Preparation method of blood dialysis membrane raw material

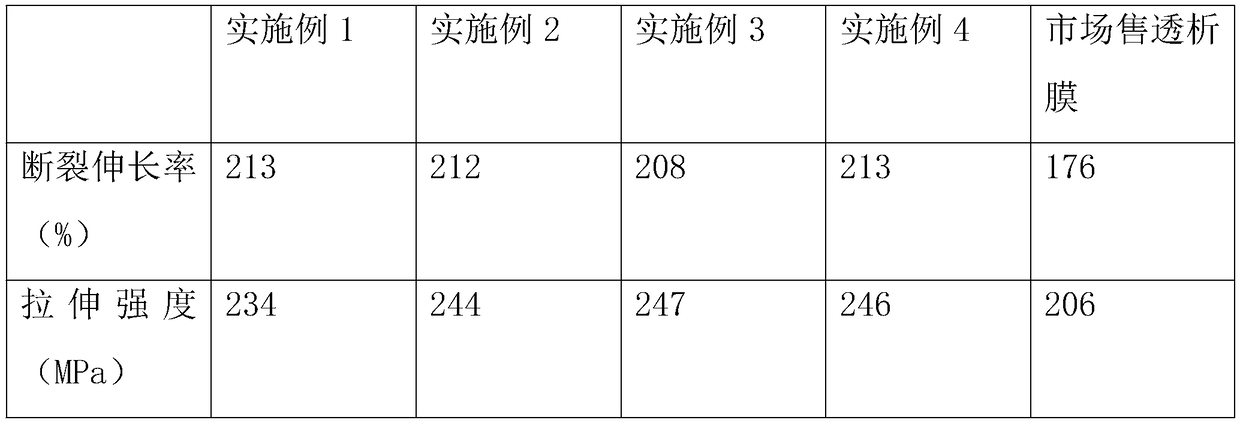

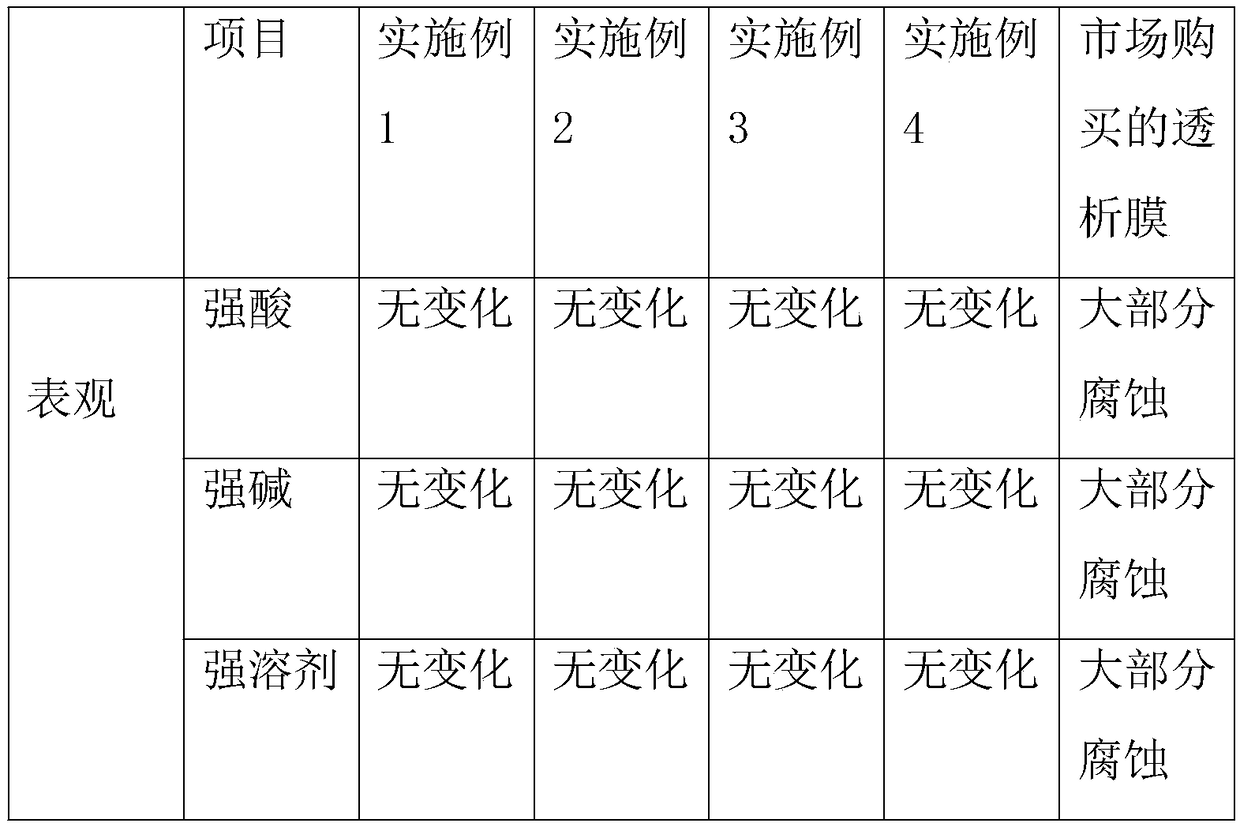

A dialysis membrane and raw material technology, applied in the field of medical materials, can solve the problems of high retention rate of small molecular proteins and high production cost, and achieve the effect of improving mechanical properties and high corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of preparation method of the dialysis membrane that hemodialysis instrument is used comprises the following steps:

[0023] In the sterile room, control the temperature of the reactor at 70°C, add 150 parts by mass of solvent and 120 parts of 50% modified polytetrafluoroethylene into the reactor, turn on the stirrer, and control the stirring speed at 250rpm, slowly 20 parts by mass of polyethylene and 3 parts of silane coupling agent are added to the reactor, and after they are completely dissolved, 2 parts of macromolecular anticoagulant and 12 parts of polylactic acid fiber are slowly Put it into the reaction kettle, and then react for 5 hours, then add 2 parts of reinforcing agent and 8 parts of polyacrylic butyl ester into the reaction, and carry out thermal polymerization reaction for 2 hours, then pour the obtained colloid into the spinning tank In the process, the spinning tank pressure is adjusted to 20 atmospheric pressure for spinning, and the temperatu...

Embodiment 2

[0031] A kind of preparation method of the dialysis membrane that hemodialysis instrument is used comprises the following steps:

[0032]In the sterile room, control the temperature of the reactor at 65°C, add 150 parts by mass of solvent and 110 parts of 55% modified polytetrafluoroethylene into the reactor, turn on the stirrer, and control the stirring speed at 250rpm, slowly 25 parts by mass of polyethylene and 4 parts of silane coupling agent are added to the reactor, and after they are completely dissolved, 1 part of macromolecular anticoagulant and 15 parts of polylactic acid fiber are slowly Put it into the reaction kettle, and then react for 5 hours, then add 3 parts of reinforcing agent and 10 parts of polyacrylamide butyl ester into the reaction, carry out thermal polymerization reaction for 2 hours, and pour the obtained colloid into the spinning tank In the process, adjust the pressure of the spinning tank to spin at 8 atmospheres, wherein the temperature of the dr...

Embodiment 3

[0040] A kind of preparation method of the dialysis membrane that hemodialysis instrument is used comprises the following steps:

[0041] In the sterile room, control the temperature of the reaction kettle at 65°C, add 200 parts by mass of solvent and 100 parts of 50% modified polytetrafluoroethylene into the reaction kettle, turn on the stirrer, and control the stirring speed at 250rpm, slowly 20 parts by mass of polyethylene and 5 parts of silane coupling agent are added to the reactor, and after they are completely dissolved, 0.5 parts of macromolecular anticoagulant and 10 parts of polylactic acid fiber are slowly Put it into the reaction kettle, and then react for 3 hours, then add 5 parts of reinforcing agent and 6 parts of polyacrylamide butyl ester into the reaction, carry out thermal polymerization reaction for 1 hour, and pour the obtained colloid into the spinning tank In the process, adjust the pressure of the spinning tank to spin at 8 atmospheres, in which the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com