Method for preparing Ni-Zn ferrite film

A ferrite thin film, ni-zn technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problem that there is no obvious effect on the improvement of microwave magnetic properties of ferrite thin film, and no iron is seen. Oxygen thin film soft magnetic properties and microwave magnetic properties, weakening and other issues, to achieve the effect of improving soft magnetic and microwave properties, optimizing soft magnetic properties, and improving soft magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

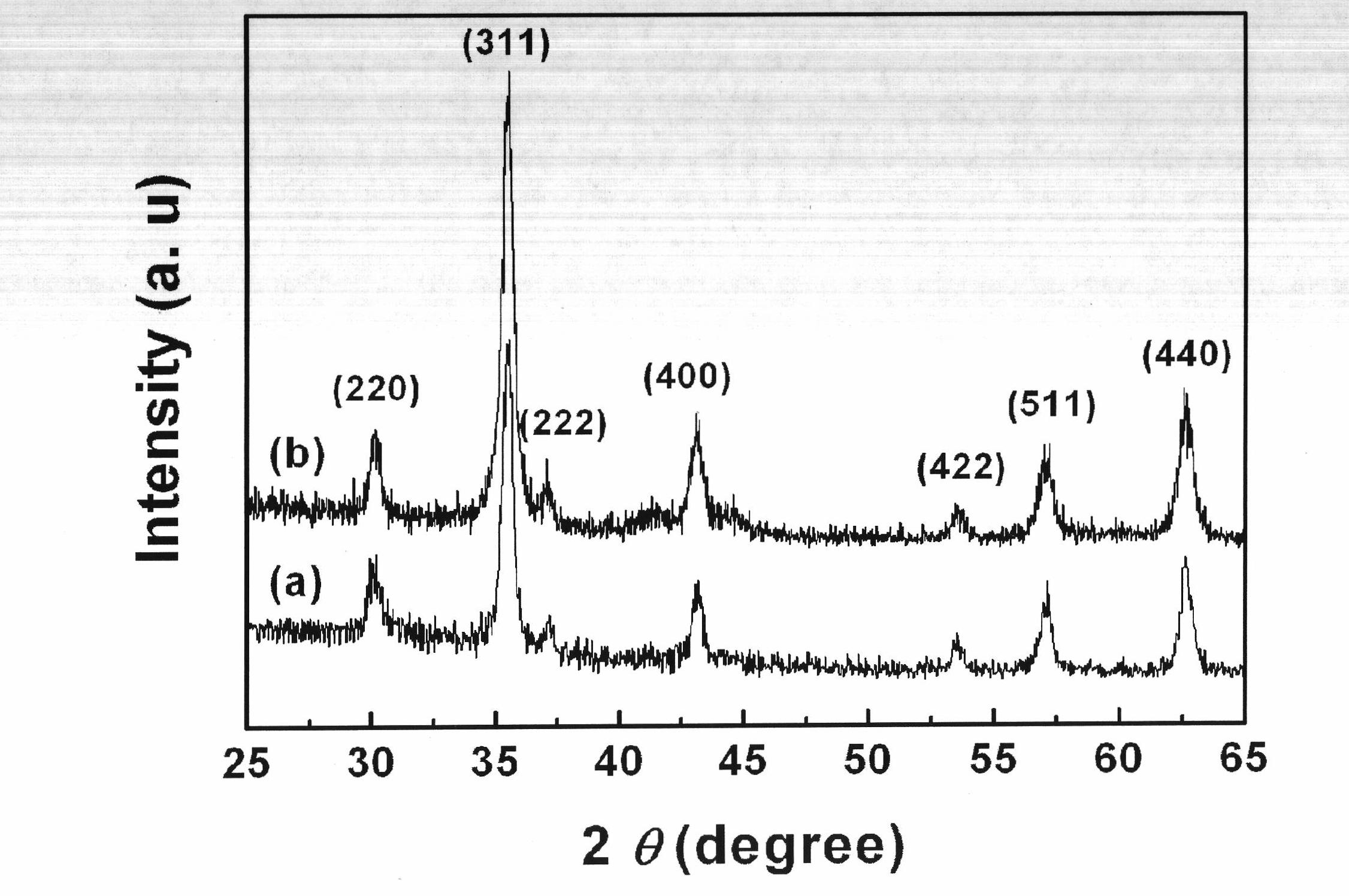

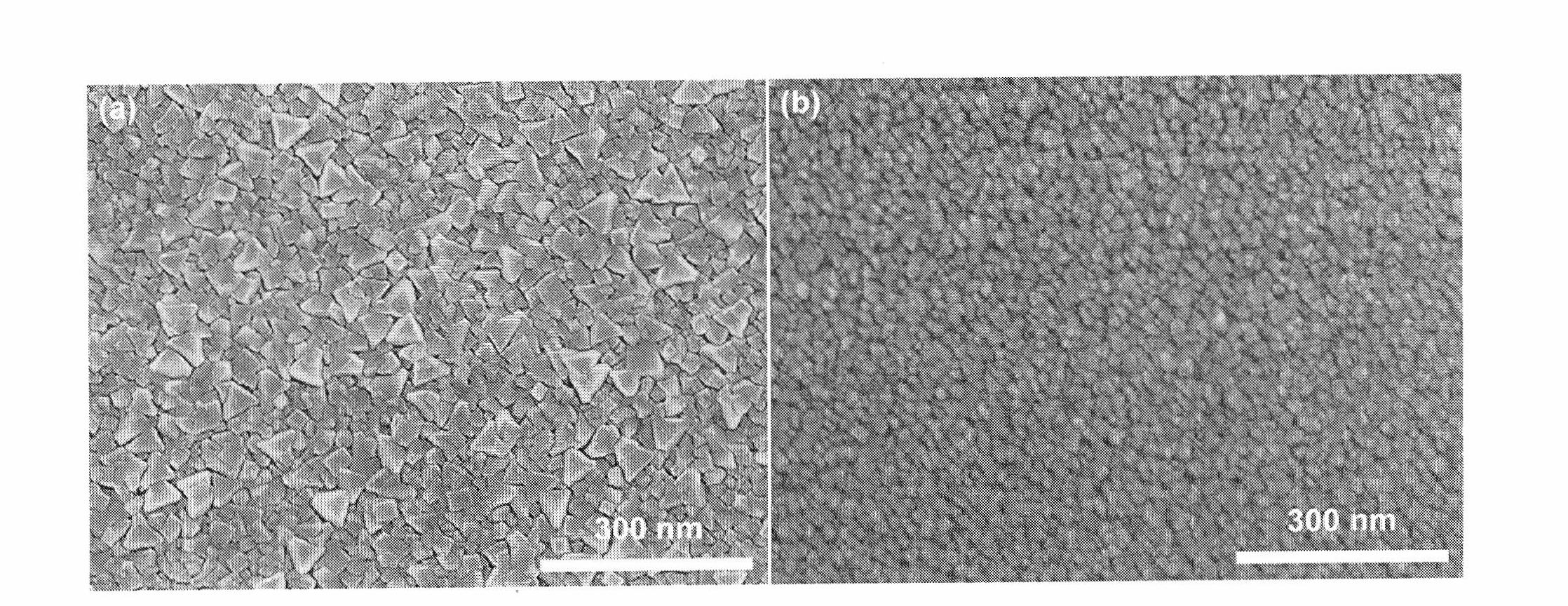

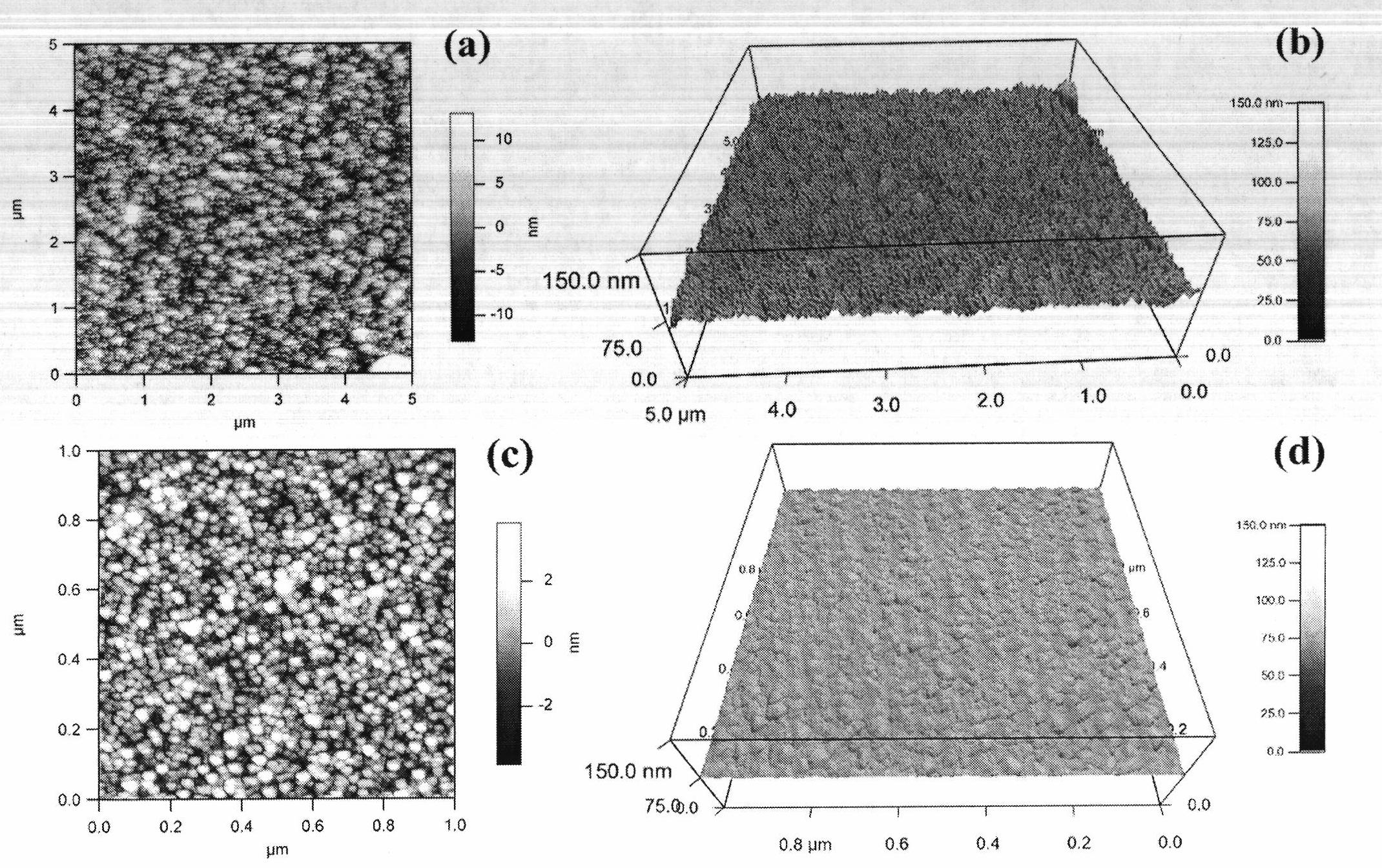

[0016] The following Ni of the present invention is combined with the embodiment 0.45 Zn 0.55 Fe 2 O 4 The preparation of the film, its soft magnetic properties and the improvement of microwave magnetic properties will be explained. In the preparation process of this example, the equipment used to deposit the film is the FJI560-I ultra-high vacuum magnetron and The RF sputtering section of an ion beam sputtering apparatus. The sputtering equipment requires two RF magnetron targets: commercial high-purity (99.99%) Fe 50 Mn 50 The target material of the Ni-Zn ferrite film is prepared by the traditional co-precipitation method, and the Ni-Zn ferrite powder is prepared by pressing and sintering. The film deposition process is: first pump the vacuum of the vacuum chamber to 5.0×10 -5 Below, a layer of Fe with a thickness of 25nm is deposited on the single crystal Si(111) substrate under the condition that the RF power supply is 50W, the sputtering gas is high-purity Ar gas, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com