Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "Hydromagnesite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydromagnesite is a hydrated magnesium carbonate mineral with the formula Mg₅(CO₃)₄(OH)₂·4H₂O. It generally occurs associated with the weathering products of magnesium containing minerals such as serpentine or brucite. It occurs as incrustations and vein or fracture fillings in ultramafic rocks and serpentinites. It occurs in hydrothermally altered dolomite and marble. It commonly appears in caves as speleothems and "moonmilk", deposited from water that has seeped through magnesium rich rocks. It is the most common cave carbonate after calcite and aragonite. It thermally decomposes, over a temperature range of approximately 220 °C to 550 °C, releasing water and carbon dioxide leaving a magnesium oxide residue.

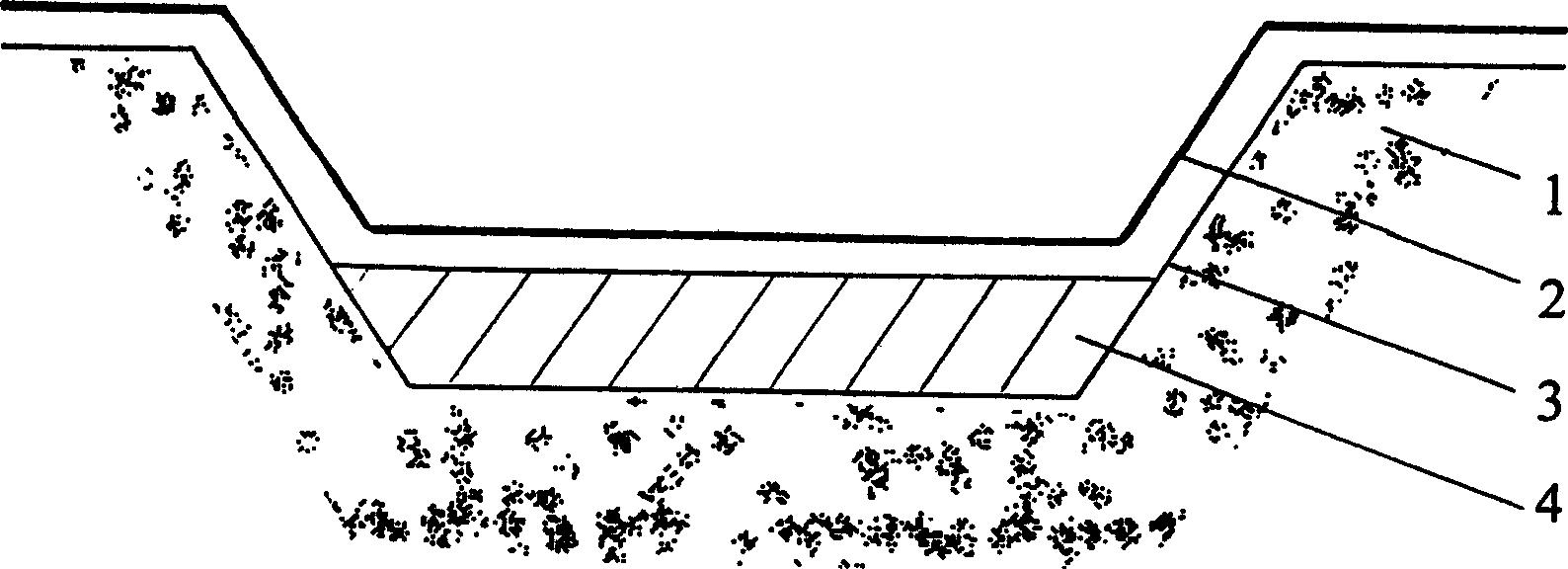

Lithium carbonate crystal separating process from carbonate-type bittern by means of solar battery

InactiveCN1398786AReduce consumptionLow costSolution crystallizationLithium carbonates/bicarbonatesLithium carbonateHydromagnesite

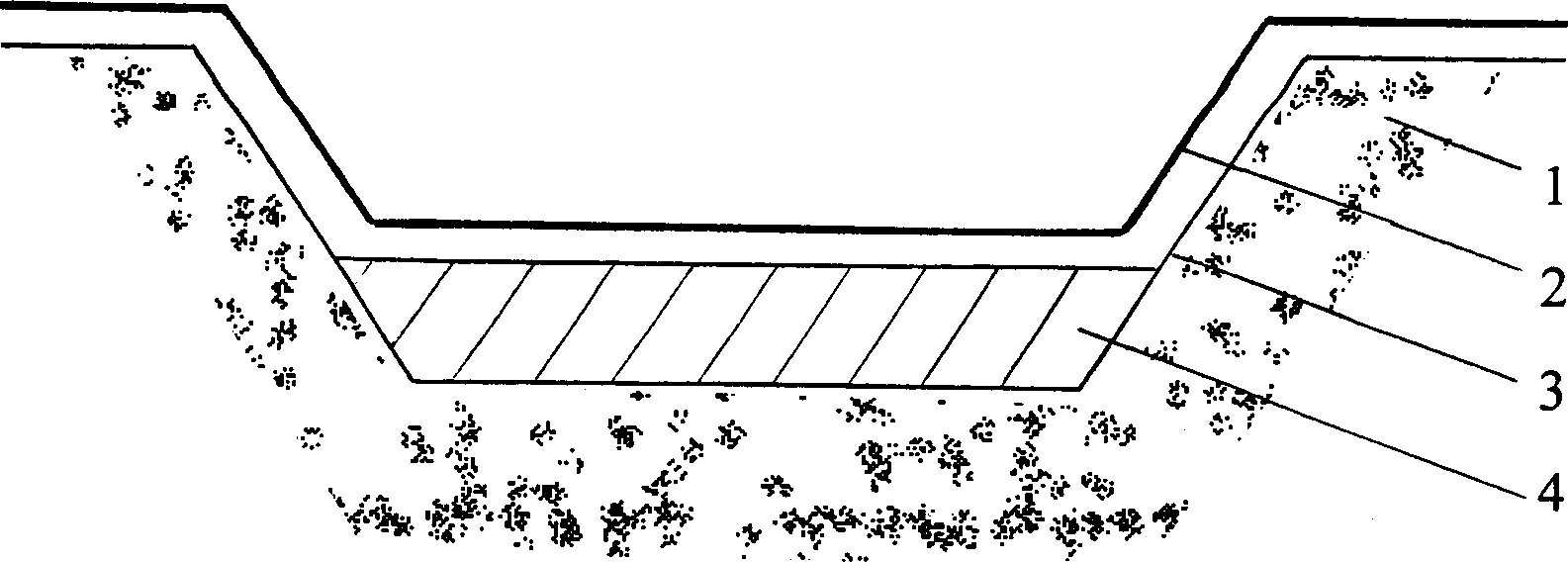

The present invention is a method of utilizing solar pond as crystallizing pond for separating lithium carbonate crystal from carbnate-type bittern. The solar pond with lighting area of 1000-10000 sq m and depth of 3-4 m has raw material of bittern as working medium and is built with clay enclosure, sandwith structure of plastic film and hydromagnesite in the bottom, and black geotechnical membrane or high-density polyethylene or polyvinyl chloride lining laid on the internal wall. By combining the heat accumulation of solar pond and the separation of lithium carbonate, great amount of lithium carbonate is deposited and mixed salt with lithium carbonate content over 80% may be produced at low cost.

Owner:SALT LAKE & HOT WATER RESOURCE RES DEV CENT CHINESE ACAD OF GEOLOGICAL SCI

Charring-boosting low-smoke zero-halogen nanometer flame-retardant composite material of ethylene-vinyl acetate copolymer and preparation method thereof

InactiveCN106496759AImproving the quality of condensed phase char formationPlay the role of synergistic flame retardantProcedure AgentsHydromagnesite

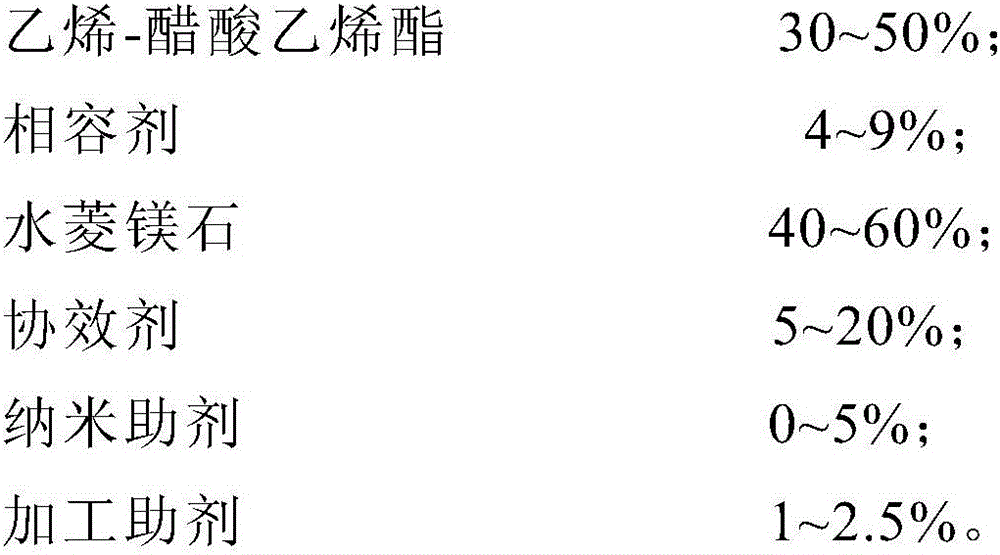

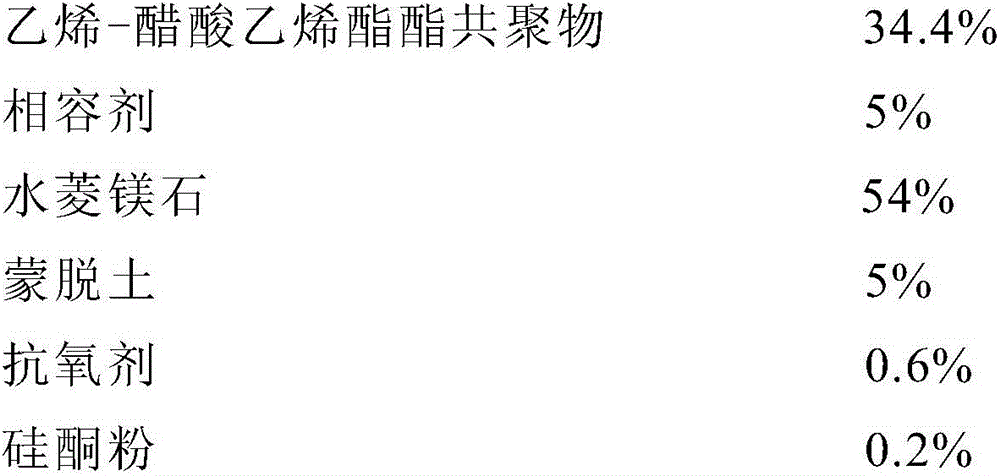

The invention relates to a charring-boosting low-smoke zero-halogen nanometer flame-retardant composite material of an ethylene-vinyl acetate copolymer and a preparation method thereof, and specifically relates to a nanometer flame-retardant composite material of the ethylene-vinyl acetate copolymer based on a nanometer composite flame retardant and the preparation method thereof, belonging to the technical field of flame-retardant materials. The method comprises the following steps: melting and extruding the materials, including the ethylene-vinyl acetate copolymer, hydromagnesite, a compatilizer, a synergist, nanometer auxiliaries, processing agents, and the like, step by step in a high-shear twin-screw extruder in different charging sequences, and then pelletizing and performing injection molding, thereby acquiring the ethylene-vinyl acetate nanometer flame-retardant composite material. The ethylene-vinyl acetate composite material provided by the invention has the advantages that the flue gas release volume is relatively low, the condensation phase charring can be boosted, the charring process is improved, the charring quality is promoted, the flame retardant property is effectively improved, and the popularization and application values are better.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Cordierite porous fireproofing material and preparation method thereof

The invention relates to a cordierite porous fireproofing material and a preparation method thereof, belonging to the technical field of fireproofing materials. The invention is characterized in that coal ash and natural raw mineral material magneiste or tailing thereof are main raw materials, and the cordierite porous fireproofing material is prepared by burdening, mixing, forming, drying, sintering and other technical processes. In the raw material proportion of the invention, the addictive amount of the coal ash is 2.0%-99.0% by weight and the addictive amount of the magneiste is 1.0-96.0% by weight; and in addition, the addictive amount of pore-forming agent is 0.0%-20.0% by weight and the addictive amount of binding agent is 0.1%-10.0% by weight. A main phase of the porous fireproofing material prepared at high temperature is cordierite and forsterite, which has the characteristics of high porosity, small volume density, high strength, good heat insulation, low cost and the like. The invention provides a brand new technical way for high-efficiency value-added utility of solid waste materials and gioberite such as the coal ash.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

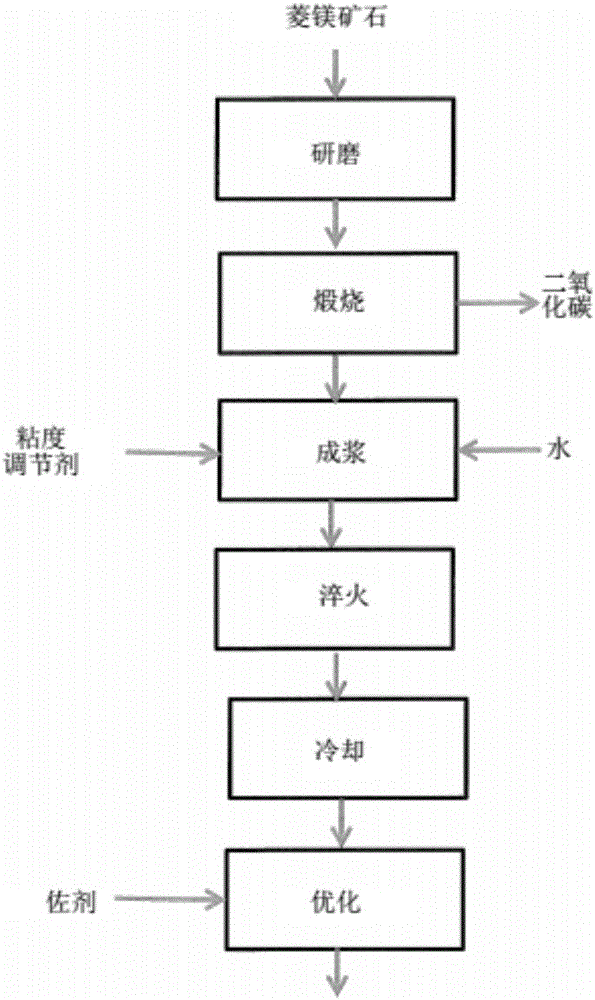

Method for producing high-activity nano magnesia by utilizing low-grade magnesite

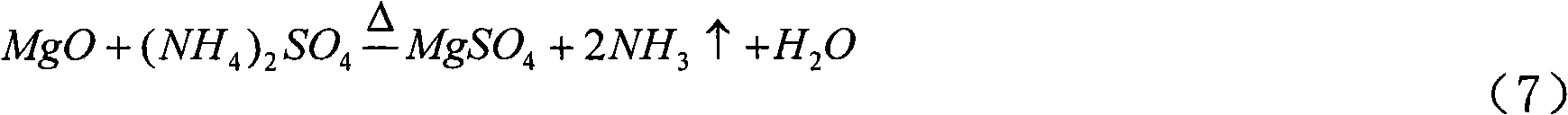

InactiveCN101941723AHigh activityQuality improvementMagnesiaMagnesium hydroxideChemical reactionMagnesium salt

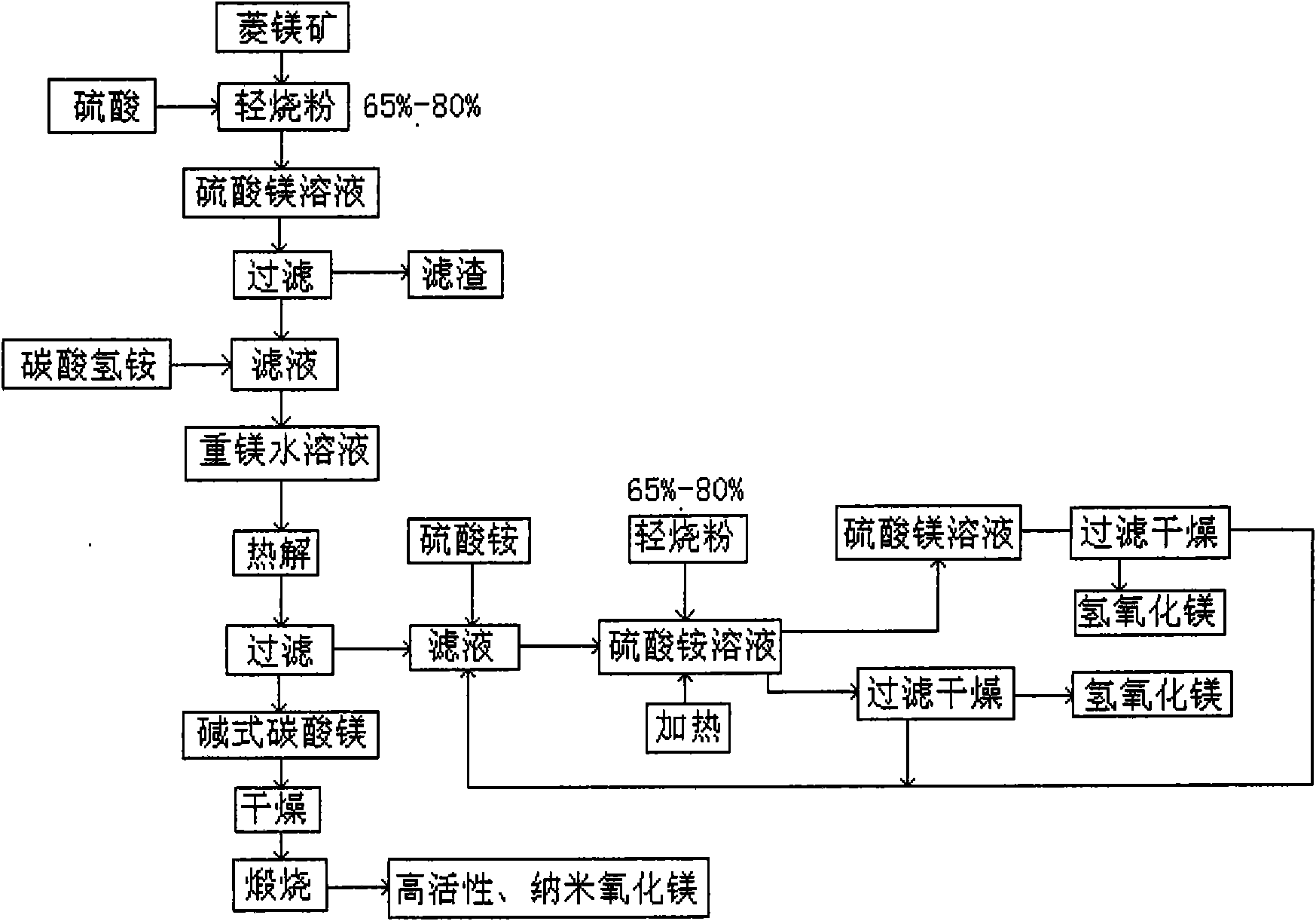

The invention relates to a method for producing high-activity nano magnesia by utilizing low-grade magnesite, in particular to a method for producing nano magnesite. The method utilizes a chemical reaction principle and comprises the following steps of: firstly, roasting low-grade magnesite or powdered ore to obtain magnesia, reacting the magnesia and sulphuric acid and filtering to obtain a magnesium sulfate solution; purifying the solution by adopting a neutralizer and an oxidant to obtain a purified magnesium sulfate solution; adding ammonium bicarbonate and a surfactant to the purified magnesium sulfate solution and roasting to obtain high-activity nano magnesia; heating and decomposing the ammonium sulfate contained filtrate obtained in the last step and light burning powder to obtain magnesium hydroxide at a flame retardant level; and filtering the magnesium hydroxide in a reactor to obtain magnesium hydroxide at an environmental protection level and recycling the filtrate without emission. Fibrous magnesium hydroxide, basic magnesium carbonate and high-activity nano magnesia are widely applied to flame retardance, smoke suppression, filling and reinforcement of rubber products, can be used as an adiabatic and high-temperature-resistant insulation material or can be used for manufacturing high-grade glass products, magnesium salts, paints, and the like.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Precipitated magnesium carbonate

ActiveUS20140004347A1Small particle sizeHigh absolute densityCalcium/strontium/barium carbonatesPigmenting treatmentPlastics industryPolymer science

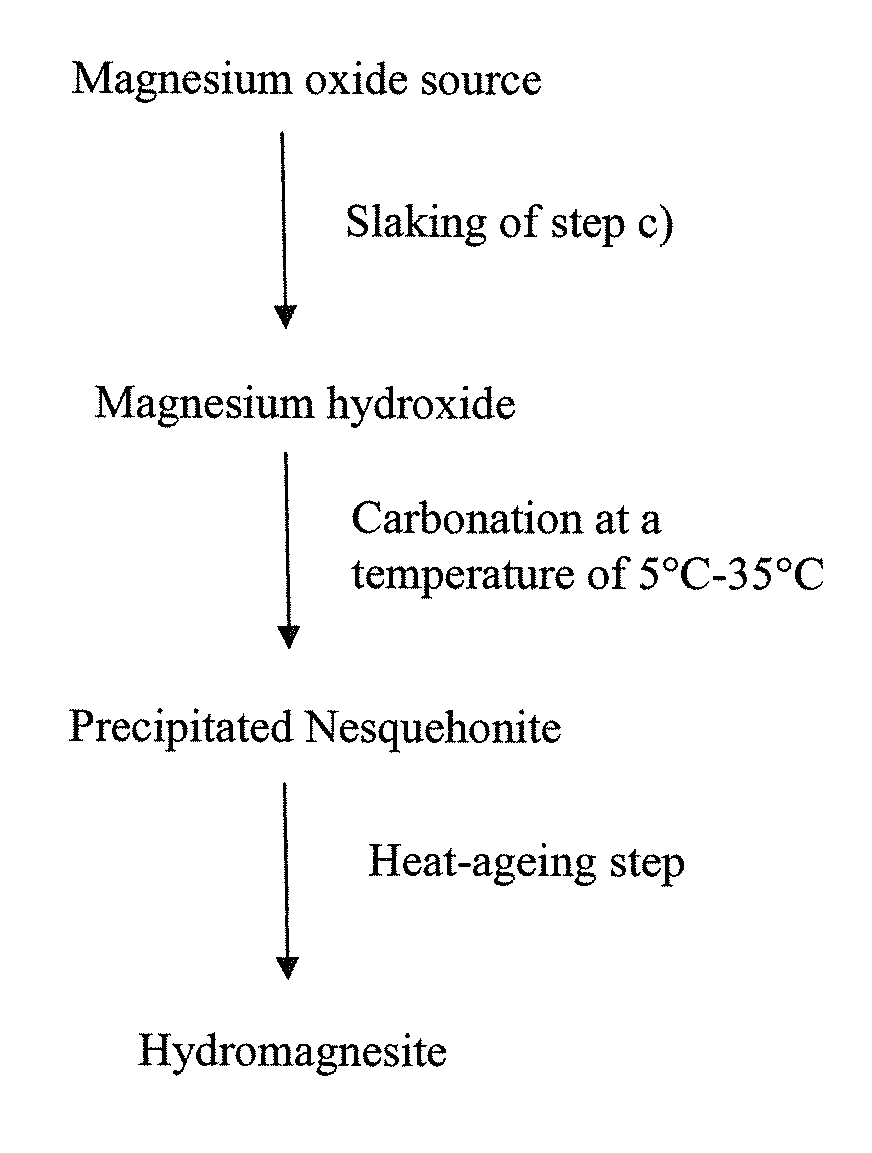

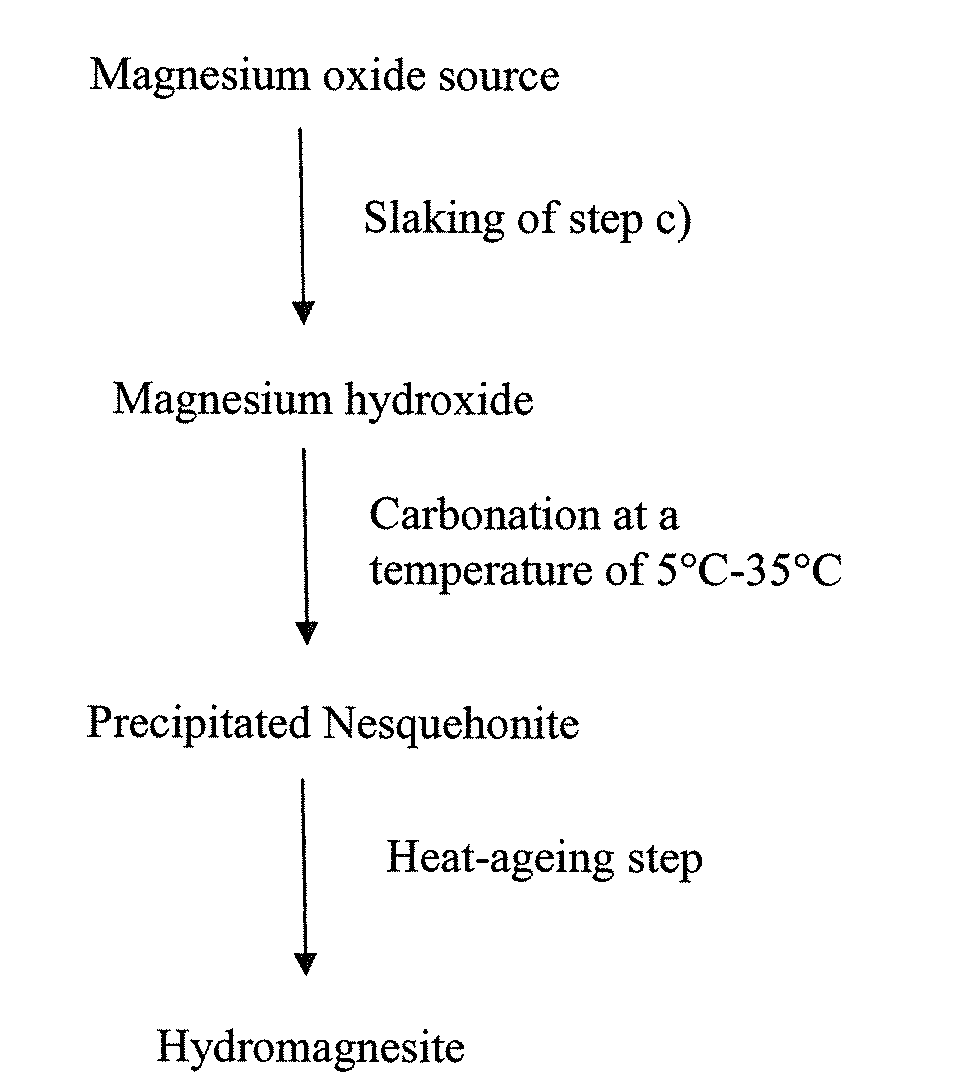

The present invention relates to a process for preparing hydromagnesite in an aqueous environment. The invention further relates to such hydromagnesite having a specific platy-like morphology in combination with a specific average particle size and to their use as minerals, fillers and pigments in the paper, paint, rubber and plastics industries and to the use as flame-retardant.

Owner:OMYA INT AG

Composite synergistic flame retardant and smoke suppression low smoke halogen-free skeleton material

ActiveCN104403186AImprove flame retardant performanceImprove mechanical propertiesAntioxidantHydromagnesite

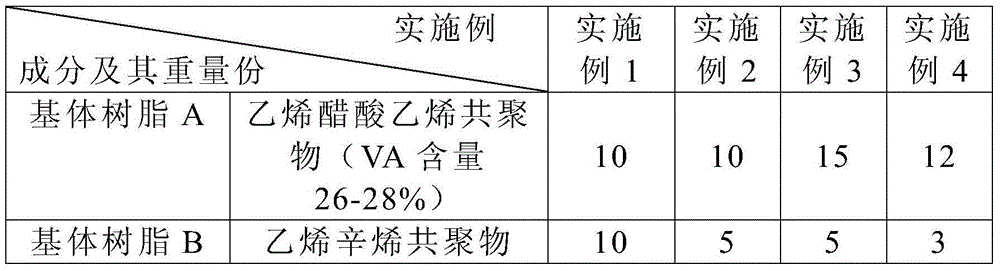

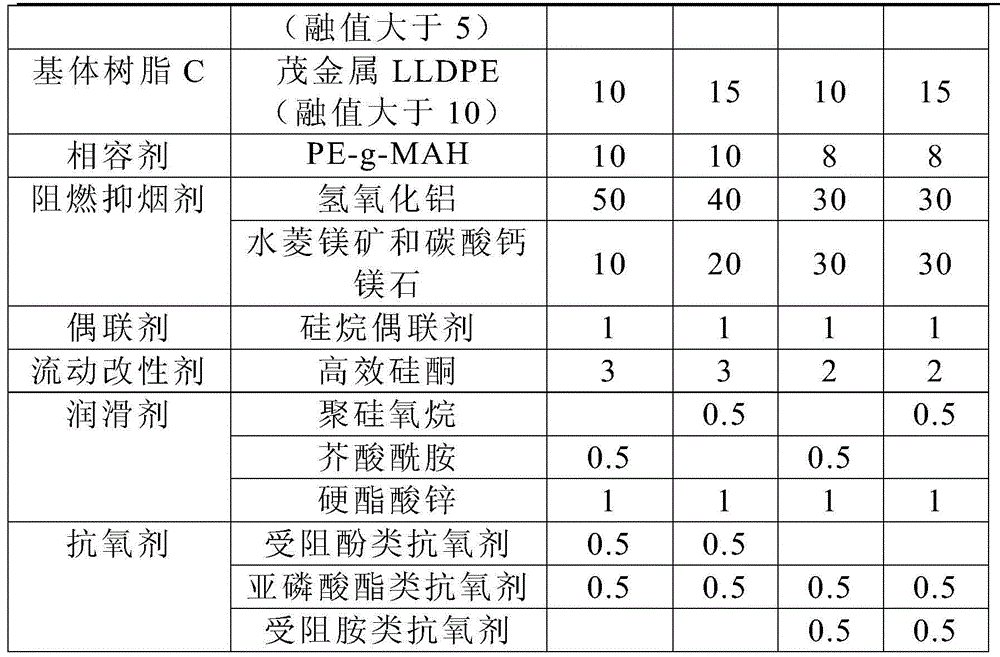

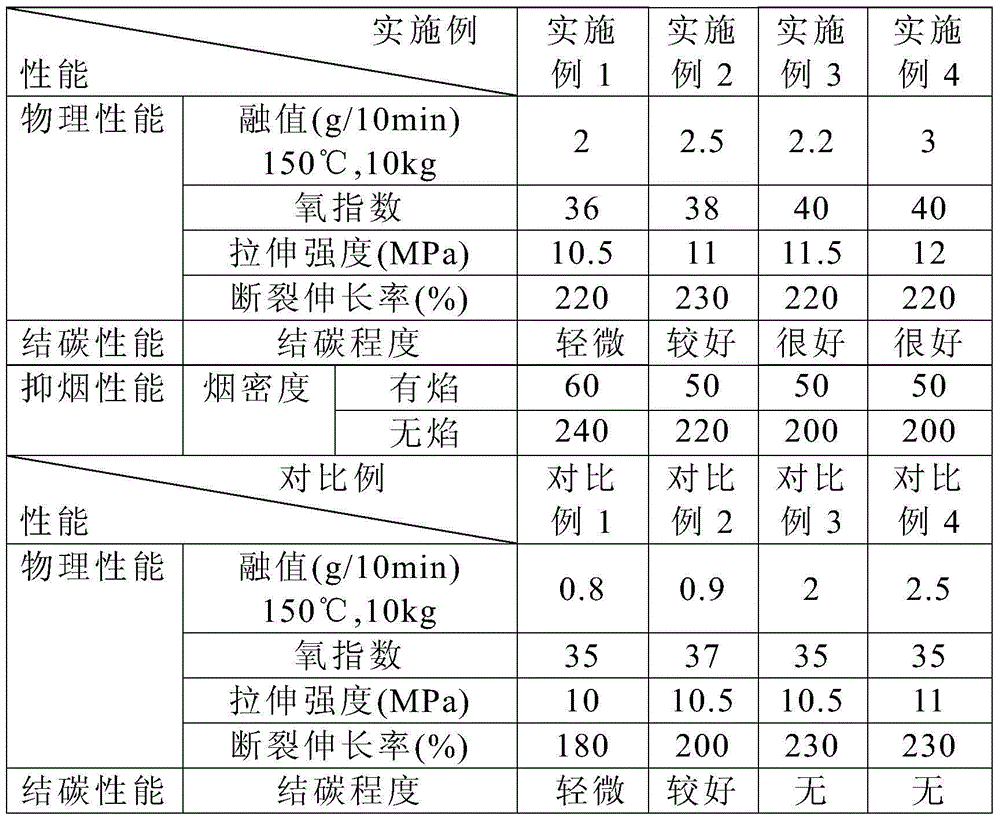

Belonging to the technical field of new materials, the invention relates to a hydromagnesite, huntite and aluminum hydroxide composite synergistic flame retardant and smoke suppression low smoke halogen-free skeleton material. The low smoke halogen-free skeleton material is composed of the following components by weight: 10-20 parts of matrix resin A, 5-10 parts of matrix resin B, 15-30 parts of matrix resin C, 10-20 parts of a compatilizer, 40-60 parts of a flame retardant and smoke suppression agent, 0.5-2 parts of a coupling agent, 2-4 parts of a flow promoter, 0.5-2 parts of a lubricant, and 0.5-2 parts of an antioxidant. Specifically, the flame retardant and smoke suppression agent is a composite synergistic flame retardant and smoke suppression agent formed by hydromagnesite-huntite and aluminum hydroxide in a ratio of 1:1-2. The matrix resin A is an ethylene-vinyl acetate copolymer, the matrix resin B is an ethylene-octene copolymer, and the matrix resin C is polyethylene. The mechanical properties of the low smoke halogen-free skeleton material provided by the invention are improved, and at the same time the flame retardancy is also greatly enhanced.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

Preparation method of superfine active hydromagnesite flame-retardant filler

InactiveCN106220890AAvoid hard clumpingLow oil absorptionPlastic/resin/waxes insulatorsMicrometerHydromagnesite

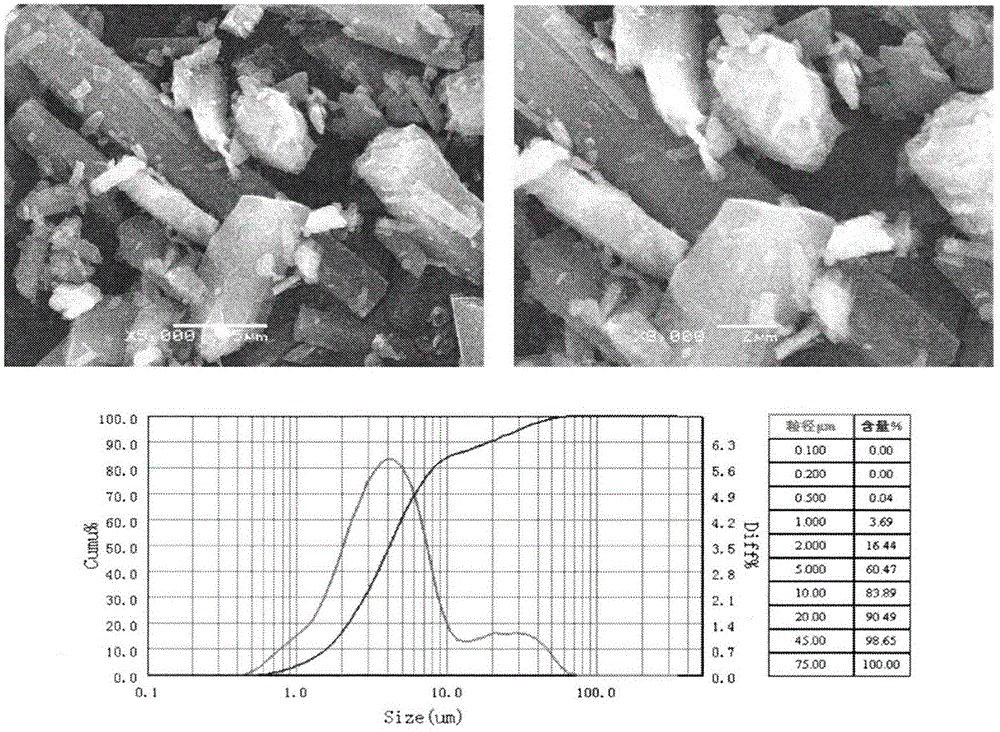

The invention discloses a preparation method of superfine active hydromagnesite flame-retardant filler. The preparation method comprises the steps that hydromagnesite powder and an inorganic dispersant are added into water to prepare powder slurry with the mass concentration of 35%-55%; the powder slurry is fed into a horizontal sand mill for superfine grinding, and meanwhile a silane coupling agent is added for first-time surface modification according to the mass ratio 1,000:(3-10) of the hydromagnesite powder to the silane coupling agent; after grinding size distribution reaches the conditions that d50 is equal to 1 micrometer to 3 micrometers and d97 is equal to 3 micrometers to 10 micrometers, press filter dewatering is conducted; filter cakes are fed into a beehive mill to be dried and depolymerized, a modifying agent is added according to the mass ratio 1,000:(5-15) of the hydromagnesite powder to the modifying agent, and after second-time surface modification is conducted at the temperature of 110 DEG C to 180 DEG C, the superfine active hydromagnesite flame-retardant filler is obtained. According to the preparation method, wet surface organic modification is conducted while superfine grinding is conducted through the horizontal sand mill, dry surface organic modification is conducted while depolymerizing and drying are conducted through the beehive mill, and therefore the superfine active hydromagnesite flame-retardant filler which is fine in size distribution and full in surface organic modification can be prepared.

Owner:江苏西贝力新材料有限公司 +1

Spandex fiber with excellent chlorine resistance, and preparation method thereof

ActiveCN102666947AMaintain whitenessEnsure retentionMonocomponent polyurethanes artificial filamentArtifical filament manufactureFiberPolymer science

The present invention relates to a spandex fiber of which the chlorine resistance is improved by comprising an inorganic chlorine resistant agent such as a hydrotalcite compound, a mixture mineral of huntite and hydromagnesite, hydromagnesite, zinc oxide, magnesium oxide and the like, and a symmetrically di-hindered hydroxyphenyl-based additive, and a preparation method thereof. Since the spandex fiber of the present invention has excellent chlorine resistance, it can be more effectively used in sports or leisure clothes such as swimwear and the like.

Owner:HYOSUNG CORP

Preparation method for low-cost and high-whiteness calcined talcum

The invention relates to a preparation method for low-cost and high-whiteness calcined talcum, belonging to the technical field of ceramic raw materials. The preparation method is characterized by comprising the following preparation steps: preparing the following raw materials by weight: 15 to 60 parts of magnesite or magnesite flotation tailings, 15 to 60 parts of silica and 0 to 20 parts of talcum / talcum slag; mixing the raw materials, then carrying out calcination at 1000 DEG C to 1500 DEG C for 1 h to 8 h, and carrying out cooling to 25 DEG C to 40 DEG C so as to obtain calcined talcum powder / blocks. The method provided by the invention prepares a calcined talcum substitute used for ceramics by using the magnesite or the magnesite flotation tailings and the silica as main raw materials, utilizes cheap and low-grade magnesite or the magnesite flotation tailings and the silica and adopts a high-temperature solid-phase reaction process to directly prepare the calcined talcum substitute, and has low cost.

Owner:YINGKOU TENGLONG NEW MATERIALS +1

Method and apparatus for production of basic magnesium carbonate and magnesium oxide whisker from magnesite

InactiveCN106012024AIndustrial operation safetyRealize material carbon steelPolycrystalline material growthSingle crystal growth detailsHydromagnesiteCarbonization

The invention relates to a method and apparatus for production of basic magnesium carbonate and magnesium oxide whisker from magnesite. The invention utilizes non-acidolysis and non-alkalifying of magnesite to synthesize a precursor, then calcination is carried out to obtain magnesium oxide whisker, magnesite can be utilized to automatically synthesize basic magnesium carbonate and magnesium oxide whisker. The method consists of: taking magnesite as the raw material, carrying out calcination, powdering, carbonization and deslagging on the raw material to obtain a heavy magnesium solution, resolving the heavy magnesium solution to obtain a precursor, and drying the precursor to obtain magnesium carbonate whisker. The method does not involved acid or alkali, can enable automatic synthesis of the precursor and magnesium oxide whisker from magnesite, in the future the industrialized operation can be safer, and the equipment and pipeline can realize material carbon tempering. Also the carbon dioxide and water produced in the process can be recycled, thus realizing a green process.

Owner:李治涛

Magnesium phosphate cement stabilized macadam road base material

The invention discloses a magnesium phosphate cement stabilized macadam road base material. The road base material is characterized by comprising the following components: sintered magnesia powder, phosphate, an admixture, aggregate and water, wherein the sintered magnesia powder is one or a composition of more than one in magnesite light calcined powder, dolomite caustic powder, basic magnesium carbonate calcined product or calcined product of magnesium hydroxide; the phosphate is one or a mixture of several in ammonium dihydrogen phosphate, potassium dihydrogen phosphate and sodium dihydrogen phosphate; the admixture is boric acid or borax; and the aggregate comprises various kinds of macadam, pebble, artificial stone, river sand, hilly sand, manufactured sand and the like. The road basematerial disclosed by the invention has the advantages of convenience in construction, simpility in operation, fast setting and hardening,and high strength, and is capable of shortening the pavementrepair time and easy to popularize and use.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

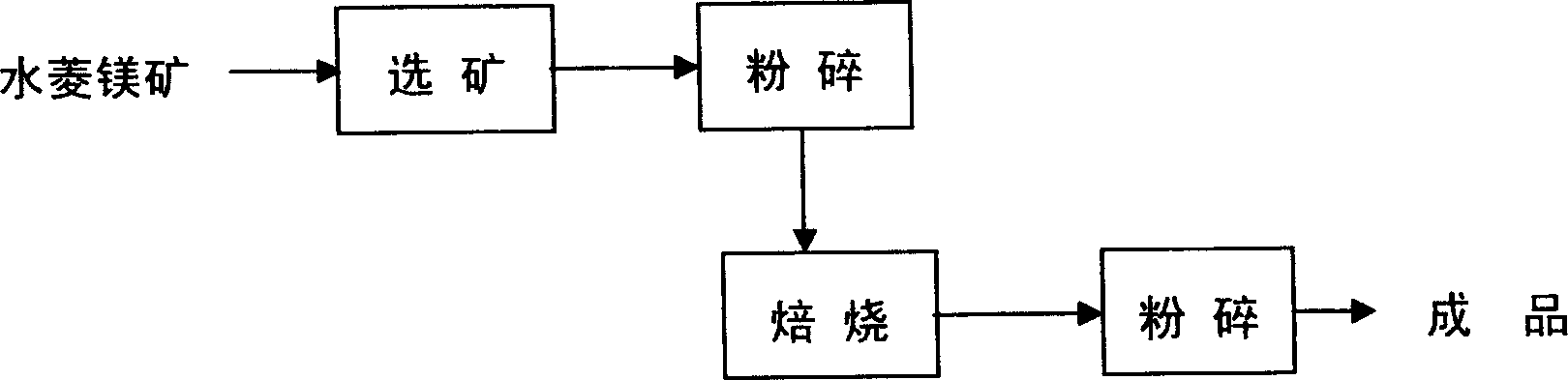

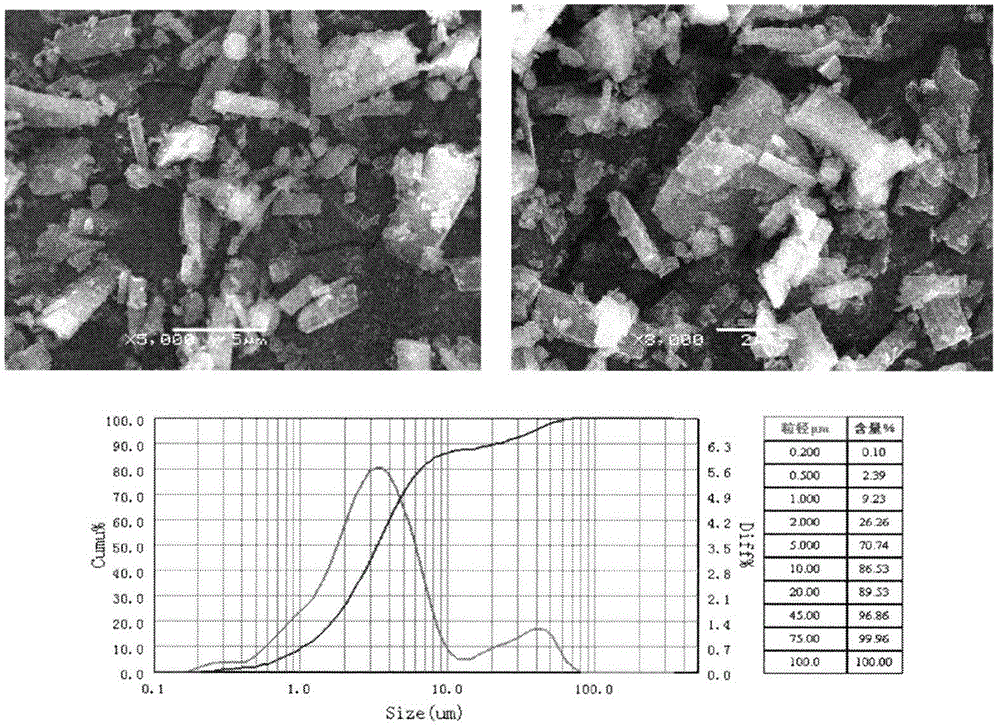

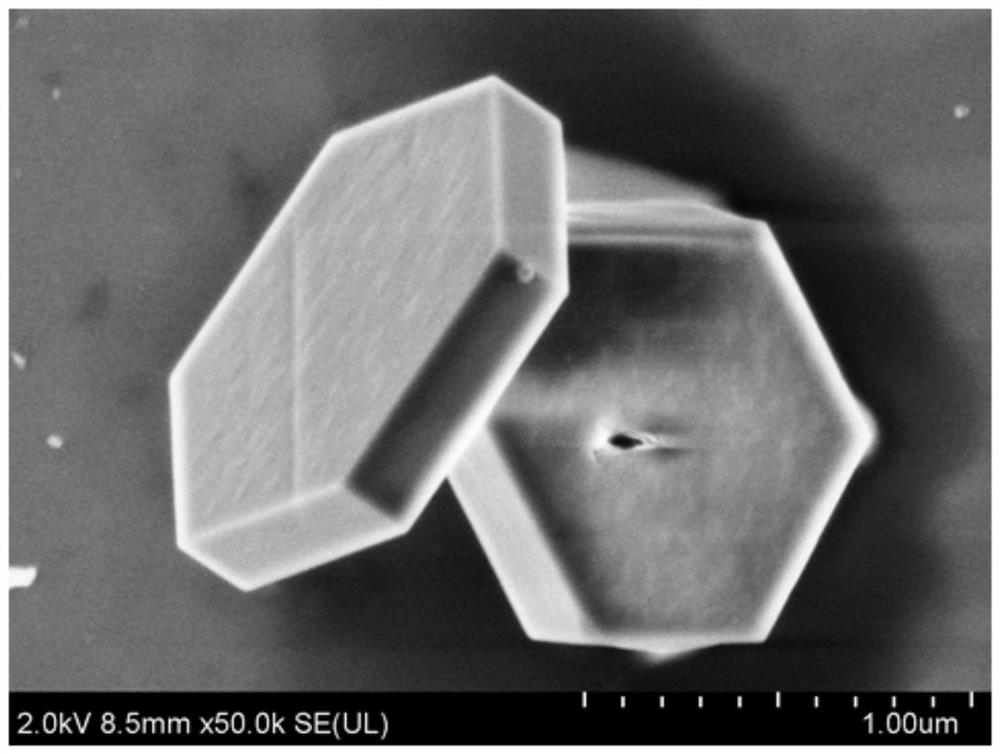

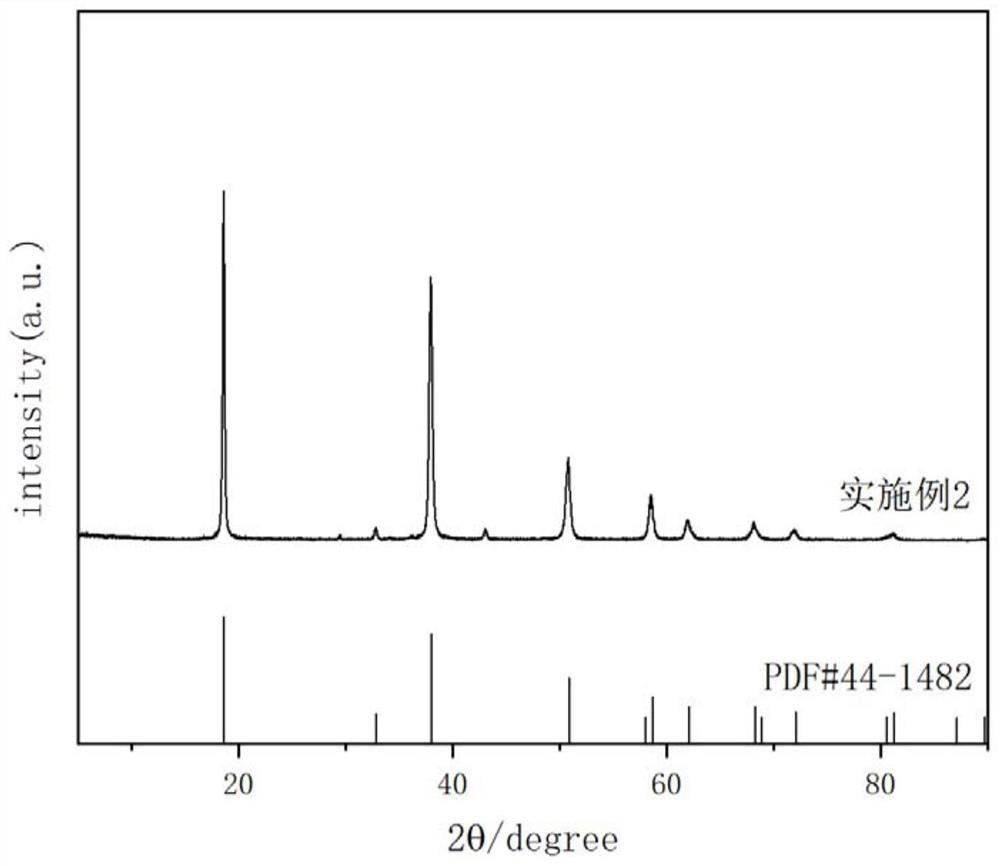

Method for preparing hexagonal flaky flame-retardant magnesium hydroxide from natural hydromagnesite

The invention discloses a method for preparing hexagonal flaky flame-retardant magnesium hydroxide from natural hydromagnesite. The method comprises the following steps of S1, crushing and screening the natural hydromagnesite, S2, calcining the crushed and screened natural hydromagnesite to obtain active magnesium oxide, S3, screening the active magnesium oxide, S4, preparing a magnesium oxide suspension by taking active magnesium oxide as a raw material and deionized water as a solvent, S5, putting the magnesium oxide suspension into a closed heating device for heating reaction to obtain a solution, and S6, taking out the solution, naturally cooling to room temperature to obtain a product, and filtering, washing and drying the product to obtain the hexagonal flaky magnesium hydroxide. The hexagonal flaky flame-retardant magnesium hydroxide with good dispersity and regular morphology can be obtained without adding any other raw materials or auxiliaries in the process of the method, and the method has the advantages of low raw material cost, simplicity in operation, high product purity and the like.

Owner:GREEN IND INNOVATION RES INST OF ANHUI UNIV

Sulfur-oxygen-magnesium cement stable gravel road surface base material

InactiveCN108033758AExcellent resistance to brine corrosionReduce construction difficultyMagnesium phosphatePhosphoric acid

The invention discloses a sulfur-oxygen-magnesium cement stable gravel road surface base material. The material comprises the following components: active magnesium oxide powder, a magnesium sulfate solution, an additive, an aggregate and water, wherein the active magnesium oxide powder is one or a compound of more selected from a group consisting of magnesite light burning powder, dolomite caustic powder, a calcined product of basic magnesium carbonate, and various calcined products of magnesium hydroxide, wherein the content of the active magnesium oxide is greater than or equal to 60%, theadditive is one or more selected from phosphoric acid, phosphates and citric acid, and the aggregate comprises one or more selected from various gravel, pebbles, artificial stones, river sand, mountain sand, artificial sand and the like. The magnesium phosphate cement stable gravel road surface base material is used for construction according to a semi-rigid base construction method, and is used for paving roads with high salt-halogen corrosion in coastal areas and western salt lake areas of China. The construction is convenient, the operation is simple, and the material is easy to promote andapply.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

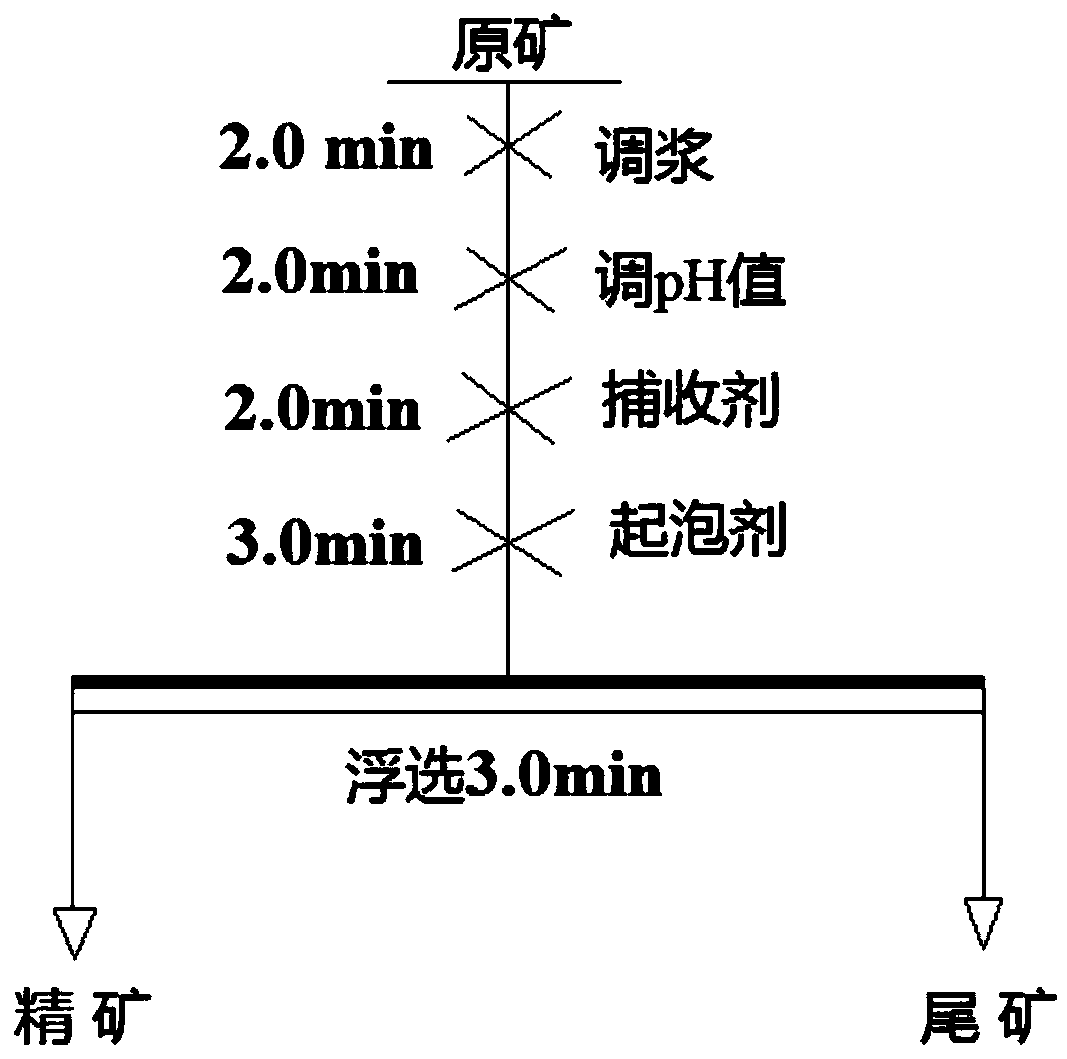

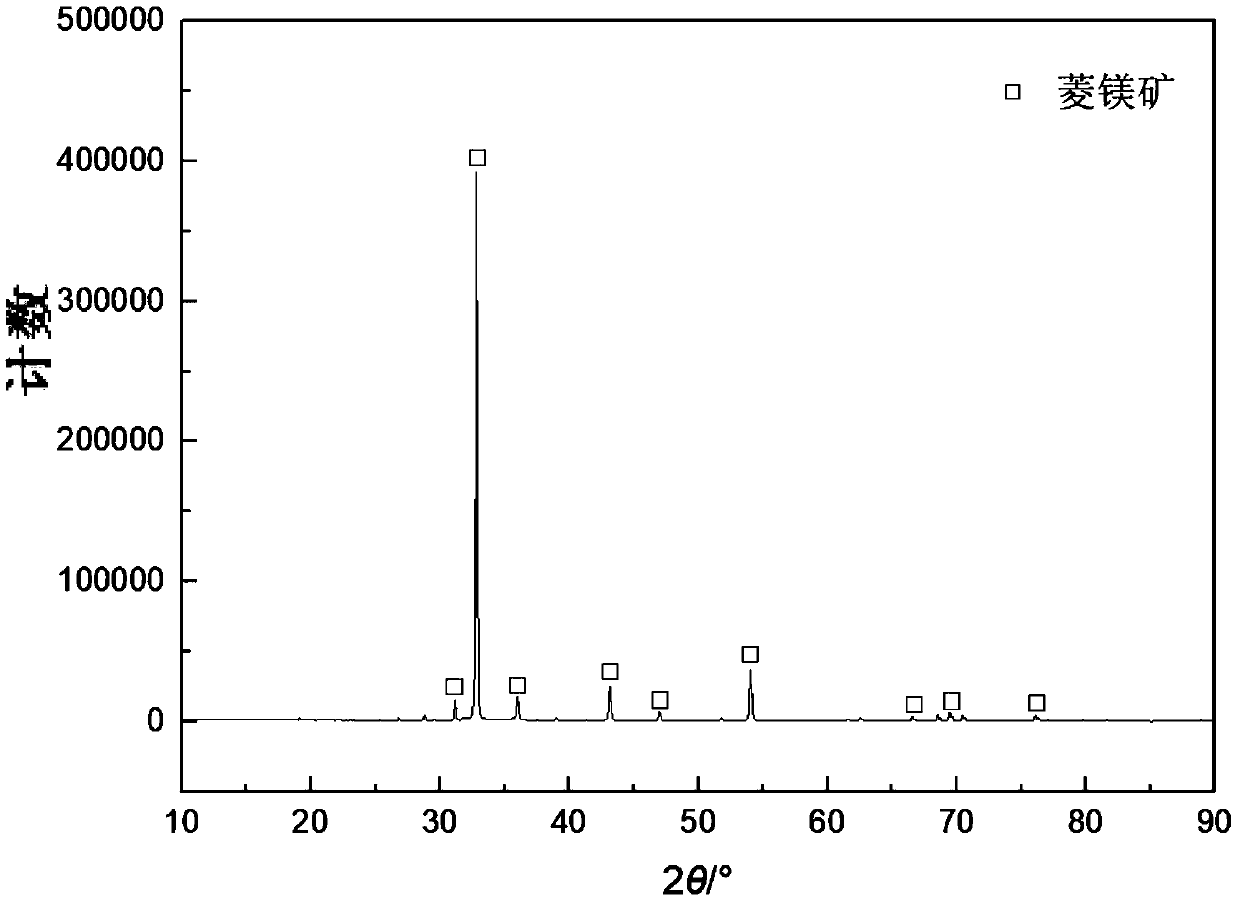

Method for temperature-control flotation and decalcification of magnesite

The invention relates to a method for temperature-control flotation and decalcification of magnesite, and belongs to the technical field of magnesite ore dressing and purification processes. The method comprises the steps of crushing and sieving high-calcium low-grade magnesite to obtain magnesite powder with the particle size of 38-74 microns; adding deionized water for mixing and slurry blendingto obtain magnesite slurry with the mass concentration of 10-40%, wherein the temperature of the magnesite slurry is 5-20 DEG C; adding NaOH to the magnesite slurry to adjust the pH value to 10-12, firstly adding an aqueous solution of a collecting agent sodium oleate for uniform stirring, and then conducting direct flotation roughing to obtain low-calcium magnesite concentrate. By means of the method, according to the difference in floatability of magnesite and impurity minerals dolomite in magnesite at different slurry temperatures, calcium minerals in magnesite are removed, the quality ofmagnesite is improved, and a new technology is provided for ore dressing and decalcification of high-calcium low-grade magnesite.

Owner:NORTHEASTERN UNIV

Preparation method of low-silicon high-calcium macrocrystalline fused magnesite

The invention discloses a preparation method of a low-silicon high-calcium macrocrystalline fused magnesite. The preparation method comprises the following steps: putting magnesite with the MgO content of over 45% into a light roasting furnace for continuous calcinations for 4 h, uniformly adding an Na2CO3 solution during calcinations, and smashing a product after calcinations to obtain a high-activity MgO powder; adding the high-purity graphite powder into the high-activity MgO powder, putting the mixture into a full-automatic electric smelting electric-arc furnace for smelting for 5 to 8 h,and carrying out classification crushing after the smelting is ended so as to obtain the low-silicon high-calcium macrocrystalline fused magnesite. According to the preparation method, a sodium carbonate solution is added, so that the melting point is effectively reduced, the calcination temperature is reduced, and the energy is saved; moreover, sodium silicate and carbon dioxide can be generatedthrough the reaction of sodium carbonate and impurity silicon dioxide, and the silicon dioxide impurity inside the magnesite can be effectively removed, so that the content of magnesium oxide is improved; the content of MgO inside the product reaches 99.90% or more than 99.90%, the calcium-silicate ratio reaches 2.30 or more, the fused magnesite has high high-temperature fire resistance and high-temperature scouring resistance, and the fused magnesite can be applied to the industries such as spaceflight, electrons, steel, metallurgy and the like as a high-quality advanced refractory material.

Owner:LIAONING XINFAZHAN REFRACTORY MATERIAL GRP

Precipitated magnesium carbonate

ActiveUS9061920B2Good optical performanceHigh whitenessCalcium/strontium/barium carbonatesPigmenting treatmentPlastics industryPhysical chemistry

Owner:OMYA INT AG

Architectural decoration coating material and preparation method thereof

The present invention discloses one kind of water soluble solid paint powder for protecting and decorating building surface and its preparation process. The paint powder is prepared through the following steps: constant temperature calcining magnesite, brucite or hydromagnesite with low impurity content to obtain light burning magnesia; adding magnesium chloride hexahydrate, borax decahydrate, iron oxide or other inorganic pigment; grinding in a grinder to 300-500 mesh and packing. The water soluble solid paint powder has simple preparation process, high waterproof and fireproof property, high wear resistance, high strength and other advantages, and may be used widely in building.

Owner:西藏日喀则地区贡嘉硼加工有限公司

Decomposition control-based hydromagnesite high efficiency fire retardant and preparation method thereof

The invention discloses a decomposition control-based hydromagnesite high efficiency fire retardant and a preparation method thereof, and belongs to the fields of inorganic fire retardation and organic synergistic fire retardation. The decomposition control-based hydromagnesite high efficiency fire retardant comprises, by mass, 20-30 parts of hydromagnesite (HM), 20-30 parts of polyvinyl chloride (PVC), 2 parts of a calcium-zinc heat stabilizer and 3 parts of chlorinated paraffin. The action principle of the fire retardant is that gaseous HCl generated after decomposition of the PVC promotes decomposition of the HM and the ratio and the structure are regulated to realize good decomposition performance of the HM in the combustion process, so the fire retardant prepared through the method has high efficiency, and the method has the advantages of low production cost, strong operability and obvious action effect.

Owner:CHANGZHOU UNIV

Low-smoke, zero-halogen and environment-friendly flame-retardant PVC (polyvinyl chloride) composite

InactiveCN105968644AGood flame retardant functionMechanical strength is not affectedEnvironmental resistanceHydromagnesite

The invention discloses a low-smoke, zero-halogen and environment-friendly flame-retardant PVC (polyvinyl chloride) composite. The composite is prepared from components of raw materials in parts by weight as follows: 100 parts of PVC, 45-55 parts of DOP (dioctyl phthalate), 25-35 parts of calcium carbonate, 75-85 parts of hydromagnesite powder and huntite powder, 3-5 parts of antimonous oxide, 6-8 parts of a heat stabilizer, 1.4-1.8 parts of a lubricant and 0.4-0.6 parts of a metal deactivator. The prepared low-smoke, zero-halogen and environment-friendly flame-retardant PVC composite has an excellent flame retardant function and cannot affect the mechanical strength of plastics.

Owner:陈旭

High-flame-retardant thermoplastic low-smoke halogen-free polyolefin material

InactiveCN108129742AAvoid rapid degradationReduce the temperaturePlastic/resin/waxes insulatorsPolyolefinPolymer science

The invention relates to a high-flame-retardant thermoplastic low-smoke halogen-free polyolefin material. The material comprises the following components in percentage by weight: 10-20% of EVA, 5-15%of POP, 5-10% of a compatilizer, 45-60% of a mixture containing a hydromagnesite flame retardant and a surface treatment agent, 5-8% of a phosphorus-nitrogen flame retardant, 1-2% of a lubricant and 0.5-1.5% of an antioxidant. According to the material provided by the invention, the EVA and the POP are adopted as a resin main body through collocation, and excellent physical property and flexibility are achieved; the hydromagnesite is used as the main flame retardant, the hydromagnesite starts to decompose and releases water at 220 DEG C, an endothermic reaction is carried out, and heat of about 1,000 J / g is absorbed, so that the surface temperature of the material is effectively reduced, the material is prevented from being degraded quickly; and meanwhile, the hydromagnesite can accumulateon the surface of the material during a combustion process to form a stable cement-like hard shell layer, so that the supply of oxygen is blocked, and then the combustion process is prevented from further spreading; and the phosphorus-nitrogen flame retardant is adopted as an auxiliary flame retardant, so that the flame-retardant effect is greatly improved.

Owner:SUZHOU CPLUS NEW MATERIAL

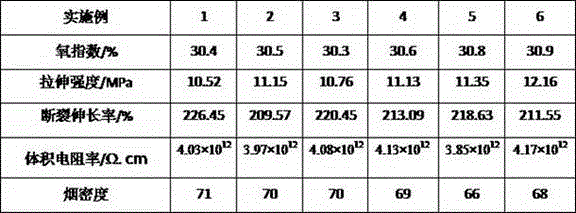

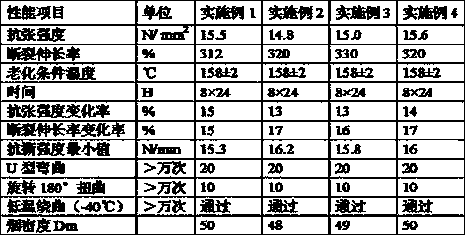

Hydromagnesite/huntite flame-retardant EVA/LLDPE (ethylene-vinyl acetate/linear low-density polyethylene) material

InactiveCN105949598ASolve the problem of flame retardant performanceImprove flame retardant performanceLow-density polyethyleneLinear low-density polyethylene

The invention discloses a hydromagnesite / huntite flame-retardant EVA / LLDPE (ethylene-vinyl acetate / linear low-density polyethylene) material which is prepared from the following components in parts by weight: 100 parts of base resins A (EVA and LLDPE), 20-30 parts of compatilizer B maleic anhydride grafted polyethylene (PE-g-MAH), 170-190 parts of inorganic flame retardants C (hydromagnesite powder and huntite powder), 0.5-1 part of antioxidant D and 2.5-4 parts of lubricant E. The preparation method comprises the following steps: uniformly mixing the raw materials, and treating at the plastifying temperature of 140-150 DEG C and the curing temperature of 160-180 DEG C. The EVA / LLDPE flame-retardant composite material disclosed by the invention has the advantages of favorable flame retardancy, excellent tensile strength and excellent elongation at break.

Owner:陈旭

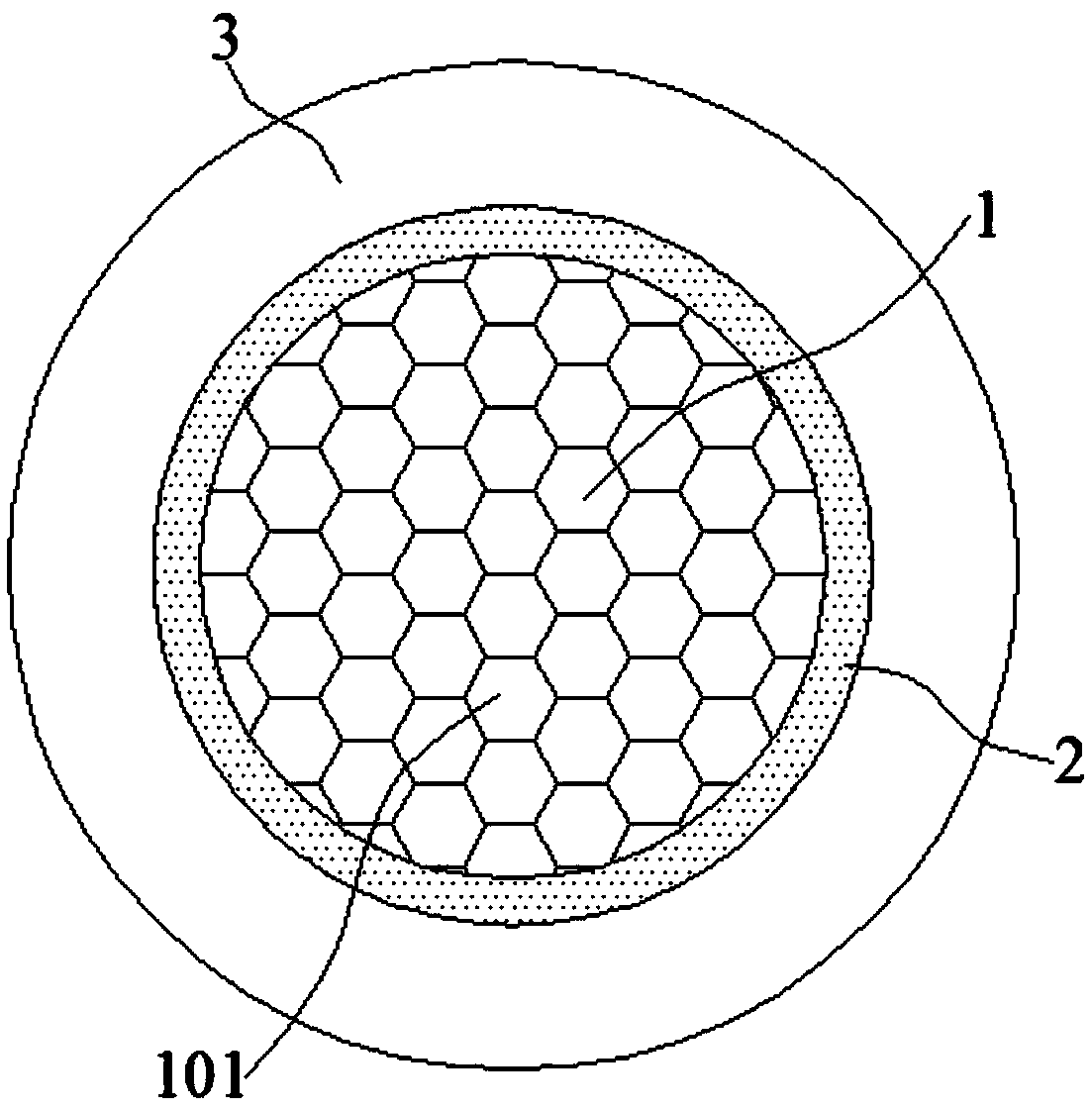

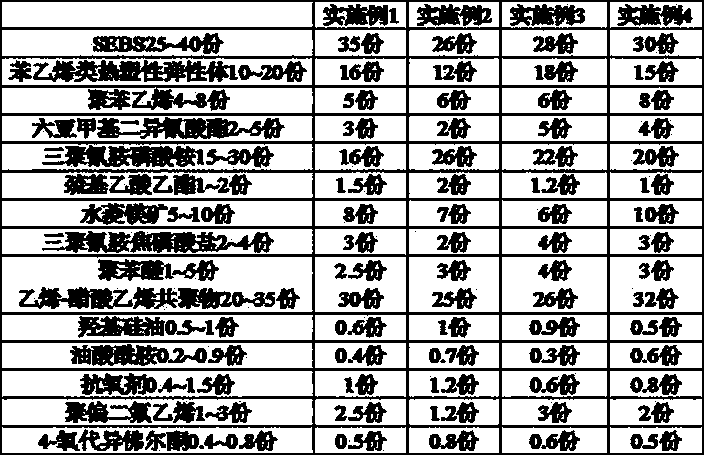

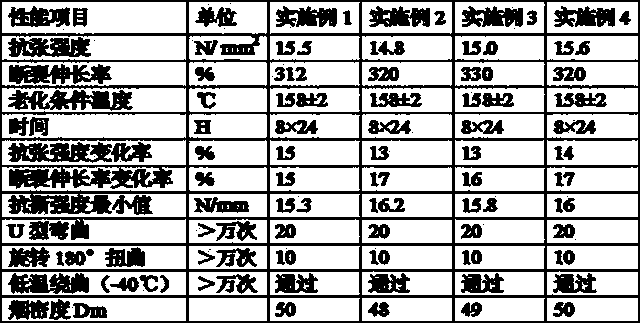

Bending-resistant halogen-free photovoltaic cable

InactiveCN109486086AImprove flexibilityImprove toughnessPlastic/resin/waxes insulatorsCopper conductorAntioxidant

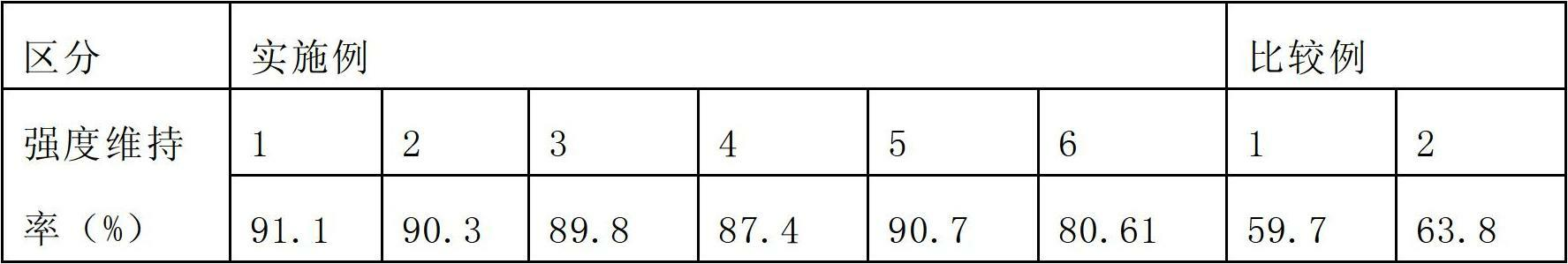

The invention discloses a bending-resistant halogen-free photovoltaic cable which comprises a copper conductor, an inner insulative layer coating the outer surface of the copper conductor and an outerjacket layer. The copper conductor is formed by twisting a plurality of copper wires. The outer jacket layer coats the outer surface of the inner insulative layer and is prepared from the following components in parts by weight: SEBS, a styrene class thermoplastic elastomer, polystyrene, hexamethylene diisocyanate, ethyl thioglycolate, ammonium melamine phosphate, hydromagnesite, melamine pyrophosphate, polyphenyl ether, a vinyl-vinyl acetate copolymer, hydroxyl silicone oil, oleamide, an antioxidant, pvdf and 4-oxo isophorone. The distortion performance of the bending-resistant halogen-freephotovoltaic cable can reach over 200 thousand times of U shaped bending. Being distorted and bent for over 100 thousand times at 180 DEG C, the cable has relatively excellent high-temperature resistance, reaches the temperature resistance level of 125 DEG C, can be aged by 7 days at 158 DEG C, and the mechanical property is retained over 80%.

Owner:WUXI XINHONGYE WIRE & CABLE

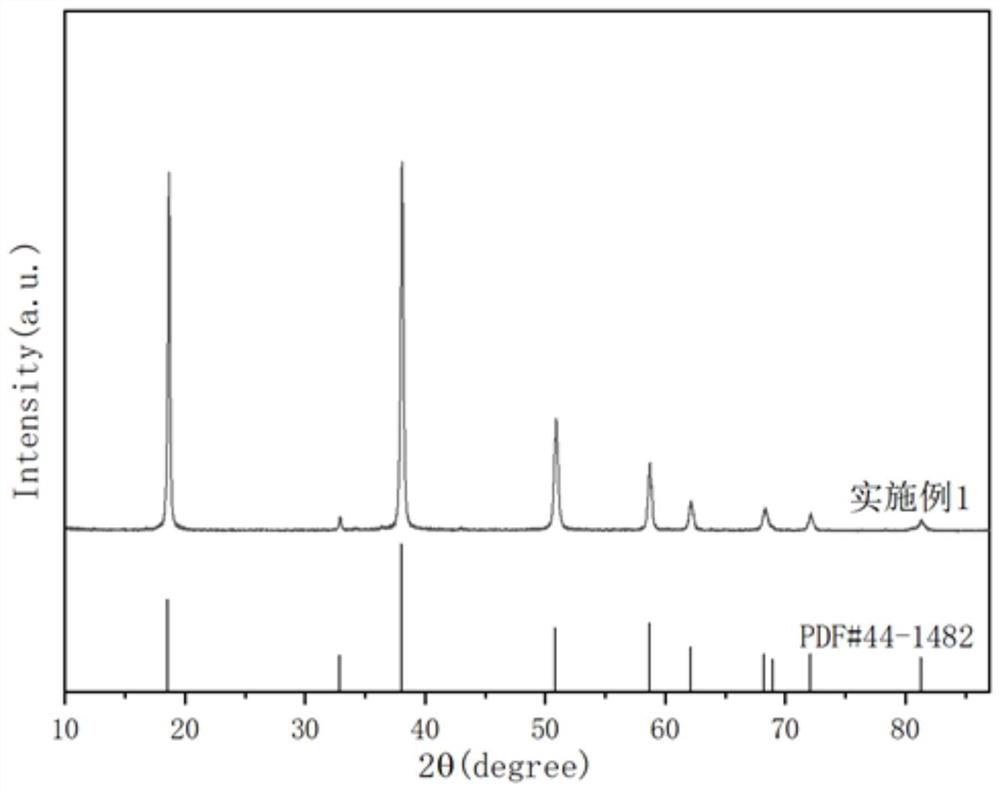

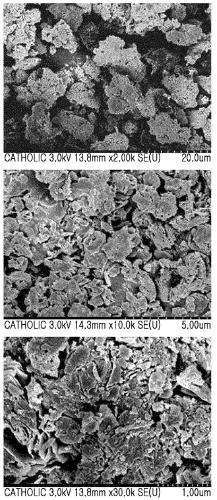

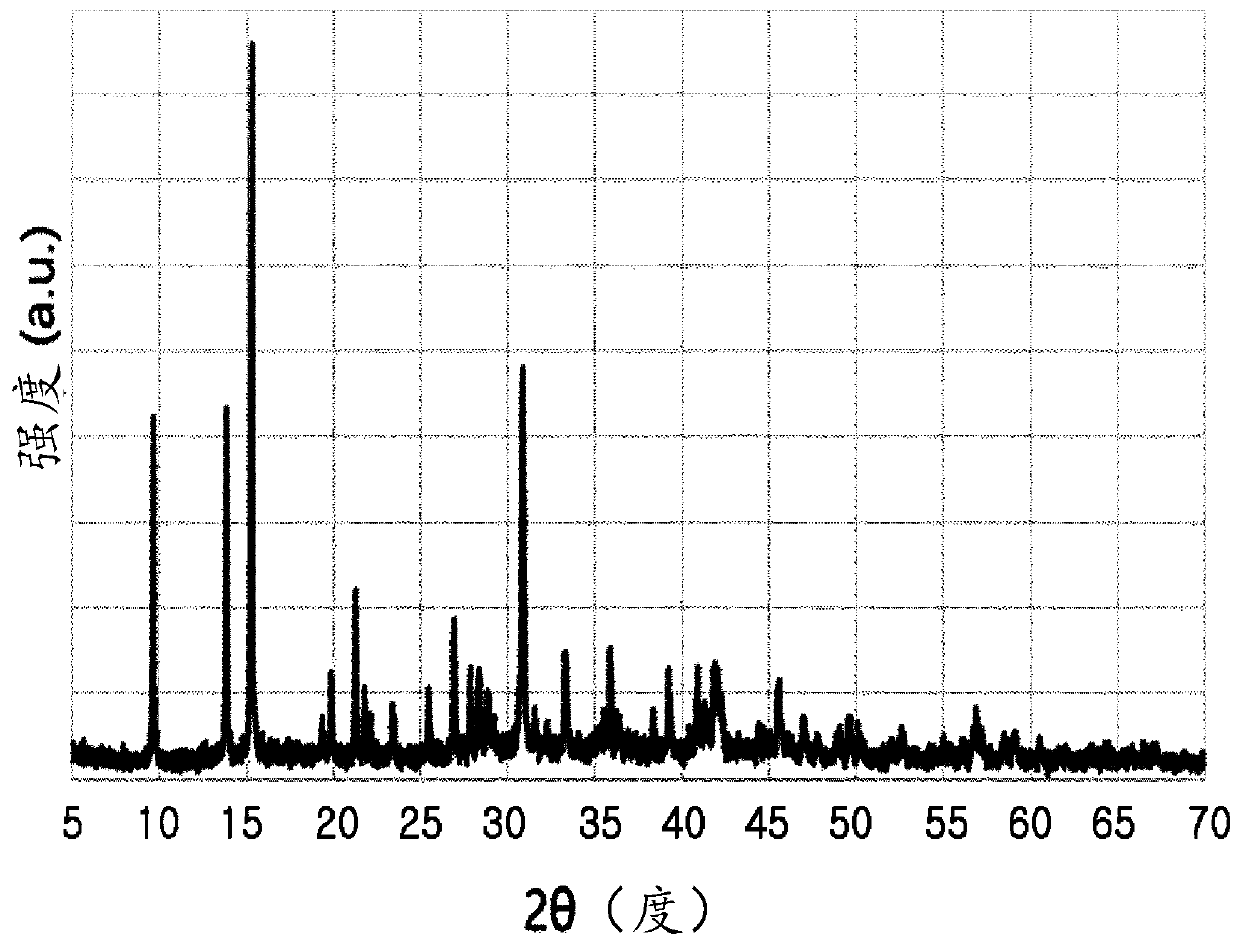

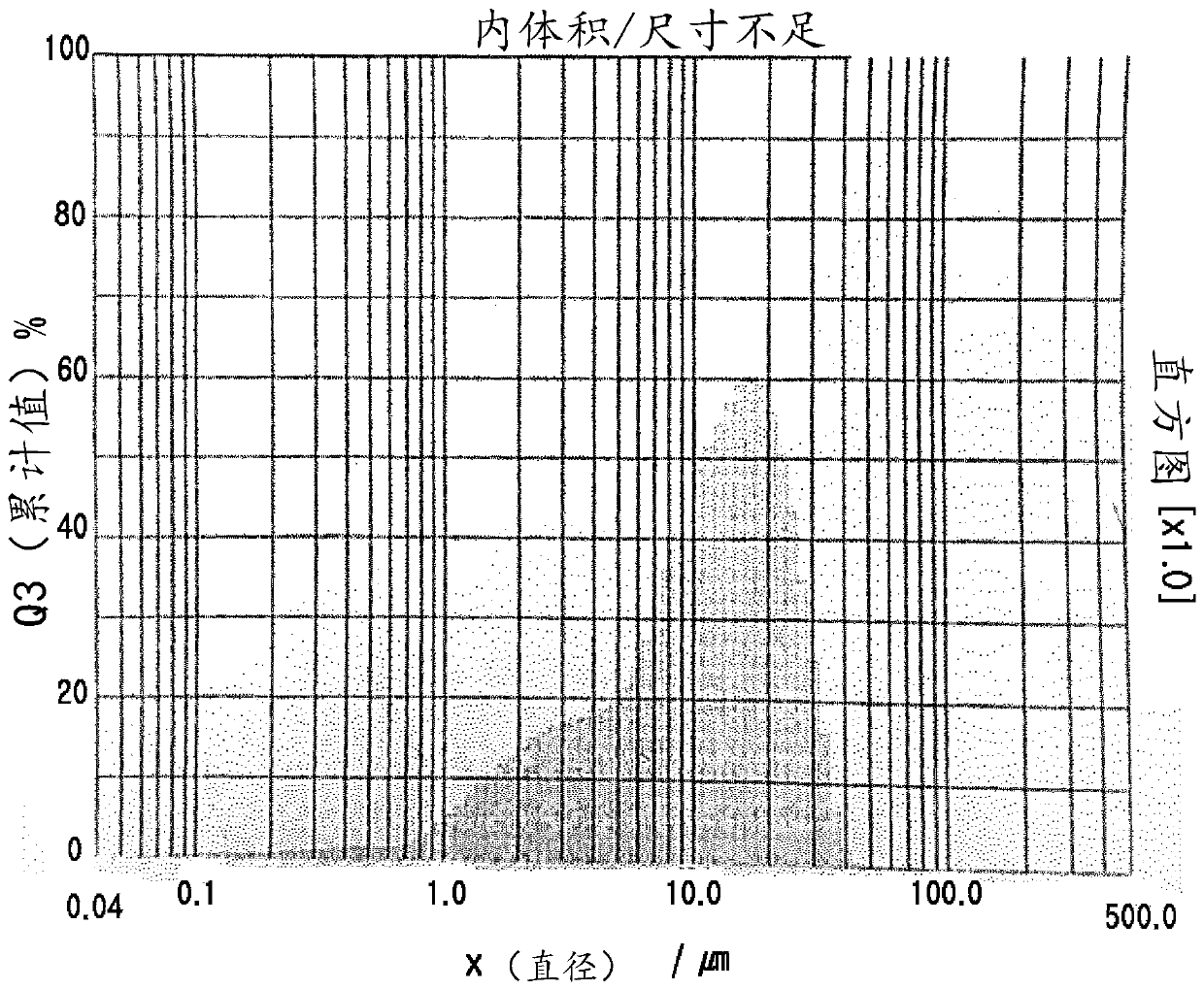

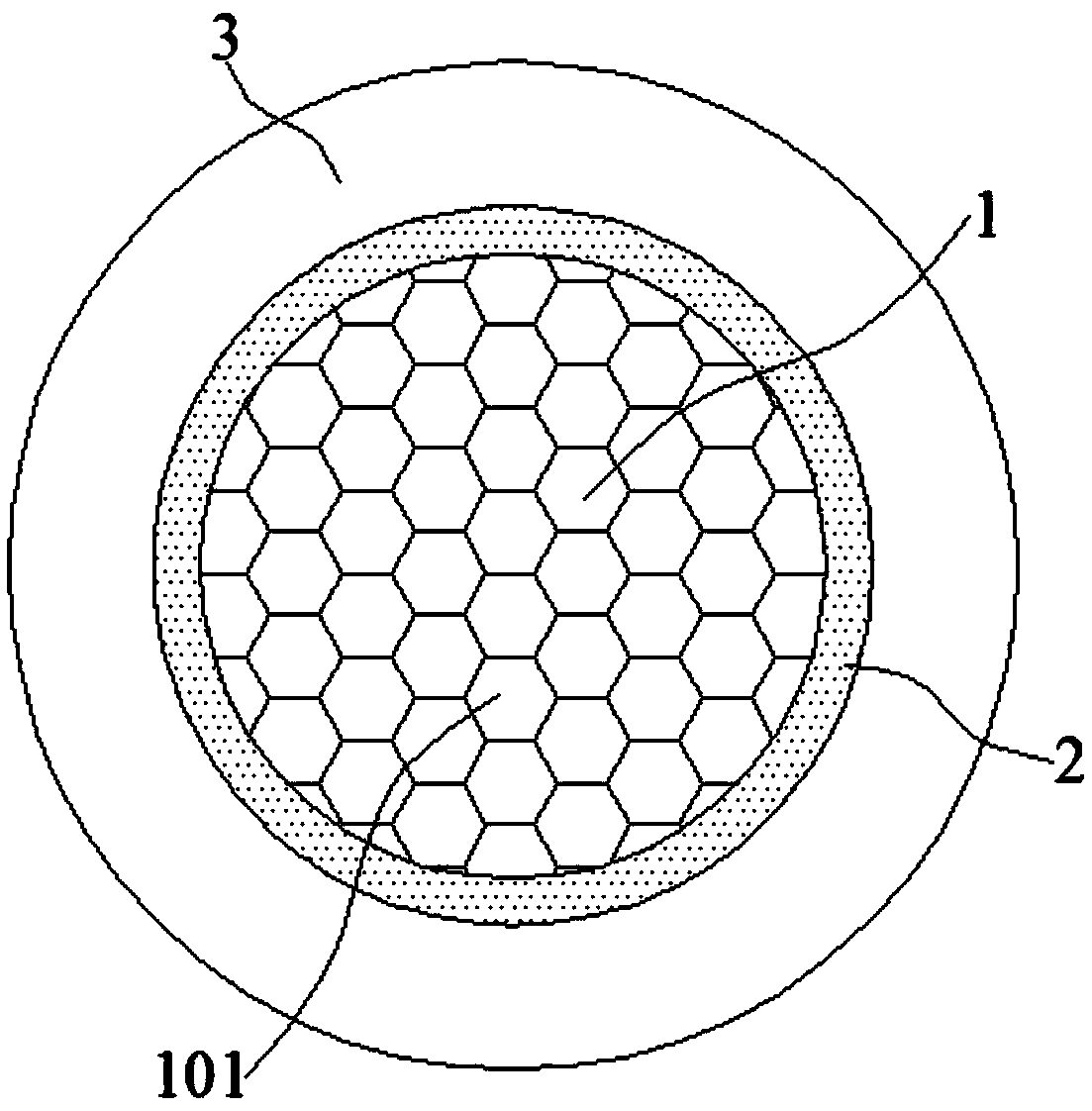

Synthetic hydromagnesite particle and method for producing same

InactiveCN109790043AUniform and cheap preparationImprove liquidityMagnesium compoundsHydromagnesiteChemistry

Disclosed are a synthetic hydromagnesite particle and a method for producing the same, the synthetic hydromagnesite particle being characterized by the following (1) to (3): (1) general formula Mg<3.8-5.2>(OH)<1.8-2.15>(CO<3>)<3.7-4.2>.mH<2>O (wherein, m is 0 to 5.); (2) the synthetic hydromagnesite has an average particle size of 0.5 to 2.3[mu]m, and the particle has a form in which plate-like materials having uneven edges are stacked in several directions; and (3) the synthetic hydromagnesite particle has a specific surface area of 20 to 55 m<2> / g as measured by a BET method.

Owner:丹石产业株式会社

Preparation technology of low-smoke and high temperature-resistant photovoltaic cable

InactiveCN109679266AImprove flexibilityImprove toughnessPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePhosphate

The invention discloses a preparation technology of a low-smoke and high temperature-resistant photovoltaic cable. The preparation technology comprises the following steps: adding SEBS, a styrenic thermoplastic elastomer, polystyrene, hexamethylene diisocyanate and ethyl thioglycolate into a high-speed mixer, mixing by stirring at a speed of 500-800rpm at 95-105 DEG C, and then putting 20-35 partsof an ethylene-vinyl acetate copolymer into a twin-screw extruder, then adding magnesium stearate, and performing extrusion granulation; adding ammonium tripolycyanamide phosphate, hydromagnesite, tripolycyanamide pyrophosphate, polyphenylene ether, hydroxyl silicone oil and prepared granules into a mixer for mixing to obtain a rubber compound. The bending-resistant halogen-free photovoltaic cable has the twisting performance as high as more than 200,000 times of U bending, can be twisted and bent by more than 100,000 times at 180 DEG C, has excellent high temperature resistance, reaches thetemperature-resistant rating of 125 DEG C, can pass 7-day aging at 158 DEG C, and has the mechanical property retention rate of 80% or above.

Owner:WUXI XINHONGYE WIRE & CABLE

A Curable Polyurethane Composition for the Preparation of Outdoor Articles, and the Articles Obtained Therefrom

A curable composition comprising(A) a mixture of homopolymers of polyisocyanates comprising(a1) from 50 wt % to 90 wt % of at least one homopolymer of an aliphatic poly-isocyanate, and(a2) from 10 wt % to 50 wt % of at least one homopolymer of a cycloaliphatic poly-isocyanate, each based on the total weight of (a1) and (a2),(B) at least one polyol selected from the group of polyether polyol and polyester polyol,(C) at least one filler selected from the group of quartz sand, quartz powder, silica, aluminium oxide, titanium oxide, zirconium oxide, Mg(OH)2, AI(OH)3, dolomite [CaMg (CO3)2], AIO(OH), silicon nitride, boron nitride, aluminium nitride, silicon carbide, boron carbide, chalk, calcium carbonate, barite, gypsum, hydromagnesite, zeolites, talcum, mica, kaolin and wollastonite, wherein the at least one filler may be silanized,which, in particular, is suitable for the manufacture of outdoor insulation system articles for electrical engineering by casting, potting, encapsulation, and impregnation processes, wherein said articles exhibit good mechanical, electrical and dielectrical properties, and can be used as insulators, bushings, switchgears and instrument transformers.

Owner:HUNTSMAN ADVANCED MATERIALS LICENSING SWITZERLAND GMBH

Oxide products formed from calcined carbonate powder for use as biocide, chemical detoxifier and catalyst support products.

A process and apparatus for manufacture of oxide products for use as biocide, chemical detoxifying, and catalytic support products, from caustic calcined carbonate powder, preferably from magnesite, dolomite, or hydromagnesite, is described. These oxide particles are characterised by high surface area, high porosity and a high degree of calcination, and the method of manufacture of utilises an indirectly heated counterflow reactor. The oxides may be used as a powder, granules, or formulated into a slurry and used as a spray, emulsion, foam or fog, or the powder product may be directly applied. Also described is the formation of particles with microstructures defined by at least one nano-crystalline structure positioned on the outer surface of the particles.

Owner:CALIX PTY LTD

General halogen-free and flame-retardant low-smoke cable material for sheath and insulation materials and preparation method of cable material

InactiveCN108727676AImprove flame retardant performanceGuaranteed mechanical propertiesPlastic/resin/waxes insulatorsProcedure AgentsHydromagnesite

The invention provides a general halogen-free and flame-retardant low-smoke cable material for sheath and insulation materials. The general halogen-free and flame-retardant low-smoke cable material comprises the following components in parts by weight: 5-10 parts of polyethylene, 10-30 parts of an ethylene-vinyl acetate copolymer, 3-15 parts of an ethylene-octene copolymer, 32-70 parts of a main flame retardant, 0-20 parts of an auxiliary flame retardant, 1-4 parts of a surface activating agent and 2-8 parts of a processing aid. A preparation method comprises the following steps: respectivelyadding the main flame retardant, the auxiliary flame retardant and the surface activating agent into a high-speed mixer; activating at 80-140 DEG C for 5-40 min to obtain a highly active flame-retardant filler; and mixing and granulating the highly active flame-retardant filler with other components in mixing equipment to obtain the halogen-free and flame-retardant low-smoke cable material. The preparation method provided by the invention has the advantages that hydromagnesite is used as the main flame retardant to improve flame retardancy of the cable material and maintain mechanical properties, electrical properties and processing properties of the cable material at the same time on the premise of high filling, i.e., high cost performance.

Owner:JIANGSU BAOYUAN GAOXIN ELECTRIC

Preparation process for highly-flame-retardant, irradiation-crosslinked, low-fume and low-halogen polyolefin material

The invention provides a preparation process for a highly-flame-retardant, irradiation-crosslinked, low-fume and low-halogen polyolefin material. The preparation process comprises the following steps:subjecting EEA, PE, POP and a compatibilizing agent to premixing and modifying, and carrying out granulating for subsequent usage; adding hydromagnesite powder into a surfactant, carrying out mixing,and subjecting mixed particles, powder, a halogen-based flame retardant, antimonous oxide, zinc borate, a lubricant, an antioxidant and a crosslinking agent to mixing at a high speed; subjecting a mixed semi-finished product to high-temperature melting in a formula proportion, after the material is completely molten into a material lump, carrying out further mixing and dispersing, then carrying out discharging, and subjecting a remixed material to granulating; after completion of molding and granulating, allowing the material to pass through a honeycomb plate located at the front end of a single screw, and carrying out granulating; and after the material is granulated, carrying out cooling and sieving through a pipeline, selecting particles with a length of 3 to 5 mm as qualified products, and carrying out packaging. According to the invention, through combination of a plurality of flame retardants, excellent flame retardancy is achieved; meanwhile, compared with a PVC material, the material provided by the invention is greatly reduced in the amount of fuming, and has the advantages of low fume density and excellent and stable physical properties.

Owner:SUZHOU CPLUS NEW MATERIAL

Lithium carbonate crystal separating process from carbonate-type bittern by means of solar battery

InactiveCN1179885CReduce consumptionLow costSolution crystallizationLithium carbonates/bicarbonatesGeomembraneLithium carbonate

The present invention is a method of utilizing solar pond as crystallizing pond for separating lithium carbonate crystal from carbnate-type bittern. The solar pond with lighting area of 1000-10000 sq m and depth of 3-4 m has raw material of bittern as working medium and is built with clay enclosure, sandwith structure of plastic film and hydromagnesite in the bottom, and black geotechnical membrane or high-density polyethylene or polyvinyl chloride lining laid on the internal wall. By combining the heat accumulation of solar pond and the separation of lithium carbonate, great amount of lithium carbonate is deposited and mixed salt with lithium carbonate content over 80% may be produced at low cost.

Owner:SALT LAKE & HOT WATER RESOURCE RES DEV CENT CHINESE ACAD OF GEOLOGICAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com