Preparation method of hydroxypropyl methylcellulose acetate succinate in novel solvent system

A technology of hydroxypropylmethylcellulose and hydroxypropylmethyl acetate, which is applied in the field of preparation of hydroxypropylmethylcellulose succinate in a new solvent system, can solve the problem of the deterioration of product storage performance and the impact of acetic acid Product quality and performance, non-recyclable solvents and other issues, to achieve the effect of lowering the temperature, shortening the reaction time, and reducing the residual acetic acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

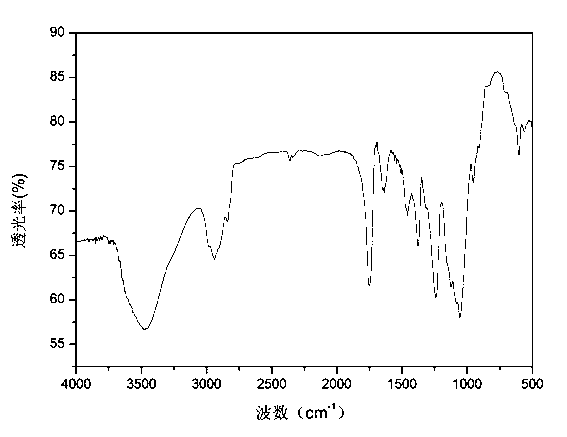

Image

Examples

Embodiment 1

[0026] (1) Esterification reaction: Add 10g of raw material hydroxypropyl methylcellulose, 80mL of solvent acetone, 8g of esterification agent succinic anhydride and 40mL of acetic anhydride, and 0.5g of catalyst 4-dimethylaminopyridine into the autoclave. The mixed system was reacted for 2 hours under the conditions of a pressure of 2 bar and a temperature of 85° C., and then the reaction was stopped.

[0027] (2) Product extraction: After the esterification reaction is completed, lower it to normal temperature, add an appropriate amount of water to the product, precipitate the product, wash it with boiling water for 3 times until it is odorless, dry it at 60°C, and distill and separate acetone to obtain the product , after detection, the content of acetyl group is 8.2% (mass fraction, the same below), and the content of succinyl group is 12.5% (mass fraction, the same below).

Embodiment 2

[0029] (1) Esterification reaction: Add 10g of raw material hydroxypropyl methylcellulose, 80mL of solvent acetone, 9g of succinic anhydride, and 1g of catalyst 4-dimethylaminopyridine into the autoclave. React at 85°C for 30 minutes, then add 40 mL of acetic anhydride into the autoclave, keep the original reaction temperature constant, continue the reaction for 2 hours, and then stop the reaction.

[0030] (2) Product purification: After the esterification reaction, cool down to room temperature, add an appropriate amount of dilute hydrochloric acid to the container to precipitate the product, filter under normal pressure, wash the product with boiling water for 3 times until it is odorless, and then dry it in an oven at 60°C , acetone was separated by distillation to obtain the target product, and the acetyl group content was found to be 8.9% after detection , The succinyl content is 13.2%.

Embodiment 3

[0032] (1) Esterification reaction: Add 10g of raw material hydroxypropyl methylcellulose, 500mL of solvent acetone, 8g of succinic anhydride, 1g of catalyst 4-dimethylaminopyridine, and 60mL of acetic anhydride into the autoclave. It was reacted for 4 hours under the conditions of 5 bar and 95° C., and the reaction was stopped.

[0033] (2) Product purification: After the esterification reaction, cool down to room temperature, add an appropriate amount of water to the container to precipitate the product, filter under normal pressure, wash the product with boiling water for 3 times until it is odorless, and then dry it in an oven at 60°C , acetone was separated by distillation to obtain the target product, and the acetyl content was 9.4% and the succinyl content was 11.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com