Bending-resistant halogen-free photovoltaic cable

A photovoltaic cable and folding-resistant technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of cable insulation damage, injury, fire personnel and other problems, achieve excellent high temperature resistance performance, improve bending performance, the effect of improving flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

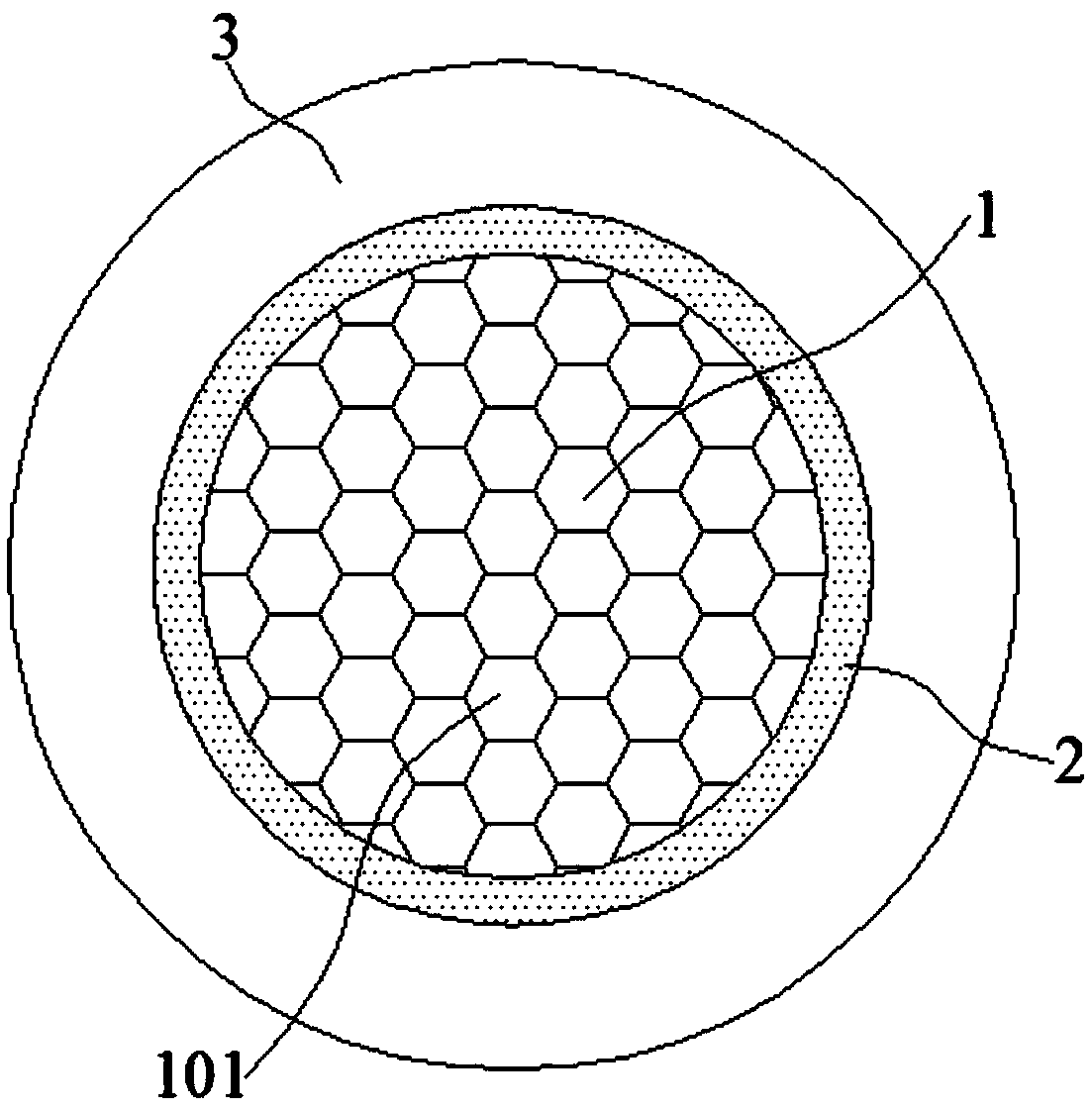

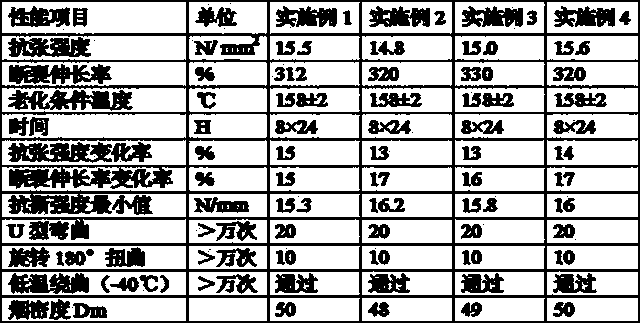

[0035] Embodiments 1 to 4: A bending-resistant halogen-free photovoltaic cable, the bending-resistant halogen-free photovoltaic cable includes a copper conductor 1, an inner insulating layer 2 and an outer sheath layer 3 coated on the outer surface of the copper conductor 1, The copper conductor 1 is formed by twisting several copper wires 101, and the outer sheath layer 3 is covered on the outer surface of the inner insulating layer 2;

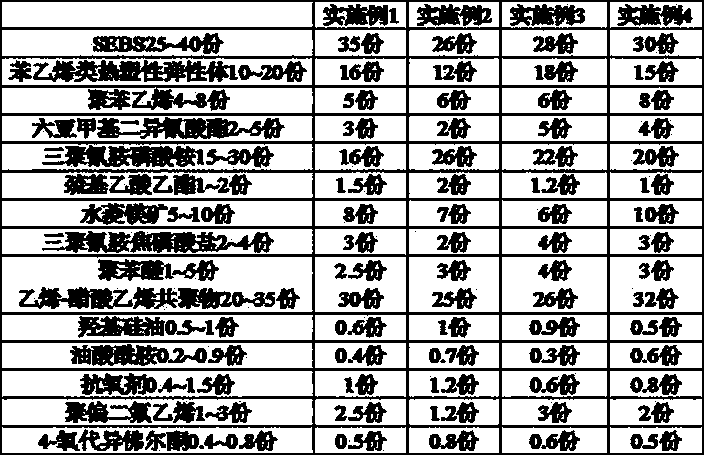

[0036] The outer sheath layer 3 is composed of the following components by weight: as shown in Table 1:

[0037] Table 1

[0038]

Embodiment 1

[0039] The antioxidant of embodiment 1 is antioxidant 1010, the antioxidant of embodiment 2 is antioxidant 245, the antioxidant of embodiment 3 is distearyl thiodipropionate, the antioxidant of embodiment 4 The agent is antioxidant 168;

[0040] The content of vinyl acetate in the above-mentioned ethylene-vinyl acetate copolymer is 16-40%.

[0041] The above-mentioned SEBS is a linear three-block copolymer with polystyrene as the terminal block and ethylene-butylene copolymer as the middle elastic block.

[0042] The copper wire 101 is a type 5 annealed copper wire or a type 6 annealed copper wire, and the shape of the protrusion 4 is a semicircle.

[0043] The above-mentioned outer sheath layer 3 is obtained through the following steps:

[0044] Step 1. Add 25~40 parts of SEBS, 10~20 parts of styrene-based thermoplastic elastomer, 4~8 parts of polystyrene, 2~5 parts of hexamethylene diisocyanate, and 1~2 parts of ethyl thioglycolate into high-speed mixing In the extruder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com