Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Methyl vinyl ketone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

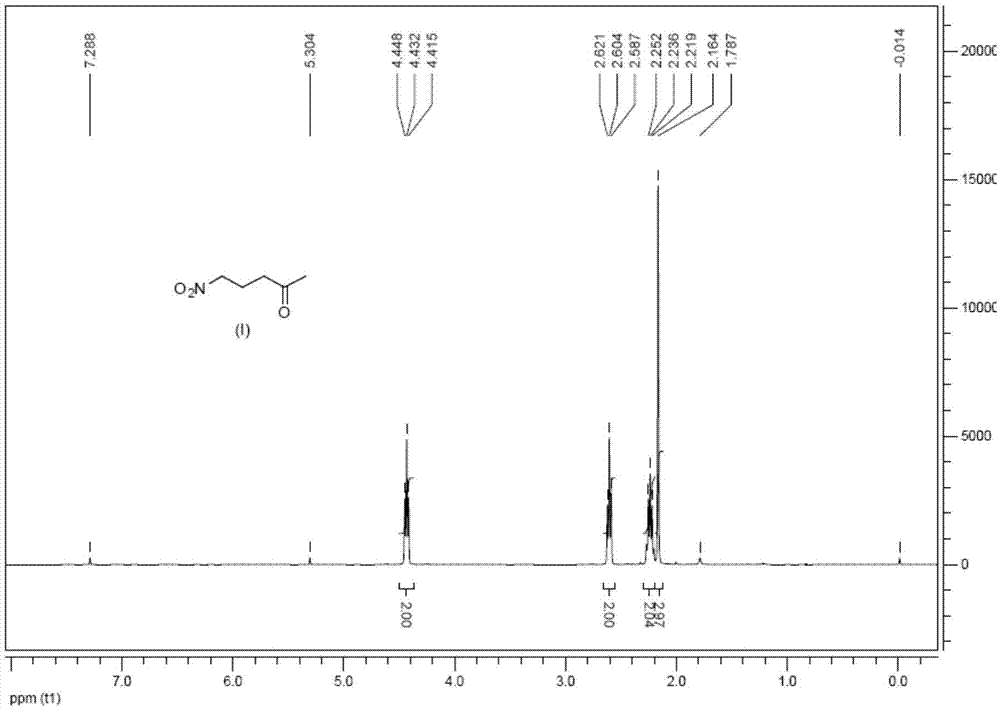

Methyl vinyl ketone (MVK, IUPAC name: butenone) is the organic compound with the formula CH₃C(O)CH=CH₂. It is a reactive compound classified as an enone, in fact the simplest example thereof. It is a colorless, flammable, highly toxic liquid with a pungent odor. It is soluble in water and polar organic solvents. It is a useful intermediate in the synthesis of other compounds.

Method for coproduction of methyl isobutyl ketone and methyl isobutyl carbinol

ActiveCN103420786ALow costImprove stabilityOxygen-containing compound preparationOrganic compound preparationChemical industryReaction temperature

The invention relates to a method for coproduction of methyl isobutyl ketone and methyl isobutyl carbinol, and particularly to the production method for simultaneously coproducing methyl isobutyl ketone and methyl isobutyl carbinol with acetone and hydrogen as raw materials, employing a non-pure noble metal catalyst especially employing a catalyst with a brand number of BC-A-61 and produced by Beijing Research Institute of Chemical Industry, and under reaction conditions of the reaction temperature of 170-230 DEG C, the reaction pressure of 1.0-6.0 MPa, the acetone liquid phase airspeed of 0.5-3.0 h<-1> and the hydrogen and ketone molar ratio of 0.3-1. The method of the invention has the advantages of relatively low catalyst cost, reasonable and simple technological process and low energy consumption, simultaneously coproduces two kinds of products which are methyl isobutyl ketone and methyl isobutyl carbinol and have supply and demand gaps existing in markets, and has few by-product heavy components.

Owner:ZHEJIANG XINHUA CHEM +1

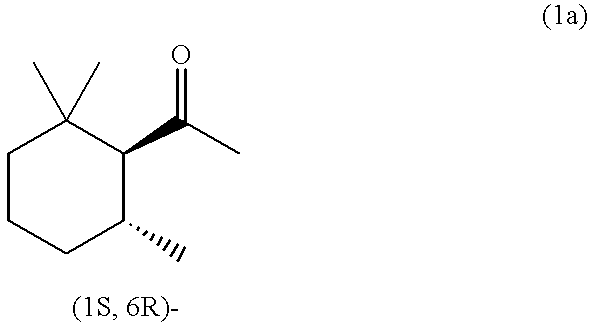

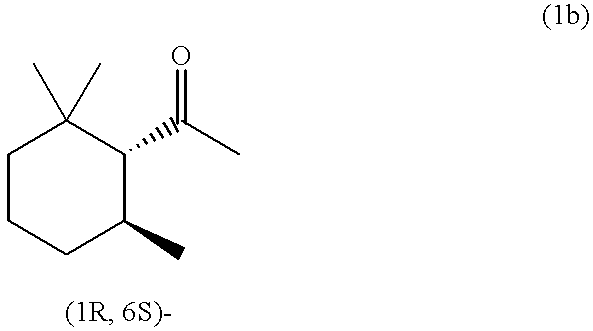

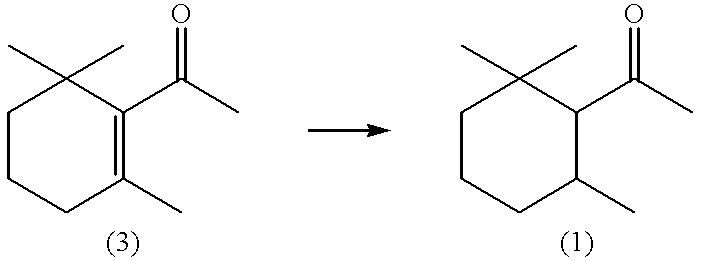

(1S,6R)-2,2,6-Trimethylcyclohexyl methyl ketone and/or (1R,6S)-2,2,6-trimethylcyclohexyl methyl ketone, process for producing the same, and perfume composition containing the same

InactiveUS20020042356A1Simple materialHigh selectivityCosmetic preparationsHydrocarbon by isomerisationKetoneMethyl Ketone

Trans-2,2,6-trimethylcyclohexyl methyl ketone, including (1S,6R)-2,2,6-trimethylcyclohexyl methyl ketone represented by the formula (1a): and (1R,6S)-2,2,6-trimethylcyclohexyl methyl ketone represented by the formula (1b): are useful components in a perfume composition. A process for producing the same is also described. A unique eucalyptus, mint-like and white floral perfume material is provided using the ketone compounds disclosed in the present invention. The process of the present invention produces the optically active ketone compounds having optical purity up to at least 98.0% e.e.

Owner:TAKASAGO INTERNATIONAL CORPORATION

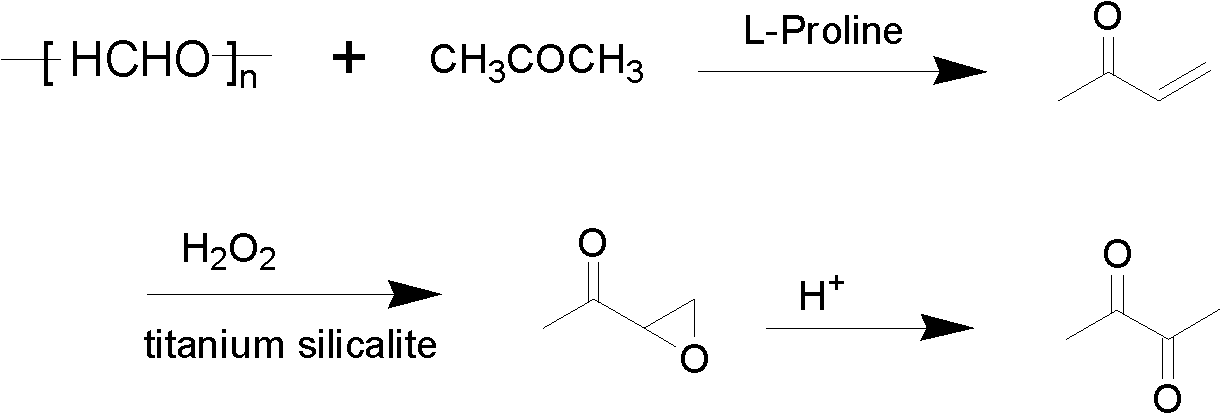

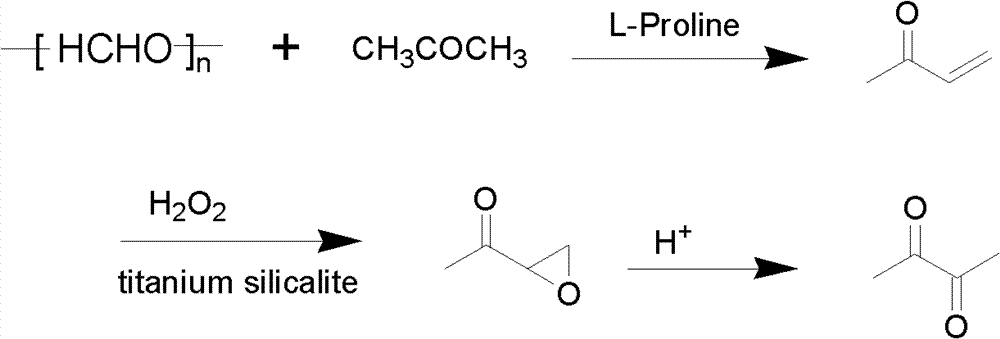

Method for preparing 2,3-butanedione from paraformaldehyde

InactiveCN101973860AReduce dosageImprove conversion ratePreparation from heterocyclic compoundsCatalytic oxidationKetone

The invention discloses a method for preparing 2,3-butanedione from paraformaldehyde. The method comprises the following steps of: preparing methyl vinyl ketone in one step from paraformaldehyde and acetone which serve as raw materials and L-proline serving as a catalyst through a condensation reaction of aldehydes and ketone and a dehydration reaction; and preparing 1,2-epoxy butanone from the methyl vinyl ketone serving as a raw material, hydrogen peroxide serving as an oxidant and a titanium and silicon molecular sieve serving as a catalyst by a catalytic oxidation method, and adding sodium hydrogensulfite for heating, and performing pinacol rearrangement to prepare 2,3-butanedione. Compared with the conventional method for preparing the 2,3-butanedione, the method has the characteristics of low cost, environmental-friendliness, high conversion rate of the paraformaldehyde and selectivity of the 2,3-butanedione and the like, and provides an environmental-friendly synthetic method for the industrial production of the 2,3-butanedione.

Owner:HUNAN NORMAL UNIVERSITY

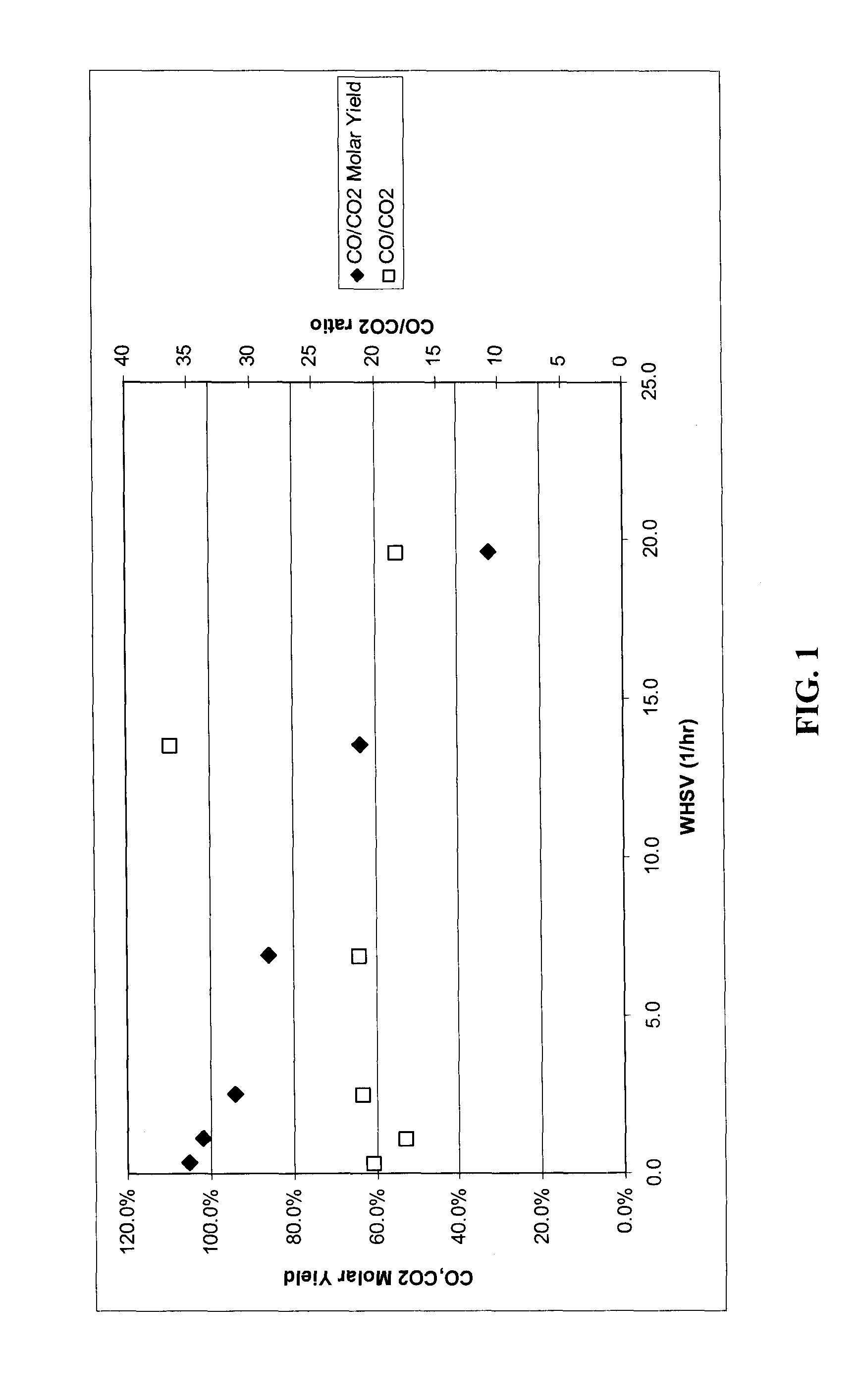

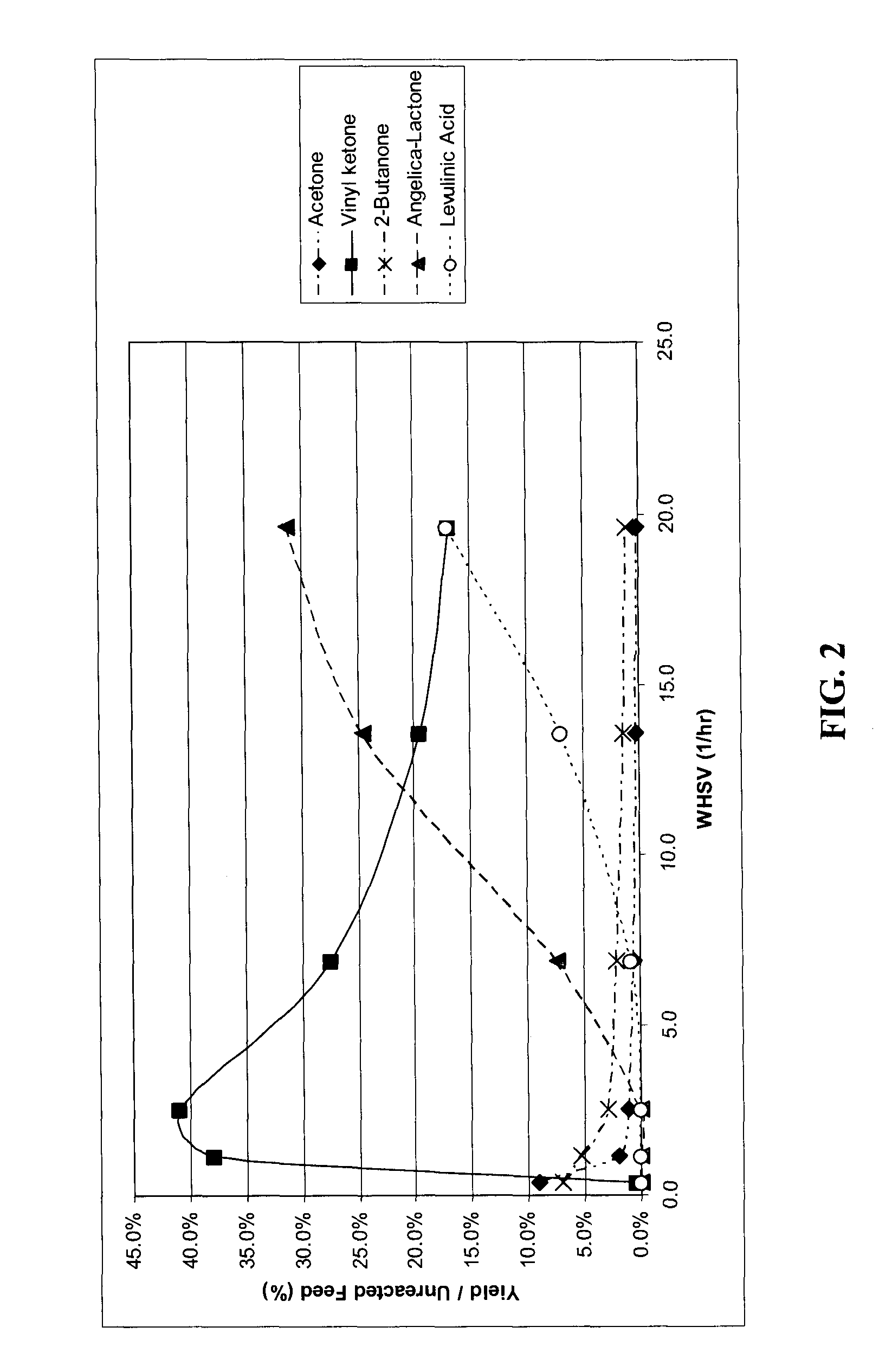

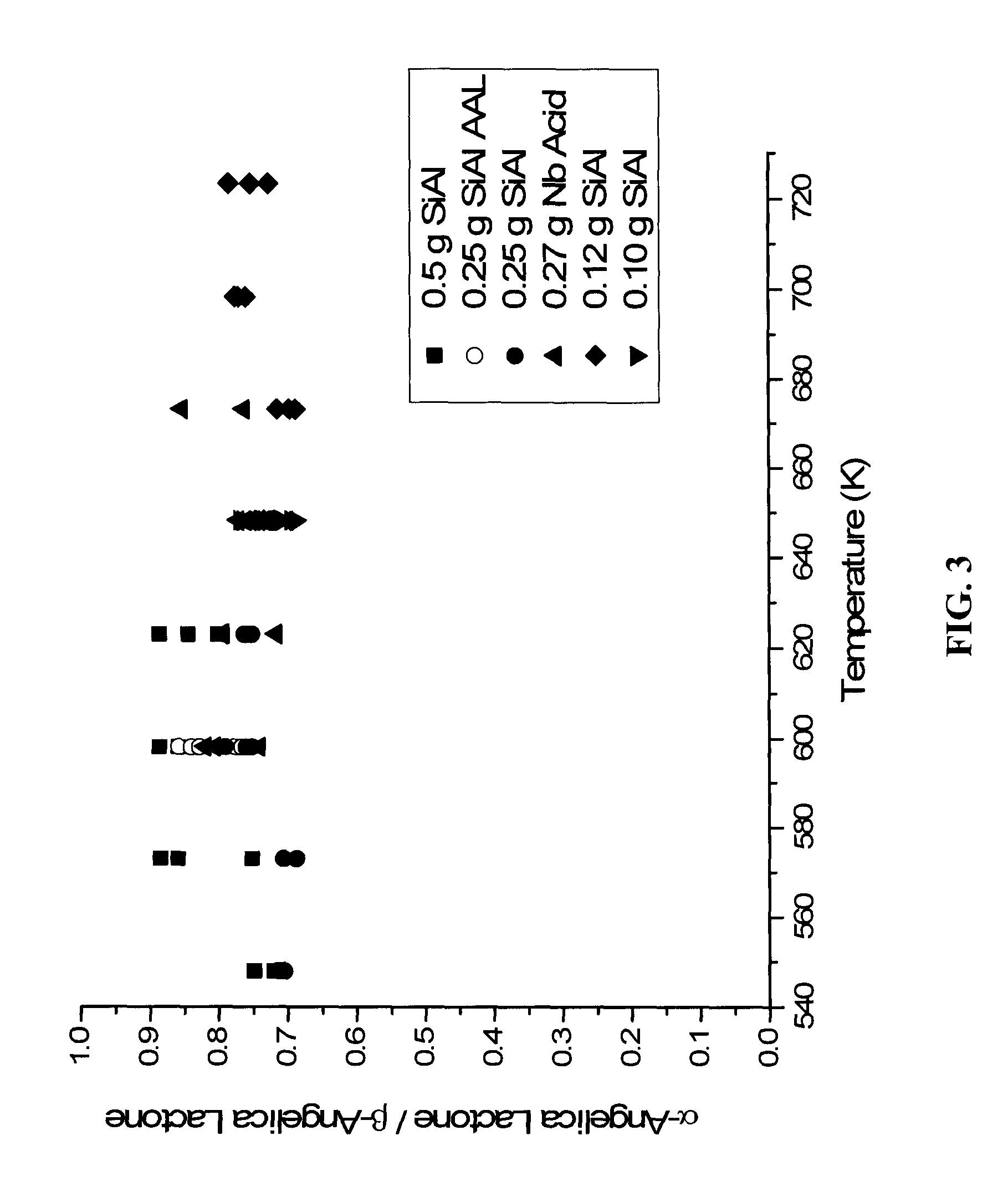

Production of methyl-vinyl ketone from levulinic acid

ActiveUS7960592B1Easy to chargeImprove bindingOrganic compound preparationCarbonyl compound preparationLevulinic acidRoom temperature

A method for converting levulinic acid to methyl vinyl ketone is described. The method includes the steps of reacting an aqueous solution of levulinic acid, over an acid catalyst, at a temperature of from room temperature to about 1100 K. Methyl vinyl ketone is thereby formed.

Owner:WISCONSIN ALUMNI RES FOUND

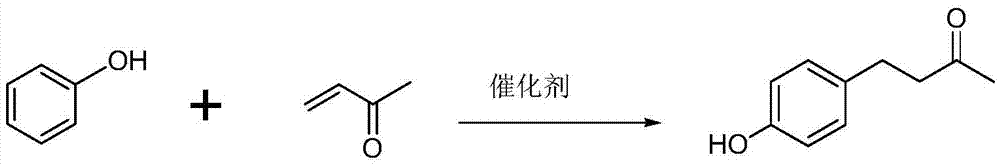

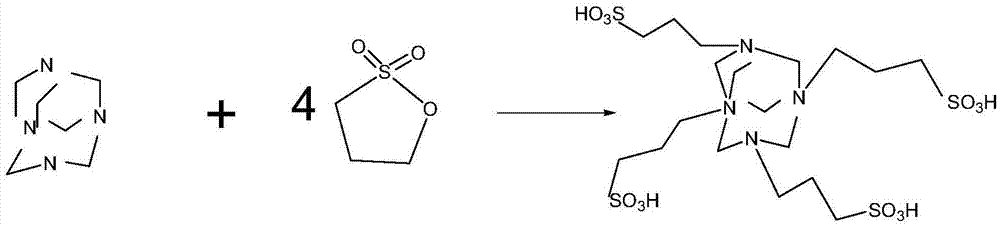

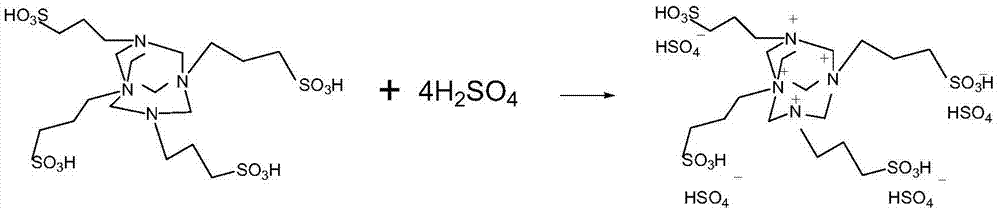

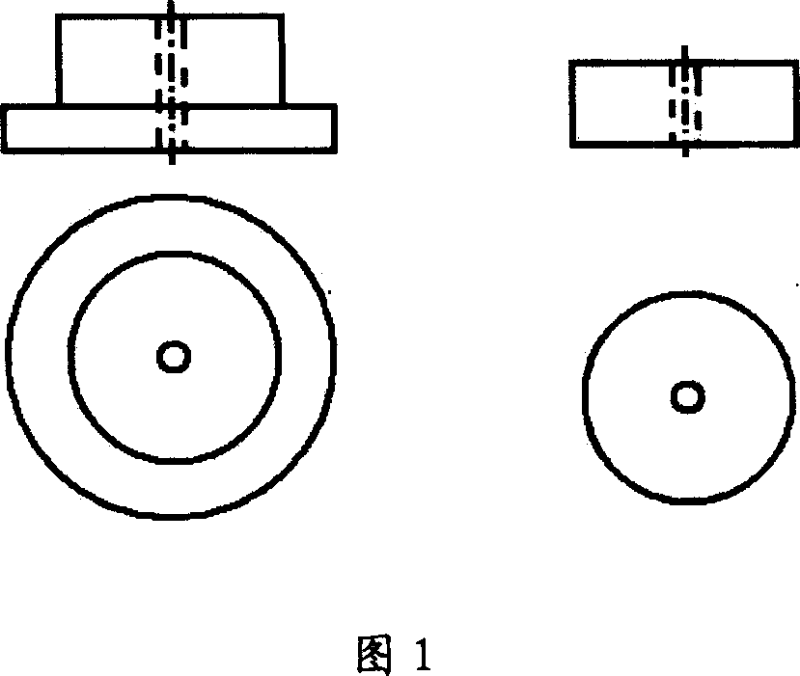

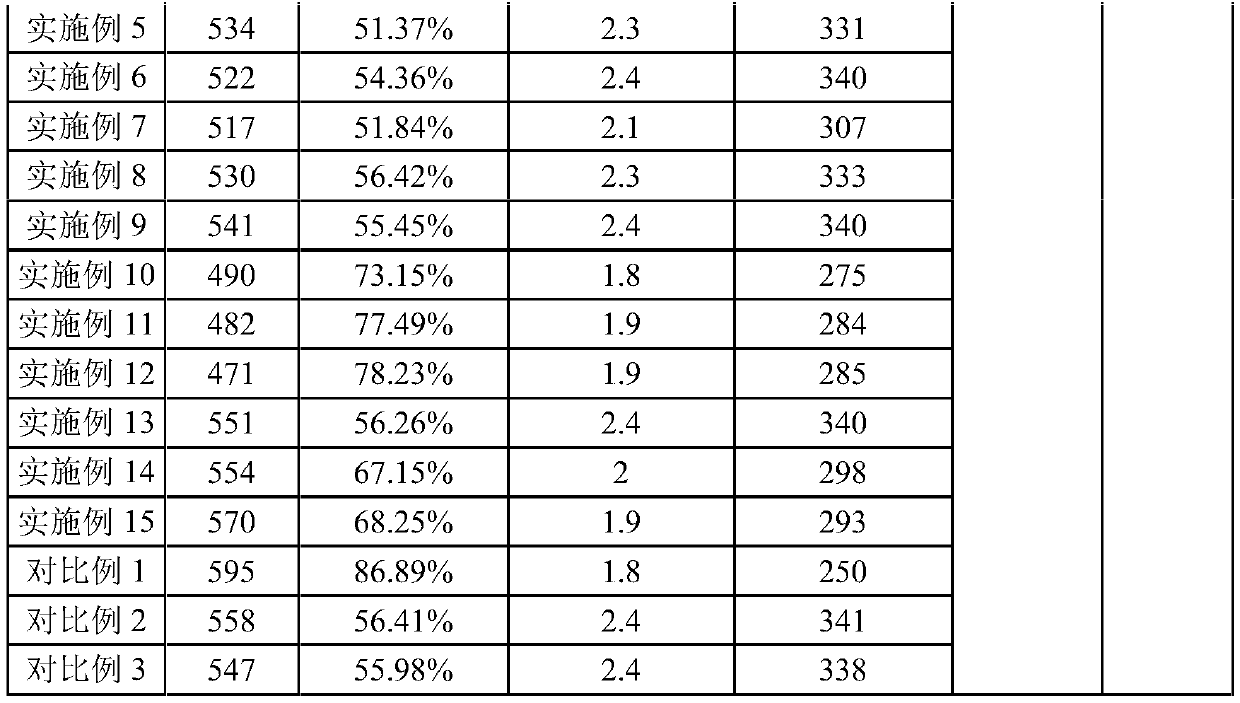

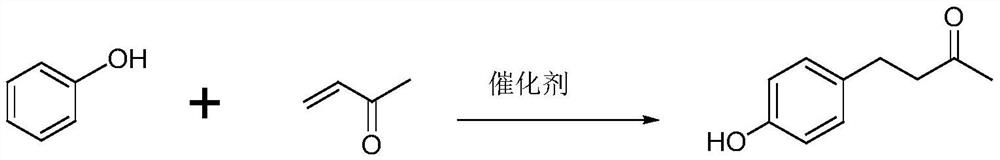

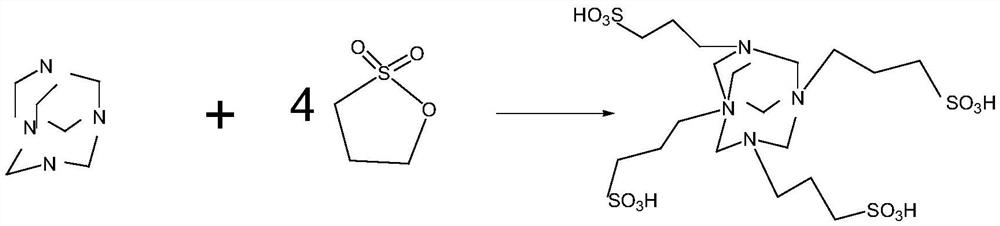

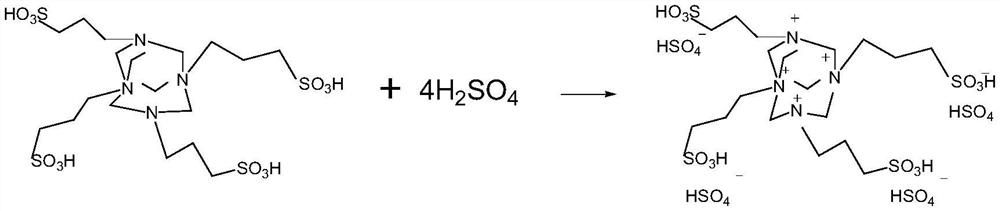

Method for preparing raspberry ketone under catalysis of multi-sulfonic functionalized ionic liquid

ActiveCN106916059AIncrease acidityHigh catalytic efficiencyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcid valueRoom temperature

The invention discloses a method for preparing raspberry ketone under the catalysis of multi-sulfonic functionalized ionic liquid. According to the method, phenol and methyl vinyl ketone are used as raw materials and the multi-sulfonic functionalized ionic liquid is used as a catalyst for selective catalytic synthesis of raspberry ketone. The ionic catalyst has the advantages of high acid value, low synthesis cost, good catalysis efficiency and reaction activity at room temperature compared with conventional ionic catalysts.

Owner:SHANGYU NHU BIOCHEM IND

Method of preparing photosensitivity multipolymer doped with optical-fibre preformed bar and the fiber core material

InactiveCN101041270AAvoid pollutionAvoid accumulationOptical articlesOptical light guidesRare earthRefractive index

Owner:UNIV OF SCI & TECH OF CHINA

Method for preparing (2E,4E)-2-methyl-6-oxo-2,4-heptadienal

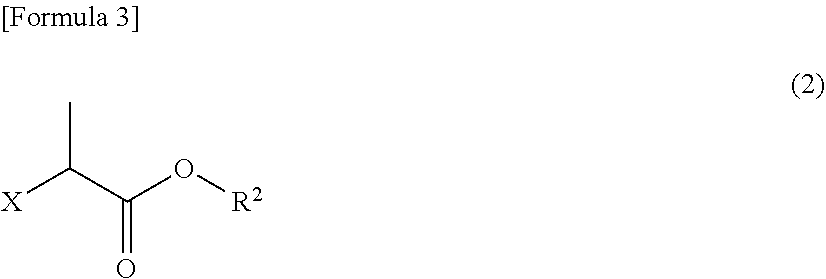

InactiveCN101229994AHigh reaction yieldEasy to purifyCarbonyl compound preparation by oxidationIodineCoupling reaction

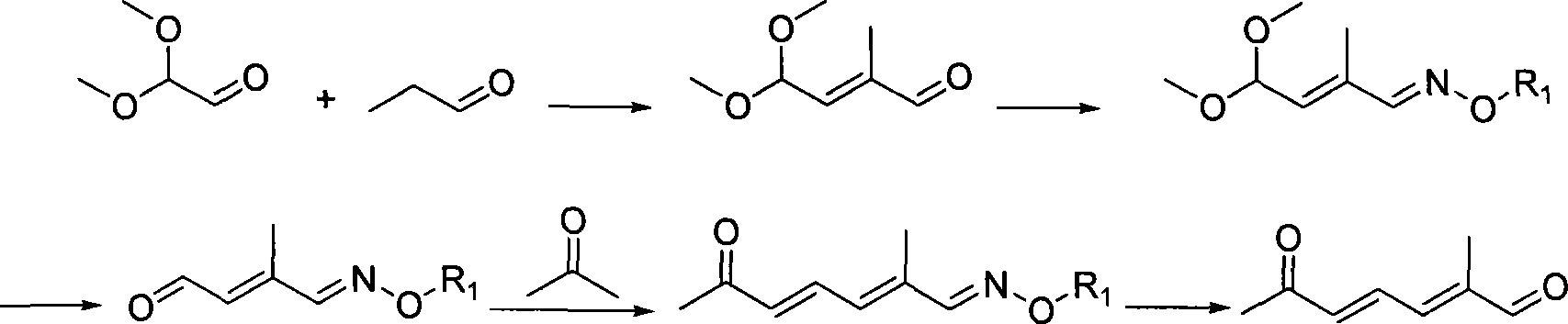

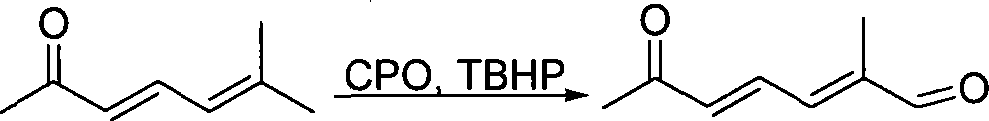

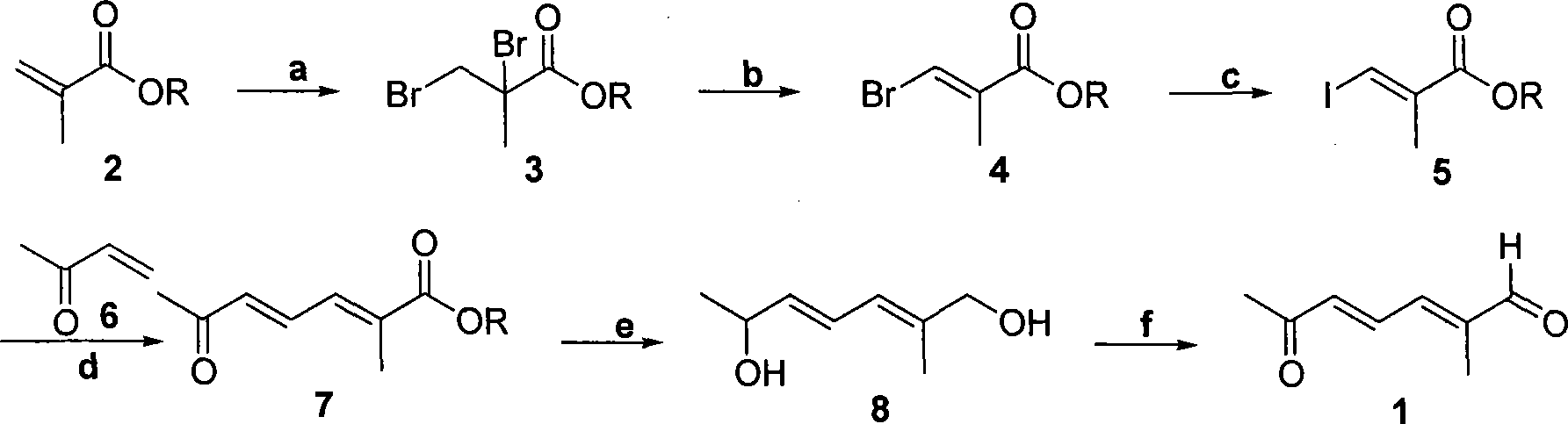

The invention discloses a synthetic method of (2E, 4E)-2-methyl-6-oxo-2 and 4- heptadiene aldehyde. The method of the invention comprises the processes: 2-methacrylate and alkyl methacrylate ester is transformed to 3-iodine-2-methacrylate and alkyl methacrylate esters through bromine addition, elimination and iodine exchanging; then a coupling reaction is carried out between the 3-iodine-2-methacrylate and alkyl methacrylate esters and methyl vinyl ketone to generate the (2E, 4E)-2-methyl-6-oxo-2 and the 4- heptadiene aldehyde; the (2E, 4E)-2-methyl-6-oxo-2 and the 4-heptadiene aldehyde are transformed to (2E, 4E)-2-methyl-2, 4-heptadiene-1 and 6-menthandiol through a reduction reaction; the (2E, 4E)-2-methyl-2, the 4-heptadiene-1 and the 6- menthandiol are oxidized to obtain the (2E, 4E)-2-methyl-6-oxo-2 and the 4- heptadiene aldehyde.

Owner:LANZHOU UNIVERSITY

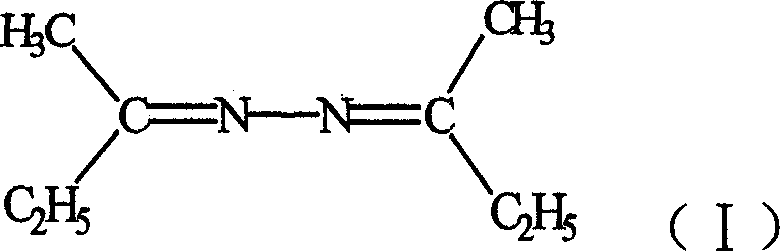

Synthesis process of methyl ethyl ketone azine

The synthesis process of methyl ethyl ketone azine includes the synthesis of ammonia, hydrogen peroxide and methyl ethyl ketone in work solution containing catalyst and ionic liquid at 20-100 deg.c, and post-treatment to obtain product. The synthesis process inside ionic liquid of the present invention has high safety, high dissolubility on organic matter and inorganic matter, homogeneous reaction condition, easy operation and treatment, and high product yield. The ammonia water, methyl ethyl ketone and methyl cyanide distilled out of the reacted liquid may be reused without influence on the yield.

Owner:ZHEJIANG UNIV OF TECH

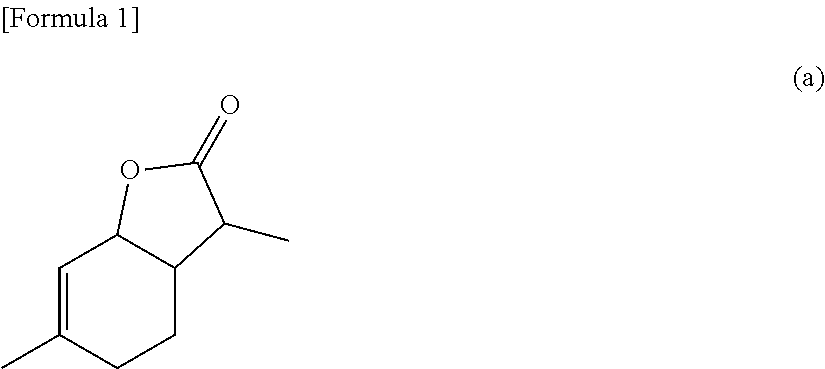

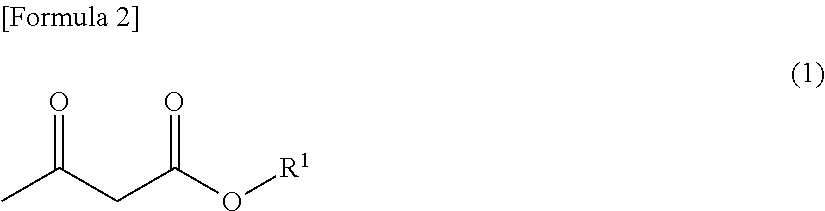

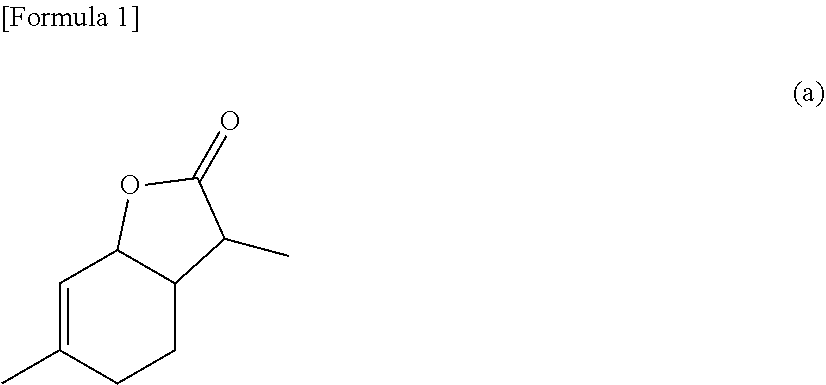

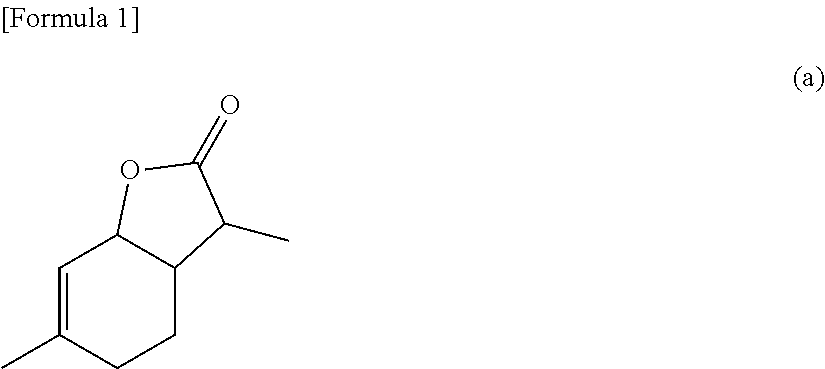

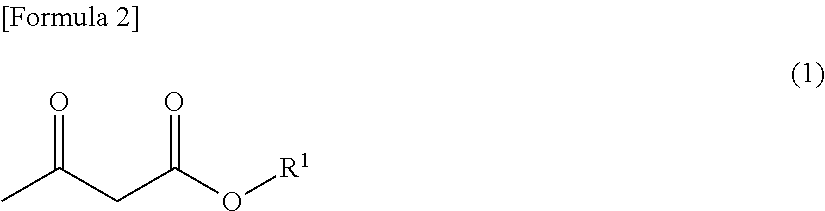

Process for producing wine lactone

The present invention relates to a method comprising (A) reacting a β-keto ester with a 2-halo ester under basic conditions to obtain a 2-aceto-3-methyl-succinic acid ester; (B) reacting the resulting 2-aceto-3-methyl-succinic acid ester with methyl vinyl ketone under basic conditions, optionally followed by a decarboxylation reaction and hydrolysis, etc., to obtain an α-methyl-γ-keto acid; and (C) reducing the resulting α-methyl-γ-keto acid to obtain wine lactone or a stereoisomer thereof or a mixture thereof. Alternatively, the present invention relates to a method comprising step (A) as recited above; (B) reacting the resulting 2-aceto-3-methyl-succinic acid ester with methyl vinyl ketone under basic conditions, followed by decarboxylation reaction to obtain an α-methyl-γ-keto acid ester; and (E) reducing the resulting α-methyl-γ-keto acid ester in the presence of a ruthenium complex having a specific structure and in the presence of a hydrogen donor to obtain wine lactone or a stereoisomer thereof or a mixture thereof.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Production method of 4-hydroxy-2-butanone

InactiveCN110105187AImprove responseImprove conversion rateOrganic compound preparationPreparation by dehydrogenationChemical reactionDistillation

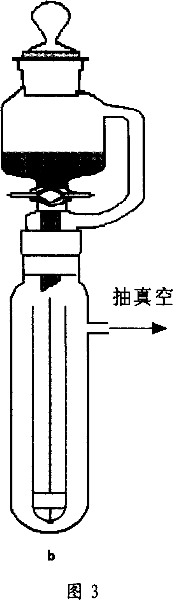

Belonging to the field of fine chemicals, the invention discloses a production method of 4-hydroxy-2-butanone, and solves the problem of low yield of existing synthetic methods. The method provided bythe invention includes the steps of: adding 1, 3-butanediol, a catalyst, an assistant, water and a water-carrying agent into a reaction kettle, and performing heating to 55-60DEGC; adding hydrogen peroxide dropwise into the mixed solution, and conducting reduced pressure distillation of water; stopping adding hydrogen peroxide, and further performing stirring for 1-1.5h to distill the water-carrying agent out; controlling the temperature of the system not higher than 60DEGC, and conducting reduced pressure rectification to obtain the final product 4-hydroxy-2-butanone. By adding the assistant, 1, 3-butanediol can better participate in the reaction, and the conversion rate can be improved. The chemical reaction carried out in the invention is carried out under a negative pressure condition, and the temperature is controlled not higher than 60DEG C, thus avoiding the generation of methyl vinyl ketone; and in a negative pressure system, the reaction can be fully carried out under a low temperature condition, the product is easier to distill, and impurities are not easily produced.

Owner:GANSU RES INSTION OF CHEM IND GRICI +1

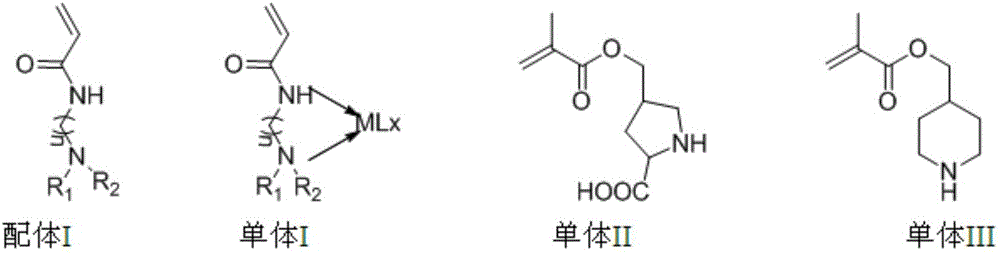

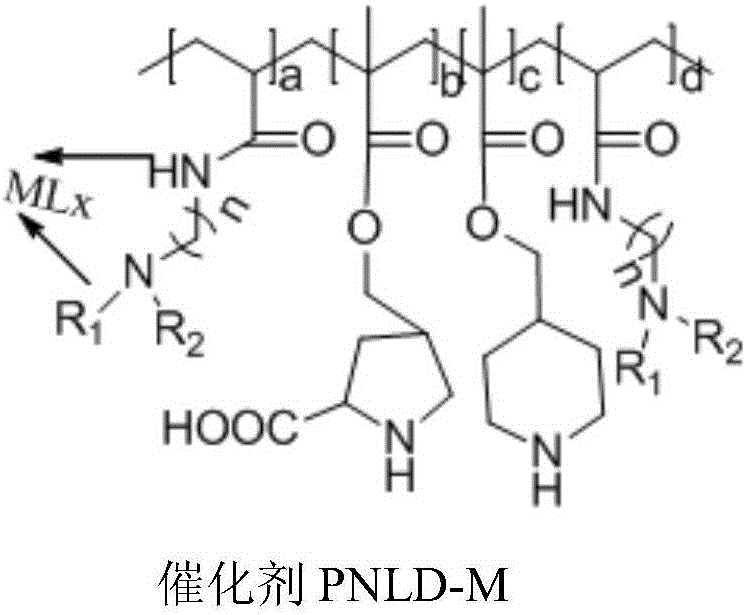

Polymer metal complex catalyst for synthesizing methyl isobutyl ketone

ActiveCN106040301AEffective recoveryEfficient condensationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPolymer metalHydrogen

The invention belongs to the technical field of catalysis and relates to a preparation method for synthesizing a methyl isobutyl ketone catalyst and application thereof, particularly to a preparation method for synthesizing methyl isobutyl ketone at a single state by using acetone and isopropanol as materials, and application of the method. The acetone and isopropanol are catalyzed with the self-made polymer metal complex catalyst to directly synthesize MIBK at one step, the temperature is 80-120 DEG C, reaction time is 10-24 hours, 35.9-38% of acetone conversion rate, MIBK is 94.3-95.9% in selectivity, and the catalyst may be used stably. During reaction, the isopropanol is used as a hydrogen source to release hydrogen of a molecule, the byproduct is acetone and may be used as a material for synthetic MIBK for reuse, and at the consideration of a while, the method has no need for hydrogen, reacting is at normal pressure or micro normal powder, no waste is produced, and the need for green and clean production is met.

Owner:NANJING UNIV +2

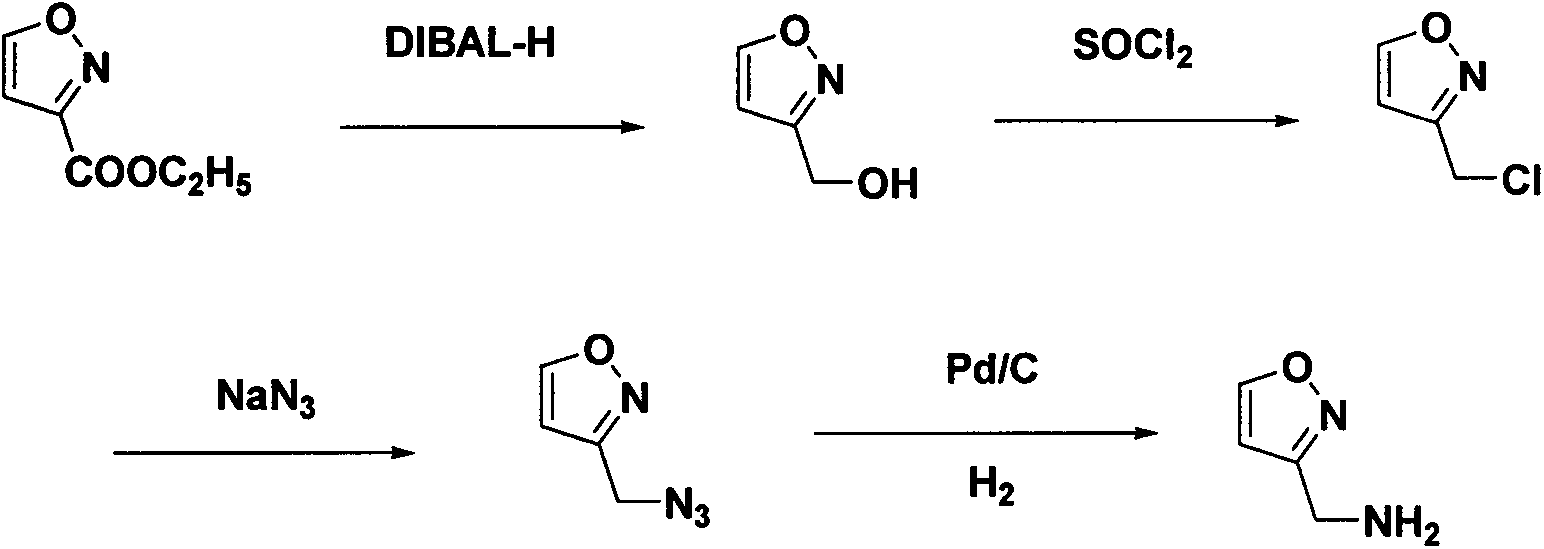

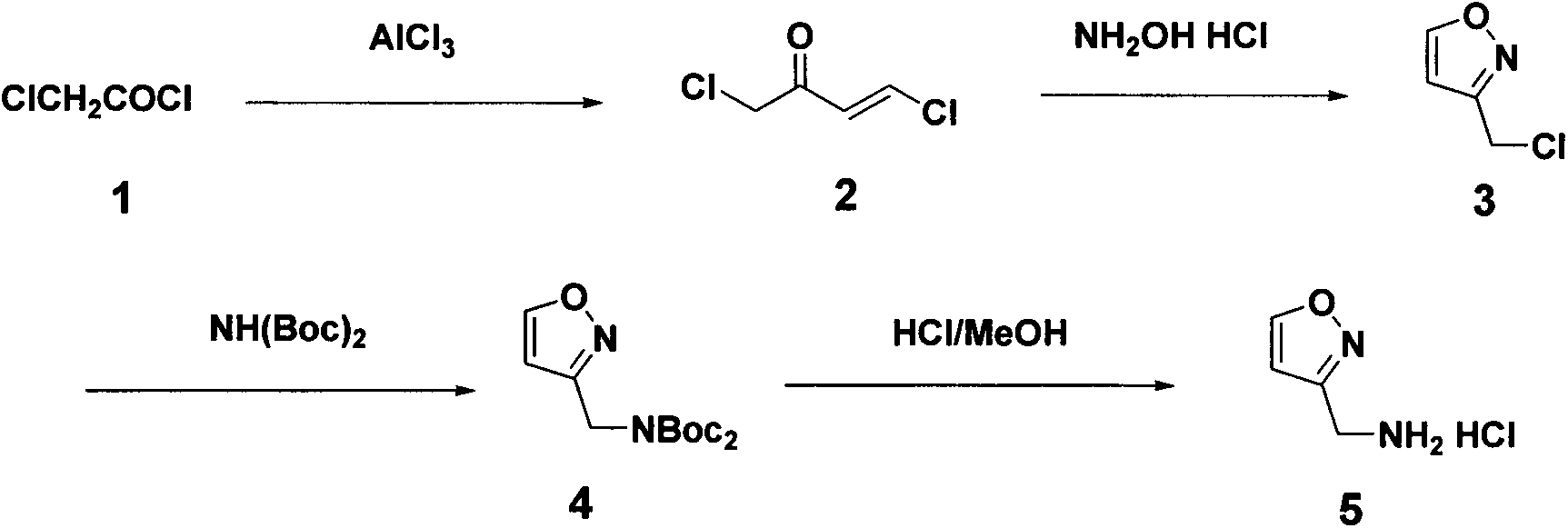

Synthetic method of 3-aminomethyl-isoxazole hydrochloride

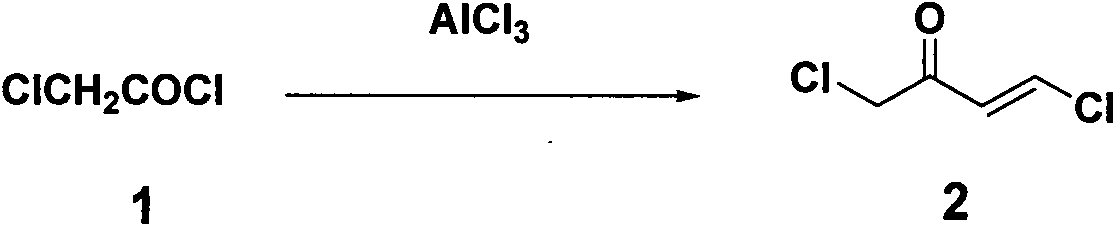

InactiveCN103242256ASimple ingredientsRaw materials are easy to getOrganic chemistryAluminium chlorideAcetonitrile

The invention discloses a synthetic method of 3-aminomethyl-isoxazole hydrochloride. The synthetic method comprises the steps that with aluminium chloride as a catalyst, chloroacetyl chloride reacts with acetylene to obtain 2,4-dichloro-2-methyl vinyl ketone, then the 2,4-dichloro-2-methyl vinyl ketone and hydroxylamine hydrochloride carry out reflux ring closure in methanol to obtain 3-chloromethyl-isoxazole, then the 3-chloromethyl-isoxazole reacts with NH(Boc)2 in acetonitrile to obtain a key intermediate bi-Boc aminomethyl-isoxazole, and finally Boc is removed in a hydrochloric acid-methanol solution to obtain the target product 3-aminomethyl-isoxazole hydrochloride. The method is mild and simple in reaction conditions, low in cost, high in yield, simple and convenient to operate and suitable for industrial production.

Owner:苏州科捷生物医药有限公司

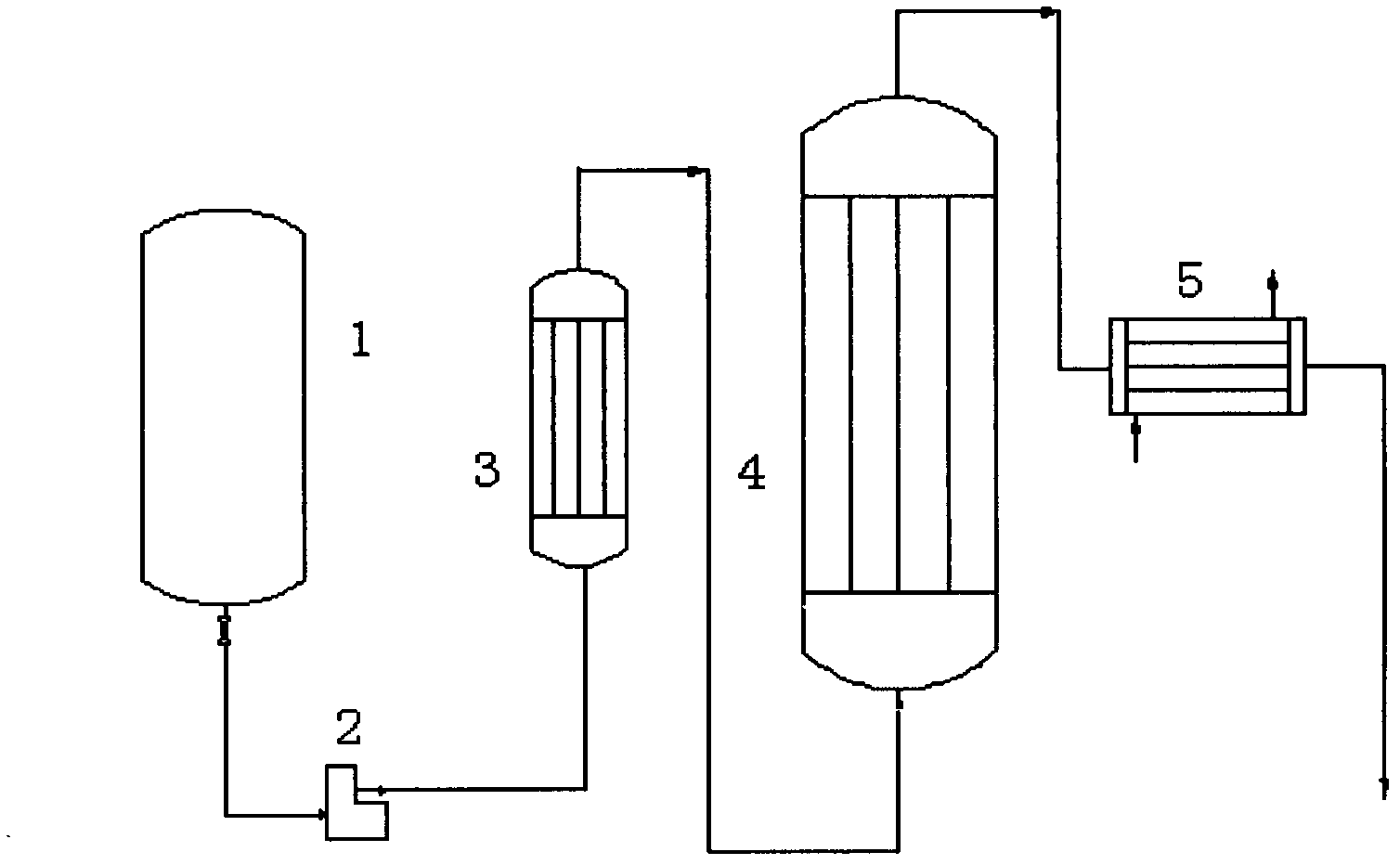

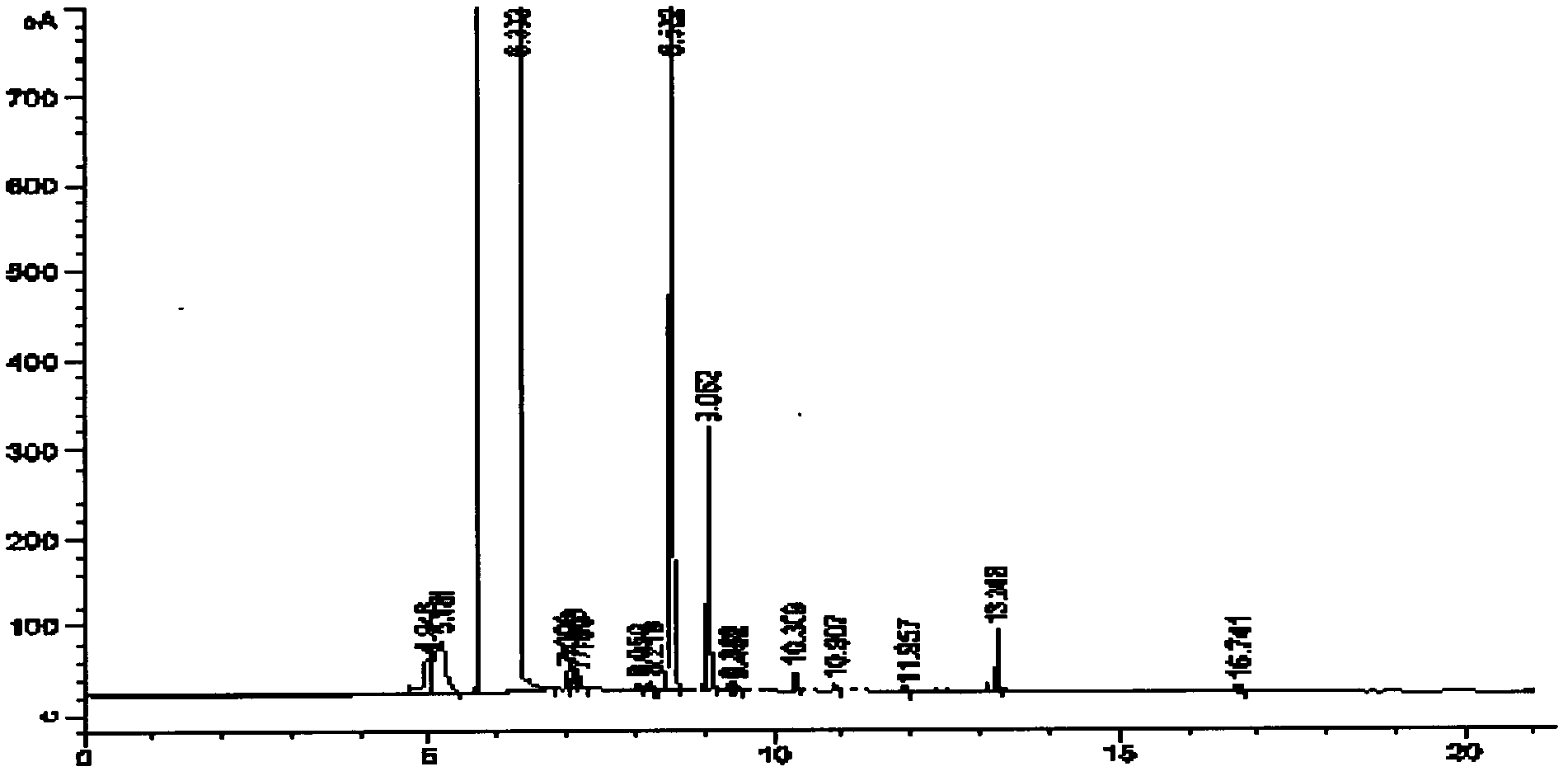

Method of using modified alumina catalyst to continuously prepare methyl vinyl ketone

InactiveCN102633611BEasy to handleImprove conversion ratePhysical/chemical process catalystsOrganic compound preparationWastewaterOrganic chemistry

The invention relates to a method of using a modified alumina catalyst to continuously prepare methyl vinyl ketone, which includes the steps: reacting crude methylolacetone in the existence of the modified alumina catalyst at the temperature of 80-150 DEG C, and condensing and drying effluence to obtain the methyl vinyl ketone. Crude methyl vinyl ketone high in water content can be treated by the method, selectivity of the methyl vinyl ketone can be higher than 95%, and conversion rate of the methyl vinyl ketone is effectively increased while selectivity of the methyl vinyl ketone is effectively improved. Further, the method using the continuous production process is simple in procedure, stable in production process, easy to control, safe and reliable in production, low in energy consumption and less in waste water.

Owner:NANKAI UNIV

Process for producing wine lactone

The present invention relates to a method comprising (A) reacting a β-keto ester with a 2-halo ester under basic conditions to obtain a 2-aceto-3-methyl-succinic acid ester; (B) reacting the resulting 2-aceto-3-methyl-succinic acid ester with methyl vinyl ketone under basic conditions, optionally followed by a decarboxylation reaction and hydrolysis, etc., to obtain an α-methyl-γ-keto acid; and (C) reducing the resulting α-methyl-γ-keto acid to obtain wine lactone or a stereoisomer thereof or a mixture thereof. Alternatively, the present invention relates to a method comprising step (A) as recited above; (B) reacting the resulting 2-aceto-3-methyl-succinic acid ester with methyl vinyl ketone under basic conditions, followed by decarboxylation reaction to obtain an α-methyl-γ-keto acid ester; and (E) reducing the resulting α-methyl-γ-keto acid ester in the presence of a ruthenium complex having a specific structure and in the presence of a hydrogen donor to obtain wine lactone or a stereoisomer thereof or a mixture thereof.

Owner:TAKASAGO INTERNATIONAL CORPORATION

High-resistance nickel-chromium electrothermal alloy material for electric heating elements

InactiveCN106350806AExcellent abrasion resistanceAntioxidant is goodMetallic material coating processesHigh resistanceEpoxy

The invention discloses a high-resistance nickel-chromium electrothermal alloy material for electric heating elements. The alloy material comprises a nickel-chromium alloy main body, wherein the nickel-chromium alloy main body is subjected to film coating treatment; the film coating treatment comprises the following steps: (1) sequentially adding 1-2 parts (by weight) of sodium hydroxide, 3.3 parts (by weight) of amino trimethylene phosphonic acid, 2.1 parts (by weight) of gamma-epoxy propyl ether trimethoxysilane and 1.1 parts (by weight) of nonylphenol ethyl oxide carboxylate into 40 parts (by weight) of deionized water, and carrying out uniform stirring; (2) then, sequentially adding 5.5 parts (by weight) of diethylene glycol phenyl ether, 2.6 parts (by weight) of methyl vinyl ketone, 0.5 part (by weight) of secondary sodium alkyl sulfate and 0.7 part (by weight) of benzotriazole e into the solution, and continuing to carry out stirring until thorough and uniform mixing is achieved, so as to prepare a film coating treatment solution; (3) dipping the nickel-chromium alloy main body in the film coating treatment solution, taking out the nickel-chromium alloy main body, and then, baking the nickel-chromium alloy main body. According to the high-resistance nickel-chromium electrothermal alloy material for the electric heating elements, disclosed by the invention, the surface of the nickel-chromium alloy main body is coated with a protective film, so that the performance is good, and the surface smoothness is good.

Owner:CHANGSHU MEILI ALLOY MATERIAL CO LTD

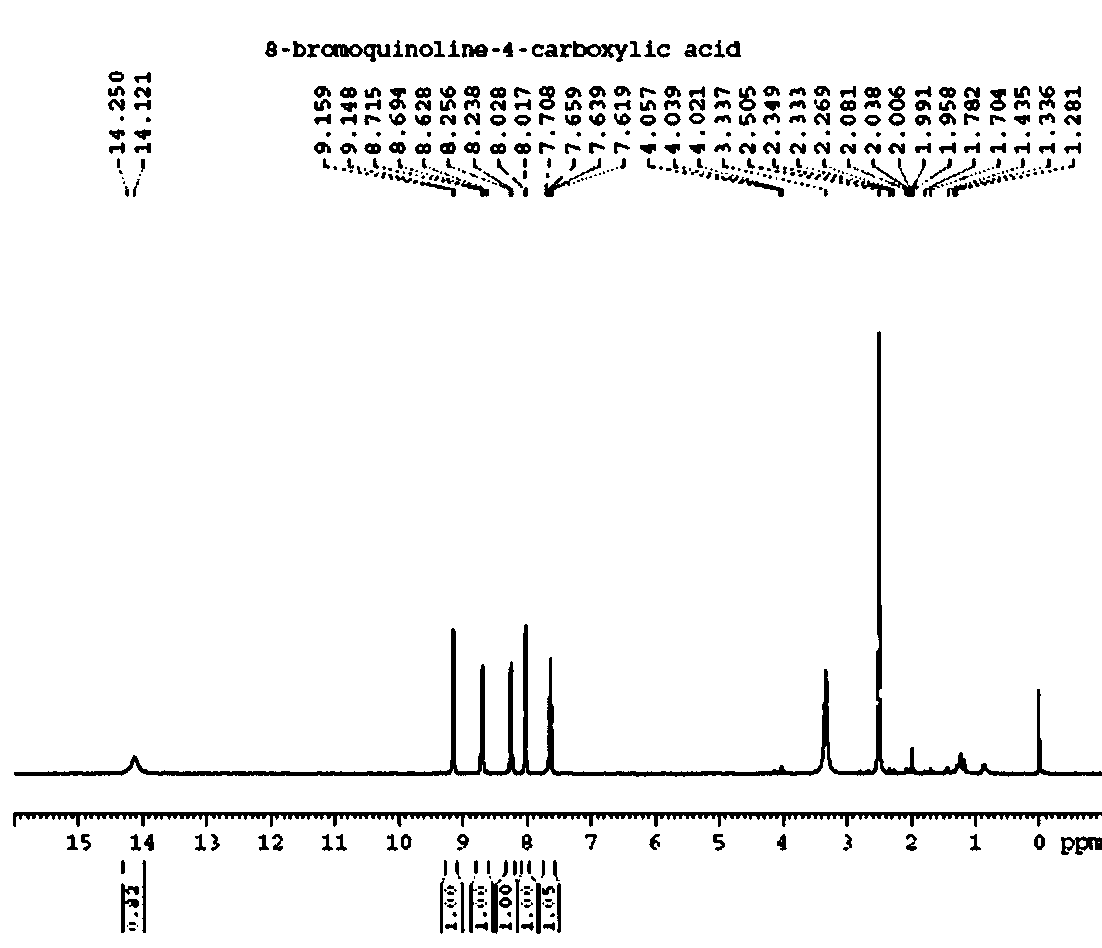

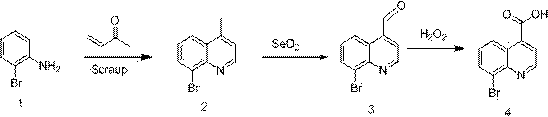

Synthesis method of 8-bromine-4-carboxyl quinoline

InactiveCN103467374AThe synthesis steps are simpleHigh synthetic yieldOrganic chemistryCarboxyl radicalOrganic solvent

The invention discloses a synthesis method of 8-bromine-4-carboxyl quinoline, which comprises the following steps of (1) allowing bromoaniline to react with methyl vinyl ketone to form 8-bromine-4-methyl quinoline under the catalysis of ferric trichloride, (2) oxidizing 8-bromine-4-methyl quinoline with selenium dioxide in an organic solvent to form 8-bromoquinoline-4-methanal, and (3) oxidizing 8-bromoquinoline-4-methanal with hydrogen peroxide in an acid medium to form 8-bromine-4-carboxyl quinoline. The method takes cheaper bromoaniline as a raw material, and is simple in synthesis step, high in synthesis yield and high in selectivity.

Owner:CHEMFUTURE PHARMATECH JIANGSU

Process for producing wine lactone

The present invention relates to a method comprising (A) reacting a β-keto ester with a 2-halo ester under basic conditions to obtain a 2-aceto-3-methyl-succinic acid ester; (B) reacting the resulting 2-aceto-3-methyl-succinic acid ester with methyl vinyl ketone under basic conditions, optionally followed by a decarboxylation reaction and hydrolysis, etc., to obtain an α-methyl-γ-keto acid; and (C) reducing the resulting α-methyl-γ-keto acid to obtain wine lactone or a stereoisomer thereof or a mixture thereof. Alternatively, the present invention relates to a method comprising step (A) as recited above; (B) reacting the resulting 2-aceto-3-methyl-succinic acid ester with methyl vinyl ketone under basic conditions, followed by decarboxylation reaction to obtain an α-methyl-γ-keto acid ester; and (E) reducing the resulting α-methyl-γ-keto acid ester in the presence of a ruthenium complex having a specific structure and in the presence of a hydrogen donor to obtain wine lactone or a stereoisomer thereof or a mixture thereof.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Method for preparing 2,3-butanedione from paraformaldehyde

InactiveCN101973860BReduce dosageImprove conversion ratePreparation from heterocyclic compoundsCatalytic oxidationKetone

The invention discloses a method for preparing 2,3-butanedione from paraformaldehyde. The method comprises the following steps of: preparing methyl vinyl ketone in one step from paraformaldehyde and acetone which serve as raw materials and L-proline serving as a catalyst through a condensation reaction of aldehydes and ketone and a dehydration reaction; and preparing 1,2-epoxy butanone from the methyl vinyl ketone serving as a raw material, hydrogen peroxide serving as an oxidant and a titanium and silicon molecular sieve serving as a catalyst by a catalytic oxidation method, and adding sodium hydrogensulfite for heating, and performing pinacol rearrangement to prepare 2,3-butanedione. Compared with the conventional method for preparing the 2,3-butanedione, the method has the characteristics of low cost, environmental-friendliness, high conversion rate of the paraformaldehyde and selectivity of the 2,3-butanedione and the like, and provides an environmental-friendly synthetic method for the industrial production of the 2,3-butanedione.

Owner:HUNAN NORMAL UNIVERSITY

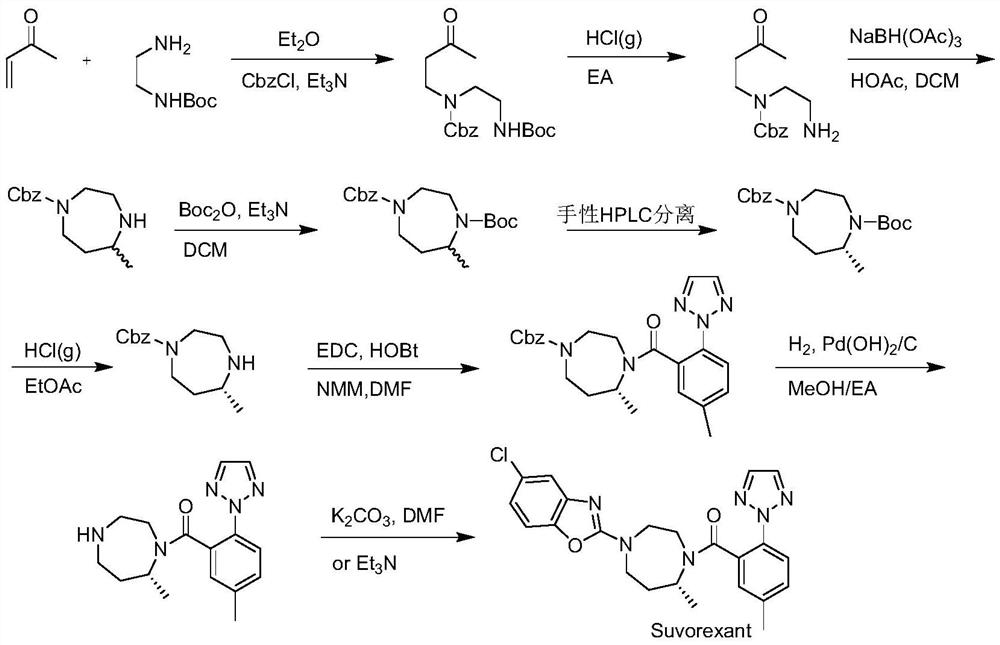

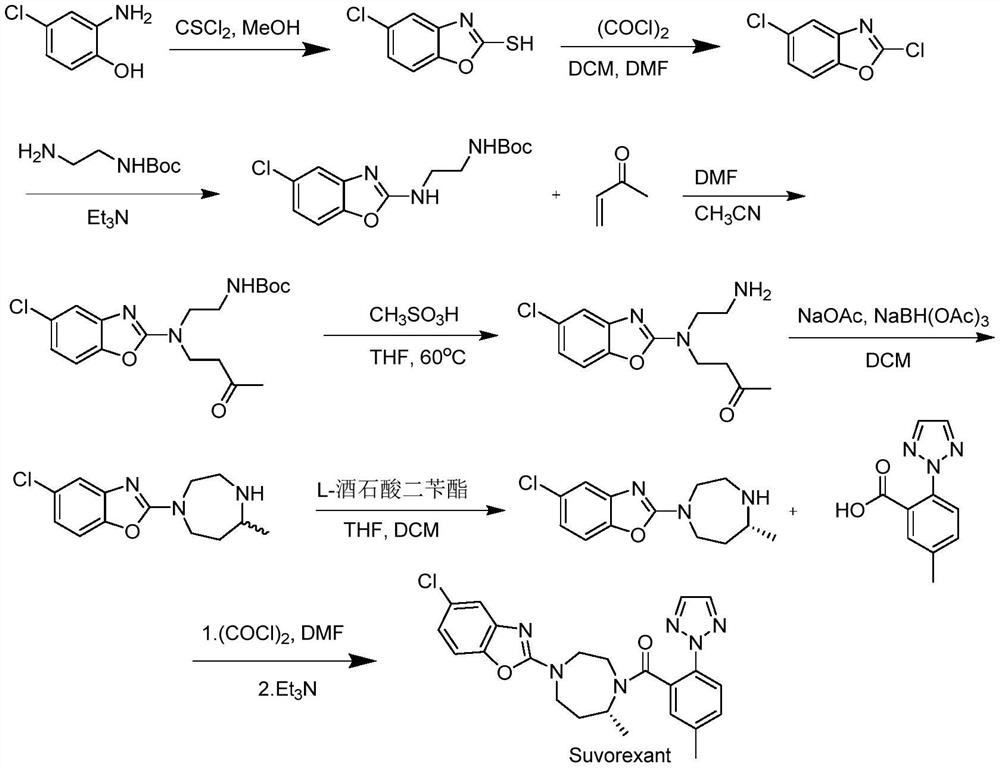

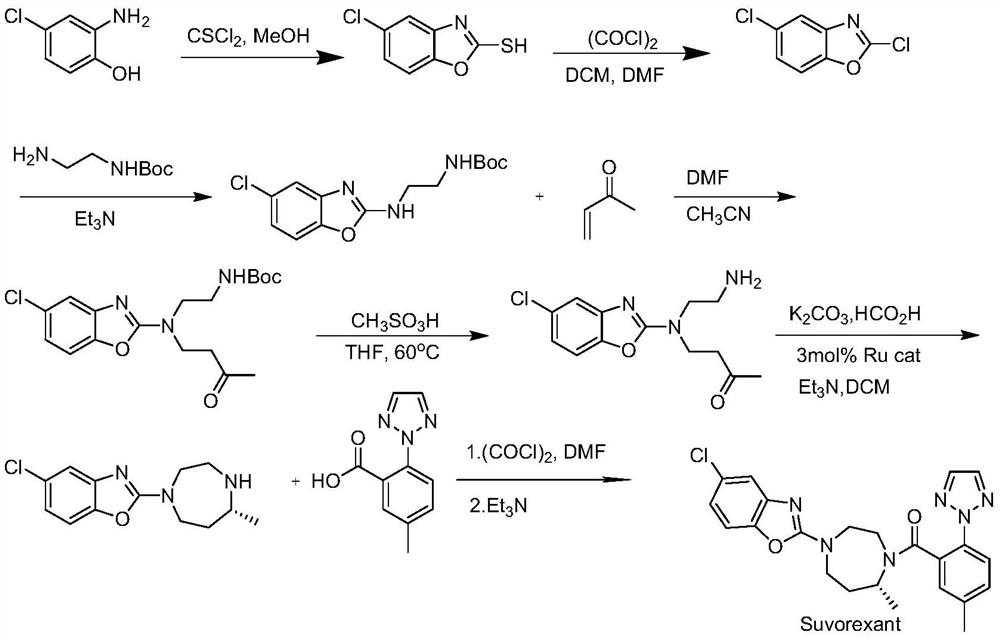

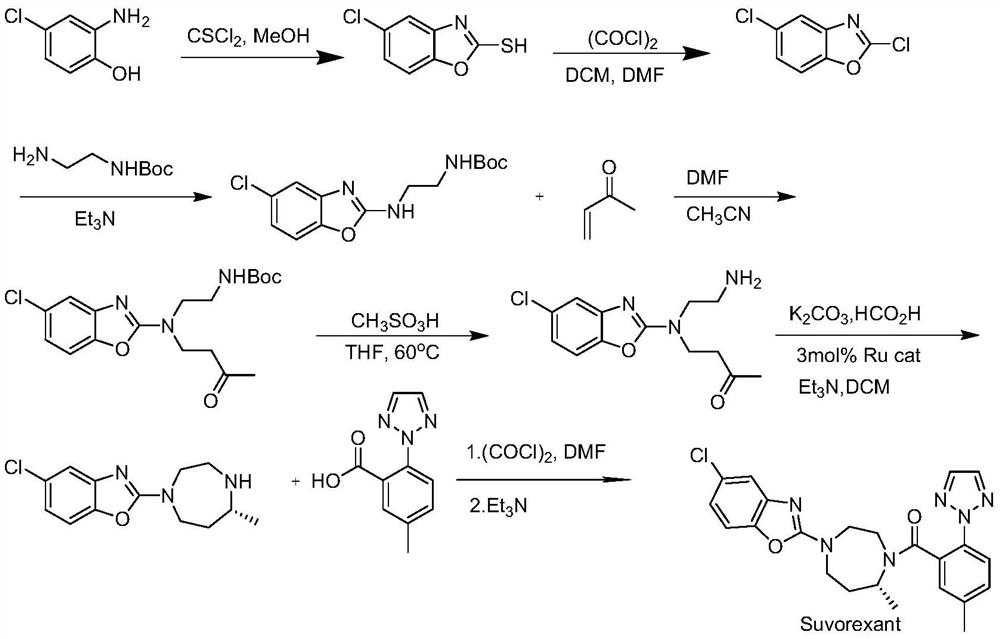

A kind of Suwo Lexan intermediate and preparation method thereof

ActiveCN111943945BReduce usageAvoid separationCarbamic acid derivatives preparationOrganic compound preparationEthyl groupCombinatorial chemistry

The invention discloses a Suvorexan intermediate and a preparation method thereof. Said Suvorexan intermediate is wherein, R represents methyl or ethyl, and PG1 and PG2 represent amino protecting groups. The preparation method is as follows: carrying out a Michael addition reaction with the compound III to obtain compound III; removing the amino protecting group from compound III to generate compound IV; reducing compound IV to obtain compound V; protecting the secondary amine in compound V with an amino protecting group to obtain compound IV VI. The invention avoids the use of the highly toxic compound methyl vinyl ketone, obtains the intermediate of Suvorexan in the desired configuration by using the chiral starting material, and avoids the use of a chiral resolving agent or separation by chiral HPLC , as well as avoiding the use of transition metals and biological enzyme preparations for chiral catalysis. The reaction conditions have the advantages of simple post-processing, easy separation and purification, high yield, high ee value, and easy industrialization.

Owner:SHANGHAI INST OF TECH

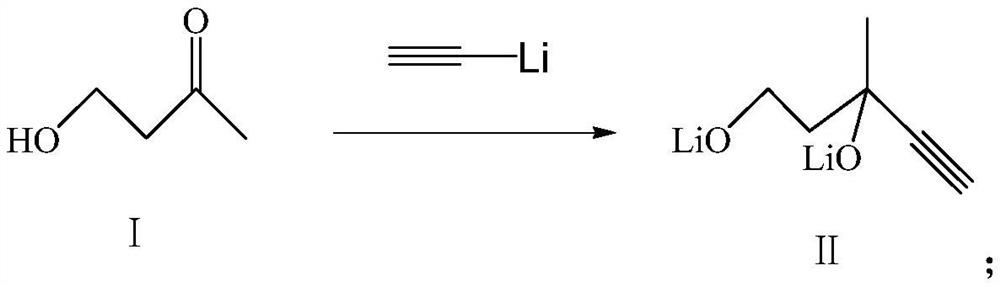

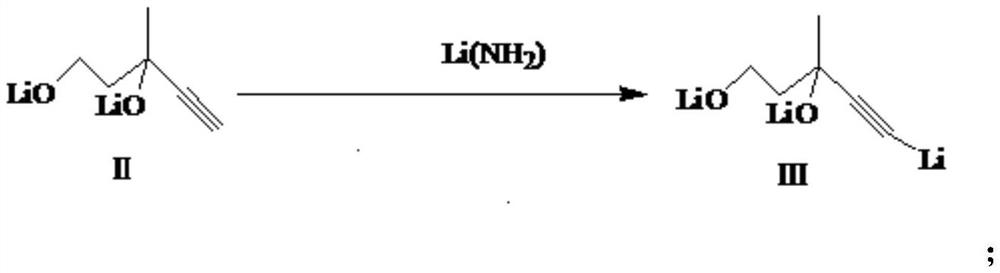

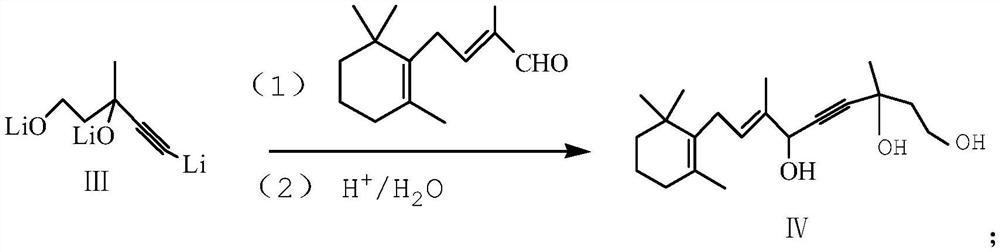

Preparation method of vitamin A acetate

ActiveCN114685338AHigh purityImprove overall utilizationLithium organic compoundsOrganic compound preparationD-alpha-Tocopheryl AcetatePartial hydrogenation

The invention discloses a preparation method of vitamin A acetate. The preparation method comprises the following steps: reacting a compound (I) with acetylene to obtain a compound (II); (2) reacting the compound (II) with lithium amide to obtain a compound (III); (3) reacting the compound (III) with tetradecanal, and hydrolyzing to obtain a compound (IV); (4) carrying out partial hydrogenation reaction on the compound (IV) to obtain a compound (V); (5) carrying out esterification reaction on the compound (V) to obtain a compound (VI); and (6) carrying out bromination and debromination reactions on the compound (VI) to obtain vitamin A acetate (VII), and then crystallizing to obtain a vitamin A acetate crystal product. According to the method, the 4-hydroxy-2-butanone and the acetylene directly react, and preparation and purification processes of methyl vinyl ketone and cis-hexol are not carried out, so that the safety of the process route is improved, and the raw material utilization rate of the 4-hydroxy-2-butanone is greatly improved.

Owner:SHANGYU NHU BIOCHEM IND +2

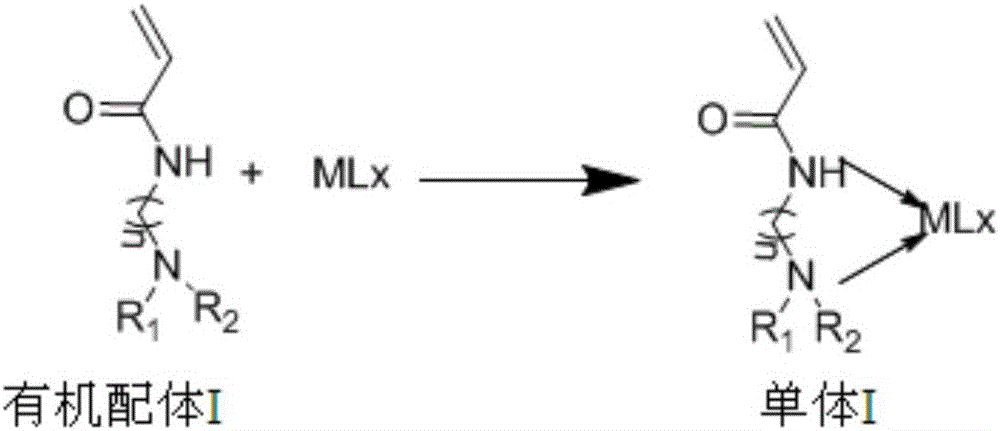

Method of preparing photosensitivity multipolymer doped with optical-fibre preformed bar and the fiber core material

InactiveCN100480028CAvoid pollutionAvoid accumulationOptical articlesOptical light guidesRare earthRefractive index

The invention discloses a manufacturing method for photosensitive polymer optical fiber preform rod and the core material. Under the high pressure, Teflon rope technology is used to manufacture single-mode or few-mode functional polymer optical fiber preform rod and optical fiber by two-step method. Main components of core material are polymethyl methacrylate pmma, additive with higher refractive index, methacrylic acid ester and copolymer of photosensitive monomer, methyl vinyl ketone, azo monomer, monomer complex with rare earth and methyl methacrylate pmma. As the functional optical fiber is manufactured by doping copolymer, the upper limit of doping concentration of photosensitive matter is improved greatly while the diffusion of small molecule in copolymerization process is avoided. It is easier to control the fiber size and the refraction of fiber core.

Owner:UNIV OF SCI & TECH OF CHINA

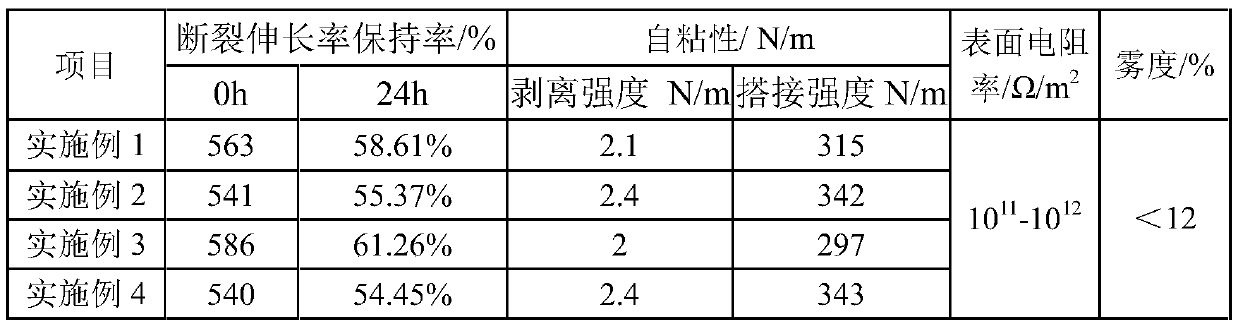

Photodegradable PE wrapping film and preparation method thereof

ActiveCN111393738ANo white pollution problemImprove initial elongation at breakLinear low-density polyethylenePolymer science

The invention relates to a photodegradable PE wrapping film and a preparation method thereof. The wrapping film comprises the following components: 100 parts of modified linear low density polyethylene (LLDPE) and 3-5 parts of a viscous agent, wherein the modified LLDPE is formed by copolymerization of ethylene, 1-butene, 1-hexene and a ketone-containing monomer with alkenyl. The modified LLDPE isprepared by adding the ketone-containing comonomer in the preparation process of linear low-density polyethylene, and the photodegradable PE wrapping film prepared from the modified LLDPE can be automatically degraded under sunlight irradiation after being used. According to the invention, by adjusting the dosage and proportion of diacetone acrylamide and methyl vinyl ketone and / or ethyl vinyl ketone, the elongation at break of the PE wrapping film can be synergistically improved, also the self-adhesion of the PE wrapping film can be improved, and the dosage of an adhesive is properly reduced. An antistatic agent alkoxy amine salt is added in the preparation process of linear low-density polyethylene, so that the antistatic properties of the material is improved, and the photodegradationproperties of the material can be further improved by virtue of a proper amount of alkoxy amine salt.

Owner:江苏祎唯诺新材料科技有限公司

Novel HS white gravure ink

The invention discloses novel HS white gravure ink. The novel HS white gravure ink relates to the field of printing ink. The novel HS white gravure ink comprises: 18 to 23% of synthetic wax, 7 to 12% of a black pigment, 1 to 2% of an additive, 1 to 2% of alcohol, 3 to 8% of vinyl acetate, 25 to 30% of methyl vinyl ketone and 33 to 38% of toluene. The novel HS white gravure ink can be prepared into sticky ink after being attached with a heat-sealing material, saves processes, reduces the number of product layers, has a downy tactility and broadens a use range.

Owner:SHANGHAI SHENYUE INK

Film applied to lithium ion batteries

The invention discloses a film applied to lithium ion batteries. The film is used for covering the surface of a battery body, and is prepared from the following components: fatty acid methyl ester sulfonate, sodium tripolyphosphate, polyisobutene, bis-thiodipropionate, methanol polyoxyethylene ether phosphate, vinyl trimethoxy silane, benzoyl peroxide, ethyl acetoacetate, methyl vinyl ketone and propylene glycol methyl ether acetate. The film has double properties of insulation and heat conduction; after the film coveres on the surface of the battery body, the safety performance of the batterycan be effectively improved.

Owner:SUZHOU GREEN POWER TECH CO LTD

High-strength degradable plastic material and preparation method thereof

The invention discloses a high-strength degradable plastic material. The plastic material is prepared from the following components in parts by weight: 30 to 40 parts of polyvinyl alcohol fiber, 25 to 30 parts of phenolic resin, 8 to 12 parts of polyvinyl acetate, 4 to 6 parts of chitosan, 9 to 13 parts of propylene glycol monomethyl ether, 2 to 5 parts of sodium oxamate, 7 to 11 parts of cellulose, 3 to 5 parts of dopamine hydrochloride, 6 to 10 parts of 2-mercaptoethanol, 1 to 3 parts of zinc sulfate heptahydrate, 2 to 5 parts of methyl vinyl ketone, 1 to 3 parts of polyvinyl pyrrolidone, and 5 to 8 parts of 1, 1, 3, 3-tetramethyldisiloxane. The plastic material has degradability, the subsequent processing cost of waste plastic materials is reduced, and the strength property of the plastic material is not reduced by the degradability, so that the plastic material can meet actual demands.

Owner:SUZHOU JIN TENG ELECTRONICS TECH

A kind of method for preparing raspberry ketone by catalysis of polysulfonic acid group functional ionic liquid

ActiveCN106916059BIncrease acidityHigh catalytic efficiencyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPhenol

The invention discloses a method for preparing raspberry ketone under the catalysis of multi-sulfonic functionalized ionic liquid. According to the method, phenol and methyl vinyl ketone are used as raw materials and the multi-sulfonic functionalized ionic liquid is used as a catalyst for selective catalytic synthesis of raspberry ketone. The ionic catalyst has the advantages of high acid value, low synthesis cost, good catalysis efficiency and reaction activity at room temperature compared with conventional ionic catalysts.

Owner:SHANGYU NHU BIOCHEM IND

A catalyst for immobilized MPV reaction, its preparation method and its application in the production of nerol and geraniol

ActiveCN107321387BRealize real immobilizationNo significant decrease in activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationMethylvinyl ketonePolystyrene

Owner:WANHUA CHEM GRP CO LTD

Preparing naphthalene buthanone using 4-digit subsituted 2-buthanone

Palladium catalyzed coupling of aryl and alkenyl halides to vinyl compounds is disclosed. A preferred embodiment involving the palladium catalyzed coupling of 4-substituted and 6-substituted 2-methoxynaphthalenes to nabumetone is also disclosed. The advantage of this new reaction is that methyl vinyl ketone, which is generally used directly in the art for the preparation of nabumetone, is formed in situ. We discovered a mechanism to utilize the in situ formed methyl vinyl ketone, thereby avoiding the use of expensive, toxic, and unstable methyl vinyl ketone starting materials. This reaction can be used in the preparation of various pharmaceutically active and non-pharmaceutically active compounds.

Owner:CELANESE POLYMER SPECIALTIES COMPANY

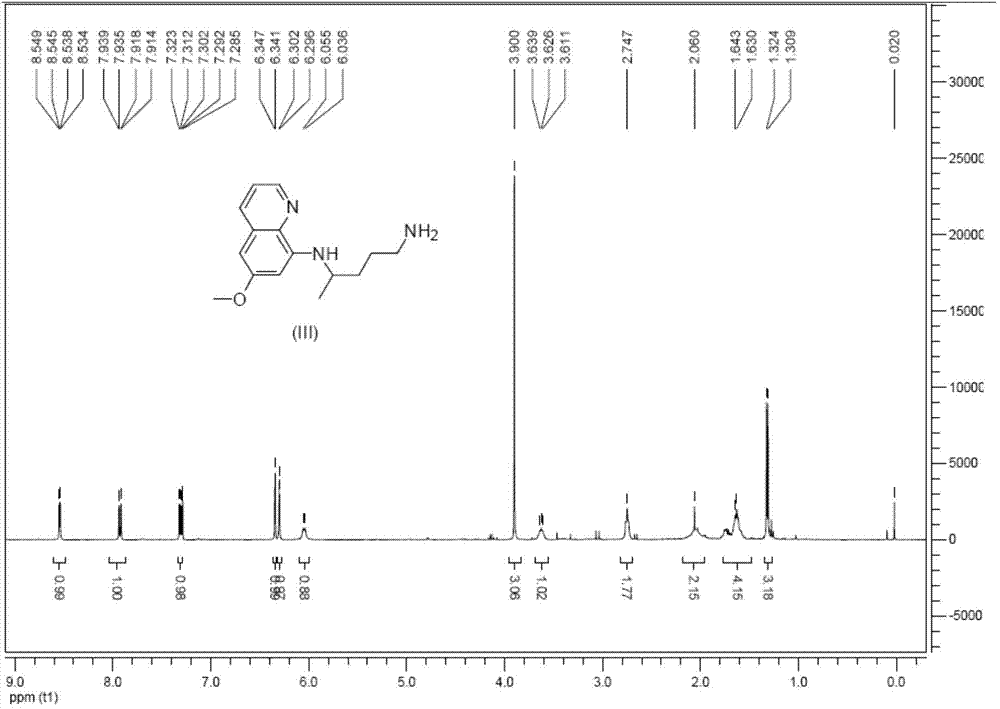

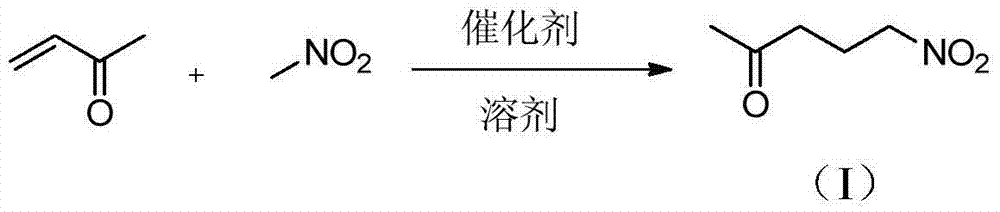

A kind of method for preparing primaquine phosphate

The invention relates to a method for preparing primaquine diphosphate. The method comprises the following steps: enabling methyl vinyl ketone and nitromethane to react to prepare 5-amylnitrite-2-ketone; then carrying out a condensation reaction on the 5-amylnitrite-2-ketone and 6-methoxyl-8-aminoquinoline to generate an imine intermediate product; carrying out a reduction reaction on the obtained imine intermediate product to generate primaquine; and acidifying to form salt by using phosphoric acid, and the like. According to the method disclosed by the invention, a primaquine diphosphate finished product can be obtained by recrystallizing the obtained primaquine diphosphate. Due to the adoption of the new synthetic route disclosed by the invention, the primaquine phosphate can be fast obtained from common industrial raw materials.

Owner:HUNAN FURUI BIOPHARMA TECH CO LTD

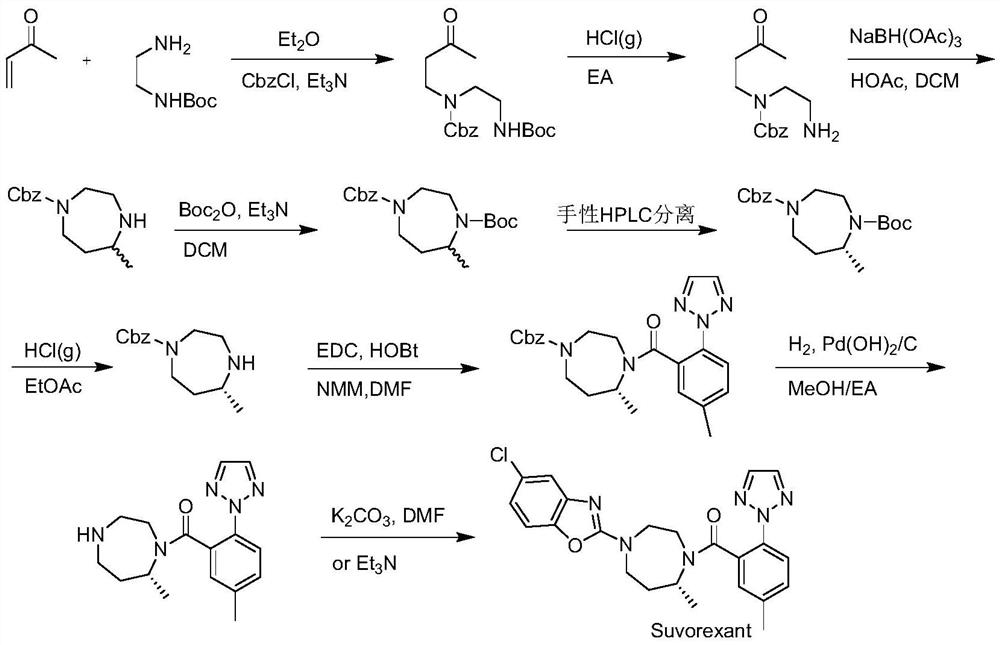

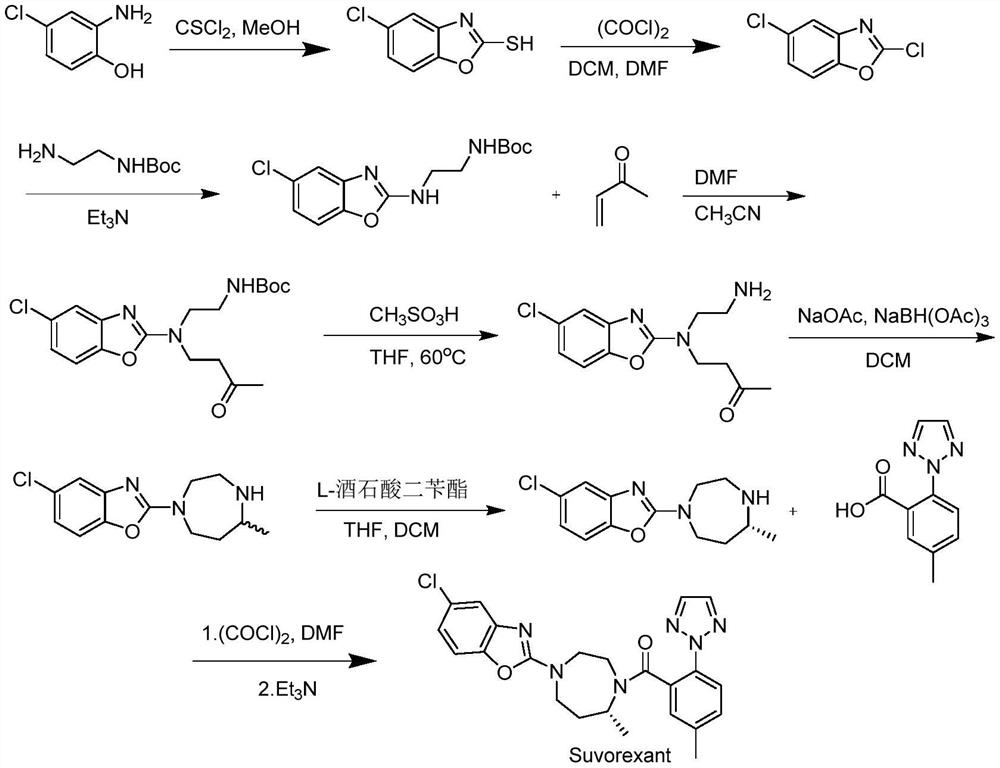

Suvorexant intermediate and preparation method thereof

ActiveCN111943945AReduce usageAvoid separationCarbamic acid derivatives preparationOrganic compound preparationEthyl groupMethyl palmoxirate

The invention discloses a suvorexant intermediate and a preparation method thereof. In the suvorexant intermediate, R represents methyl or ethyl, and PG1 and PG2 represent amino protecting groups. Thepreparation method comprises the following steps: carrying out Michael addition reaction to obtain a compound III; removing an amino protecting group from the compound III to generate a compound IV;reducing the compound IV to obtain a compound V; and protecting secondary amine in the compound V by using an amino protecting group to obtain a compound VI. According to the method disclosed by the invention, the use of a highly toxic compound methyl vinyl ketone is avoided, the suvorexant intermediate with the required configuration is obtained by using chiral starting raw materials, the separation by using a chiral resolving agent or chiral HPLC (High Performance Liquid Chromatography) is avoided, and the use of transition metal and a biological enzyme preparation for chiral catalysis is avoided. The reaction conditions have the advantages of simple post-treatment, easiness in separation and purification, high yield, high ee value, easiness in industrialization and the like.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com