Method for preparing metal Ti by using hydrogen to induce Mg to restore TiO2

A metal and hydrogen pressure technology, applied in the field of metal materials, can solve the problems of complex process, restriction of titanium development and commercial application, high cost of titanium and titanium alloy preparation, and achieve simple process, short preparation time and less impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

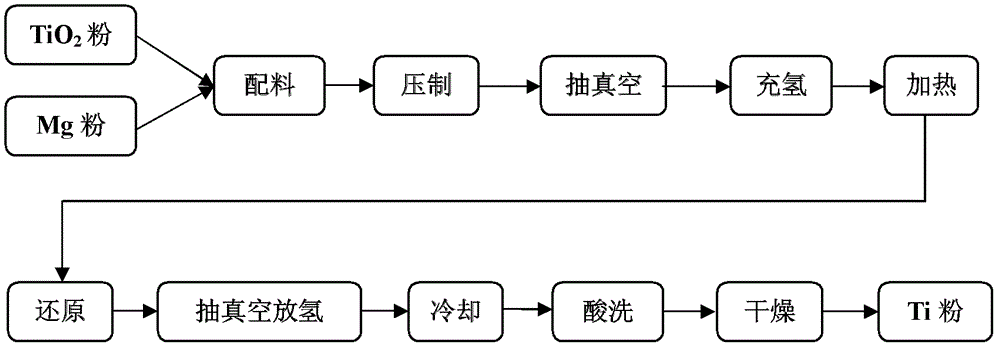

Method used

Image

Examples

Embodiment 1

[0018] Weigh TiO with a mass ratio of 4.5:3.5 2 and Mg, grind and mix in an agate mortar until the composition is uniform, and press it to Ф10×10mm under a pressure of 700MPa 2 The billet is put into the furnace and vacuumed to 10 -1 Pa, filled with 1.0MPa high-purity hydrogen, then heated up to 700°C at a rate of 10°C / min, and kept at 700°C for 3 hours to obtain TiH 2 Mixed powder with MgO, then evacuated to pressure ≤ 10 -1 Pa, then raise the temperature to 800°C for 2 hours to dehydrogenate in vacuum to obtain Ti and MgO, and after cooling to room temperature, pickle and dry to obtain powdered titanium metal.

Embodiment 2

[0020] Weigh TiO with a mass ratio of 5.5:2.5 2 and Mg, grind and mix in an agate mortar until the composition is uniform, and press it to Ф10×10mm under a pressure of 700MPa 2 The billet is put into the furnace and vacuumed to 10 -1 Pa, filled with 0.1MPa of high-purity hydrogen. Then the temperature was raised to 800°C at a rate of 10°C / min, and kept at 800°C for 5 hours to obtain TiH 2 Mixed powder with MgO, then evacuated to pressure ≤ 10 -1 Pa, then raise the temperature to 900°C for 1h to dehydrogenate in vacuum to obtain Ti and MgO, and after cooling to room temperature, pickle and dry to obtain powdered titanium metal.

Embodiment 3

[0022] Weigh TiO with a mass ratio of 5:3 2 and Mg, grind and mix in an agate mortar until the composition is uniform, and press it to Ф10×10mm under a pressure of 700MPa 2 The billet is put into the furnace and vacuumed to 10 -1 Pa, filled with 0.3MPa high-purity hydrogen, then heated up to 750°C at a rate of 10°C / min, and kept at 750°C for 2 hours to obtain TiH 2 Mixed powder with MgO, then evacuated to pressure ≤ 10 -1 Pa, then raise the temperature to 1000°C for 1h vacuum dehydrogenation to obtain Ti and MgO, after cooling to room temperature, pickling and drying to obtain powdered titanium metal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com