Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Short reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery negative material, preparation method thereof and lithium ion battery

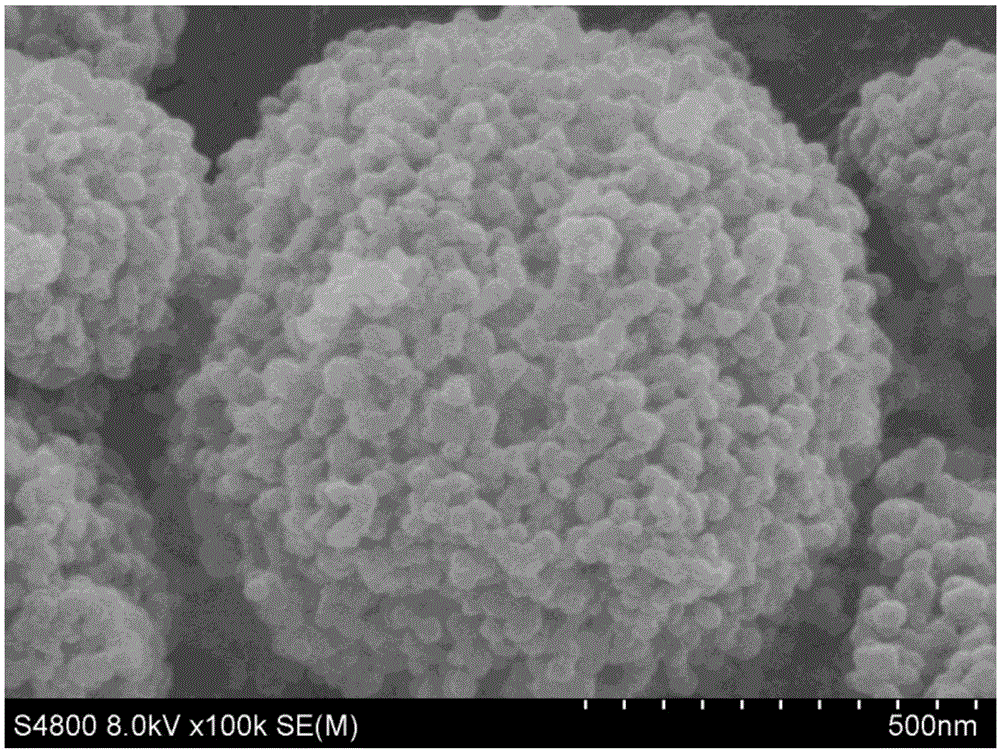

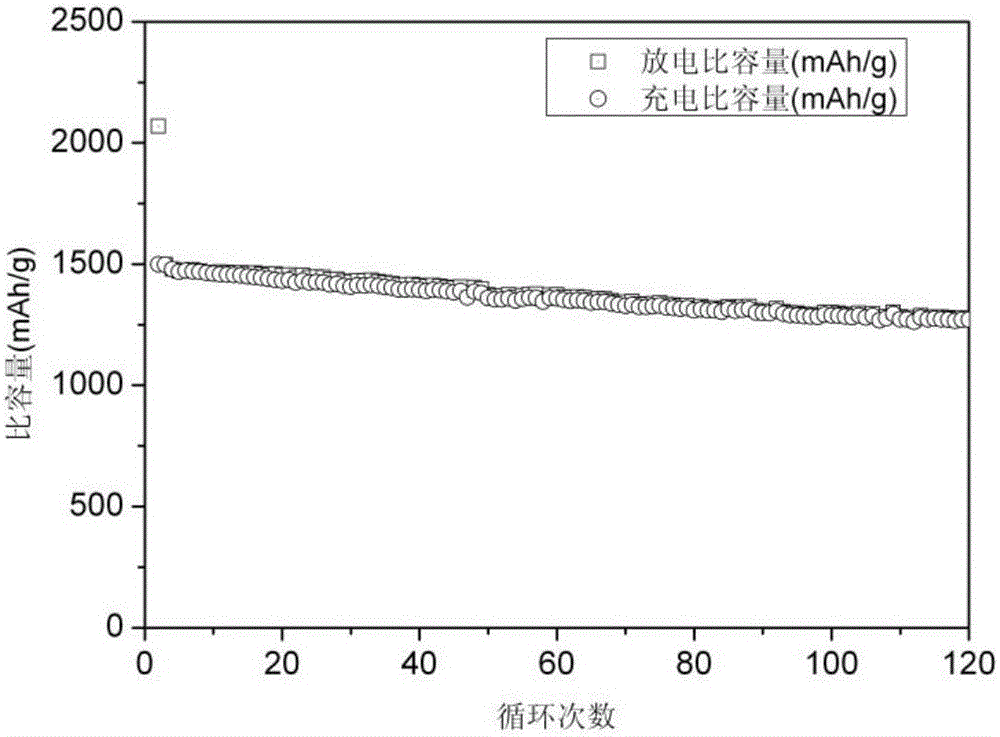

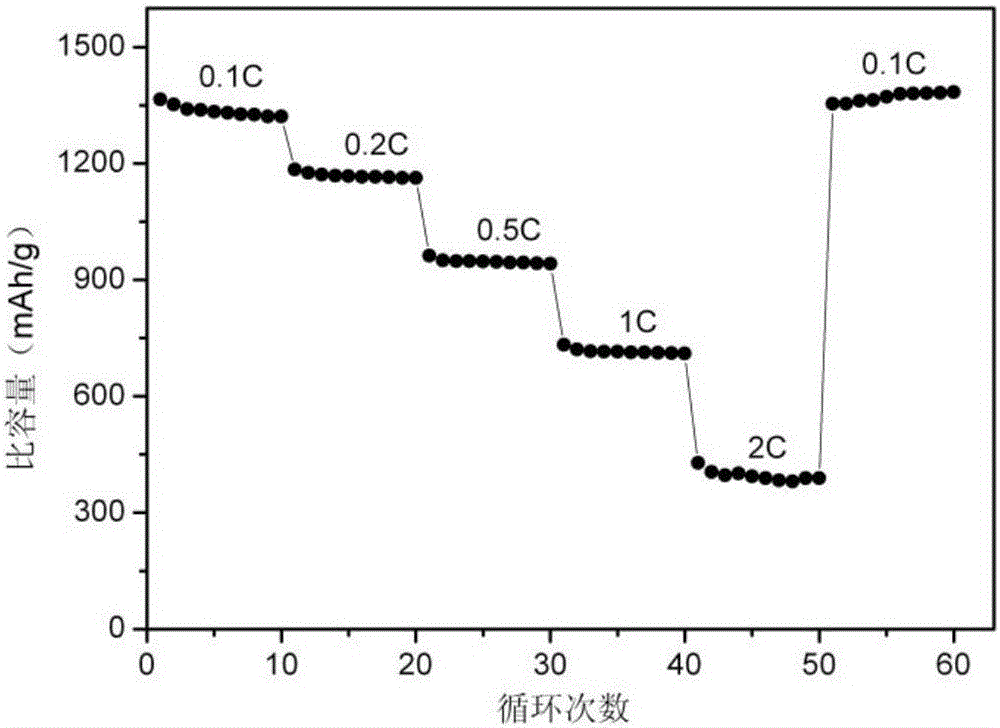

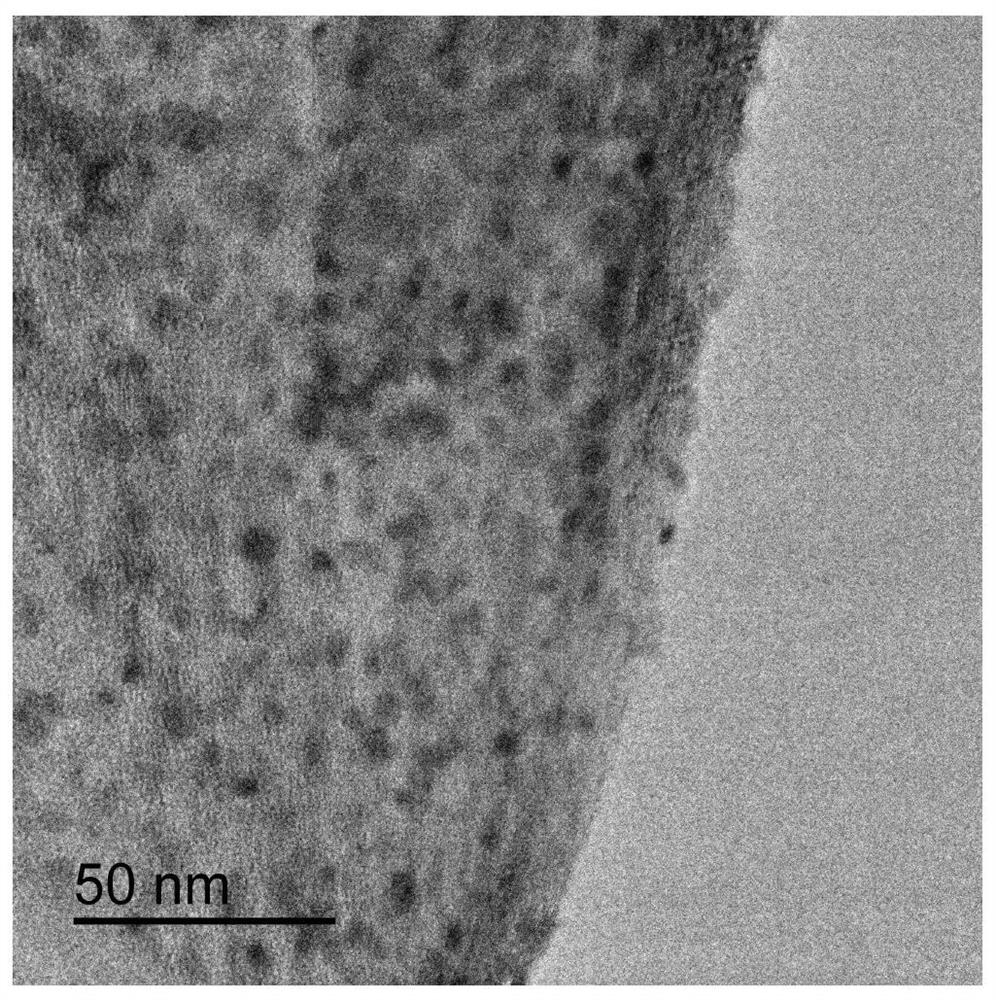

ActiveCN105742611AImprove electrochemical cycle performanceImproved magnification performanceCell electrodesSecondary cellsCarbon compositesMicrosphere

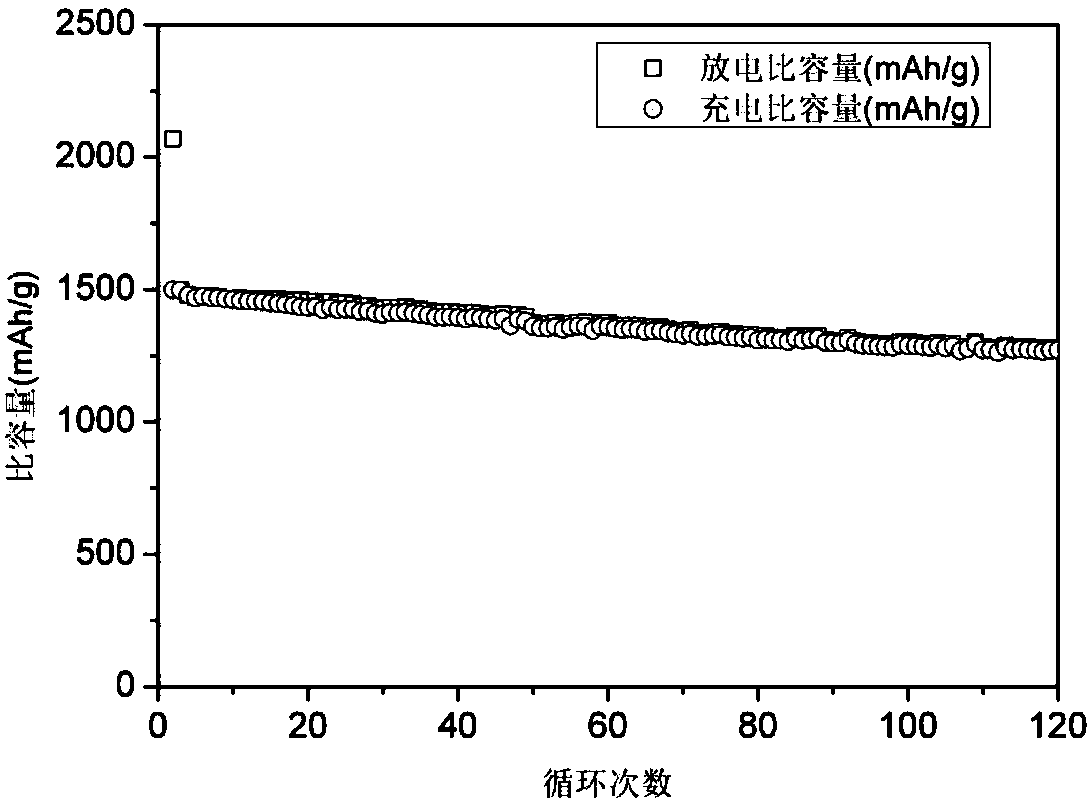

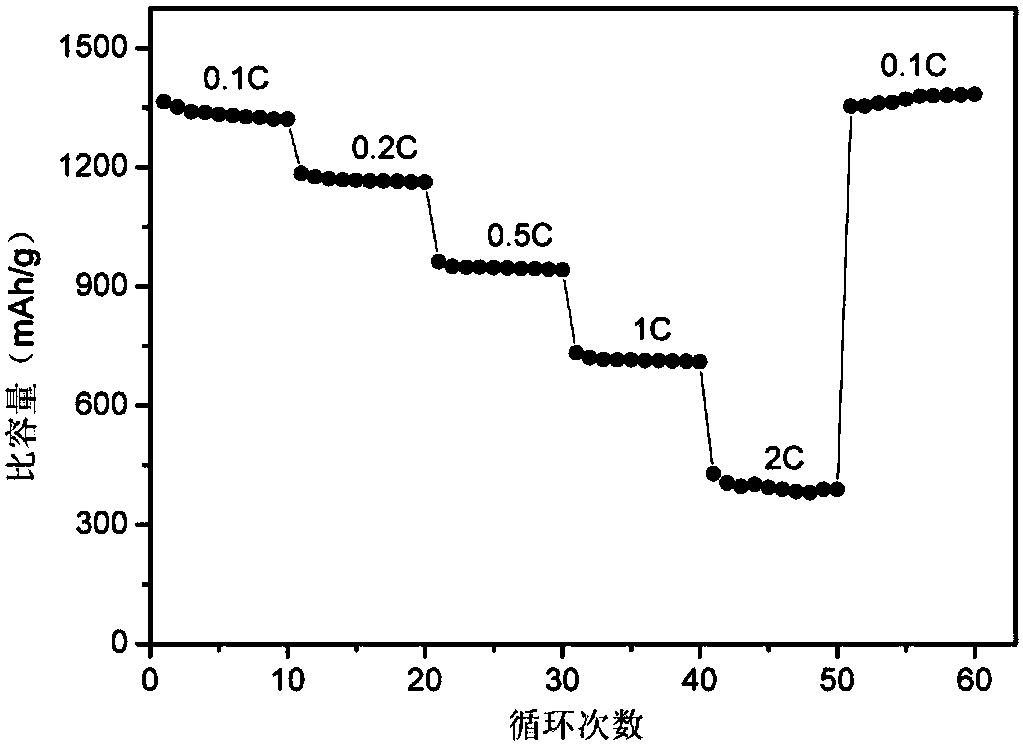

The invention provides a lithium ion battery negative material. The lithium ion battery negative material comprises nano silicon particles and carbon material particles, wherein the nano silicon particles are uniformly dispersed among the carbon material particles to form microspheres; and the carbon material particles are carbonized metallic organic skeleton materials. The microsphere structural silicon-carbon composite material is obtained by adopting a micro-emulsion method. Compared with the prior art of embedding nano silicon into each single carbon material particle to form a core-shell structure, a lithium ion battery manufactured with the negative material has higher electrochemical cycling performance and multiplying power performance; and meanwhile, the preparation method is simple and easy, and is low in reaction temperature, short in preparation time, good in controllability and favorable for mass production. An experiment shows that the primary discharge specific capacity of the prepared lithium ion battery at the multiplying power of 0.1C is 1800 to 2069 mAh / g, and after the lithium ion battery is circulated for 120 times, the discharge specific capacity is 1000 to 1280 mAh / g.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

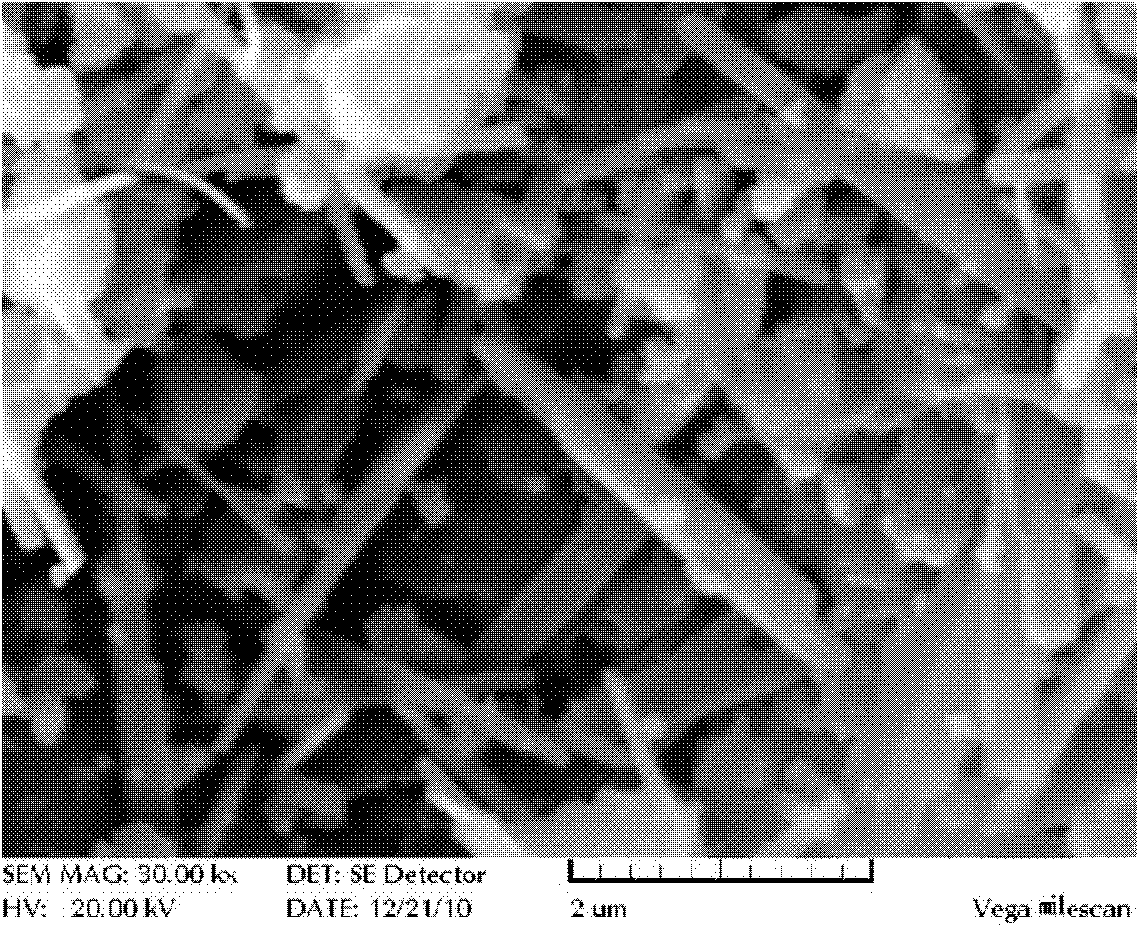

Method for preparing NH4V3O8 anode material for lithium ion battery

ActiveCN104701517APromote absorptionIncrease profitCell electrodesVanadium compoundsFiberCarbon fibers

The invention discloses a method for preparing an NH4V3O8 anode material for a lithium ion battery. The method comprises the steps that ammonium metavanadate is dissolved in deionized water, an NH4VO3 solution is prepared, pre-oxidization short carbon fibers of 1 mm to 3 mm are added, the NH4VO3 solution is transferred into a reaction still after the pH value is adjusted, forced mixing is carried out, after the reaction still is sealed, the reaction still is placed in a water and heat induction heater, and suspension liquid is obtained after a heating reaction; centrifugal separation is carried out on the suspension liquid to obtain a powder product, the powder product is soaked in the deionized water and the absolute ethyl alcohol, repeated washing is carried out, and then drying and grinding are carried out. The NH4V3O8 microcrystal prepared through the method is uniform in chemical component, high in purity and uniform in form, and the electrochemical performance of the material can be effectively improved. The preparation method is simple, low in reaction temperature, short in reaction period, high in productivity, free of any subsequent treatment, environmentally friendly and capable of being suitable for large-scale production.

Owner:安徽翰邦科技咨询有限公司

Method for preparing tetragonal phase zirconia nanorod

InactiveCN102126752APromote crystallizationHigh purityNanotechnologyZirconium oxidesMicrowaveReaction temperature

The invention provides a method for preparing a tetragonal phase zirconia nanorod. The method comprises the following steps of: adding a mineralizing agent into aqueous solution containing zirconium ions to obtain hydroxide suspension; and performing microwave hydrothermal reaction, washing and drying to obtain the tetragonal phase zirconia nanorod. The diameter and the length of the tetragonal phase zirconia nanorod can be controlled by controlling the temperature, the pressure and the time of the microwave hydrothermal reaction. The tetragonal phase zirconia nanorod prepared by the method has high crystallinity and higher purity; the diameter of a single nanorod is about 60 to 180nm; and the length of the nanorod is 0.5 to 4 mu m. The method for preparing the tetragonal phase zirconia nanorod has the advantages of high purity of a tetragonal phase product, short reaction time, low reaction temperature, high repeatability and the like and is easy to operate.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing glucosamine hydrochloride

InactiveCN101775045AShort reaction timeInhibit side effectsSugar derivativesSugar derivatives preparationGas explosionChemistry

The invention relates to a method for preparing glucosamine hydrochloride, which is characterized by comprising the following steps: 1) treatment of chitin in a gas explosion expanding method: feeding chitin as a raw material into a gas explosion expanding tank, and injecting a gas explosion expanding medium into the gas explosion expanding tank, wherein the gas explosion expanding medium is one of the four substances, namely, steam, water, ammonium hydroxide and ethanol; and instantly releasing the pressure of the gas explosion expanding tank, and discharging the raw material chitin into an atmospheric vessel, thereby obtaining chitin concentrate; 2) hydrolysis with hydrochloric acid; 3) decolorization; 4) filtration; 5) concentration and crystallization; and 6) secondary crystallization. Compared with the prior art, the invention has the following advantages that: 1) the chitin pretreated in the gas explosion expanding method is used as the raw material, and due to the high chemical activity thereof, the invention can achieve a higher product yield; 2) almost no 'coking' can be caused in the process of hydrolysis; 3) the extraction of GAH can be completed at one step during the technological process of technology, thereby simplifying the preparation of GAH; and 4) the hydrochloric acid can be recycled, thereby realizing the clean production of GAH.

Owner:汪昔奇 +1

Preparation method of hydroxypropyl methylcellulose acetate succinate in novel solvent system

InactiveCN102702363AReduce the temperatureShort reaction timeHydroxypropylmethyl celluloseMethyl cellulose

The invention discloses a preparation method of hydroxypropyl methylcellulose acetate succinate in a novel solvent system. The preparation method comprises the steps as follows: adding hydroxypropyl methylcellulose, inert solvents, esterifying agents and catalyzers into a reaction vessel, and heating and stirring for esterification; lowering the temperature to the room temperature after esterification, and adding precipitants for settling out products; washing the products, and distilling to separate the inert solvents, thereby obtaining hydroxypropyl methylcellulose acetate succinate. According to the invention, the preparation method has the advantages that the reaction condition is mild, the reaction rate is high, the solvents can be recovered, and the post processing for the products is simple.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing liquid octylated diphenylamine antioxidant

InactiveCN102320983APrevent thermal oxidation and elastic flex agingGood oil solubilityAmino preparation from aminesAmino compound preparation by condensation/addition reactionsChemical synthesisViscous liquid

The invention discloses a method for preparing a liquid octylated diphenylamine antioxidant, which belongs to the field of chemical synthesis, and particularly relates to a method for synthesizing high-content mono-octyl diphenylamine. The method comprises the following steps of: under the action of a catalyst, making diphenylamine react with diisobutylene to generate an octylated diphenylamine mixture; introducing isobutene for reacting; and distilling to obtain the liquid octylated diphenylamine antioxidant, wherein the catalyst is dehydrated active white clay. The prepared liquid octylated diphenylamine antioxidant is a light-yellow viscous liquid at normal temperature, and the moving viscosity is 50-300 mm<2> / s at the temperature 40 DEG C. The liquid octylated diphenylamine antioxidant can be effectively applied to turbines, aircrafts and various oil products and lubricating agents which are applied at high operation temperatures, and can be applied to high-polymer rubber products to prevent rubber from being thermally oxidized and aged by elastic deflection.

Owner:JIANGSU FEIYA CHEM IND

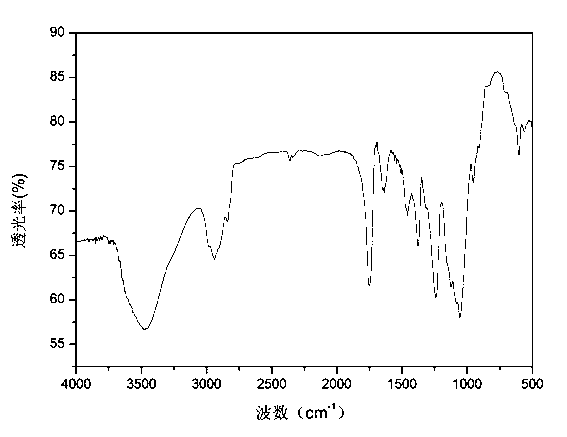

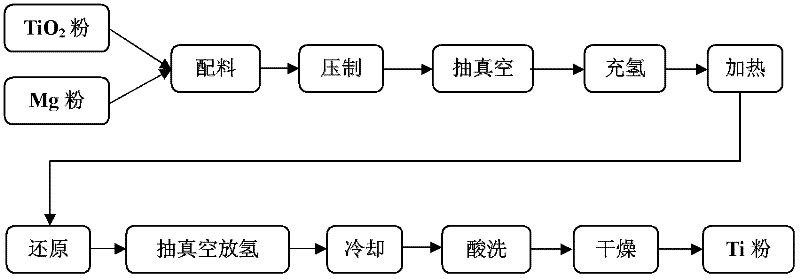

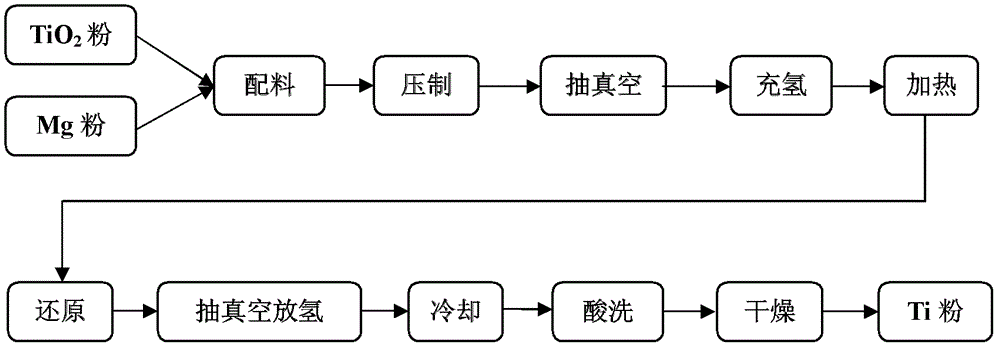

Method for preparing metal Ti by using hydrogen to induce Mg to restore TiO2

The invention belongs to the field of metal materials and relates to a method for preparing metal Ti by using hydrogen to induce Mg to restore TiO2, which is characterized in that industrial TiO2 powder and industrial Mg powder are adopted as raw materials and are mixed uniformly to be pressed into blocks, mixtures of TiH2 and MgO are obtained through reduction reaction in a certain hydrogen pressure range and a certain temperature range, and metal Ti powder is obtained after vacuum hydrogen releasing processing and pickling drying of the mixtures. Compared with the existing other preparing processes of metal Ti, the method is simple in process, low in cost, short in reaction time and free of environment pollution. The preparing process of the method has wide prospect in industrialized production of Ti and other alloy.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing terpinyl acetate

InactiveCN101503354AReduce manufacturing costOvercome many deficienciesPhysical/chemical process catalystsOrganic compound preparationAcetic acidAcetic anhydride

The invention relates to a method for preparing terpinyl acetate, comprising: terpilenol and acetic anhydride are respectively added into a reaction kettle to be stirred, the mixture is added with phosphoric acid to be evenly stirred and then added with SnCl4.5H2O at the room temperature until the SnCl4.5H2O is completely dissolved, and the reaction is carried out under agitation while the temperature gradually raises; the reaction liquid is cooled to be room temperature and added with Na2CO3 to neutralize H3PO4 and SnCl4, and is directly distilled after being neutralized by carbonic acid, so that most acetic acid is evaporated; reaction product is washed by 10% of NaOH solution and saturated saline solution to remove the residual acetic acid until neutrality and then processed by fractionation, so that the terpinyl acetate is obtained. The method has the advantages of providing a novel composite catalyst system and a new technique for synthesizing the terpinyl acetate, being low in cost and simple in post treatment and having higher catalytic activity and reaction selectivity. The method also can ensure the yield of terpinyl acetate, shorten the reaction time, reduce the wastewater in the production and improve the recovery rate of acetic acid byproduct and the concentration of acetic acid.

Owner:NANJING FORESTRY UNIV

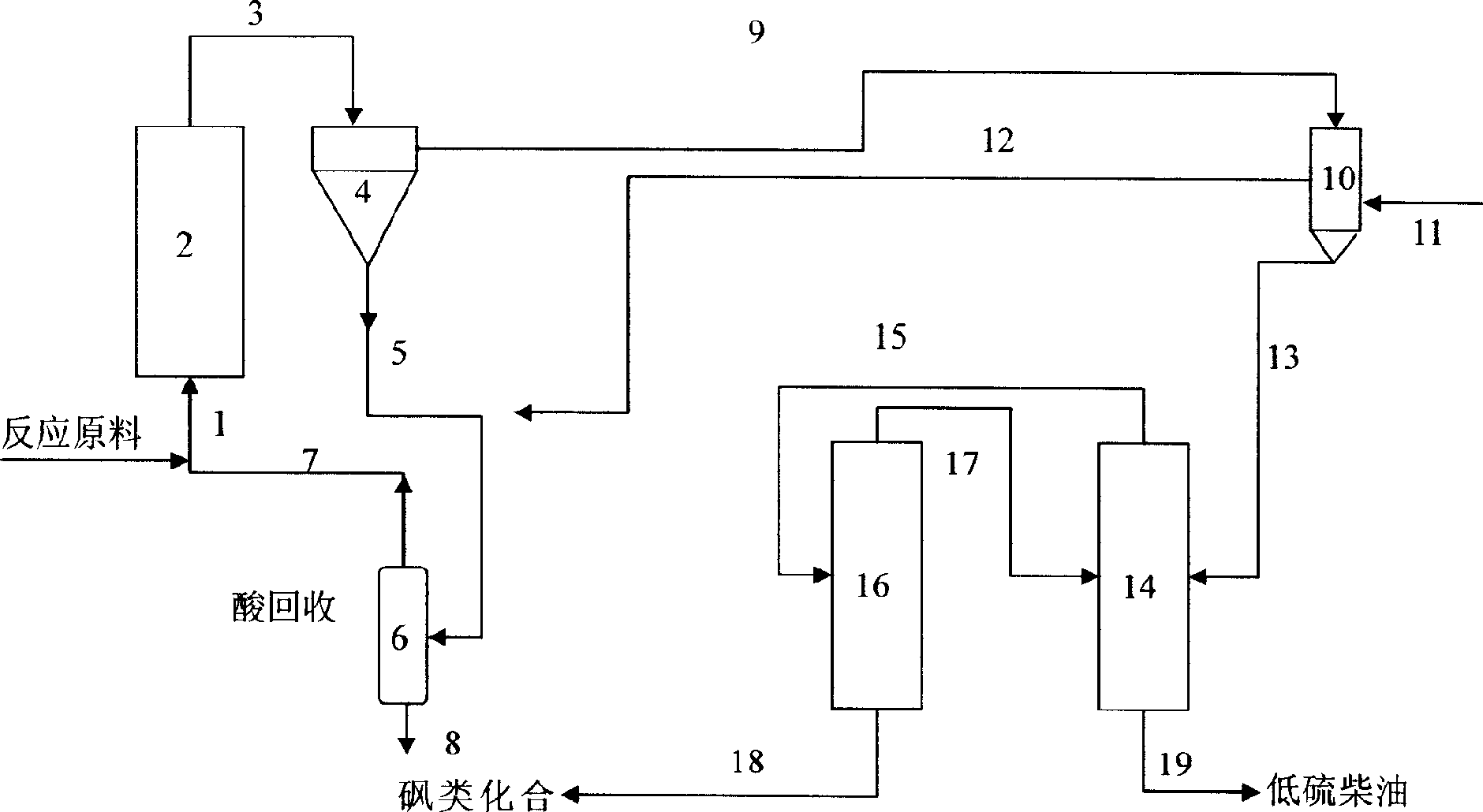

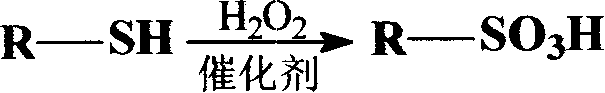

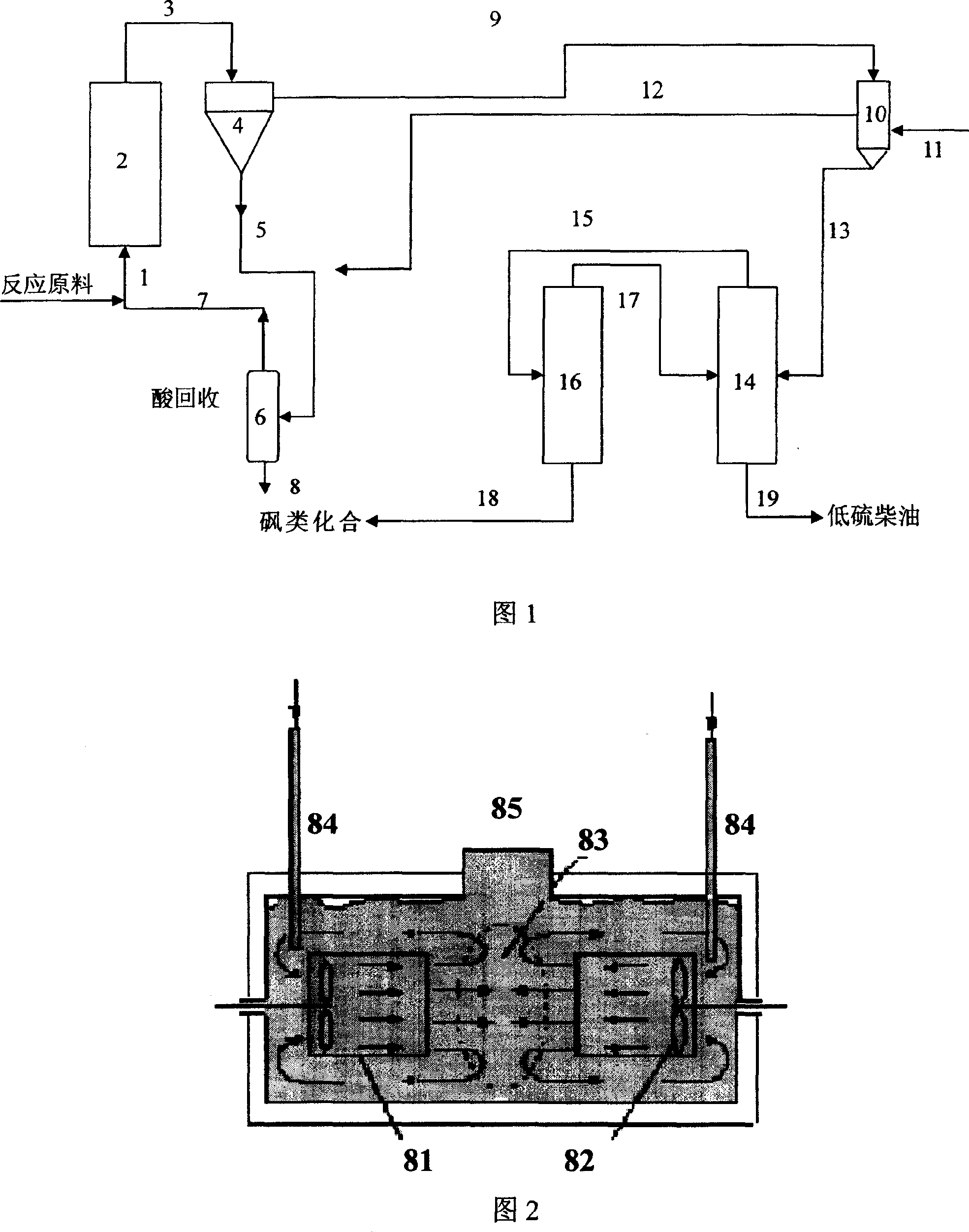

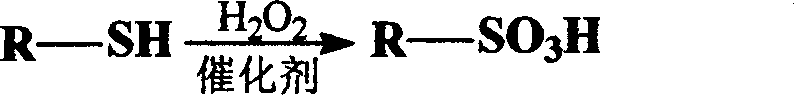

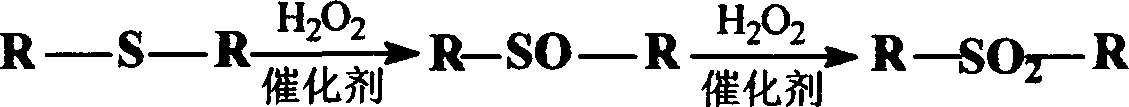

Cut-fracted oil oxidation desulfurizing method

ActiveCN1814709AReduce dosageLow mass transfer efficiencyRefining with oxygen compoundsOil oxidationReagent

This invention discloses an oxidizing and desulfurizing method for fraction oil, which includes that a fraction oil raw material and hydrogen peroxide are reacted in a high effective mass transfer reactor with intensified onflow internal components, such as an impact flow reactor, the reactants in it can be mixed fully in short time and the reaction efficiency is increased obviously since the effective collision among molecules arises quick reaction and the reaction condition is more relax than ordinary beat up reactors when the same desulfurized result is got.

Owner:CHINA PETROLEUM & CHEM CORP +1

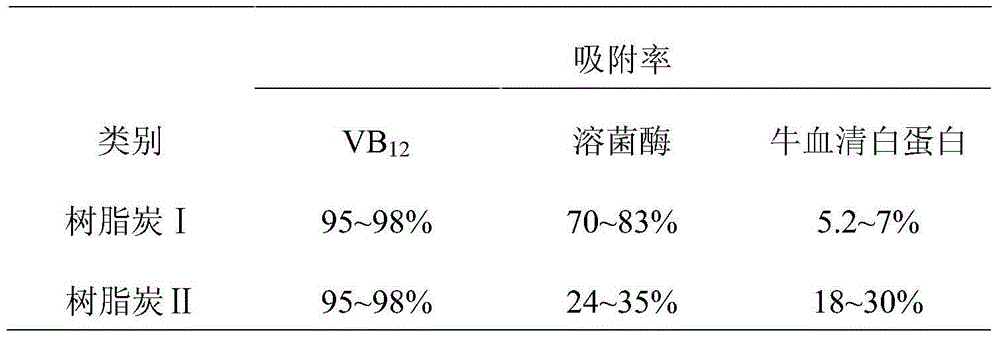

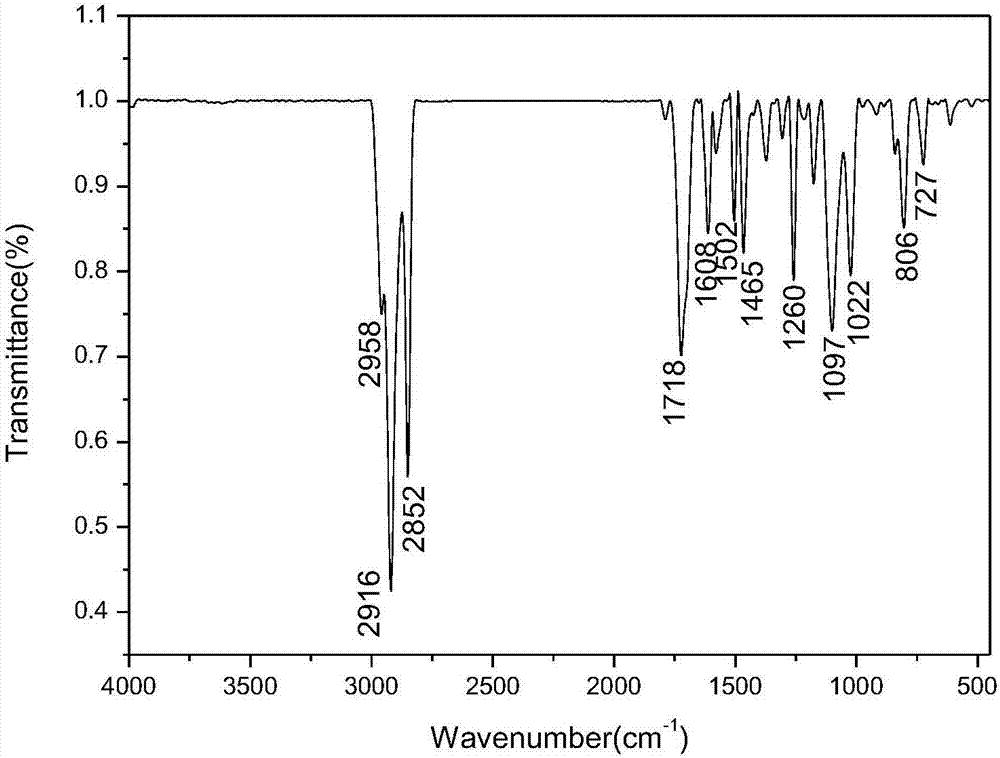

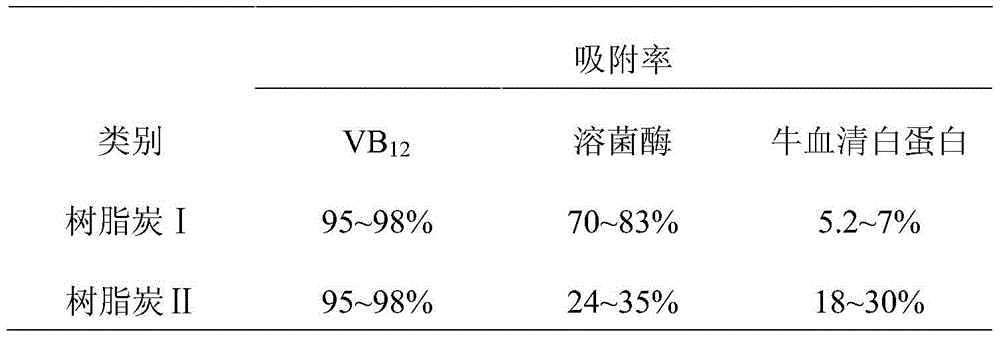

Preparation method of resin carbon for blood purification

ActiveCN104437360AImprove adsorption capacityNo joinCarbon compoundsOther chemical processesMiddle moleculeDivinylbenzene

The invention discloses a preparation method of resin carbon for blood purification. The preparation method comprises the following steps: preparing chloromethylated styrene-divinylbenzene microspheres from p-chloromethyl styrene monomers and divinylbenzene monomers; preparing polystyrene-divinylbenzene microspheres from the chloromethylated styrene-divinylbenzene microspheres; dipping the polystyrene-divinylbenzene microspheres by using a zinc-chloride solution to obtain dipped microspheres; and carbonizing the dipped microspheres, and activating the dipped microspheres after the carbonizing so as to obtain a finished product. The preparation method disclosed by the invention has the obvious effects that the resin carbon with the excellent absorbing effect for middle molecules can be prepared and obtained at relatively low temperature and within shorter time, the preparation process is simple, the pollution is slight, the product yield is high and the purity is high.

Owner:重庆希尔康血液净化器材研发有限公司

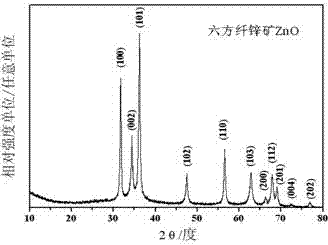

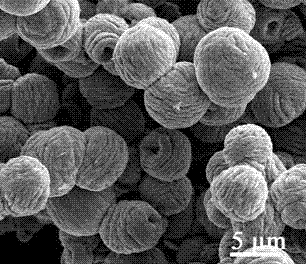

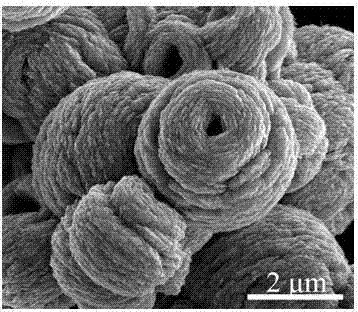

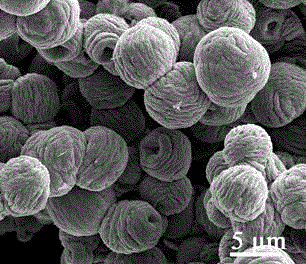

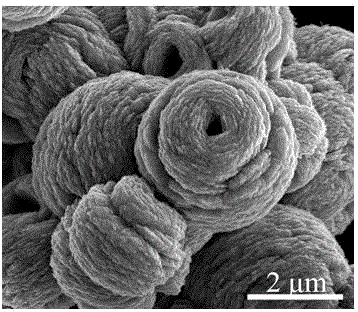

Zinc oxide microspheres and preparation method thereof

InactiveCN104118902AControl shapeControl granularityMaterial nanotechnologyZinc oxides/hydroxidesHexamethylenetetramineMicrosphere

The invention discloses yarn ball-like zinc oxide microspheres and a preparation method thereof. The grain size of the microspheres is 2-9mu m, the microspheres consist of zinc oxide thin sheets, and a part of the microspheres have a large hole in the center. The preparation method comprises the following steps: dissolving zinc salt in water to prepare a solution, then, adding hexamethylenetetramine, stirring at room temperature till the solution is clarified, and then adding tartaric acid and uniformly stirring to obtain a reaction solution; and transferring the solution to a reaction kettle, reacting at 120-180 DEG C to prepare zinc oxide; after reaction, carrying out centrifugal separation and washing to obtain the zinc oxide microspheres. The preparation method of the zinc oxide microspheres disclosed by the invention has the advantages that the needed materials are cheap, the preparation process is simple and convenient to operate, the reaction temperature is low and the reaction time is short. The prepared product is regular in shape, has large specific surface area, strong morphologic controllability, good stability and repeatability and strong operability and practicality and has a potential application value and strong practicality in the field of photocatalytic performance, gas sensitivity and the like.

Owner:UNIV OF JINAN

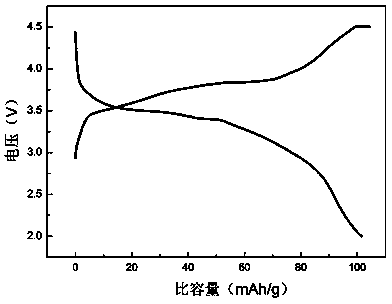

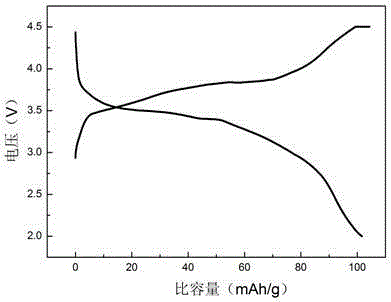

Method for synthesizing carbon-coated lithium ferrous pyrophosphate by hydrothermal method

ActiveCN103985870ALow costSave the wrapping processCell electrodesSecondary cellsWater bathsSynthesis methods

The invention discloses a method for synthesizing carbon-coated lithium ferrous pyrophosphate by a hydrothermal method. The method comprises the following steps of (1) weighing raw materials, dissolving a carbon source into distilled water or deionized water, and heating, stirring and dissolving in a water bath at the temperature of 50-90 DEG C; respectively dissolving a lithium source, an iron source and a phosphorus source into the deionized water, uniformly stirring the sources, sequentially adding the iron source and the lithium source into a solution dissolved with the carbon source, adding ammonia water to adjust the pH of the mixed solution to 4-6, adding the phosphorus source, heating the mixed solution in the water bath at the temperature of 50-90 DEG C, and stirring for 1-2 hours; (2) performing reaction on the mixed solution at 150-350 DEG C and the pressure of 1-10MPa for 3-10 hours, cooling to room temperature after the reaction is finished, and performing solid-liquid separation to obtain a solid which is a precursor solid-phase product; (3) drying the precursor solid-phase product, and then sintering to obtain the carbon-coated lithium ferrous pyrophosphate. The method has the advantage that the reaction temperature is relatively low, and the synthesis method is simple; the prepared carbon-coated lithium ferrous pyrophosphate serving as a positive electrode material is excellent in electrochemical performance.

Owner:CENT SOUTH UNIV

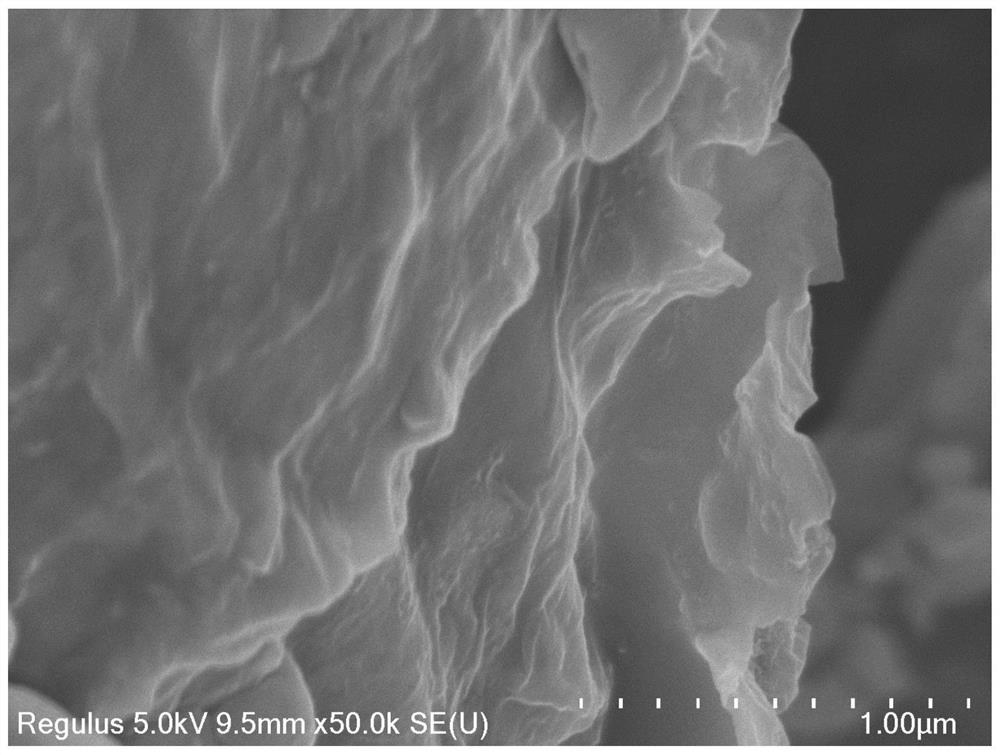

Carbon-coated SnSe/r-GO@ C compound with sandwich-like structure and preparation method and application thereof

ActiveCN113097484AImprove structural stabilityImprove conductivityMaterial nanotechnologyNegative electrodesActive agentSurface-active agents

The invention discloses a carbon-coated SnSe / r-GO@ C compound with a sandwich-like structure and a preparation method and application thereof. The carbon-coated SnSe / r-GOcompound with the sandwich-like structure is prepared with from ethylene glycol or glycerin serving as a solvent, inorganic tin salt servingas a tin source, a reducing agent and a surface active agent through a simple solvothermal method, wherein the reducing agent not only can reduce selenium powder and provide Se < 2->, but also can reduceoxygen-containing functional groups on the graphene oxide, so that the conductivity of the graphene in the composite material is further improved; and the added reducing agent can be effectively complexed with Sn < 2 + >, the size of the product is controlled, and the nanocrystallization material is more effective for improving the electrochemical performance. The preparation method is simple and high in repeatability, the conductivity of the SnSe-based composite material is improved after the graphene oxide is added and a hydrothermal reaction is carried out, the structural stability of the composite material is further improved by coating a layer of pyrolytic carbon, and the composite material has good electrochemical performance as a sodium ion electrode material.

Owner:SHAANXI UNIV OF SCI & TECH

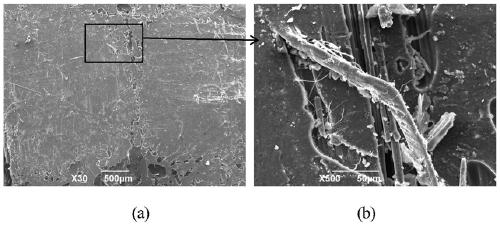

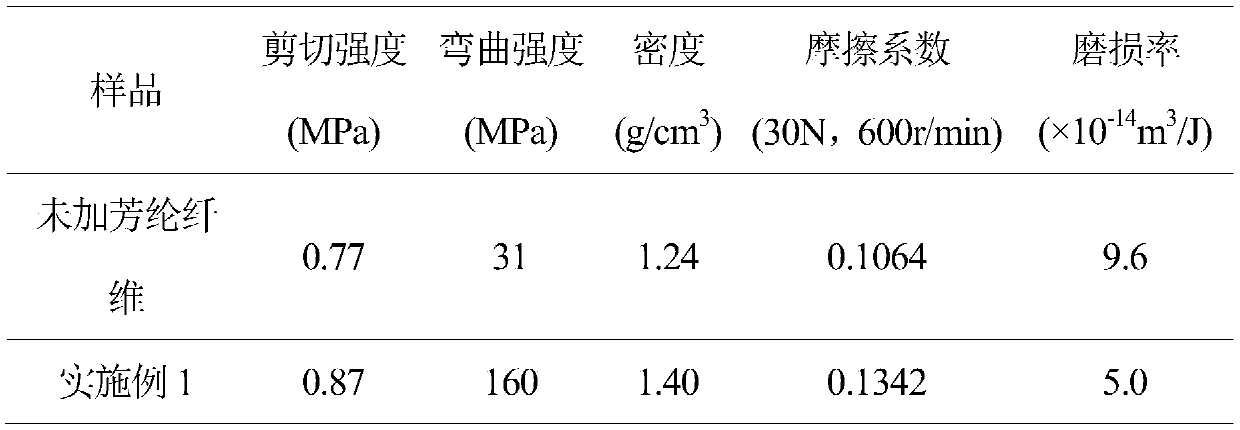

Preparation method of biomass carbon nano powder/resin composite material

The invention provides a preparation method of a biomass carbon nano powder / resin composite material. The preparation method comprises the steps that a solid superacid solution and an ethanol solutionare added into a biomass preform to form a mixed solution C; the mixed solution C is transferred into a homogeneous reaction kettle for a hydrothermal reaction to obtain a precursor D; the precursorD is evenly mixed with KOH after washing and suction filtration, and then the mixture is transferred into a tubular atmosphere furnace to obtain a carbonized product E; the carbonized product E is washed, dried and grinded to obtain a carbon nano powder material F; resin is dissolved in absolute ethyl alcohol to obtain a solution G; organic fiber is added into water to carry out defibering to obtain an organic fiber solution H; the carbon nano powder F is uniformly laid on the bottom of a beaker, and then an organic fiber solution H is added into the beaker for suction filtration and drying toobtain a sample wafer I; the resin in the solution G is added into the sample wafer I to obtain a preform J; hot-press molding is carried out on the preform J to obtain the biomass carbon nano powder / resin composite material. The method is simple in technological process, the reaction temperature is low, the reaction time is short, subsequent treatment is not needed, and the method is environmentally friendly.

Owner:SHAANXI UNIV OF SCI & TECH

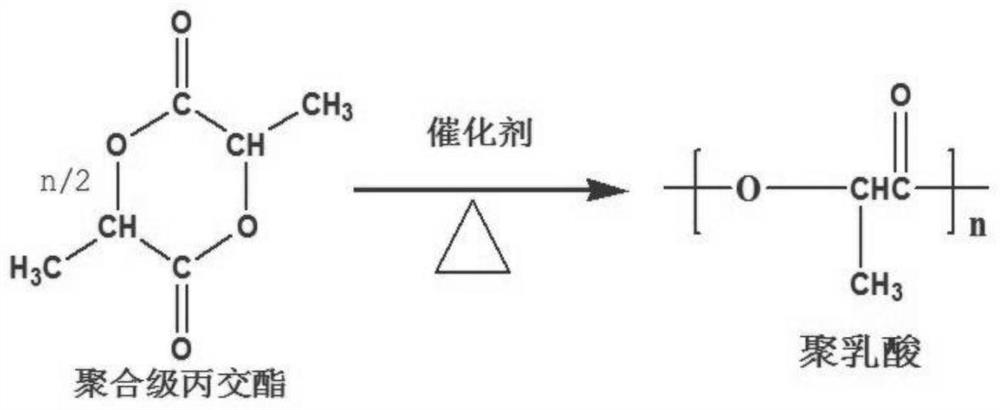

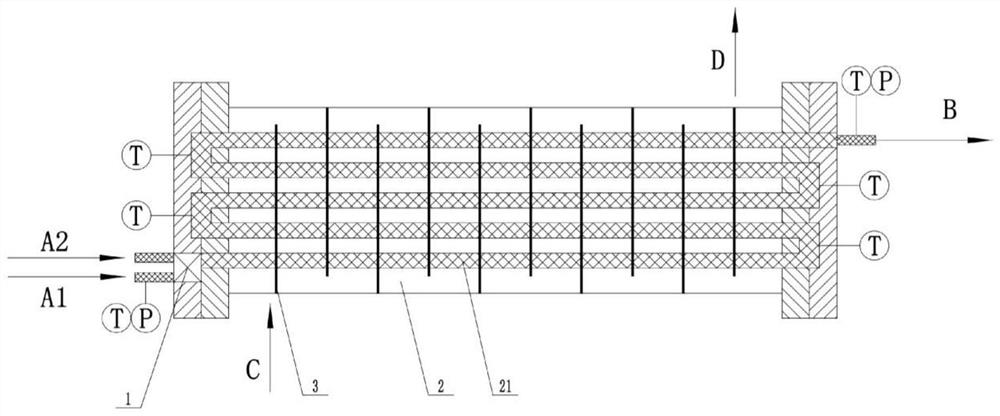

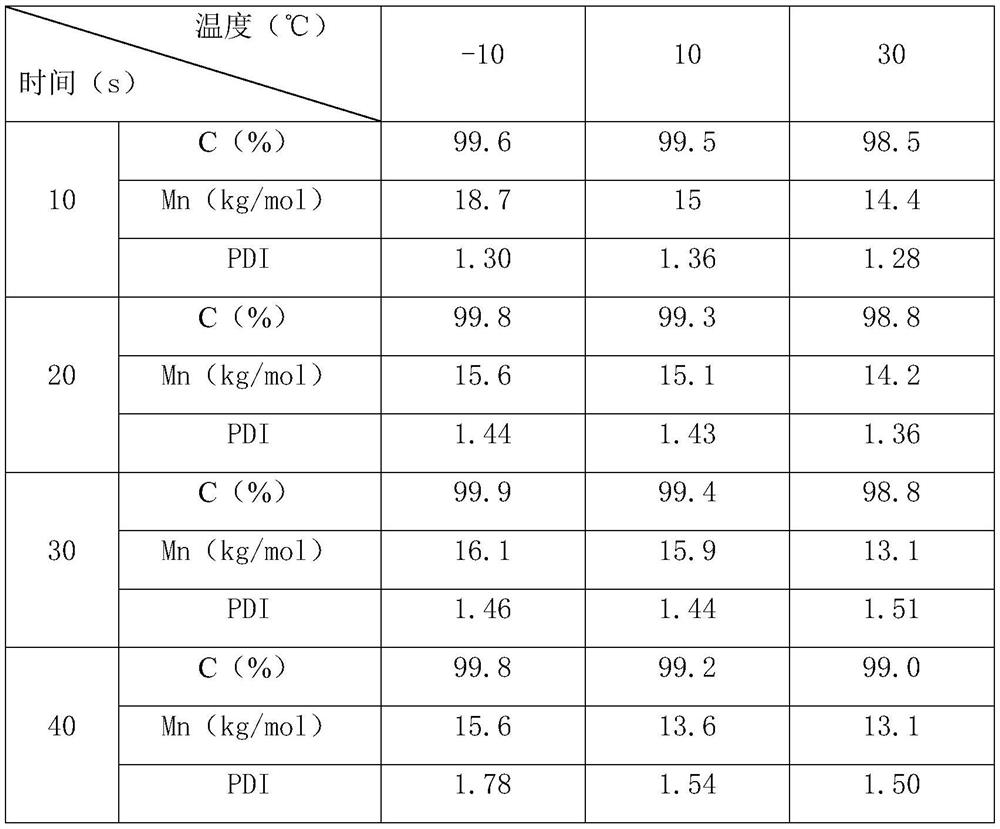

Method for synthesizing polylactic acid by adopting large-channel continuous flow microreactor

The invention belongs to the technical field of organic synthesis, and particularly discloses a method for synthesizing polylactic acid by adopting a large-channel continuous flow microreactor, and the method comprises the following steps of: dissolving lactide in an organic solvent, then injecting a lactide solution and a non-metal organic catalyst into the large-channel continuous flow microreactor, and carrying out polymerization reaction to synthesize the polylactic acid. According to the method, the non-metal organic catalyst is combined with the continuous flow microreactor, so that the continuous material ratio, the reaction temperature and the reaction time can be precisely controlled, the reaction realizes rapid mixing and mass transfer, and the obtained product is good in reproducibility, stable in quality, high in monomer conversion rate, high in polymerization degree and low in molecular weight distribution index, and can be controlled to meet the high requirement of 1.1-1.3, the yellow index is low, expanded production in industrial reaction is facilitated, and the problems of high synthesis reaction temperature, many side reactions, long residence time, low production efficiency and the like of polylactic acid in the prior art can be effectively solved.

Owner:上海东庚化工技术有限公司

New method for osmium powder purification

InactiveCN108660323AImprove dissolution efficiencyImprove direct yieldProcess efficiency improvementHydrogenReaction temperature

The invention relates to a new method for osmium powder purification. A direct distillation method with hydrochloric acid and sodium hypochlorite is adopted, and mixtures of osmium and osmium oxides based on osmium elementary substance are obtained; and then osmium powder with the purity of 99.5% and above is obtained through hydrogen reduction. According to the new method, the oxidation distillation with the sodium hypochlorite and the hydrochloric acid is adopted directly, and new dissolution reagents and the new method are applied; the working procedure of alkali fusion is omitted, and thetechnological process is shortened; the production cost is reduced; distillation residues are neutral, and can be discharged directly; the method is low in reaction temperature and less in impurity inclusions, and the product quality is guaranteed. The new method has the advantages of a short technological process, relatively less scattered wastes, and high dissolving efficiency and direct recovery rate of the osmium.

Owner:南京东锐铂业有限公司 +1

A method for synthesizing carbon-coated lithium iron pyrophosphate by hydrothermal method

ActiveCN103985870BLow costSave the wrapping processCell electrodesSecondary cellsWater bathsSynthesis methods

The invention discloses a method for synthesizing carbon-coated lithium ferrous pyrophosphate by a hydrothermal method. The method comprises the following steps of (1) weighing raw materials, dissolving a carbon source into distilled water or deionized water, and heating, stirring and dissolving in a water bath at the temperature of 50-90 DEG C; respectively dissolving a lithium source, an iron source and a phosphorus source into the deionized water, uniformly stirring the sources, sequentially adding the iron source and the lithium source into a solution dissolved with the carbon source, adding ammonia water to adjust the pH of the mixed solution to 4-6, adding the phosphorus source, heating the mixed solution in the water bath at the temperature of 50-90 DEG C, and stirring for 1-2 hours; (2) performing reaction on the mixed solution at 150-350 DEG C and the pressure of 1-10MPa for 3-10 hours, cooling to room temperature after the reaction is finished, and performing solid-liquid separation to obtain a solid which is a precursor solid-phase product; (3) drying the precursor solid-phase product, and then sintering to obtain the carbon-coated lithium ferrous pyrophosphate. The method has the advantage that the reaction temperature is relatively low, and the synthesis method is simple; the prepared carbon-coated lithium ferrous pyrophosphate serving as a positive electrode material is excellent in electrochemical performance.

Owner:CENT SOUTH UNIV

Method for preparing ferrocenyl oxadiazole-based Mannich alkali

The invention provides a method for preparing ferrocenyl oxadiazole-based Mannich alkali. The method comprises the following steps: putting A mol 2-amino-5-substituted 1,3,4-oxadiazole, B mol substituted aldehyde, an E mol catalyst and a solvent, namely absolute ethyl alcohol into a dry three-mouth flask with a backflow condensation tube, putting an absolute ethyl alcohol solution of C mol acetyl ferrocene, performing reaction at room temperature for 3-6 hours, wherein the ratio of A to B to C to E is (0.7-1):(1-45):1:(1.1-1.5), after the reaction is completed, performing vacuum distillation on a reaction mixed liquid so as to remove the solvent, and treating with column chromatography, thereby obtaining the ferrocenyl oxadiazole-based Mannich alkali. The method is simple to operate, gentle in reaction condition, low in equipment requirement and high in product purity, and the catalyst is bismuth nitrate which is cheap and easy to obtain.

Owner:SHAANXI UNIV OF SCI & TECH

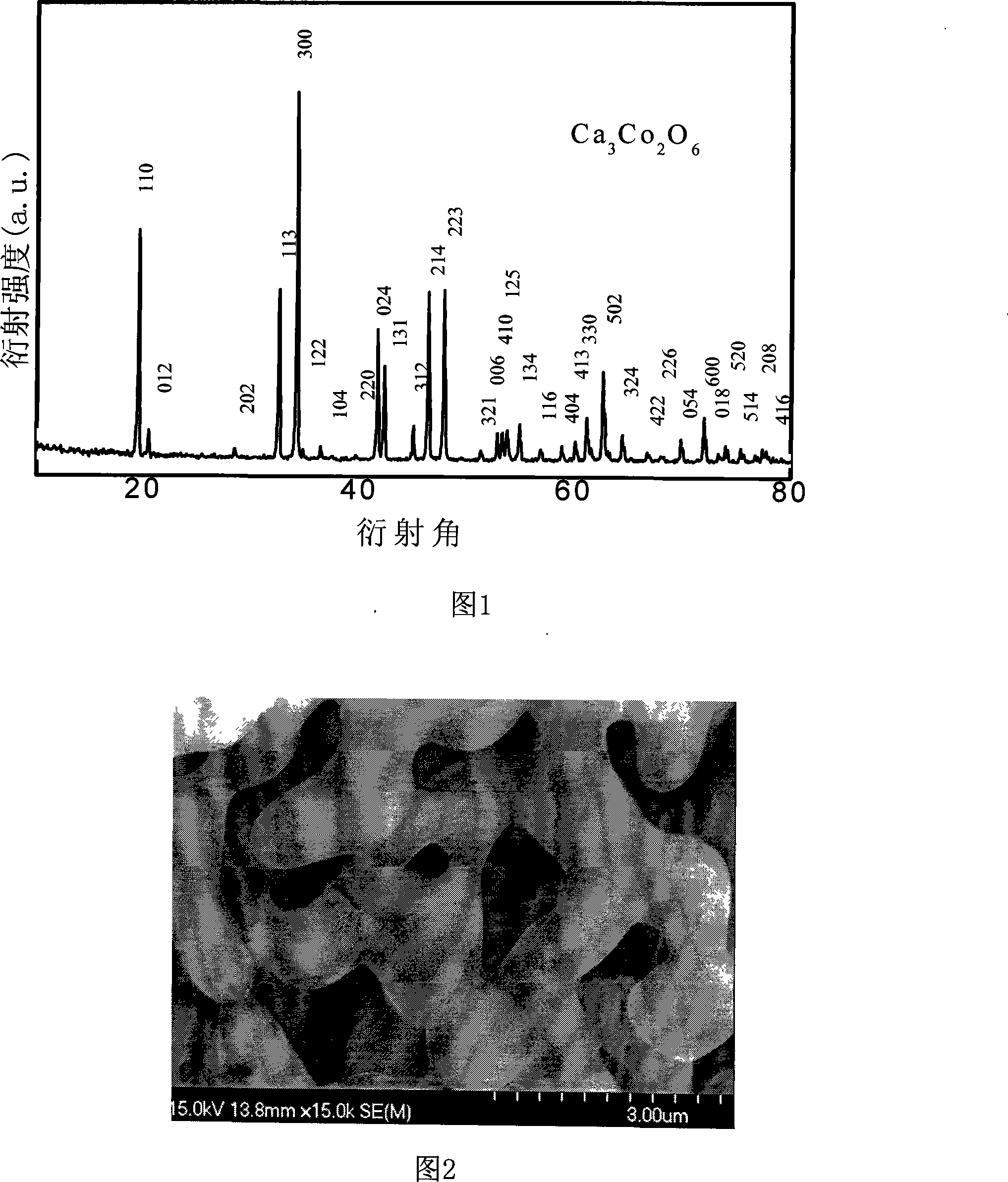

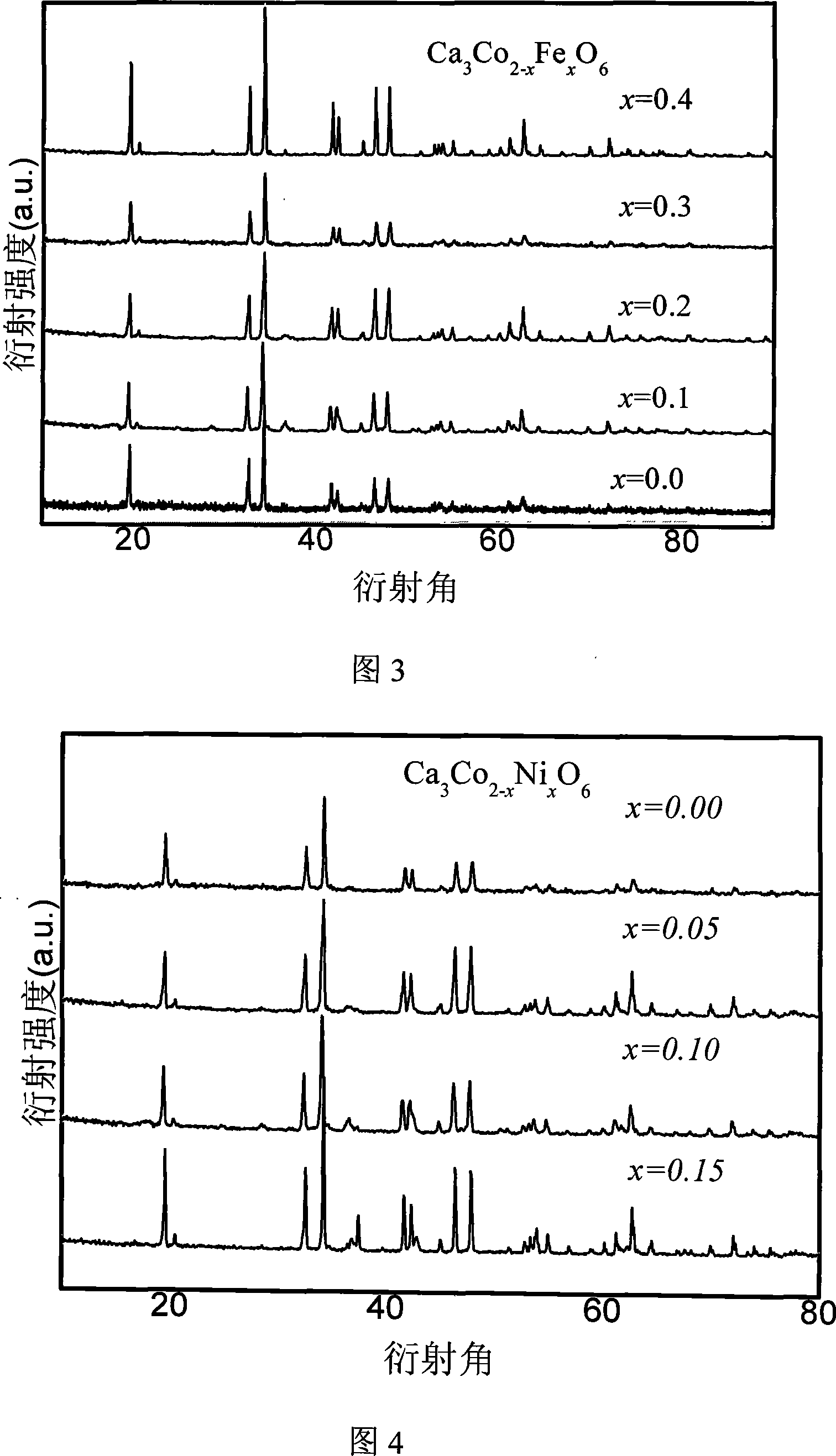

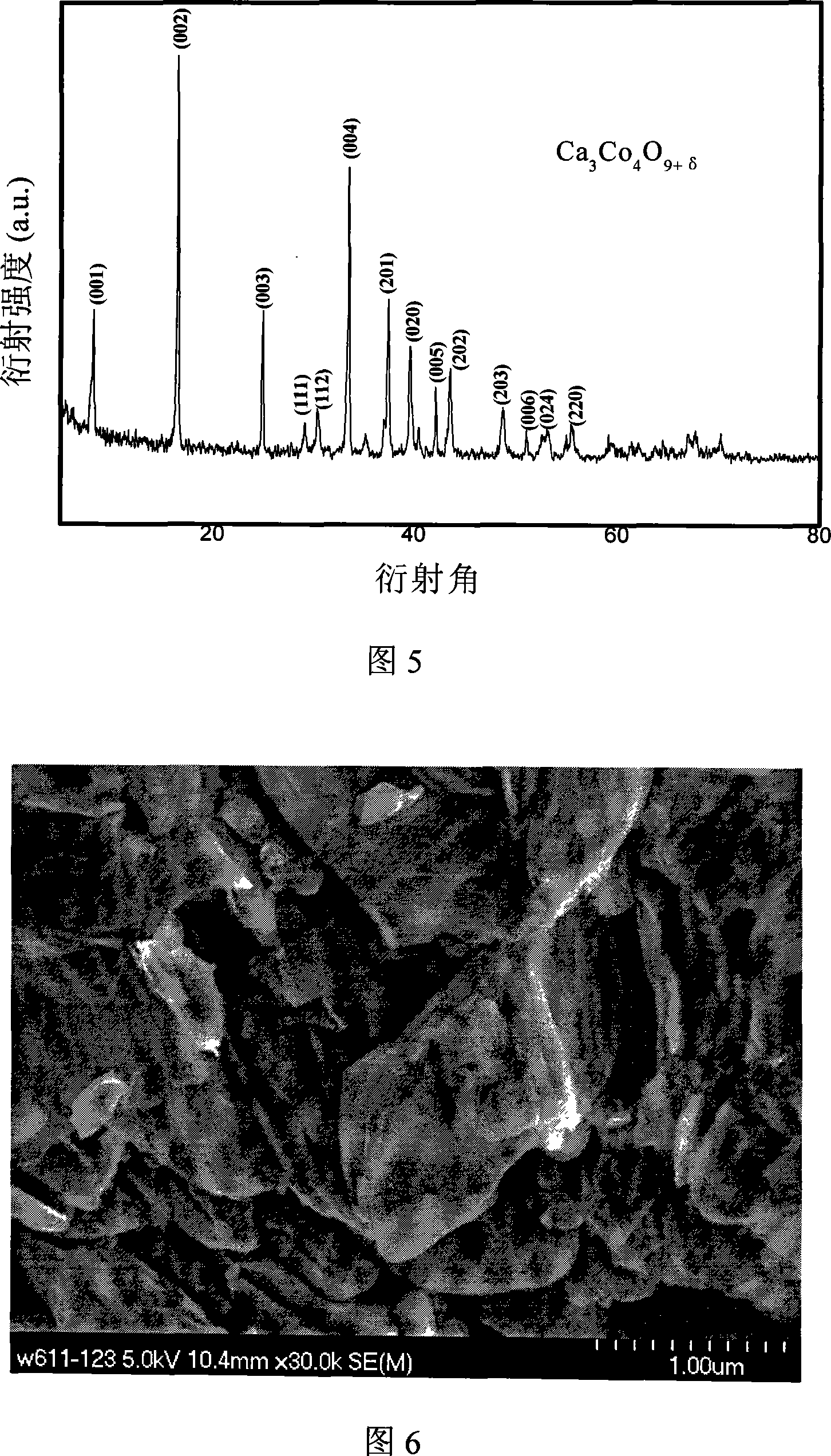

Modified Ca-Co-O system doped transition metal composite oxides and preparation method thereof

InactiveCN101157482BUniform particlesWell formedCobalt oxides/hydroxidesCalcium/strontium/barium oxides/hydroxidesThermoelectric materialsReaction temperature

The invention discloses modified Ca-Co-O system doped composite oxide of transition metals and the preparing method thereof, and relates to thermoelectric material and the preparing method thereof. The invention solves the problems of high reaction temperature, long reaction time and easy impurity production of the prior Ca-Co-O system preparing method. The general formula of the composite oxide is Ca3Co2-xMxO6 or Ca3-x-yMxNyCo4O9+Delta, wherein, M refers to Fe, Ni, Nd or Er, and N refers to Na or Bi. The method contains the following procedures: firstly, dissolving materials into deionized water according to the respective stoichiometric ratio of the molecular formula, mixing the water solution of raw materials uniformly, slowly injecting citric acid solution and performing ultrasonic oscillation to produce homogeneous sol; secondly, heating for dehydration with microwave to get wet sol; thirdly, drying the wet sol to get dry sol and allowing self-propagating combustion; fourthly, baking after grinding. Compared with the prior art, the invention has the advantages of short reaction time, low baking temperature and simple operation. The powder of the material of the invention has uniform particle distribution and high purity; the powder has flaky structure and the particle diameter is smaller than 200nm.

Owner:HARBIN INST OF TECH

A kind of preparation method of efficient and environment-friendly 2-hydroxyethylpyridine

The invention discloses a high-efficiency environment-friendly preparation method of 2-hydroxyethylpyridine, which comprises the following steps: proportionally adding 2-methylpyridine and formaldehyde into a high-pressure autoclave, adding a solid superhigh acid catalyst, heating while stirring to react, quickly cooling the high-pressure autoclave, filtering out the solid superhigh acid catalyst, distilling the mixed solution under reduced pressure, and distilling off unreacted 2-methylpyridine, formaldehyde and water under the pressure of 10-100 mmHg to obtain the 2-hydroxyethylpyridine end product. Abundant experiments are performed to screen out the optimal proportion of the reactant raw material to the catalyst thereof; and abundant experiments are performed to screen out the optimum reaction temperature, reaction time and reaction pressure. The whole method has the advantages of reasonable technique, small environmental pollution, low reaction temperature, short reaction time, high reaction efficiency, low production cost, high yield and high purity of the prepared 2-hydroxyethylpyridine.

Owner:SOUTHEAST UNIV +1

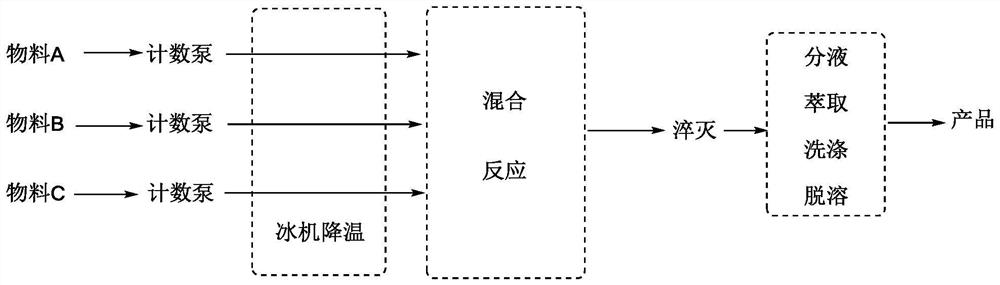

Method for synthesizing rosuvastatin calcium intermediate by using continuous flow microchannel reactor

PendingCN114436834AShort reaction timeMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationSolventChemistry

The invention relates to the technical field of drug intermediate synthesis, in particular to a method for synthesizing a rosuvastatin calcium intermediate by using a continuous flow microchannel reactor, which comprises the following steps: 1) mixing a compound II with a solvent, stirring and dissolving to obtain a material A; 2) mixing lithium diisopropylamide with a solvent, stirring and dissolving to obtain a material B; 3) mixing tert-butyl acetate with a solvent, and stirring for dissolving to obtain a material C; 4) respectively pumping the material B and the material C into a micro-channel reactor, uniformly mixing, and then pumping the material A for chemical reaction; and after the reaction is finished, quenching with hydrochloric acid, adjusting the pH value to 3-4, and carrying out liquid separation, extraction, washing and drying to obtain a target product. By adopting the method, the reaction time is extremely short, the reaction condition is mild, the target product yield is high, the yield reaches 90% or above, the purity reaches 99% or above, the cost is low, resources are saved, the product aftertreatment is simple, and the method is environmentally friendly.

Owner:JIANGSU ALPHA PHARM CO LTD

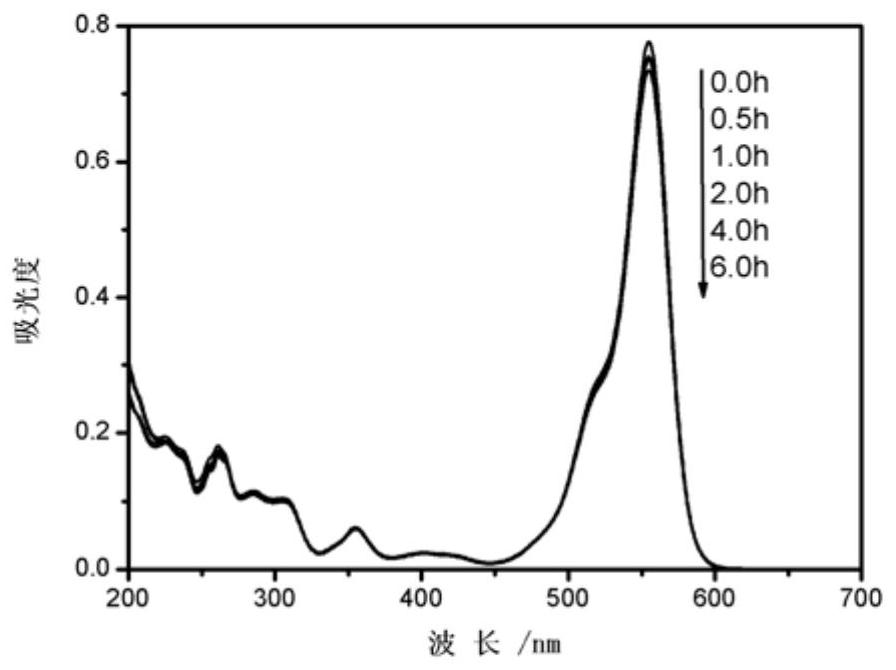

Preparation method of 8-hydroxyquinoline iron organic dye photodegradation catalyst

ActiveCN108080028BShort reaction timeFew synthetic stepsWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystOrganic dye

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for preparing metal Ti by using hydrogen to induce Mg to restore TiO2

The invention belongs to the field of metal materials and relates to a method for preparing metal Ti by using hydrogen to induce Mg to restore TiO2, which is characterized in that industrial TiO2 powder and industrial Mg powder are adopted as raw materials and are mixed uniformly to be pressed into blocks, mixtures of TiH2 and MgO are obtained through reduction reaction in a certain hydrogen pressure range and a certain temperature range, and metal Ti powder is obtained after vacuum hydrogen releasing processing and pickling drying of the mixtures. Compared with the existing other preparing processes of metal Ti, the method is simple in process, low in cost, short in reaction time and free of environment pollution. The preparing process of the method has wide prospect in industrialized production of Ti and other alloy.

Owner:UNIV OF SCI & TECH BEIJING

Cut-fracted oil oxidation desulfurizing method

ActiveCN100352893CReduce dosageLow mass transfer efficiencyRefining with oxygen compoundsOil oxidationReagent

This invention discloses an oxidizing and desulfurizing method for fraction oil, which includes that a fraction oil raw material and hydrogen peroxide are reacted in a high effective mass transfer reactor with intensified onflow internal components, such as an impact flow reactor, the reactants in it can be mixed fully in short time and the reaction efficiency is increased obviously since the effective collision among molecules arises quick reaction and the reaction condition is more relax than ordinary beat up reactors when the same desulfurized result is got.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of resin carbon for blood purification

ActiveCN104437360BImprove adsorption capacityNo joinOther chemical processesCarbon compoundsMiddle moleculeMicrosphere

The invention discloses a preparation method of resin carbon for blood purification. The preparation method comprises the following steps: preparing chloromethylated styrene-divinylbenzene microspheres from p-chloromethyl styrene monomers and divinylbenzene monomers; preparing polystyrene-divinylbenzene microspheres from the chloromethylated styrene-divinylbenzene microspheres; dipping the polystyrene-divinylbenzene microspheres by using a zinc-chloride solution to obtain dipped microspheres; and carbonizing the dipped microspheres, and activating the dipped microspheres after the carbonizing so as to obtain a finished product. The preparation method disclosed by the invention has the obvious effects that the resin carbon with the excellent absorbing effect for middle molecules can be prepared and obtained at relatively low temperature and within shorter time, the preparation process is simple, the pollution is slight, the product yield is high and the purity is high.

Owner:重庆希尔康血液净化器材研发有限公司

A kind of zinc oxide microsphere and preparation method thereof

InactiveCN104118902BControl shapeControl granularityMaterial nanotechnologyZinc oxides/hydroxidesHexamethylenetetramineMicrosphere

The invention discloses yarn ball-like zinc oxide microspheres and a preparation method thereof. The grain size of the microspheres is 2-9mu m, the microspheres consist of zinc oxide thin sheets, and a part of the microspheres have a large hole in the center. The preparation method comprises the following steps: dissolving zinc salt in water to prepare a solution, then, adding hexamethylenetetramine, stirring at room temperature till the solution is clarified, and then adding tartaric acid and uniformly stirring to obtain a reaction solution; and transferring the solution to a reaction kettle, reacting at 120-180 DEG C to prepare zinc oxide; after reaction, carrying out centrifugal separation and washing to obtain the zinc oxide microspheres. The preparation method of the zinc oxide microspheres disclosed by the invention has the advantages that the needed materials are cheap, the preparation process is simple and convenient to operate, the reaction temperature is low and the reaction time is short. The prepared product is regular in shape, has large specific surface area, strong morphologic controllability, good stability and repeatability and strong operability and practicality and has a potential application value and strong practicality in the field of photocatalytic performance, gas sensitivity and the like.

Owner:UNIV OF JINAN

A method for depolymerizing biomass and coproducing furfural, cellulose and lignin

ActiveCN108530404BLow reaction temperatureShort reaction temperaturePulping with acid salts/anhydridesLignin derivativesCelluloseO-Phosphoric Acid

The invention discloses a method for co-producing furaldehyde, cellulose and lignin by depolymerizing biomasses. According to the method, in a mixed solvent of water and acetone, depolymerization andseparation of the biomasses are catalyzed in a one-step manner under the synergistic effect of phosphoric acid and sulfuric acid, the reaction temperature of furaldehyde production is effectively reduced, the reaction time of furaldehyde production is effectively shortened, energy conservation and emission reduction are achieved, the production cost of furaldehyde products is greatly reduced, highyield of the furaldehyde products is achieved, lignin components and cellulose components in biomass raw materials are efficiently separated, the purity of cellulose in residues is high, the cellulose can serve as a commodity or a raw material to be reused, and the method solves the problems that according to an existing furaldehyde production process, reaction steps are more, reaction temperature is high, reaction time is long, yield is low, and components cannot be efficiently separated.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Synthetic method for diaryl urea compound

InactiveCN103044287BHigh yieldShort reaction timeUrea derivatives preparationOrganic compound preparationRoom temperatureSolvent

The invention discloses a synthetic method for a diaryl urea compound. The method comprises the following steps: an aniline compound, bis (trichloromethyl)carbonate and a tertiary amine compound, expressed in the formula II, are reacted at the room temperature in a reaction solution, and are tracked and detected by TLC (Thin Layer Chromatography) till the reaction is totally finished; and the diaryl urea compound which is expressed in the formula I can be prepared by aftertreatment of the reaction liquid . The method adopts triphosgene as an acylation reagent, and adopts the tertiary amine compound as a catalyst and acid-binding agent, so that the reaction time is short, the reaction is generally finished within 1-2 hours, the conversion rate of raw materials achieves 100%, the product yield is high above 95%, the aftertreatment is convenient, and the purity is high.

Owner:WENZHOU UNIVERSITY

A kind of method for preparing glucosamine hydrochloride

InactiveCN101775045BInhibitionAvoid decompositionSugar derivativesSugar derivatives preparationWater vaporEthanol

Owner:汪昔奇 +1

A kind of negative electrode material of lithium ion battery, its preparation method and lithium ion battery

ActiveCN105742611BImprove electrochemical cycle performanceImproved magnification performanceCell electrodesSecondary cellsCarbon compositesMicrosphere

The invention provides a lithium ion battery negative material. The lithium ion battery negative material comprises nano silicon particles and carbon material particles, wherein the nano silicon particles are uniformly dispersed among the carbon material particles to form microspheres; and the carbon material particles are carbonized metallic organic skeleton materials. The microsphere structural silicon-carbon composite material is obtained by adopting a micro-emulsion method. Compared with the prior art of embedding nano silicon into each single carbon material particle to form a core-shell structure, a lithium ion battery manufactured with the negative material has higher electrochemical cycling performance and multiplying power performance; and meanwhile, the preparation method is simple and easy, and is low in reaction temperature, short in preparation time, good in controllability and favorable for mass production. An experiment shows that the primary discharge specific capacity of the prepared lithium ion battery at the multiplying power of 0.1C is 1800 to 2069 mAh / g, and after the lithium ion battery is circulated for 120 times, the discharge specific capacity is 1000 to 1280 mAh / g.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com