Method for preparing tetragonal phase zirconia nanorod

A phase zirconia and nanorod technology, applied in the field of preparing tetragonal zirconia nanorods, can solve the problems of high preparation cost and low efficiency, and achieve the effects of short reaction time, good repeatability and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

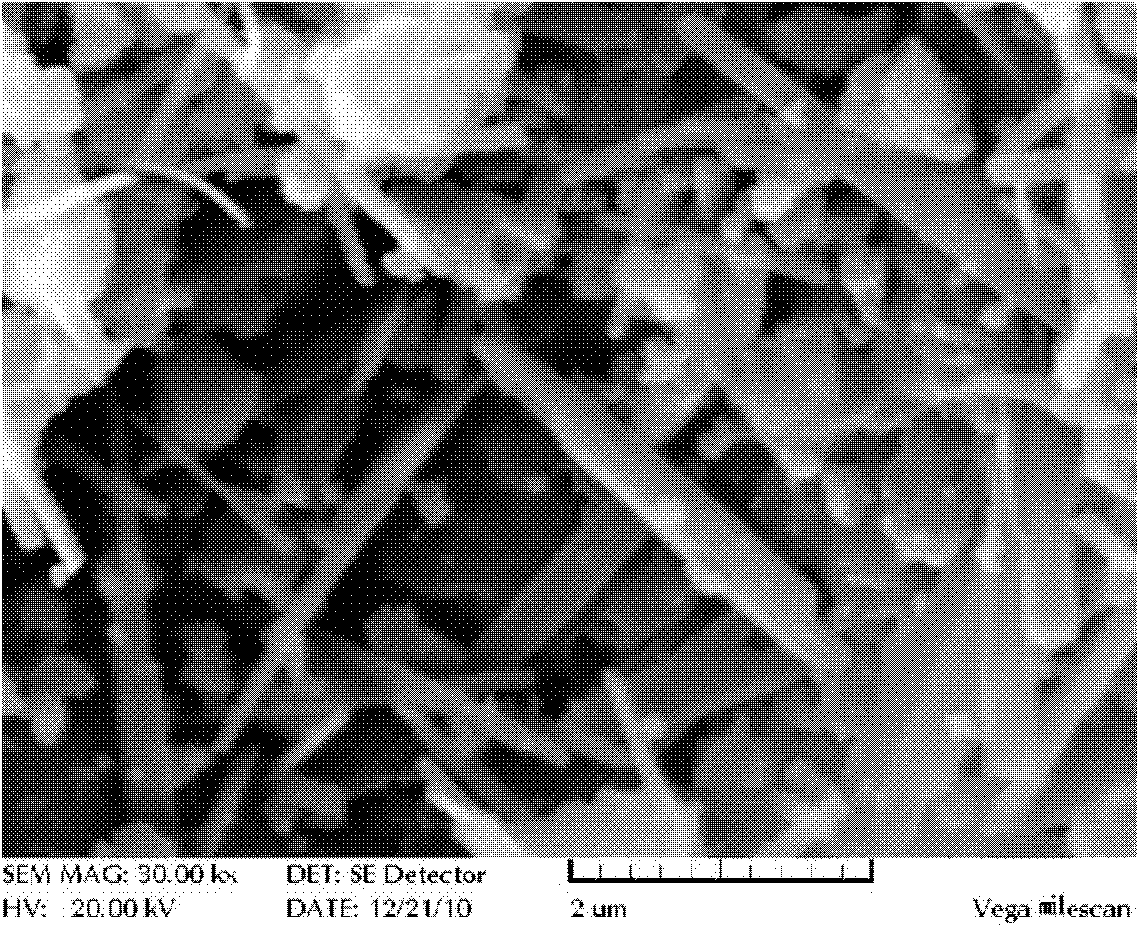

Image

Examples

Embodiment 1

[0019] Step 1: Select high-purity water-soluble ZrOCl 2 ·8H 2 O is dissolved in deionized water and configured into a solution, and the concentration of zirconium ions in the solution is 0.2mol / L;

[0020] Step 2: Add the NaOH mineralizer with a concentration of 0.1mol / L to the solution obtained in Step 1, and place it on a constant temperature magnetic stirrer at 50°C for 20 minutes, wherein the volume ratio of the zirconium salt solution to the mineralizer is 1:3;

[0021] Step 3: Add the precursor solution obtained in step 2 into a microwave digestion tank, and then move the microwave digestion tank into a microwave hydrothermal synthesizer for a synthesis reaction. The microwave hydrothermal synthesis reaction time is 40 minutes, and the microwave hydrothermal synthesis reaction temperature is 180°C. The reaction pressure of microwave hydrothermal synthesis is 1MPa, and it is naturally cooled to room temperature after the reaction;

[0022] Step 4: The product obtained ...

Embodiment 2

[0025] Step 1: Select high-purity water-soluble ZrOCl 2 ·8H 2 O is dissolved in deionized water and configured into a solution, and the concentration of zirconium ions in the solution is 0.4mol / L;

[0026] Step 2: Add the NaOH mineralizer with a concentration of 0.2mol / L to the solution obtained in step 1, and place it on a constant temperature magnetic stirrer at 50°C for 40 minutes, wherein the volume ratio of the zirconium salt solution to the mineralizer is 1:5;

[0027] Step 3: Add the precursor solution obtained in step 2 into a microwave digestion tank, and then move the microwave digestion tank into a microwave hydrothermal synthesizer for synthesis reaction. The microwave hydrothermal synthesis reaction time is 45 minutes, and the microwave hydrothermal synthesis reaction temperature is 190°C. The reaction pressure of microwave hydrothermal synthesis is 2MPa, and it is naturally cooled to room temperature after the reaction;

[0028] Step 4: The product obtained in...

Embodiment 3

[0031] Step 1: Select high-purity water-soluble ZrCl 4 Dissolved in deionized water, configured into a solution, the concentration of zirconium ions in the solution is 0.6mol / L;

[0032] Step 2: Add NaOH mineralizer with a concentration of 0.3mol / L to the solution obtained in step 1, and place it on a constant temperature magnetic stirrer at 50°C for 60 minutes, wherein the volume ratio of the zirconium salt solution to the mineralizer is is 1:7;

[0033] Step 3: Add the precursor solution obtained in step 2 into a microwave digestion tank, and then move the microwave digestion tank into a microwave hydrothermal synthesizer for synthesis reaction. The microwave hydrothermal synthesis reaction time is 50 minutes, and the microwave hydrothermal synthesis reaction temperature is 200°C. The reaction pressure of microwave hydrothermal synthesis is 3MPa, and it is naturally cooled to room temperature after the reaction;

[0034] Step 4: The product obtained in step 3 was collected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com