Method and device for manufacturing non-glomeration nano-oxide powder body

A technology for preparing nano-oxides and devices, applied in the direction of oxide/hydroxide preparation, chemical instruments and methods, inorganic chemistry, etc., can solve difficulties, hard agglomeration and other problems, achieve low cost, overcome hard agglomeration, and device structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

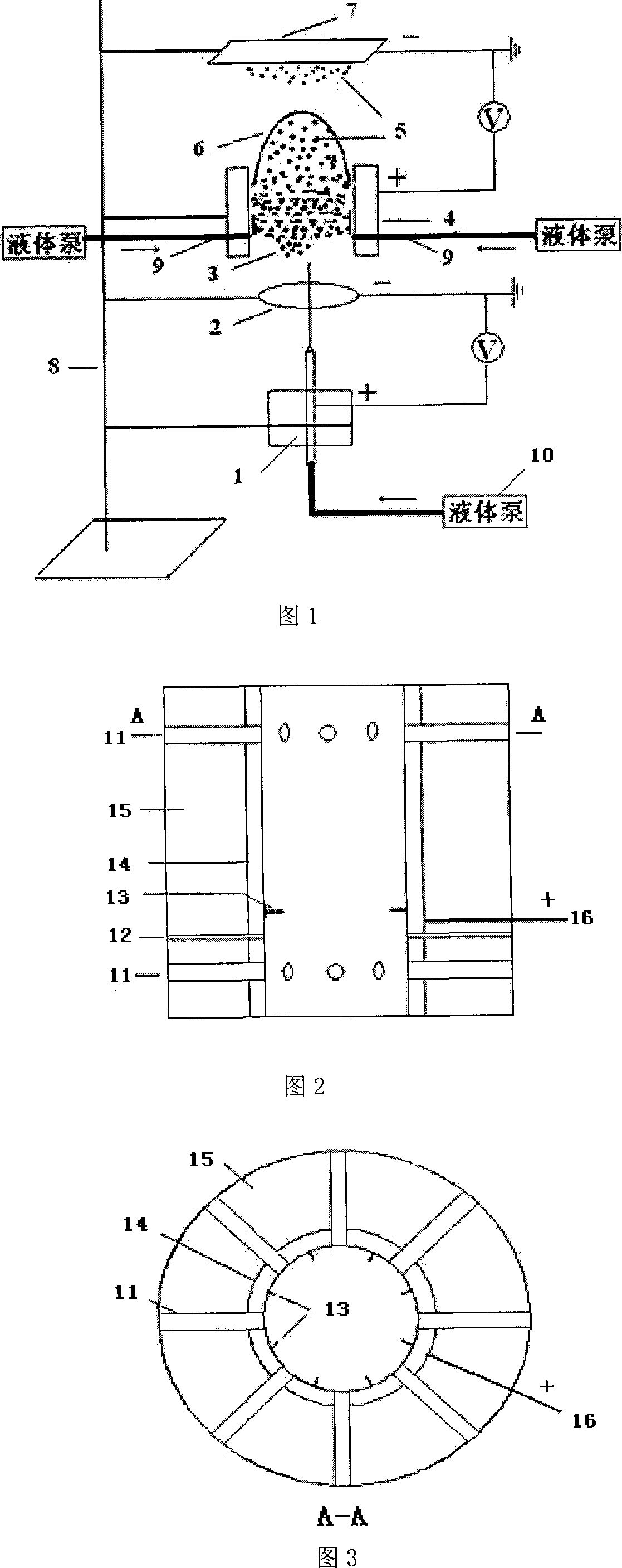

[0029] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

[0030] Referring to Figure 4 and Figure 1, the preparation method of the non-agglomerated nano-oxide powder, the detailed process is as follows:

[0031] The electrospray-nano-flame method uses common inorganic salts as raw materials, and does not require complex chemical processes such as the preparation of sols. It has the advantages of simplicity and wide application range. By changing the solute ratio, powders with corresponding chemical compositions can be obtained; by changing the solute concentration and electrospray process parameters, the particle size of the prepared oxide powder can be adjusted. In addition, the powder output can be increased by adopting the array method.

[0032] The process of using this method to prepare ZnO nanopowder in this embodiment is described as follows, see Figure 5,

[0033] 1. Prepare Zn(NO 3 ) 2 ethanol soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com