Composite synergistic flame retardant and smoke suppression low smoke halogen-free skeleton material

A technology of synergistic flame retardant and skeleton material, which is applied in the field of composite synergistic flame retardant and smoke-suppression low-smoke halogen-free skeleton material and low-smoke halogen-free skeleton material. , can not use low-smoke halogen-free framework and other problems, to improve mechanical properties, improve the effect of flame retardant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

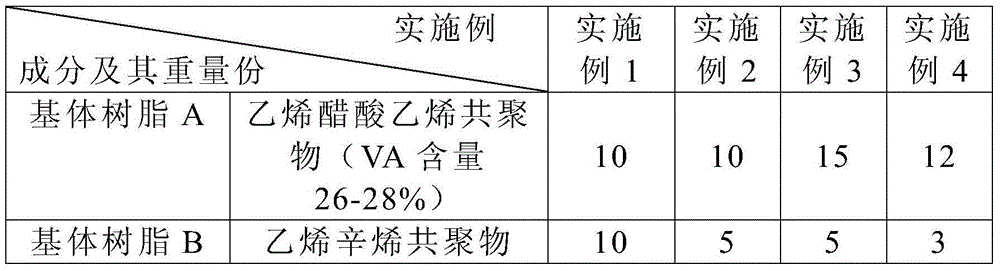

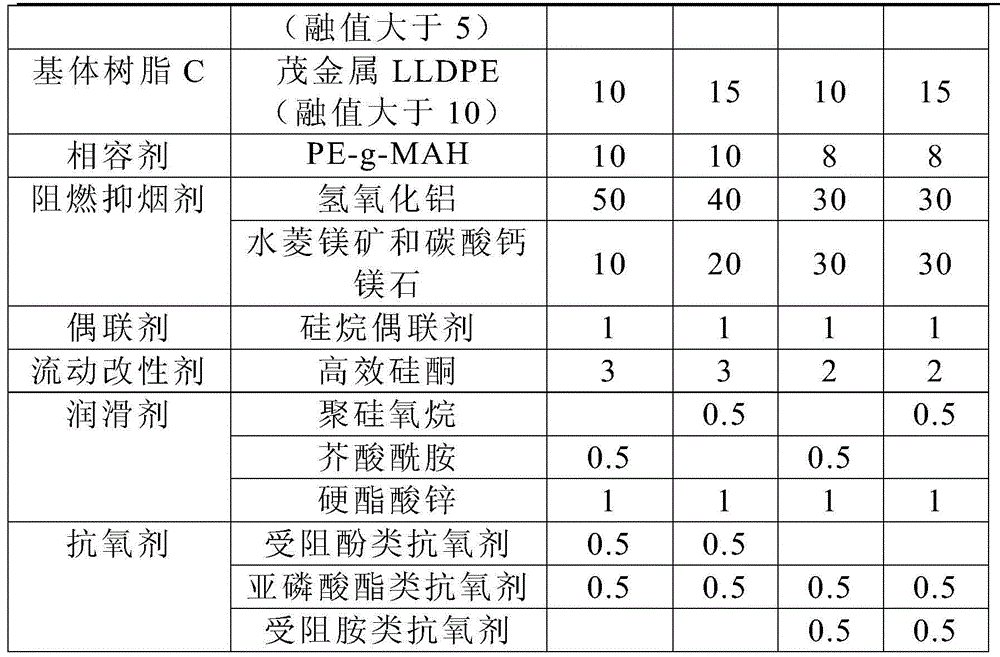

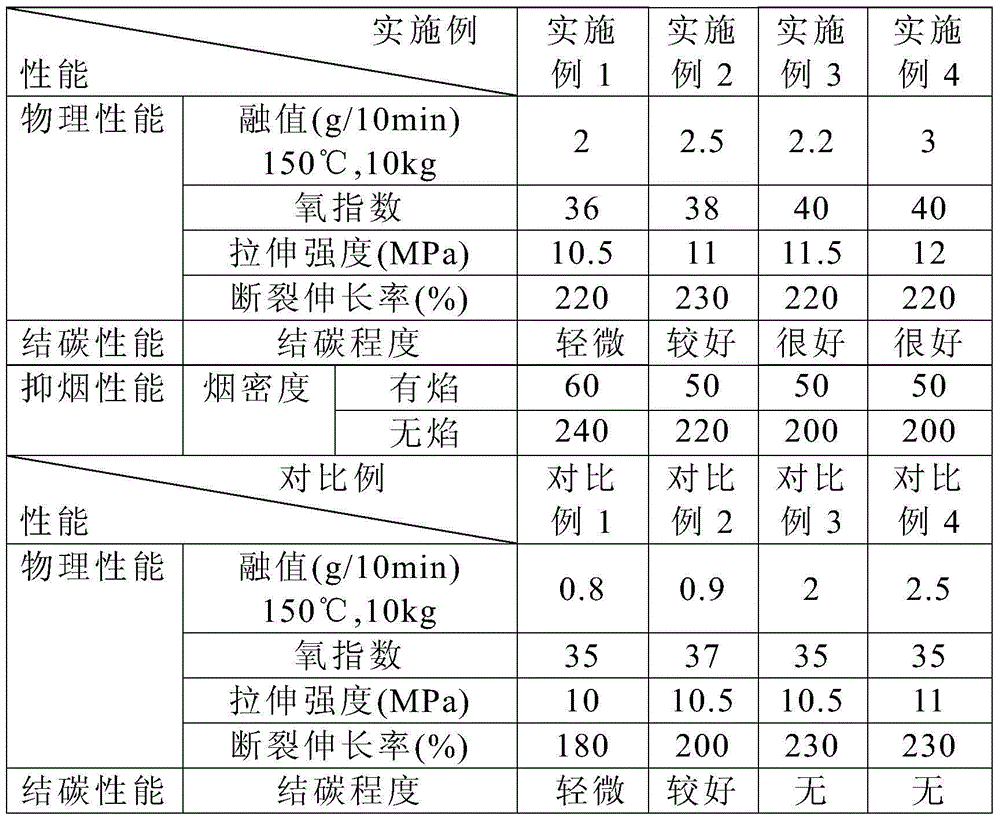

[0029] Example 1: Take the raw materials according to the components of the low-smoke halogen-free skeleton material described in Example 1 in Table 1 and their parts by weight; Then add it to the high mixer together with the rest of the components, stir at high speed for 5 minutes, feed into the internal mixer, and banbury for 10-15 minutes, until the banbury temperature reaches 130-135°C and discharge; then feed into the twin-screw In the extruder feeder, the temperature of the twin-screw extruder is 145°C-160°C, the feeding frequency is 30 Hz, and the main engine speed is 300 rpm; then it enters the single-screw extruder to extrude from the head, and then It is granulated by a granulator, and finally air-cooled to obtain a low-smoke and halogen-free skeleton material.

Embodiment 2

[0030] Embodiment 2: The raw materials are weighed according to the components and the parts by weight thereof in Embodiment 2 in Table 1, and other technological processes are the same as in Embodiment 1, and will not be repeated.

Embodiment 3

[0031] Embodiment 3: The raw materials are weighed according to the components of Embodiment 3 in Table 1 and the parts by weight thereof, and the other technological processes are the same as in Embodiment 1, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com