Preparation method of 8-hydroxyquinoline iron organic dye photodegradation catalyst

A technology of iron hydroxyquinoline and organic dyes, applied in the direction of organic chemical methods, iron organic compounds, iron group organic compounds without C-metal bonds, etc., can solve the difficulties of preparation and recovery separation, low efficiency of solar energy utilization, prohibition of titanium dioxide Bandwidth and other issues, to achieve the effect of high catalytic efficiency, cheap reaction raw materials, and short synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] ①Dissolve 27~165mg (E)-2-[2-(4-pyridyl)vinyl]-8-hydroxyquinoline in N,N-dimethylformamide or methanol, dissolve 40~240mg iron salt In 1~5mL of methanol or N,N-dimethylformamide, mix the two, then stir at room temperature, then raise the temperature of the reaction solution to 60~80°C, react at 60~80°C, after the reaction Slowly lower to room temperature to obtain brown-black blocky crystals, which are then washed in methanol and dried to obtain catalytically active 8-hydroxyquinoline catalyst a.

[0038] ②Dissolve 10mg of rhodamine B in 100mL of water, then add 5mg of the above catalyst, stir, and catalyze degradation under the irradiation of visible light. After sampling and centrifuging at regular intervals, the supernatant was taken to measure the ultraviolet-visible absorption spectrum, and the degradation rate of Rhodamine B was determined.

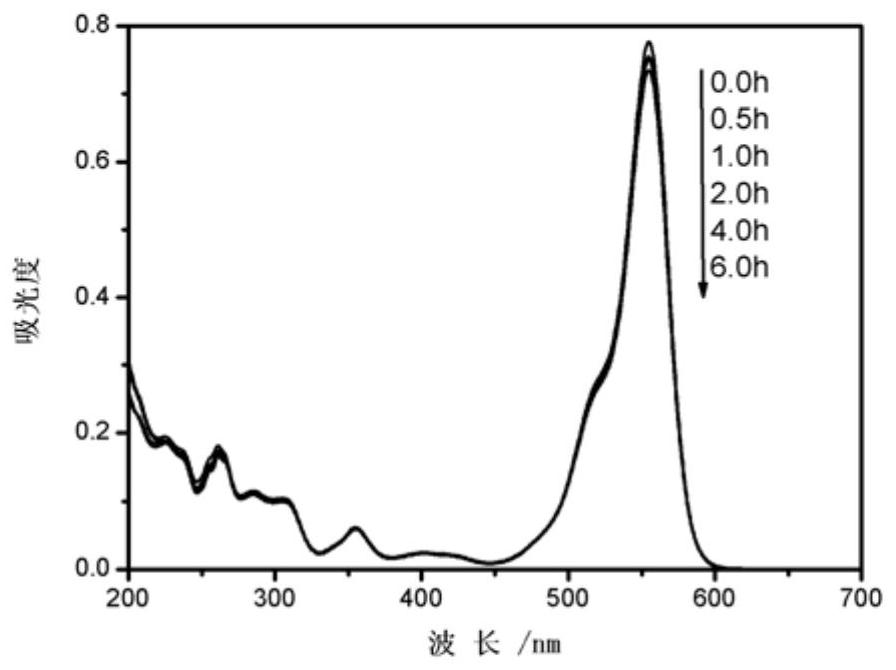

[0039] Such as Figure 4 As shown, as the illumination time prolongs, the intensity of the characteristic peak 554nm of Rh...

Embodiment 2

[0041] ①Dissolve 27~165mg (E)-2-[2-(3-nitrophenyl)vinyl]-8-hydroxyquinoline in N,N-dimethylformamide or methanol, 40~240mg iron Dissolve the salt in 1-5mL of methanol or N,N-dimethylformamide, mix the two, then stir at room temperature, then raise the temperature of the reaction solution to 60-80°C, react at a temperature of 60-80°C, and react Slowly lower to room temperature after the end to obtain brown-black bulk crystals, which are then washed in methanol and dried to obtain catalytically active 8-hydroxyquinoline catalyst b.

[0042] ②Dissolve 10mg of rhodamine B in 100mL of water, then add 5mg of the above catalyst, stir, and catalyze degradation under the irradiation of visible light. After sampling and centrifuging at regular intervals, the supernatant was taken to measure the ultraviolet-visible absorption spectrum, and the degradation rate of Rhodamine B was determined.

[0043] Such as Figure 5 As shown, with the prolongation of the light time, the intensity of t...

Embodiment 3

[0045] ①Dissolve 27~165mg (E)-2-[2-(4-methoxyphenyl)vinyl]-8-hydroxyquinoline in N,N-dimethylformamide or methanol, 40~240mg Dissolve the iron salt in 1-5mL of methanol or N,N-dimethylformamide, mix the two, and then stir at room temperature, then raise the temperature of the reaction solution to 60-80°C, and react at a temperature of 60-80°C. After the reaction was finished, it was slowly lowered to room temperature to obtain brown-black blocky crystals, which were then washed in methanol and dried to obtain the catalytically active 8-hydroxyquinoline catalyst c.

[0046] ②Dissolve 10mg of rhodamine B in 100mL of water, then add 5mg of the above catalyst, stir, and catalyze degradation under the irradiation of visible light. After sampling and centrifuging at regular intervals, the supernatant was taken to measure the ultraviolet-visible absorption spectrum, and the degradation rate of Rhodamine B was determined.

[0047] Such as Figure 6 As shown, with the extension of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com