Method of using modified alumina catalyst to continuously prepare methyl vinyl ketone

A kind of alumina and catalyst technology, applied in the direction of physical/chemical process catalysts, carbon-based compound preparation, chemical instruments and methods, etc., can solve the problems of high pressure resistance and leakage prevention requirements of production equipment, large safety hazards in the production process, and corrosion resistance Higher requirements and other issues, to achieve the effect of safe and reliable production, improved conversion rate and selectivity, and stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

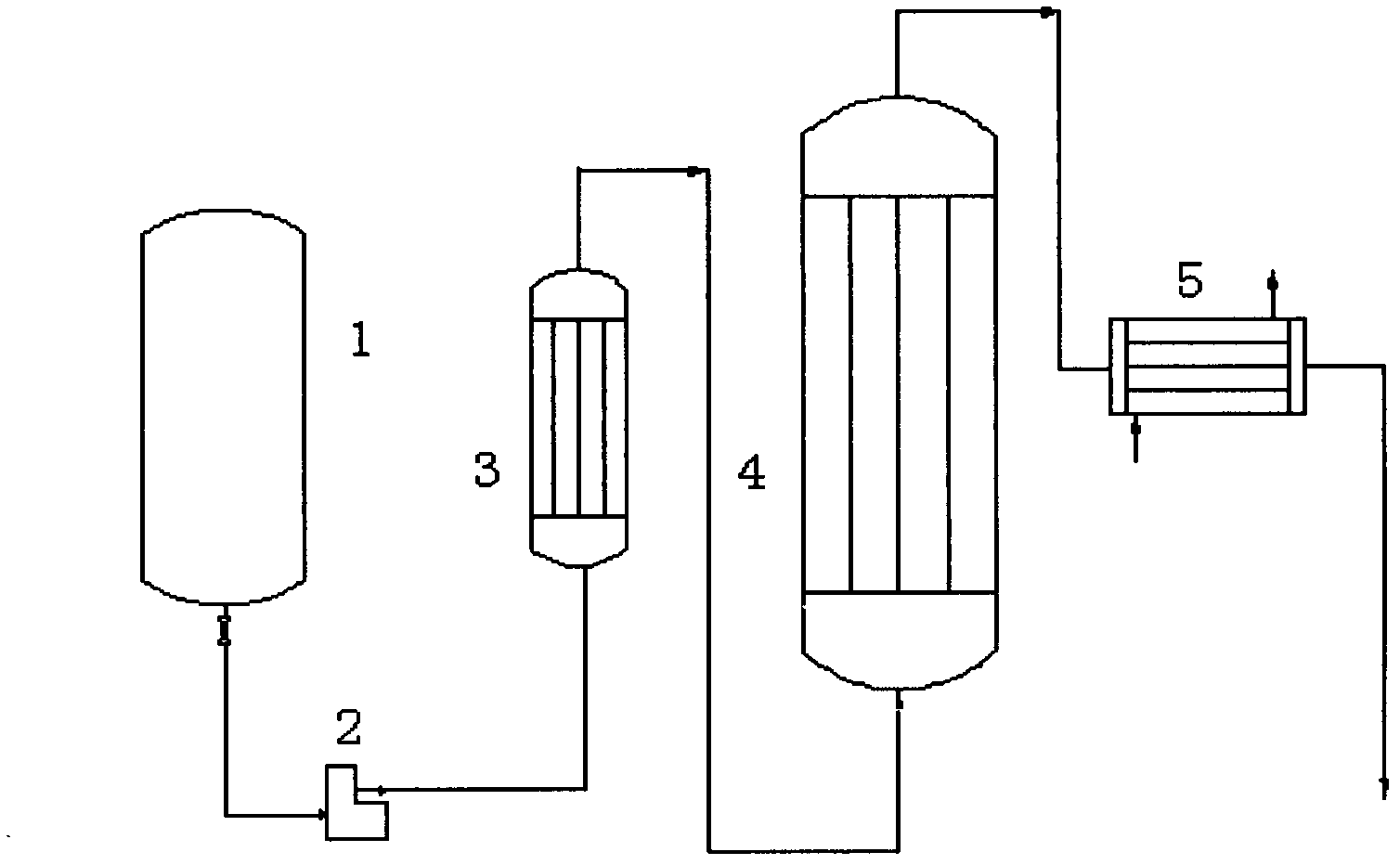

Image

Examples

Embodiment 1

[0022] Weigh Ti(SO 4 ) 2 50.0g, add 3000ml distilled water, stir to dissolve, and weigh another commercially available powdered γ-Al 2 o 3 (A: specific surface area 2900m 2 / g) 950.0g, pour the above Ti(SO 4 ) 2 solution, stir to form a paste. Put it at room temperature for 5 hours, then rotary evaporate under vacuum to obtain a solid, extrude it into a clover shape, then dry it at 110°C for 2 hours, and finally bake it at 450°C for 1.5 hours to make Ti(SO 4 ) 2 Modified γ-Al 2 o 3 , to obtain catalyst B, the resulting modified γ-Al 2 o 3 Contains SO 4 2- 4wt%.

Embodiment 2

[0024] Weigh (NH 4 ) 2 SO 4 27.1g, add 2000ml distilled water, stir to dissolve, and weigh another commercially available powdered γ-Al 2 o 3 (A: specific surface area 2900m 2 / g) 490.0g, pour the above (NH 4 ) 2 SO 4 solution, stir to form a paste. Place it at room temperature for 5 hours, and rotate it under vacuum to obtain a solid, extrude it into a clover shape, then dry it at 110°C for 2 hours, and finally bake it at 450°C for 1.5 hours to make (NH 4 ) 2 SO 4 Modified γ-Al 2 o 3 , to obtain catalyst C, the resulting modified γ-Al 2 o 3 Contains SO 4 2- 4wt%.

Embodiment 3

[0026] Add 20g of Catalyst B into a shell and tube reactor with a diameter of 8mm and a length of 400mm, start to use a metering pump to input the crude butanone alcohol into the reactor at a speed of 5ml / min, and keep the outlet temperature of the preheater at 95--100°C. The temperature of the reactor is maintained at 100--105°C, and the reaction is continued for 100 hours. The product is collected and dried. The product has a purity of 99.5% (GC), moisture: 0.16% (KF), and a yield of 90%.

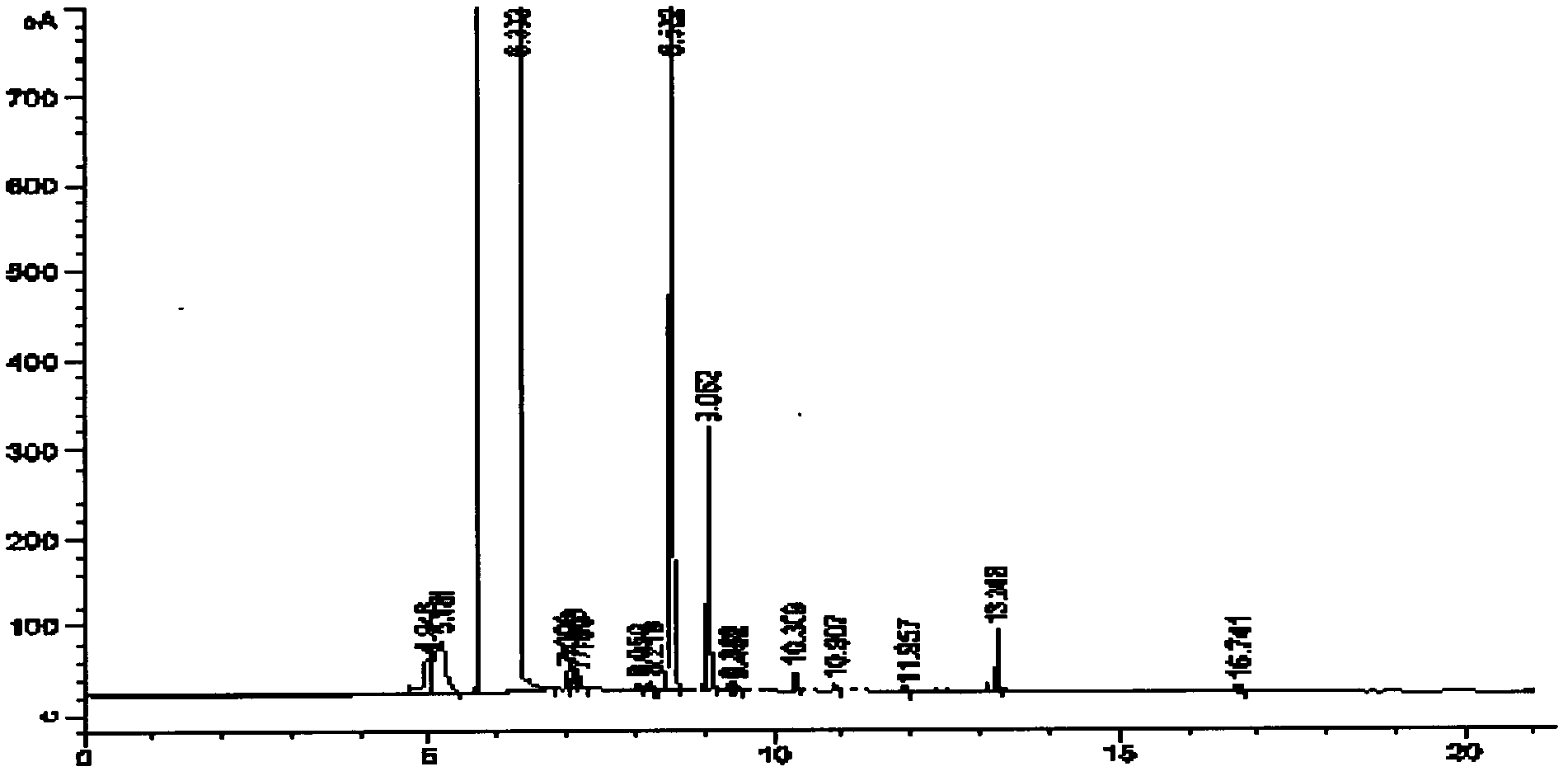

[0027] The composition of the product was detected by gas chromatography (GC): DB~5MS capillary column (30m*0.25mm*0.25um) was selected and analyzed on an Agilent6890 gas chromatograph with a hydrogen flame ion detector. Detection conditions: initial temperature of 40°C, maintained for 5 minutes, programmed temperature increase at 10°C / min, final temperature of 120°C, maintained for 5 minutes. Injection port temperature: 220°C, detector temperature: 260°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com