Ceramic powder for denture preparation and preparation method of ceramic powder

A technology for ceramic materials and dentures, applied in dental preparations, dental prostheses, pharmaceutical formulations, etc., can solve the problems of difficult reaction control, poor powder dispersion, complex production process, etc., to avoid hard agglomeration, prevent agglomeration, and evenly distribute Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

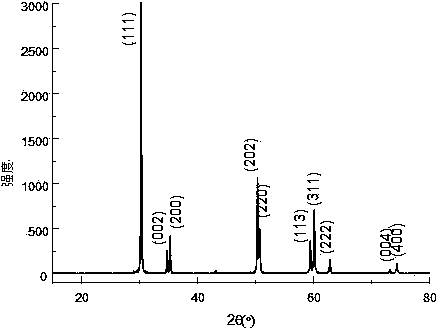

[0022] An embodiment of the present invention discloses a ceramic material powder for denture preparation, including 90% to 95% of stabilized tetragonal zirconia, and 2.5 to 3.49% of yttrium oxide as a stabilizer; wherein the ceramic material A precursor is obtained from the powder through co-precipitation reaction; the precursor is sequentially subjected to vacuum freeze-drying, high-temperature calcination and ball milling to form a powder with a bending strength greater than 600 MPa. like figure 2 The transmission electron microscope TEM image of the ceramic material powder shows that the particle size of the prepared powder is small, the average particle size is 20~50nm, and the dispersion is uniform; combined with figure 1 The XRD figure shows that, with the standard tetragonal phase ZrO 2 In contrast, the detected powder is a tetragonal phase. Further, the powder composition was analyzed by atomic emission spectrometer, which was ZrO 2 +HfO 2 +Y 2 o 3 ≥99.0%, Y 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com