Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90 results about "Ferrite thin films" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

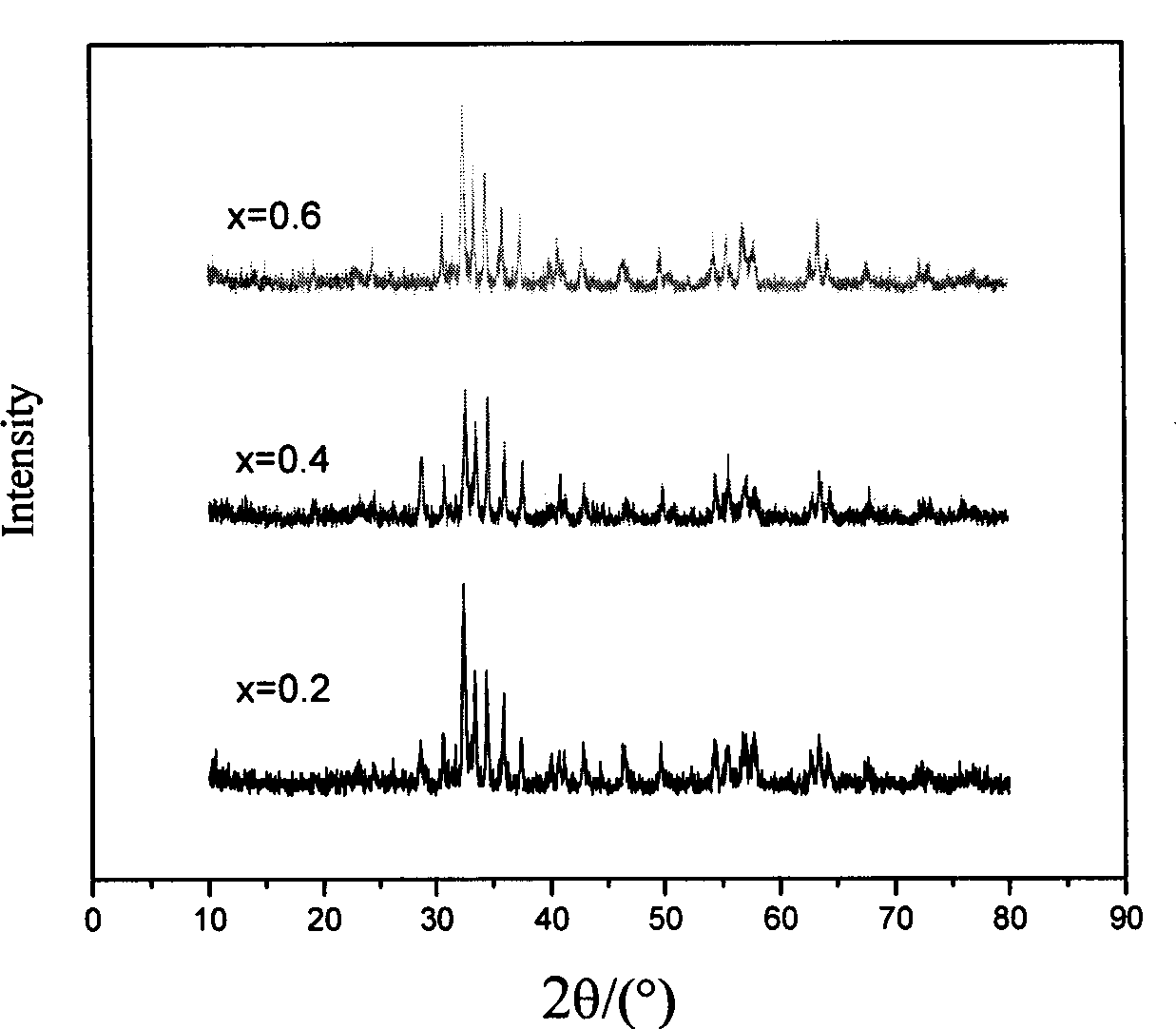

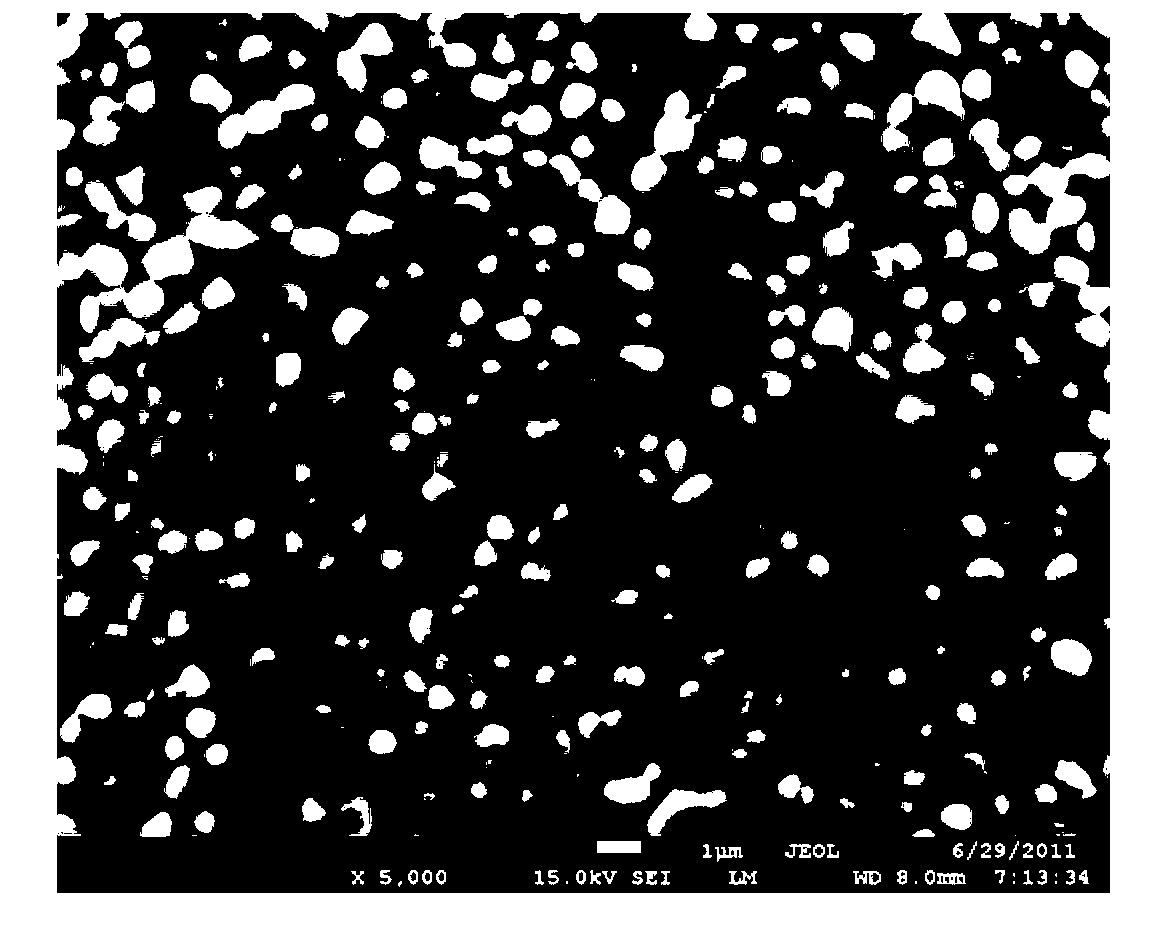

Lanthanum doped nano barium ferrite film and method of manufacturing the same

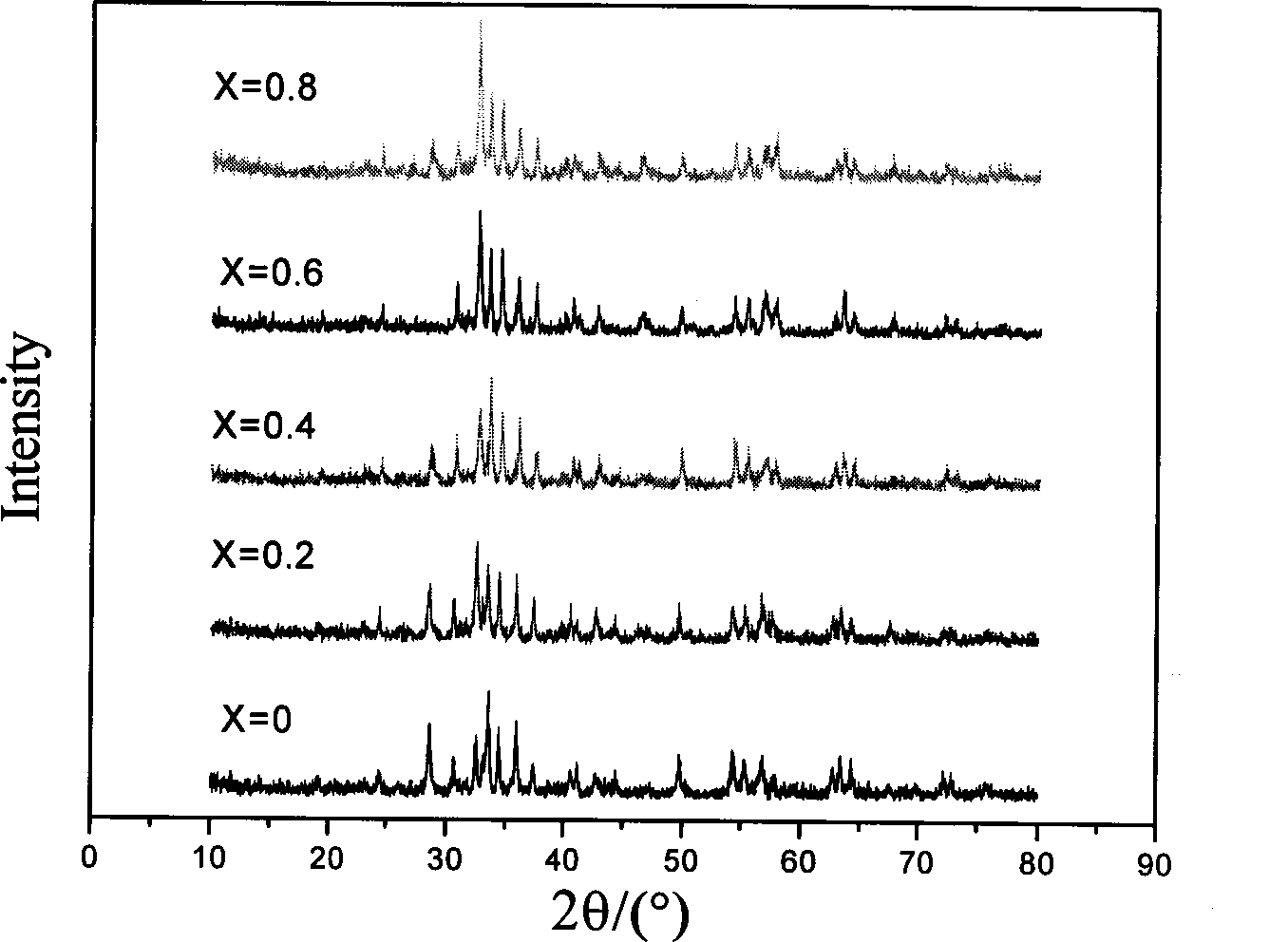

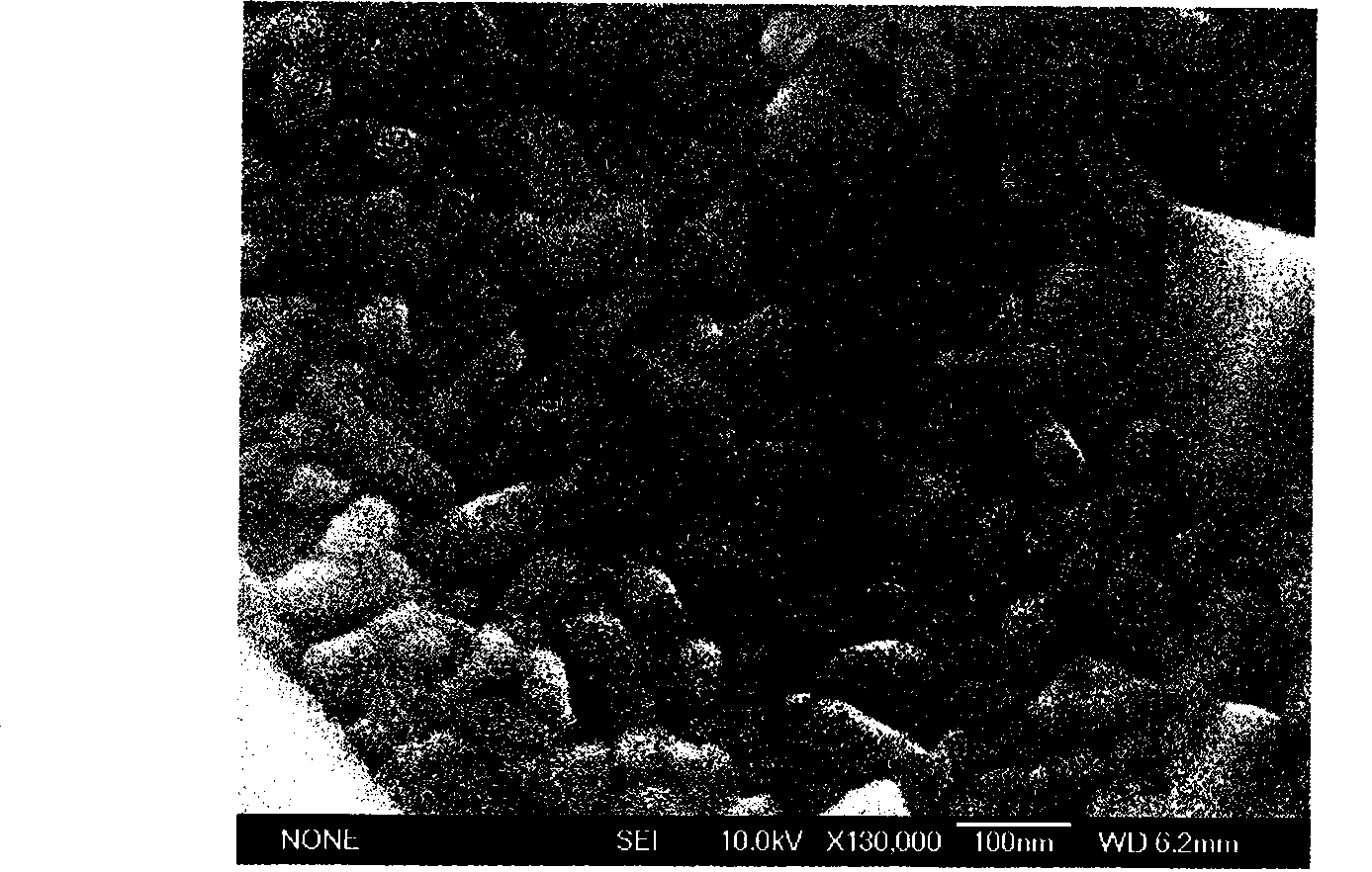

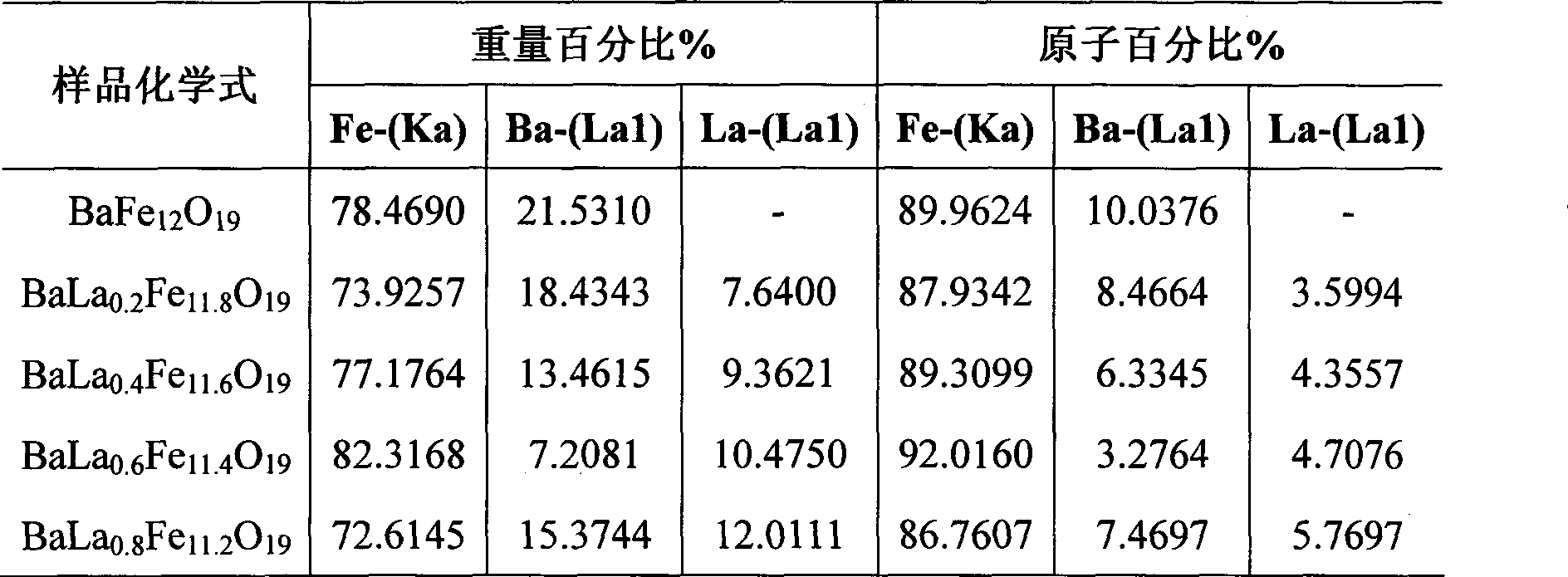

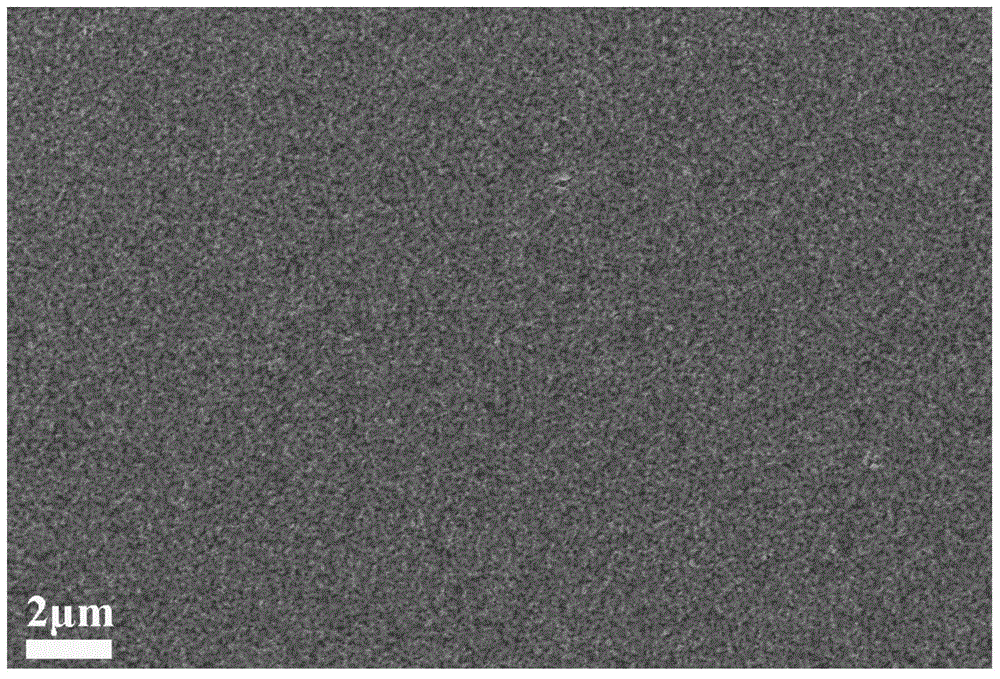

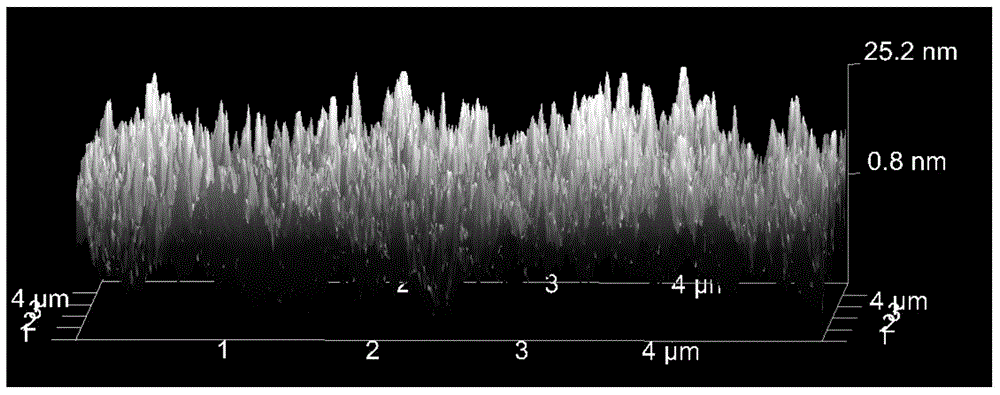

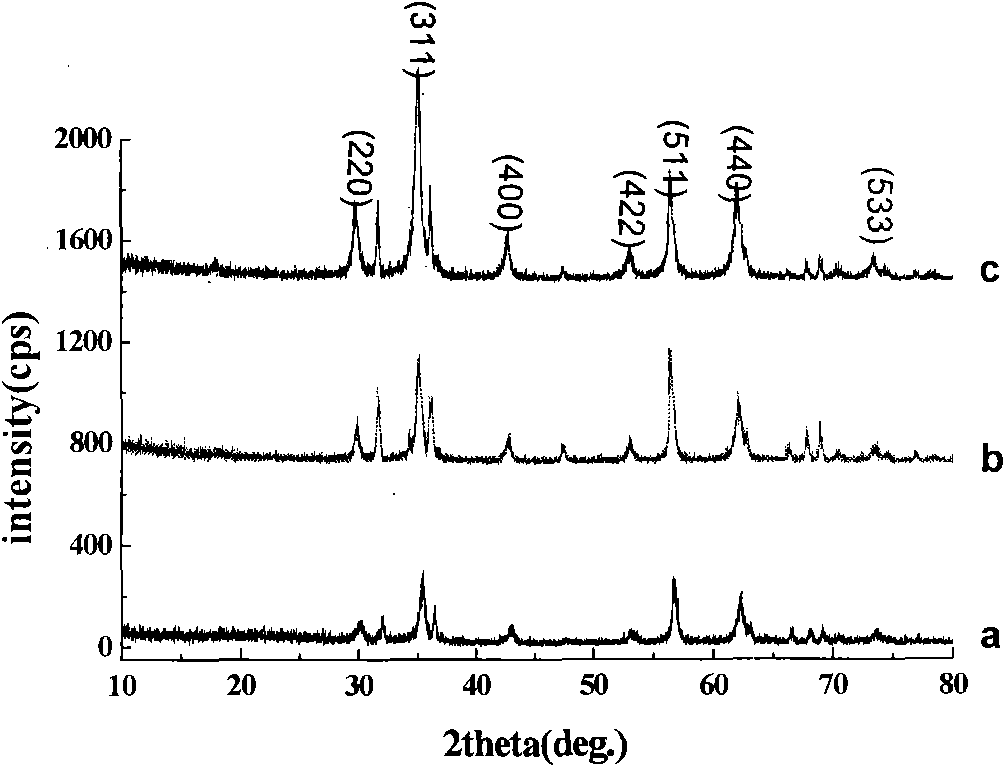

The invention relates to a lanthanum doping nanometer barium ferrite thin film and a preparation method thereof, which is technically characterized in that the prescription is as follows: 1.48 g / 100 ml to 1.60 g / 100 ml of glycol, 2.51 g / 100 ml to 2.71 g / 100 ml of citric acid, 1.74 g / 100 ml of iron nitrate, 0.125 g / 100 ml of barium nitrate and 0.03 g / 100 ml to 0.125 g / 100 ml lanthanum nitrate. The preparation method is that the iron nitrate, the barium nitrate, the lanthanum nitrate, and the like, serve as raw materials to prepare a forerunner body the forerunner body of the lanthanum doping nanometer barium ferrite in a sol-gel method; sol-gel method; clean silicon dioxide serves as a support base, the iron nitrate, the barium nitrate and the lanthanum nitrate serve as main salt, the citric acid serves as complexing agent, the glycol serves as complexing agent assist, and the soakage-drawing method is adopted to make the film. The method has the advantages of simple process flow and low cost; the method is convenient for preparing the thin film on bases with different shapes, the lanthanum doping nanometer barium ferrite thin film with high purity is obtained, and the thin film can be used for preparing magnetic recording materials and absorbing materials.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

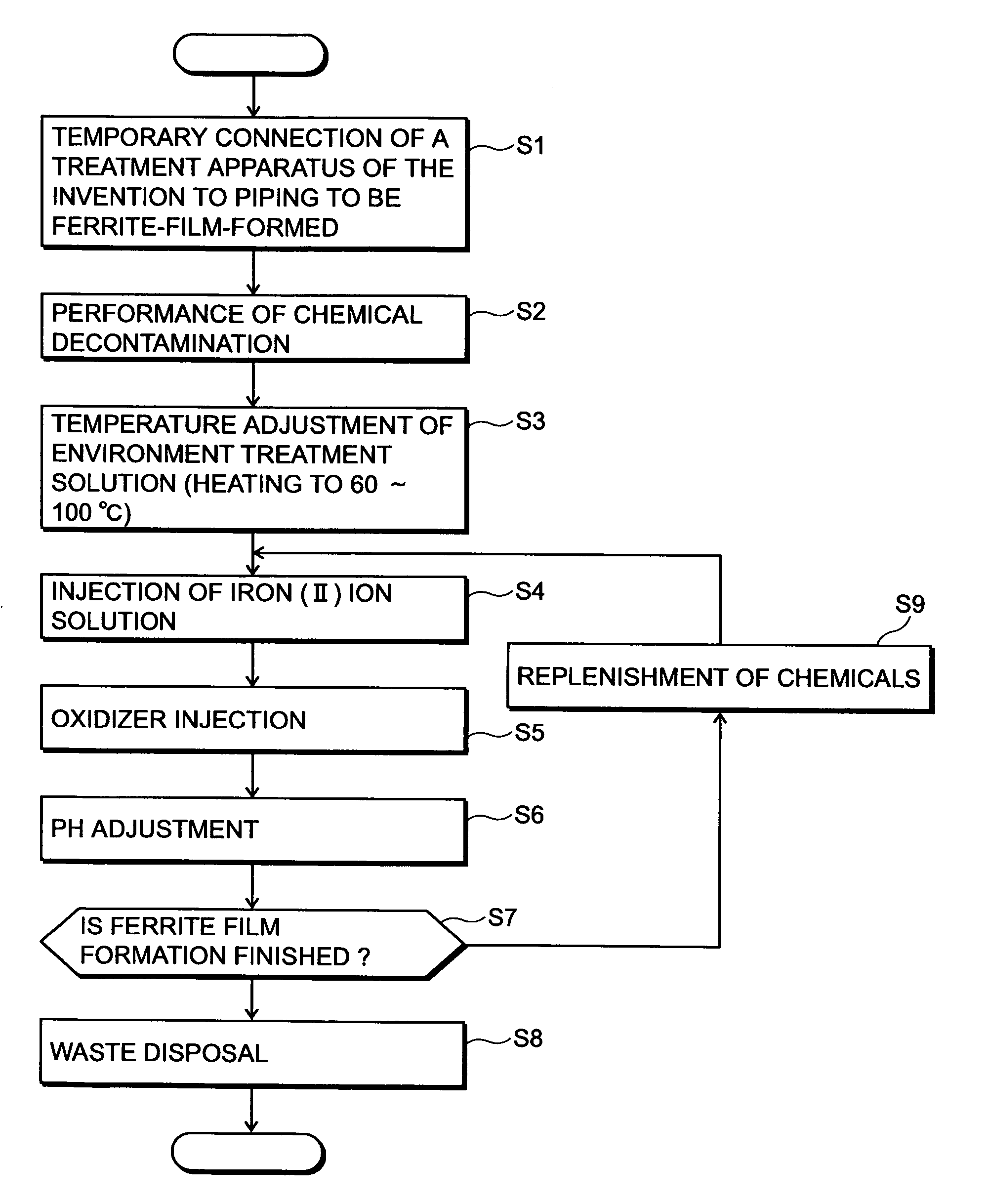

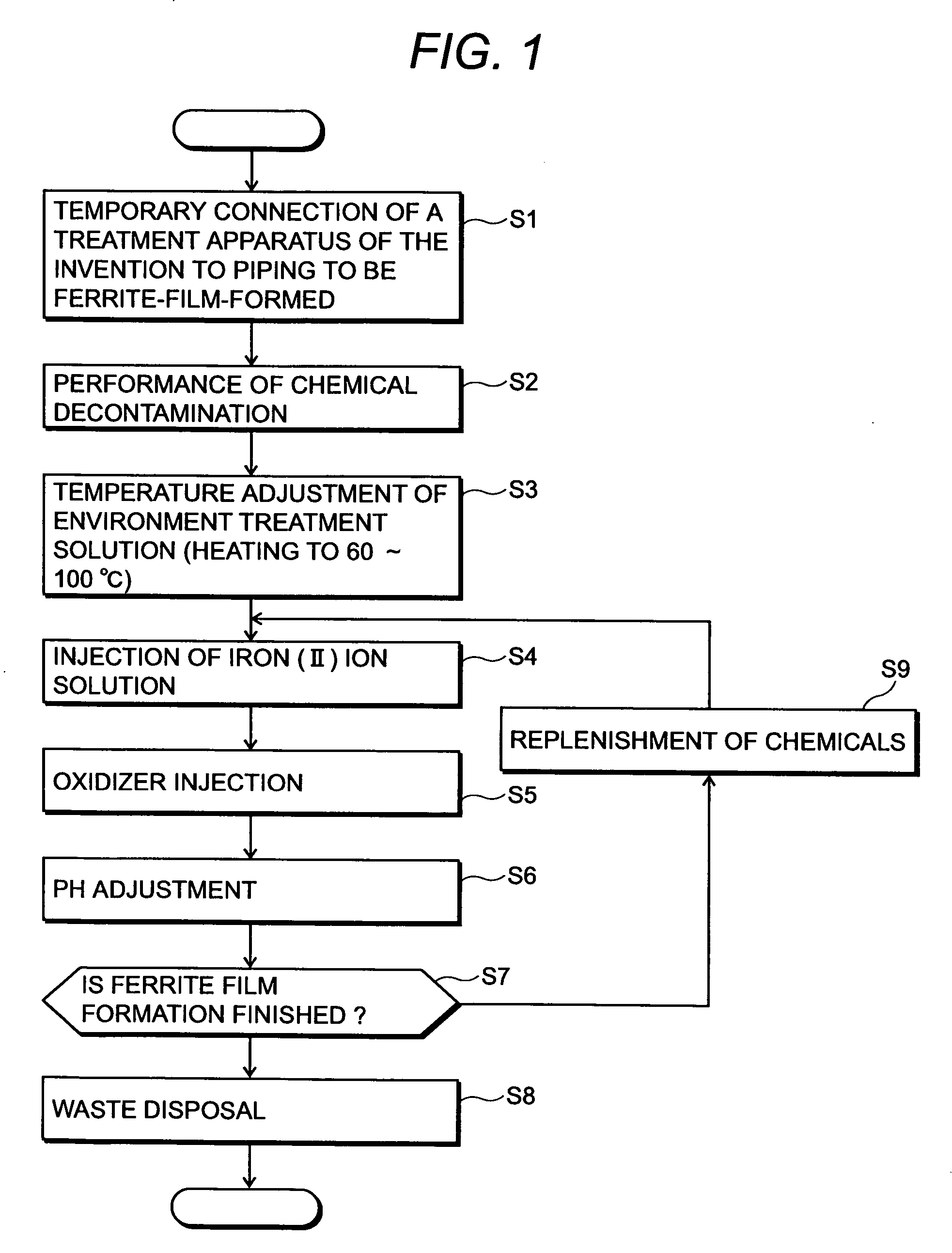

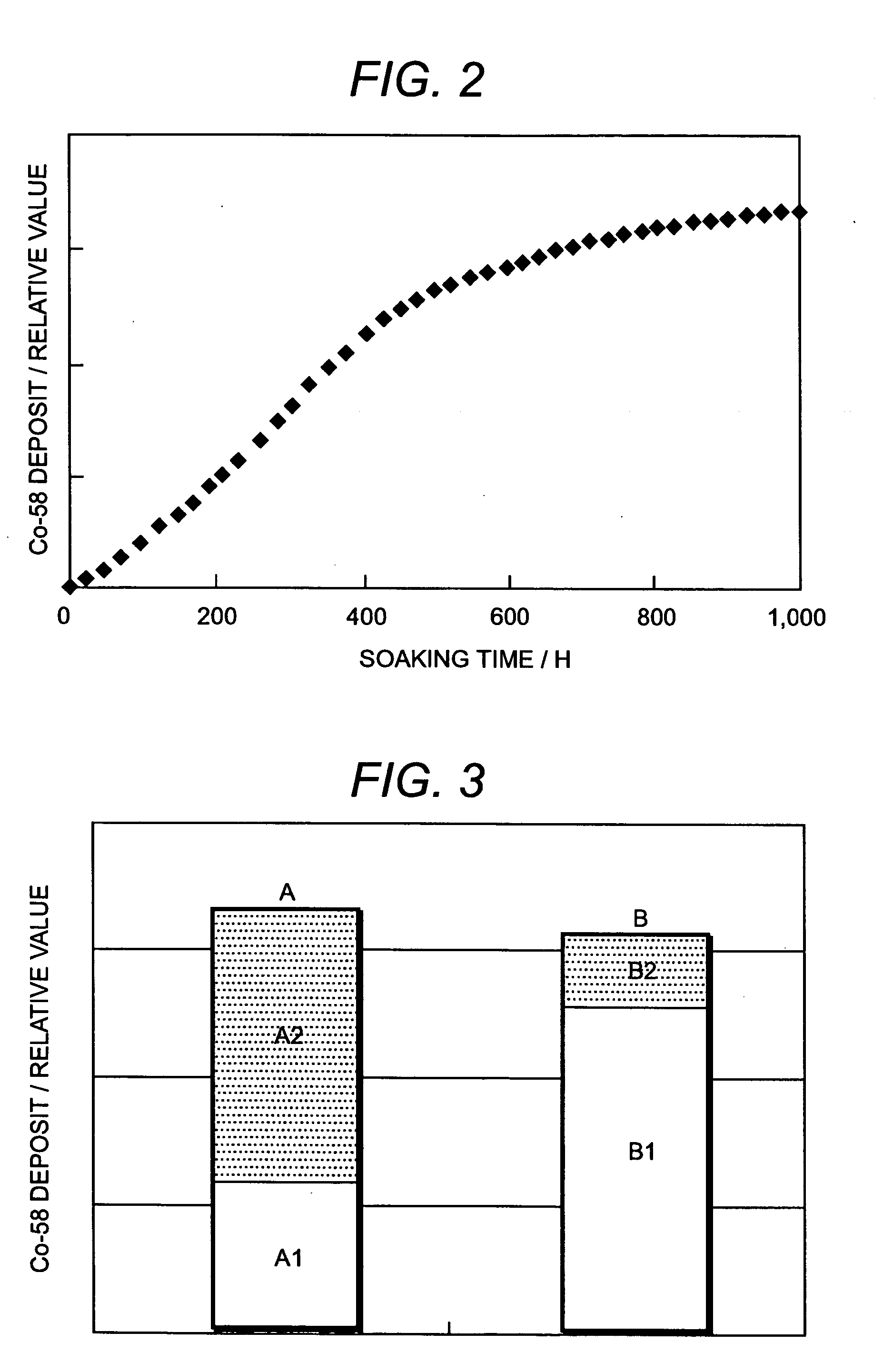

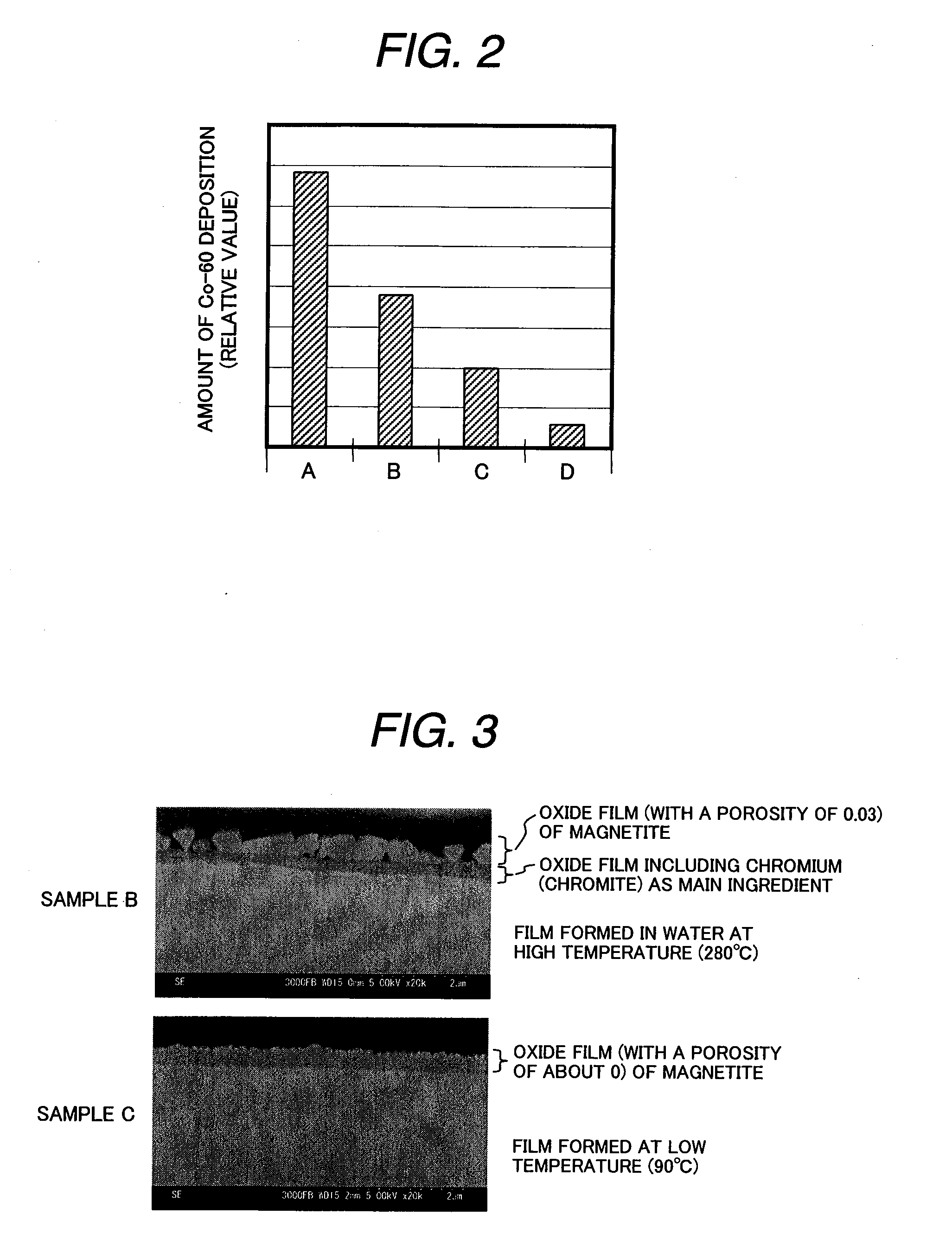

Suppression method of radionuclide deposition on reactor component of nuclear power plant and ferrite film formation apparatus

InactiveUS20060067455A1Avoid depositionNuclear energy generationNuclear monitoringNuclear plantCompound (substance)

A method of suppressing deposition of radionuclides on components of a nuclear power plant comprises forming a ferrite film by contacting a first chemical including iron (II) ions, a second chemical for oxidizing the iron (II) ions to iron (III) ions, and a third chemical for adjusting the pH of a processing solution containing a mixture of the first and second chemicals to be 5.5 to 9.0 with the metal member surface in a time period from a finishing stage in decontamination step of removing contaminants formed on the surface of metal member composing the nuclear power plant, and suppressing deposition of radionuclides on the metal member by the ferrite film.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

Cerium-doped nanometer barium ferrite thin film and method for making same

InactiveCN101452756AImprove absorbing performanceAdjust the magneticMagnetic layersCerium nitrateCerium nitrate hexahydrate

The invention relates to a cerium-doped nanometer barium ferrite film and a preparation method thereof. The film is characterized in that the formula comprises 1.48 to 1.60g / 100ml of glycol, 2.51 to 2.71g / 100ml of citric acid, 1.74g / 100ml of ferric nitrate, 0.125g / 100ml of barium nitrate, and 0.04 to 0.125g / 100ml of cerium nitrate. The preparation method comprises: a crystalline nanometer barium ferrite film is prepared on a quartz substrate; the cerium-doped nanometer barium ferrite film with high purity is obtained through the optimization of preparation technology; and the film can be used for preparing magnetic recording materials and wave-absorbing materials. The method has the advantages that the method has simple process flow and low cost, is convenient for preparing films on various substrates with different shapes, is easy to obtain an uniform and multi-component oxide film, is easy for quantitative doping, and can effectively control the constituents and a microscopic structure of the film.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Composite wave absorbing material and production thereof

InactiveCN1644546AWide absorption frequency rangeRadiation-absorbing paintsCITRATE ESTERFerrite thin films

A composite wave-absorbing material and its production are disclosed. The multi-hole glass phase micro-particle surface is coated by barium ferrite thin film, the mass ratio of multi-hole glass phase and ferrite is 0.1-10:1. The barium ferrite layer is produced on multi-hole glass phase micro-particle surface by citrate sol-gel method. The absorbing frequency range of composite material is wider than the barium ferrite. It can be used for electromagnetic wave absorbing material of aircraft and building coating.

Owner:TONGJI UNIV

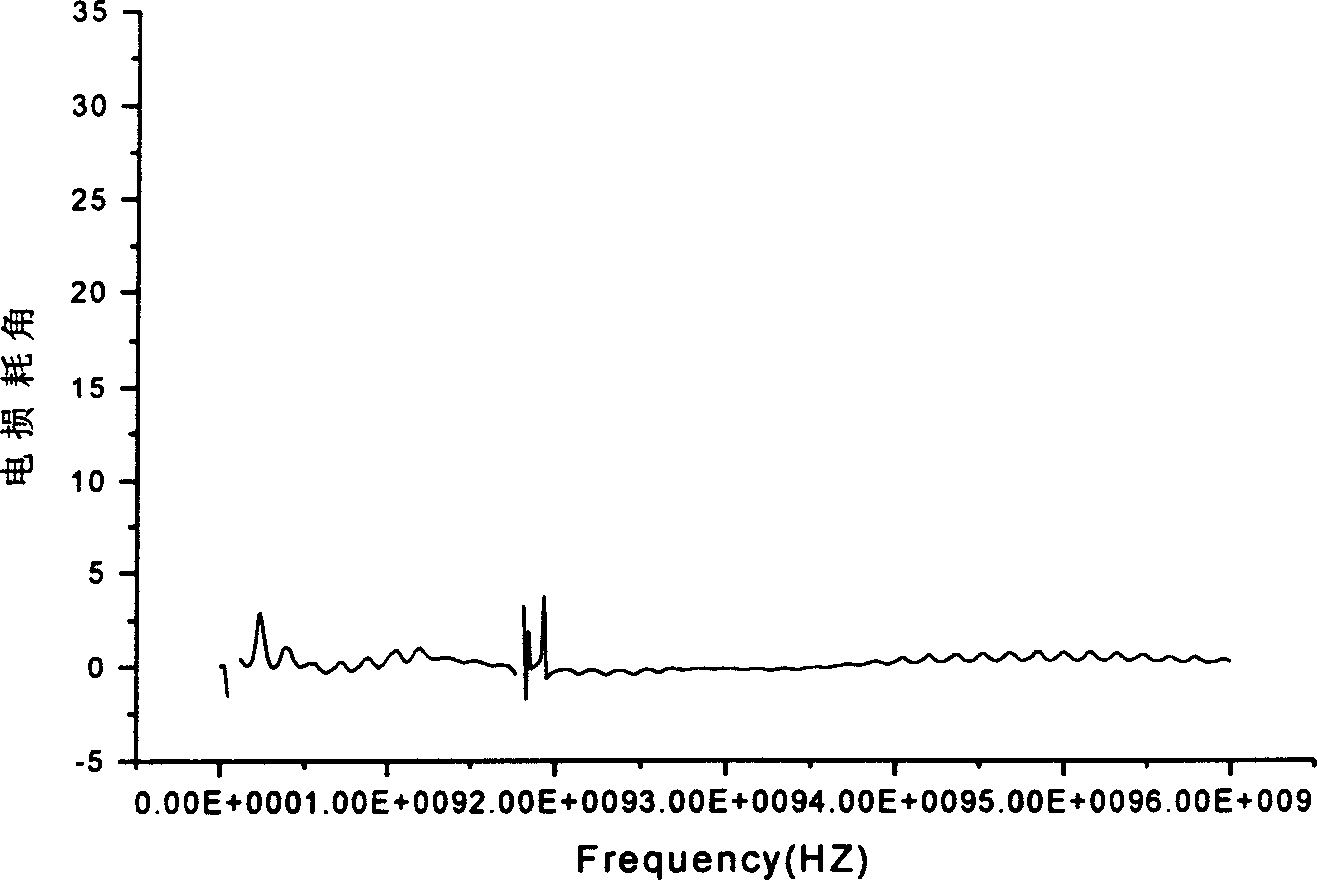

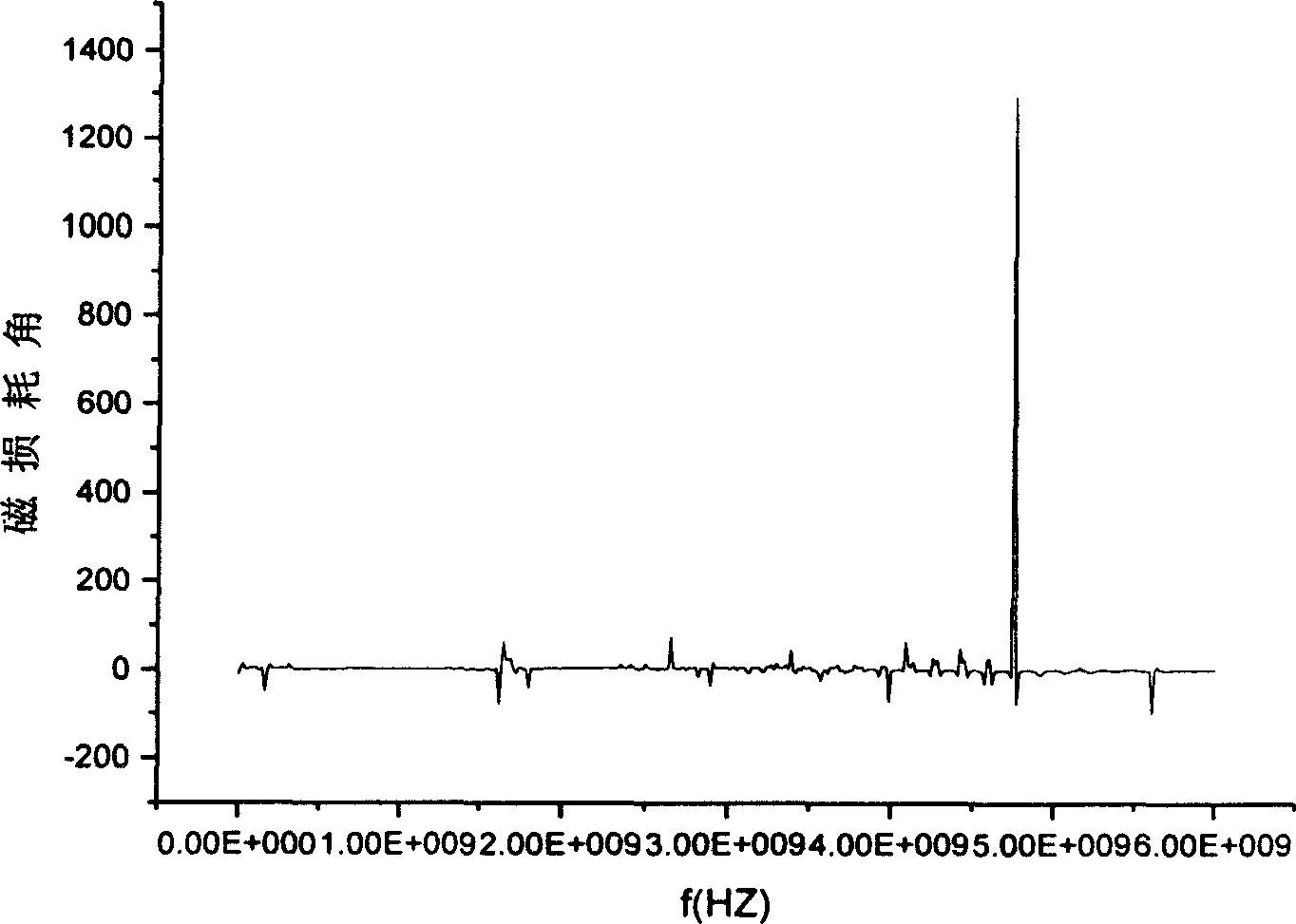

Ferrite thin film, method of manufacturing the same and electromagnetic noise suppressor using the same

InactiveUS20070077369A1Increase formation rateIncrease productivityMagnetic materials for record carriersLiquid applicationMagnetic anisotropySuppressor

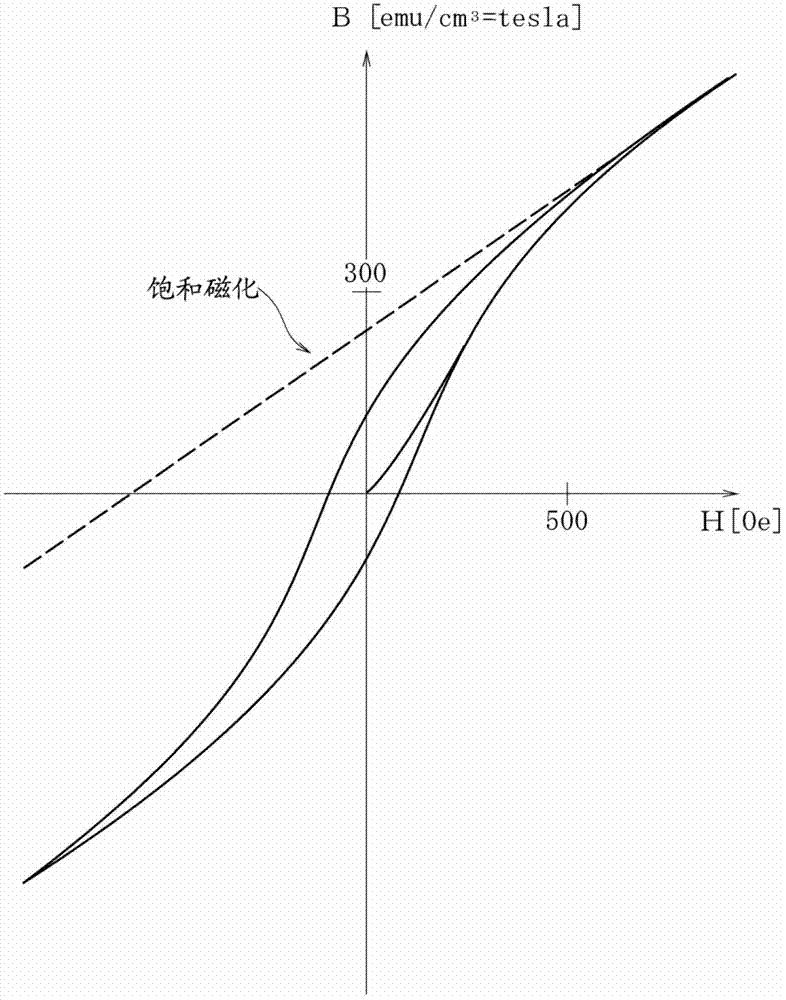

A ferrite film is formed by regularly arranging constituents such as magnetized grains or one analogous to that. In the ferrite film, the constituents have at least one of the uniaxial anisotropy and the multiaxial anisotropy. The ferrite film has the magnetic anisotropy or the magnetic isotropy. The ferrite film is formed by the use of the plating method in the presence of a magnetic field. Furthermore, an electromagnetic noise suppressor includes the ferrite film.

Owner:TOKIN CORP

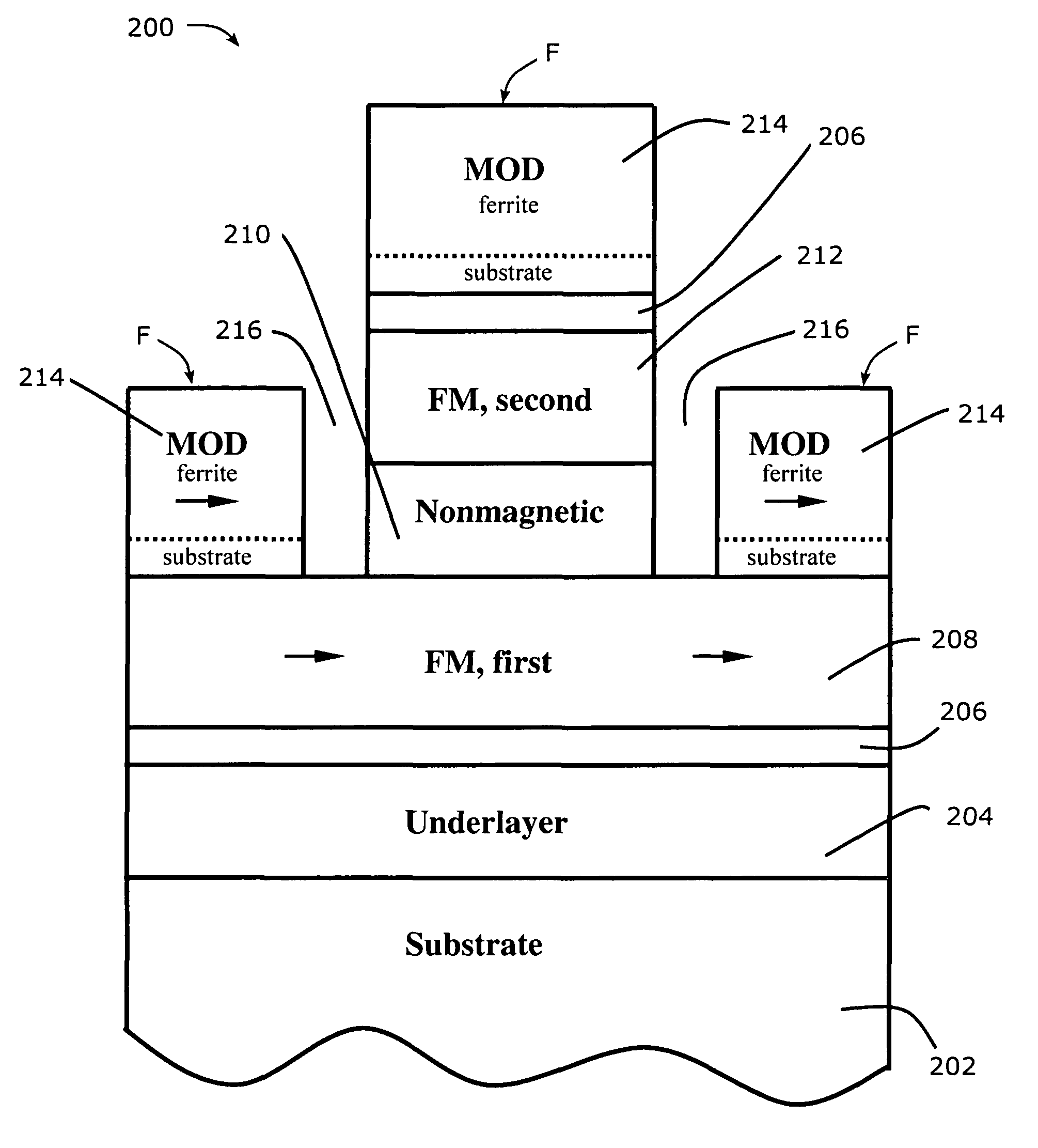

Magneto-optical device with an optically induced magnetization

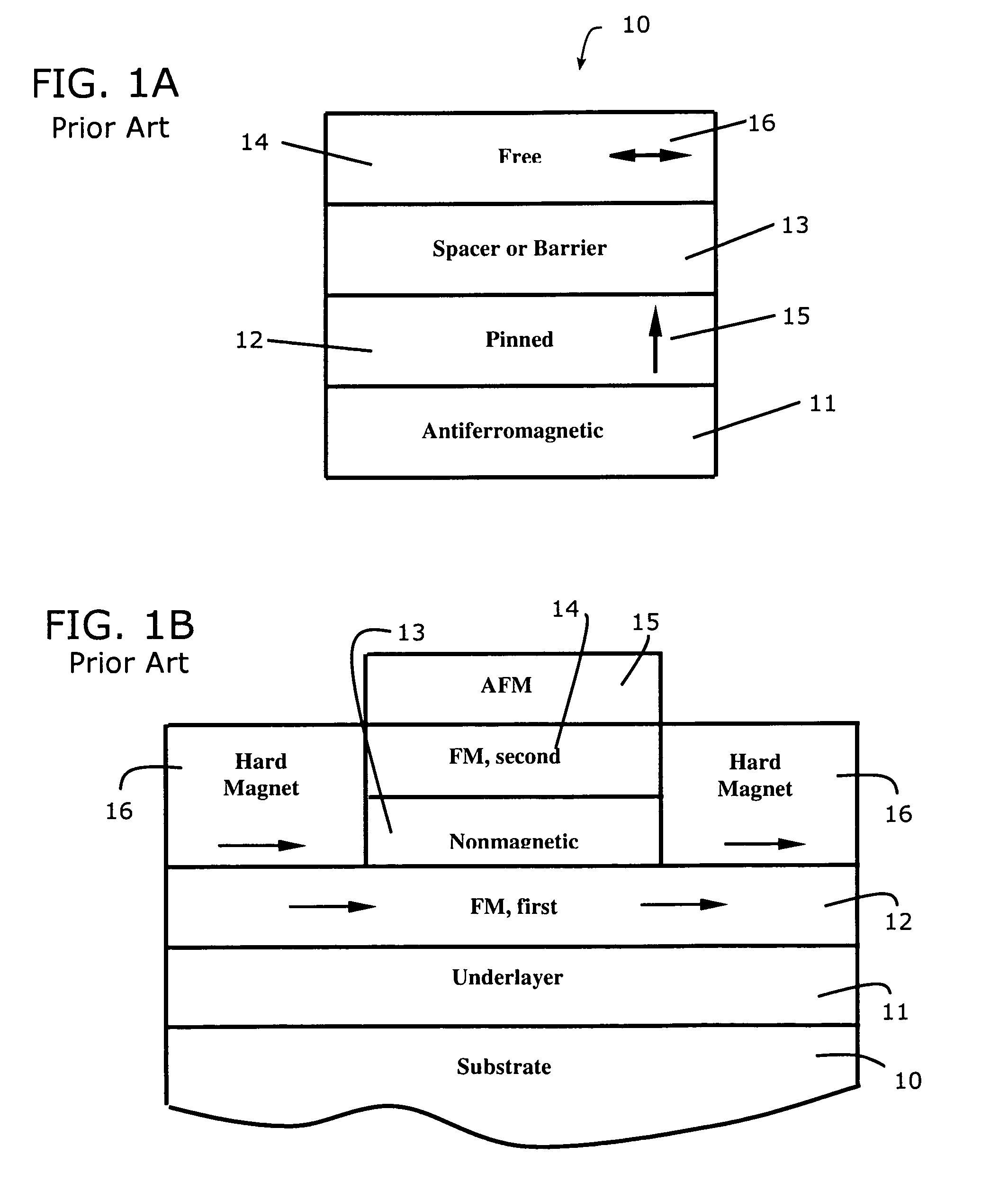

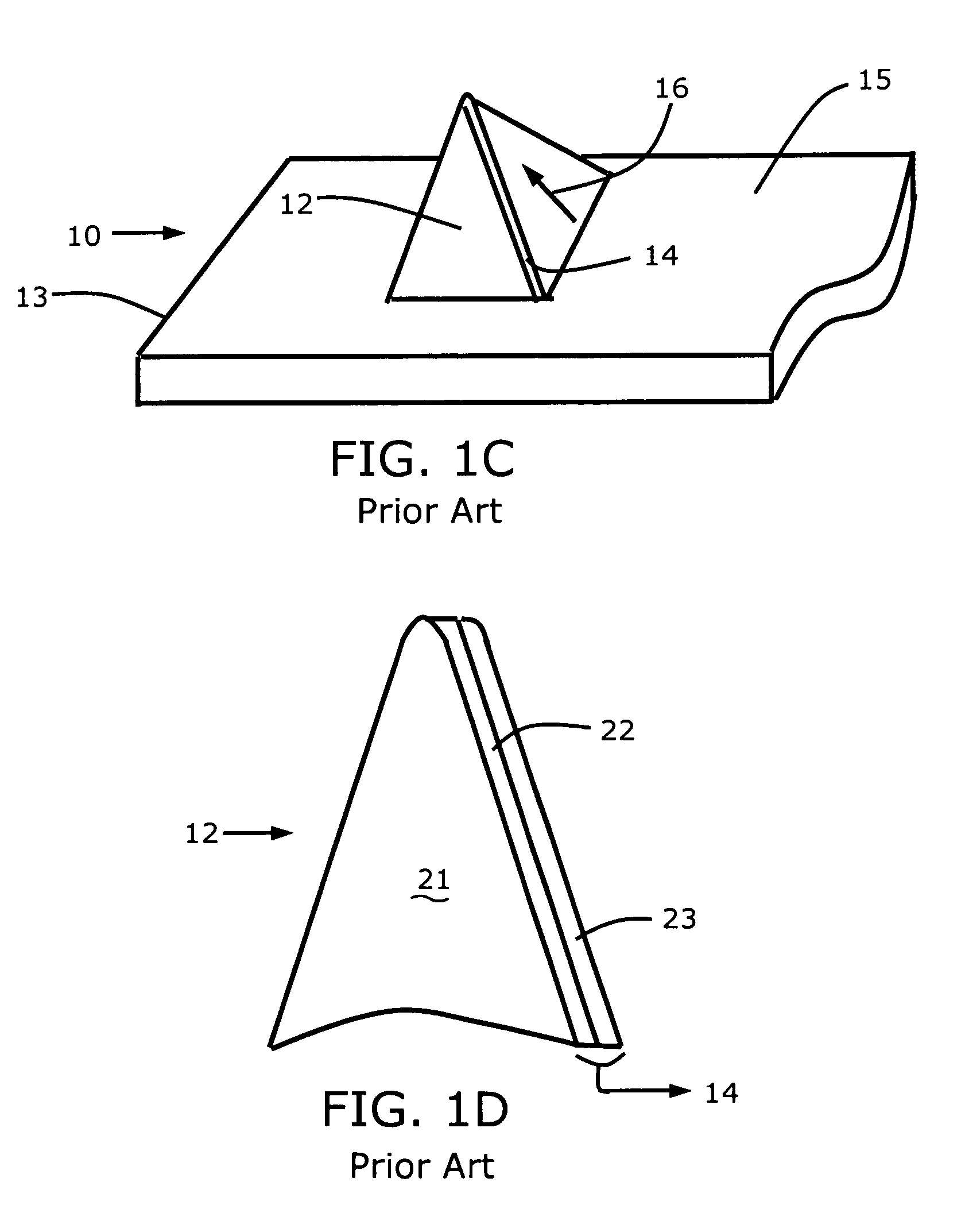

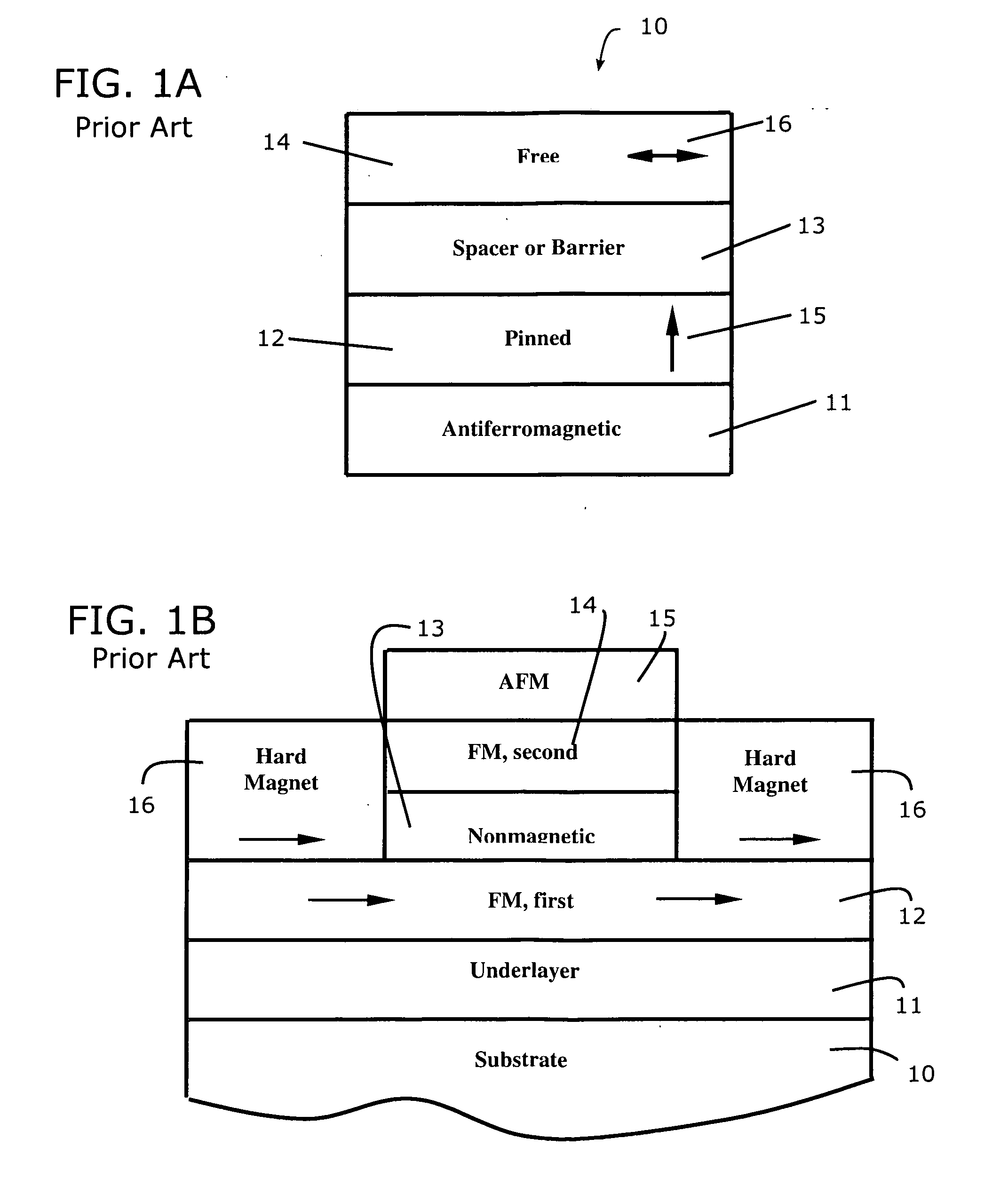

ActiveUS8154957B1Total current dropEasy to manufactureCombination recordingDifferent record carrier formsMagnetic memoryMagnetization

A magneto-optical device (MOD) with optically induced magnetization for use in magnetic field sensors as a magnetic element pinning a magnetization in a preferred direction of a ferromagnetic layer as well as a magnetic memory cell for magneto-optical recording. The MOD comprises the Mg—Mg—Co ferrite film deposited on a magnesium oxide (MgO) substrate. The ferrite film is illuminated at room temperature with a circularly polarized light (CPL) in a static magnetic H-field (about of 3 kOe) normal to the illuminated ferrite film surface. At certain (“writing”) combinations of H, sigma (CPL helicity), the long-lived optically induced magnetization with a unidirectional anisotropy, stable to a conventional demagnetization occurs. For readout of information, conventional magnetoresistive sensors and MFM can be used. To erase information, the ferrite film should be illuminated with two field-light combinations, other than “writing”, or annealed at temperature higher than 530 degrees C.

Owner:KATSNELSON ESFIR Z +1

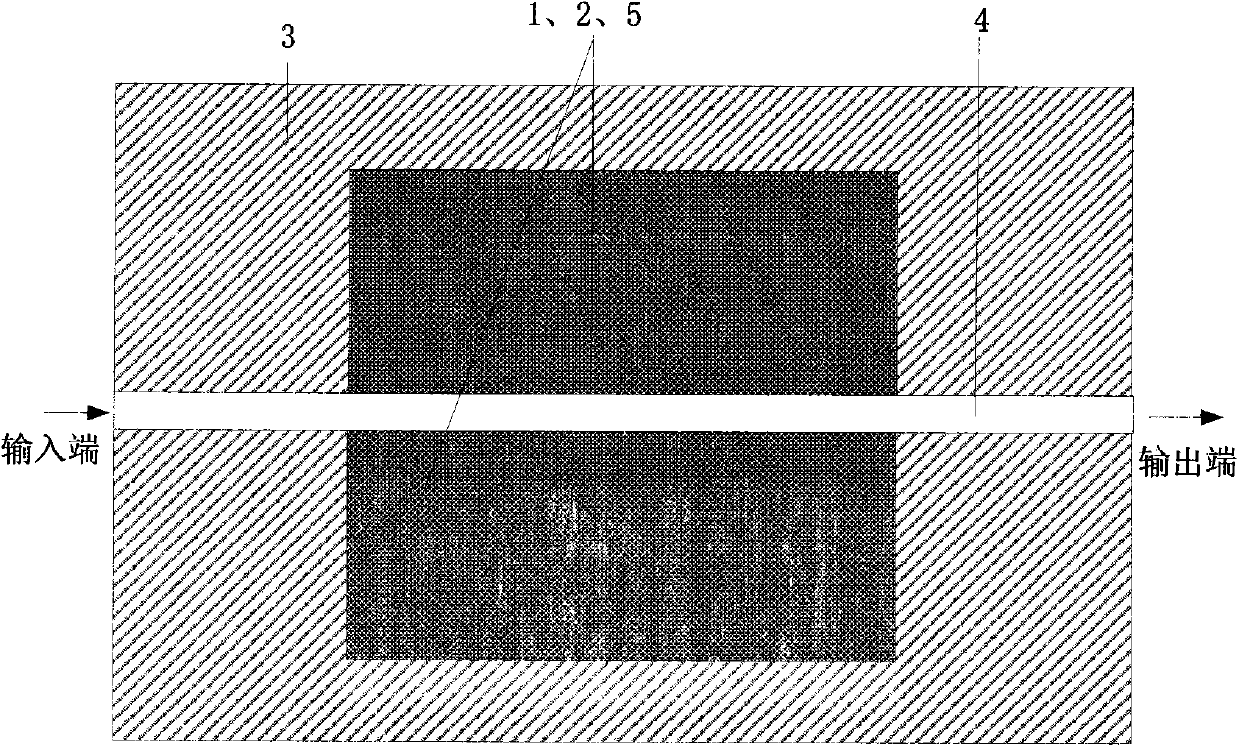

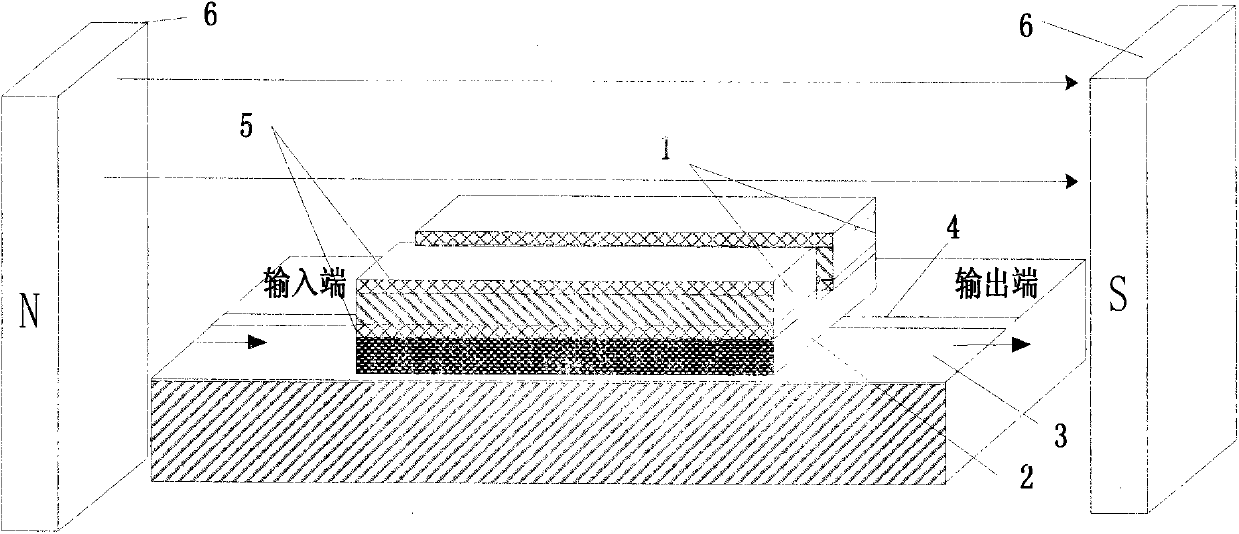

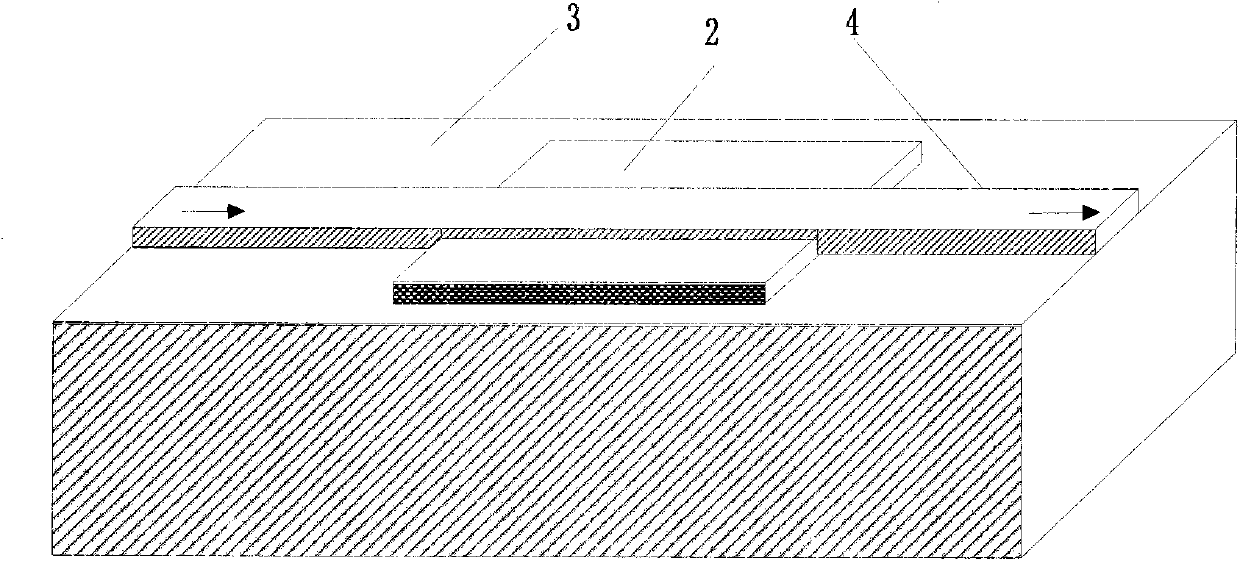

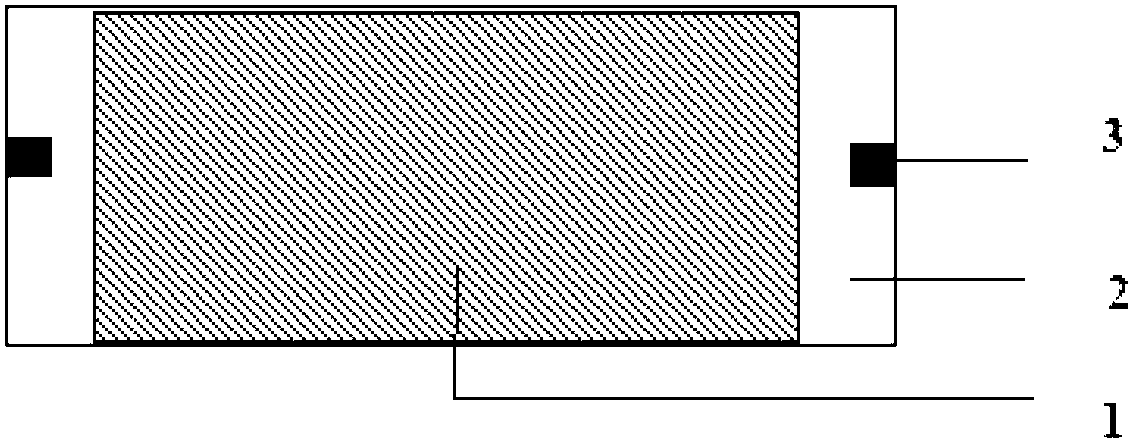

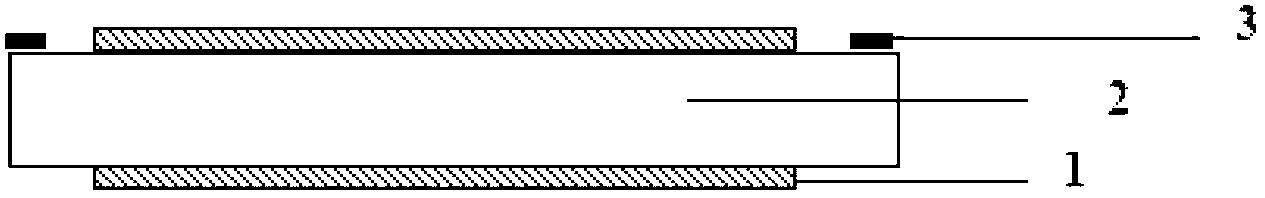

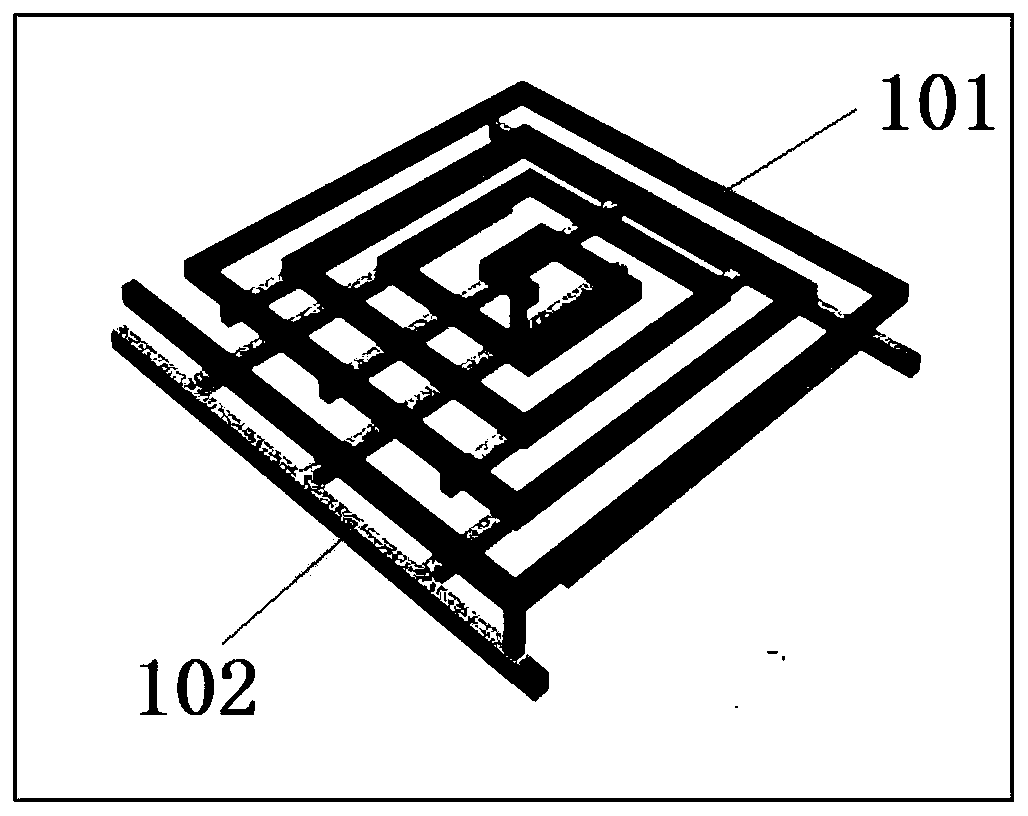

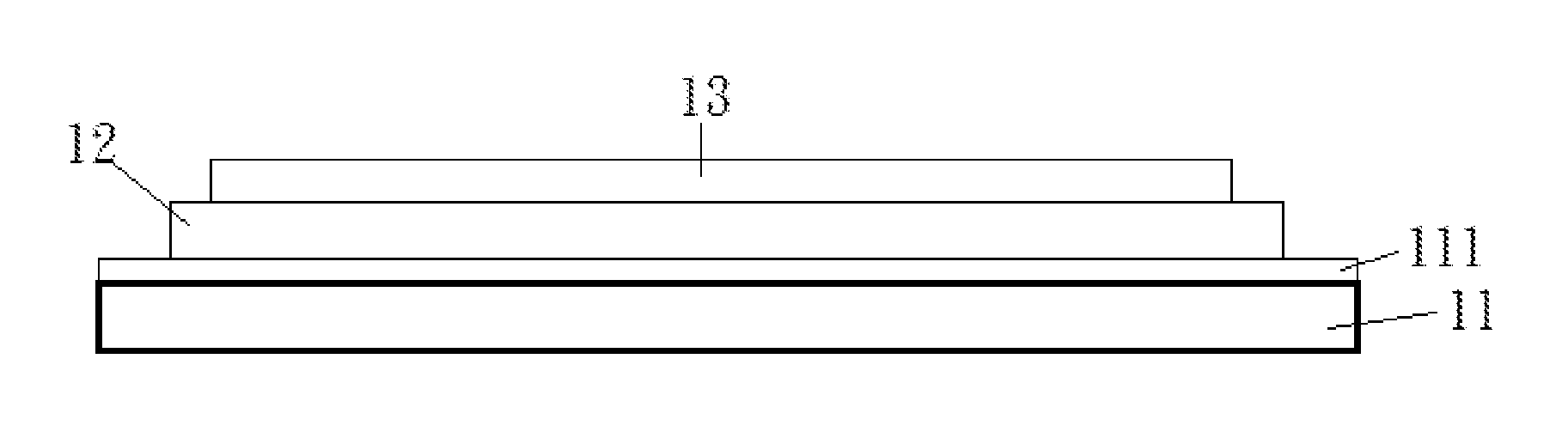

Micro-strip line filter sharing substrate with YIG (Yttrium Iron Garnet) thin film material, and regulation method thereof

InactiveCN103401047AReduce volumeSimple structureWaveguide type devicesAntennasElectricityGadolinium gallium garnet

The invention discloses a micro-strip line filter sharing a substrate with YIG (Yttrium Iron Garnet) thin film material, and a regulation method thereof. The micro-strip line filter comprises two piezoelectric layers (1), one YIG layer (2), GGG (Gadolinium Gallium Garnet) substrate material (3) and a metal micro-strip line (4); the micro-strip line filter takes the GGG substrate material (3), needed for the growth of the YIG layer (2), as a substrate; a layer of metal micro-strip line (4) in single conduction band is printed on the upper surface of the GGG substrate material (3), on which the YIG layer (2) is grown, along a central axis in a length direction; the two piezoelectric layers (1) are respectively arranged at two sides of the metal micro-strip line. Compared with a traditional micro-strip line filter, the miniaturization of the micro-strip line filter can be realized due to the advantages of high dielectric constant (epsilon is greater than 10) and high magnetic permeability (mu is greater than 10) of YIG material and piezoelectric material. According to the micro-strip line filter disclosed by the invention, the GGG substrate material of which the length-width size is the same as that of a YIG thin film is selected, and thus the selecting difficulty on size of the YIG material is reduced.

Owner:CHINA JILIANG UNIV

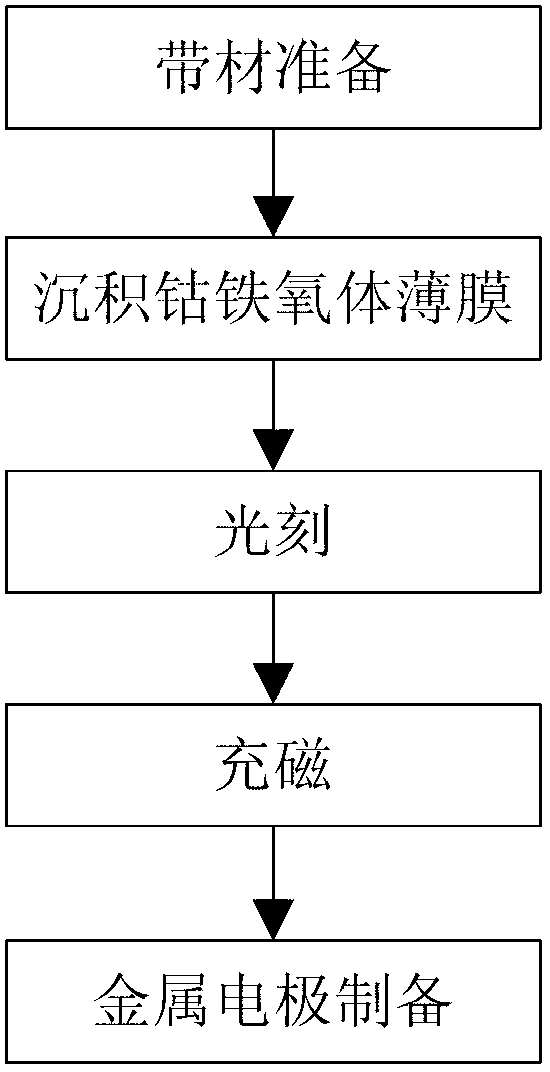

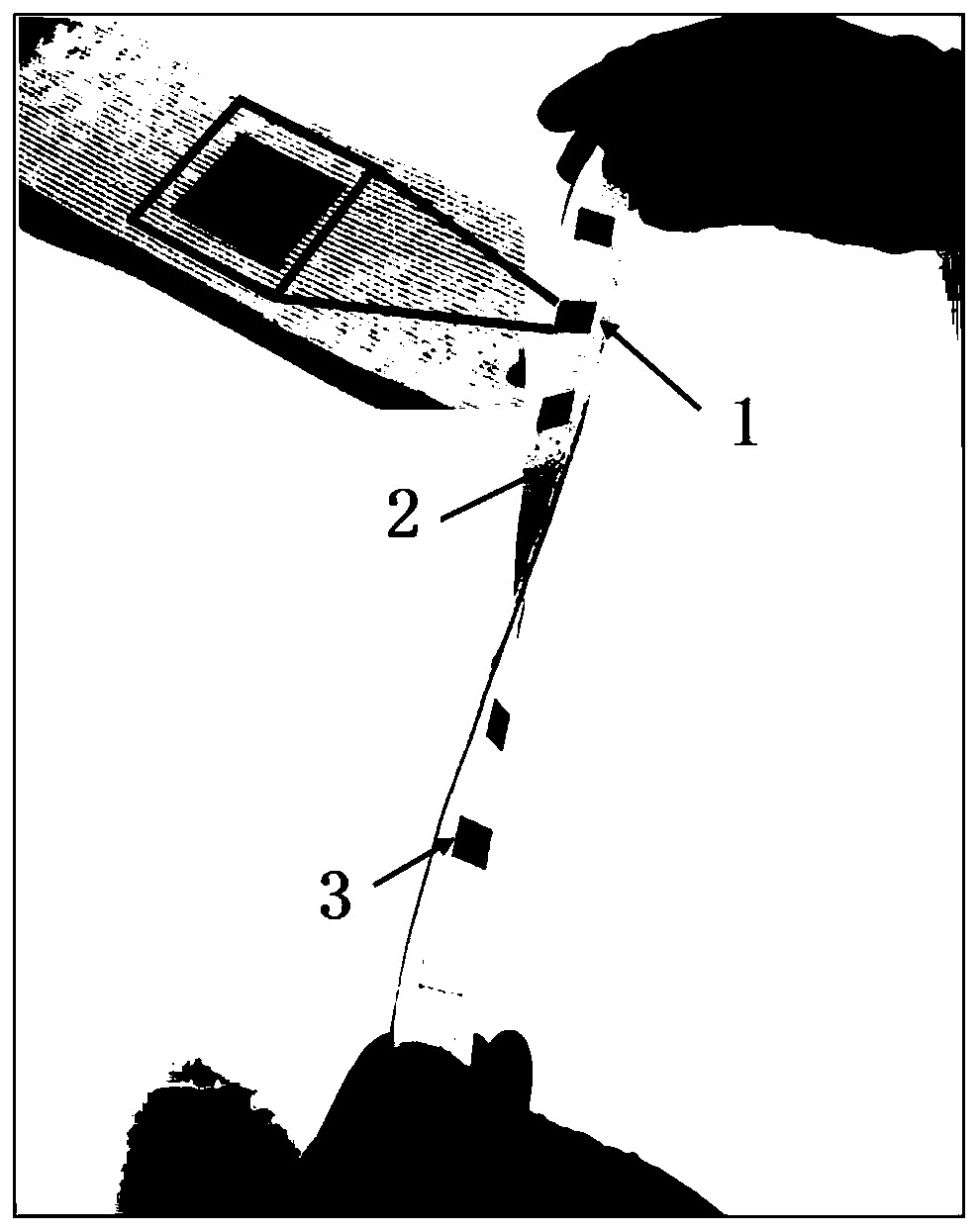

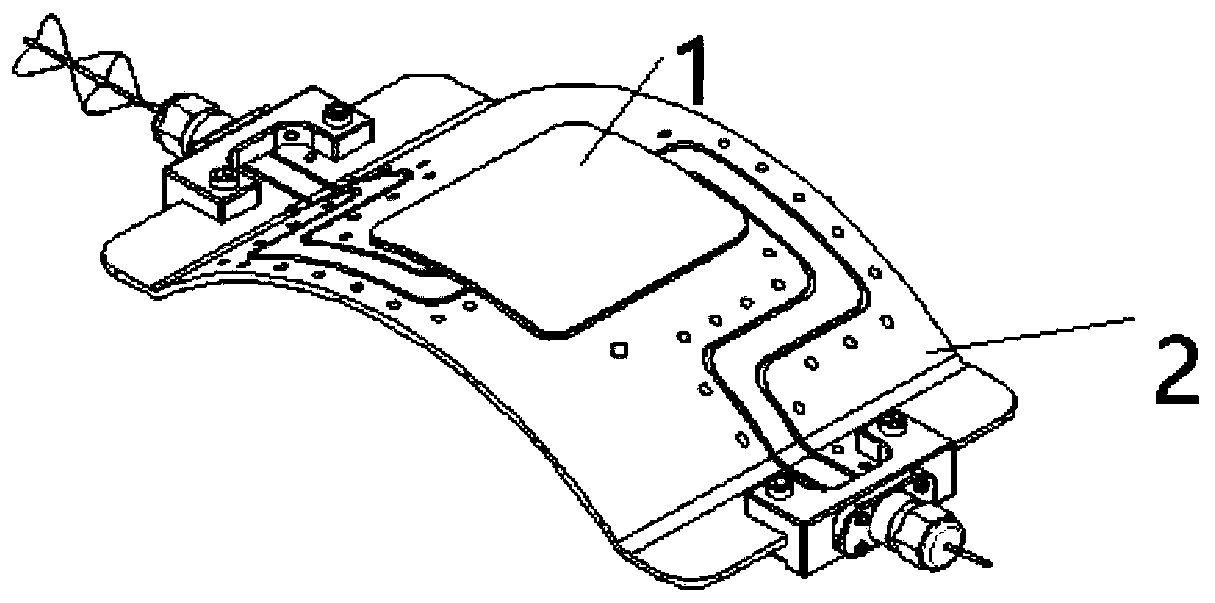

Self-biased giant magneto-impedance sensor probe and preparation method thereof

InactiveCN102707247APlay a protective effectImprove job stabilityMagnetic measurementsManufacture of electrical instrumentsMagnetic phaseRadio frequency magnetron sputtering

A self-biased giant magneto-impedance sensor probe and a preparation method thereof belong to the technical field of information functional devices. The probe comprises an amorphous strap-shaped magnetic material and metal counter electrodes positioned at two ends of the surface of the amorphous strap-shaped magnetic material, wherein two vectolite films are respectively deposited on two sides of the amorphous strap-shaped magnetic material between the metal counter electrodes; and the upper and the lower vectolite films have consistent hard magnetic phase characteristic in the length direction of the amorphous strap-shaped magnetic material. During preparation of the probe, the key process is that the vectolite films are deposited on the amorphous strap-shaped magnetic material through the radio-frequency magnetron sputtering technology and are magnetized through a magnetizer to present hard magnetic phase. The self-biased giant magneto-impedance sensor probe provided by the invention has the characteristics of small size, easiness in integration and no extra power consumption; the product is simple to prepare, the process is controllable and the stability is high; and a wider linear working space can be obtained and the sensitivity is greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

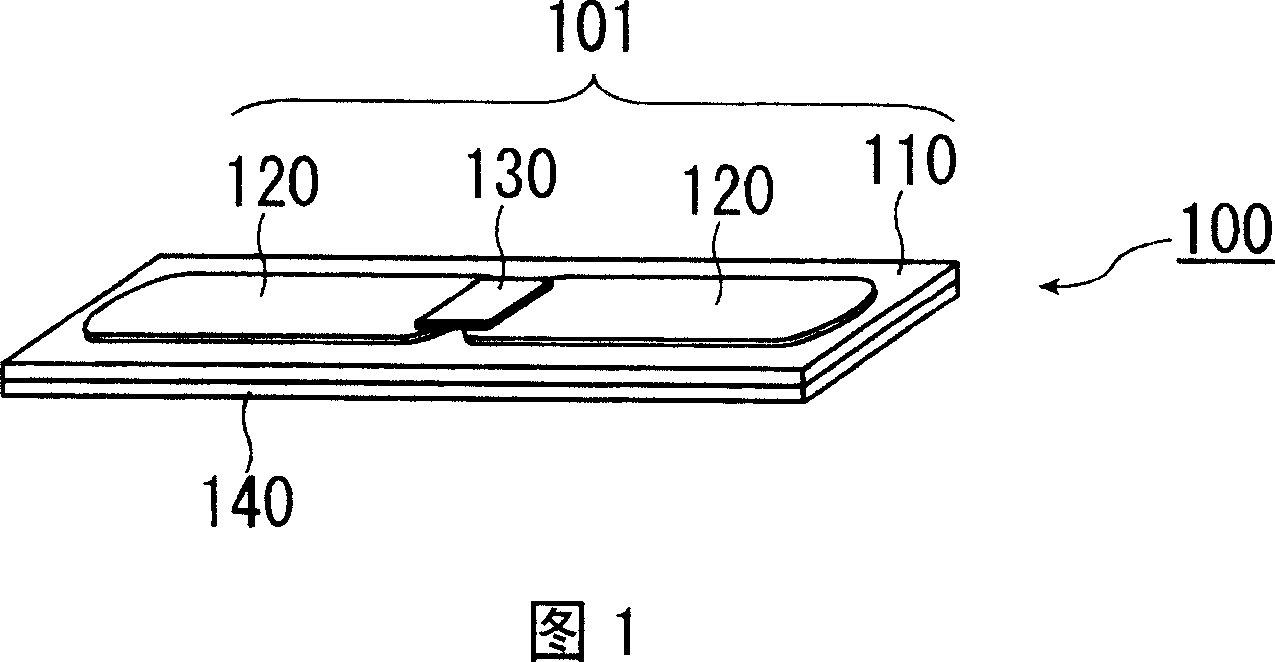

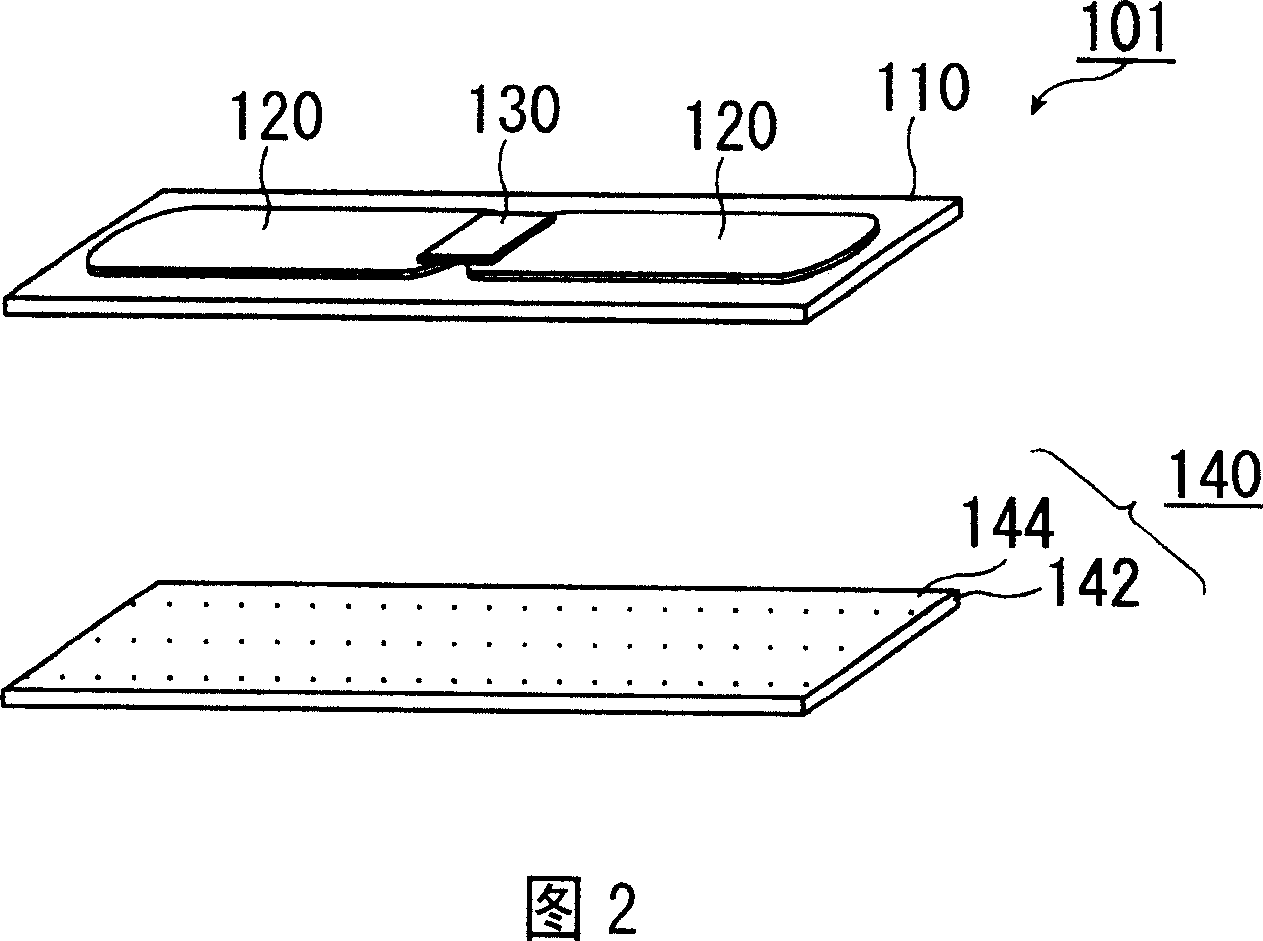

Wireless pressure sensor and manufacturing method thereof

PendingCN109738094AHigh sensitivityAvoid interferenceTransmission systemsForce measurementConductive materialsEngineering

The invention discloses a wireless pressure sensor and a manufacturing method thereof. The wireless pressure sensor comprises a fabric partition; one side of the fabric partition is provided with a plurality of passive antennas arranged in an array, and the other side of the fabric partition is provided with a plurality of ferrite films; and the ferrite films are arranged in one-to-one correspondence with the passive antennas, and the positions are aligned with each other. The invention can centralizedly absorb the magnetic energy from the passive antennas through the ferrite films, thereby effectively improving the sensitivity of the device and avoiding interference of conductive materials.

Owner:SUZHOU BIGVISION MEDICAL TECH CO LTD

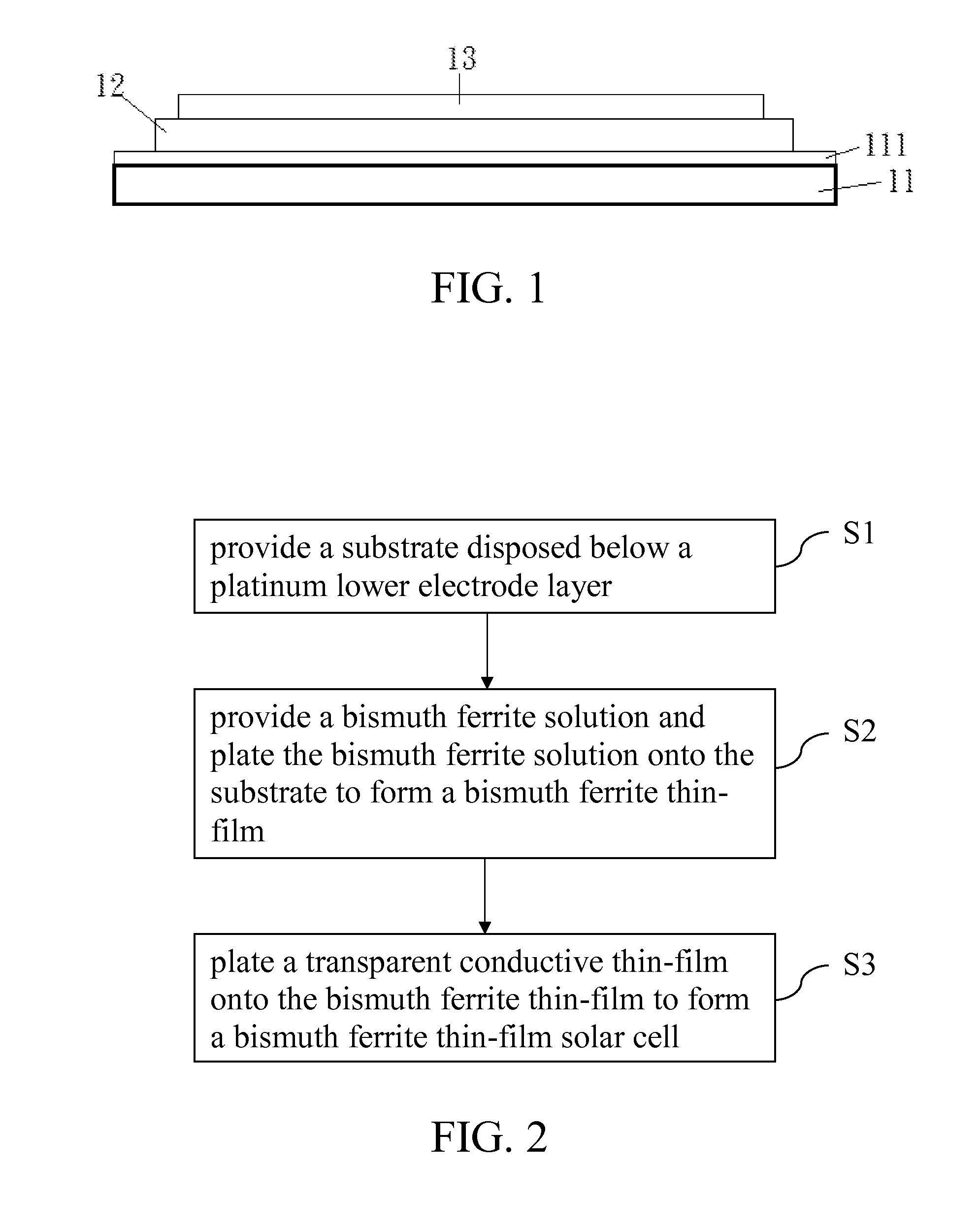

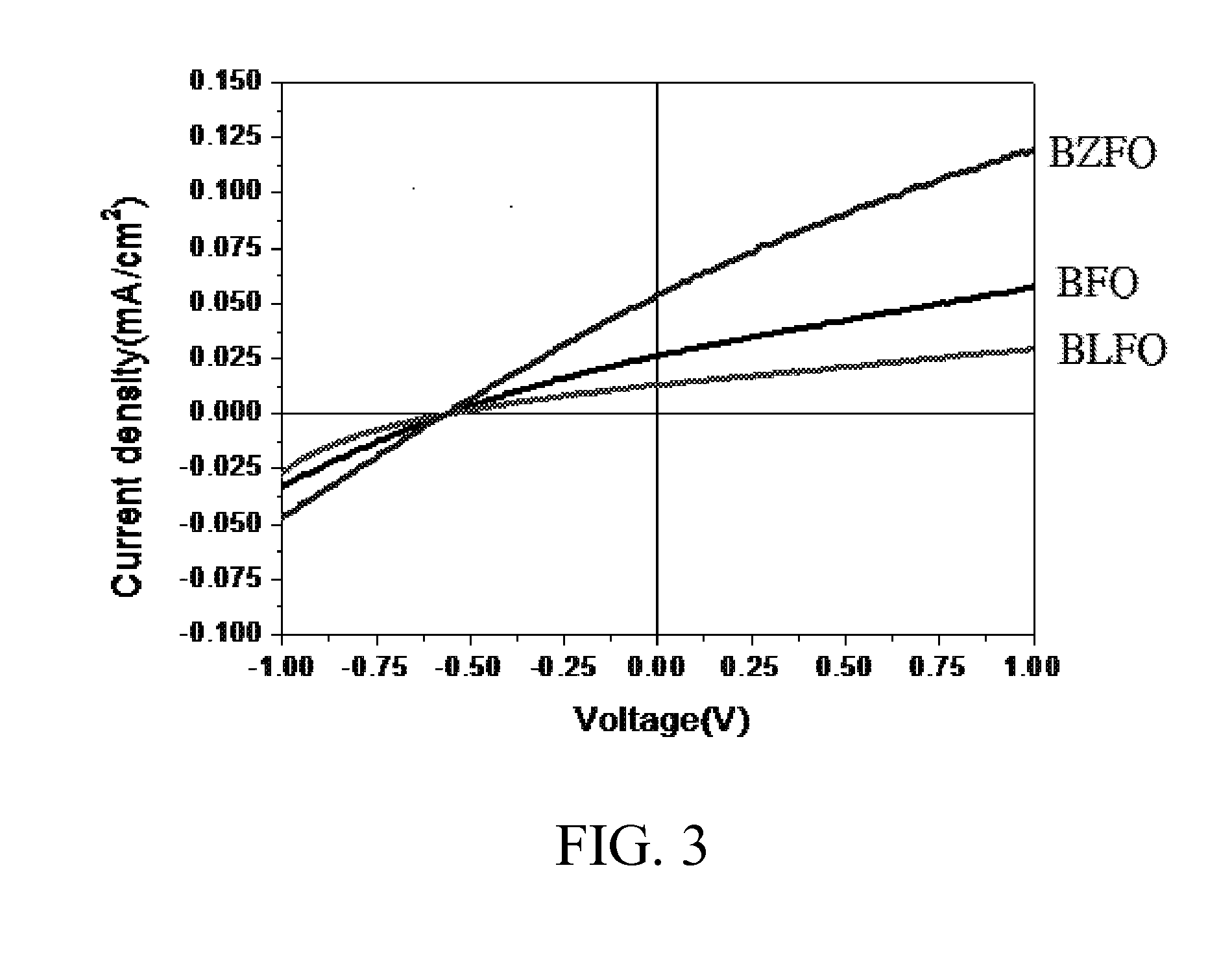

Bismuth ferrite thin-film solar cell and method of manufacturing the same

ActiveUS20160181451A1Reduce in quantityIncrease of closed-circuit current densityVacuum evaporation coatingSputtering coatingFerrite thin filmsZinc

A bismuth ferrite thin-film solar cell and a method of manufacturing the same control the quantity of Fe2+ defected in the bismuth ferrite thin-film by doping with zinc. Reduction of the quantity of Fe2+ defects in the bismuth ferrite thin-film is conducive to the increase of closed-circuit current density and enhancement of photoelectric conversion efficiency.

Owner:NAT CHUNG SHAN INST SCI & TECH

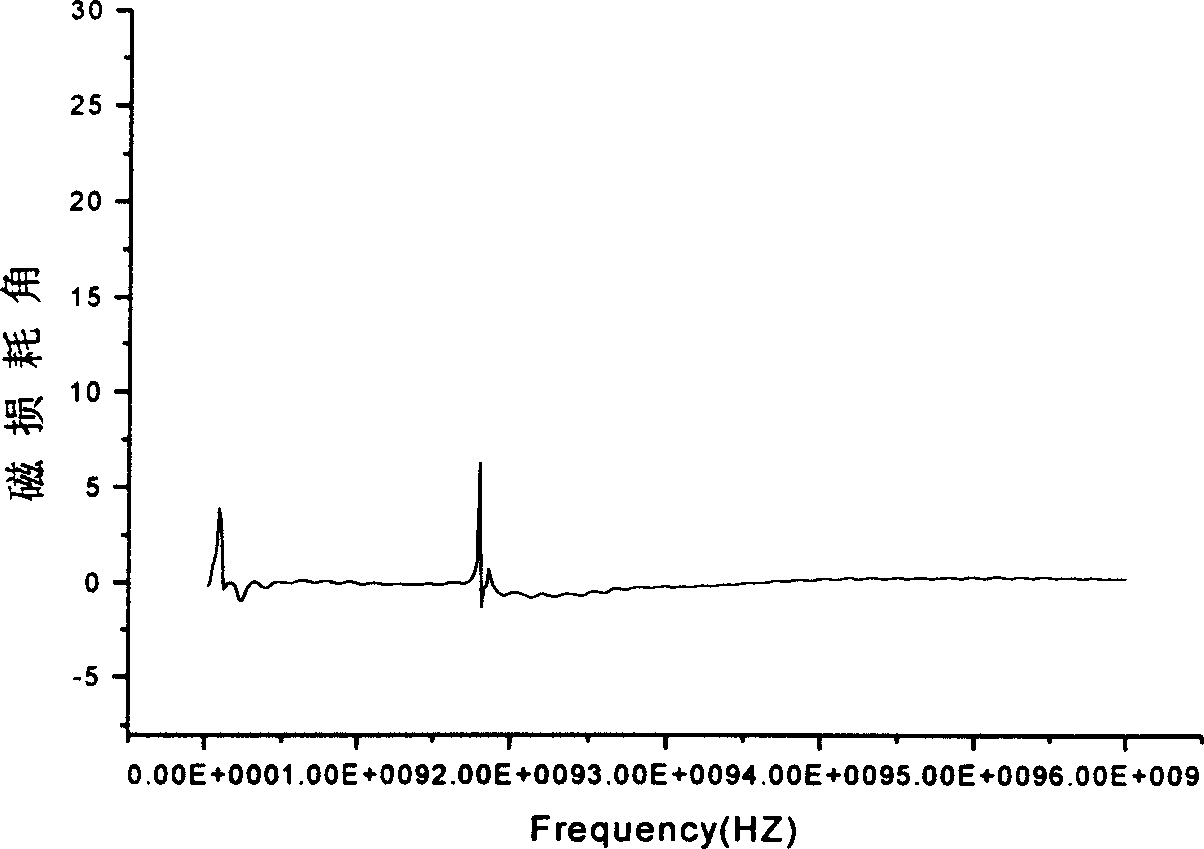

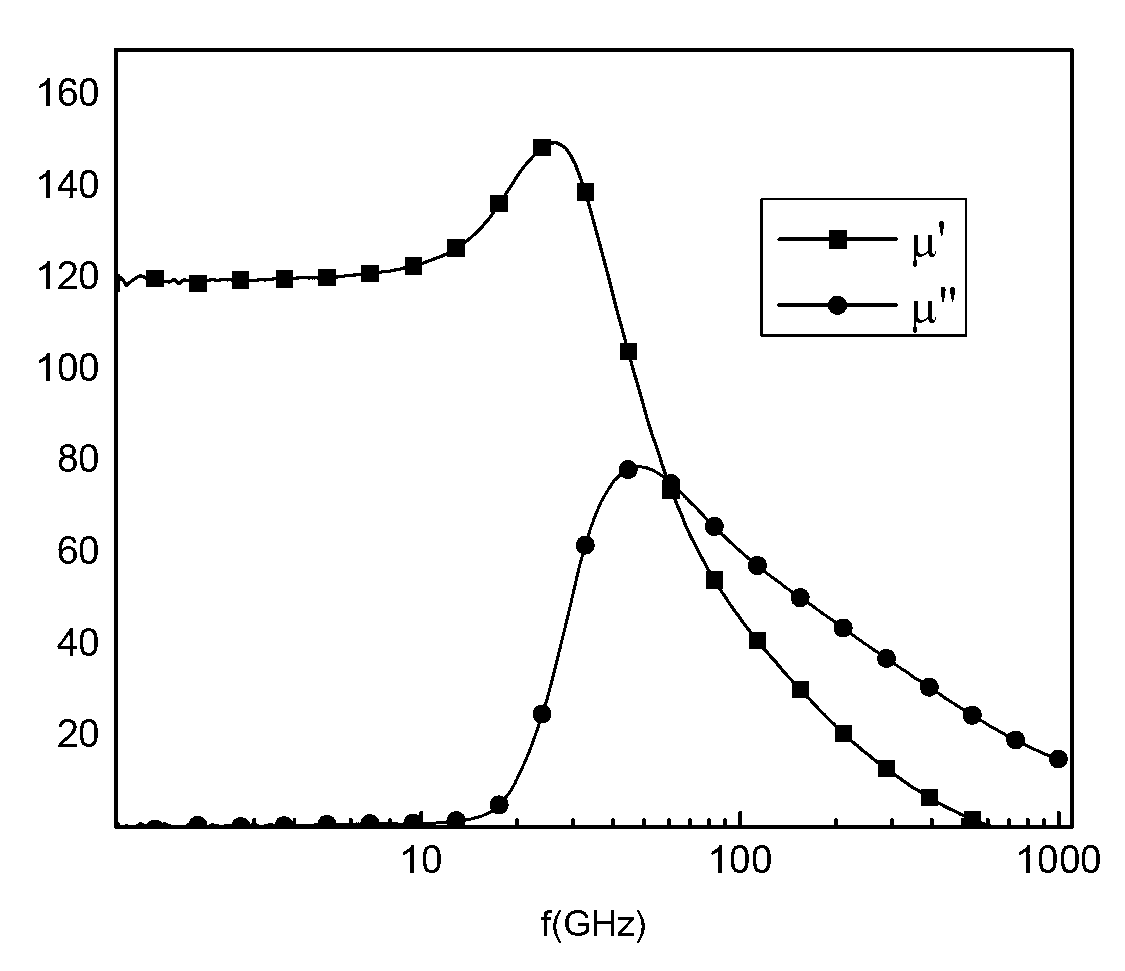

High conductivity and low loss ferrite material, ferrite thin film and preparation method thereof

A high conductivity and low loss ferrite material, a ferrite thin film and a preparation method of the ferrite material relate to electronic materials. The ferrite material comprises main components and doping components, and is characterized in that the main components and the doping components are taken in terms of oxides; and the main components comprise the following main materials at mole percentage: 50 mol% of Fe2O3, 20 mol% to 30 mol% of NiO, 15mol% to 25mol% of ZnO, and 5mol% of CuO; and the doping components comprise the following materials by weight percentage: 0 to 1.2 wt% of CoO, and 0 to 1.2 wt% of V2O5. The preparation method provided by the invention is an ordinary oxide method, is simple in operation and process flow, and is pollution-free. The prepared ferrite material is high in magnetic permeability and is also small in loss, wherein for the 13.56M, when mu' is about 100, mu'' is less than 2. The obtained ferrite film is adjustable in thickness and size, is smooth and flat in surface and is light in density.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

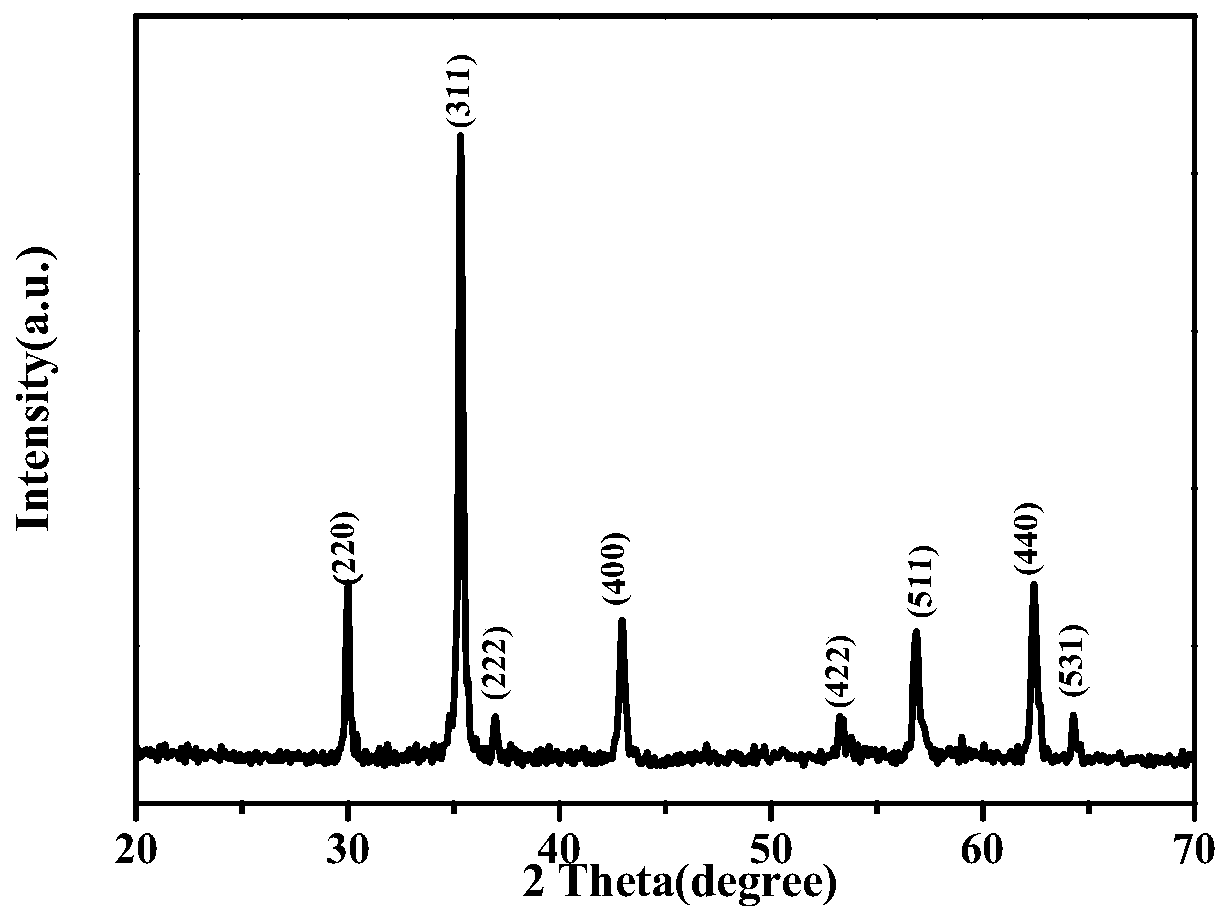

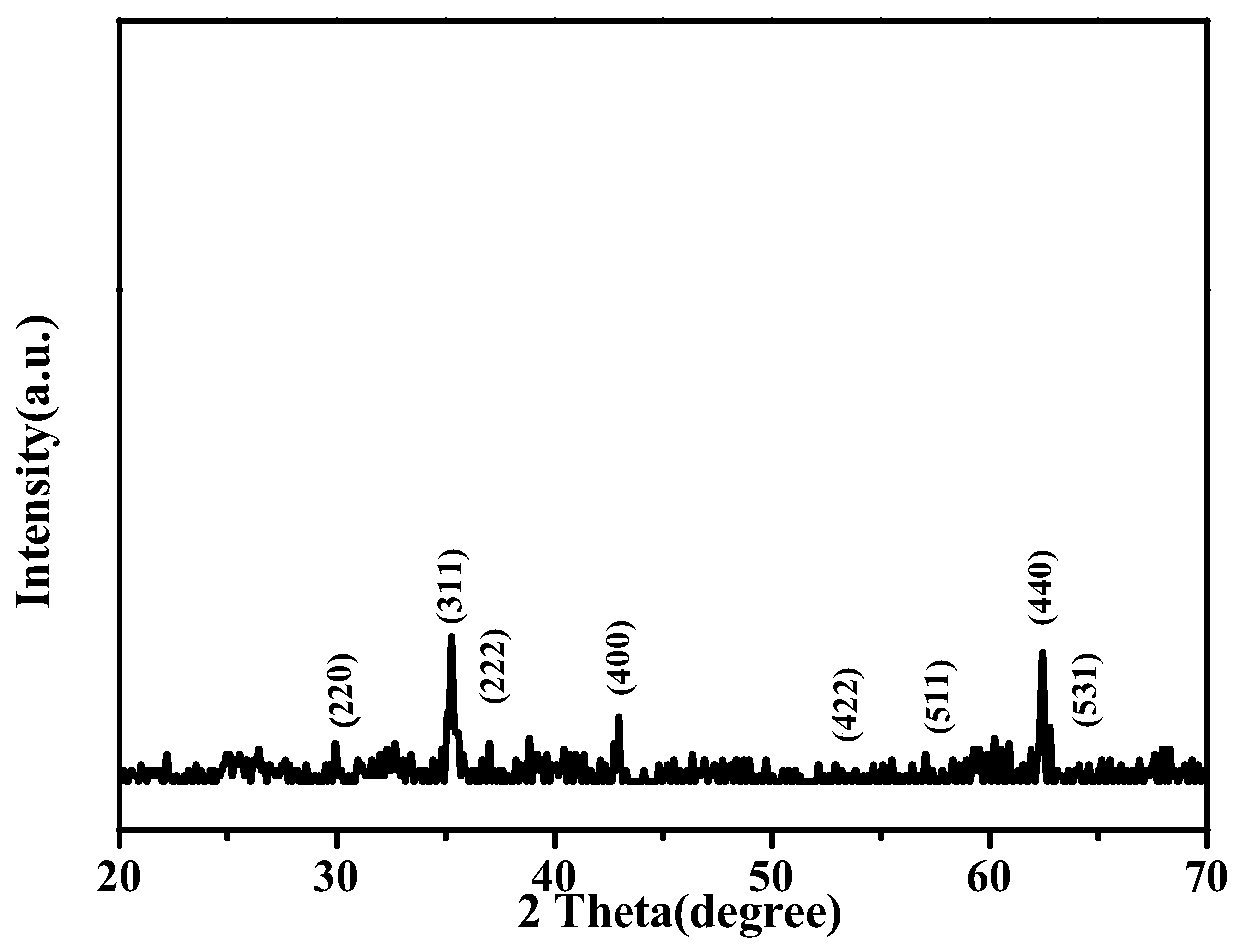

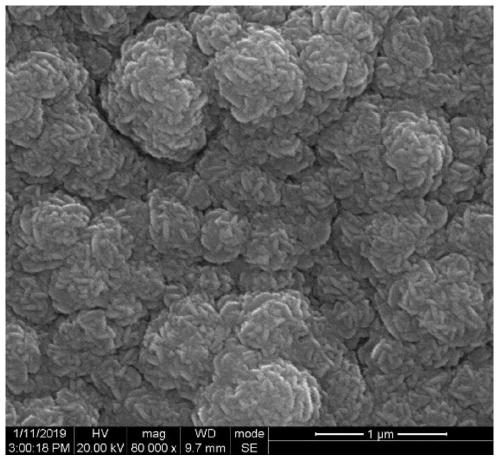

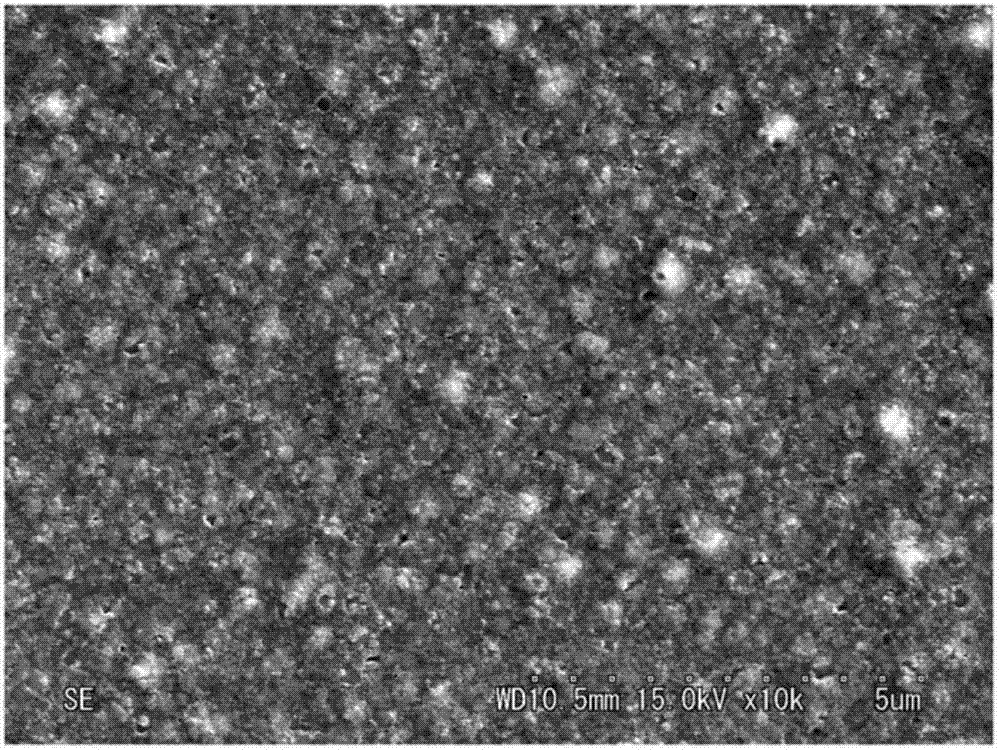

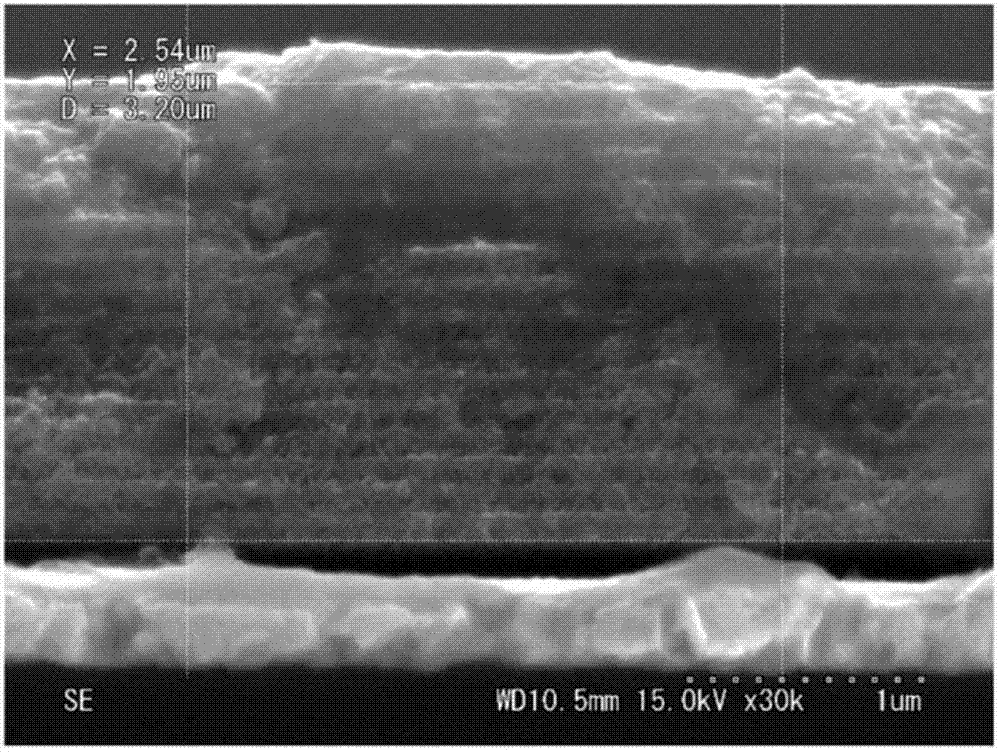

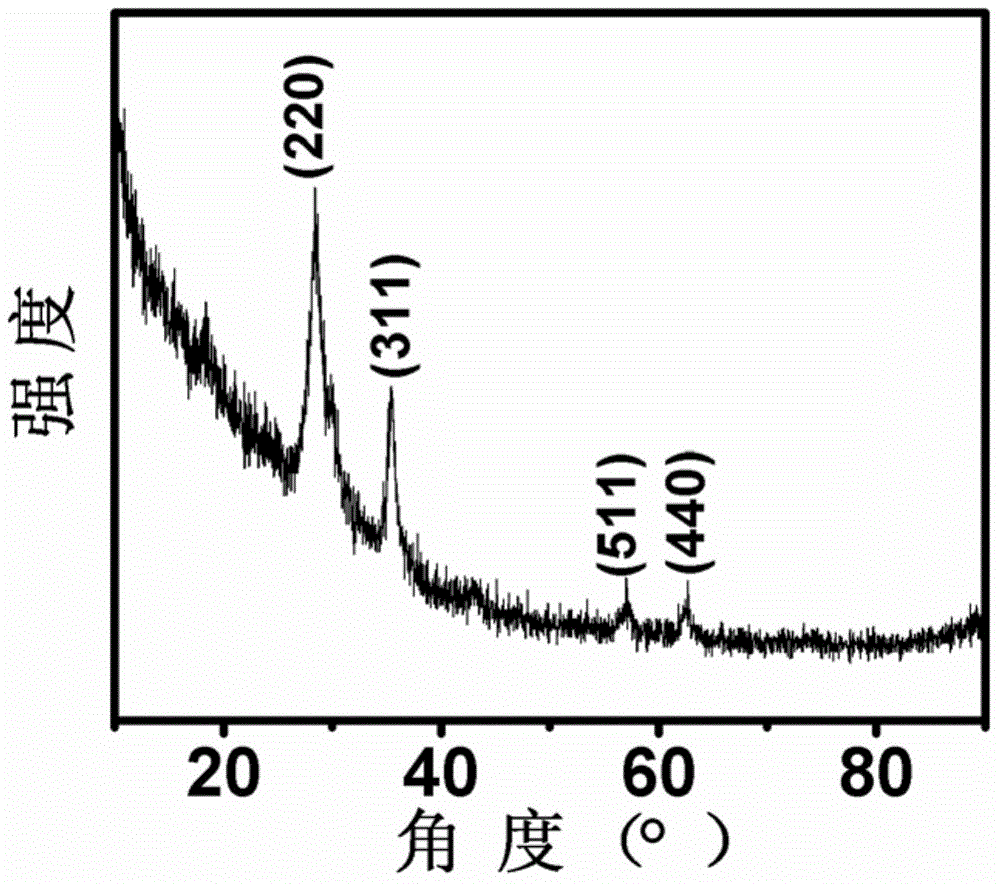

Preparation method for NiZn ferrite film

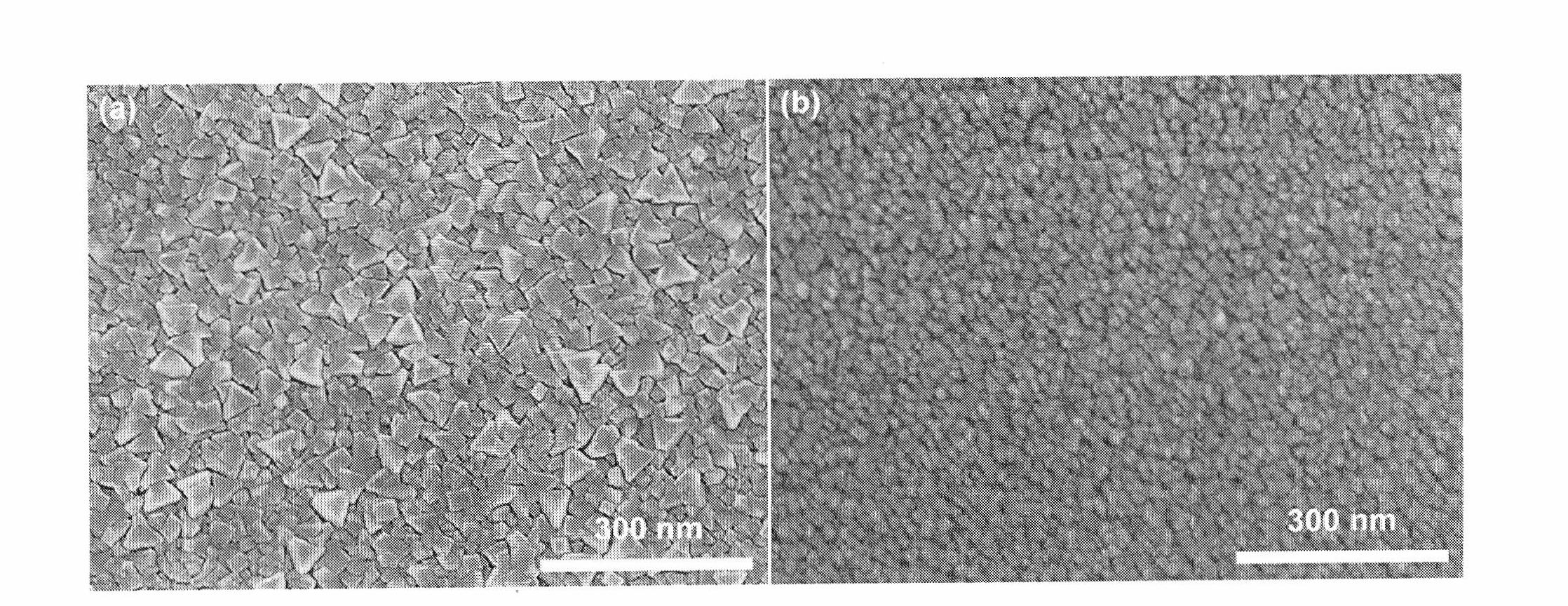

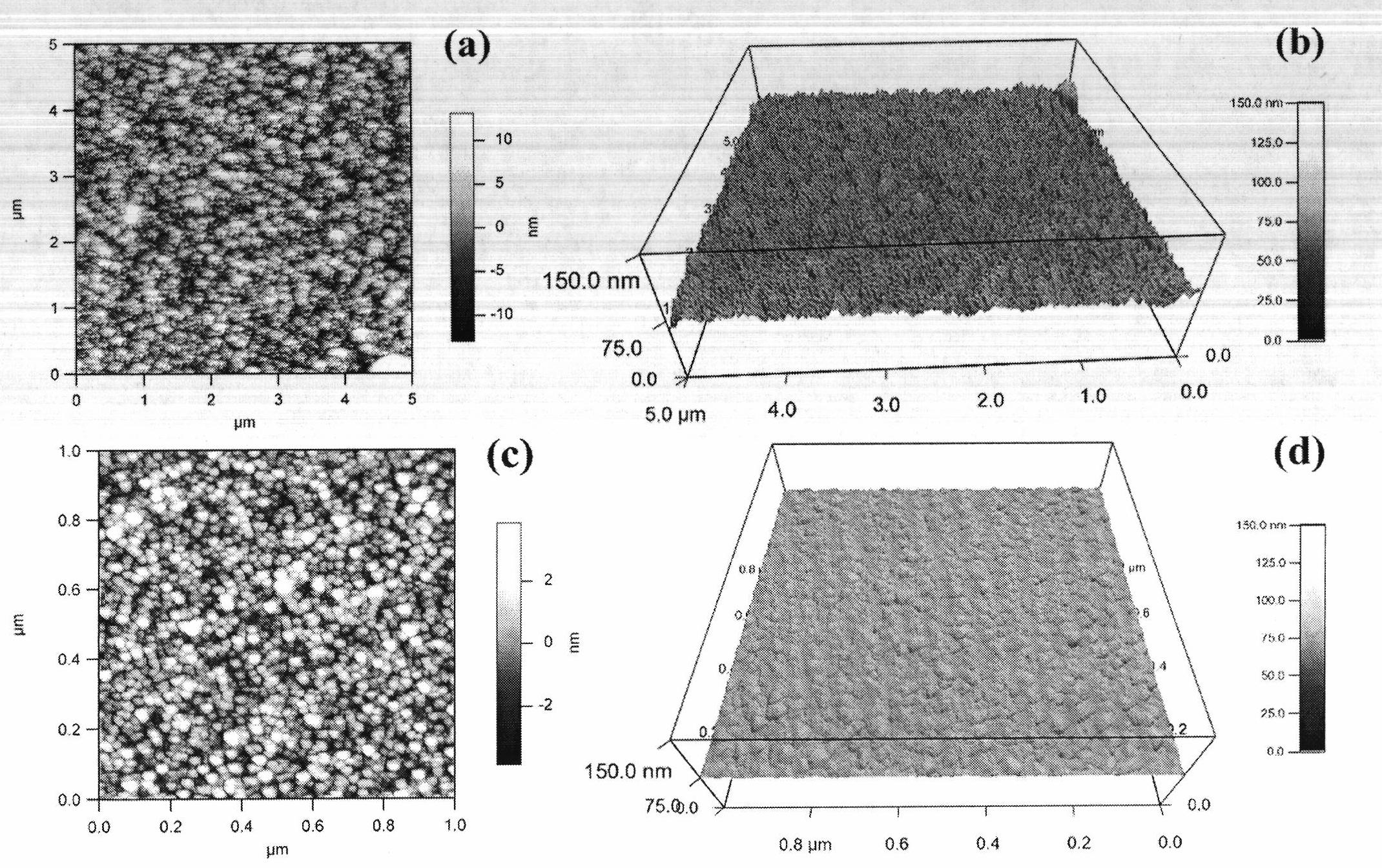

ActiveCN109852929AHigh crystallinityVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringMagnetization

The invention discloses a preparation method for a NiZn ferrite film, and belongs to the technical field of film preparation. According to the method, firstly, a rotary spraying method is adopted to prepare a NiZn ferrite seed layer on a glass substrate, and then a radio frequency magnetic controlled sputtering method is adopted to deposit the NiZn ferrite film on the seed layer. The NiZn ferritefilm prepared by the preparation method does not need the follow-up high temperature annealing processing, the problem of the incompatibility of the ferrite film with a semiconductor process in the follow-up device application is solved, meanwhile, through the inducing of the NiZn seed layer prepared by the rotary spraying method, at the low temperature condition, the NiZn film prepared by the radio frequency magnetic controlled sputtering method has better crystallization properties, and the saturated magnetization strength 4piMs (no less than 5900 Gs), the starting magnetic conductivity of mui (no less than 200) and the cut-off frequency fr ( no less than 1.85 GHz) are significantly increased.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

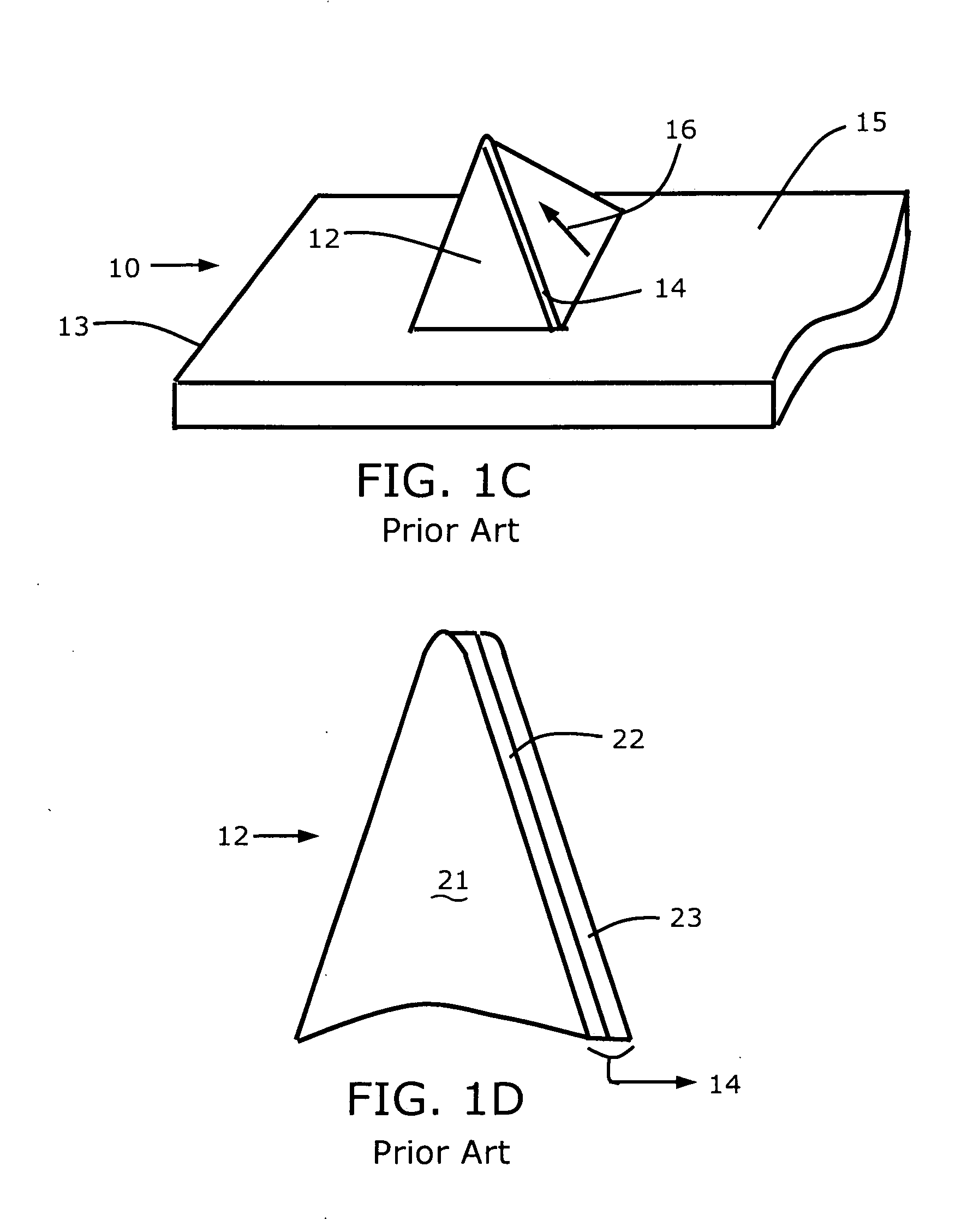

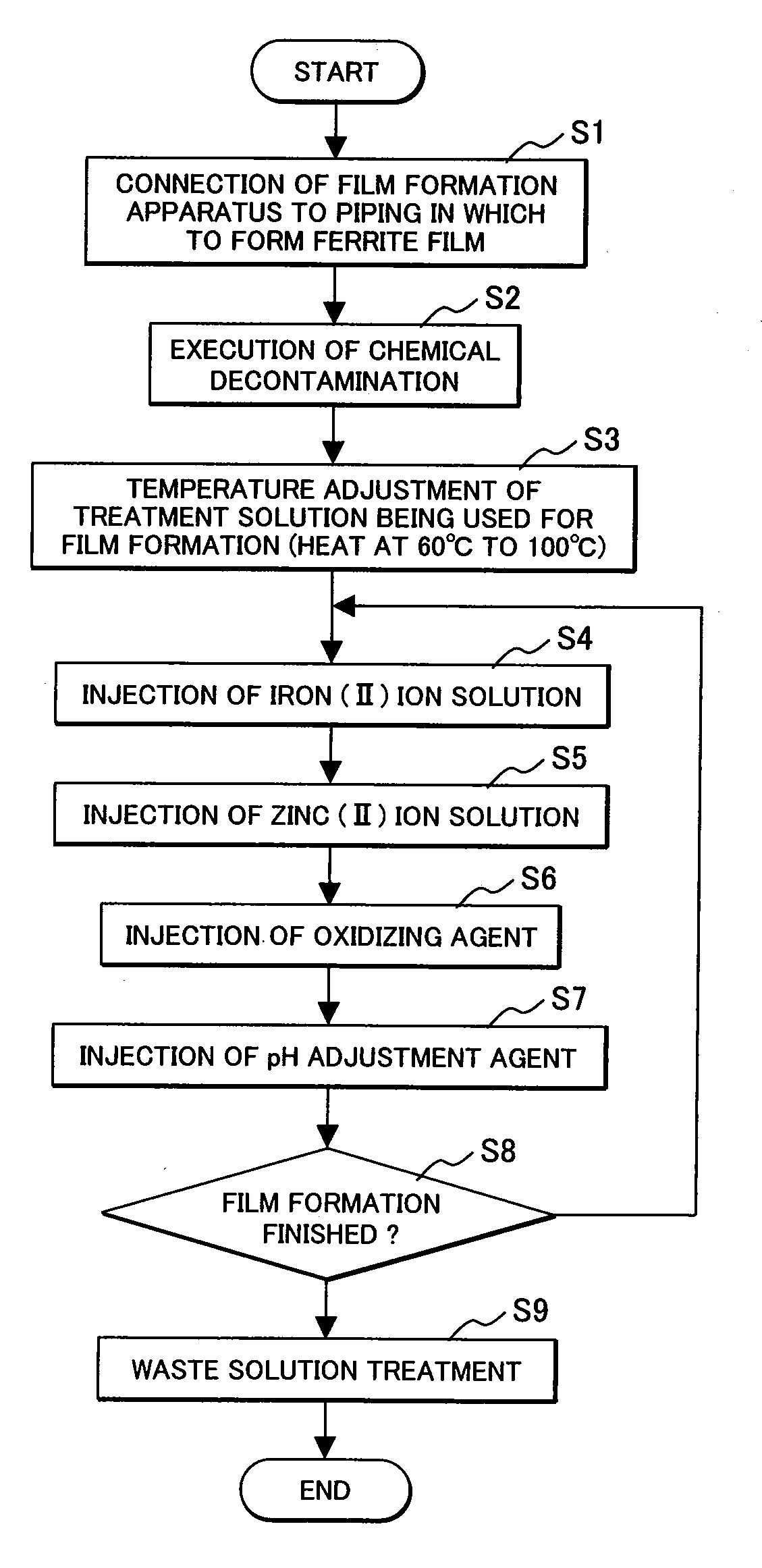

Suppression method of radionuclide deposition on reactor component of nuclear power plant and ferrite film formation apparatus

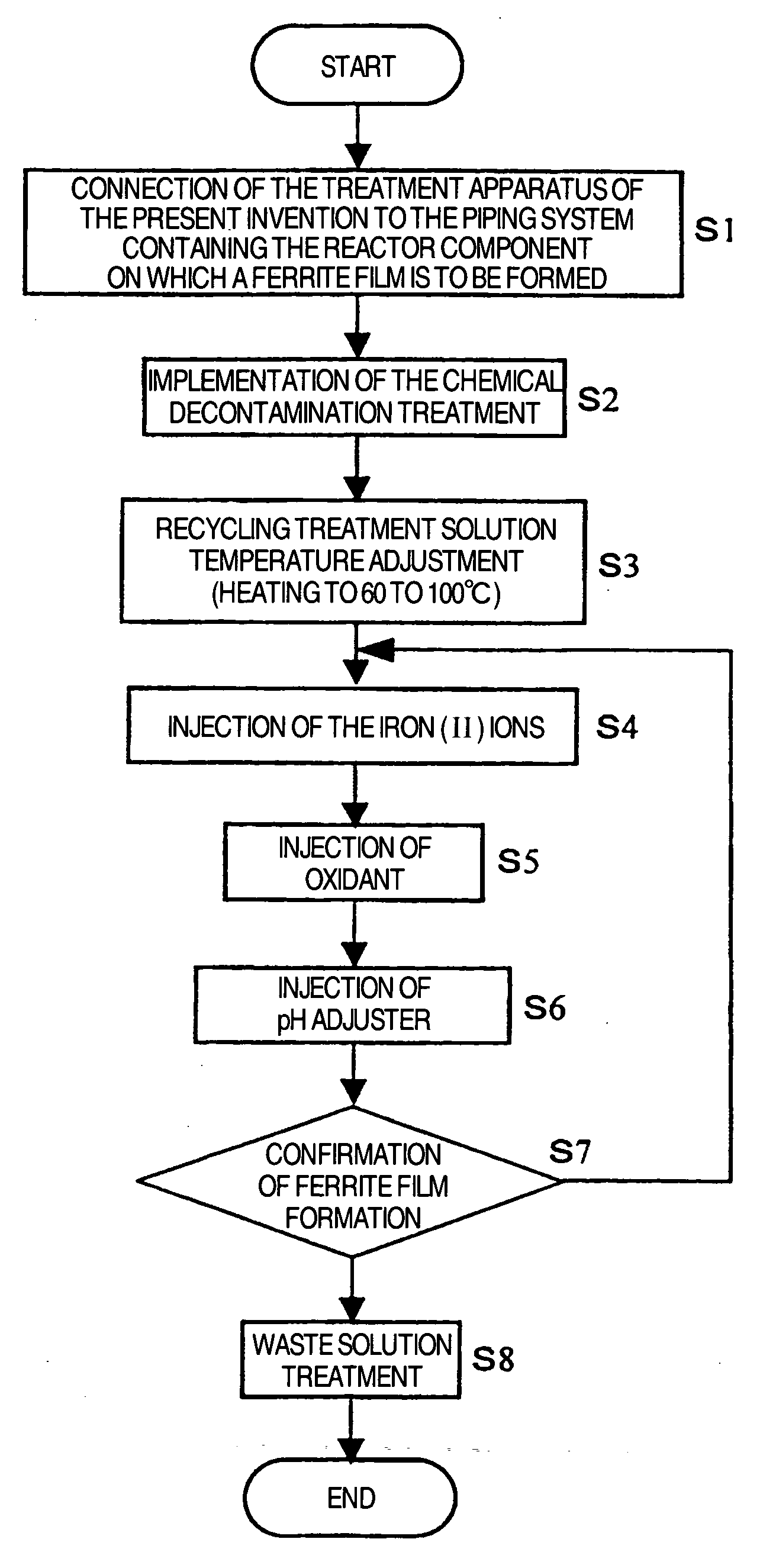

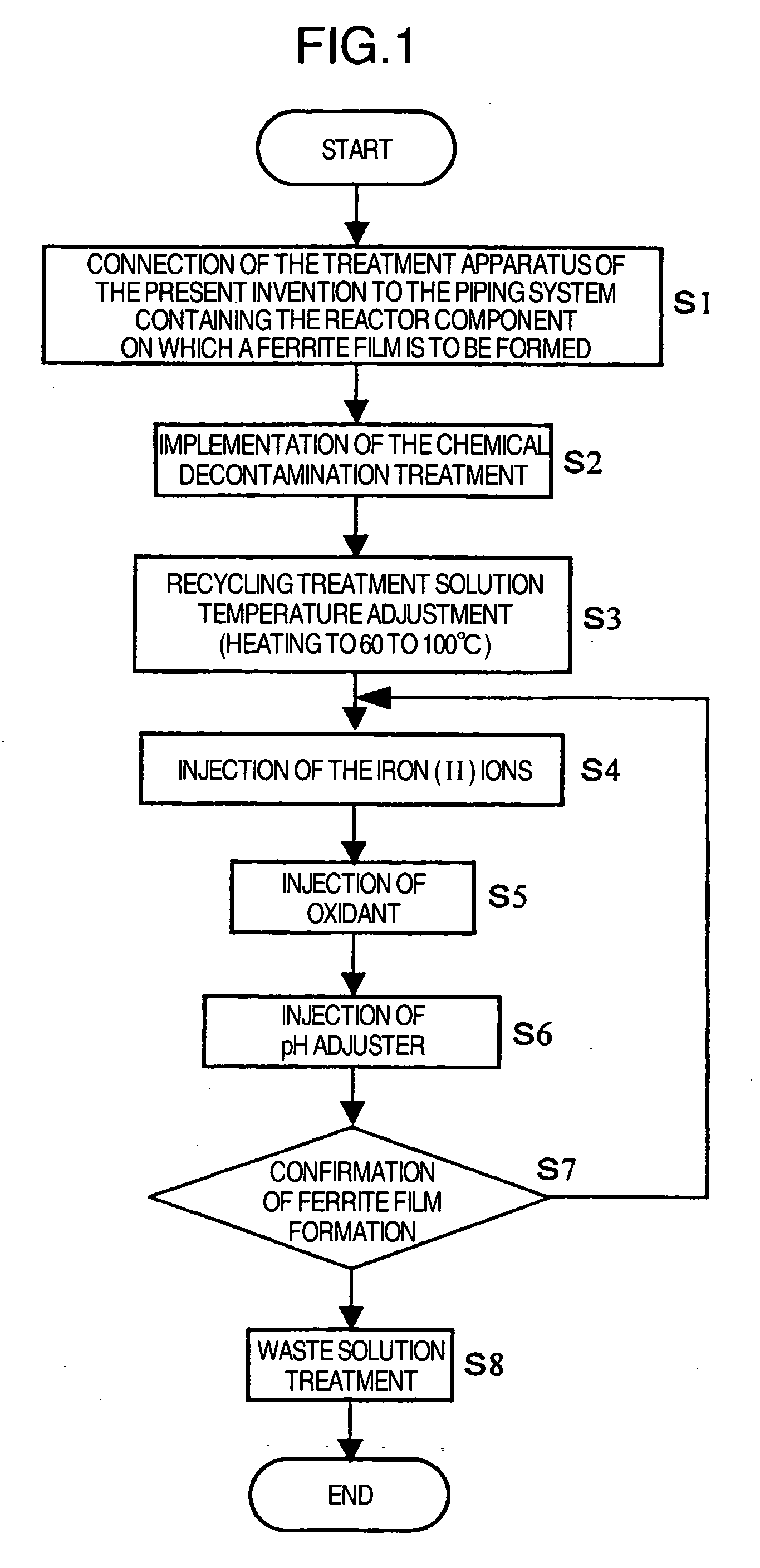

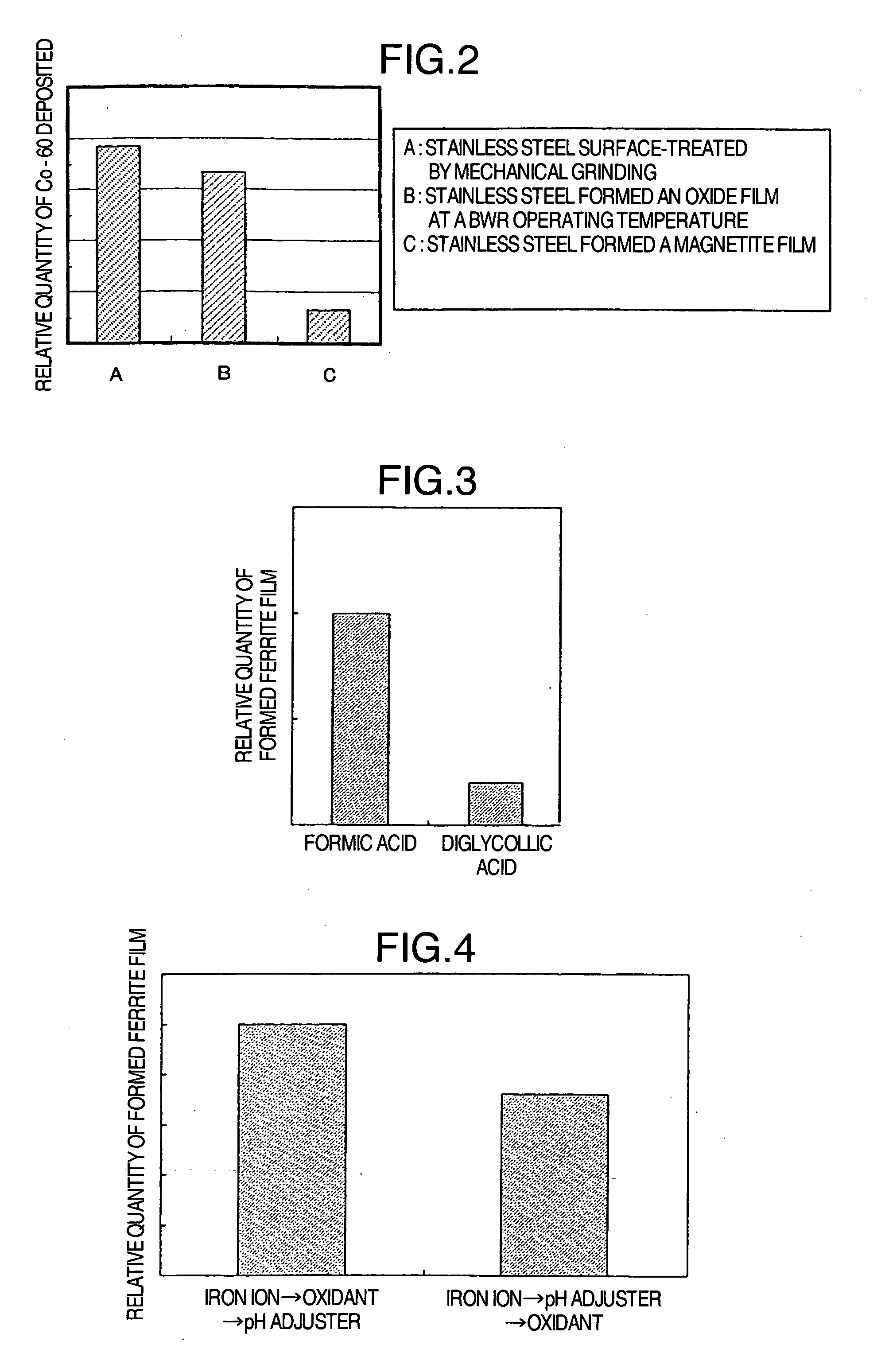

ActiveUS20070127619A1Efficiently suppress radionuclide depositionNuclear energy generationSolid state diffusion coatingNuclear plantNuclear engineering

It is an object of the present invention to efficiently suppress radionuclide deposition on a reactor component of nuclear power plant. Radionuclide deposition on the surface of a metallic reactor component of nuclear power plant is suppressed by forming a ferrite film on the component, wherein the film is formed, after decontamination for removing radionuclides contaminants from the component surface is completed and before the plant is started up, by contacting a treatment solution which mixes a first agent containing the iron (II) ions, a second agent for oxidizing the iron (II) ions into the iron (III) ions and a third agent for adjusting pH level of a solution to 5.5 to 9.0 in this order with the reactor component surface.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

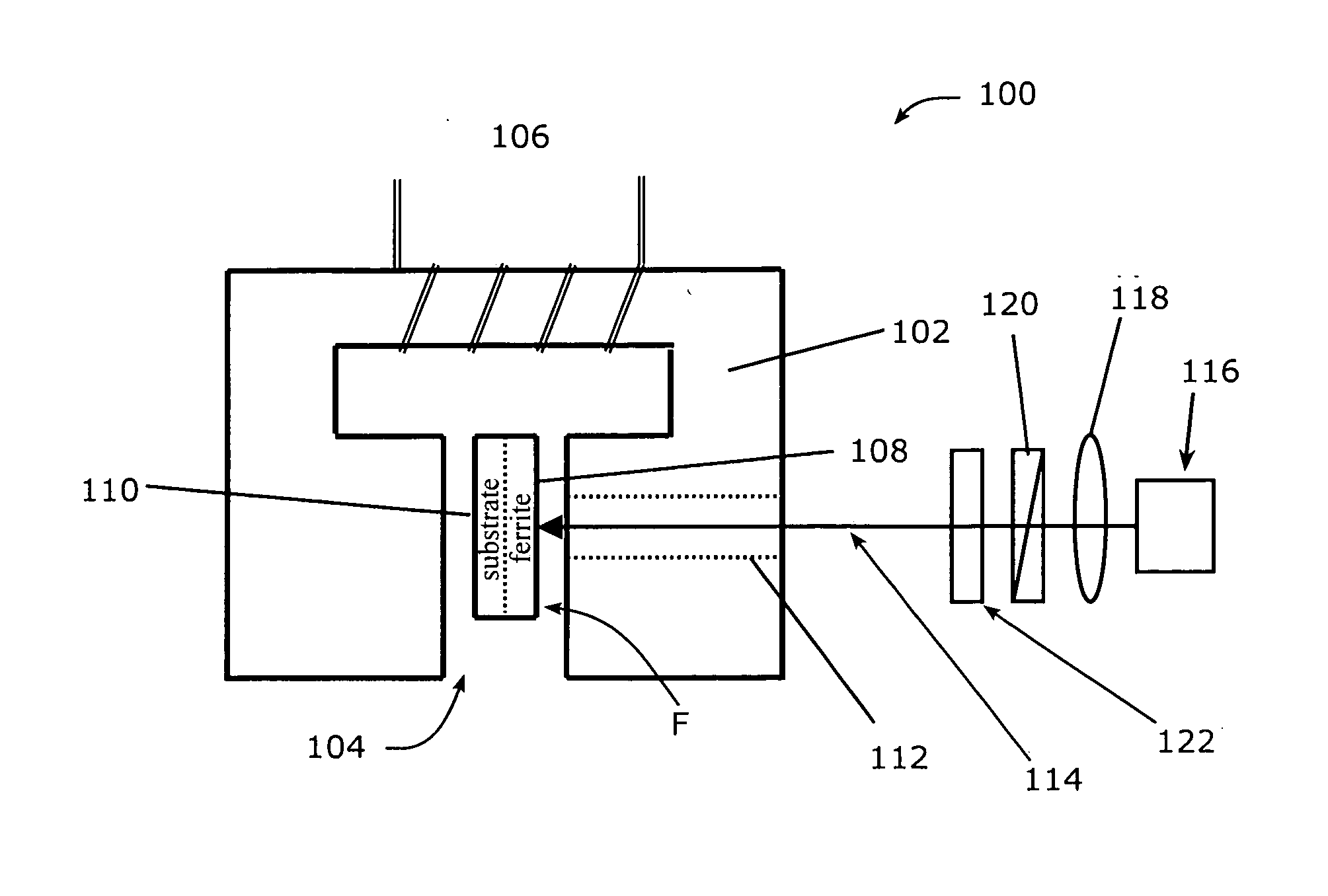

Magneto-optical device with an optically induced magnetization

ActiveUS20120207002A1Different record carrier formsRecord information storageMagnetic memoryMagnetization

A magneto-optical device (MOD) with optically induced magnetization for use in magnetic field sensors as a magnetic element pinning a magnetization in a preferred direction of a ferromagnetic layer as well as a magnetic memory cell for magneto-optical recording. The MOD comprises the Mg—Mg—Co ferrite film deposited on a magnesium oxide (MgO) substrate. The ferrite film is illuminated at room temperature with a circularly polarized light (CPL) in a static magnetic H-field (about of 3 kOe) normal to the illuminated ferrite film surface. At certain (“writing”) combinations of H, sigma (CPL helicity), the long-lived optically induced magnetization with a unidirectional anisotropy, stable to a conventional demagnetization occurs. For readout of information, conventional magnetoresistive sensors and MFM can be used. To erase information, the ferrite film should be illuminated with two field-light combinations, other than “writing”, or annealed at temperature higher than 530 degrees C.

Owner:KATSNELSON ESFIR Z +1

Method for suppressing deposit of radionuclide onto structure member composing nuclear power plant and ferrite film formation apparatus

InactiveUS20090316852A1Avoid depositionImprove stabilityNuclear energy generationNuclear monitoringNuclear powerFerrite thin films

A method for suppressing deposit of radionuclide onto structure member composing a nuclear power plant, comprising the steps of:bringing film formation liquid including iron (II) ions and either of zinc (II) ions and nickel (II) ions into contact with a surface of the structure member; andforming either of a ferrite film including the zinc and a ferrite film including the nickel on the surface of the structure member.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

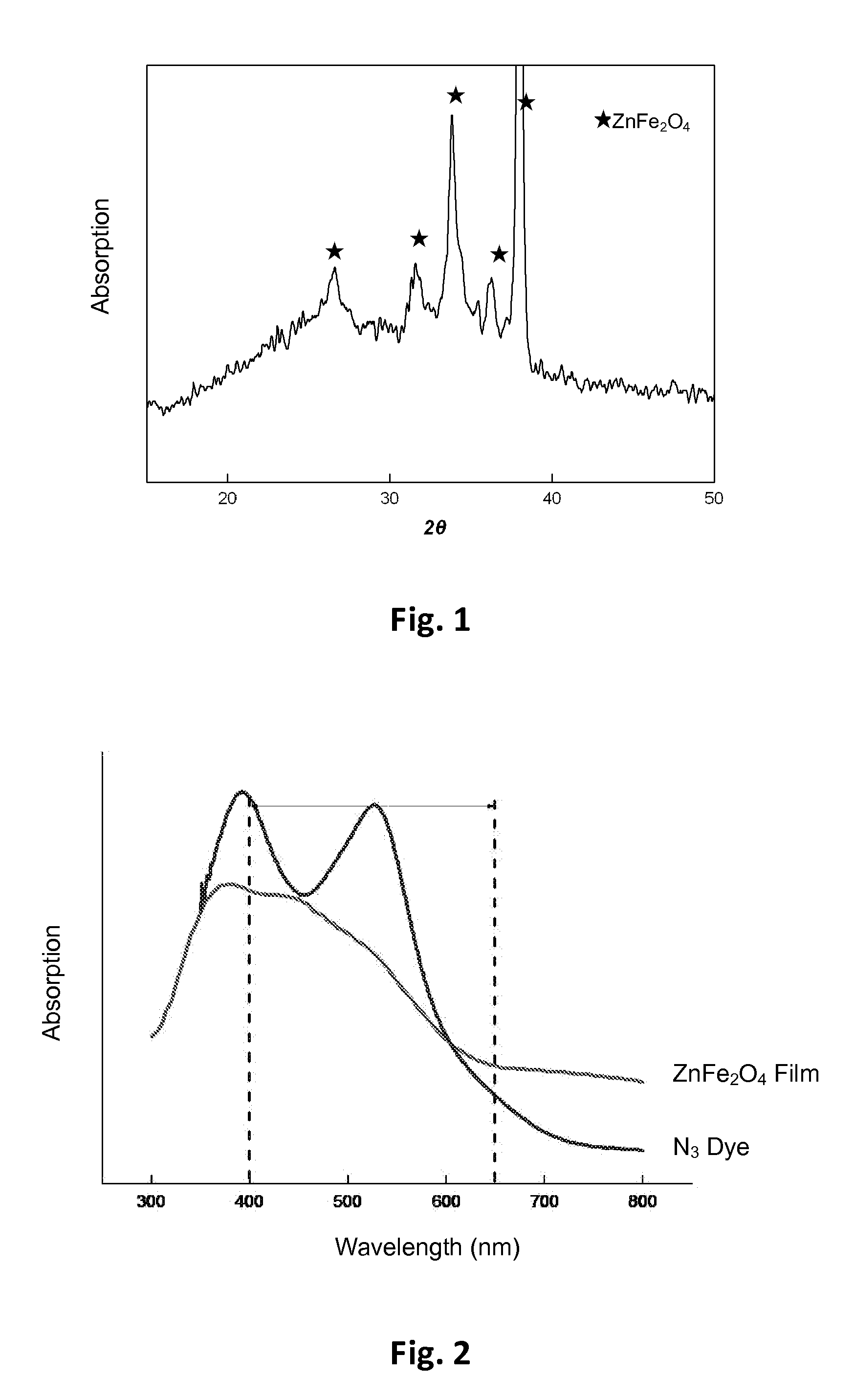

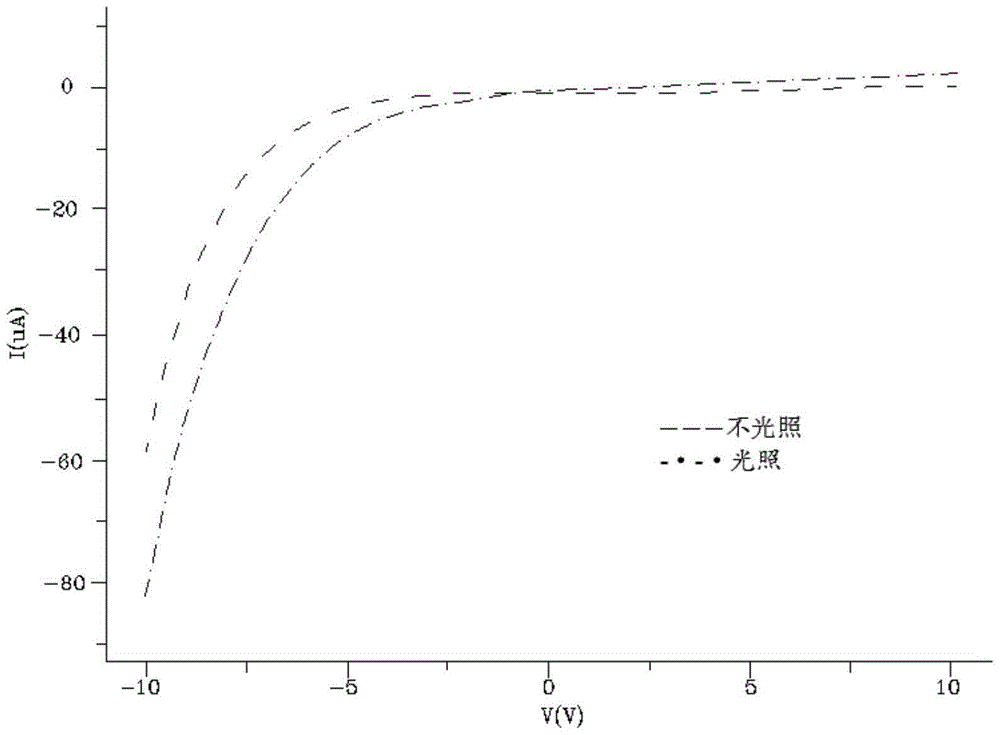

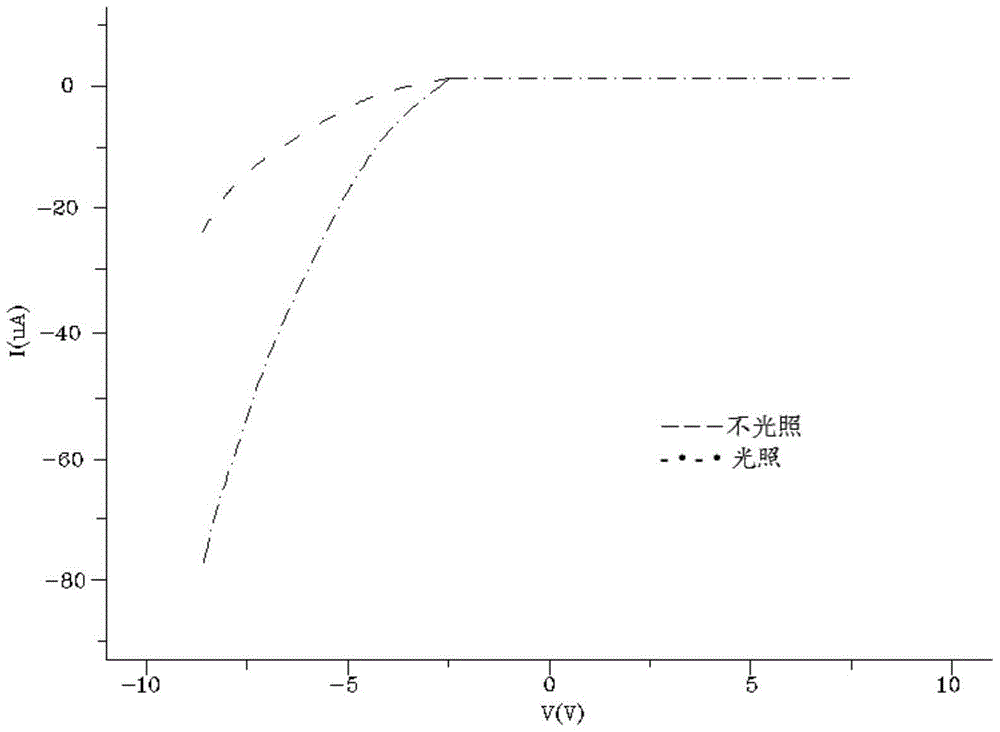

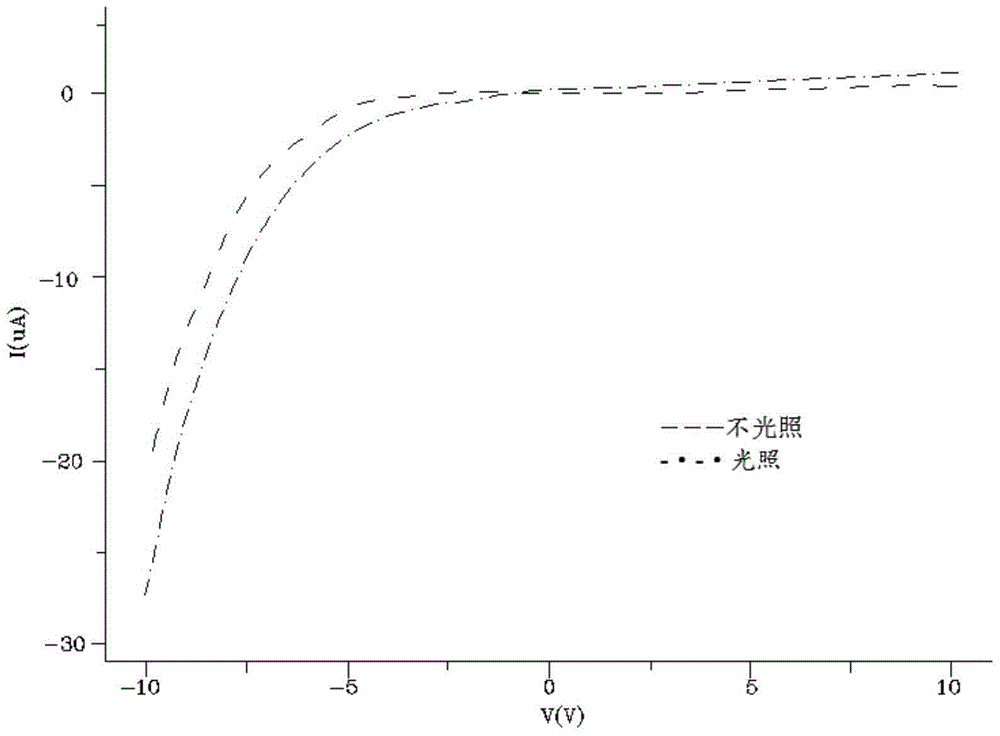

Zinc Ferrite Thin Film, Method for Manufacturing the Same and Application Thereof

ActiveUS20100154884A1Less complicated apparatusLow annealing temperatureMirrorsDuplicating/marking methodsMetallurgyZinc nitrate

Electrochemical methods for manufacturing a zinc ferrite (ZnFe2O4) thin film include preparing an electrodeposition solution and forming the zinc ferrite thin film on a conductive substrate under suitable conditions. The electrodeposition solution includes about 10−2 M to about 10−1 M zinc nitrate aqueous solution and about 10−3 M to about 10−2 M ferric nitrate aqueous solution.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

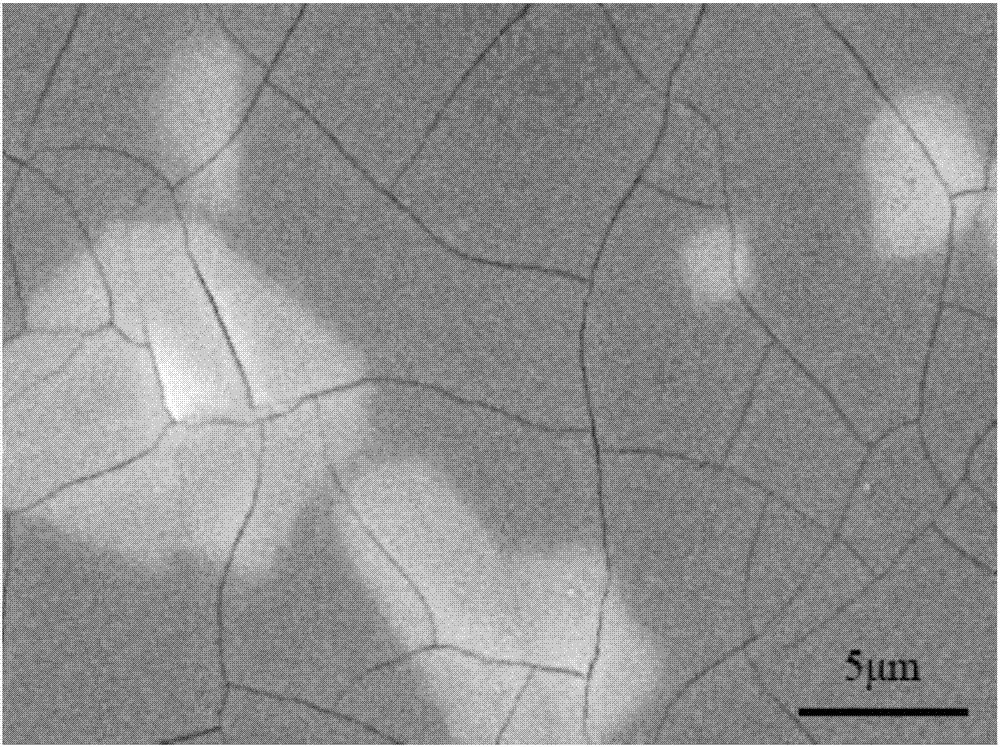

Method for preparing submicron order crack-free ferrite film through step-by-step annealing technology

InactiveCN107022749AReduce residual stressIncreasing the thicknessVacuum evaporation coatingSputtering coatingMicrowaveCrack free

The invention discloses a method for preparing a submicron order crack-free ferrite film through a step-by-step annealing technology. A microwave ferrite material is related to the method, the vacuum sputtering deposition technology is utilized, and the ferrite film is deposited on a single-crystal substrate. Due to the fact that the heat expansion coefficients and the lattice constants of the single-chip substrate and the ferrite film are not matched, residual stress can be generated by the film in the crystallizing process, and when the residual stress exceeds a certain value, the cracking phenomenon of the film can happen. However, the residual stress can be effectively released through the step-by-step annealing method, film cracks are prevented, and the thickness of the crack-free film is finally increased. By means of the method, the preparing process is simple, the production cost is low, the prepared film has high compactness, and cracking is not likely to happen.

Owner:HANGZHOU DIANZI UNIV

Method of forming ferrite thin film and ferrite thin film obtained using the same

InactiveCN103360043AAvoid tensile stressExcellent magnetic propertiesChemical vapor deposition applicationLiquid applicationHeat resistanceOptoelectronics

[Task] To provide a method of forming a ferrite thin film in which it is possible to manufacture a thick film having a film thickness of 1 µm or more using a sol-gel method without causing cracking. [Means for Resolution] A method of forming a ferrite thin film by carrying out a process for forming a coated film by coating a ferrite thin film-forming composition on a heat-resistant substrate and a process for calcining the coated film once or a plurality of times so that the thickness of the calcined film on the substrate becomes a desired thickness, and firing the calcined film formed on the substrate, in which the conditions for firing the calcined film formed on the substrate are under the atmosphere or an oxygen gas or inert gas atmosphere, a temperature-rise rate of 1°C / minute to 50°C / minute, a holding temperature of 500°C to 800°C, and a holding time of 30 minutes to 120 minutes.

Owner:MITSUBISHI MATERIALS CORP

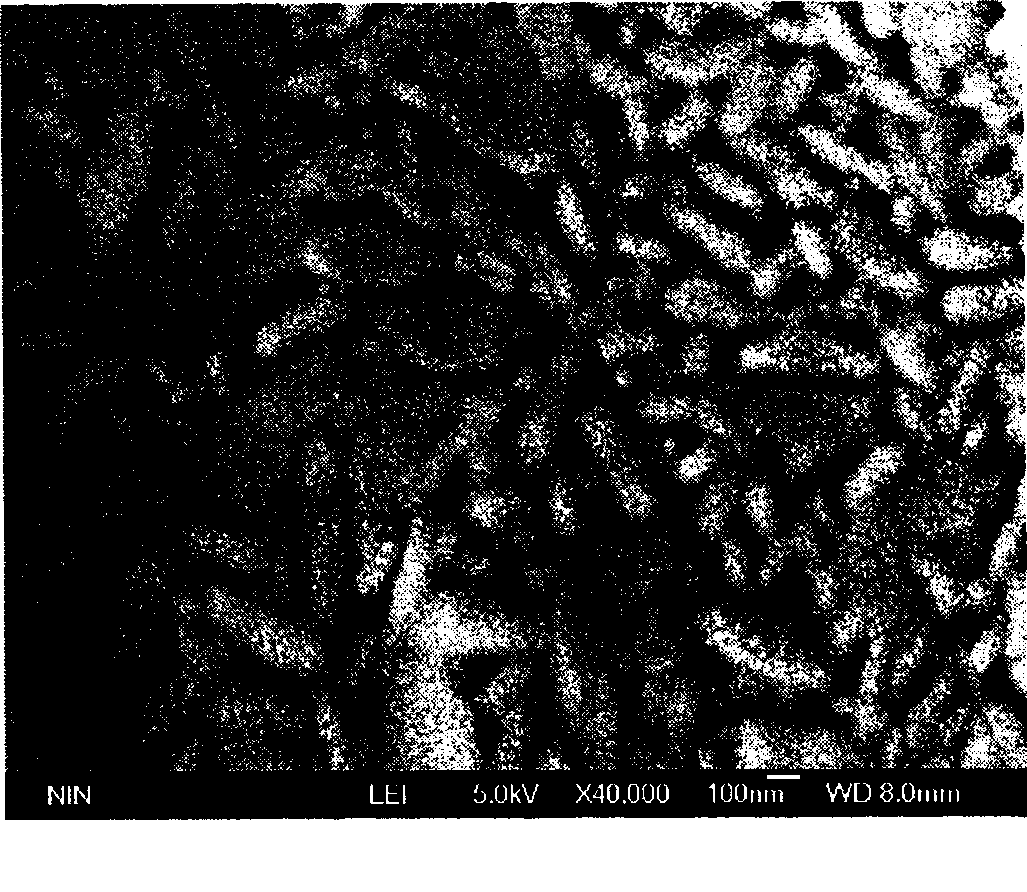

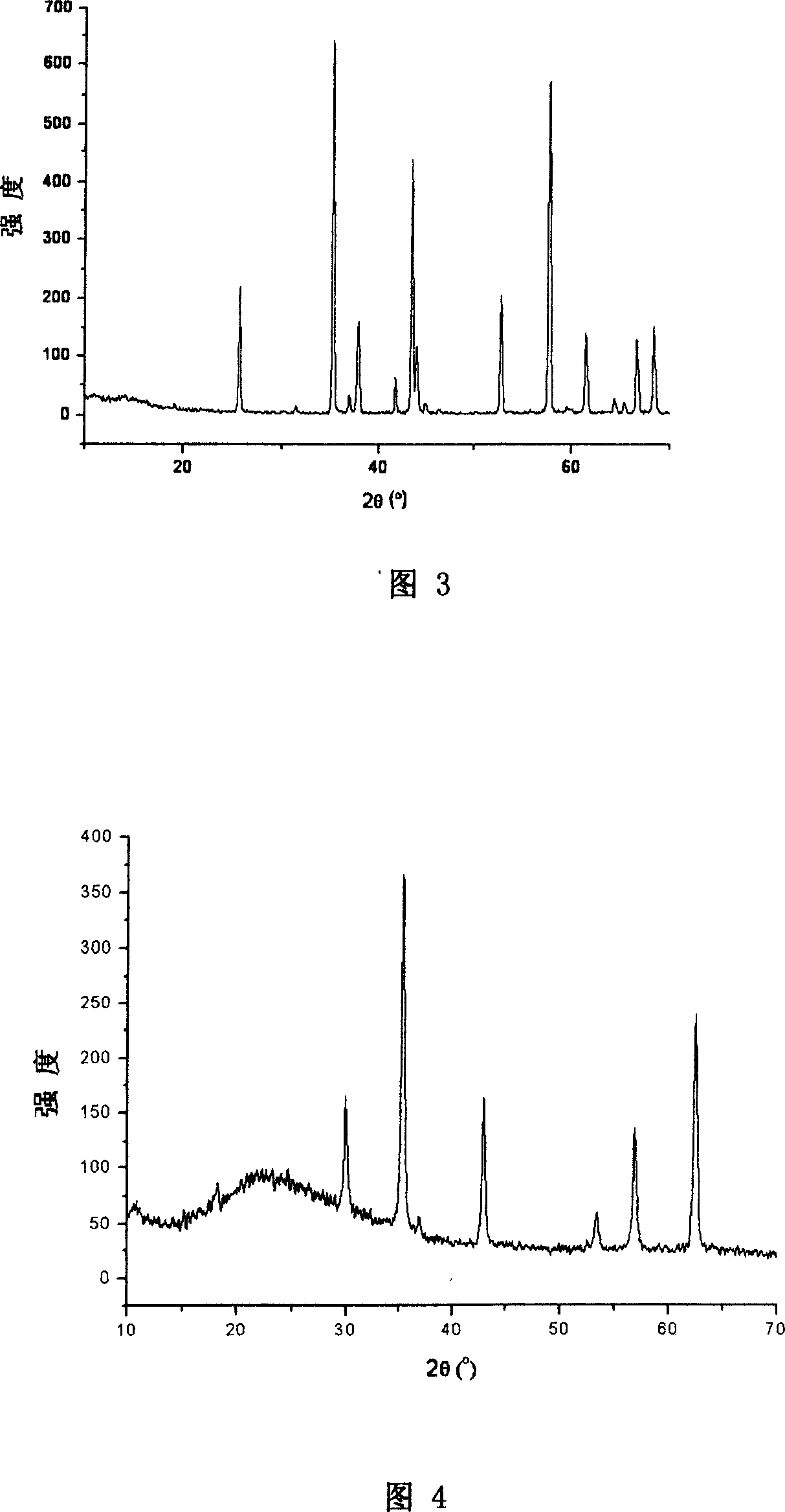

Method for manufacturing silicon base body stephanoporate ferrite thin film with hydrotalcite forerunner method

InactiveCN101244931AImprove magnetic propertiesUniform domain structureCeramicwareHigh pressurePolytetrafluoroethylene

A preparation method which uses hydrotalcite precursor method for producing Si substrate porous ferrite film belongs to the technical field of metal-oxide film preparation, the Si substrate after sulfur treatment is completely contacted with salt ion solution, then the Si substrate attached with salt ion is put into the high-pressure reaction kettle with a polyfluortetraethylene liner for hydro-thermal synthesis crystallization so as to produce uniform and compact hydotalcite film which is then sintered with high temperature to be transferred into the coextruded film of spinel type ferrite and metal oxide, at last, after metal oxide selectively is eliminated, porous ferrite film can be obtained; the method has the advantages that the magnetic domain structure of the magnetic film is uniform so as to improve the magnetic performance, the purpose of controlling the porous ferrite film without magnetic performance can be reached, the operating method is simple, the preparation cost and the energy consumption are low and the film is beneficial to the industrialized application.

Owner:BEIJING UNIV OF CHEM TECH

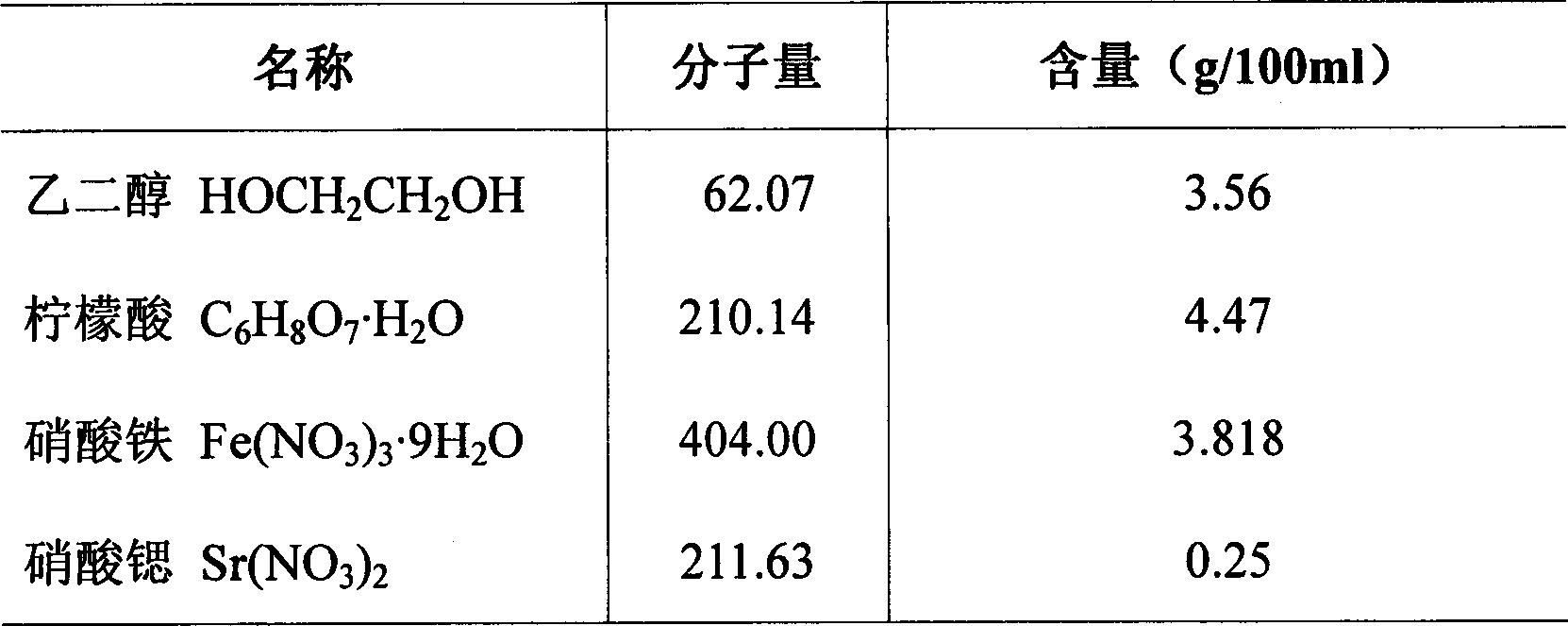

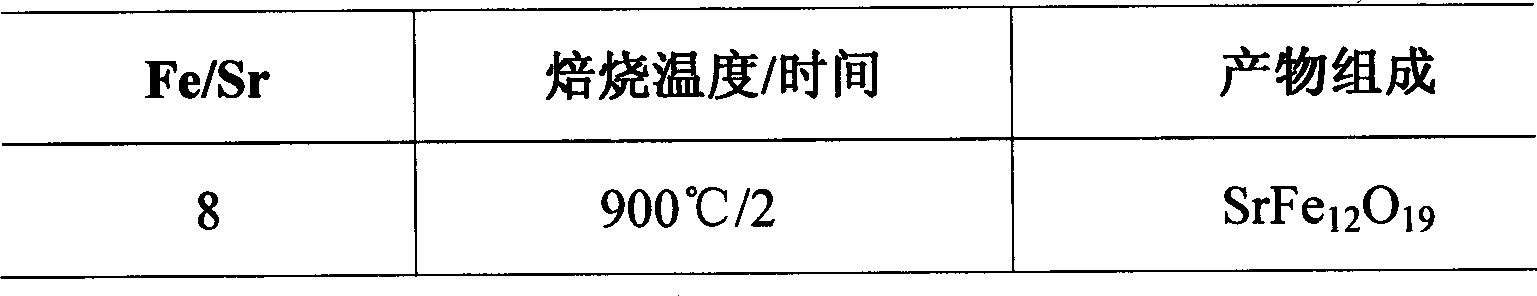

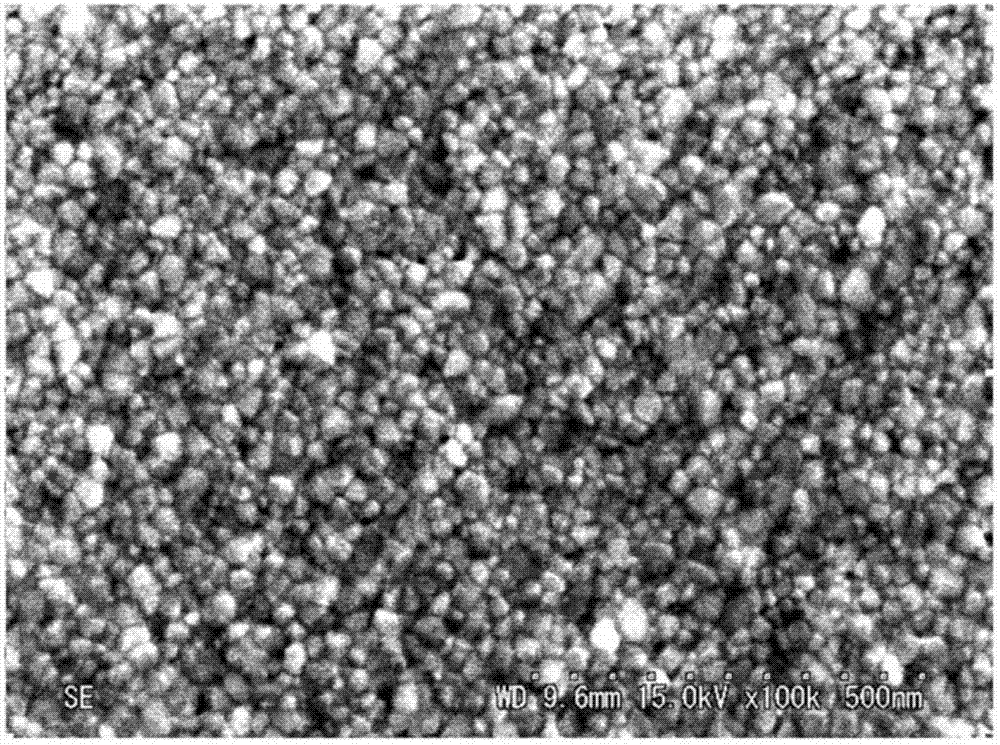

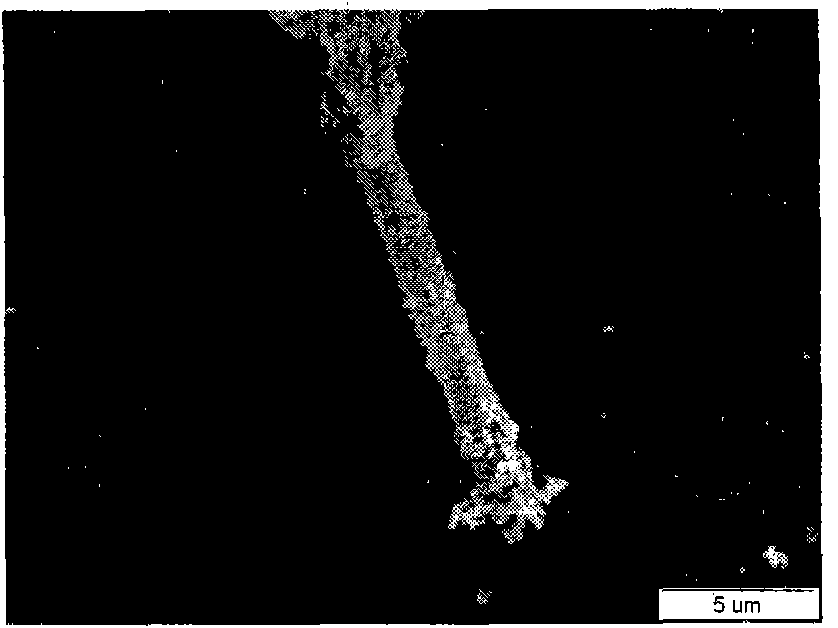

Method of manufacturing nano-strontium ferrite film

The invention relates to a preparation method of a nanometer strontium ferrite thin film, which is characterized in that the invention is made through the following steps: iron nitrate, strontium nitrate, and the like, mainly serve as raw materials to prepare a forerunner body of the nanometer strontium ferrite in a sol-gel method; clean silicon dioxide serves as a support base, the iron nitrate and the strontium nitrate salt, citric acid serves as complexing agent, glycol serves as complexing agent assist, the silicon dioxide support base is arranged in the forerunner body, namely is soaked in the sol, and a soakage-drawing method is adopted to make the film. The preparation method of a nanometer strontium ferrite thin film has the characteristics that firstly, the sol-gel method is adopted to prepare, and the nanometer thin film with high purity is obtained through optimizing preparation technology, and basic components of the nanometer strontium ferrite thin film can be seen in a table 2; secondly, the grain size of the nanometer strontium ferrite thin film is 40mm to 60mm, the grain size is evenly distributed, and the thin film surface is compact and is composed of bar-shaped crystal particles which are stacked; thirdly, the electromagnetic performance of the nanometer strontium ferrite thin film is good.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

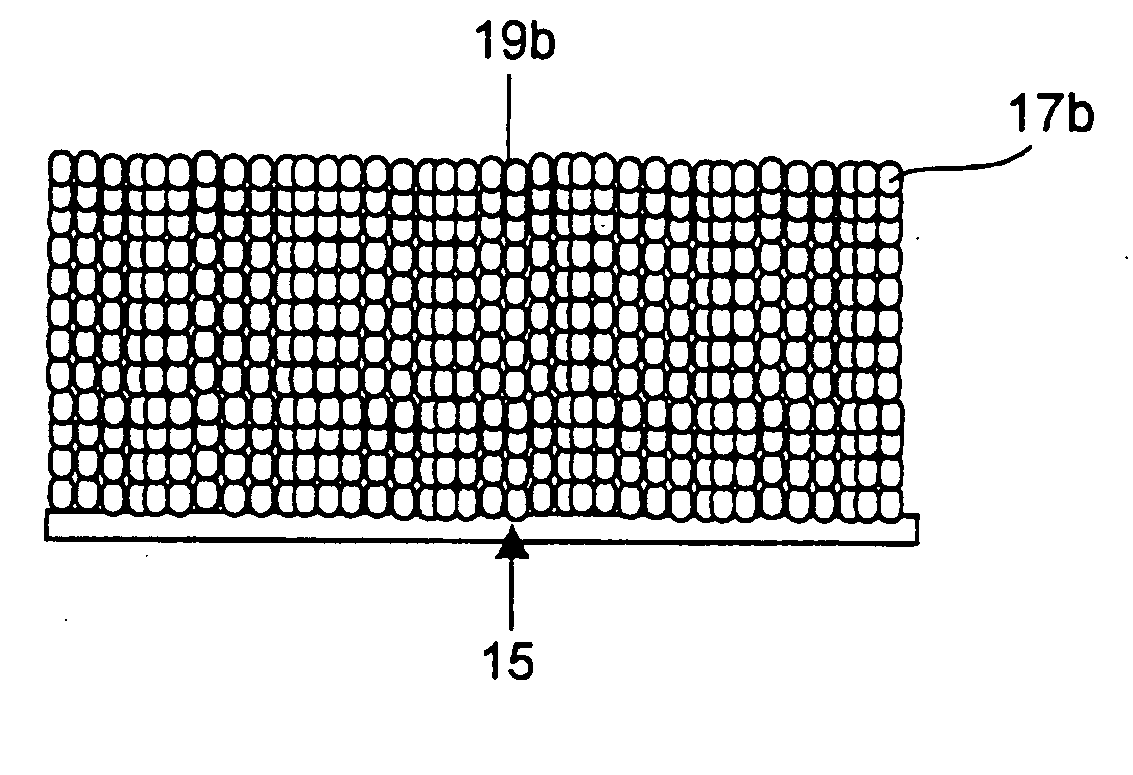

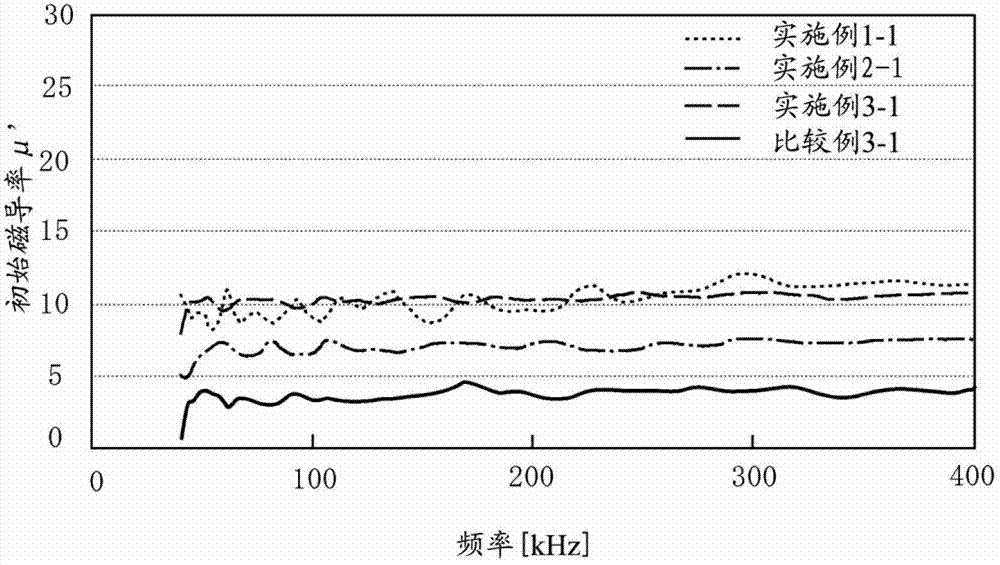

Ferrite material, ferrite film formed thereof, and radio frequency identification tag with ferrite film

ActiveCN101055781ALoop antennas with ferromagnetic coreCo-operative working arrangementsThin membraneFerrite thin films

A ferrite material is disclosed, consisting of an oxide metal composition, the metal composition having the formula of FeaNibZncCod, where: a+b+c+d=3.0; 2.1<=a<=2.7; 0<=b<=0.4; 0<=c<=0.4; and 0.1<=d<=0.5. A ferrite film is made of the ferrite material. Preferably, the ferrite film is formed by a ferrite plating method to have a thickness of 30 mum or less and an aspect ratio of 30 or more. The ferrite film is arranged or provided in the vicinity of an antenna conductor of a radio frequency identification tag. The ferrite film may be in direct contact with the antenna conductor.

Owner:TOKIN CORP

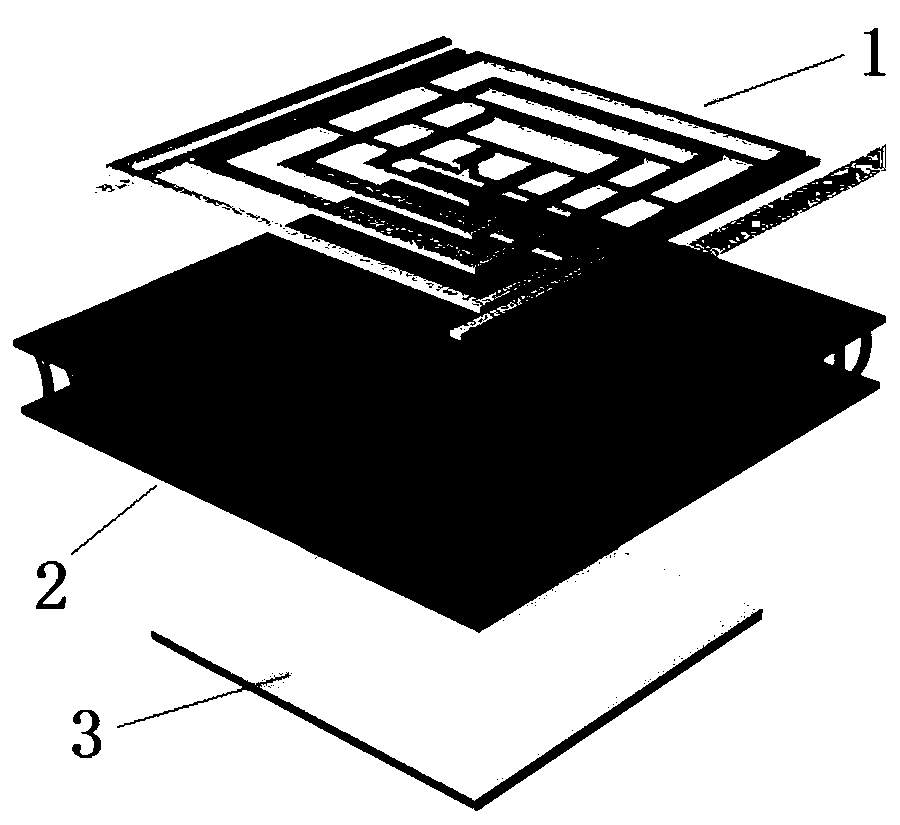

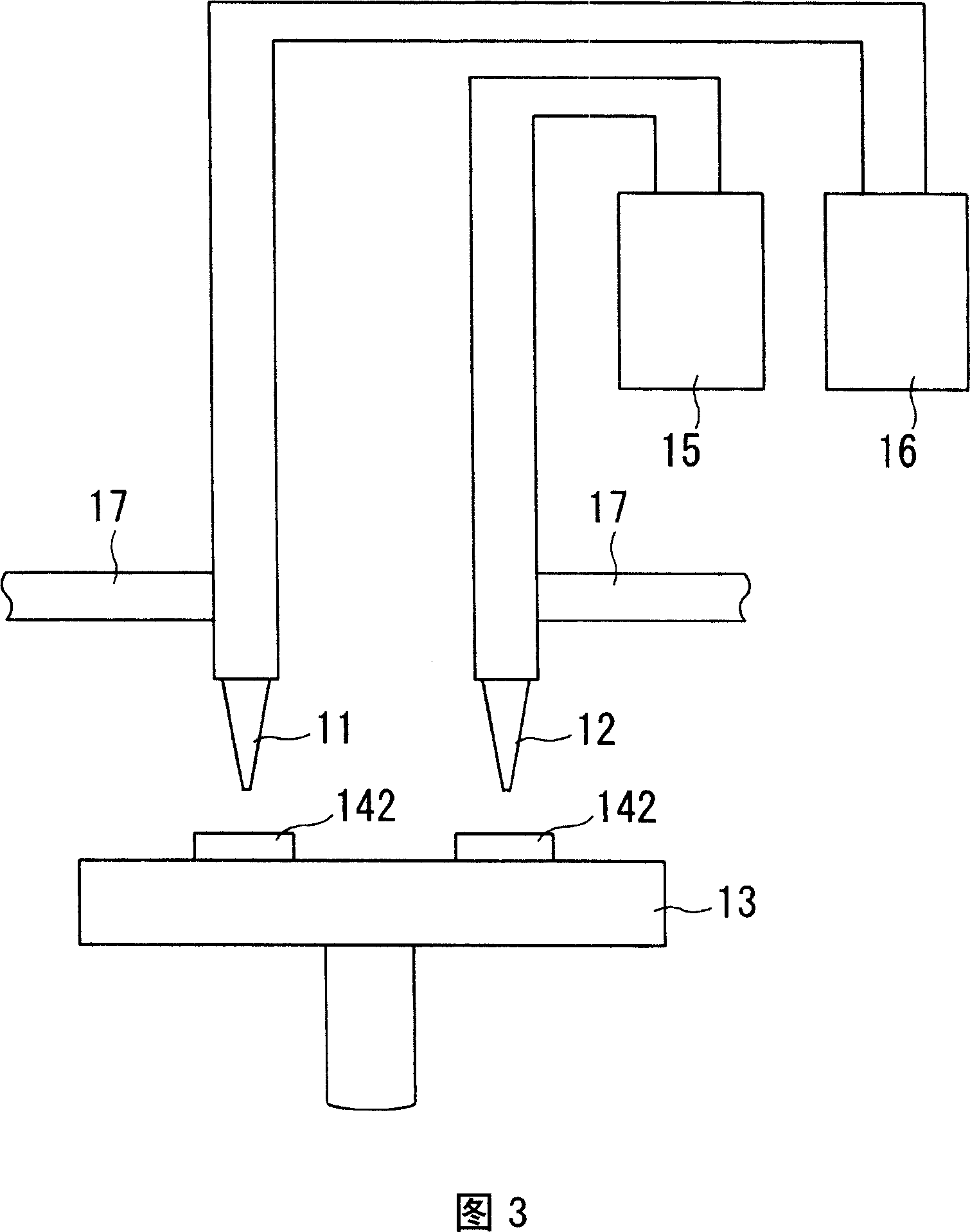

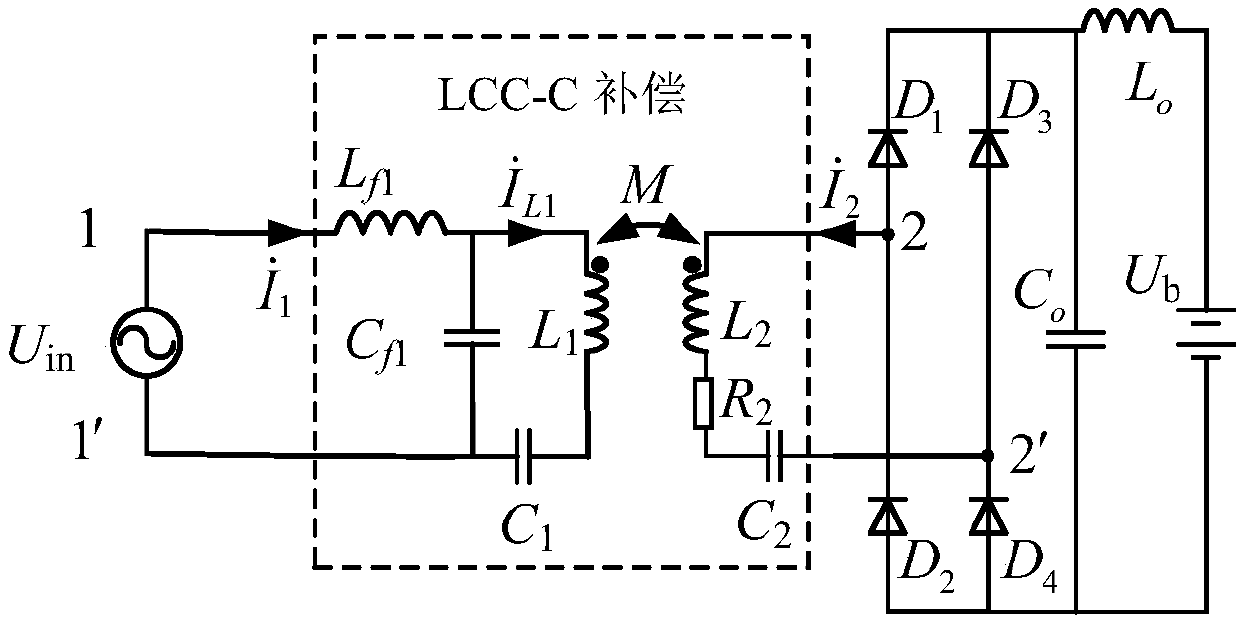

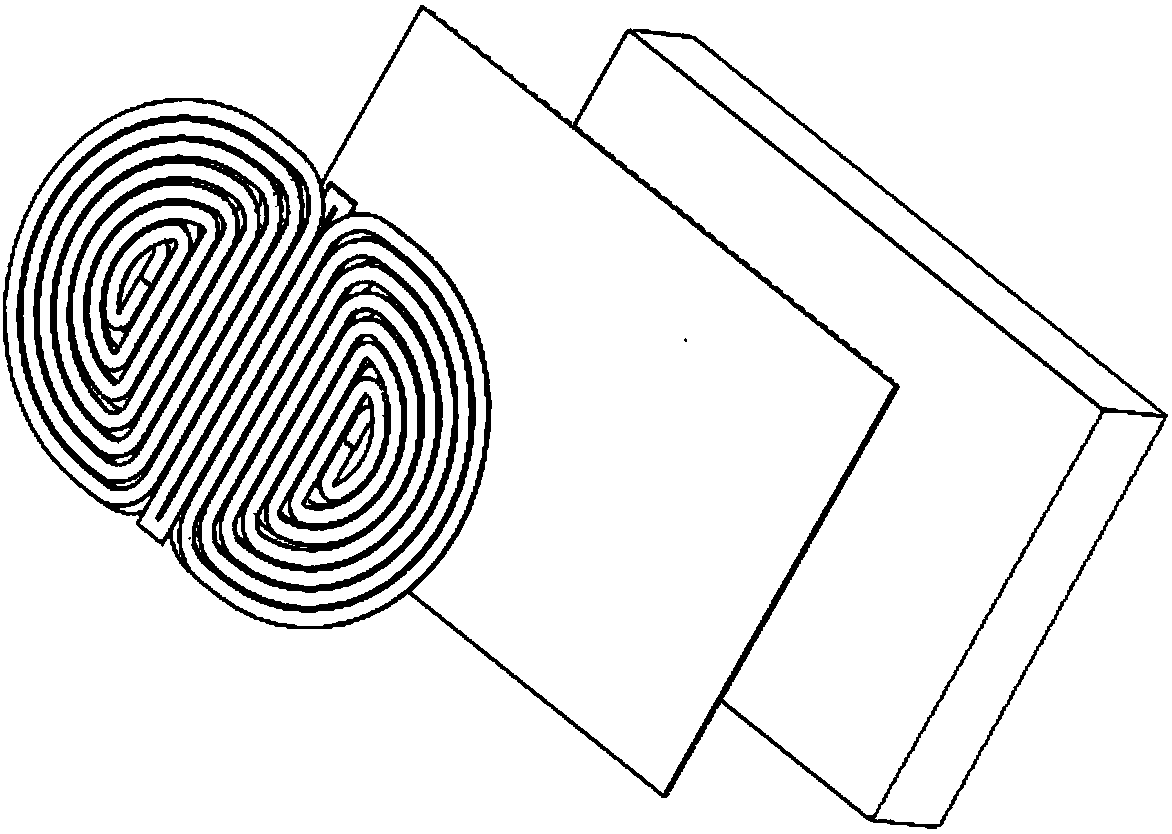

Implantable device, electric energy emission and receiving unit thereof and electric energy transmission device

InactiveCN108551200AImprove transmission efficiencyImprove electromagnetic safetyBatteries circuit arrangementsTransformersElectrical polarityEngineering

The invention discloses an implantable device, electric energy emission and receiving units thereof and an electric energy transmission device. The electric energy emission unit comprises a first ferrite film and an emission coil installed on the first ferrite film. The emission coil comprises a bipolarity coil with multiple coils. The electric energy receiving unit comprises a second first ferrite film and a receiving coil installed on the second ferrite film. The receiving coil comprises a bipolarity coil with multiple coils. According to the invention, bipolarity coils are used in the emission coil and the receiving coil, so compared with a unipolarity coil, through the parallel structure of the bipolarity coils, the wireless electric energy transmission efficiency is improved and the electromagnetic safety of a wireless electric energy transmission device is further improved.

Owner:BEIHANG UNIV

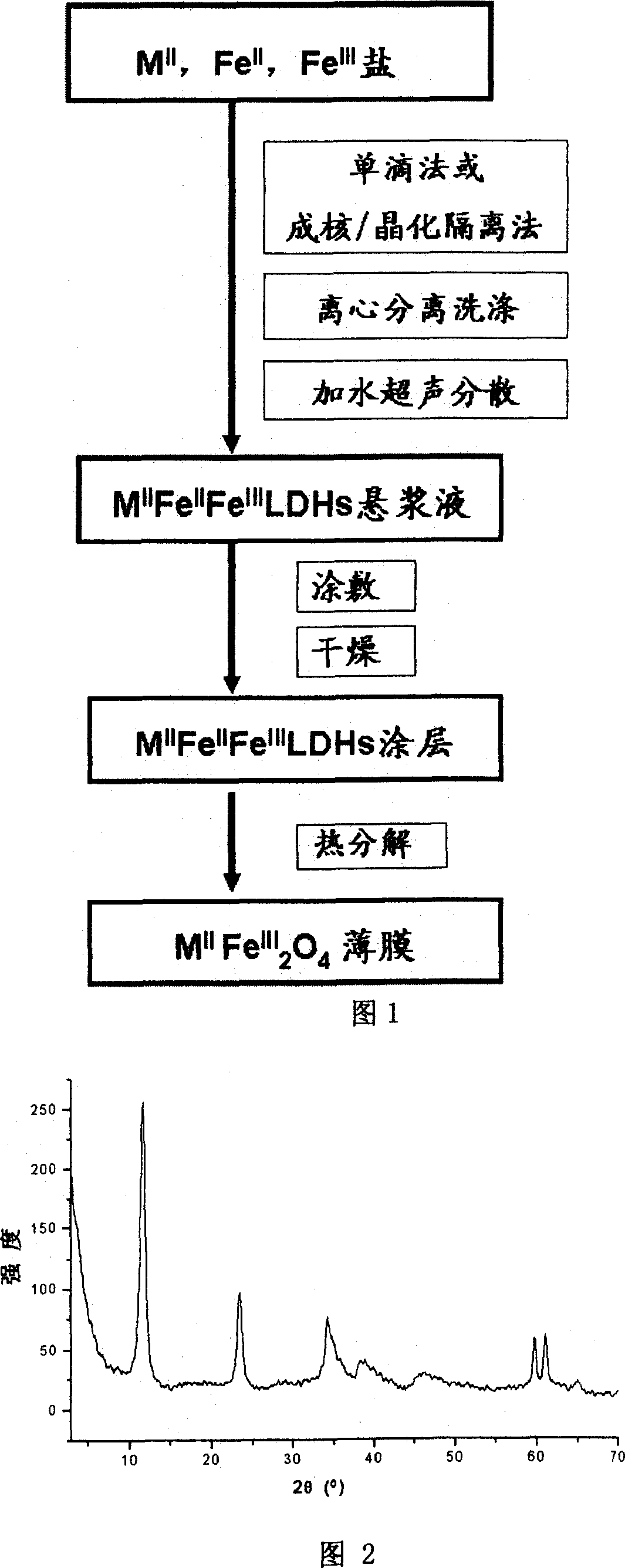

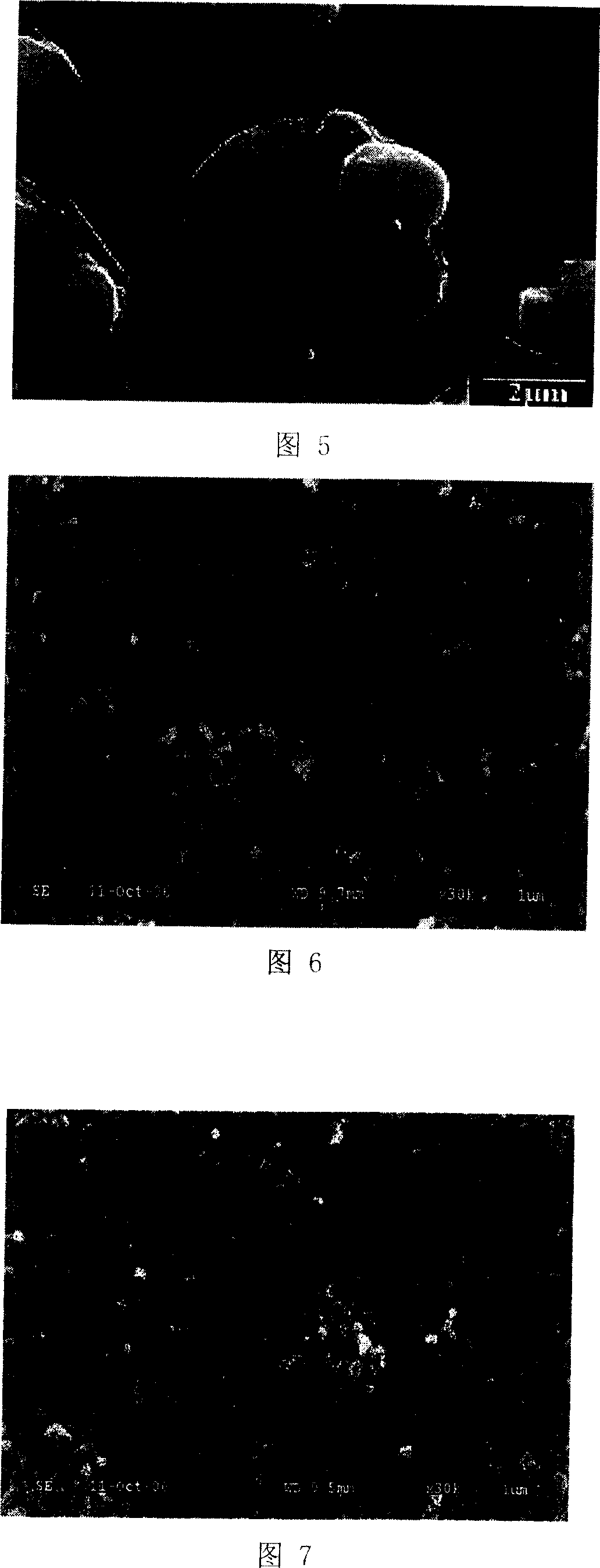

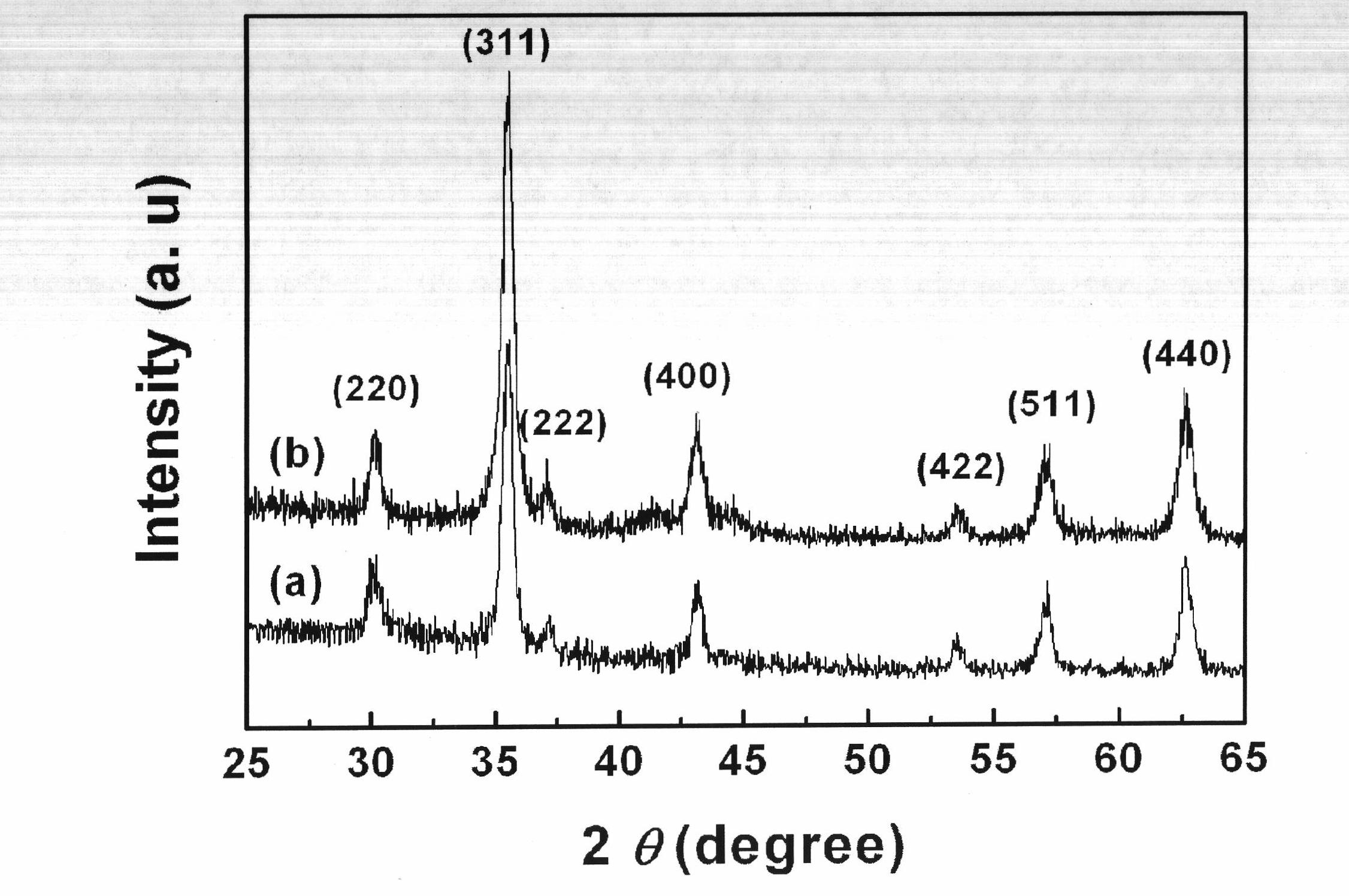

Process of thermally decomposing hydrotalcite-like coating to prepare stoichiometric ferrite film

The process of thermally decomposing hydrotalcite-like coating to prepare stoichiometric ferrite film belongs to the field of ferrite film preparing technology. The process includes the first preparing hydrotalcite-like slurry through single dropping or nucleation / crystallization isolating, coating the slurry on the substrate to obtain hydrotalcite-like coating precursor, and high temperature thermal decomposing to obtain stoichiometric ferrite film. The simple process has low cost and environment friendship, and can prepare compact ferrite film with single crystal phase and excellent magnetic performance.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing Ni-Zn ferrite film

InactiveCN102321863AImprove soft magneticImprove Microwave PerformanceVacuum evaporation coatingSputtering coatingMicrowaveFerrite thin films

The invention discloses a method for preparing a ferrite film, in particular to a method which can obtain a spinel type Ni-Zn ferrite film with better soft magnetic and microwave properties. The method includes the following steps: first depositing a layer of antiferromagnetic material Fe50Mn50 on a substrate, and then depositing a Ni-Zn ferrite film layer on the Fe50Mn50 layer. The method can also prepare multiple layers of Ni-Zn ferrite films. The adoption of the method can enhance the soft magnetic and microwave properties of the prepared Ni-Zn ferrite film.

Owner:LANZHOU UNIVERSITY

Flexible microwave device and preparation method thereof

ActiveCN110202880AAdjust working frequencyReduce lossSynthetic resin layered productsVacuum evaporation coatingDielectric antennasThe Internet

The invention provides a flexible microwave device and a preparation method thereof. The device includes a flexible waveguide and flexible ferrite films; the flexible ferrite films are formed on the upper surface of the flexible waveguide. The surface of the flexible waveguide is provided with two parallel S-shaped channels, the flexible ferrite films are located in the middles of the S-shaped channels, and one end of each S-shaped channel is externally connected with an electromagnetic wave generator. The flexible microwave device is simple in structure, small in size, low in cost and good inperformance, can be used for preparing flexible microwave signal processing devices such as isolators, circulators, phase shifters, diplexers, filters, microwave dielectric antennas and ferrite switches, and has important application prospects in microwave communication, the Internet of Things, intelligent household appliances and other fields.

Owner:XI AN JIAOTONG UNIV

Ferrite thin film-forming composition material, ferrite thin film, and method of forming ferrite thin film

InactiveCN103360044AGood storage stabilityExcellent film performanceChemical vapor deposition applicationMagnetic paintsSolventFerrite thin films

To provide a ferrite thin film-forming composition material that is a composition material for forming a ferrite thin film by using the sol-gel method which can form a thin ferrite thin film having a uniform thickness and, furthermore, has excellent long-term storage stability, a method of forming a ferrite thin film using the above composition material, and a ferrite thin film formed by using the above method. A ferrite thin film-forming composition material is a composition material for forming a NiZn ferrite, CuZn ferrite, or NiCuZn ferrite thin film by using a sol-gel method, in which the composition material is formed by dissolving metallic raw materials in a solvent including acetonitrile, and the fraction of acetonitrile is 30 mass% to 60 mass% with respect to 100 mass% of the composition material.

Owner:MITSUBISHI MATERIALS CORP

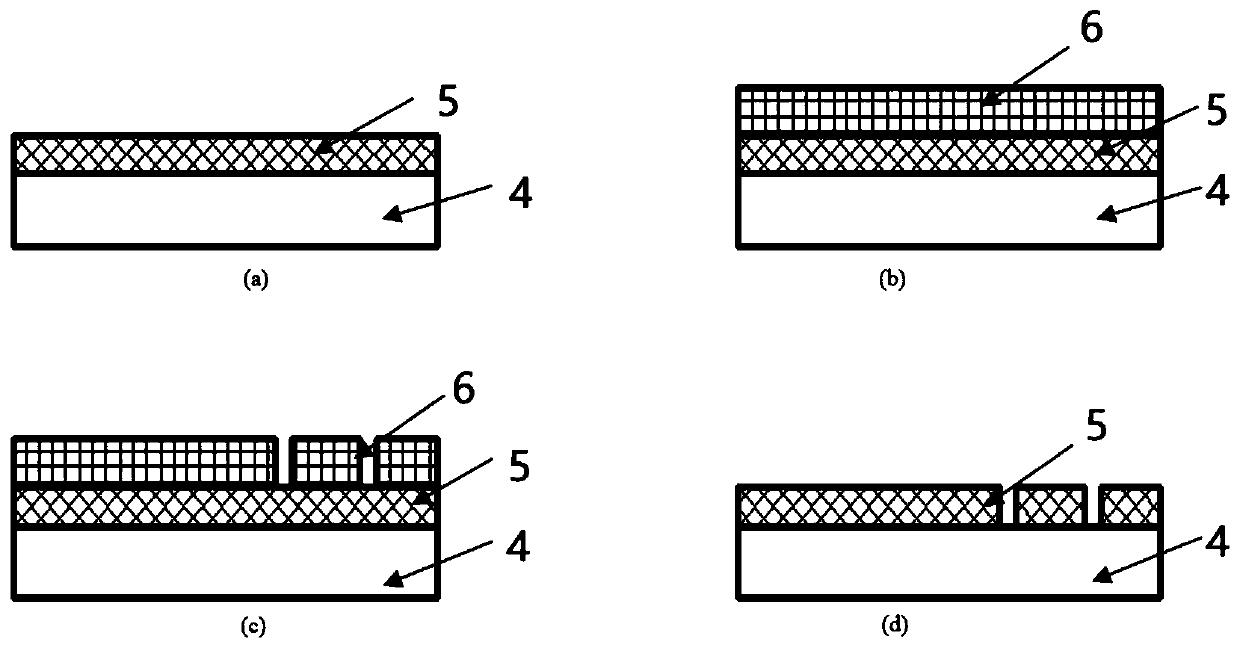

Method for manufacturing manganese zinc ferrite film through sol-gel method

ActiveCN104599807ASimple processLow costLiquid applicationSolid/suspension decomposition chemical coatingFurnace temperatureZinc nitrate

Disclosed is a method for manufacturing a manganese zinc ferrite film through a sol-gel method. The method comprises the steps that 1, ferric nitrate and zinc nitrate are weighed according to the Mn<0.5>Zn<0.5>Fe<2>O<4> stoichiometric proportion, and the two raw materials are dissolved in deionized water; 2, a manganous nitrate solution is added to a solution obtained in the step 1, citric acid is added as a complexing agent, and a mixed solution is obtained; 3, ammonia water is added to the mixed solution obtained in the step 2, the pH value of the solution is adjusted to range from six to seven, sol is obtained, and then polyvinylpyrrolidone is added in the sol; 4, a silicon substrate is washed through a hydrochloric acid and hydrofluoric acid mixed aqueous solution and is blow-dried through nitrogen; 5, the manganese zinc ferrite sol obtained in the step 3 is dropped on the silicon substrate washed in the step 4, a KW-4A spin coater is used for whirl coating by 2,000-3,000 r / min, the sol is evenly distributed on the surface of the silicon substrate, then after the silicon substrate is placed in a muffle furnace of 250 DEG C to 300 DEG C for heat treatment for 20-30 min, the silicon substrate is heated to 500 DEG C along with the furnace, and the silicon substrate is taken out after heat preservation is kept for 20-30 min. the temperature rise rate along with the furnace is 10-20 DEG C / min, and the furnace temperature change is within + / -5 DEG C.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

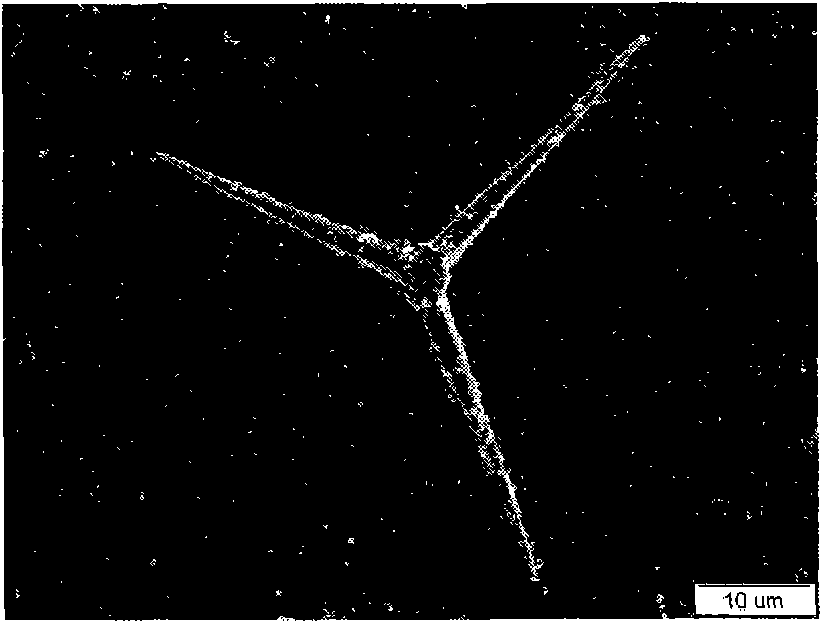

Tetrapod-like zinc oxide/ferrite film material and preparation method thereof

InactiveCN101899708AWith absorbing propertiesPolycrystalline material growthAfter-treatment detailsChemical platingWhiskers

The invention discloses a tetrapod-like zinc oxide whisker / ferrite film material and a preparation method thereof. The tetrapod-like zinc oxide whisker / ferrite film material has good wave absorbing performance. The preparation method for the tetrapod-like zinc oxide whisker / ferrite film material realizes chemical plating of ferrite on the surface of the tetrapod-like zinc oxide whisker under the condition of the low temperature of between 60 and 80DEG C, and successfully prepares a layer of ferrite film on the surface of the tetrapod-like zinc oxide whisker.

Owner:BEIHANG UNIV

Preparation method of ferroelectric film with texture

InactiveCN105206710AGood effectTexturedFinal product manufactureSemiconductor devicesFerroelectric thin filmsFerrite thin films

The invention discloses a preparation method of a ferroelectric film with a texture. The key point of the preparation method lies in that: firstly, a magnetic nanometer chain is prepared on a film forming carrier, and then the ferroelectric film is grown on the magnetic nanometer chain. The preparation method has the following benefits: the length, thickness and orientation of the magnetic nanometer chain can be adjusted and controlled through changing the size, direction and gradient of a magnetic field, so that the texture and purity of a ferrite film are controlled; the preparation method is simple and good in effect.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

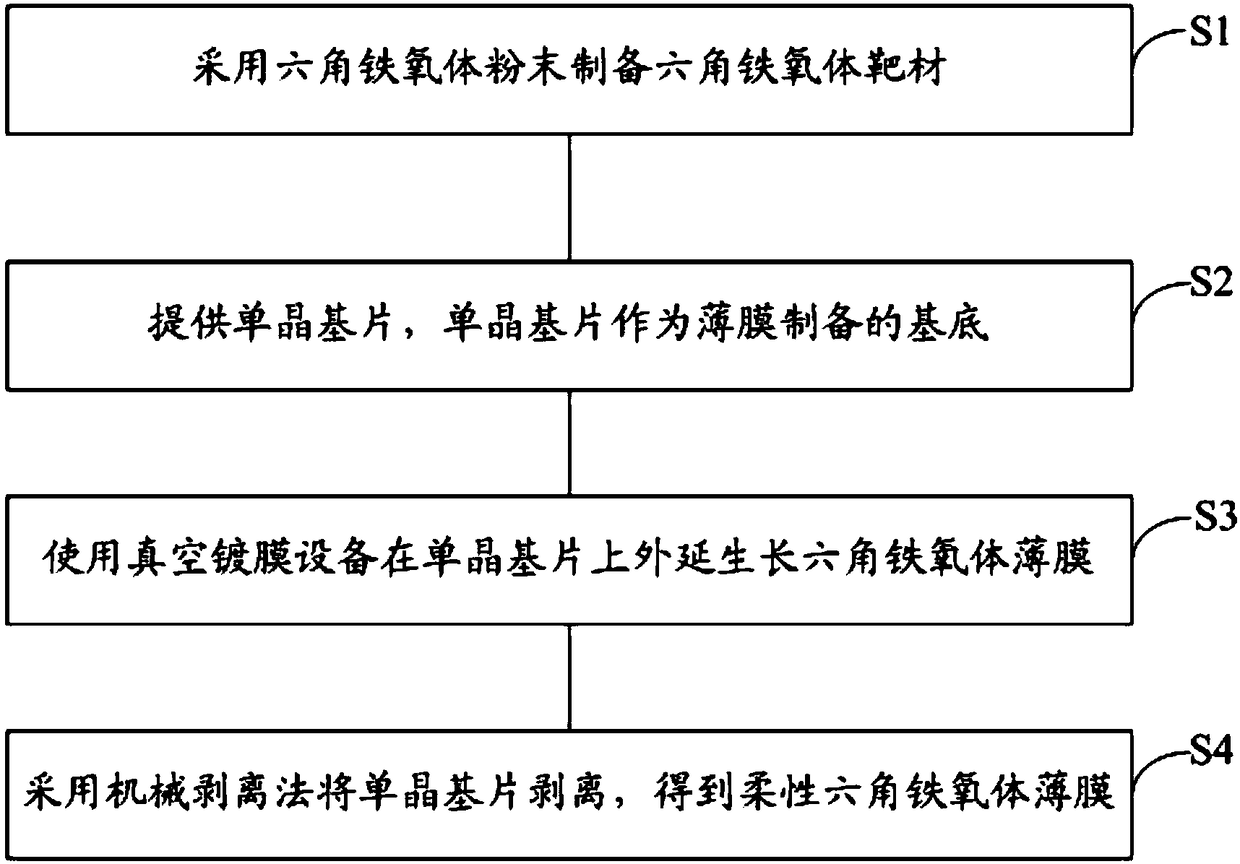

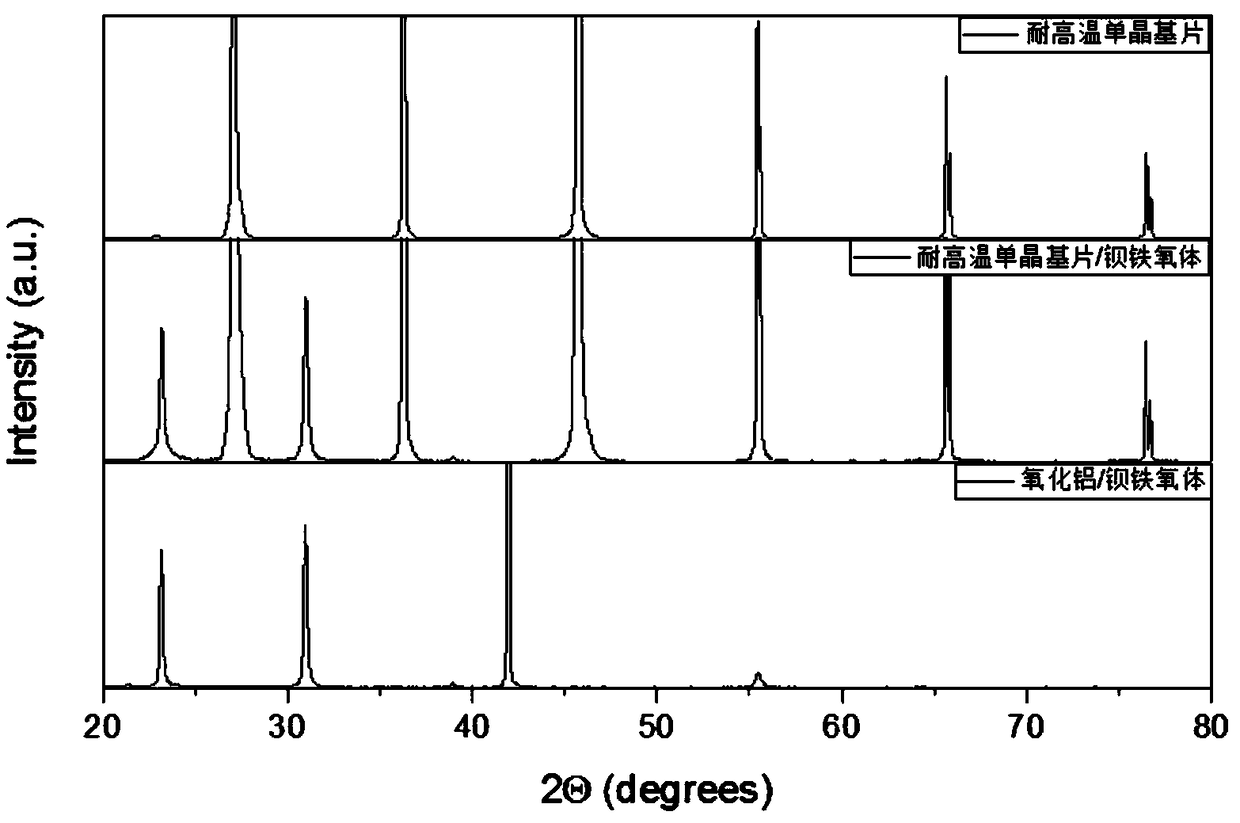

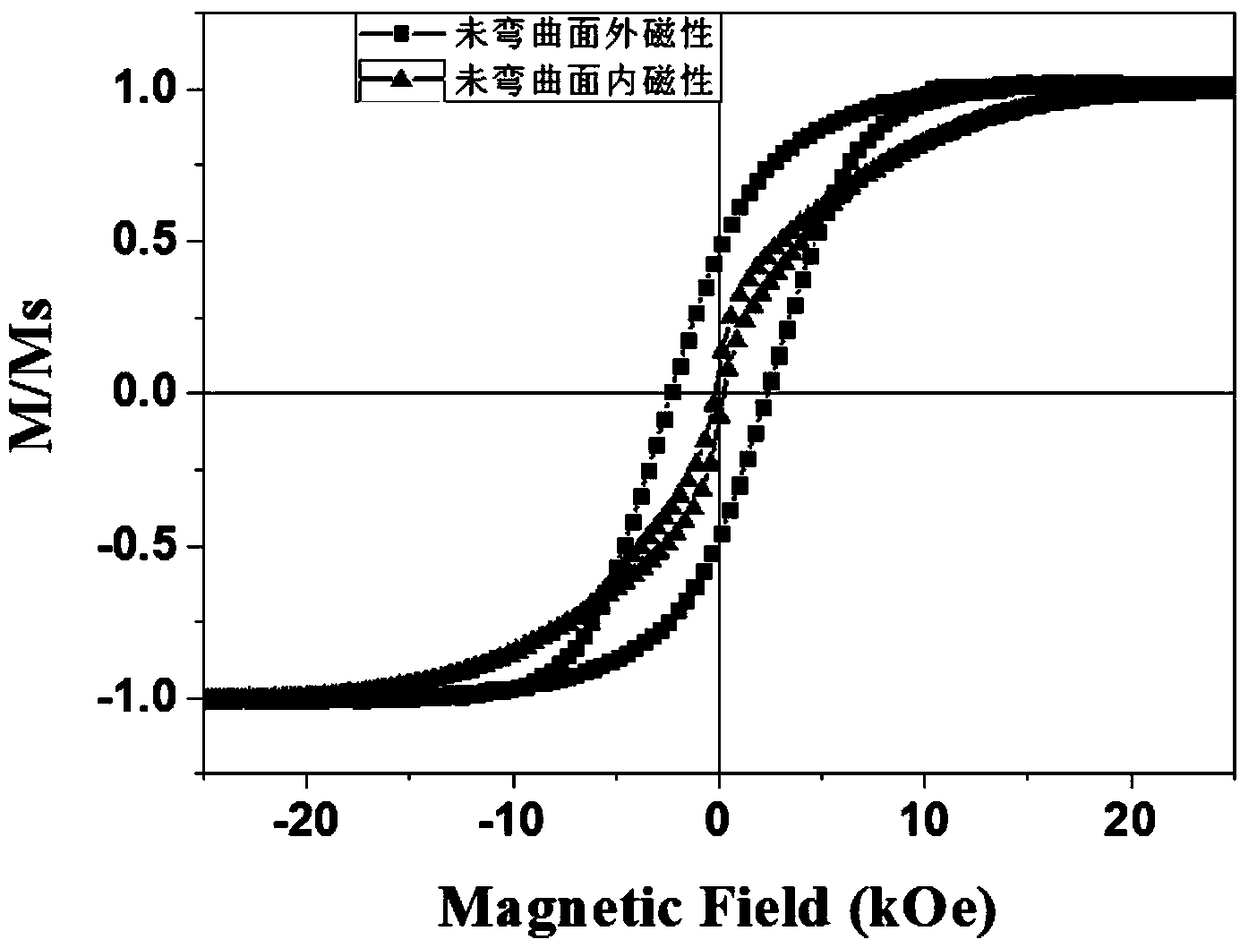

Flexible hexagonal ferrite thin film and preparation method thereof

ActiveCN108823531ABendableThe magnetism has not changedVacuum evaporation coatingSputtering coatingSingle crystal substrateSingle crystal

The invention discloses a flexible hexagonal ferrite thin film and a preparation method thereof. The preparation method comprises: S1, preparing a hexagonal ferrite target material by adopting hexagonal ferrite powder; S2, providing a single crystal substrate, wherein the single crystal substrate is used as a substrate for thin film preparation; S3, carrying out epitaxial growth of a hexagonal ferrite thin film on the single crystal substrate by using vacuum coating equipment; S4, stripping the single crystal substrate by adopting a mechanical stripping method so as to obtain the flexible hexagonal ferrite thin film. According to the invention, the flexible thin film is successfully prepared by the method of growing the hexagonal ferrite thin film with height preferred orientation on the high-temperature resistant single crystal substrate by adopting a vacuum coating method and then stripping the high-temperature resistant single crystal substrate by the mechanical method; the flexiblehexagonal ferrite thin film has bendability, and after the flexible hexagonal ferrite thin film is bent, magnetism is basically not changed, and thus, the flexible hexagonal ferrite thin film has potential value for a flexible device.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com