Preparation method of superfine active hydromagnesite flame-retardant filler

A technology of flame-retardant filler and hydromagnesite powder, which is applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problem of inability to restore product fineness by powder, and achieve easy dispersion of binding force, good resistance Combustibility, compatibility improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

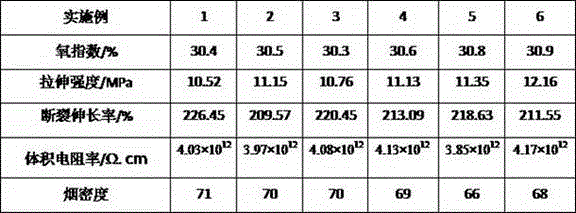

Examples

Embodiment 1

[0022] Embodiment 1: Taking 100 kg of hydromagnesite powder as a benchmark. (1) Add 100 kg of hydromagnesite powder and 0.2 kg of sodium hexametaphosphate into water to fully stir and disperse to form a powder slurry with a mass concentration of 35%; (2) Add the powder slurry to a horizontal sand mill for Ultrafine grinding, at the same time add 0.6kg of aminosilane according to the mass ratio of hydromagnesite powder: aminosilane = 1000: 6, and carry out a surface organic modification; (3) Hydromagnesite powder is fully ultrafine grinding, and the particle size distribution is detected reach d 50 =2.15μm, d 97 =4.56μm, and then carry out pressure filtration and dehydration; (4) Put the filter cake obtained from pressure filtration and dehydration into a honeycomb mill for drying and depolymerization, and at the same time add hydromagnesite powder: stearic acid at a mass ratio of 1000: 10 1.0kg of stearic acid was subjected to secondary surface organic modification at a temp...

Embodiment 2

[0023] Embodiment 2: Taking 100 kg of hydromagnesite powder as a benchmark. (1) Add 100 kg of hydromagnesite powder and 0.3 kg of sodium hexametaphosphate into water to fully stir and disperse to form a powder slurry with a mass concentration of 40%; (2) Add the powder slurry to a horizontal sand mill for Ultrafine grinding, at the same time add 0.7kg of aminosilane according to the mass ratio of hydromagnesite powder:aminosilane=1000:7, and carry out a surface organic modification; (3) Hydromagnesite powder is fully ultrafinely ground, and the particle size distribution is detected reach d 50 =1.56μm, d 97 =3.49μm, and then carry out pressure filtration dehydration; (4) Put the filter cake obtained from pressure filtration dehydration into a honeycomb mill for drying and depolymerization, and at the same time add hydromagnesite powder: stearic acid in a mass ratio of 1000: 12 1.2kg of stearic acid was subjected to secondary surface organic modification at a temperature of 1...

Embodiment 3

[0024] Embodiment 3: Taking 100 kg of hydromagnesite powder as a benchmark. (1) Add 100kg of hydromagnesite powder and 0.4kg of sodium hexametaphosphate into water to fully stir and disperse to form a powder slurry with a mass concentration of 45%; (2) Add the powder slurry to a horizontal sand mill for ultra- Finely grind, and at the same time, add 0.8kg of aminosilane according to the mass ratio of hydromagnesite powder:aminosilane=1000:8, and carry out a surface organic modification; (3) The hydromagnesite powder is fully ultra-finely ground, and the particle size distribution of the detection reaches d 50 =2.50μm, d 97 =5.22μm, and then carry out pressure filtration dehydration; (4) Put the filter cake obtained from pressure filtration dehydration into the honeycomb mill for drying and depolymerization, and add hydromagnesite powder:aluminate=1000:8 mass ratio 0.8kg of aluminate was subjected to secondary surface organic modification at a temperature of 150°C to obtain u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

| Particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com