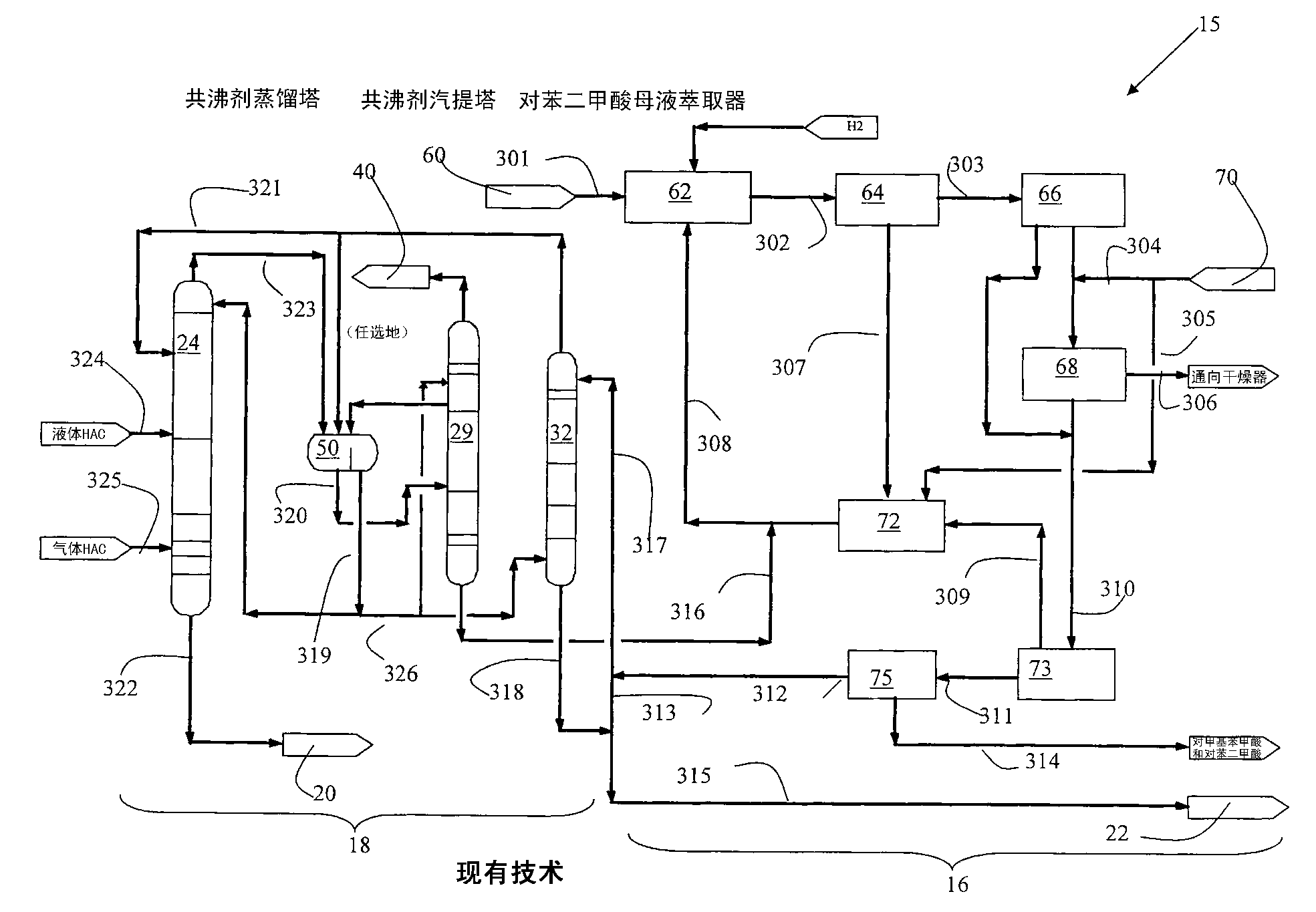

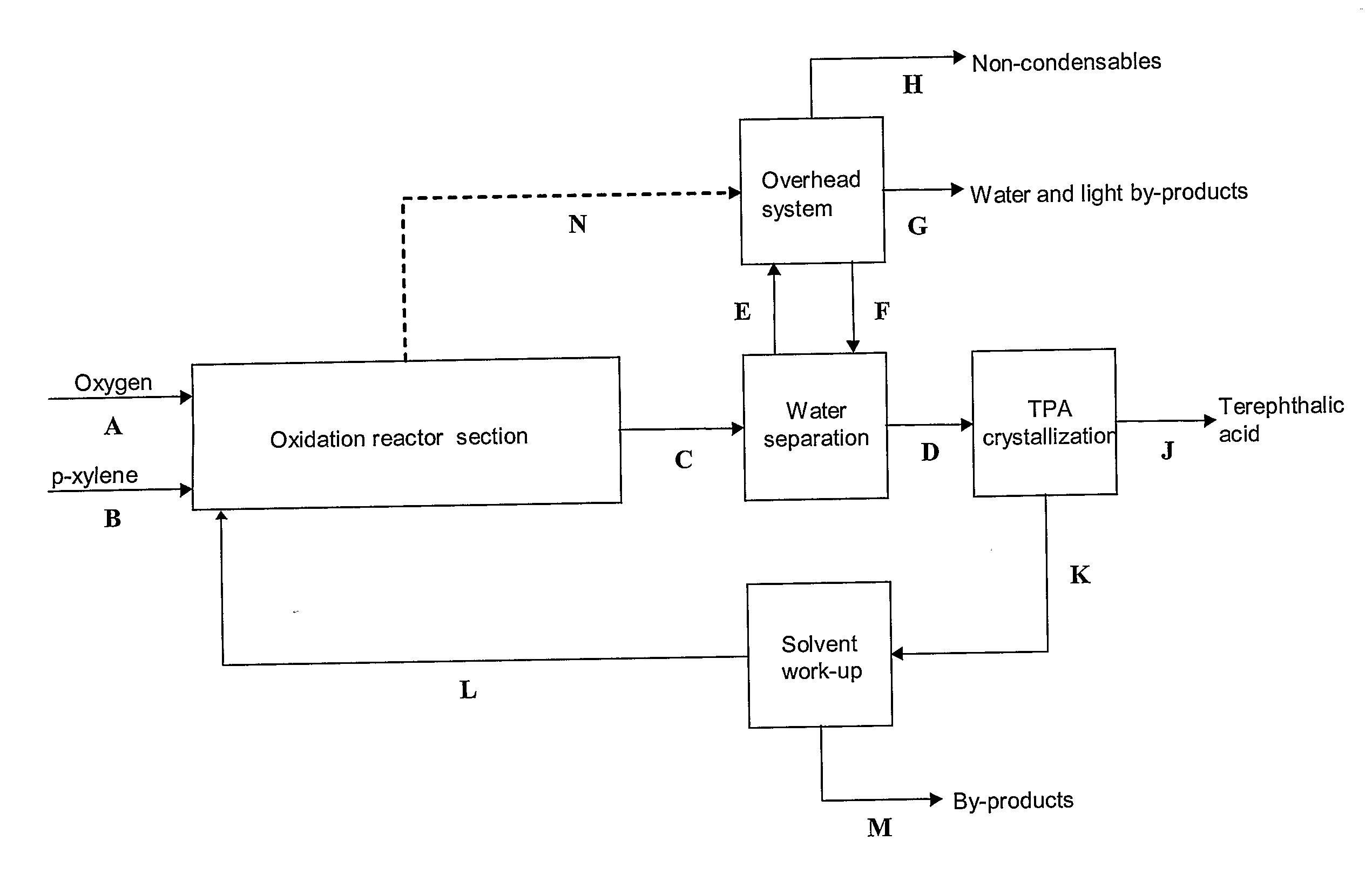

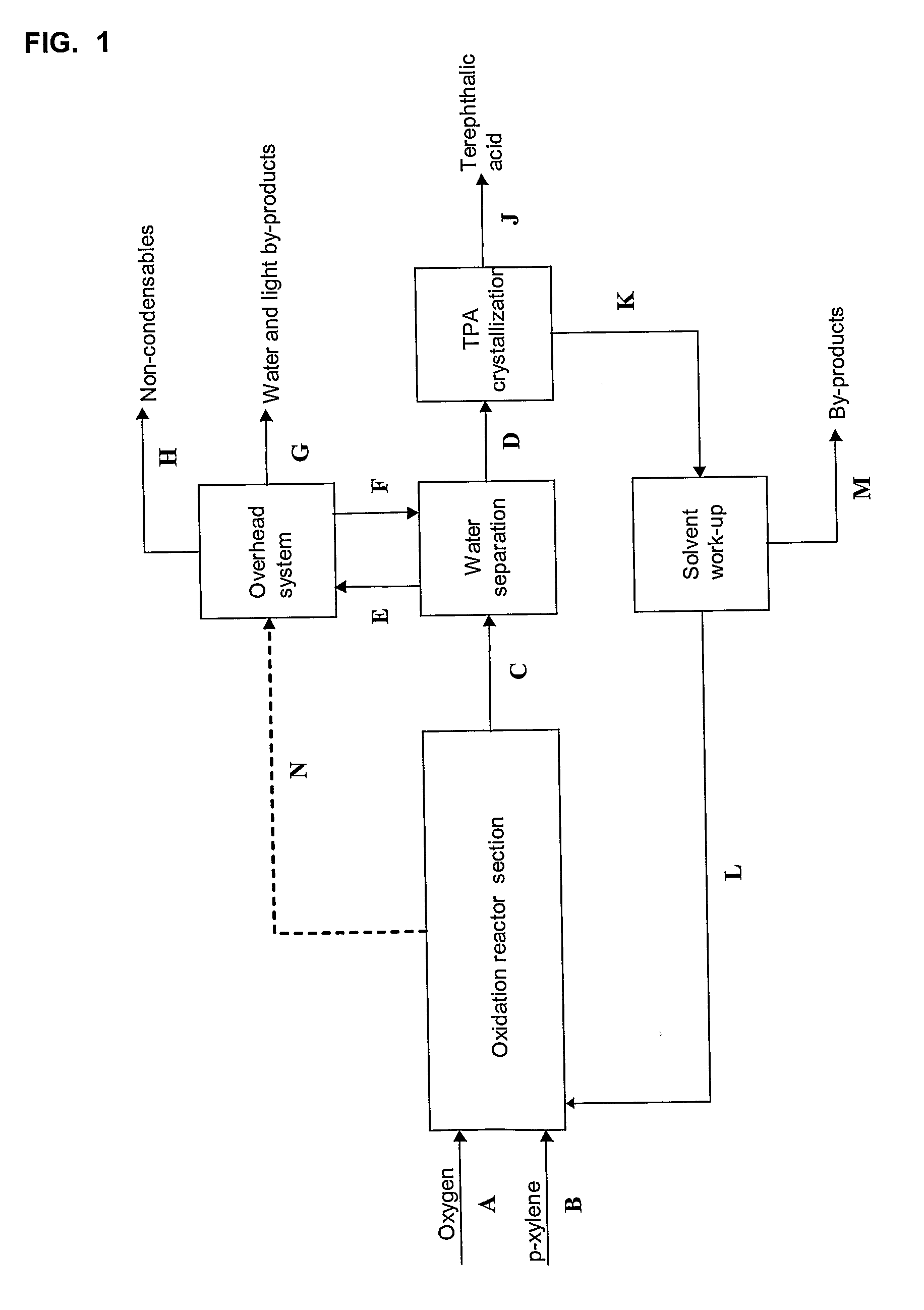

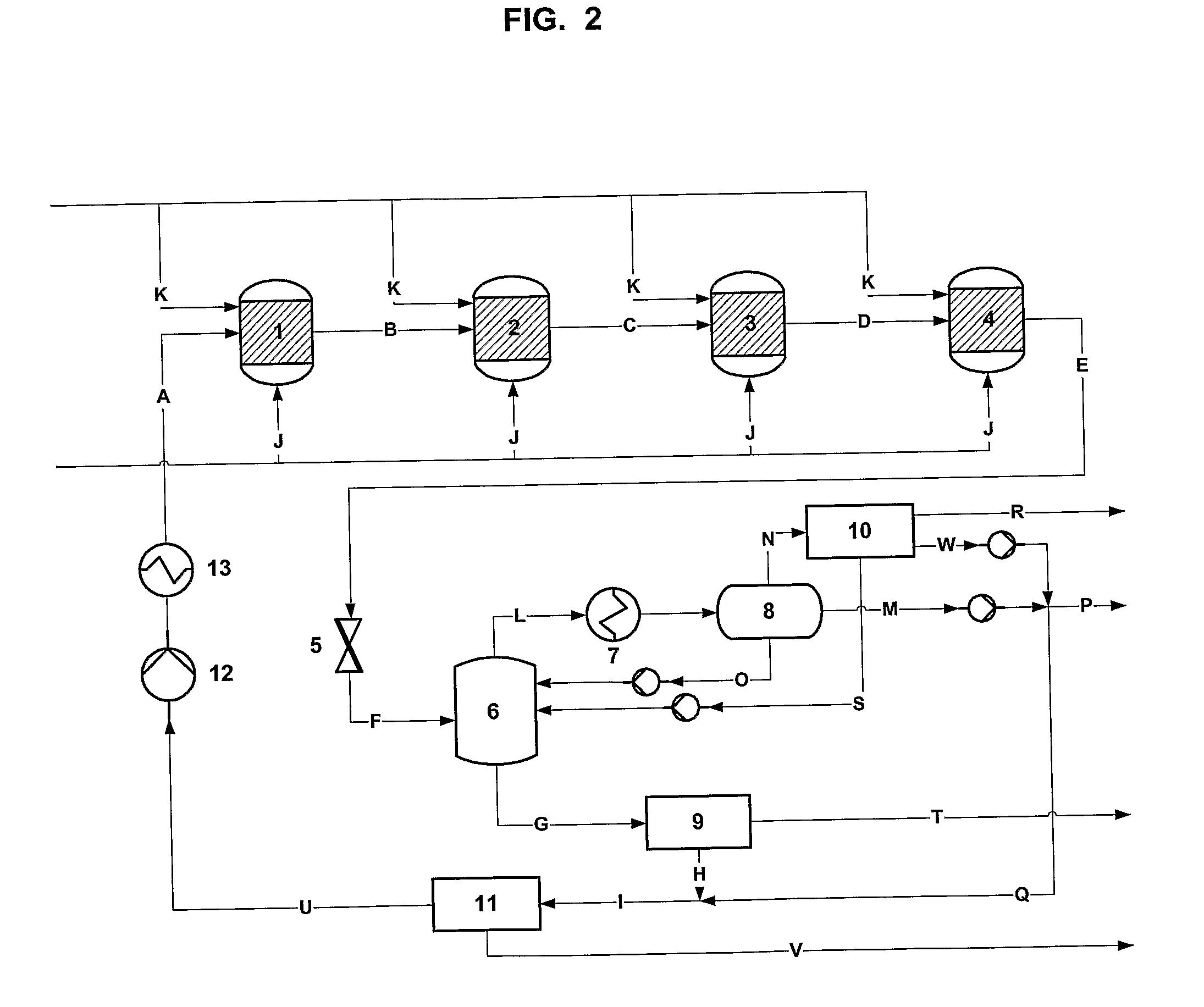

System and method for reduction of water consumption in purified terephthalic acid production

ActiveCN103140266AEasy to installNo capital expenditureOrganic compounds purification/separation/stabilisationExtractive distillationAcetic acidSolvent

The invention disclosed is an apparatus and method for the recovery of acetic acid, azeotropic agent, extraction agent, re -usable water and other reaction products such as p-toluic acid, from an aqueous stream generated during a terephthalic acid production process, having superior energy efficiency and reduced water consumption.; The apparatus of the invention includes: an azeotropic distillation column to remove water from acetic acid, a pair of mother liquor extraction columns sequentially connected in series for primary recovery of extraction solvent and other organics, an azeotropic agent stripper for recovery of azeotropic agent and a post-separation solvent stripper distillation column for further separation of the aqueous bottoms stream from said extraction columns into a volatiles stream comprising mainly organics with a very low amount of water and a liquid stream comprising water containing very low amounts of organics, each stream being sufficiently pure that it can be recycled for reuse in the purification of crude terephthalic acid.

Owner:AMT INT INC

Method for preparing terephthalic acid by oxidation refining process

InactiveCN103012120AReduce contentReduce total usageOrganic compound preparationCarboxylic compound preparationBenzaldehydeCatalytic oxidation

The invention discloses a method for preparing terephthalic acid by an oxidation refining process. Terephthalic acid is prepared by implementing a liquid-phase catalytic oxidation reaction on p-xylene and oxygen in the presence of a catalyst, wherein the oxidation reaction is performed in a plurality of oxidation reaction zones by various steps; in a first oxidation reaction zone, Co-Mn-Ce is taken as a main body, and a catalytic system in which trace amount of bromide is added is applied to the liquid-phase catalytic oxidation; after adding a bromine catalyst to the product, the liquid-phase catalytic oxidation is further implemented in a second oxidation reaction zone; an oxidation product in the second oxidation reaction zone is directly, or after a liquid-solid separation, processed by a liquid-phase catalytic oxidation in a third oxidation reaction zone to purify, and the purified product is extracted to produce the terephthalic acid product. The method disclosed by the invention adopts different catalytic systems through a selectivity, in order to improve the selectivity of the oxidation process, reduce the catalytic combustion loss, and lower contents of p-toluic acid and p-carboxyl benzaldehyde; and meanwhile, the total amount of bromine in the oxidation process is reduced, so that the corrosion of the catalyst on the equipment is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

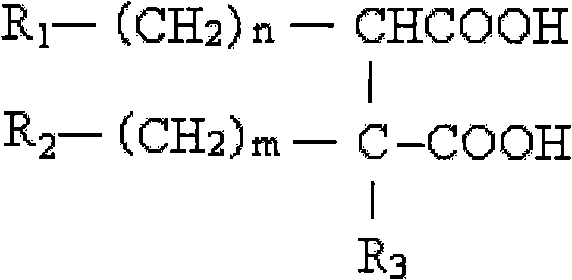

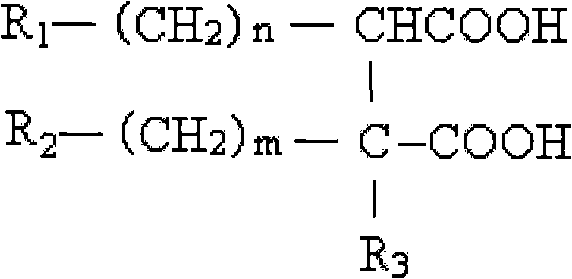

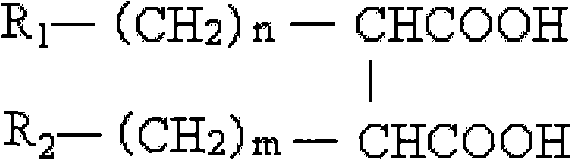

Method for preparing high-activity palladium/carbon catalyst

InactiveCN101637724AOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsDispersityHydrogenation reaction

The invention relates to a method for preparing a high-activity palladium / carbon catalyst and mainly aims to solve the problem that the prepared Pd / C catalyst in the prior art has the drawbacks of lowmetal Pd dispersity, low micro crystal content, poor thermal stability and low 4-carboxybenzaldehyde conversion rate. In the method, active carbon serving as a carrier is impregnated or sprayed witha solution containing Pd to form the palladium / carbon, wherein the solution containing Pd is added with an additive (represented by a formula); and in the formula, n or m is an integer selected from arange from 0 to 5, R1 and R2 may be H, CH3, NH2, OH or COOH, R3 may be H or R4-(CH2)l-CHCOOH, I is an integer selected from a range from 0 to 5, and R4 may be H, CH3, NH2, OH or COOH. Therefore, theproblems can be better solved by the technical scheme. The method can also be applied to the industrialized production of the p-toluic acid catalyst which is prepared by selective hydrogenation of the4-carboxybenzaldehyde.

Owner:CHINA PETROLEUM & CHEM CORP +1

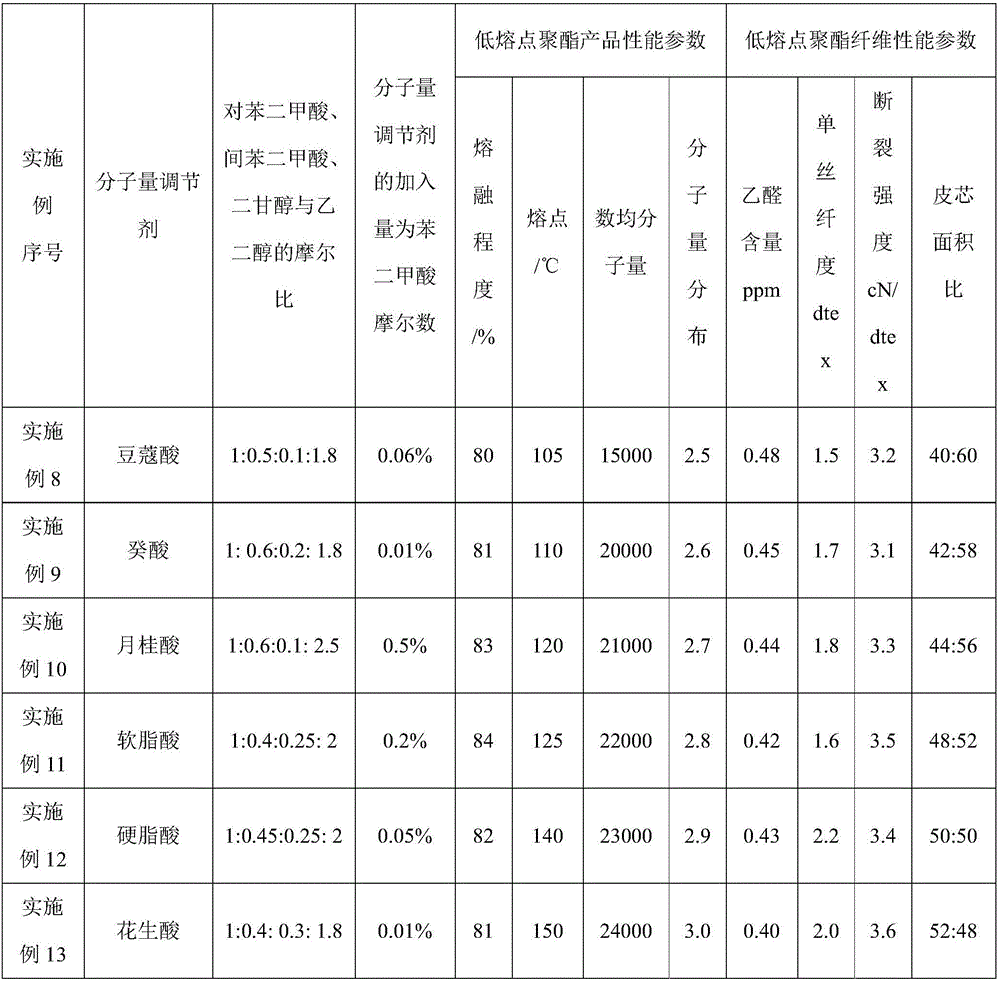

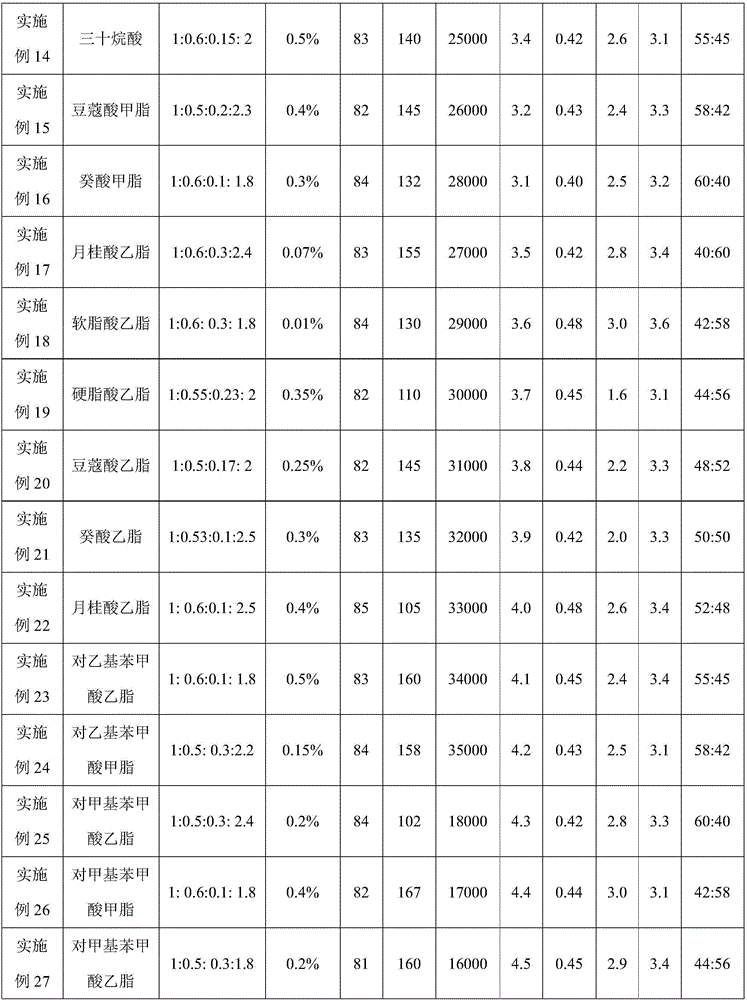

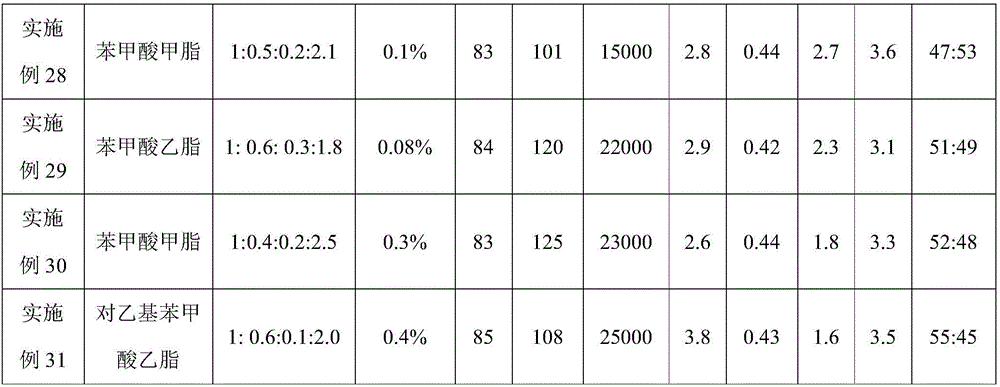

Polyester fiber with low melting point and method for preparing polyester fiber

ActiveCN106757444AIncrease relative volatilityFacilitated DiffusionFilament/thread formingConjugated synthetic polymer artificial filamentsBenzoic acidPolymer science

The invention relates to a polyester fiber with a low melting point and a method for preparing the polyester fiber. The polyester fiber with the low melting point is of a skin-core structure, skin layers are made of polyester with a low melting point, and core layers are made of PET (polyethylene terephthalate); the polyester with the low melting point comprises terephthalic acid chain segments, isophthalic acid chain segments, ethylene glycol chain segments, diethylene glycol chain segments and molecular weight regulator end-capping groups; corresponding molecular weight regulators of the molecular weight regulator end-capping groups particularly comprise benzoic acid, p-toluic acid or ethylbenzoic acid, or methyl ester or ethyl ester corresponding to the benzoic acid, the p-toluic acid or the ethylbenzoic acid, or saturated fatty acid or methyl ester or ethyl ester corresponding to the saturated fatty acid; the content of acetaldehyde in the polyester fiber with the low melting point is lower than 0.5 ppm. The method includes steps of polymerizing the polyester with the low melting point and carrying out composite spinning on skin and cores; carrying out back spinning by the aid of drafting-washing processes; carrying out oil-bath drafting by the aid of added sodium sulfite; carrying out crimping, cutting-off and drying to obtain the polyester fiber with the low melting point. The polyester fiber with the low melting point and the method have the advantages that the polyester fiber prepared by the aid of the method has the low melting point and is low in acetaldehyde content.

Owner:扬州富威尔复合材料有限公司

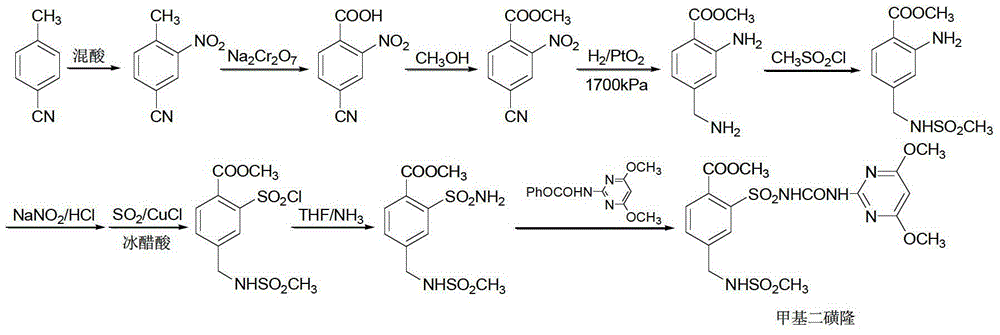

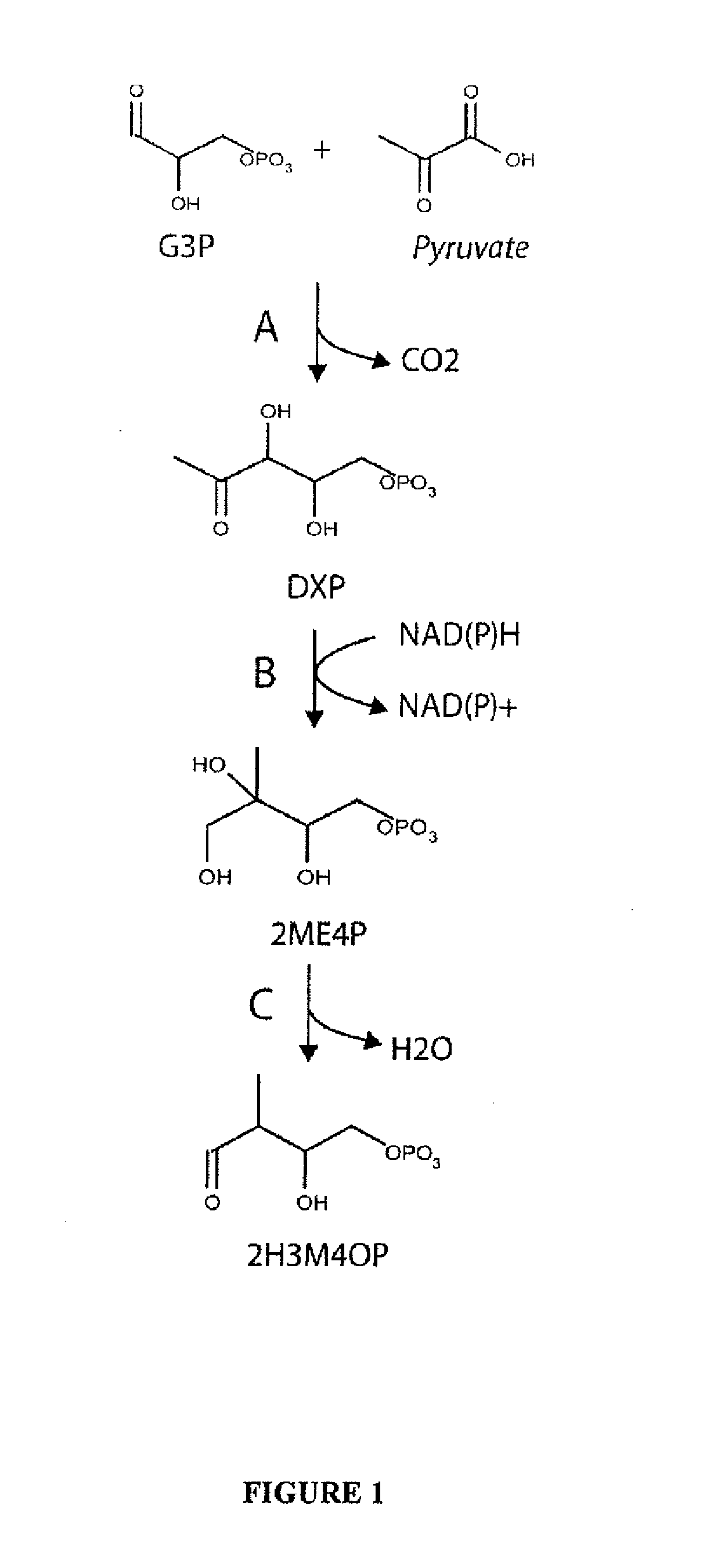

Microorganisms and methods for the biosynthesis of (2-hydroxy-3methyl-4-oxobutoxy) phosphonate

The invention provides non-naturally occurring microbial organisms having a (2-hydroxy-3-methyl-4-oxobutoxy)phosphonate pathway, p-toluate pathway, and / or terephthalate pathway. The invention additionally provides methods of using such organisms to produce (2-hydroxy-3-methyl-4-oxobutoxy)phosphonate pathway, p-toluate pathway or terephthalate pathway.

Owner:GENOMATICA INC

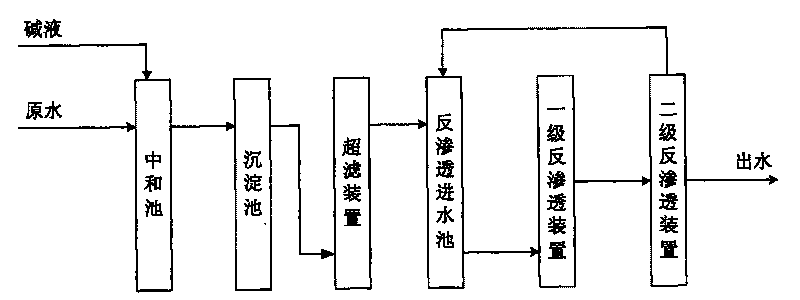

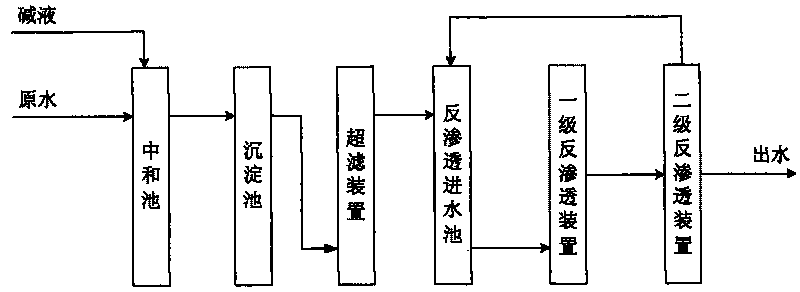

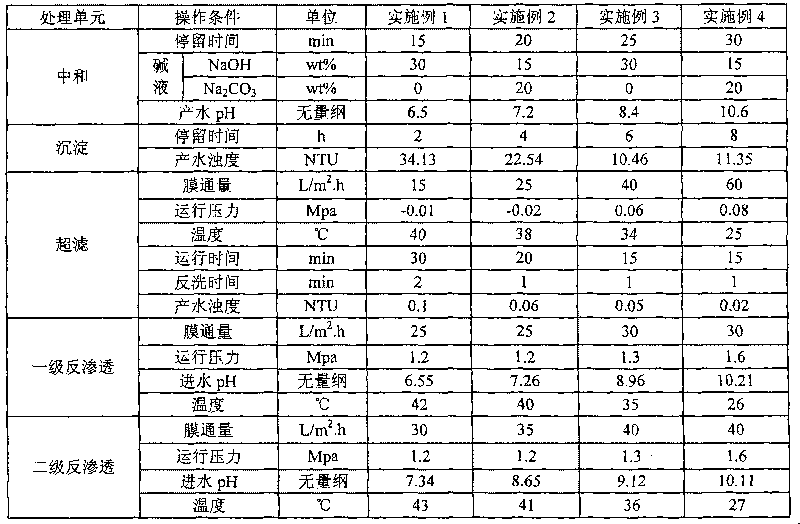

Treatment and reuse method of purified terephthalic acid refining wastewater

ActiveCN101723531AEfficient removalGuaranteed uptimeWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentBenzoic acidWater use

The invention provides a treatment and reuse method of purified terephthalic acid refining wastewater. In the method, neutralization and solid-liquid separation is adopted as pretreatment before film treatment, and a double-film method technology combining ultrafiltration and two-level reverse osmosis is used to conduct film treatment, therefore, suspended matters in wastewater are efficiently removed, the removal rate of metal ions, such as cobalt, manganese and the like, as well as organic substances, such as 4-carboxybenzaldehyde, benzoic acid, p-toluic acid and the like, which are soluble in water, are above 99 percent, the effluent electric conductivity is less than 5muS / cm, and the water using requirement of a production system refining unit is achieved. Because the efficient pretreatment before film treatment technology is adopted, the process of the film treatment can stably run for a long term with reliable treatment effect and low running cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for Preparing Aromatic Carboxylic Acids

InactiveUS20090062563A1Molecular sieve catalystsOrganic compound preparationPresent methodCarboxylic acid

The present invention relates to a process for making terephthalic acid by reacting a starting material and oxygen in the presence of a heterogeneous catalyst and p-xylene as solvent to produce a solution of terephthalic acid (TPA). The starting material is p-xylene, p-toluic acid, 4 carboxybenzaldehyde, or a mixture of any two or more thereof. No solid TPA is formed during the reaction in contrast to previous manufacturing methods that utilize acidic solvents and precipitate TPA as it forms. By avoiding the direct precipitation of TPA during formation, the present methods avoid many shortcomings of the conventional manufacturing methods used to produce TPA. In particular, the present methods do not require additional purification steps to remove reaction byproducts; film grade TPA can be obtained directly from starting material in a one-step process.

Owner:PROCESS DESIGN CENT

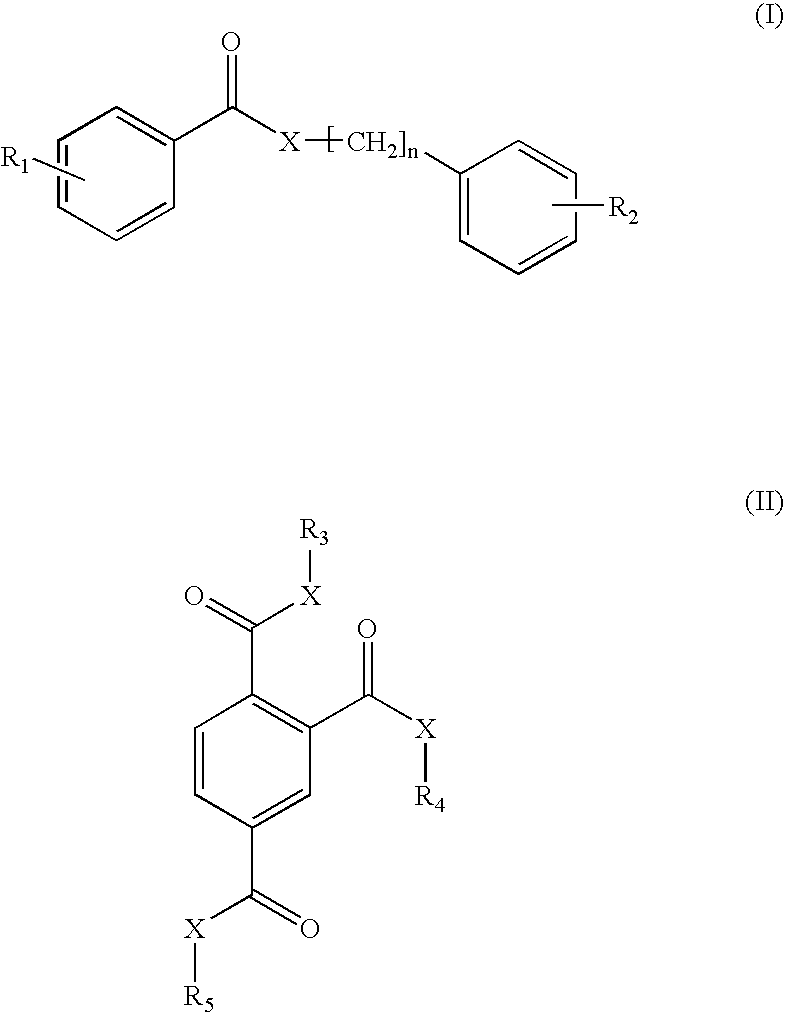

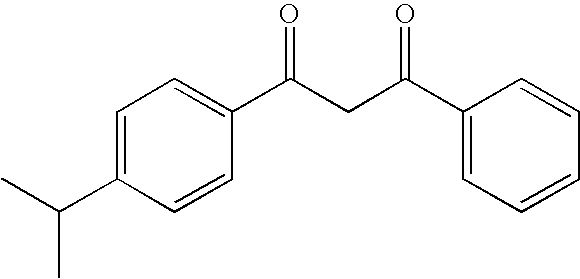

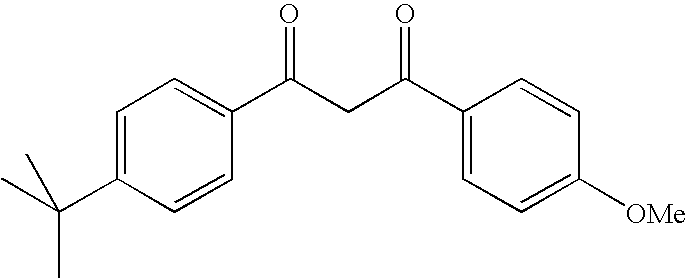

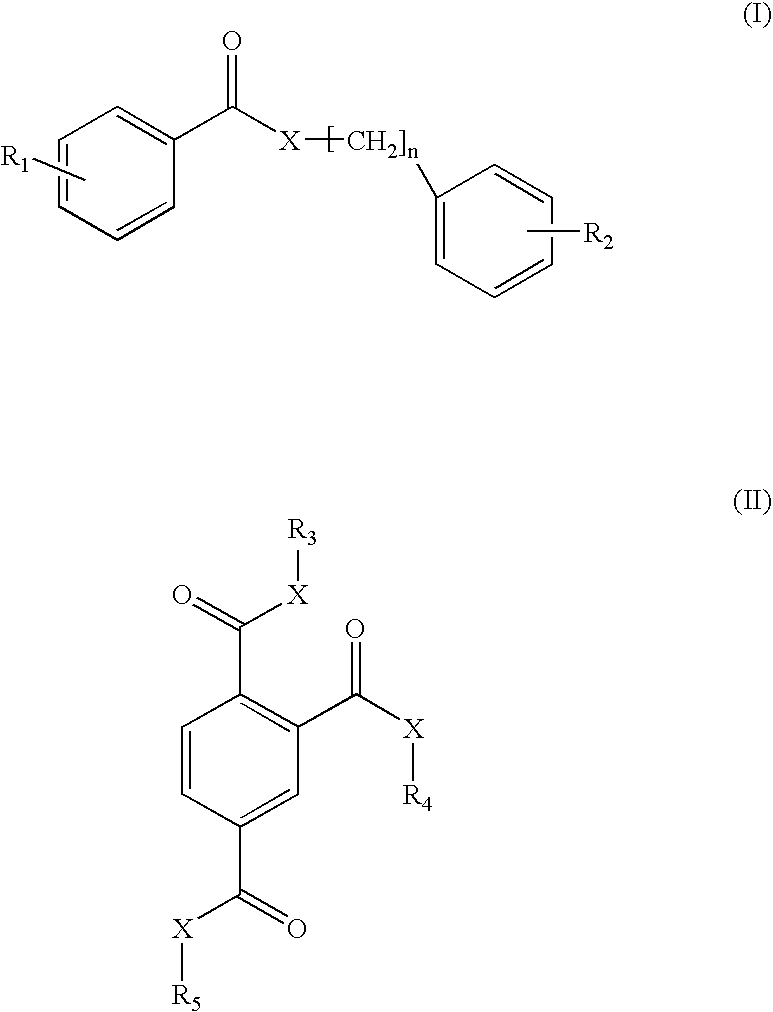

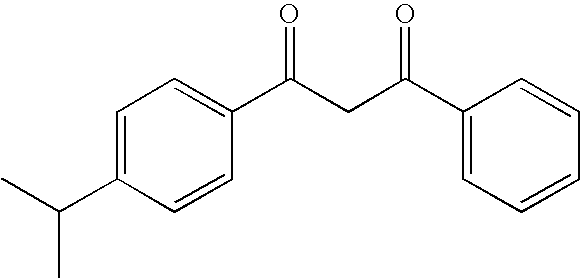

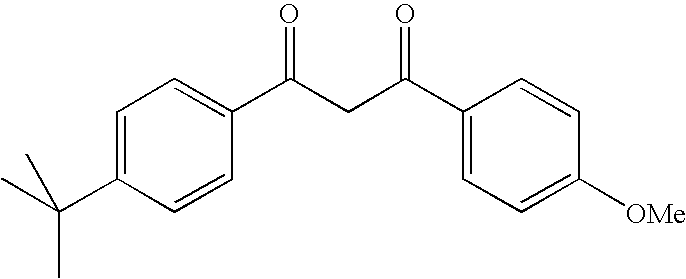

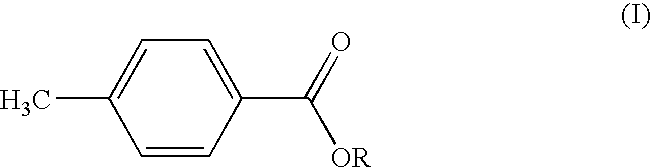

Photostabilization of dibenzoylmethane UV-screening agents with arylalkyl benzoate compounds and photoprotective cosmetic compositions comprised thereof

ActiveUS7364721B2High photochemical stabilityImprove stabilityCosmetic preparationsFluid couplingsBenzoic acidMepenzolate

Topically applicable cosmetic / dermatological photoprotective compositions contain at least one dibenzoylmethane UV-screening agent, and, as a photostabilizer therefor, at least one arylalkyl benzoate compound of formula (I) or (II) below:with the proviso that:(i) the subject compositions are characteristically devoid of any octyl methoxycinnamate; and(ii) same are other than a solution of butyl methoxydibenzoylmethane in 2-phenylethyl benzoate, 2-phenylethyl o-toluate, 2-phenylethyl p-toluate or in a 2-phenylethyl o-toluate / 2-phenylethyl p-toluate (1 / 1) mixture.

Owner:LOREAL SA

Photostabilization of dibenzoylmethane UV-screening agents with arylalkyl benzoate compounds and photoprotective cosmetic compositions comprised thereof

ActiveUS20060008430A1High photochemical stabilityImprove stabilityCosmetic preparationsFluid couplingsCompound (substance)Photochemistry

Topically applicable cosmetic / dermatological photoprotective compositions contain at least one dibenzoylmethane UV-screening agent, and, as a photostabilizer therefor, at least one arylalkyl benzoate compound of formula (I) or (II) below: with the proviso that: (i) the subject compositions are characteristically devoid of any octyl methoxycinnamate; and (ii) same are other than a solution of butyl methoxydibenzoylmethane in 2-phenylethyl benzoate, 2-phenylethyl o-toluate, 2-phenylethyl p-toluate or in a 2-phenylethyl o-toluate / 2-phenylethyl p-toluate (1 / 1) mixture.

Owner:LOREAL SA

MANUFACTURE AND USE OF ALKYL p-TOLUATES

The present invention relates to the manufacture of alkyl p-toluates from an alkyl p-toluic acid ester and a mono-functional, branched, linear or cyclic medium chain length alkyl alcohol, and their use as a plasticizer in polymers. Additionally, the present invention relates to articles and materials comprising such alkyl p-toluates.

Owner:INVISTA NORTH AMERICA R L

Preparation method of (-)-di(p-toluoyl)tartaric acid

InactiveCN101717333ASimple processEfficient processPreparation from carboxylic acid halidesRoom temperatureSolvent

The invention discloses a preparation method of (-)-di(p-toluoyl)tartaric acid. The preparation method comprises the following steps of: adding certain quantity of para-toluylicacid, solvent and catalyst into a flask which is provided with a reflux condenser, simultaneously dropwise adding thionyl chloride; and then adding certain quantity of tartaric acid after heating for reflux for a while; then continuing to heat for reflux for a while; after reaction is finished, cooling to room temperature; adjusting pH value to be neutral by using an alkali solution; after finishing pH adjusting, heating for reflux for a while; after reaction, cooling to below 20 DEG C; filtrating to obtain a crystal; washing twice with a reactive solvent; and baking to obtain the product. The process has the characteristics of simple process, high efficiency, direct product obtaining without treating a semi-finished product, and adaptability to actual production.

Owner:南通欧通置业有限公司

Process for the distillation of crude ester in the DMT/PTA process

InactiveUS6180817B1Organic compound preparationCarboxylic acid esters separation/purificationDimethyl terephthalateDistillation

A process for preparing crude dimethyl terephthalate, comprises oxidizing a mixture comprising para-xylene and methyl para-toluate, esterifying the oxidized mixture with methanol, separating the resulting crude ester into fractions. By separating the crude ester with a distillation column containing structured packing and using a lower bottom temperature, product yield is increased, and the process is made more economical.

Owner:DEGUSSA AG

Microorganisms and methods for the biosynthesis of aromatics, 2,4-pentadienoate and 1,3-butadiene

Owner:GENOMATICA INC

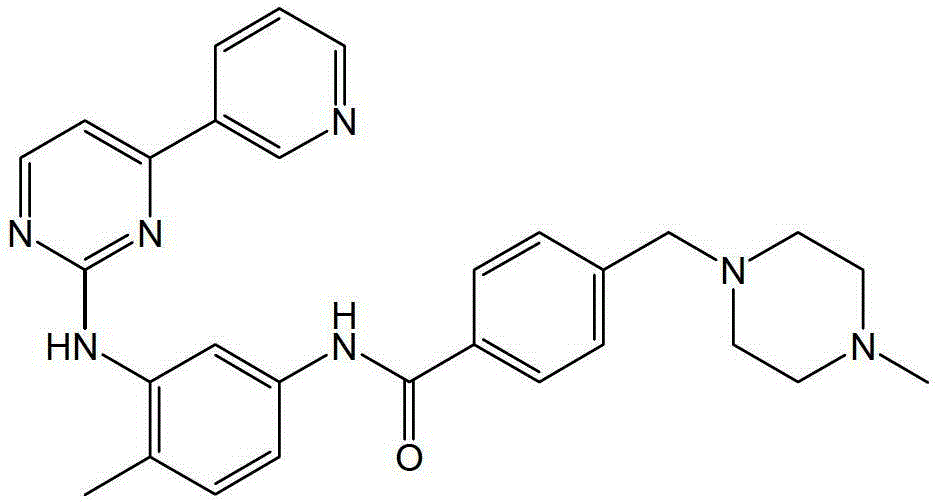

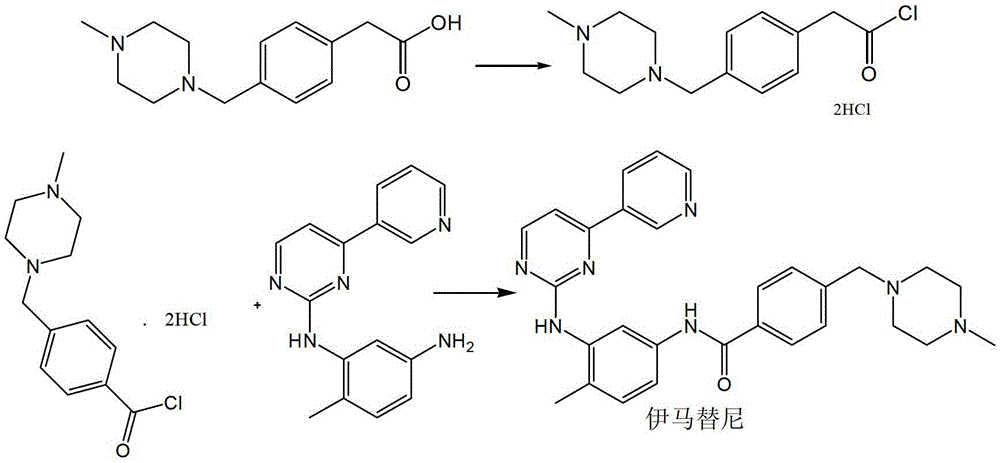

Preparation method of imatinib

ActiveCN103145693AThe reaction steps are simpleRaw materials are easy to getOrganic chemistryOrganic solventImatinib

The invention relates to a preparation method of imatinib. The preparation method provided by the invention has simple steps and can be used for preparing imatinib in two steps. The preparation method comprises the following steps: A, reacting p-Toluic acid serving as a raw material with halogenated phthalate esters or acyl chlorides in an organic solvent under catalytic action of alkali at -30 DEG C to 100 DEG C to obtain mixed anhydride; B, condensing the mixed anhydride and N-(5-Amino-2-methylphenyl)-4-(3-pyridyl)-2-pyrimidineamine under the action of alkali to obtain amide, and then further reacting amide with N-methyl piperazine to obtain imatinib. The method disclosed by the invention has the advantages that the reaction steps are simplified and only two reaction steps are needed; and the raw material is easily available, the operation is simple, the cost is low, the product yield is high and the product quality is good; therefore, the method is suitable for large-scale production.

Owner:CHENGDU BAIYU PHARMA CO LTD

Preparation method of novel fluorescent PVC wire/cable shield material

ActiveCN104774403AStrong fluorescenceExcellent fluorescence performanceInsulated cablesMonocomponent synthetic polymer artificial filamentFluorescenceAntioxidant

The invention provides a preparation method of a novel fluorescent PVC wire / cable shield material. The preparation method comprises the following steps: (1) heating and stirring a terbium chloride solution and a phenanthroline solution together, adding a p-toluic acid solution, further stirring, standing, filtering, washing, and drying to obtain white powder; dissolving the white powder in dimethyl fumarate, adding distilled water to form a suspension, then adding sodium chloride and stearic acid, stirring, taking out, filtering and drying to obtain fluorescent powder; (2) adding ACR to the fluorescent power, stirring and mixing, extruding, melt spinning to obtain fluorescent fibers; (3) adding PVC, nano-montmorillonite, a heat stabilizer, a plasticizer, calcium carbonate, a coupling agent and an antioxidant together into a high speed stirrer for stirring to obtain a mixed material; and (4) dissolving the mixed material into a solvent, adding the fluorescent fibers, uniformly stirring to obtain a prepreg, drying, transferring to a die, heating, pressurizing and insulating heat, and naturally cooling to room temperature to obtain the fluorescent PVC wire / cable shield material. The shield material prepared by the preparation method provided by the invention has a relatively good fluorescent performance.

Owner:SHAOGUAN YINGTIAN ENVIRONMENT FRIENDLY MATERIAL CO LTD

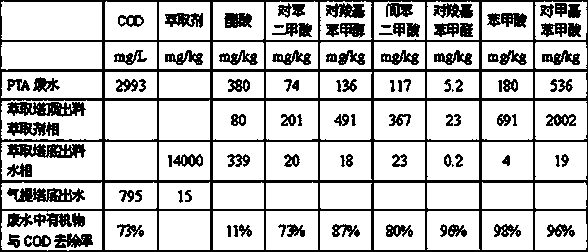

Extraction method for reducing emission of chemical oxygen demand (COD) in pure terephthalic acid (PTA) wastewater

ActiveCN102910761BAchieve emission reductionReduce COD concentrationOrganic compound preparationMultistage water/sewage treatmentBenzoic acidResource utilization

Owner:浙江化安安全技术研究院有限公司

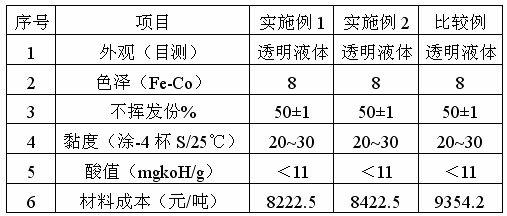

Method for preparing modified alkyd resin

InactiveCN102504221AShort reaction temperatureShorten the production cyclePolyester coatingsThermal insulationAcid value

The invention adopts the technical scheme that a method for preparing modified alkyd resin comprises the special steps as follows: (1) mixing 23 to 37 percent by weight of ricinoleic acid, 21 to 29 percent by weight of glycerin, 29 to 31percent by weight of phthalic anhydride, 10 to 18 percent by weight of crude p-toluic acid and adding the mixed liquor into a reaction vessel; and (2) adding xylene and hypophosphorous accounting for 0.06 to 0.1 percent by weight of the mixed liquor obtained from the step (1) into the reaction vessel, increasing the temperature to 190 to 201 DEG C for thermal insulation and esterification, and cooling and diluting as long as the acid value is below 21.5 mgKOH / g in esterification. In the invention, the cost is low; and polyurethane varnish made of alkyd resin prepared through the invention can reach requirements of various properties.

Owner:江苏三木化工股份有限公司

Recycling method of 2-(4-methyl phenyl)-benzoxazole synthetic process wastewater

ActiveCN105417774AEconomical and efficient recyclingNo secondary environmental pollutionOrganic compound preparationMultistage water/sewage treatmentBenzoxazoleFiltration

The invention relates to a recycling and treating method of p-toluic acid and ortho-aminophenol in wastewater of a process for synthesizing 2-(4-methyl phenyl)-benzoxazole by taking the p-toluic acid and the ortho-aminophenol as raw materials. The method is characterized by comprising the steps that p-toluic acid precipitates are firstly precipitated out through acidification, and the p-toluic acid is recycled through filtration; filtrate is treated with a reducing agent, the pH value of the filtrate is regulated to be alkali, adsorption is performed with adsorbent resin, elution and analysis are performed, the pH of eluant is regulated to 8.5-9, concentrating and temperature lowering are performed to precipitate phenol out, and filtration is performed to obtain the ortho-aminophenol. According to the method, the p-toluic acid and the ortho-aminophenol in the process wastewater can be economically and effectively recycled, the purity of the p-toluic acid and the purity of the ortho-aminophenol can reach 94.5% or above and 95.8% or above respectively, and the p-toluic acid and the ortho-aminophenol can directly serve as the raw materials to be put and used over and over again in a condensation reaction; organic solvent is not related and used in the treatment process, secondary environmental pollution is not generated, cleanliness and environmental protection are achieved.

Owner:HUBEI HONGXIN CHEM CO LTD

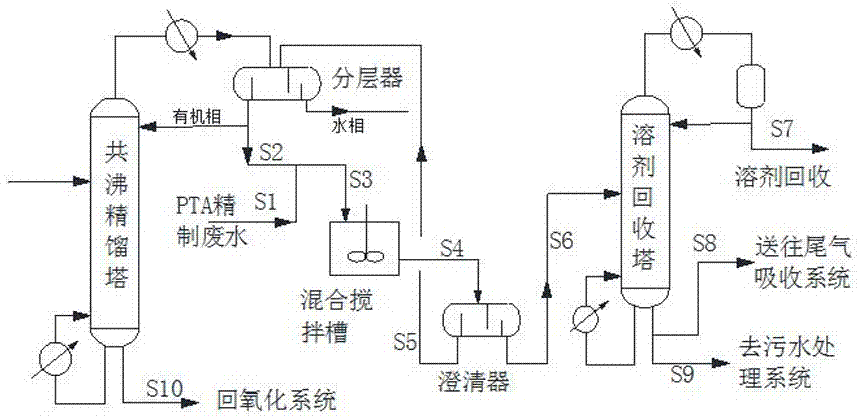

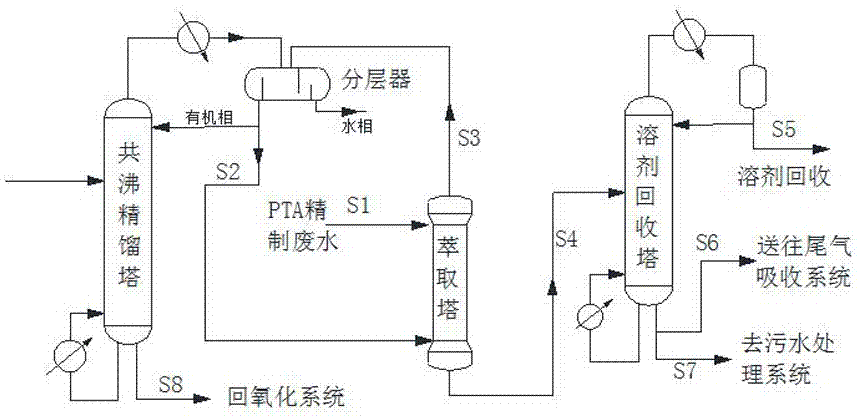

Combined process for recycling organisms in PTA (Purified Terephthalic acid) refining waste water

InactiveCN106866412AAffect qualityEasy extractionNature of treatment waterWater/sewage treatment by heatingBenzoic acidAcetic acid

The invention discloses a combined process for recycling organisms in PTA (Purified Terephthalic acid) refining waste water. The combined process combines an existing azeotropic rectification system in a PTA system with an extraction process. Firstly, by using a water-carrying agent in an acetic acid azeotropic rectification system as an extraction agent for the PTA refining waste water, the organisms (organic carboxylic acids such as a benzoic acid, a p-toluic acid, a terephthalic acid and the like) in the waste water are extracted out. An extraction phase containing the organic carboxylic acid is returned to an azeotropic rectification column, then the organic carboxylic acids are produced from a column reactor of the azeotropic rectification column and are returned to a PTA oxidative system together with acetic acid. A raffinate phase is sent to a solvent recovery tower, and an organic solvent is produced from a tower top so as to implement recover of the organic solvent in the waste water. One part of waste water produced from a column reactor of a solvent recovery tower is sent to a tail gas absorption system of the PTA oxidative system to be used as an absorbent, and the other part of the waste water is sent to a sewage treatment system. The combined process is simple in flow, implements recycling of the organic carboxylic acid and partial recycling of water in the PTA refining waste water, and is low in cost.

Owner:FUZHOU UNIV

Process of producing high purity terephthalic acid

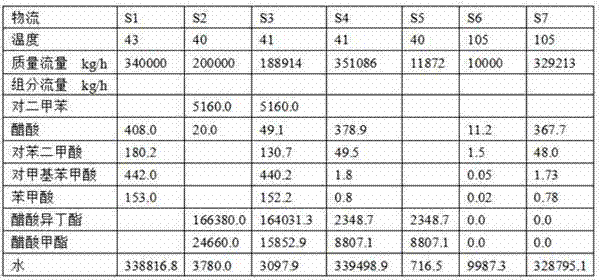

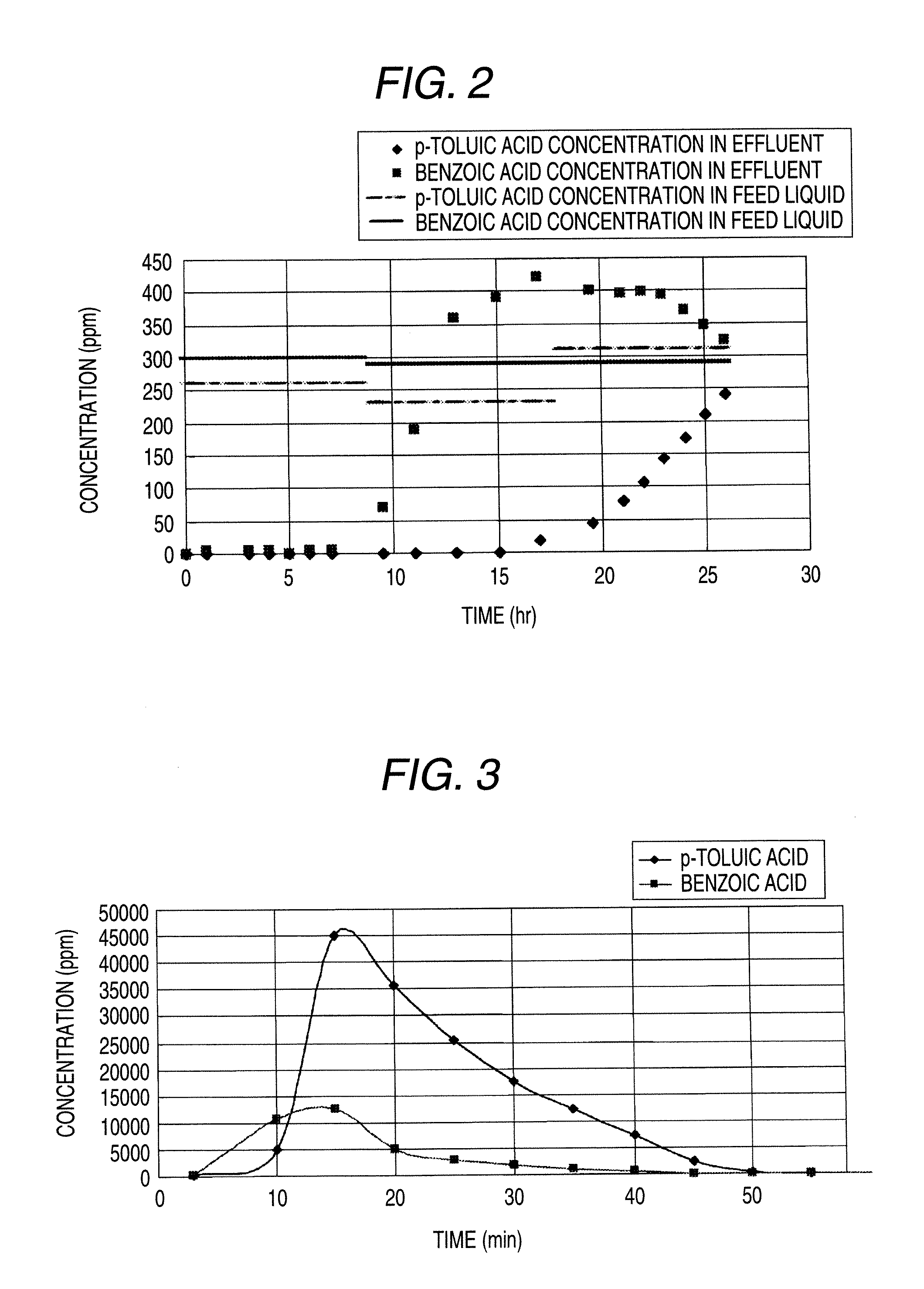

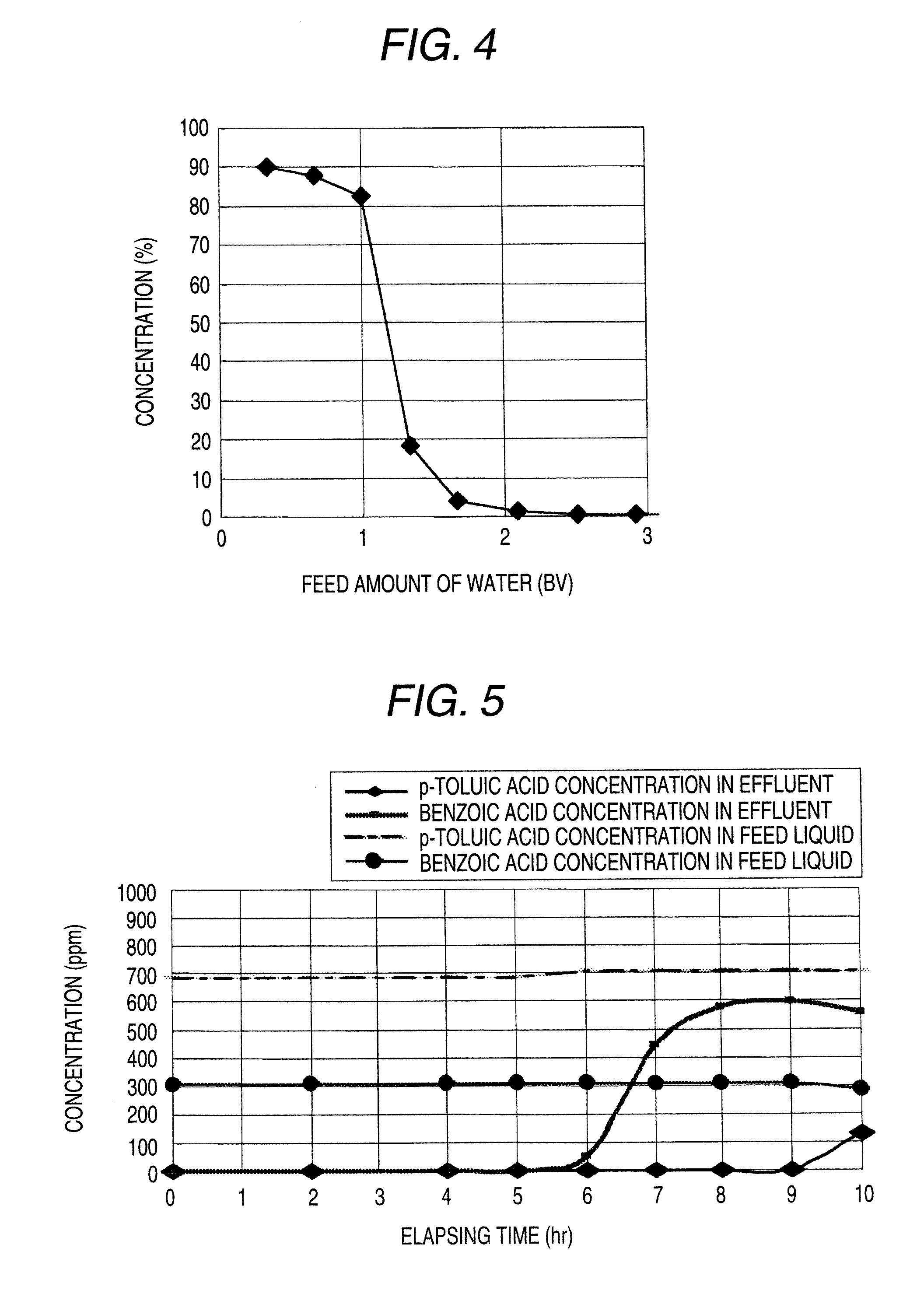

InactiveUS20090018361A1Increase productionLow costOrganic compound preparationCarboxylic preparation by oxidationBenzoic acidBreakthrough time

A problem of the invention is to provide a process of producing high purity terephthalic acid by selectively recovering p-toluic acid in wastewater which has hitherto been discarded and using it as a raw material of terephthalic acid.The invention is concerned with a process of producing high purity terephthalic acid, which is characterized in that a p-toluic acid recovery step of recovering p-toluic acid from a primary mother liquor and feeding it into an oxidation reaction step includes the following respective steps of: (I) an adsorption step of feeding, as a liquid to be treated, the primary mother liquor or a secondary mother liquor obtained by subjecting the primary mother liquor as cooled to solid-liquid separation into an adsorption tower filled with an adsorbing agent in which the breakthrough time of p-toluic acid is longer than the breakthrough time of benzoic acid to adsorb p-toluic acid and benzoic acid in the liquid to be treated to the adsorbing agent, (II) a feed stopping step of stopping the feed of the liquid to be treated into the adsorption tower at an arbitrary point of time of exceeding the breakthrough time of benzoic acid, (III) a desorption step of feeding a desorbing agent into the adsorption tower to desorb adsorbed p-toluic acid, and (IV) a circulation step of feeding p-toluic acid contained in the desorbing agent flown out from the adsorption tower into the oxidation reaction step.

Owner:MITSUBISHI CHEM CORP

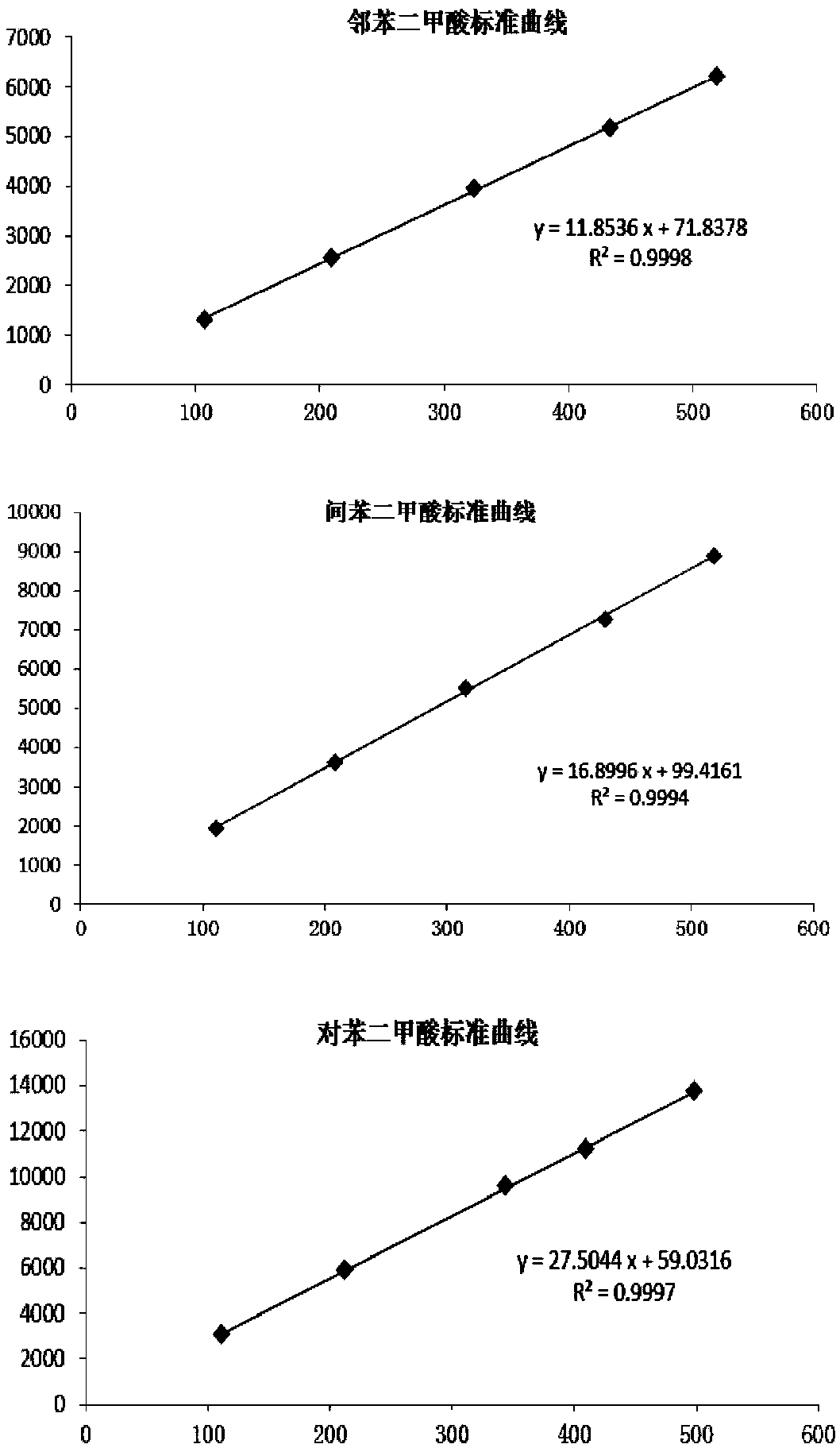

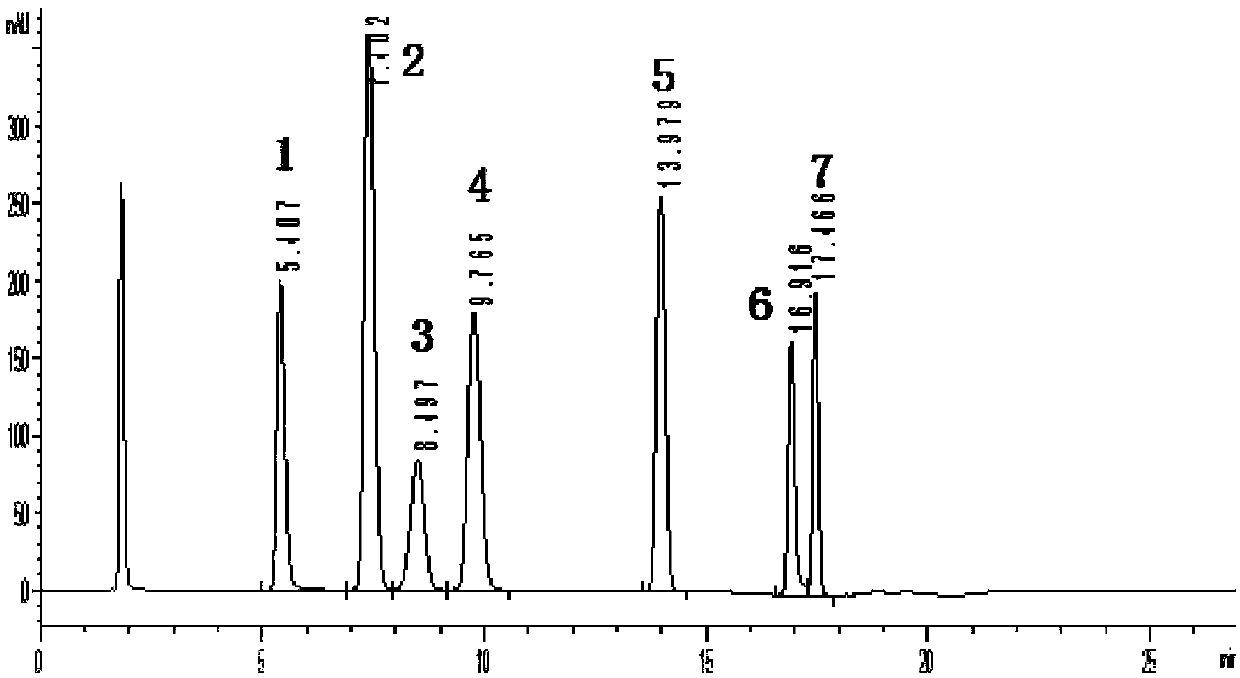

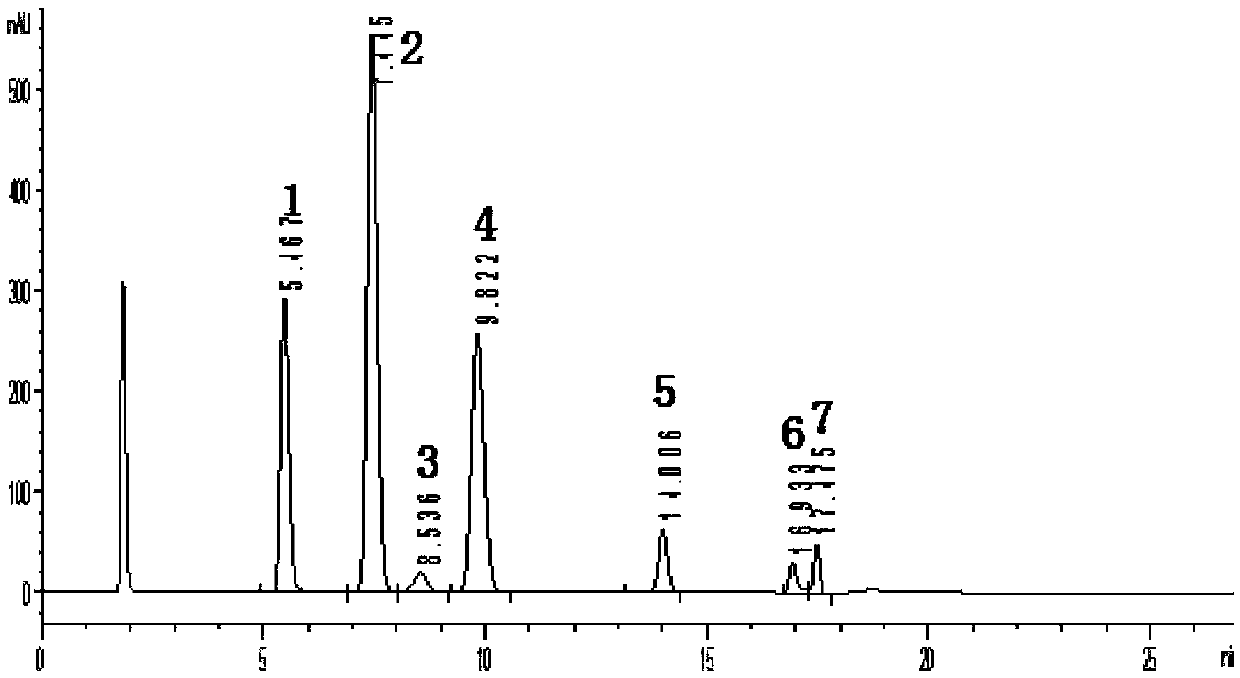

Method for measuring content of dimethylbenzene oxidation products by using HPLC external standard method

InactiveCN107907615AEfficient separationShort analysis timeComponent separationBenzoic acidUv vis absorbance

The invention discloses a method for measuring content of dimethylbenzene oxidation products by using an HPLC external standard method. According to the method, a high performance reversed-phase liquid chromatograph instrument is adopted, a C18 silica gel chromatographic column is taken as a separation column, an ultraviolet visible absorption detector is adopted, methanol and an acid aqueous solution are taken as mobile phases, phthalate, isophthalic acid and terephthalic acid are taken as standard samples, a concentration-peak area standard curve of a target component is drawn by using the external standard method so as to obtain a linear regression equation, and contents of the phthalate, isophthalic acid and terephthalic acid are calculated by using the regression equation. Through adoption of the method, three main products with similar polarity and four byproducts including 3-formylbenzoic acid, benzoic acid, paratoluic acid and p-tolualdehyde can be separated effectively, and the method takes short time in analysis, is easy and feasible, and is convenient and reliable.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

Process for producing high-purity terephthalic acid

ActiveCN1692093AExtend your lifeOrganic compound preparationCarboxylic compound separation/purificationHydrogenChemistry

The life of a reduction catalyst to be used in a reduction step where 4CBA is reduced with hydrogen to p-toluic acid is prolonged. The process for producing high-purity terephthalic acid is characterized in that, in the reduction step, the ratio of the amount of hydrogen to be fed to a hydrogenation reactor to the amount of 4CBA in a solution thereof to be fed to the reactor, hydrogen / 4CBA, is from 2 to 10 (by mole) and that the ratio of the amount of crude terephthalic acid to be treated in the reduction step to the amount of the reduction catalyst present in the hydrogenation reactor, [amount of terephthalic acid being treated (t / h)] / [amount of reduction catalyst (t)], is from 400 to 5,000 (1 / h).

Owner:MITSUBISHI RAYON CO LTD

Carbon nano-polytetrafluoroethylene valve seal ring filled with ceramic sol

InactiveCN106084583AGood resistance to extrusion deformationImprove wear resistanceAcetic anhydrideBarium strontium titanate

The invention discloses a carbon nano-polytetrafluoroethylene valve seal ring filled with ceramic sol. The seal ring is prepared from, by weight, 100 parts of polytetrafluoroethylene, 5-8 parts of carbon nanotubes, 8-10 parts of phenol, 8-10 parts of p-toluic acid, 1-2 parts of bentonite, 1-2 parts of barium strontium titanate, 5-8 parts of diphenyl ether, 1-3 parts of butyl titanate, 20-25 parts of sodium hypochlorite with the concentration of 60%-70%, 20-25 parts of EDTA, 40-50 parts of ammonia water, 80-100 parts of absolute ethyl alcohol, 3-4 parts of deionized water, 10-20 parts of glacial acetic acid, 30-40 parts of ethylene glycol monomethyl ether, 8-10 parts of a dehydrating agent acetic anhydride, 3-4 parts of polyvinyl alcohol, 3-5 parts of barium sulfate, 1-2 parts of molybdenum disulfide, 1-3 parts of a silane coupling agent kh550, 9-10 parts of ammonium chloride, 30-35 parts of urea and 30-35 parts of water. The seal ring is resistant to aging and abrasion and long in service life.

Owner:ANHUI RONGDA VALVE

Method for recycling mother solid in PTA-refining wastewater

ActiveCN101941901BAvoid wastingSolve easy blockageMultistage water/sewage treatmentCarboxylic compound separation/purificationRecovery methodSingle stage

The invention discloses a method for recycling mother solid in PTA-refining wastewater, comprises the following steps: mixing PTA-refining wastewater and paraxylene in a prepositioned mixing tank, carrying out single-stage extraction and cooling on the wastewater, dissolving and extracting the solid in mother liquor into a PX phase, returning the extract phase PX discharged from a clarification tank to an oxidizing reaction system, and delivering the wastewater to an extraction tower to be subject to multistage countercurrent extraction; delivering the wastewater discharged from the bottom ofthe extraction tower to be subject to further treatment; and returning the extraction phase discharged from the top of the extraction tower to serve as extract liquor for single-stage extraction. By adopting the method in the invention, most of organic matters, such as p-toluic acid, terephthalic acid and the like in the wastewater can be recycled, thus the purpose of recycling wastes is achieved, and wasting of resources is avoided; and the invention omits the conventional filtering unit, saves the filter cloth-replacing cost, ensures that the extraction tower can operate at appropriate operating temperature, and has the advantages of investment saving, low energy consumption, high resource recovery rate and the like.

Owner:FUZHOU UNIV

Microorganisms and processes for producing terephthalic acid and its salts

InactiveUS20150080547A1Reduced pHBacteriaGroup 5/15 element organic compoundsMicroorganismCarboxylic acid

The invention provides non-naturally occurring microbial organisms having a (2-hydroxy-3-methyl-4-oxobutoxy) phosphonate (2H3M40P) pathway, p-toluate pathway, and / or terephthalate pathway. The invention additionally provides methods of using such organisms to produce 2H3M40P, p-toluate or terephthalate. Also provided herein are processes for isolating bio-based aromatic carboxylic acid, in particular, p-toluic acid or terephthalic acid, from a culture medium, wherein the processes involve contacting the culture medium with sufficient carbon dioxide (C02) to lower the pH of the culture medium to produce a precipitate comprised of the aromatic carboxylic acid.

Owner:GENOMATICA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com