Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Haemodialysis membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for Treating Anemia in Hemodialysis Patients

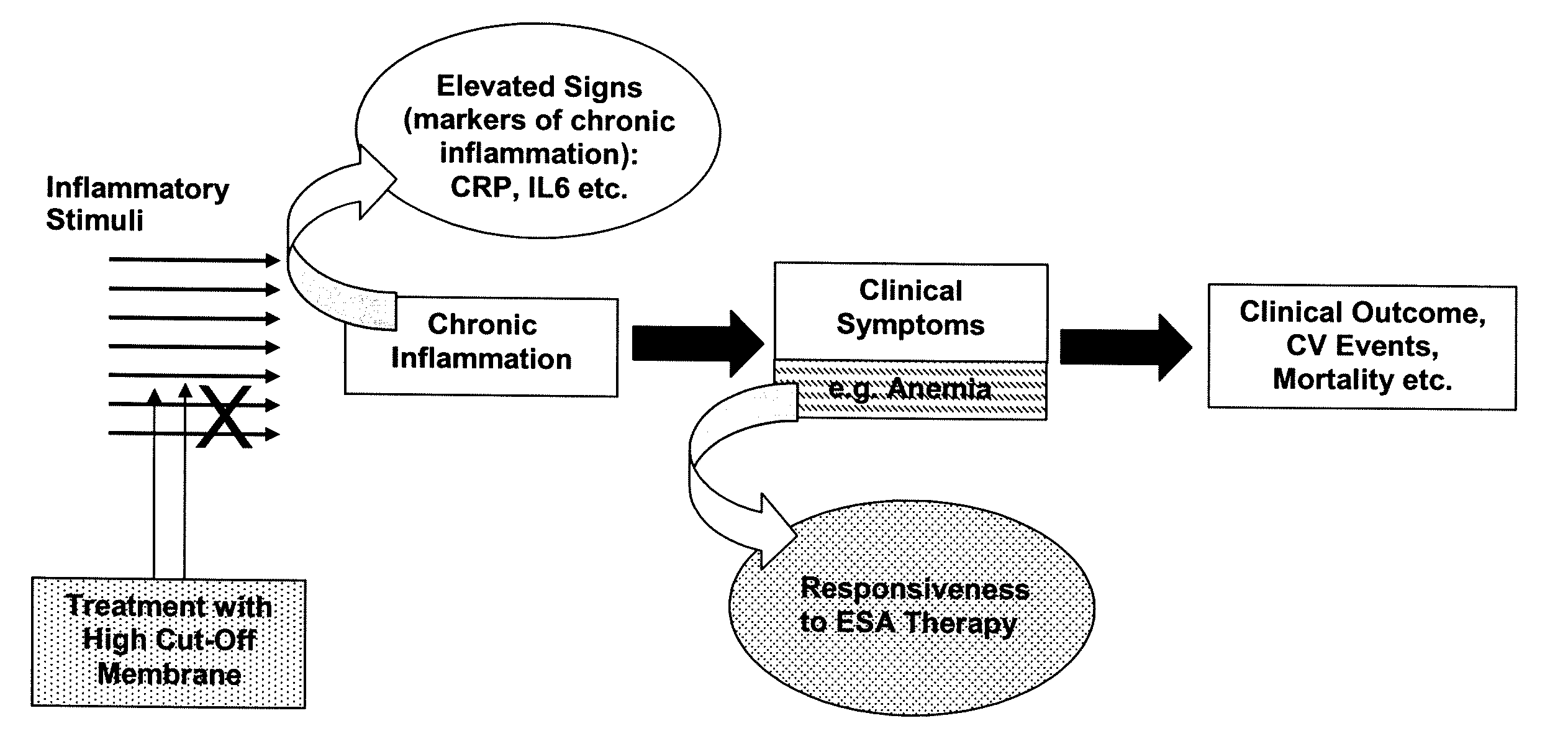

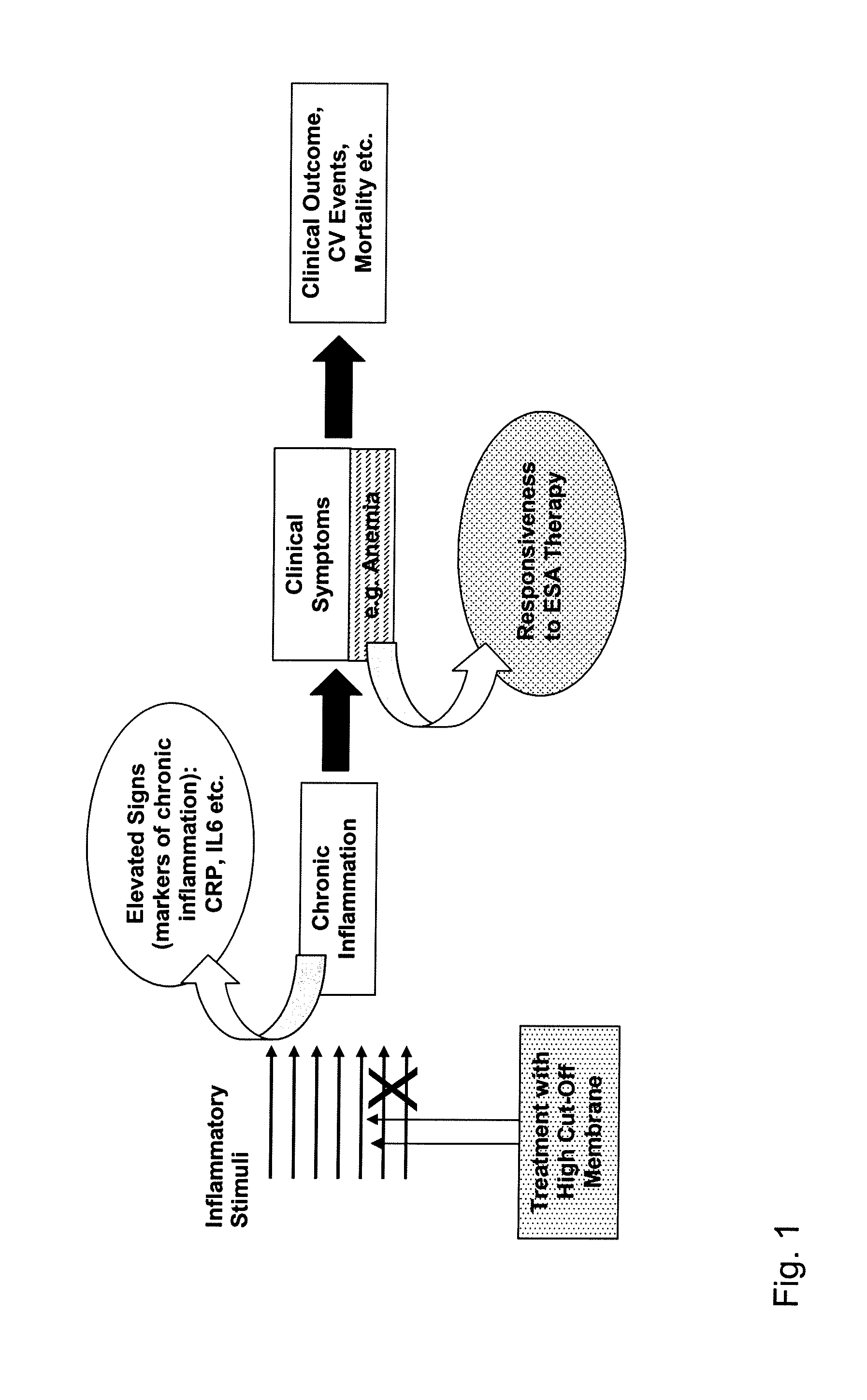

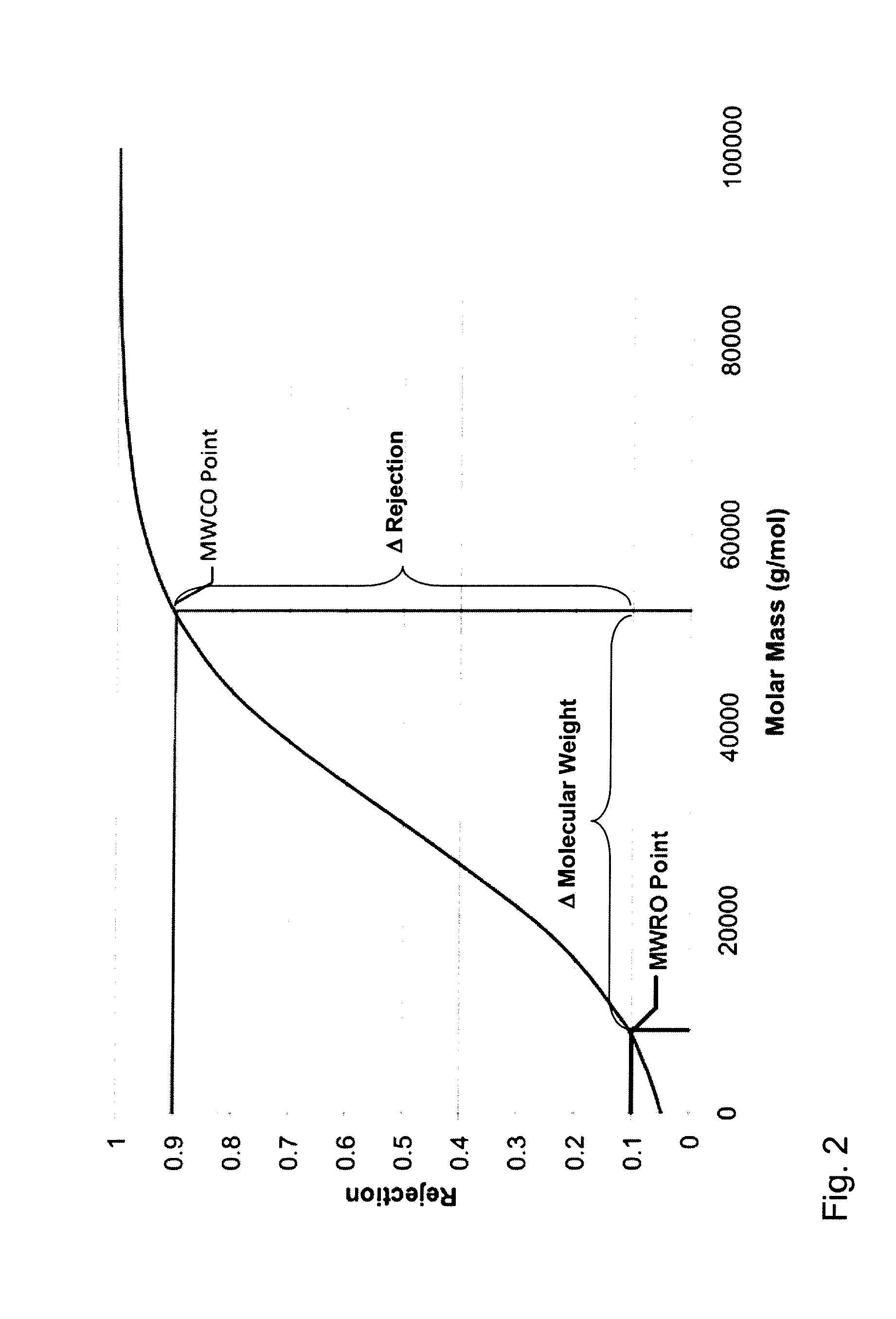

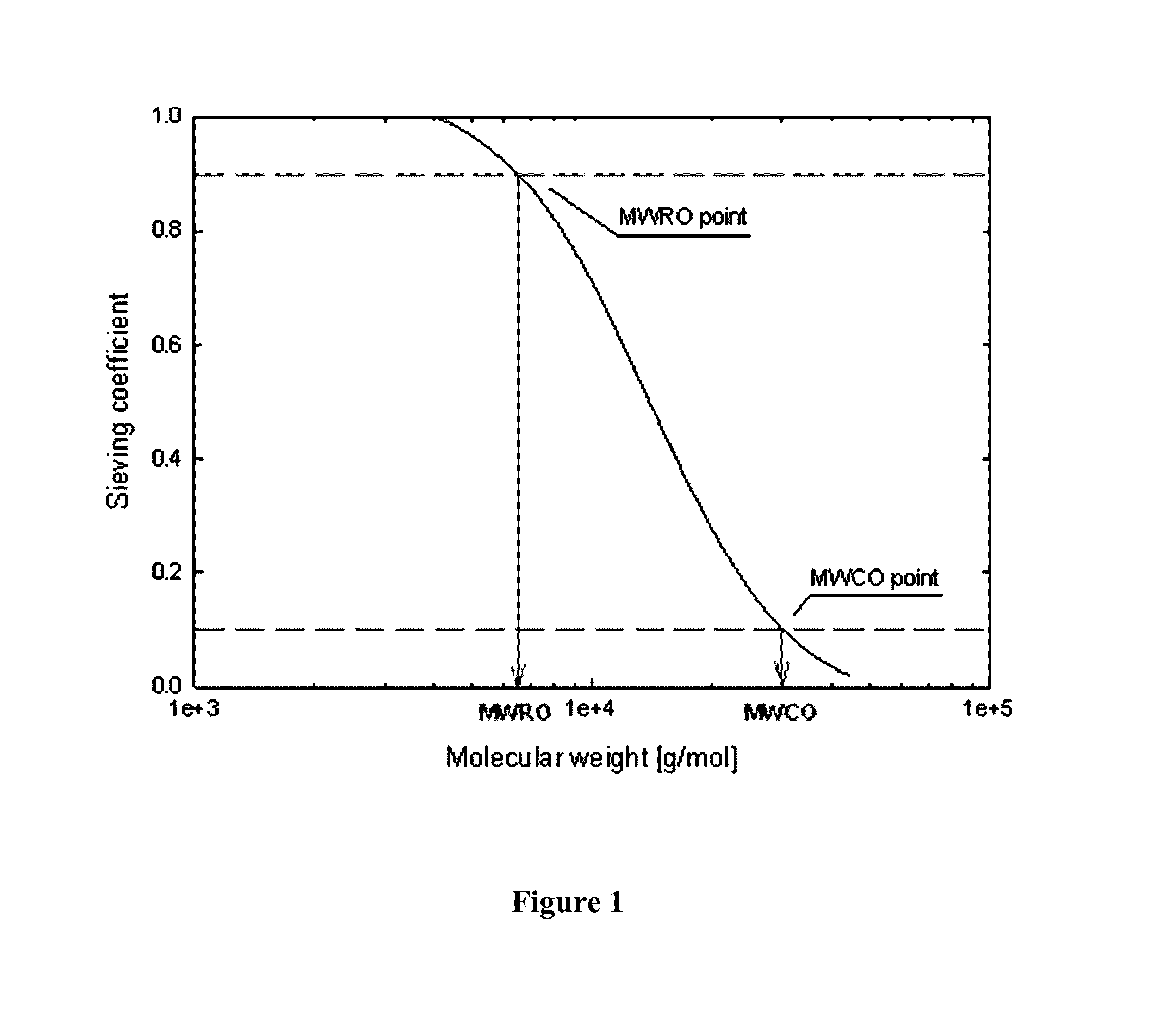

The present invention relates to a method of treating anemia especially in an EPO resistant hemodialysis patient, comprising hemodialysis with a high cut-off dialysis membrane, wherein the hemodialysis membrane is characterized in that it has a molecular weight cut-off in water, based on dextran sieving coefficients, of between 90 and 200 kD and a molecular weight retention onset in water, based on dextran sieving coefficients, of between 10 and 20 kD, and a ΔMW of between 90 and 170 kD. The invention further relates to a high cut-off hemodialysis membrane for the treatment of anemia in hemodialysis patients, especially EPO resistant hemodialysis patients.

Owner:GAMBRO LUNDIA AB

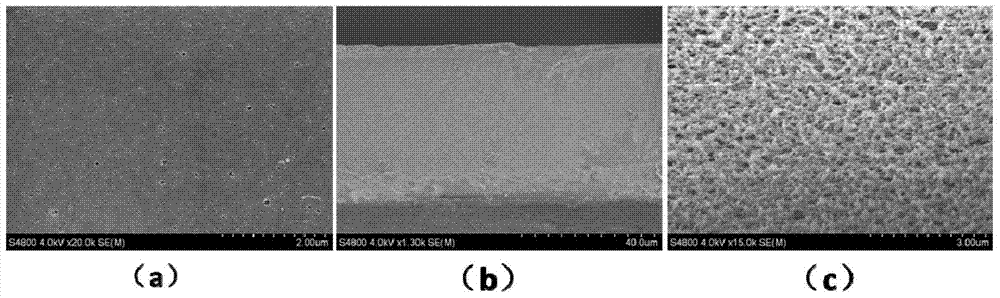

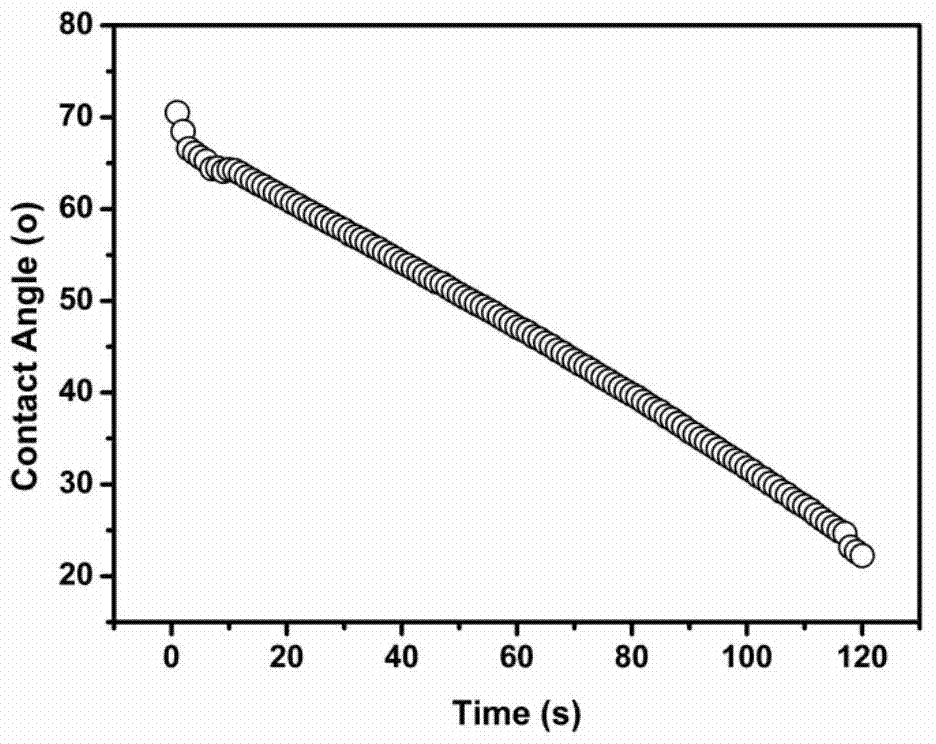

Method for fixing heparin on polylactic acid hemodialysis membrane surface

ActiveCN103316600AImprove hydrophilicityGood biocompatibilitySemi-permeable membranesHemolysisBiocompatibility Testing

The invention discloses a method for fixing heparin on polylactic acid hemodialysis membrane surface. Poly lactic acid has good biocompatibility, but has a certain of hydrophobicity, and hemodialysis membrane materials are often required to have a certain of hydrophilicity to reduce adsorption of protein and blood cells and prevent blood coagulation, so that hydrophilic modification is needed. Through use of the method of the invention, polylactic acid hemodialysis membrane surface can be modified through self-polymerization and attachment behaviors of dopamine, the heparin is covalently fixed on the membrane surface through a further reaction with heparin, and then a polylactic acid hollow fiber hematodialysis membrane having anticoagulation effect and good hydrophilicity is prepared. In the method, through utilization of the oxidation, self-polymerization, crosslinking adhesive properties of the dopamine, the heparin can be fixed on the membrane material surface. The prepared polylactic acid hollow fiber membrane has good hydrophilicity, biocompatibility, less adsorption of proteins and platelets, is not easy to cause hemolysis, and has more mild conditions than that of the prior art modification methods and obvious effects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

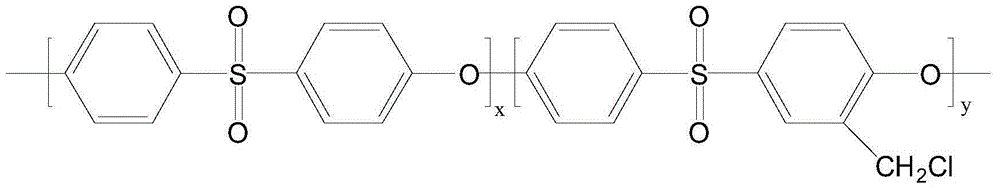

Method for preparing amino acid modified polyether sulfone hematodialysis membrane

InactiveCN104984664APermanent hydrophilicityLow protein adsorptionSemi-permeable membranesSuction devicesBiocompatibility TestingAmidogen

The invention relates to the technology of hematodialysis membranes, and aims at providing a method for preparing an amino acid modified polyether sulfone hematodialysis membrane. The method comprises the steps that chloromethyl group polyether sulfone, polarity aprotic organic solvent and a micromolecule pore-forming agent are taken and mixed to be stirred and dissolved to obtain a uniform and stable membrane casting solution; vacuum standing and bubble removing are carried out, and a chloromethyl group polyether sulfone hollow fiber membrane is prepared through a dry / wet phase inversion method and then immersed in hot water; finally, immersing is carried out through an ethanol solution, and drying is carried out; the chloromethyl group polyether membrane is immersed in a sodium hydroxide water solution to be reacted; the chloromethyl group polyether membrane is immersed in hot water; finally, the chloromethyl group polyether membrane is immersed in the ethanol solution, drying is carried out, and then the product is obtained. The chloromethyl group polyether sulfone hollow fiber membrane serves as a precursor material, and precise and controllable amidogen acidification modification can be carried out on the chloromethyl group polyether sulfone membrane through the electrophilic substitution policy. The polyether sulfone hematodialysis membrane modified through amino acid has the advantages of permanent hydrophilia, low-protein adsorbability and superior biocompatibility.

Owner:杭州汉膜新材料科技有限公司

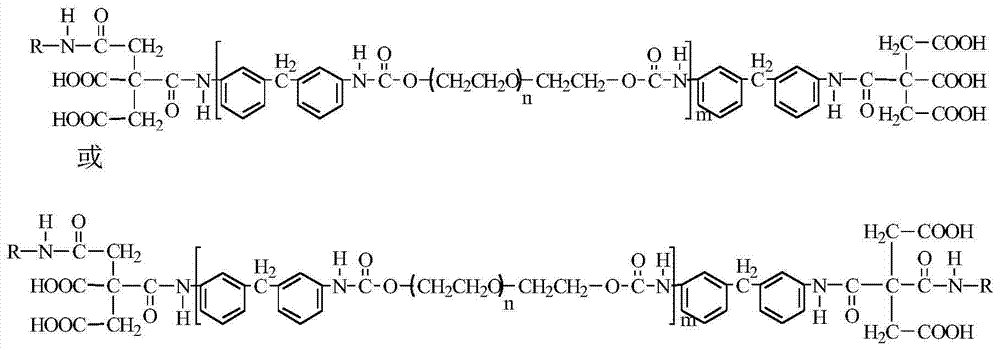

Method for covalent grafting heparin on surface of polymer film

InactiveCN1563157AImprove surface anticoagulant propertiesSimple method for covalent grafting of heparinCross-linkFiber

The method is featured as washing and extracting polymer film by alcohol, placing it in ammonium persulfate aqueous solution for forming peroxide perssad with activation initiating polymerization of vinyl monomer containing carboxy on surface by ferrisulphas ammonium, converting carboxyl to be end azyl by using 1-ethyl-3-(3-dimethyl propyl) EDC as cross-linking agent to react with a,W-aminopropyl-polyglycol and fixing heparin on polymer film surface by covalent bond through condensation of carboxyl and azyl in heparin structure.

Owner:TSINGHUA UNIV

Citric acid-chitosan-modified anticoagulation polyurethane blood dialysis membrane and preparation method thereof

InactiveCN104841285AGood blood compatibilityImprove antibacterial propertiesSemi-permeable membranesPeritoneal dialysisESCHERICHIA COLI ANTIGENDialysis membranes

The invention discloses a citric acid-chitosan-modified anticoagulation polyurethane blood dialysis membrane and a preparation method thereof. The membrane is of a hollow fibrous structure, and the inner surface and outer surface are dense cortical layers, and the middle is a porous supporting layer, so that the blood dialysis membrane is high in permeability and separating property and antibacterial property; the inner diameter is 160 to 250mu m; the membrane thickness is 30 to 50 mu m, and the ultrafiltration coefficient is 7.0 to 60 ml / m<2>.h.mmHg; citric acid-chitosan-modified anticoagulation polyurethane is taken as membrane materials, and in membrane solution, the percentage mass content of the modified anticoagulation polyurethane is 15 to 30%, and the percentage mass content of a solvent is 70 to 85%, and the blood dialysis membrane is prepared by using a nonsolvent induced phase separation method. The preparation process of the dialysis membrane is simple and easy to control, and the prepared membrane has good anticoagulant activity, biocompatibility and antibacterial property, and the clearance rates of urea, beta2-microglobulin and albumin are respectively 55 to 80%, 48 to 60%, and 2.5 to 9%, and the rate of resisting pathogenic escherichia coli is 99%.

Owner:CENT SOUTH UNIV

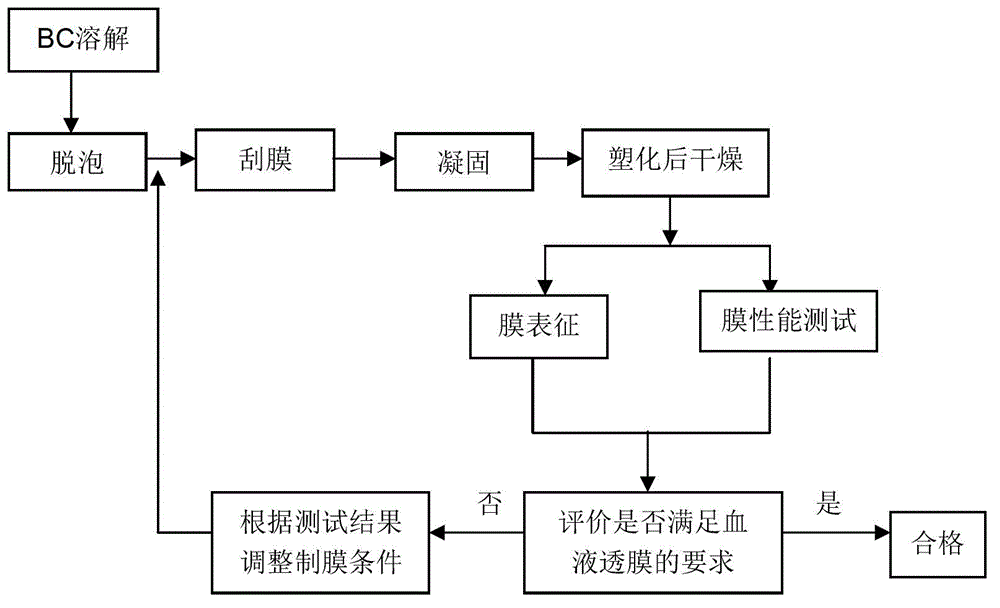

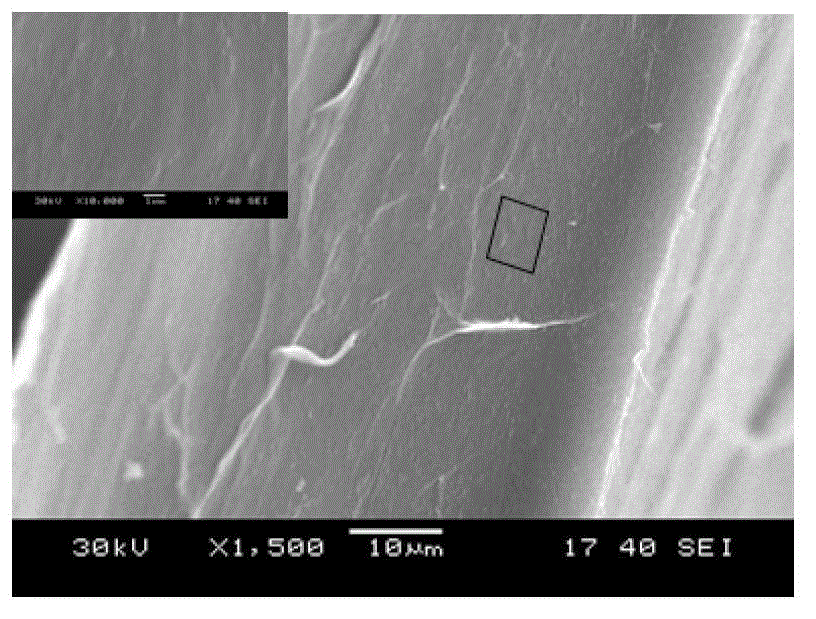

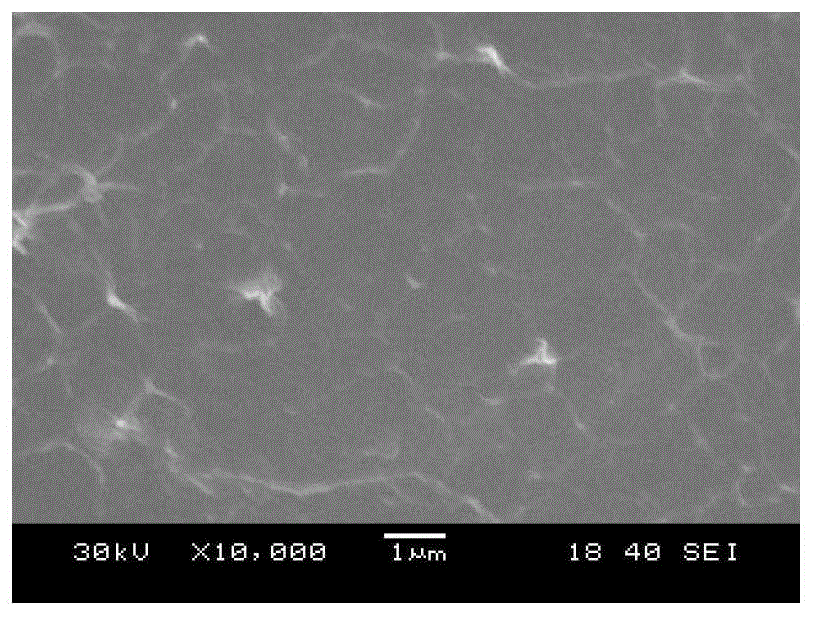

Bacteria cellulose hemodialysis membrane

InactiveCN102941023AEasy to recycleReduce the impactSemi-permeable membranesDialysis systemsLithium chlorideUltrafiltration

The invention discloses a bacteria cellulose hemodialysis membrane and a preparation method of the bacteria cellulose hemodialysis membrane. The preparation method comprises the following steps of activating bacteria cellulose powder by a NaOH (sodium hydroxide) solution, then dissolving the bacteria cellulose powder in a LiCl / DMAC (lithium chloride / N, N-dimethylacetamide) solvent system under a heating condition, cooling the dissolving system, standing and scraping the membrane; slowly immersing a membrane scraping plate in a coagulating bath, standing, and taking the membrane scraping plate out of the coagulating bath after the membrane strips from the membrane scraping plate so as to obtain the bacteria cellulose regeneration membrane for hemodialysis. Bacteria cellulose is used as raw material, the regeneration cellulose membrane is prepared by an immersing, precipitating and phase conversion method, and then the regeneration cellulose membrane can be used as a novel hemodialysis membrane for treating acute and chronic renal failure. Compared with the traditional hemodialysis membrane, the bacteria cellulose hemodialysis membrane has the advantages that the chemical purity is high, the biocompatibility is high, the mechanical strength is high, the water ultrafiltering rate is high, the simple, environment-friendly, moderate and controllable effects are realized in the preparation process, and the bacteria cellulose hemodialysis membrane is suitable for the industrial production of the hemodialysis membranes with different requirements.

Owner:NANJING UNIV OF SCI & TECH

Bio-based hemodialysis membrane and preparation method thereof

InactiveCN106076126AImprove transmittanceHigh retention rateSemi-permeable membranesMembranesBiocompatibility TestingClelands Reagent

The invention discloses a bio-based hemodialysis membrane and a preparation method thereof. The hemodialysis membrane is prepared from polylactic acid, laminarin, thiolated chitosan, silk fibroin, sodium ascorbyl phosphate, cellulose acetate, dithiothreitol, stachyose, betulin caffeate, ammonium persulfate, ferulic acid, hydroxyethyl starch, N-benzyl glycine hydrochloride, deoxycholic acid, polyhydroxyalkanoate, hexamethylenediamine, hyaluronic acid, benzoperoxide and dimethyl sulfoxide. According to the prepared hemodialysis membrane, the tensile strength is not lower than 7.0 MPa, the transmittance of urea is higher than 86%, the transmittance of beta2 microglobulin is higher than 66%, the rejection rate of macromolecular protein is higher than 95%, the biocompatibility is good, coagulation, thrombus, inflammation, poisoning and other adverse reactions do not exist, and an application prospect is wide.

Owner:林春梅

Preparation method for hydrophilic polyacrylonitrile separation film

ActiveCN107115796AImprove hydrophilicityStrong anti-pollutionSemi-permeable membranesMembranes(Hydroxyethyl)methacrylateMorpholine

The invention relates to a preparation method for a hydrophilic polyacrylonitrile separation film. The method comprises the following steps: (1) taking acrylonitrile (AN) and hydroxyethyl methacrylate (HEMA) as reaction monomers and compounding into an amphipathic copolymer PAN-co-PHEMA; (2) taking the compounded PAN-co-PHEMA as a film material and adopting an immersing phase-inversion method for preparing a panel separating film; and (3) processing the PAN-co-PHEMA panel film with acryloyl chloride, introducing a carbon-carbon double bond into the film surface and further reacting with acryloyl morpholine (ACMO), thereby acquiring the hydrophilic polyacrylonitrile separation film. The hydrophilic ACMO with a repelling property to the protein adsorption is utilized to modify the PAN film, so that the PAN separation film with an excellent antifouling property is acquired. The technology is simple, and the cost is low. The hydrophily of the prepared modified film is better than that of pure PAN film, and the protein absorbed to the film surface is obviously reduced. The hydrophilic polyacrylonitrile separation film can be developed and used as a sewage processing separation film and a hemodialysis film.

Owner:QUJING NORMAL UNIV

Heparinoid-modified polyvinyl alcohol hydrogel thin nano-compound hematodialysis film and preparation method thereof

InactiveCN105727771AImprove responsePermanent hydrophilicitySemi-permeable membranesMembranesFiberBiocompatibility Testing

The invention relates to a heparinoid-modified polyvinyl alcohol hydrogel thin nano-compound hematodialysis film and a preparation method thereof. A heparinoid hydrogel skin layer is arranged as an outer layer of a thin nano-compound hematodialysis film and a porous supporting layer with nano-pores communicated with each other is arranged as an inner layer of the thin nano-compound hematodialysis film. The preparation method comprises the following steps: performing electrostatic spinning on a PAN solution, thereby acquiring a nanometer fiber as the supporting layer of a compound film; adding sodium-hydrogen into the PVA solution, and then adding 1,3-propane sultone, reacting for 8-24h at 40-80 DEG C, filtering and drying, thereby acquiring s-PVA; mixing s-PVA with PVA, adding a solvent, adjusting pH, adding a cross-linking agent, coating on the supporting layer after cross-linking, and sealing at room temperature, thereby acquiring the heparinoid-modified polyvinyl alcohol hydrogel thin nano-compound hematodialysis film. The preparation method provided by the invention is simple in reaction process and is easily performed. The prepared thin nano-compound hematodialysis film has the characteristics of permanent hydrophily, low protein adsorbability and excellent biocompatibility.

Owner:DONGHUA UNIV

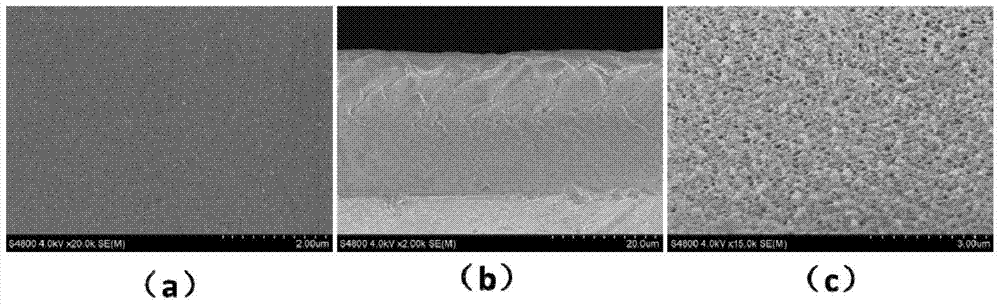

Nanofiber-based composite hemodialysis membrane and preparation method thereof

The invention relates to a nanofiber-based composite hemodialysis membrane and a preparation method thereof. The preparation method includes the steps that a high-molecular polymer solution is subjected to electrostatic spinning, a nanofiber non-woven fabricis obtained, and subjected to cold pressing, and then a nanofiber porous supporting layer is obtained; after silk is subjected to degumming, dissolving, dialyzing, vulcanizing and self-assembling, a vulcanized silk fibroin protein nanowire precursor is obtained; a prepared vulcanized silk fibroin protein nanowire and polyvinyl alcohol are added into water; and then glutaric dialdehyde is added to be crosslinked, the mixture is coated in the nanofiber porous supporting layer, and the nanofiber-based composite hemodialysis membrane can beobtained after sealing at the room temperature. According to the preparation method of the nanofiber-based composite hemodialysis membrane, silk materials with the characteristics of low cost and wide sources are used for preparing the vulcanized silk fibroin protein nanowire, the process is simple, and implementation is easy; and the obtained nanofiber-based composite hemodialysis membrane has good water permeability, the excellent dialysis efficiency and anticoagulant activity.

Owner:DONGHUA UNIV

Nano fiber composite hemodialysis membrane with directional toxin removing passage and preparation thereof

ActiveCN109647225AEfficient removal rateEfficient removalSemi-permeable membranesMembranesFiberPolyvinyl alcohol

The invention relates to a nano fiber composite hemodialysis membrane with a directional toxin removing passage and preparation thereof. A cortex of the hemodialysis membrane is a polyving akohol separation layer with a heparin functionalization carbon nanotube, and a supporting layer is a polyacrylonitrile nano fiber membrane. According to the hemodialysis membrane, the directional nano passage is provided for toxins by a nano clearance which is formed in the part between the heparin functionalization carbon nanotube and polyving akohol substrate in the cortex, and under the premise that macromolecular protein selectivity is not sacrificed, the composite hemodialysis membrane has the advantages of efficient micro and medium molecular toxin removing rate and excellent blood compatibility.

Owner:DONGHUA UNIV

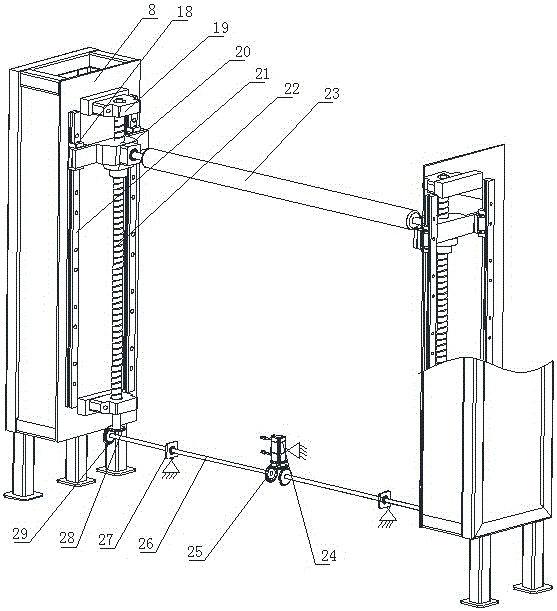

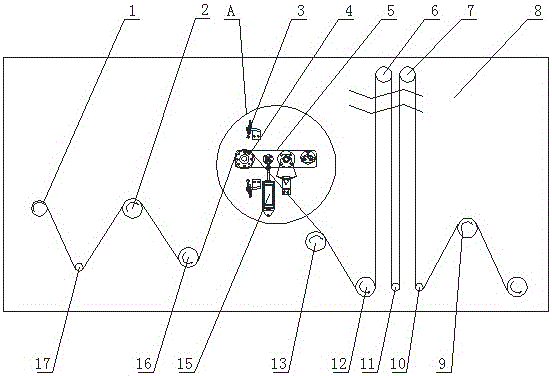

Hollow fiber blood dialysis membrane filament collecting buffering device

ActiveCN106276409ATension increases or decreasesReduce tensionFilament handlingDialysis membranesFiber

The invention provides a hollow fiber blood dialysis membrane filament collecting buffering device and relates to the technical field of hollow fiber blood dialysis membrane filament collecting devices. The hollow fiber blood dialysis membrane filament collecting buffering device is provided with a support, a speed detection roller, a floating roller device, a lifting roller device and a guide roller are arranged on the support in sequence, the guide roller is arranged below one side of the lifting roller device, and a tension detection roller is arranged on one side of the lifting roller device. A tension sensor and a lifting servo motor are connected with a controller. The hollow fiber blood dialysis membrane filament collecting buffering device is simple in structure, convenient to use and high in automation degree, the manual labor amount does not need to be increased, and the production cost is greatly reduced.

Owner:WEIHAI WEIGAO BLOOD PURIFICATION PROD

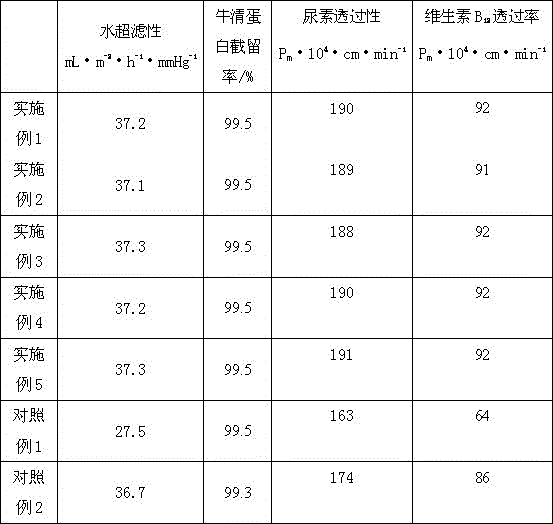

Polyacrylonitrile/cellulose acetate fiber composite hemodialysis membrane and preparation method thereof

InactiveCN104368246ASemi-hydrophilicImprove pressure resistanceSemi-permeable membranesSuction devicesHollow fibre membraneCellulose acetate

The invention discloses a polyacrylonitrile / cellulose acetate fiber composite hemodialysis membrane and a preparation method thereof, and relates to the field of biological materials. The hemodialysis membrane refers to a hollow fiber membrane, the average inner diameter of hollow fibers is 122-245 microns, and the wall thickness is 22-50 microns. The hemodialysis membrane comprises the following components in parts by mass: 35-60 parts of polyacrylonitrile fibers, 25-40 parts of cellulose acetate fibers, 3-7 parts of a coupling agent and 30-60 parts of solvents, wherein the solvents refer to acetone and DMAC or acetone and DMSO. In the method for preparing the polyacrylonitrile / cellulose acetate fiber composite hemodialysis membrane, a dry-wet preparation process is adopted. The polyacrylonitrile / cellulose acetate fiber composite hemodialysis membrane provided by the invention is relatively high in retention rate of bovine serum albumin, relatively high in biocompatibility, relatively high in permeability on vitamin B12 and relatively low in cost and is a relatively ideal hemodialysis membrane material.

Owner:SUZHOU COSMETIC MATERIALS

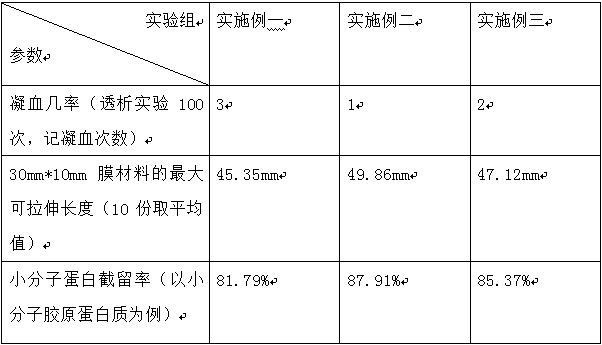

Polyester anticoagulation blood dialysis membrane and preparation method thereof

InactiveCN107737534AReduce the risk of agglomerationDialysis works wellSemi-permeable membranesPolyesterDialysis membranes

The invention discloses a polyester anticoagulation blood dialysis membrane. The dialysis membrane takes a polyester material as a main body. The polyester anticoagulation blood dialysis membrane is prepared from 10 to 24 parts of polyester material, 5 to 9 parts of polysulfone, 4 to 9 parts of polymethyl methacrylate, 6 to 9 parts of protein fiber, 15 to 20 parts of protein mixed material, 5 to 9parts of peptidoglycan, 3 to 8 parts of glycerol and 8 to 15 parts of anticoagulant. The invention further discloses a preparation method of the polyester anticoagulation blood dialysis membrane. Thepreparation method comprises the following steps: S1, mixing silk making materials; S2, removing air bubbles; S3, mixing the anticoagulant; S4, spinning. The polyester anticoagulation blood dialysismembrane has the advantages of good anticoagulation effect, higher flexibility and high retention rate of micromolecular proteins.

Owner:广州青岭医疗器械有限公司

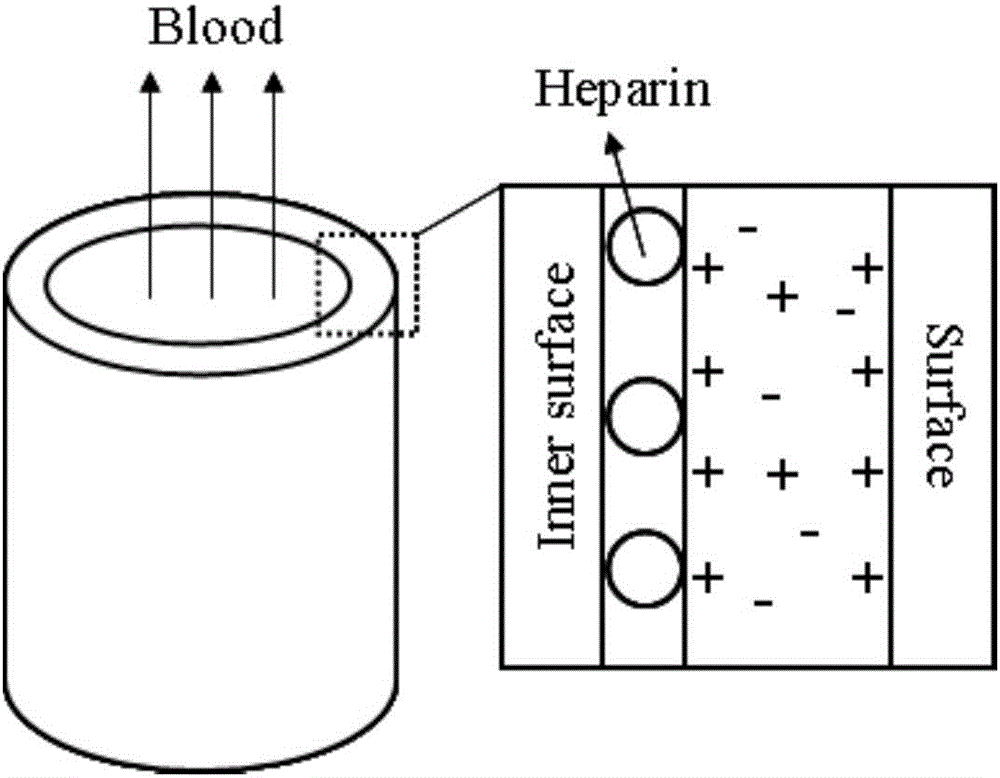

Surface heparinization hemodialysis film and preparation method thereof

InactiveCN106422822AReduced Chances of ContaminationImprove removal efficiencySemi-permeable membranesDialysis systemsWhole bodyHaemodialysis machine

The invention mainly provides a surface heparinization hemodialysis film and a preparation method thereof. The hemodialysis film is formed by heparin and a high-molecular polymer film in a physical crosslinking mode, wherein the biological compatibility of the high-molecular polymer film is high, and the surface of the high-molecular polymer film carries positive charges. The hemodialysis film is good in biological compatibility; due to the heparin with the firm surface, risks such as whole body heparinization and in-vitro coagulation are avoided, and the safety is high; due to the fact that the outer surface of the film carries the positive charges, a positive charge barrier can be formed, and the phenomenon that external bacteria enter the film is effectively restrained; the positive charges on the inner surface of the film can effectively remove beta 2-microglobulin, endotoxin and other macromolecular toxins, and the synergic treatment effect is achieved.

Owner:JIANGNAN UNIV

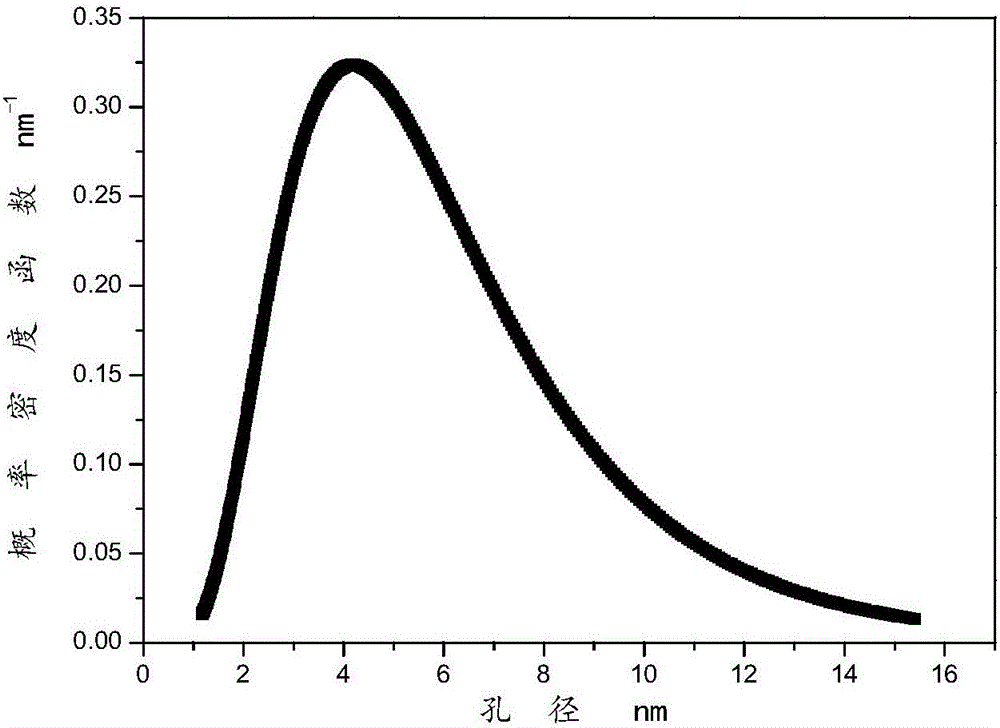

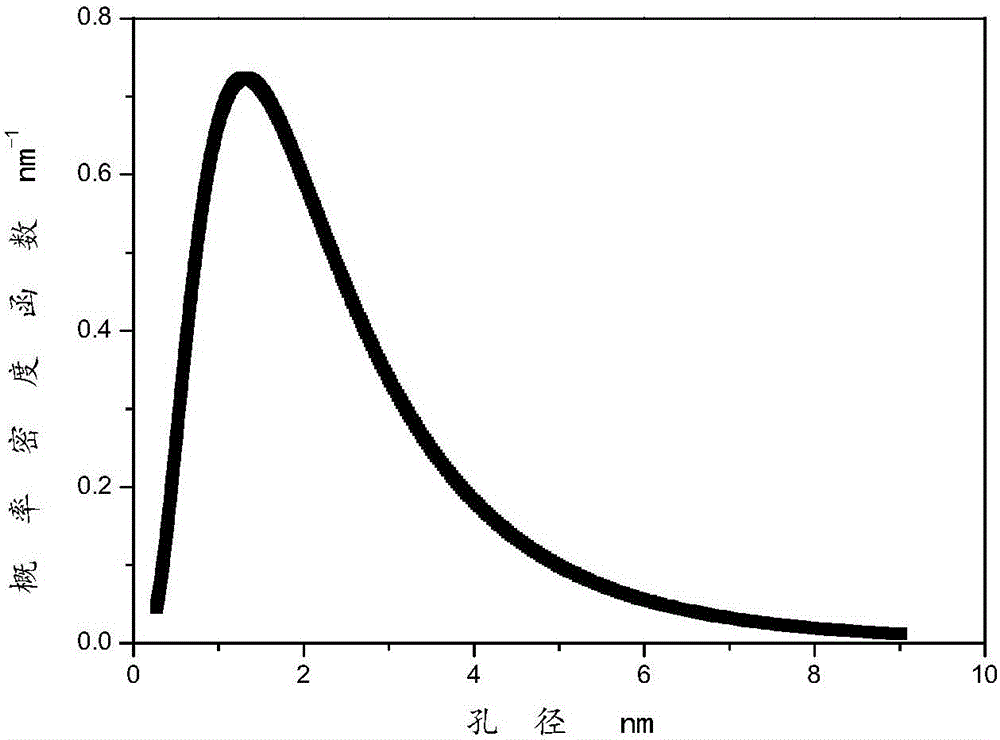

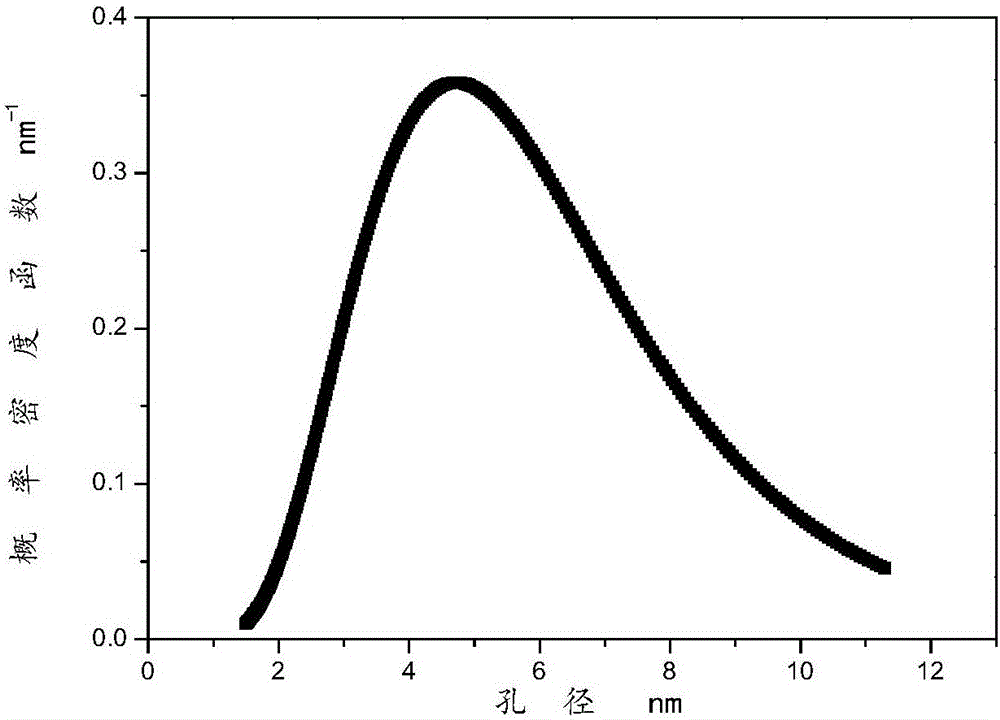

Test method of aperture distribution of hemodialysis membrane

ActiveCN106596376APore size distribution can be measuredData fluctuation is smallPermeability/surface area analysisRate curveHaemodialysis membrane

The invention discloses a test method of the aperture distribution of a hemodialysis membrane. The method comprises the following steps: dissolving one or more solutes in ultrapure water to form a simulation solution, and filtering the simulation solution through the hemodialysis membrane; testing the concentration of corresponding solute molecular weight in the simulation solution and the concentration of corresponding solute molecular weight in a filtrate; calculating a curve of the molecular diameter of the corresponding solute molecular weight and the interception rate of the hemodialysis membrane; establishing the aperture distribution function and the accumulated distribution function of the hemodialysis membrane; and carrying out nonlinear fitting on the accumulated distribution function on practically measured interception rate curve data through least squares fitting analysis software, determining the aperture distribution parameter, and substituting the aperture distribution parameter into the aperture distribution function to obtain the aperture distribution of the hemodialysis membrane. The method is used to rapidly detect the aperture distribution of the hemodialysis membrane., and has the advantages of high accuracy of measured data, simplicity and high practicality.

Owner:WEIHAI WEIGAO BLOOD PURIFICATION PROD

Polyacrylonitrile-carboxymethyl chitosan composite hemodialysis membrane and preparation method thereof

ActiveCN107551822AImprove hydrophilicityGood biocompatibilitySemi-permeable membranesDialysis systemsTO-18Biocompatibility Testing

The invention discloses a polyacrylonitrile-carboxymethyl chitosan composite hemodialysis membrane, which is prepared from the following components in parts by weight: 35 to 50 parts of polyacrylonitrile, 20 to 30 parts of carboxymethyl chitosan, 10 to 18 parts of polyacrylate, 0.005 to 0.02 part of heparin, 32 to 60 parts of solvent, and 15 to 50 parts of water. The invention also discloses a preparation method of the polyacrylonitrile-carboxymethyl chitosan composite hemodialysis membrane. Hydrophilic biomass carboxymethyl chitosan and anticoagulant heparin are introduced into the polyacrylonitrile through blended spinning, so that the hydrophilia and the biocompatibility of the polyacrylonitrile used as the hemodialysis membrane are improved, and meanwhile, a certain anticoagulation function is realized; the method is simple and practicable, rich in raw material source, low in price, and easy to popularize.

Owner:泉州市科茂利通智能科技有限公司

Anti-coagulant polyester hemodialysis membrane and preparation method thereof

ActiveCN104437127AIncrease inner diameterReduce aggregationSemi-permeable membranesPolyesterChitosan nanoparticles

The invention relates to an anti-coagulant polyester hemodialysis membrane and a preparation method of the anti-coagulant polyester hemodialysis membrane, belonging to the field of biological materials. The hemodialysis membrane is a hollow fiber membrane which is mainly made of a phosphatidylcholine polyester polymer and is added with a small amount of chitosan nanoparticles, the mean inner diameter is 132-280mum, and the wall thickness is 38-68mum; the hemodialysis membrane is prepared from the following components in part by weight: 25-45 parts of polyester, 12-20 parts of phospholipid, 10-30 parts of tetrahydrofuran, 3-7 parts of catalyst, 2-10 parts of chitosan nanoparticle and 22-48 parts of solvent. The preparation method of the anti-coagulant polyester hemodialysis membrane adopts a dry-wet method preparation process. The anti-coagulant polyester hemodialysis membrane provided by the invention has the characteristics of small inner diameter, moderate wall thickness and good film forming effect, can be well formed, and has strong pressure resistance, pore diameter reduction or pore closing can be prevented even if the hemodialysis membrane is used for a long time, and reduction of the dialytic efficiency is prevented.

Owner:南昌千麦医学检验实验室有限公司

Alginate fiber hematodialysis membrane and preparation method thereof

InactiveCN104437133AHigh mechanical strengthGood biocompatibilitySemi-permeable membranesBiocompatibility TestingPolyamide

The invention provides an alginate fiber hematodialysis membrane and a preparation method thereof, relating to the field of biological materials. The alginate fiber hematodialysis membrane is a hollow fiber membrane and comprises the following components in parts by weight: 20-35 parts of polyamide, 10-20 parts of alginate fiber, 3-8 parts of a toughening agent, 5-15 parts of polylactic acid and 30-60 parts of a solvent, wherein the average inner diameters of hollow fibers are 100-300 microns, and the wall thicknesses of the hollow fibers are 20-50 microns. According to the preparation method of the alginate fiber hematodialysis membrane, the alginate fiber hematodialysis membrane is prepared by virtue of a dry-wet method preparation process. According to the alginate fiber hematodialysis membrane, the hollow fiber membrane with good biocompatibility and high mechanical strength is prepared by virtue of the characteristic of high biocompatibility of the alginate fiber and the superiorities of the dry-wet method preparation process. By adjusting parameters in the dry-wet method preparation process, particularly the pressures of core liquid and a spinning solution tank, the prepared hollow fiber has large inner diameter and small wall thickness and is beneficial to the elimination of micromolecule toxin and the entrapment of macromolecule protein.

Owner:SUZHOU COSMETIC MATERIALS

Anticoagulant blood dialysis membrane and preparation method thereof

InactiveCN110280152AImprove solubilityImprove anticoagulant performanceSemi-permeable membranesDialysis systemsDialysis membranesSulfate

The invention relates to an anticoagulant blood dialysis membrane and a preparation method thereof. A sulfate ester or carboxylic ester chitosan derivative is selected; the sulfate ester or carboxylic ester chitosan derivative is blended with a film-forming polymer; an additive and a solvent are added to prepare a membrane preparing solution, and the membrane preparing solution is used for preparing the blood dialysis membrane. According to the anticoagulant blood dialysis membrane and the preparation method thereof, the oil-soluble chitosan derivative modified by sulfonic acid groups or carboxylic acid groups is blended with the film-forming polymer, the blood dialysis membrane is prepared by using an immersion sedimentation method or thermally induced phase separation method, the chitosan derivative exists in the prepared blood dialysis membrane, which plays a role of improving the hydrophilic and anticoagulant properties of the dialysis membrane. The method has the advantages that the process is simple, the cost is low, and the industrial amplification is easy.

Owner:JIANGSU LISHENG BLOOD PURIFICATION TECH CO LTD

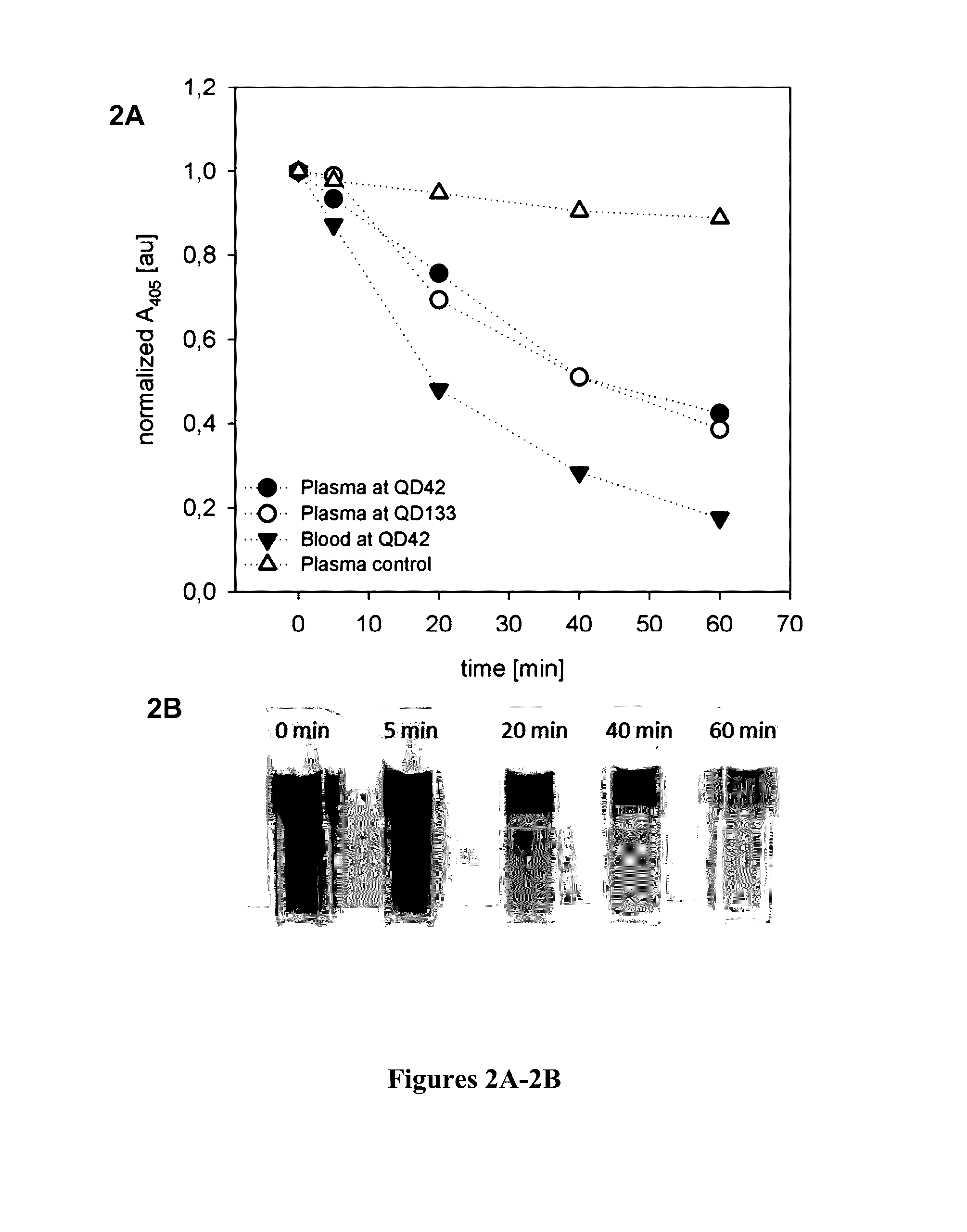

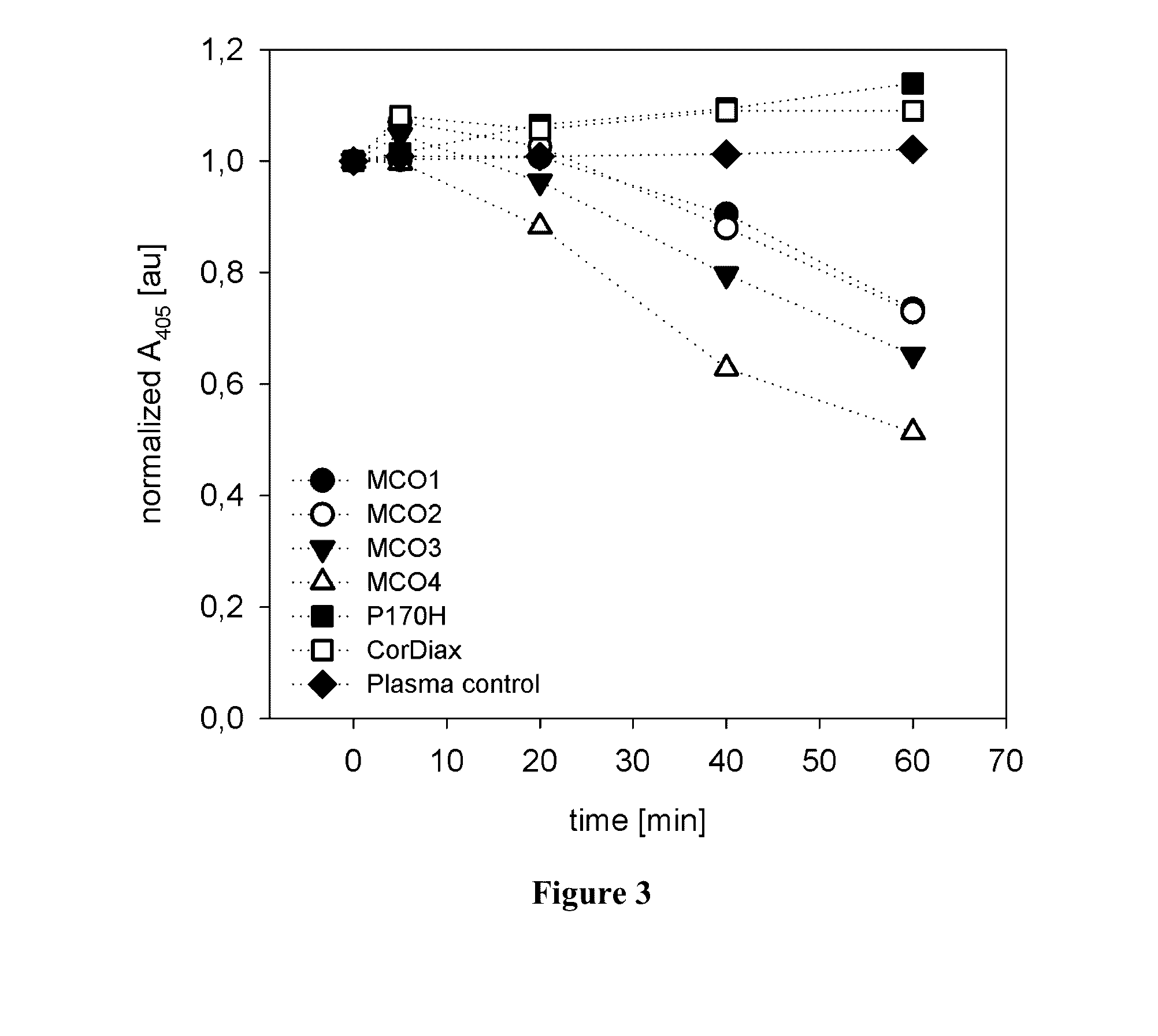

Membrane and device for treating hemolytic events

ActiveUS20160331885A1Efficient solutionIncrease the gapMembranesHaemofiltrationHydrophilic polymersMedicine

The present disclosure relates to a hemodialysis membrane for the treatment of hemolytic events, especially acute episodes of hemolysis which lead to elevated levels of plasma free hemoglobin. The present disclosure further relates to methods of removing hemoglobin from the blood of patients undergoing a hemolytic event. The treatment and method encompasses using a hemodialysis membrane which is characterized in that it comprises at least one hydrophobic polymer and at least one hydrophilic polymer and in that it has a MWRO of between 15 and 20 kD and a MWCO of between 170-320 kD, or, in the alternative, has a MWRO of between 9 and 14 kD and a MWCO of between 55 kD and 130 kD.

Owner:GAMBRO LUNDIA AB

A method for regulating the microporous structure of polylactic acid membranes by in-situ polymerization of bifunctional monomers

ActiveCN105148748BImprove throughputEfficient selective transmissionSemi-permeable membranesDialysis membranesIn situ polymerization

The invention discloses a method for regulating the micropore structure of a polylactic acid porous membrane through an in-situ polymerization method. In the method of the present invention, polylactic acid is first dissolved in an organic solvent, and after fully dissolving, a film-forming precursor solution is prepared; under nitrogen protection, a bifunctional monomer and an initiator are added to the film-forming precursor solution for in-situ polymerization, and the reaction ends After standing still for defoaming, the casting solution is obtained. The casting solution is poured onto a glass plate to obtain a nascent film, which is then immediately transferred to a deionized water bath, and after immersion for a certain period of time, a shaped polylactic acid film is obtained. By controlling the time of in-situ polymerization, the structure of the support layer of the PLA membrane can gradually change from a finger-like macroporous structure to a complete interpenetrating network structure, which has high flux, high-efficiency selective permeation and good hydrophilicity, and is suitable for As a hemodialysis membrane, it is used to separate medium molecular weight uremic solutes while retaining large molecular weight proteins.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

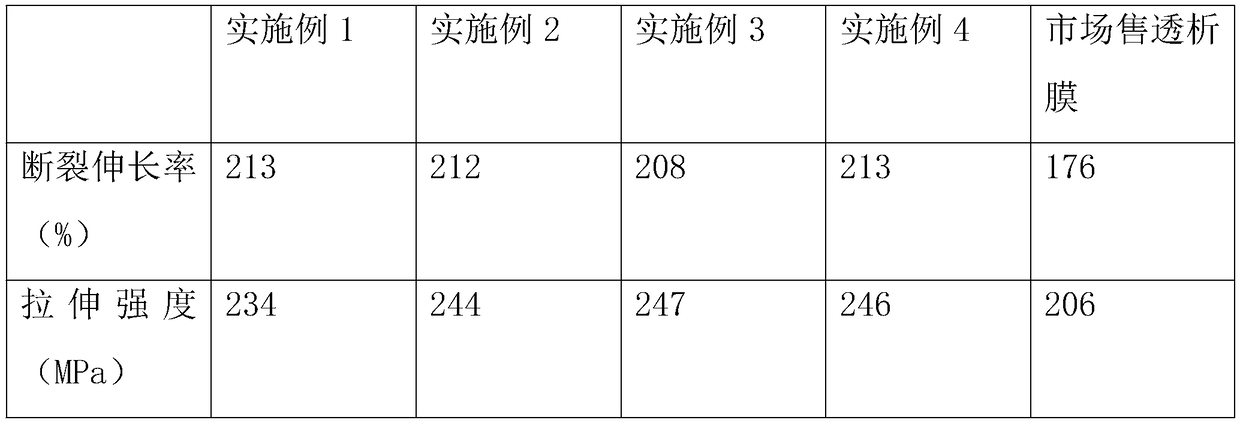

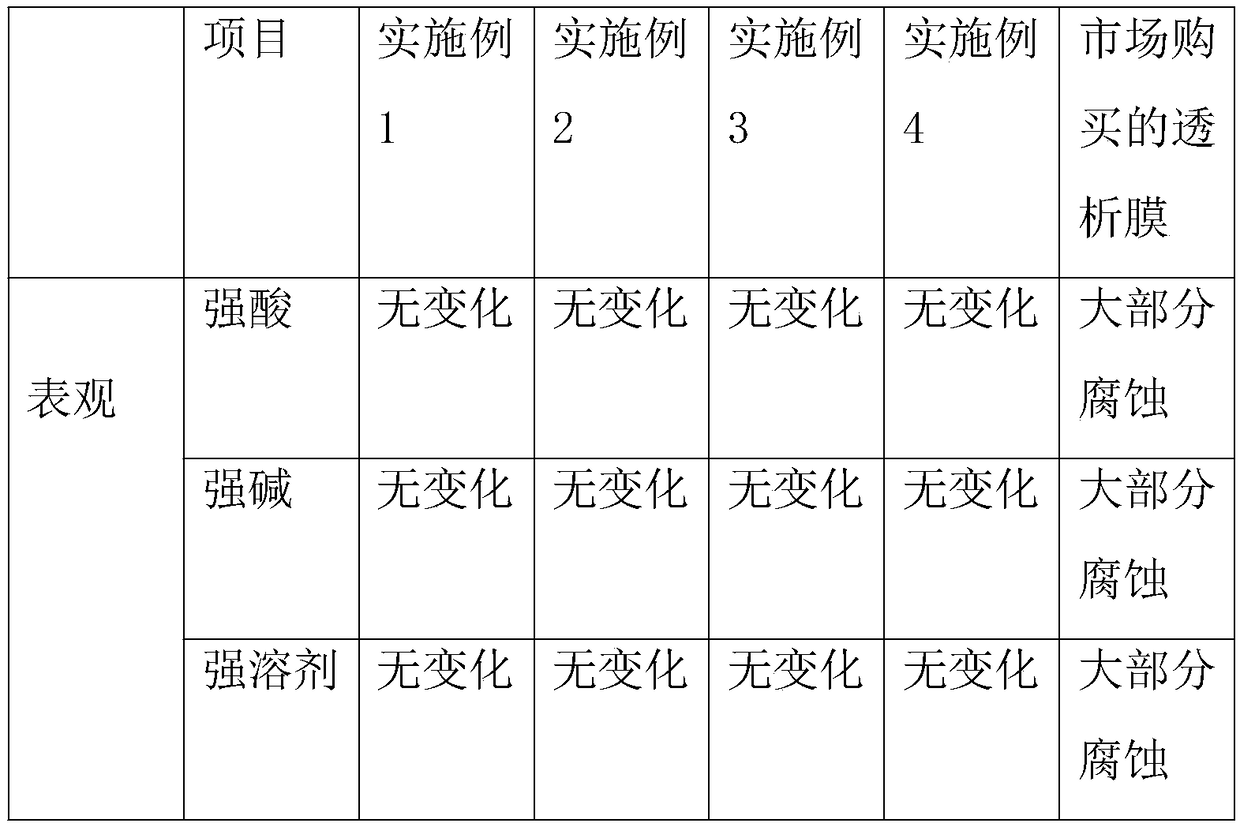

Preparation method of blood dialysis membrane raw material

InactiveCN108686520AImprove mechanical propertiesImprove corrosion resistanceSemi-permeable membranesMembranesDialysis membranesFiber

The invention belongs to the technical field of medical care material, and particularly relates to a preparation method of a blood dialysis membrane raw material. The blood dialysis membrane raw material is prepared from 100 to 120 parts by mass of 50-60 percent modified polytetrafluoroethylene, 10 to 20 parts by mass of polytetramethylene glycol, 20 to 30 parts by mass of polyethylene, 2 to 5 parts by mass of enhancing agents, 0.5 to 2 parts by mass of macromolecular anticoagulants, 10 to 20 parts by mass of polylactic acid fiber, 6 to 10 parts by mass of polypropylene butyl ester and 100 to200 parts by mass of solvents. The invention provides a preparation method of a dialysis membrane for a blood dialysis instrument. Through the proportioning ratio of various kinds of monomers and thescreening of reaction conditions, the mechanical performance of the dialysis membrane is excellent; in addition, the mechanical performance of the dialysis membrane is effectively improved through theaddition of modified polytetrafluoroethylene; meanwhile, the anti-corrosion performance is very high; the cost is lower than that in the prior art.

Owner:漳州龙文琪睿生物科技有限公司

Nanometer magnetic hemodialysis membrane and preparation method thereof

InactiveCN104437128ALarge specific surface areaImprove surface activitySemi-permeable membranesDialysis membranesPolymer modified

The invention provides a nanometer magnetic hemodialysis membrane and a preparation method thereof, and the nanometer magnetic hemodialysis membrane relates to the field of biological materials. The nanometer magnetic hemodialysis membrane comprises the following components in parts by weight: 25-40 parts of polymethyl methacrylate, 6-12 parts of polymer modified magnetic nanoparticles, 5-15 parts of polyacrylamide and 24-45 parts of a solvent, wherein the dialysis membrane is a hollow fiber membrane, the average inside diameter is 155-245 microns, the wall thickness is 32-45 microns, the solvent is acetone and DMAC, and the mass ratio of the acetone to the DMAC is (0.5-1):1. The preparation method of the nanometer magnetic hemodialysis membrane adopts a wet and dry method preparation process. The nanometer magnetic hemodialysis membrane provided by the invention can effectively provide biocompatibility and protein adsorption resistance to effectively reduce blood protein adsorption resulting from long-term use, and has high water ultrafiltration performance and small molecule dialysis transmittance, thus being a hemodialysis membrane material with excellent application prospect.

Owner:SUZHOU COSMETIC MATERIALS

Method for preparing hemodialysis membrane containing bamboo shoot fibers

InactiveCN106366350AIdeal hemodialysis performanceGood biocompatibilityDialysis systemsWet spinning methodsFiberBiopolymer

The invention relates to a method for preparing a hemodialysis membrane containing bamboo shoot fibers and belongs to the technical field of biopolymer materials. The method includes the following steps that firstly, bamboo shoot fiber powder is prepared; secondly, a primary mixed solution is prepared; thirdly, a spinning solution is prepared; fourthly, the spinning solution is placed in a spinning solution tank for vacuum defoaming; fifthly, spinning parameters are adjusted; sixthly, spinning starts, and the hemodialysis membrane containing bamboo shoot fibers is prepared. The hemodialysis membrane prepared through the method has good biocompatibility, adverse reactions in the dialysis process are overcome, and dialysis performance of the hemodialysis membrane is further improved.

Owner:张东

Method for preparing efficient blood coagulation resistant biomaterial with aqueous solution and corresponding material

ActiveCN110755697AGood anticoagulant effectOntology performance impactSurgeryPharmaceutical containersDialysis membranesCardiovascular stent

The invention discloses a method for preparing an efficient blood coagulation resistant biomaterial with an aqueous solution. The aqueous solution has a self-assembly characteristic, is high in biochemistry activity, can form hydrogen bonds with anticoagulation / antithrombus medicines, and has the characteristic of being firmly attached to the biomaterial, so that the surface of the biomaterial (such as a blood purification film, a blood purification pipeline, a cardiovascular stent and an artificial blood vessel) has anticoagulation / antithrombus activity. The surface modification process disclosed by the invention is simple in experimental condition, high in controllability, economical and environment-friendly; and the aqueous solution is high in shaping properties, so that the aqueous solution is basically suitable for anticoagulation / antithrombus modification of the surface of the biomaterial in any shape. The dopamine hydrochloride aqueous solution is prepared, a micromolecule anticoagulant medicine-argatroban is grafted to the surface of a haemodialysis film, the haemodialysis film having anticoagulation / antithrombus activity is successfully prepared, the usage of a whole bodyanticoagulant is reduced or avoided, and the bleeding risk of a haemodialysis patient is reduced.

Owner:HUNAN PROVINCIAL PEOPLES HOSPITAL

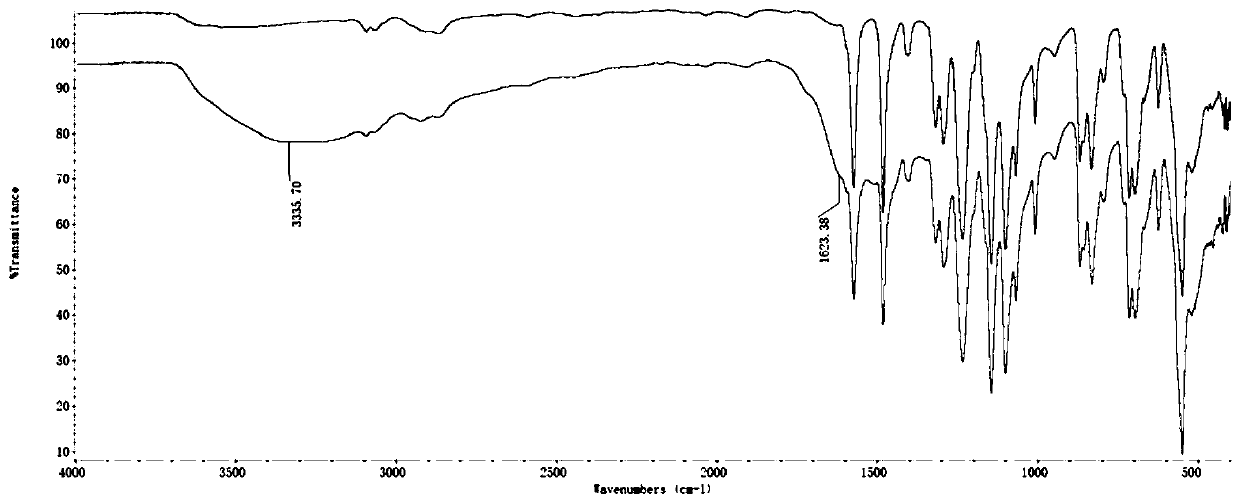

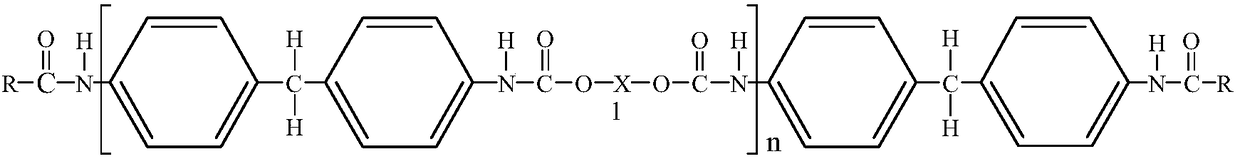

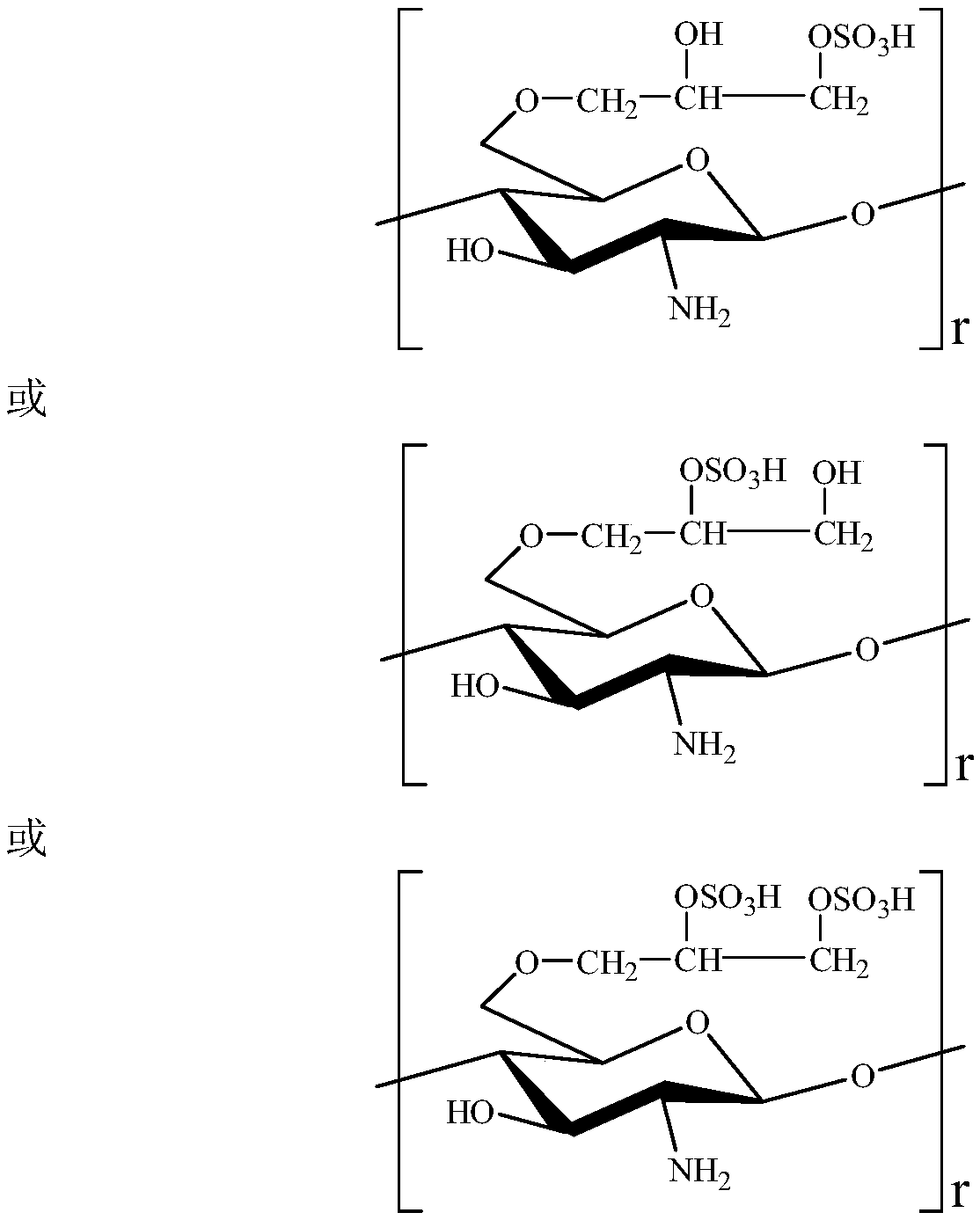

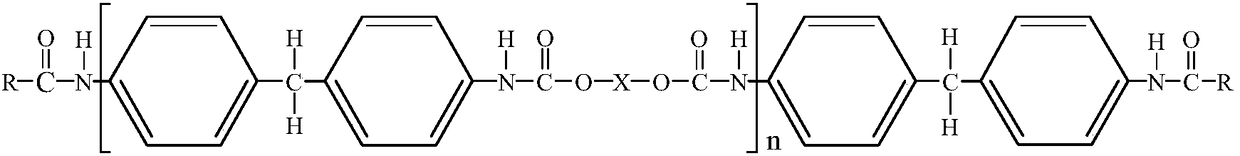

Sulfonated dihydroxypropyl chitosan modified polyurethane (SDHPCS-PU) hemodialysis membrane and preparation method thereof

ActiveCN109316985AGood chemical stabilityGood blood compatibilitySemi-permeable membranesHydroxypropyl ChitosanSolvent

The invention relates to a sulfonated dihydroxypropyl chitosan modified polyurethane (SDHPCS-PU) hemodialysis membrane and a preparation method thereof. The preparation method comprises the steps of adding 10-20% of SDHPCS-PU and 80-90% of a solvent into a dissolving kettle, controlling the temperature to be 70-90 DEG C, and stirring for 2-20 h; after the materials are completely dissolved, standing for 10-20 h for completing defoaming so as to obtain membrane liquid; after that, adopting a dry-wet spinning method to prepare the SDHPCS-PU hemodialysis membrane. The preparation method providedby the invention has the characteristic that the high-performance hemodialysis membrane is prepared by utilizing the good physical and chemical properties and blood compatibility of the SDHPCS-PU. Themembrane production process provided by the invention is simple and easy to operate.

Owner:CENT SOUTH UNIV

A hemodialysis membrane with high anticoagulant performance and its preparation method

ActiveCN105311974BImprove hydrophilicityExcellent anticoagulant propertiesUltrafiltrationDialysis membranesAtom-transfer radical-polymerization

The invention relates to a preparation method of a hemodialysis membrane with high anticoagulant performance, so as to reduce the coagulation phenomenon during the use of the dialysis membrane. The present invention takes the polysulfone hemodialysis membrane as the modification target, first prepares a triblock copolymer containing polysulfone or polyethersulfone and acrylic acid through atom transfer radical polymerization, then blends the copolymer with polysulfone, spins, Preparation of polysulfone hemodialysis membrane. The carboxyl group on the surface of the dialysis membrane is used to graft heparin onto the surface of the dialysis membrane to improve the hydrophilicity and anticoagulant performance of the dialysis membrane. The invention is easy to operate and effectively relieves the coagulation problem during the use of the hemodialysis membrane. The surface hydrophilicity of the prepared hemodialysis membrane is obviously improved, and the anticoagulant ability is obviously improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A heparin-like modified polyvinyl alcohol hydrogel thin-layer nanocomposite hemodialysis membrane and its preparation method

InactiveCN105727771BGood antifoulingImprove responseSemi-permeable membranesMembranesFiberPolymer science

The invention relates to a heparinoid-modified polyvinyl alcohol hydrogel thin nano-compound hematodialysis film and a preparation method thereof. A heparinoid hydrogel skin layer is arranged as an outer layer of a thin nano-compound hematodialysis film and a porous supporting layer with nano-pores communicated with each other is arranged as an inner layer of the thin nano-compound hematodialysis film. The preparation method comprises the following steps: performing electrostatic spinning on a PAN solution, thereby acquiring a nanometer fiber as the supporting layer of a compound film; adding sodium-hydrogen into the PVA solution, and then adding 1,3-propane sultone, reacting for 8-24h at 40-80 DEG C, filtering and drying, thereby acquiring s-PVA; mixing s-PVA with PVA, adding a solvent, adjusting pH, adding a cross-linking agent, coating on the supporting layer after cross-linking, and sealing at room temperature, thereby acquiring the heparinoid-modified polyvinyl alcohol hydrogel thin nano-compound hematodialysis film. The preparation method provided by the invention is simple in reaction process and is easily performed. The prepared thin nano-compound hematodialysis film has the characteristics of permanent hydrophily, low protein adsorbability and excellent biocompatibility.

Owner:DONGHUA UNIV

Rare earth element containing hemodialysis membrane and preparation method thereof

InactiveCN104437137AEfficient activationReduce activationSemi-permeable membranesRare-earth elementBiocompatibility Testing

The invention provides a rare earth element containing hemodialysis membrane and a preparation method thereof, and relates to the field of biological materials. The hemodialysis membrane is a hollow fiber membrane and is 150 to 250 microns in average internal diameter and 28 to 46 microns in wall thickness. The hemodialysis membrane is prepared from the following components in parts by mass: 35 to 55 parts of polysulfone, 12 to 20 parts of diacetate fiber, 0.1 to 0.5 part of nanometer samarium chloride, 4 to 10 parts of a flexibilizer, and 25 to 50 parts of a solvent. The preparation method of the rare earth element containing hemodialysis membrane adopts a dry-wet preparation process. The rare earth element containing hemodialysis membrane is outstanding in biocompatibility, high in macromolecular protein intercepting performance and relatively high in small solute transmissivity, and is an ideal hemodialysis membrane material.

Owner:SUZHOU COSMETIC MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com