Method of forming ferrite thin film and ferrite thin film obtained using the same

A ferrite thin film and coating film technology, applied in the application of magnetic film to substrate, liquid application, chemical vapor deposition application, etc., can solve the problem of property degradation, difficult to obtain magnetic film thickness, large tensile stress, etc. problem, to achieve the effect of restraining tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~1-16

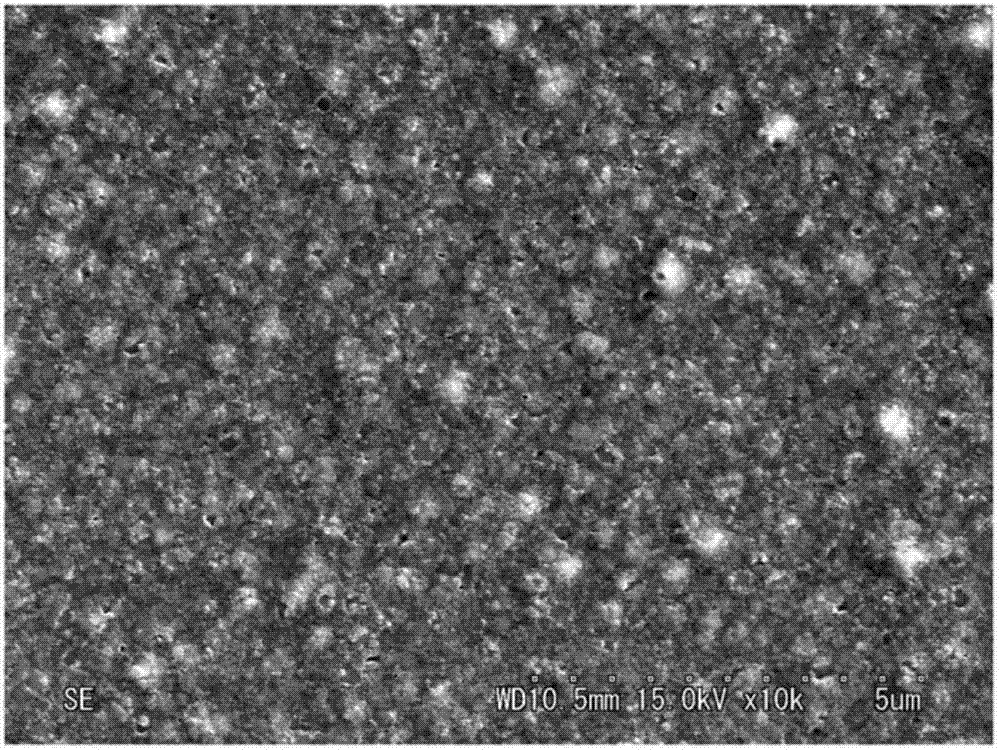

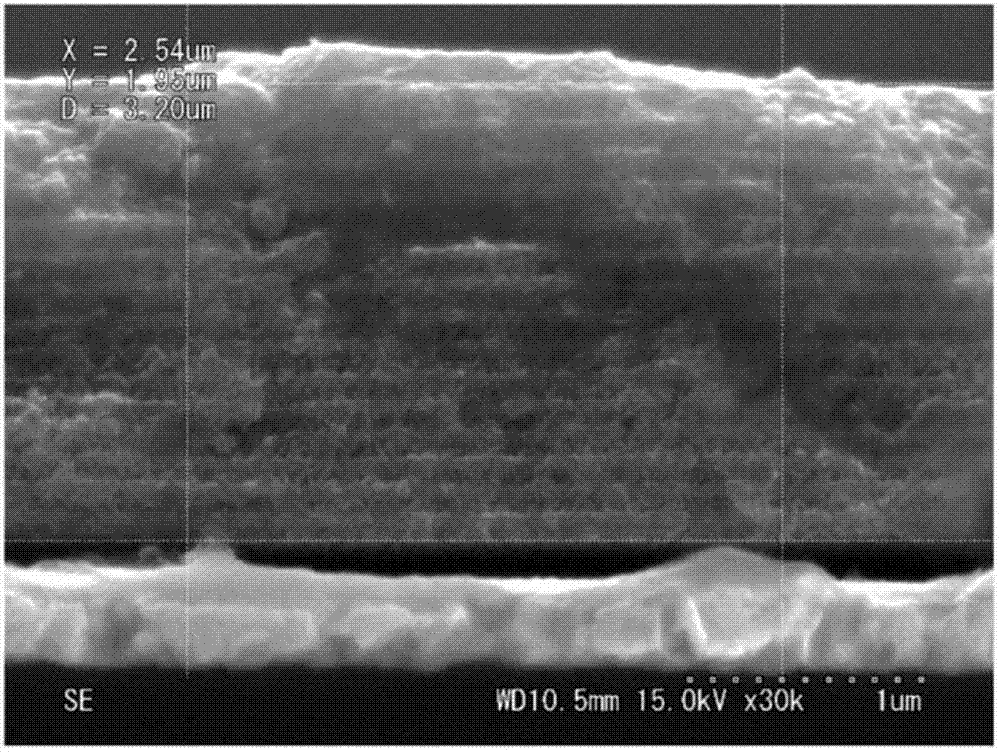

[0037] First, as a composition for forming a NiZn ferrite thin film, a metal (Ni, Zn, Fe) nitrate (nickel nitrate hexahydrate, zinc nitrate hexahydrate, iron nitrate nonahydrate), acetonitrile, propylene glycol, A sol-gel solution having a metal oxide concentration of 5% by mass and butanol. In addition, the respective metals (Ni, Zn, Fe) contained in the sol-gel solution were assumed to be (Ni 0.36 Zn 0.64 O) (Fe 2 o 3 ) with the ratio. And prepare Si / SiO 2 substrate. Next, the sol-gel solution was dropped on Si / SiO 2 On the substrate, spin coating was performed at 3000 rpm for 15 seconds to form a coating film. Then, the substrate with the coating film was mounted on a hot plate heated under the conditions shown in Table 1 below, and pre-sintered to thermally decompose the precursor. This operation is repeated 5 to 15 times to obtain an amorphous substrate with a pre-sintered film having a desired film thickness. Next, put the obtained amorphous substrate with a pre...

Embodiment 2-1~2-16

[0039] First, as a composition for forming a CuZn ferrite thin film, a concentration of a metal oxide composed of copper nitrate trihydrate, zinc acetate dihydrate, iron nitrate nonahydrate, acetonitrile, propylene glycol, and butanol was prepared at a concentration of 5 wt. % of the sol-gel solution. In addition, the respective metals (Cu, Zn, Fe) contained in the sol-gel solution were assumed to be (Cu 0.40 Zn 0.60 O) (Fe 2 o 3 ) with the ratio. And, prepare Si / SiO 2 substrate. Next, the sol-gel solution was dropped on Si / SiO 2 On the substrate, spin coating was performed at 3000 rpm for 15 seconds to form a coating film. Then, the substrate with the coating film was mounted on a hot plate heated under the conditions shown in Table 2 below, and temporarily fired to thermally decompose the precursor. This operation is repeated 5 to 10 times to obtain an amorphous substrate with a pre-sintered film having a desired film thickness. Then, put the obtained amorphous subs...

Embodiment 3-1~3-16

[0041] First, as a composition for forming a NiCuZn ferrite thin film, a metal oxide compound composed of nickel acetate tetrahydrate, copper nitrate trihydrate, zinc acetate dihydrate, iron nitrate nonahydrate, acetonitrile, propylene glycol, and butanol was prepared. The concentration of the substance is a sol-gel solution with a concentration of 5% by mass. In addition, the respective metals (Ni, Cu, Zn, Fe) contained in the sol-gel solution were assumed to have the composition of the formed film as (Ni 0.40 Cu 0.20 Zn 0.40 O) (Fe 2 o 3 ) with the ratio. And, prepare Si / SiO 2 substrate. Next, the sol-gel solution was dropped on Si / SiO 2 On the substrate, spin coating was performed at 3000 rpm for 15 seconds to form a coating film. Then, the substrate with the coating film was mounted on a hot plate heated under the conditions shown in Table 3 below, and pre-sintered to thermally decompose the precursor. This operation is repeated 5 to 15 times to obtain an amorphou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com