Treatment and reuse method of purified terephthalic acid refining wastewater

A technology for purifying terephthalic acid and purifying wastewater, which is applied in water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. Unstable system operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

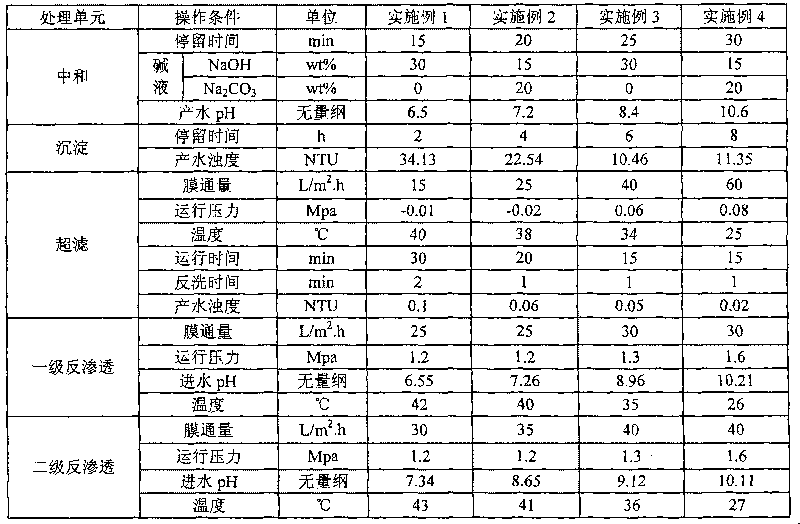

Embodiment 1~4

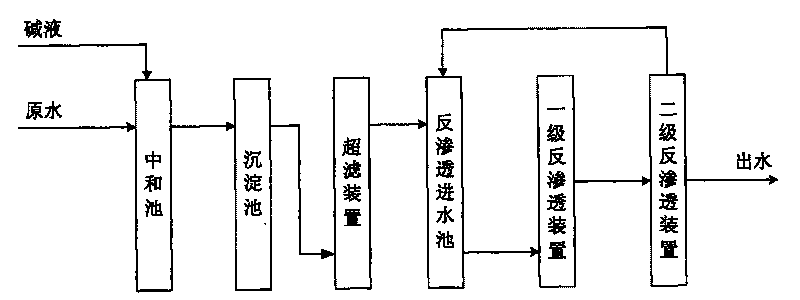

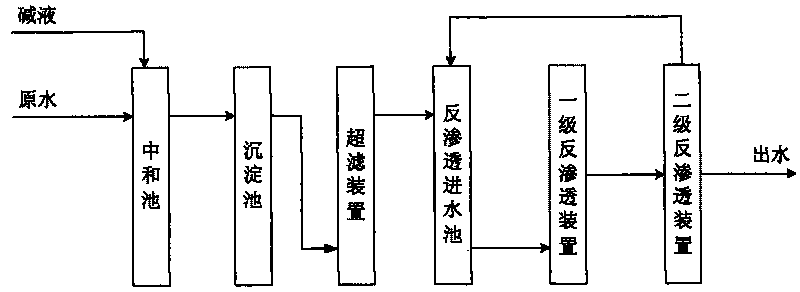

[0035] The PTA refined wastewater of an enterprise, the wastewater enters the neutralization tank, and alkali is added into the neutralization tank to adjust the pH value of the wastewater in the neutralization tank. After staying in the neutralization tank for a certain period of time, the wastewater enters the inclined plate sedimentation tank and stays in the After a certain period of time, the supernatant of the sedimentation tank enters the ultrafiltration unit for treatment, and the permeate treated by the ultrafiltration membrane enters the first-stage reverse osmosis unit for treatment, and the concentrated solution returns to the sedimentation tank to continue separation; after the first-stage reverse osmosis desalination treatment Finally, the primary reverse osmosis permeate and concentrate are obtained, and the permeate is further desalted through secondary reverse osmosis, and the concentrate can be biochemically treated by the enterprise sewage treatment unit. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com