Method and apparatus for production of basic magnesium carbonate and magnesium oxide whisker from magnesite

A technology of magnesium oxide whiskers and magnesium carbonate whiskers, which is applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problems of inability to realize carbon tempering of materials, high production cost, unfavorable environmental protection and the like, and achieves the realization of The process is green, the formation is simple, and the effect of friendliness is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Preferred preparation steps of the present invention include:

[0038] 1) Calcination: Calcining magnesite into light-burned ore, the temperature of the preheating section of the calcination kiln is controlled at 150-200°C, the temperature of the calcination section is controlled at 700-900°C, the temperature of the cooling section is controlled at 100-150°C, and the calcination time is 24 -32 hours, cooked ore activity ≤ 200S.

[0039] 2) Powder: The above cooked ore powder is made into 120 mesh 90% lightly burned powder, and its MgO content is measured, which requires more than 82%.

[0040] 3) Carbonization: Mix the ore powder and water into the tank according to the ratio of MgO13-17g / L, and send the CO2 (kiln gas) produced by the kiln calcined magnesite to the carbonization tank for carbonization after cooling, dust removal and pressurization. The end point is that the soluble MgO in the solution reaches 11-15g / L.

[0041] 4) Filter residue: Send the above-mentio...

Embodiment 2

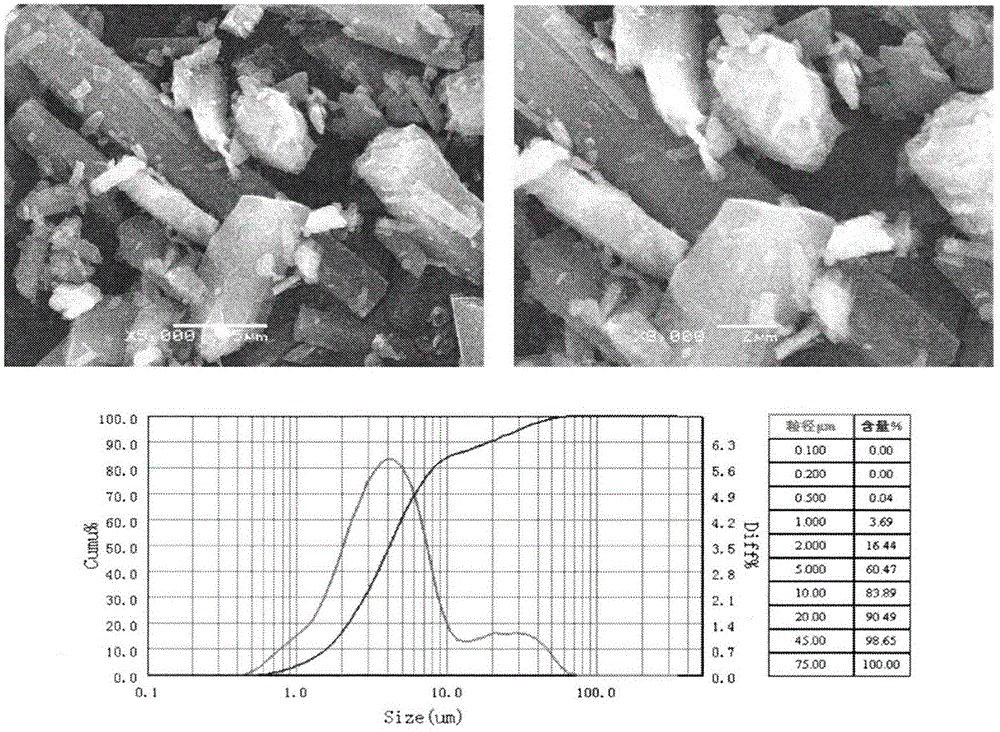

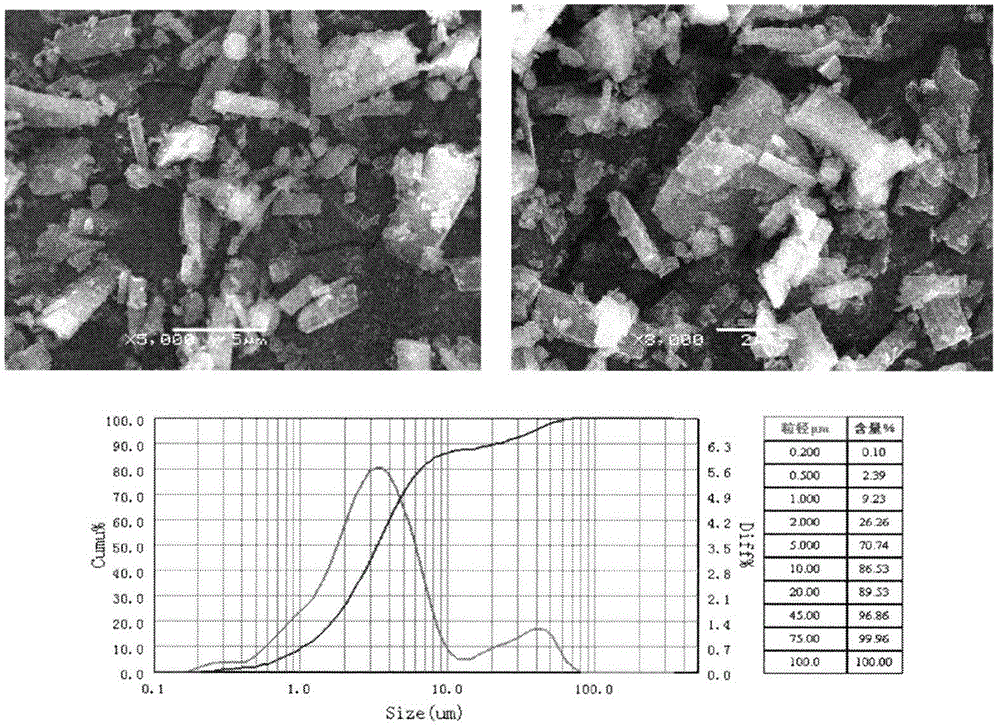

[0051] In embodiment 2 of the present invention, the magnesite is broken into 13-16 cm size ore pieces and anthracite coal pieces (calorific value 21000 joules / kg) are added to the calcining kiln at a ratio of 10:1, and the calcining temperature is controlled at 800-830 degrees The calcination time is 27 hours, and the smelted ore powder reaches 120 mesh and 90% passes through, and the magnesium oxide content is 85.5%, and the activity is 160 seconds. Put its powder and water into the carbonization tank at a ratio of 16 g / l of magnesium oxide, and send the carbon dioxide (kiln gas) produced by the calcining kiln to the carbonization tank after cooling, dust removal, and compression. The pressure is controlled at 3-4 atmospheres, and the temperature is controlled 10-20 degrees, reaction time 1.5-2.5 hours, the measured soluble magnesium oxide is greater than 14.5 g / L. It is filtered to remove slag, and the pure liquid is commonly called heavy magnesium water, which is pumped in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com