Lithium ion battery negative material, preparation method thereof and lithium ion battery

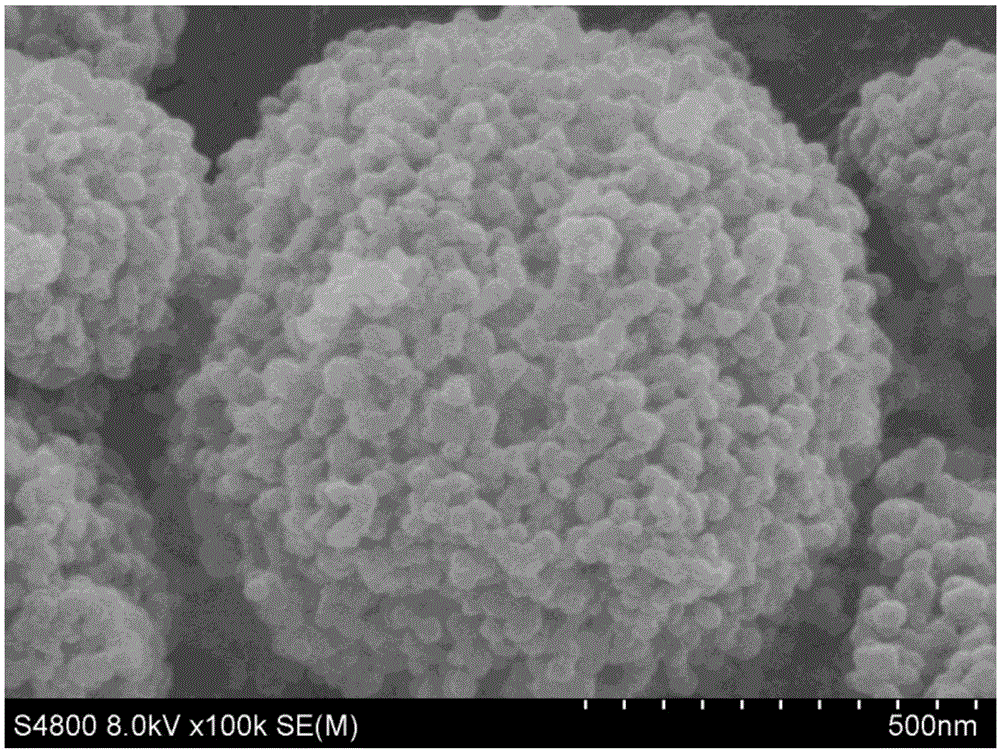

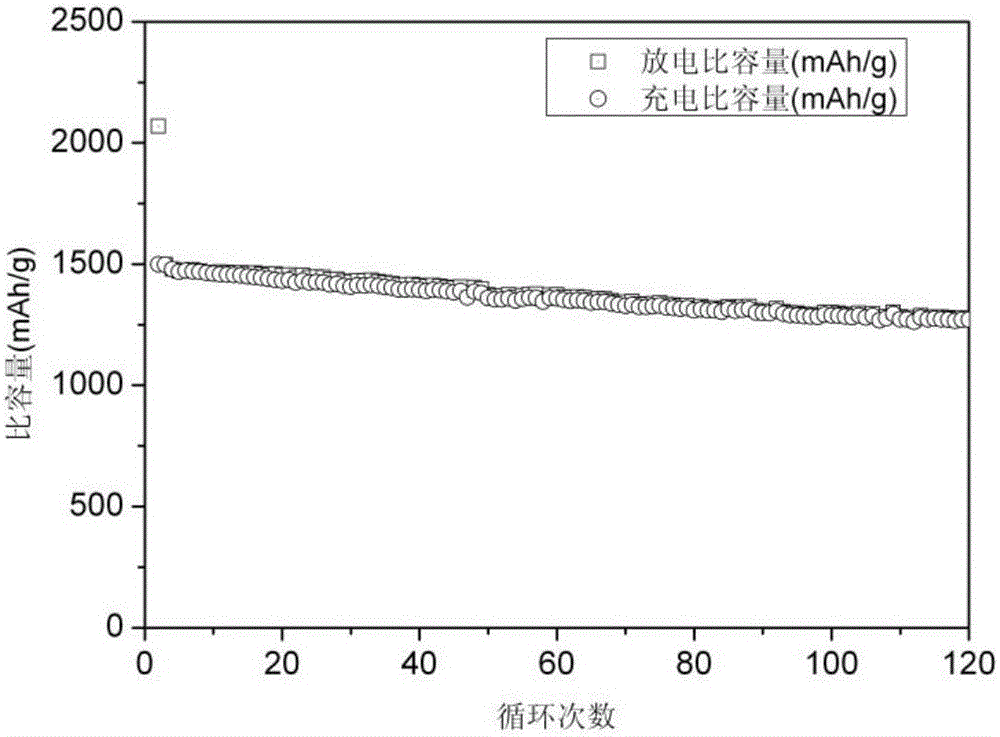

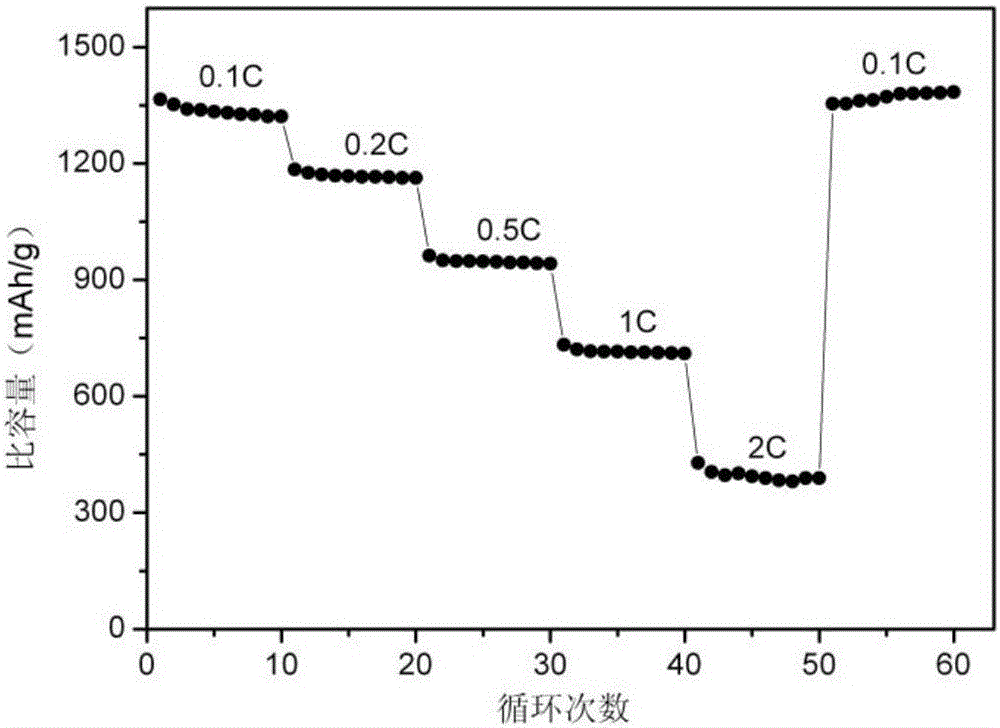

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of long preparation time, unfavorable large-scale production, cumbersome preparation steps, etc., and achieve high specific capacity and high electrochemical cycle Effects of performance and rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention provides a kind of preparation method of above-mentioned negative electrode material of lithium ion battery, comprises the following steps:

[0035] Mixing n-hexane, emulsifier, n-pentanol, deionized water, organic ligands and nano silicon powder to obtain the first microemulsion;

[0036] mixing n-hexane, emulsifier, n-pentanol, deionized water and metal inorganic salts to obtain a second microemulsion;

[0037] The first microemulsion and the second microemulsion are mixed and reacted, and the reaction product is subjected to carbonization treatment to obtain a lithium ion battery negative electrode material.

[0038] The method for preparing the first microemulsion is preferably:

[0039] Dispersing the organic ligand and nano silicon powder in deionized water to obtain the first mixed solution;

[0040] Mix n-hexane, emulsifier and n-pentanol evenly to obtain a second mixed solution;

[0041] Uniformly mixing the first mixed liquid and the sec...

Embodiment 1

[0063] Disperse the nano-silica powder in ethanol, heat it in a water bath to 60°C, add 3-aminopropyltriethoxysilane (APTES) under the condition of stirring, stir at constant temperature for 3 hours, cool to room temperature, and then add under the condition of stirring Succinic anhydride, continue to stir for 4 hours to obtain carboxylated modified nano-silicon powder; the mass ratio of the nano-silicon powder, ethanol, APTES and succinic anhydride is 200:118:1:400.

[0064] Uniformly mixing n-hexane, Span 80, n-pentanol, deionized water, 2-methylimidazole and carboxylated-modified nano silicon powder to obtain the first microemulsion. Among them, the mass ratio of 2-methylimidazole, carboxylated nano silicon powder, Span 80 and deionized water is 25:25:1400:4, and the volume ratio of n-hexane, n-pentanol and deionized water is 50 :25:1.

[0065] Mix n-hexane, Span 80, n-amyl alcohol, deionized water and zinc nitrate hexahydrate uniformly to obtain the second microemulsion. ...

Embodiment 2

[0072]Disperse the nano-silica powder in ethanol, heat it in a water bath to 60°C, add 3-aminopropyltriethoxysilane (APTES) under the condition of stirring, stir at constant temperature for 3 hours, cool to room temperature, and then add under the condition of stirring Succinic anhydride, continue to stir for 8 hours to obtain carboxylated nano-silicon powder; the mass ratio of the nano-silicon powder, ethanol, APTES and succinic anhydride is 300:180:1.5:600.

[0073] Uniformly mixing n-hexane, Span 80, n-pentanol, deionized water, trimesic acid and carboxylated nano-silica powder to obtain the first microemulsion. Among them, the mass ratio of trimesic acid, carboxylated nano silicon powder, Span 80 and deionized water is 2:1:1750:5, and the volume ratio of n-hexane, n-pentanol and deionized water is 60: 30:1.

[0074] Mix n-hexane, Span 80, n-amyl alcohol, deionized water and copper nitrate trihydrate uniformly to obtain the second microemulsion. Among them, the mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com