Lithium nitride/ceramic base composite material with high activity lithiation/delithiation performance

A composite material and lithium nitride technology are applied in the field of reversible lithium deintercalation composite active material and its preparation, lithium nitride/ceramic matrix composite negative electrode material and its preparation field, to achieve good electrochemical cycle performance and rate performance, lithium storage The effect of high capacity and wide charge-discharge voltage window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

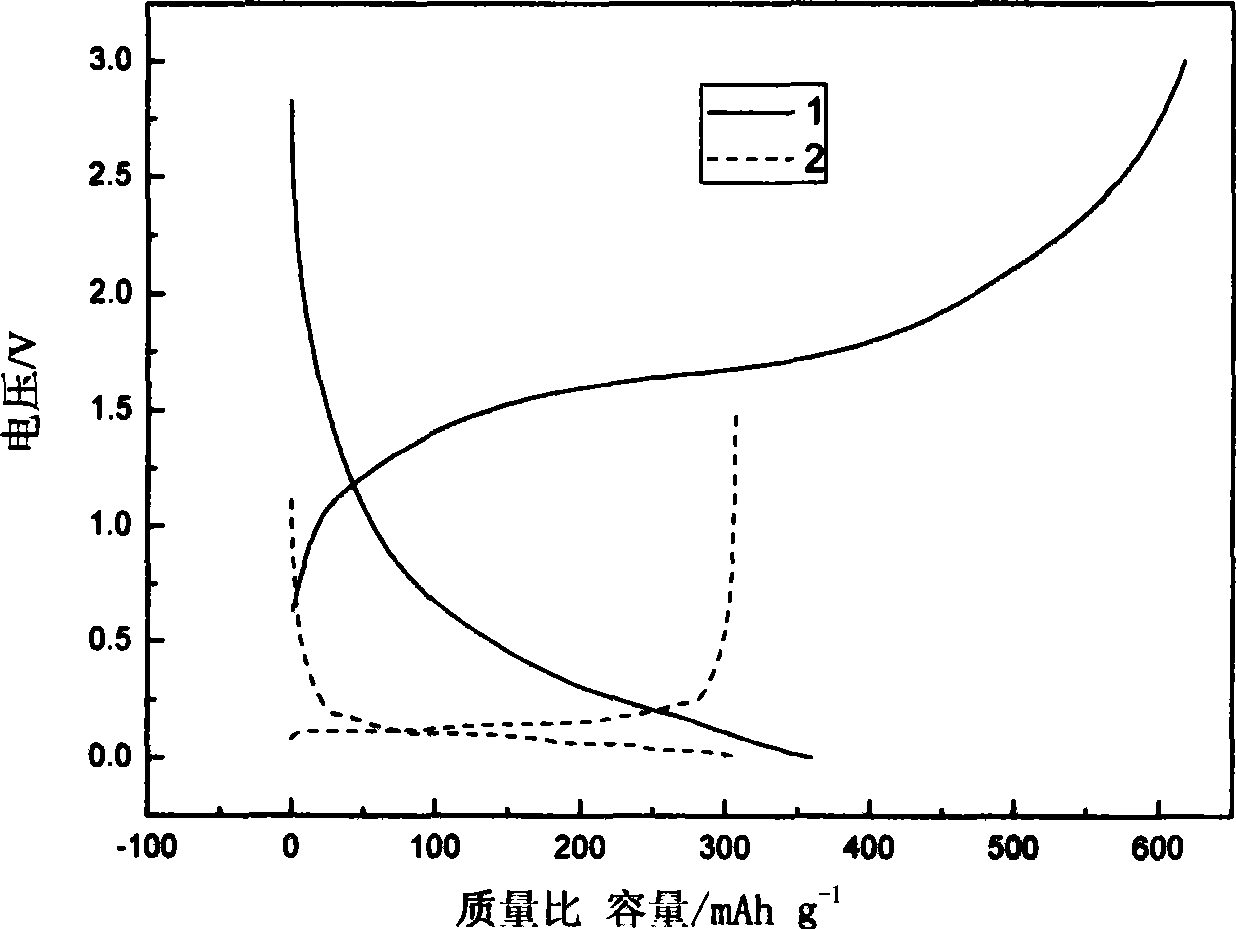

[0016] In a glove box filled with Ar gas, weigh an appropriate amount of Li at a molar ratio of 5:3 3 N and Si powder (<100 nanometers), mixed evenly, and placed in a stainless steel ball mill tank, sealed, and the tank was filled with Ar gas at this time. At room temperature, the ball mill was ball milled at a speed of 500 rpm for 5 hours to obtain the desired product.

[0017] The product after the reaction is made into an electrode sheet according to the pole piece preparation process, and the pole piece preparation method is as follows: take a certain amount of powdery ball mill product, add 20wt% acetylene black as a conductive agent, 10wt% PTFE (polytetrafluoroethylene) Ethylene) powder is used as a binder, and after being fully mixed, it is coated and pressed on a nickel foam substrate with a diameter of φ12mm as an electrode sheet for electrochemical testing. The prepared pole piece and metal Li are used as the counter electrode to make a button battery, and the elect...

Embodiment 2

[0019] In a glove box filled with Ar gas, weigh Li at a molar ratio of 1:3 3 N and nano-silicon nitride powder were mixed evenly, placed in a stainless steel ball mill jar in a glove box filled with argon, and sealed. At room temperature, the ball mill was milled at a frequency of 450 rpm for 10 hours to obtain the desired product. For the reacted product, the cut-off charge and discharge voltage of the electrochemical test process is 0-3V, and the others are the same as in Embodiment 1. The prepared composite negative electrode material has lithium intercalation activity, the first reversible capacity reaches more than 500mAh / g, and the first charge and discharge efficiency is more than 80%.

Embodiment 3

[0021] In a glove box filled with Ar gas, weigh an appropriate amount of Li at a molar ratio of 3:1 3 N and SiO 2 Powder, mixed evenly, and placed in a stainless steel ball mill jar, sealed, at this time the ball mill jar was full of Ar gas. At room temperature, the ball mill was milled at a frequency of 600 rpm for 5 hours. The desired product is obtained. The reaction product, the electrochemical test process is the same as in Example 1. The prepared composite anode material has a reversible capacity of more than 600mAh / g for the first time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com