Preparation method for hydrophilic polyacrylonitrile separation film

A technology of polyacrylonitrile and separation membrane, applied in chemical instruments and methods, semi-permeable membrane separation, membrane, etc., to achieve good anti-pollution performance, low cost, and protein reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

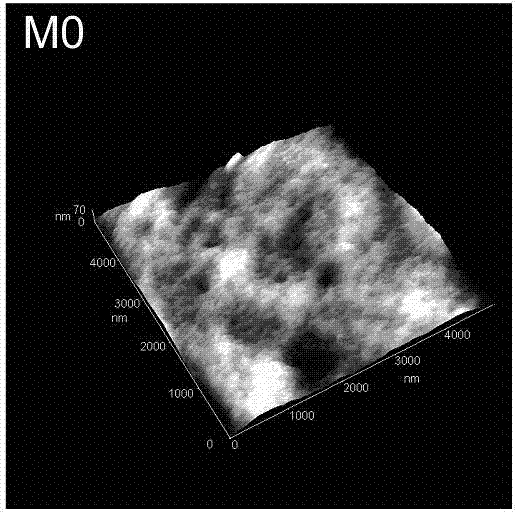

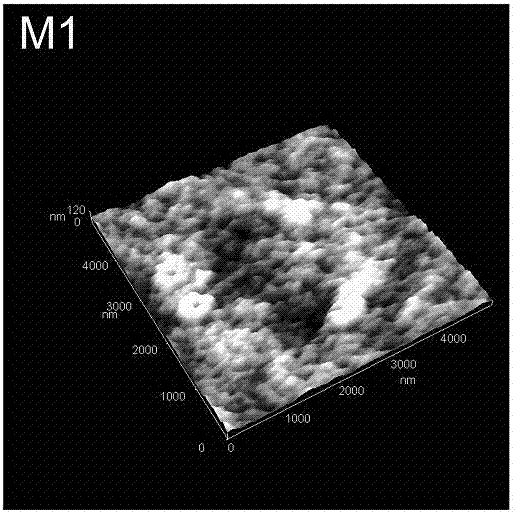

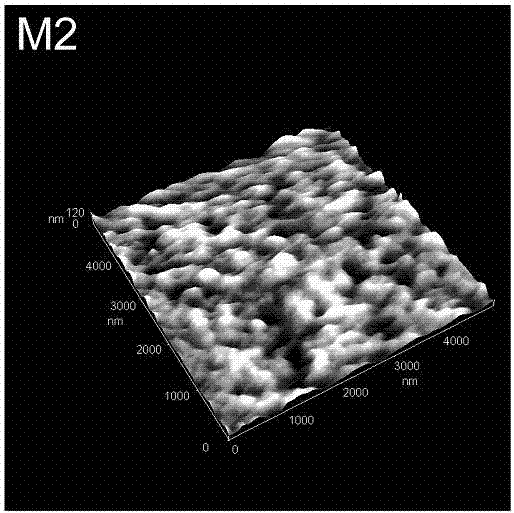

Image

Examples

Embodiment 1

[0036] (1) Synthesis method of PAN-co-PHEMA copolymer: Weigh 0.32 mol of AN and 0.04 mol of HEMA and disperse them in 50ml of pure water. After passing nitrogen for 15 minutes, add initiator 0.046g of ammonium persulfate and 0.02g of sulfite sodium hydrogen. After continuing to pass nitrogen gas for 10 min, the reaction vessel was sealed. React at 60°C for 5 h. After the reaction, the product was filtered, washed with pure water, and dried in an oven at 60°C.

[0037] (2) Preparation of PAN-co-PHEMA copolymer flat film: Weigh 10g of PAN-co-PHEMA copolymer, put it in a 250 ml three-neck flask containing 90g of DMSO, stir and dissolve in an oil bath at 60°C, and wait for the dissolution After standing still for 24 h for defoaming. Scratch the primary film with a 200 μm doctor knife, and immerse it in a pure water coagulation bath at 25°C to solidify to form a film. After the film sample is formed and peeled off from the glass plate, place it in distilled water for 24 hours. ...

Embodiment 2

[0041] (1) ZrO 2 - Synthesis of g-PACMO: Same as Example 1.

[0042] (2) Preparation of PAN-co-PHEMA copolymer flat film: Same as Example 1.

[0043] (3) Preparation of polyacryloylmorpholine (PACMO) modified PAN film: the main preparation process is the same as in Example 1. The main difference is that the amount of ACMO monomer added during the reaction is 0.06mol.

[0044] In this example, the obtained PACMO modified PAN membrane (marked as M3) had an initial water contact angle of 56º and an adsorption capacity of BSA of 25.6 μg / cm 2 .

Embodiment 3

[0046] (1) ZrO 2 - Synthesis of g-PACMO: Same as Example 1.

[0047] (2) Preparation of PAN-co-PHEMA copolymer flat film: Same as Example 1.

[0048] (3) Preparation of polyacryloylmorpholine (PACMO) modified PAN film: the main preparation process is the same as in Example 1. The main difference is that the amount of ACMO monomer added during the reaction is 0.08mol.

[0049] In this example, the obtained PACMO modified PAN membrane (marked as M4) had an initial water contact angle of 51º and an adsorption capacity of BSA of 16.8 μg / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com